Drive rivet

A technology of rivets and mandrels, applied in the field of rivets, can solve the problems of insufficient force of the cap and the strength of riveting to be improved, and achieve the effect of strengthening the strength of riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

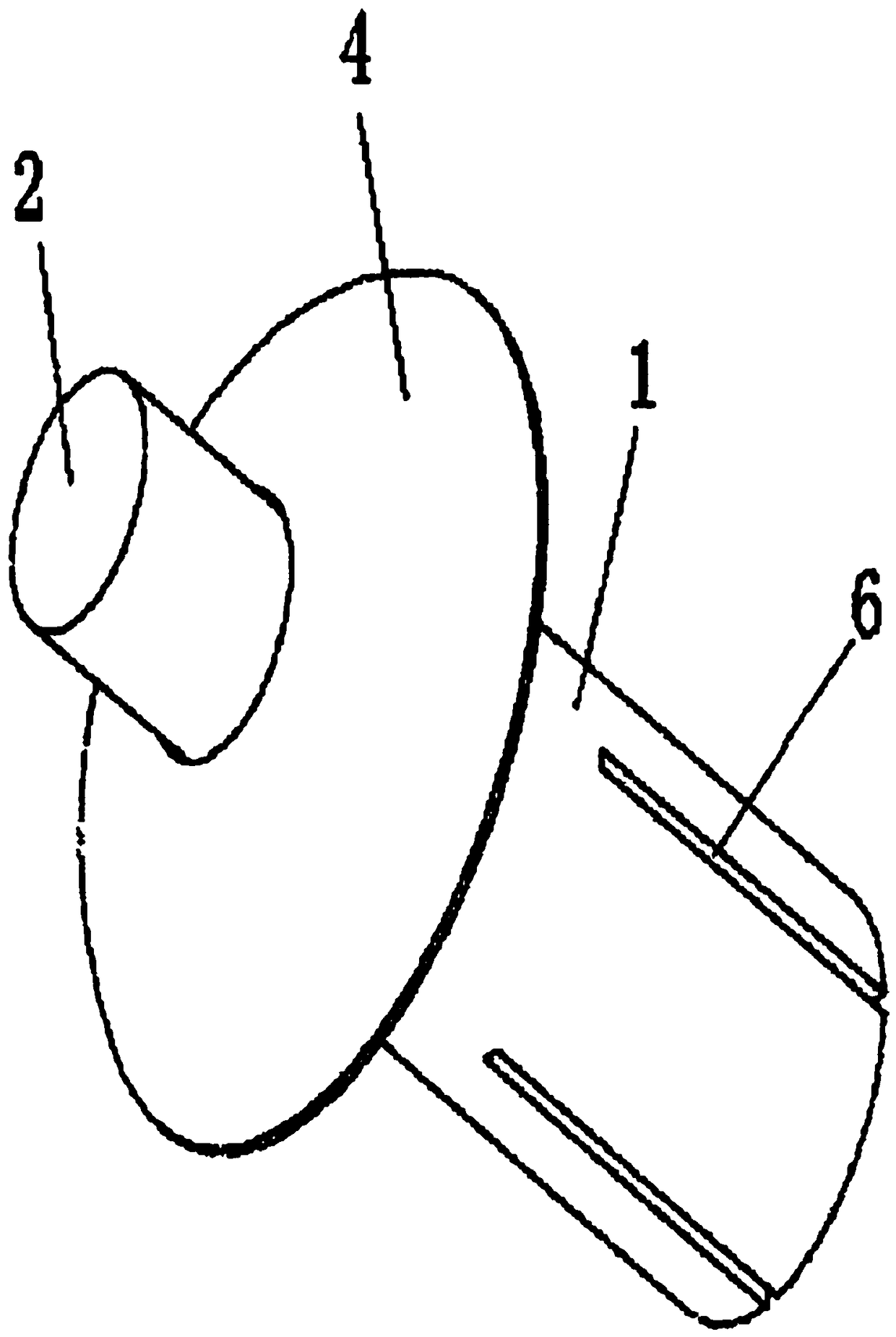

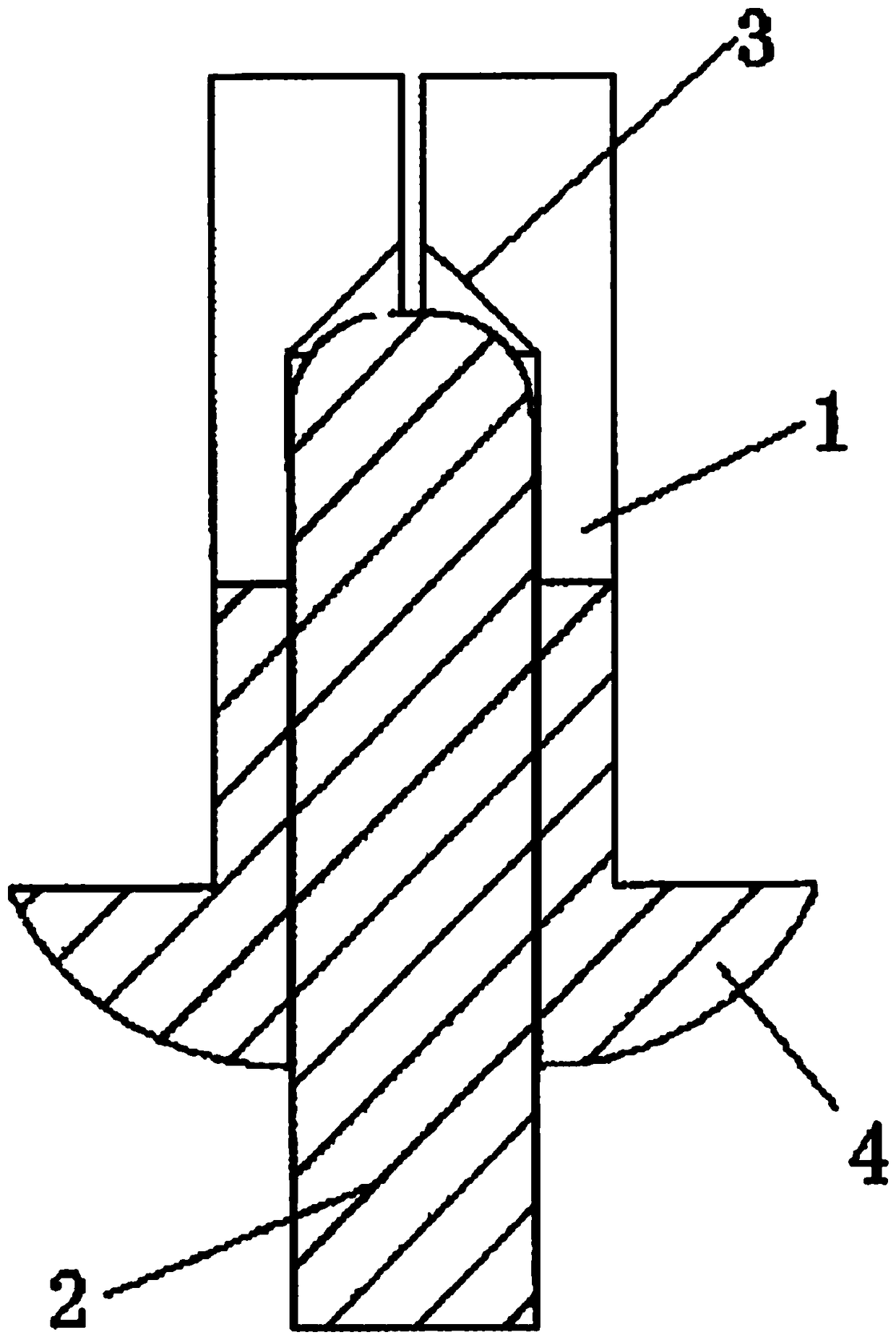

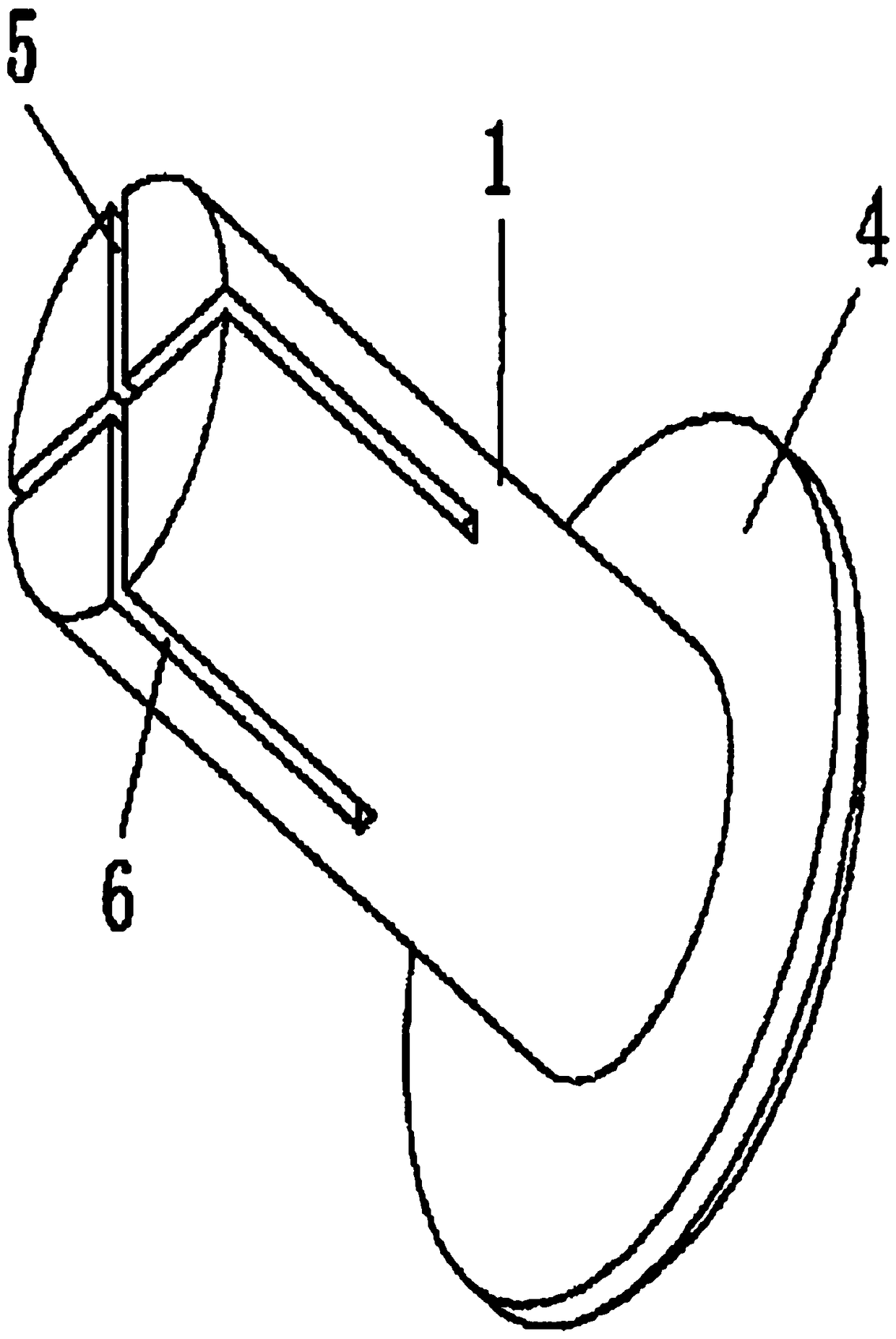

[0013] refer to figure 1 , figure 2 , image 3 , a core rivet, comprising a cap 1, the cap 1 is provided with a crack, the cap 1 has an insertion cavity, a mandrel 2 is inserted in the cavity, and the insertion cavity The bottom surface 3 is conical with the tip of the cone facing outwards. In this embodiment, the rear end of the cap 1 is provided with a flange 4 .

[0014] In this embodiment, there are four cracks, and the four cracks are evenly distributed on the cap; each crack includes a radial crack 5 and an axial crack 6, and the radial crack 5 starts from The center of the front end face of the cap extends outwards, and the head of the axial crack 6 connects with the tail of the radial crack 5 and extends backward on the side wall of the cap 1 .

[0015] The usage method of the present invention is the same as the usage method of the existing core rivet, and will not be repeated here.

[0016] Since the bottom surface 3 of the insertion cavity is in the shape of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com