Nickel-cobalt lithium aluminate material coated with sodium-based oxidizing agent and preparation method thereof

A technology of nickel-cobalt lithium aluminate and oxidant, which is applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of unstable structure, poor electrochemical cycle performance, etc., to improve processing performance and reduce diffusion activation energy , the effect of increasing the layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a nickel-cobalt-lithium-aluminate material coated with a sodium-based oxidant, comprising the following steps:

[0027] Step 1. Preparation of raw materials. Mix the nickel-cobalt-aluminum hydroxide precursor, additives, and lithium source evenly, place them in high-temperature equipment and perform a calcination under an oxygen atmosphere to obtain a nickel-cobalt-lithium aluminate ternary material;

[0028] Step 2, preparation of the mixture, uniformly mixing the sodium-based oxidant and the nickel-cobalt-lithium-aluminate ternary material.

[0029] Step 3, preparation of modified materials, placing the mixed materials in high temperature equipment for secondary calcination.

[0030] In step 1, the nickel element content in the nickel cobalt aluminum hydroxide precursor is 70%-90% of its total molar content, the cobalt element content is 5%-20% of its total molar content, and the aluminum element content is its total molar content. 0.5%-10% of...

Embodiment 1

[0036] Step 1. Mix lithium hydroxide, nickel-cobalt-aluminum hydroxide precursor and additive magnesium hydroxide evenly, wherein the molar ratio of the three metal elements of nickel-cobalt-aluminum in the nickel-cobalt-aluminum hydroxide precursor is 70:20:10 , the molar ratio of lithium hydroxide to the nickel-cobalt-aluminum hydroxide precursor is 1:1, and the magnesium element content in the magnesium hydroxide is 0.01% of the content of the nickel-cobalt-aluminum hydroxide precursor. The mixture is calcined in a high-temperature equipment under an oxygen atmosphere. The temperature of the first stage of calcination is 480°C, and the holding time is 10h. The temperature of the second stage of calcination is 650°C, and the holding time is 15h. Nickel cobalt lithium aluminate ternary material;

[0037] Step 2, mixing sodium antimonate powder with the obtained nickel-cobalt-lithium-aluminate ternary material evenly, wherein the sodium antimonate is 0.01% of the molar mass of...

Embodiment 1 and comparative example 1

[0042] Embodiment 1 and comparative example 1 performance detection

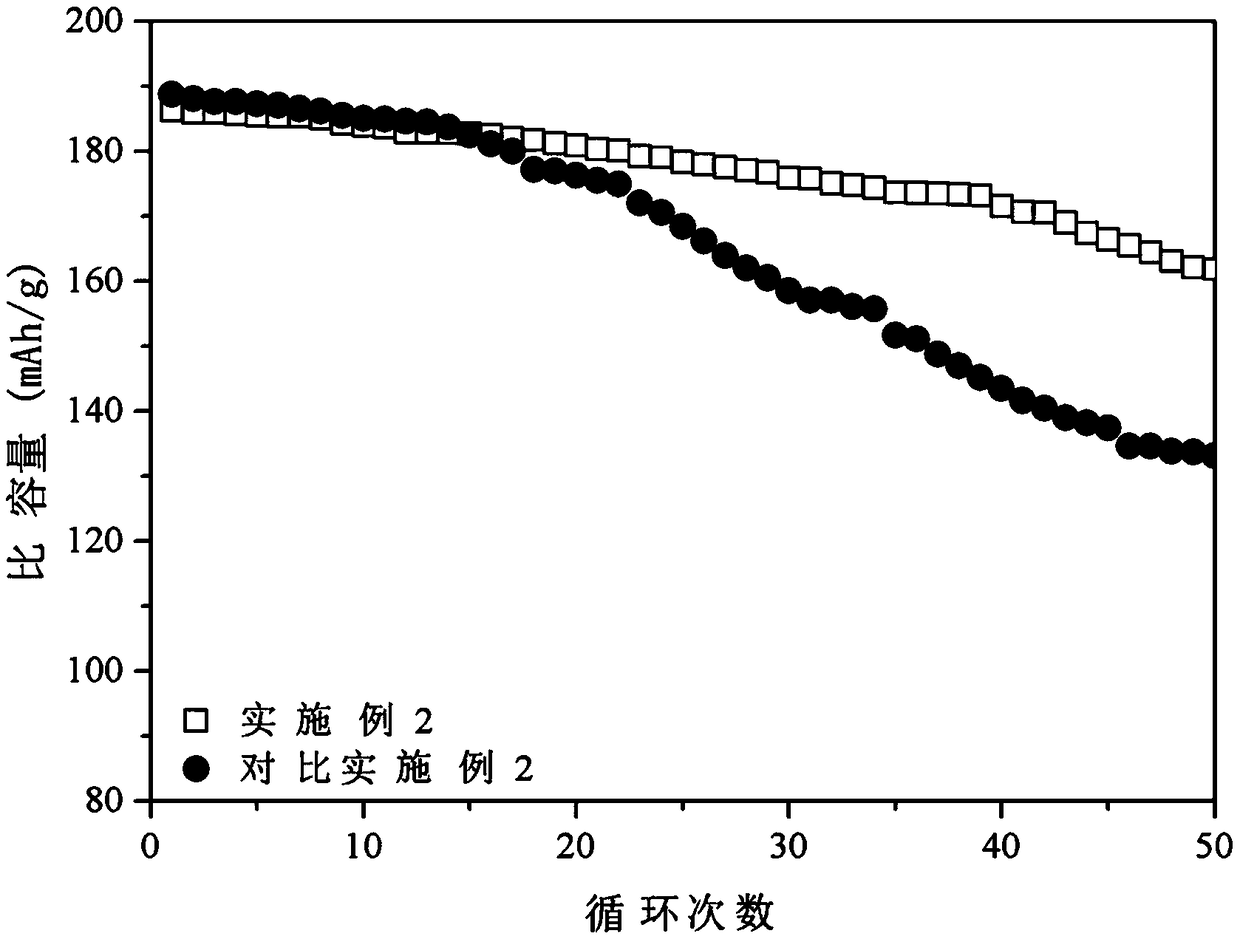

[0043] Using the nickel-cobalt-lithium-aluminate coated with sodium antimonate in Example 1 of the present invention and the nickel-cobalt-lithium-aluminate positive electrode material in Comparative Example 1, respectively assemble CR2025 button batteries, and charge them at 3.0-4.5V and 1C respectively. discharge cycle test, thus obtaining as figure 1 The comparison diagram of the cycle performance curve shown. Depend on figure 1 It can be seen that compared with the nickel-cobalt-aluminate lithium coated with sodium antimonate in Comparative Example 1, the nickel-cobalt-aluminate lithium coated with sodium antimonate in Example 1 of the present invention has a high discharge capacity. It can be confirmed that the coating modification of sodium antimonate can improve the cycle performance of nickel-cobalt-lithium-aluminate materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com