Method for decomposing titanium-containing blast-furnace slag through fused salt

A technology of blast furnace slag and blast furnace titanium slag, which is applied in the fields of hydrometallurgy and metal oxide preparation, can solve the problems of low titanium leaching rate, secondary pollution, and small processing capacity, so as to avoid secondary pollution and reduce production capacity The effect of reducing consumption and slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

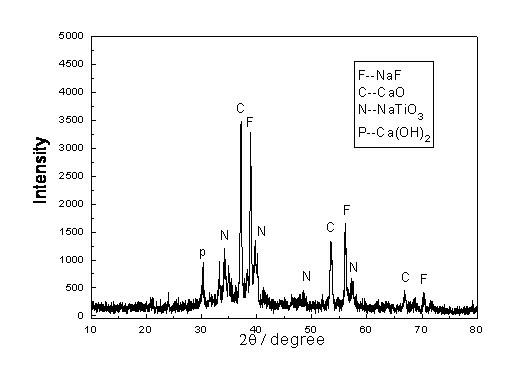

[0026] The titanium-containing blast furnace slag that is ball-milled to a particle size of less than 0.074mm is mixed with NaOH+NaF evenly, and reacted at 500°C for 4 hours, wherein the mass ratio of NaOH to titanium-containing blast furnace slag is 4:1, and the molar ratio of NaOH:NaF is 4 : 1, after the reaction, solid mesophase is obtained, and the XRD figure of solid mesophase is as attached figure 2 shown;

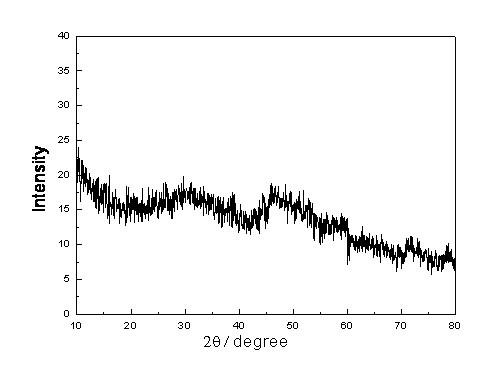

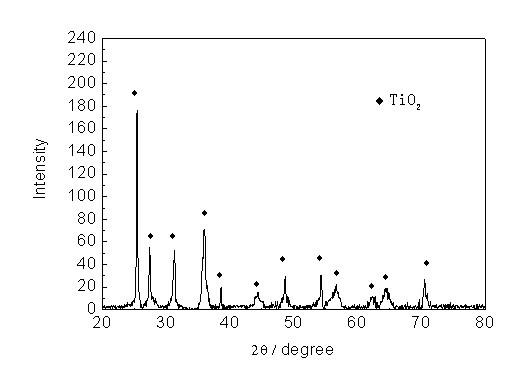

[0027] Wash the solid mesophase with water, the washing temperature is 60°C, the washing solid-liquid mass ratio is 1:20, and the XRD spectrum of the product after washing is shown in the attached image 3 As shown, all generate an amorphous phase; then the product after washing is suction filtered, and the solid phase obtained is a solid intermediate product containing Ti and impurities Fe, Ca and Mg, and the filtrate is a solid intermediate product containing NaOH, NaF and impurities Si, Al and Mn mixed lye;

[0028] Add CaO to the obtained mixed lye containing ...

Embodiment 2

[0032] The titanium-containing blast furnace slag that is ball-milled to a particle size of less than 0.074mm is uniformly mixed with NaOH+NaF, and reacted at 200°C for 10 hours, wherein the mass ratio of NaOH to titanium-containing blast furnace slag is 10:1, and the molar ratio of NaOH:NaF is 10 : 1, obtain solid mesophase after the reaction;

[0033] Wash the solid interphase with water, the washing temperature is 60°C, and the washing solid-to-liquid mass ratio is 1:20; then the washed product is subjected to suction filtration, and the obtained solid phase is a solid intermediate product containing Ti and impurities Fe, Ca and Mg , the filtrate is a mixed lye containing NaOH, NaF and impurities Si, Al and Mn;

[0034] Add CaO to the obtained mixed lye containing NaOH, NaF and impurities Si, Al and Mn according to the mass ratio of calcium to silicon: 1: (1-3), convert Si and Al into insoluble aluminosilicate, filter to remove, filter The final solution is evaporated and ...

Embodiment 3

[0038] The titanium-containing blast furnace slag that is ball-milled to a particle size of less than 0.074mm is uniformly mixed with NaOH+NaF, and reacted at 700°C for 1 hour, wherein the mass ratio of NaOH to titanium-containing blast furnace slag is 1:1, and the molar ratio of NaOH:NaF is 1 : 1, obtain solid mesophase after the reaction;

[0039] The intermediate phase is washed with water at a washing temperature of 70°C, and the washing solid-to-liquid mass ratio is 1:30; then the washed product is subjected to suction filtration, and the obtained solid phase is a solid intermediate product containing Ti and impurities Fe, Ca and Mg, The filtrate is a mixed lye containing NaOH, NaF and impurities Si, Al and Mn;

[0040] Add CaO to the obtained mixed lye containing NaOH, NaF and impurities Si, Al and Mn according to the mass ratio of calcium to silicon: 1: (1-3), convert Si and Al into insoluble aluminosilicate, filter to remove, filter The final solution is evaporated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com