Anticorrosion surface coating for flat-plate solar collector and preparation technology thereof

A flat-panel solar energy and surface coating technology, which is applied to solar collectors, solar collector safety, anti-corrosion coatings, etc., can solve the problems of insignificant use effect, easy peeling off of the coating, insignificant effect, etc. , No environmental pollution, obvious effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An anti-corrosion surface coating for a flat solar heat collector is prepared from the following raw materials:

[0021] Modified silicone resin 50kg, epoxy resin 40kg, polyamide resin 30kg, phenalkamine resin 10kg, polyethylene glycol 2kg, silicon bath soil 6kg, glass powder 5kg, flame retardant polyether polyol 15kg, nano calcium carbonate 5kg, Tetramethylsilane 5kg, zinc oxide 3kg, graphite powder 5kg, modified plant fiber powder 15kg, deionized water 100kg;

[0022] The preparation method of the modified plant fiber powder is as follows: soak the ashes of plant stalks with 8% hydrochloric acid for 2 days, then wash them with deionized water, then soak them with 8% sodium hydroxide solution for 3 days, and wash them with deionized water until Neutral, dry, preliminarily grind to obtain ashes, then add 4% phosphoric acid, 2% pepinga, and 5% citric acid by weight of plant straw ashes, control the speed at 3500r / min, stir for 5 hours, and then discharge and dry It can ...

Embodiment 2

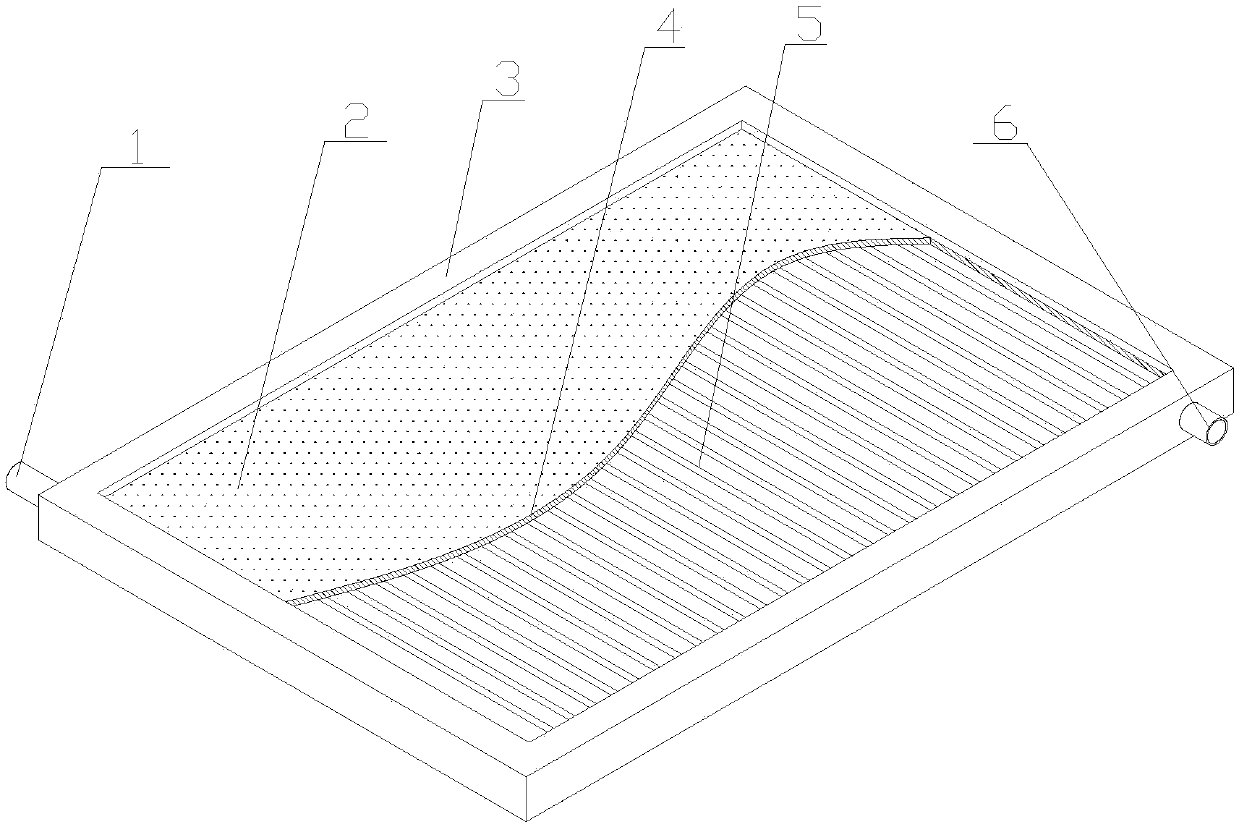

[0029] Such as figure 1 As mentioned above, as another embodiment of the present invention, a high heat-absorbing solar collector includes a frame body 3, a connecting copper pipe 5 installed inside the frame body 3, and a layer of hollow tempered steel is added on the connecting copper pipe 5. Glass 4, the frame body 3 is provided with a liquid inlet 1 and a liquid outlet 6, the outer wall of the hollow tempered glass 4 is provided with dense granules 2, and the outer wall of the hollow tempered glass 4 is painted with an anti-corrosion surface layer The coating absorbs heat through the action of hollow tempered glass, and the heat absorption in the connecting copper pipe heats the internal liquid medium to realize temperature conversion, and the role of granules realizes the full adhesion of the anti-corrosion surface coating, which is more Fasten;

[0030] The anti-corrosion surface coating of the flat solar heat collector is prepared from the following raw materials:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com