Cast-in-place lightweight wallboard and floor

A light-weight wallboard and floor covering technology, applied to floors, ceramic products, and other household appliances, can solve the problem of sound insulation, waterproof performance, poor fireproof performance and earthquake resistance, poor bending resistance, poor impact resistance, and market competitiveness. Small and other problems, to achieve the effect of good shock resistance, excellent weather resistance, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited to the following embodiments, and it can be foreseen that those skilled in the art may produce various changes in the implementation situation in combination with the prior art.

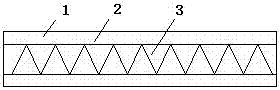

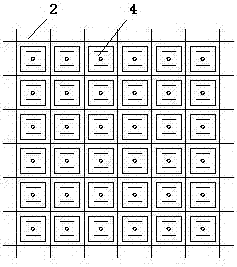

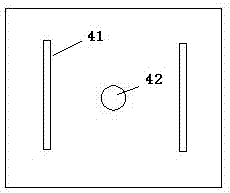

[0019] Such as figure 1 and figure 2 , a cast-in-place lightweight wallboard and floor covering, comprising a gypsum mortar board 1, a steel wire mesh 2 and an inner mold 4, the steel wire mesh 2 is in the shape of a grid, and consists of upper and lower layers, with a "W" shape between the layers The supporting steel wire 3, the inner mold 4 is placed in the grid of the two-layer steel wire mesh 2; the gypsum mortar board is composed of the following raw materials and parts by weight: 80-100 parts of gypsum powder, 10-15 parts of fly ash 5-8 parts of organic silicon waterproofing agent, 3-5 parts of pulp, 3-4 parts of fiber, 5-8 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com