Eccenterfixed on vibrating motor

A technology of vibrating motors and motors, applied in the direction of electric components, controlling mechanical energy, electrical components, etc., can solve problems such as weak riveting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

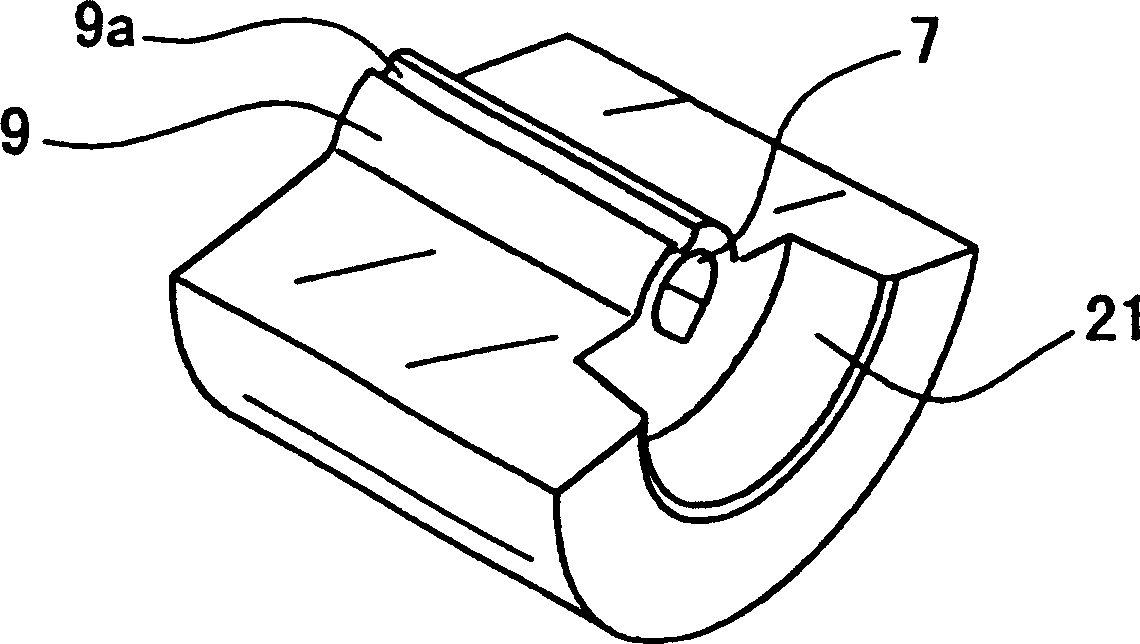

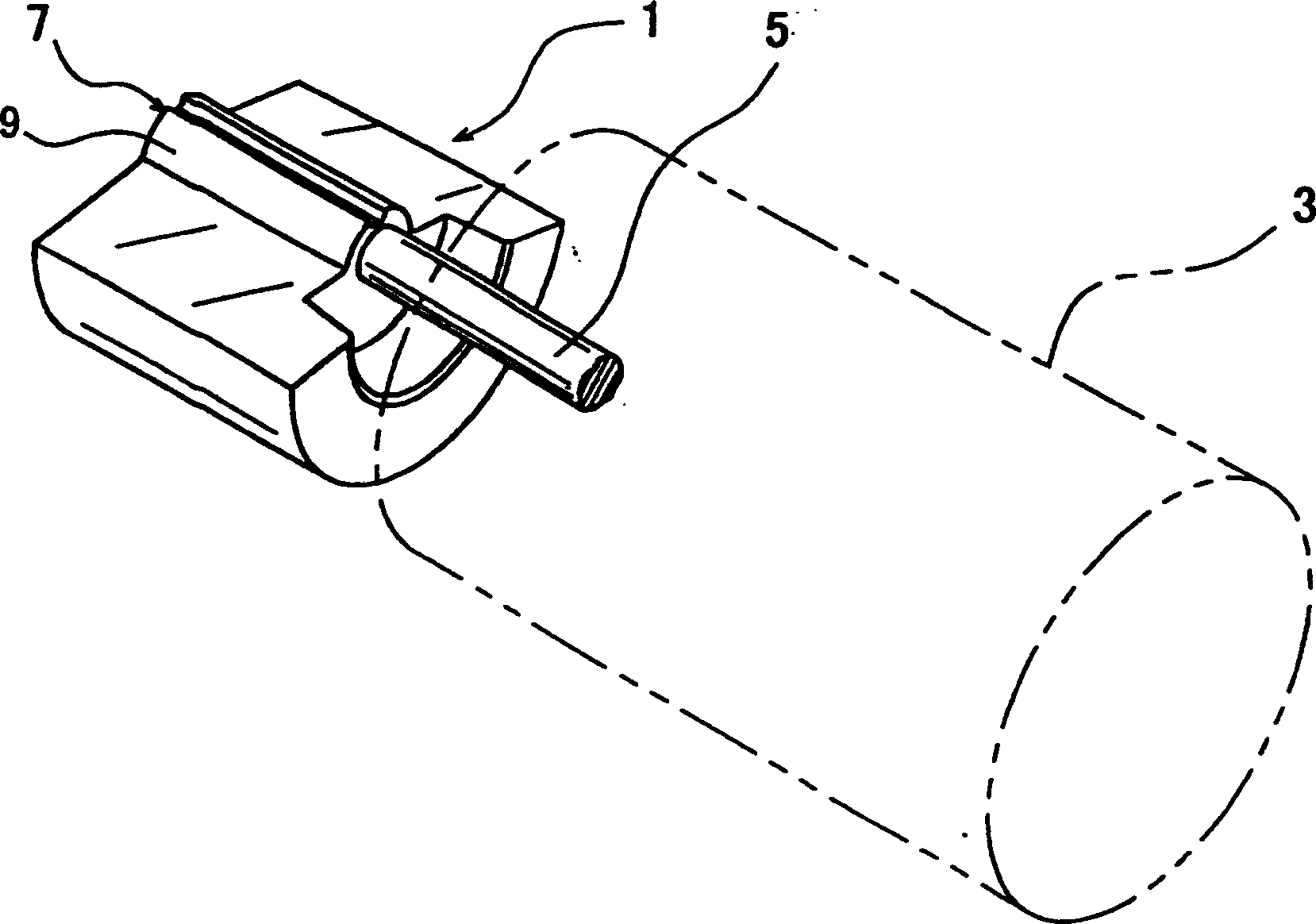

[0020] Please see first figure 2 and combine figure 1 Shown, the present invention divides copper 1 and is used for fixing vibrating motor 3 ( figure 2 Shown with double dotted lines), the rotating shaft 5 of the vibrating motor 3 is fixed on the copper, and when the motor 3 rotates, the copper 1 vibrates. Vibration motors 3 of this type are commonly