Method for treating high-impurity lithium iron phosphate waste powder by using low-consumption phosphoric acid

A technology for the treatment of lithium iron phosphate and phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem that battery-grade iron phosphate cannot be directly recovered, the purity of iron phosphate is not high, and the ratio of iron to phosphorus cannot be guaranteed, etc. problem, to achieve good aluminum removal effect, avoid structure damage, and achieve the effect of pollution-free recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

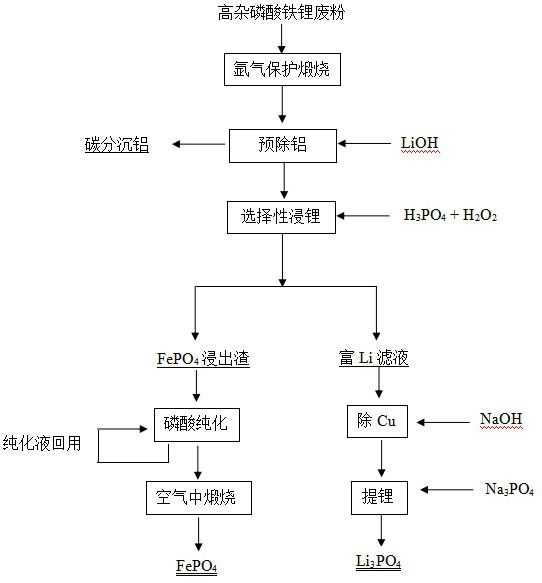

[0049] A method for treating high-heterotype lithium iron phosphate waste powder with low-consumption phosphoric acid, the process flow is as follows figure 1 shown, including the following steps:

[0050] The disassembled high-heterolithium iron phosphate waste powder (mass percentage content of impurities C, Cu, and Al is 6.21%, 0.07% and 1.85% respectively, and contains a small amount of PVDF and diaphragm) is calcined at 550°C in an argon atmosphere 6h, to fully decompose the binder PVDF and the diaphragm. Slurry the waste powder from the removal of PVDF and diaphragm with ultrapure water at a solid-to-liquid ratio of 1:3, and use energy to convert Al into AlO 2- 1.2 times the theoretical molar amount of LiOH to remove aluminum, the concentration of LiOH in the system is 0.5mol / L, the reaction time is 0.5h, and filtered after the reaction. The carbon of the filtrate is precipitated into aluminum, and after the filter residue is dried, continue to mix the slurry with ultr...

Embodiment 2

[0052] A method for treating high-hetero-hetero lithium iron phosphate waste powder with low consumption of phosphoric acid, comprising the following steps:

[0053] The dismantled high-heterolithium iron phosphate waste powder (mass percentages of impurities C, Cu, and Al are 5.27%, 0.02%, and 1.06% respectively, and contains a small amount of PVDF) is calcined at 550°C for 6 hours in an argon atmosphere. Fully decompose the binder PVDF. Slurry the waste powder after removing PVDF with ultrapure water at a solid-to-liquid ratio of 1:3, and use energy to convert Al into AlO 2- 1.3 times the theoretical molar amount of LiOH to remove aluminum, the concentration of LiOH in the system is 0.6mol / L, the reaction time is 0.5h, and filter after the reaction. The carbon of the filtrate is precipitated into aluminum, and after the filter residue is dried, continue to mix the slurry with ultrapure water and slowly add phosphoric acid with a molar mass of 0.5 times the molar mass of lit...

Embodiment 3

[0055] A method for treating high-hetero-hetero lithium iron phosphate waste powder with low consumption of phosphoric acid, comprising the following steps:

[0056]The disassembled high-heterolithium iron phosphate waste powder (mass percentages of impurities C, Cu, and Al are 4.51%, 0.05%, and 0.56%, respectively, and contain a small amount of PVDF) is calcined at 550°C for 6 hours in an argon atmosphere. Fully decompose the binder PVDF. Slurry the waste powder after removing PVDF with ultrapure water at a solid-to-liquid ratio of 1:3, and use energy to convert Al into AlO 2- 1.2 times the theoretical molar amount of LiOH to remove aluminum, the concentration of LiOH in the system is 0.5mol / L, the reaction time is 0.5h, and filtered after the reaction. The filtrate is carbonized to precipitate aluminum, and after the filter residue is dried, continue to slurry with ultrapure water and slowly add phosphoric acid with a molar mass of 0.8 times the molar mass of lithium in lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com