Method for leaching out inpurity iron in bauxite by chemical-biological method

A biological method and ore technology, applied in the direction of improving process efficiency, etc., can solve problems such as low cost and energy consumption, long iron removal time, and slow biological reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

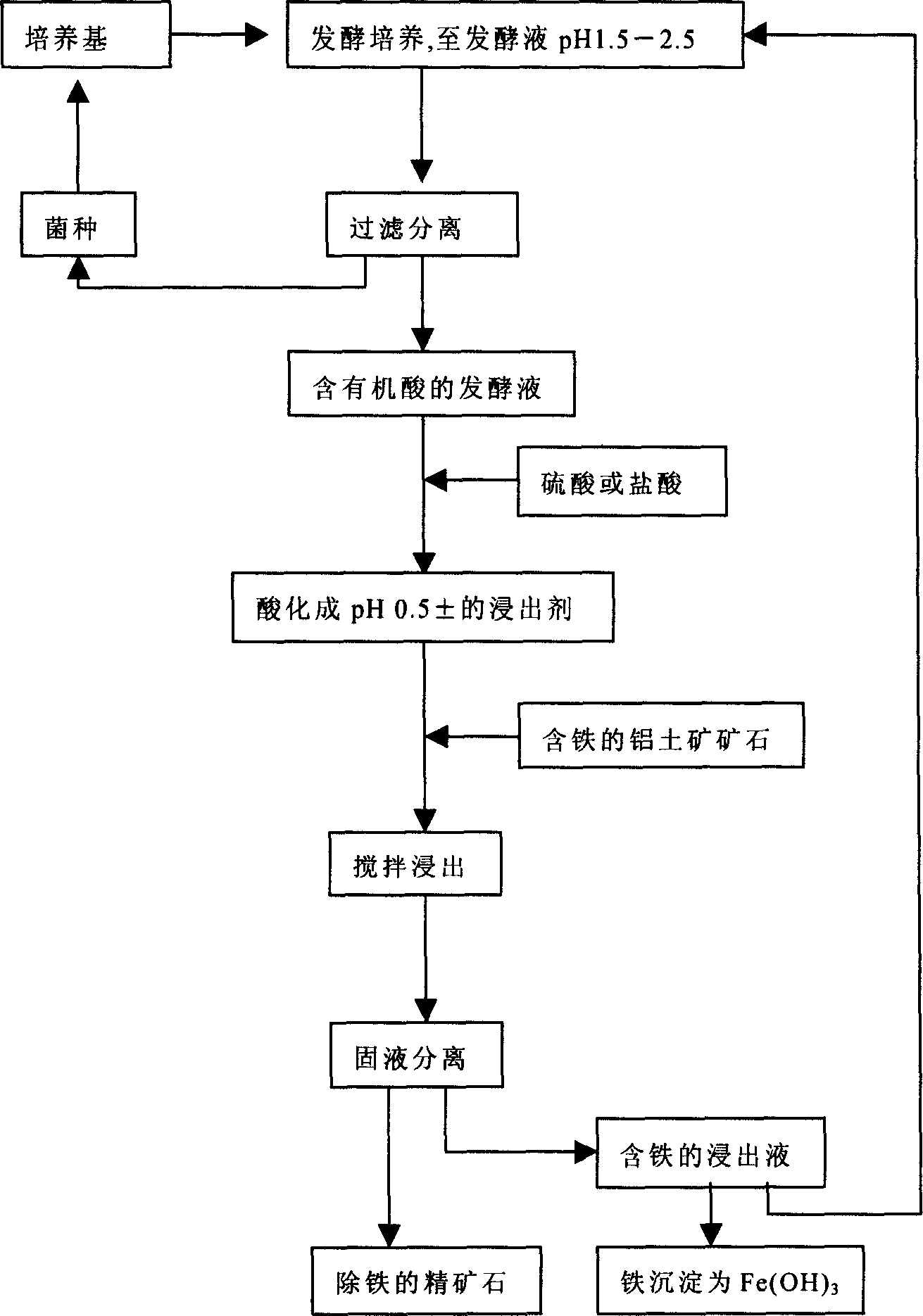

Method used

Image

Examples

preparation example Construction

[0020] (1) Preparation of leaching solution

[0021] Chase Medium: NaNO 3 2g, K 2 HPO 4 1g, KCl 0.5g, MgSO 4 0.5g, FeSO 4 0.01g, 30g molasses, 1000mL water, natural pH, sterilized at 121°C for 20 minutes; after cooling the culture medium, inoculate the mycelia or spores of Aspergillus niger strain; culture conditions: temperature 25°C-35°C, culture time 3 days- 5 days; when the pH of the culture solution drops to 1.5-2.5, filter the culture solution to remove the mycelium, adjust the pH of the fermentation solution to 0.5-1.0 with sulfuric acid, and make a leachate;

[0022] (2) Ore leaching and iron removal

[0023] After the leach solution is prepared, stir and leach impurity iron in the ore at 80°C-90°C; use a stirring intensity of 150r / min-250r / min, a pulp concentration of 10%-30%, and a treatment time of 6h, and then filter. washing.

Embodiment 1

[0025] First prepare the leaching solution; Cha's medium: NaNO 3 2g,K 2 HPO 4 1g, KCl 0.5g, MgSO 4 0.5g, FeSO 4 0.01g, molasses 30g, water 1000mL, pH natural, sterilized at 121°C for 20min. After cooling the medium, inoculate Aspergillus niger YJY-1 # The mycelium or spores of the strain. The culture conditions are: temperature 35° C., rotation speed 150 r / min, and culture for 5 days. When the pH of the culture solution is reduced to 1.5, the culture solution is filtered to remove the mycelium, and the fermented solution is adjusted to pH 0.5 with sulfuric acid to prepare a leaching agent.

[0026] take 1 # The iron oxide content in the ore is 13.18%. The ore is crushed and ball-milled until the particle size is less than 174μm, and then leached. The leaching conditions are: leaching temperature 80°C, solid content weight concentration of the pulp during leaching is 10%, shaking table speed 150r / min, The leaching time is 6h. Filtrate and wash while hot, and detect...

Embodiment 2

[0028] First prepare the leaching solution; Cha's medium: NaNO 3 2g,K 2 HPO 4 1g, KCl 0.5g, MgSO 4 0.5g, FeSO 4 0.01g, molasses 30g, water 1000mL, pH natural, sterilized at 121°C for 20min. After cooling the medium, inoculate Aspergillus niger YJY-1 # The mycelium or spores of the strain. The culture conditions are as follows: the temperature is 25° C., the rotation speed is 250 r / min, and the culture time is 5 days. When the pH of the culture solution is reduced to 2.5, the culture solution is filtered to remove the mycelium, and the fermented solution is adjusted to pH 1.0 with sulfuric acid to prepare a leaching agent.

[0029] take 2 # The content of iron oxide in the ore is 4.31%, 2 # The ore is bauxite beneficiation tailings, directly leached. The ore leaching conditions are: leaching temperature 85°C, pulp solid content weight concentration 20%, shaker speed 200r / min, leaching time 6h. Filtrate and wash while hot, and detect the content of iron, aluminum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com