used in such occasions as pagers and other similar occasions in which users are notified by vibrating when a call occurs.

[0021] In this embodiment, as seen from the axial direction (horizontal direction) of the rotating shaft 5 of the vibration motor 3, it is slightly semi-cylindrical. The material of the sub-copper 1 is not particularly limited, but it is generally better to use a material with a larger specific gravity and better extensibility. It is usually composed of tungsten alloys such as W-Ni-Fe, W-Ni-Cu, W-Mo-Ni-Fe and other series.

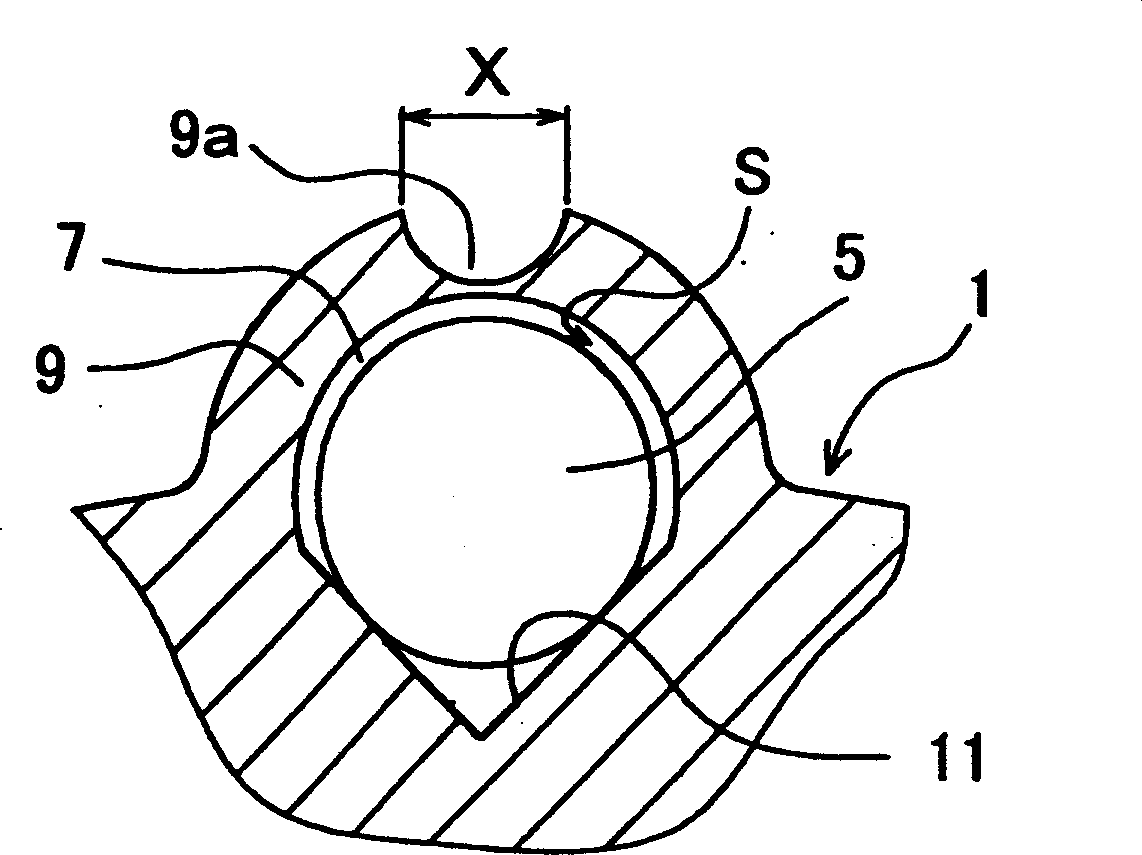

[0022] Sub-copper 1 structure such as image 3 As shown, it has a through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com