Unloading mechanism based on aquatic product carrier vehicle

A technology of unloading mechanism and transport vehicle, applied in the fields of production and aquatic product transportation, can solve the problems of heavy weight, large water content, labor-intensive and other problems, and achieve the effects of convenient operation and use, reducing labor intensity and avoiding excessive water accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

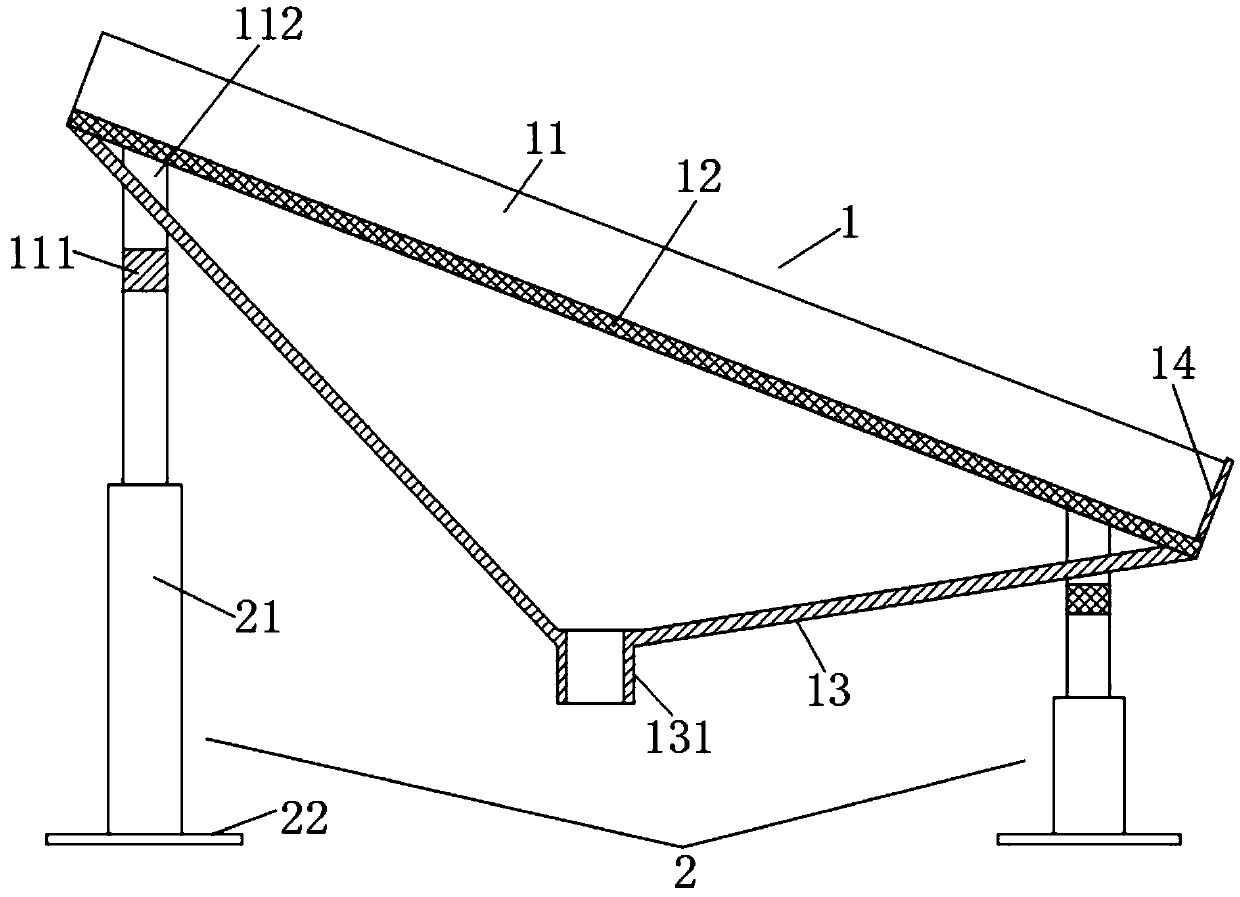

[0030] Example: such as figure 1 and 2 As shown, the unloading mechanism based on the aquatic product transport vehicle in this embodiment includes a discharge trough 1 and two groups of lifting mechanisms 2;

[0031] The above-mentioned unloading chute 1 is a tank body with both ends open, one end is a feed port, the other end is a discharge port, and the level of the discharge port is lower than the level of the feed port;

[0032] Two groups of the above-mentioned lifting mechanisms 2 are respectively installed at the lower ends of the two ends of the above-mentioned unloading chute 1 to adjust the overall inclination angle and height of the above-mentioned unloading chute 1;

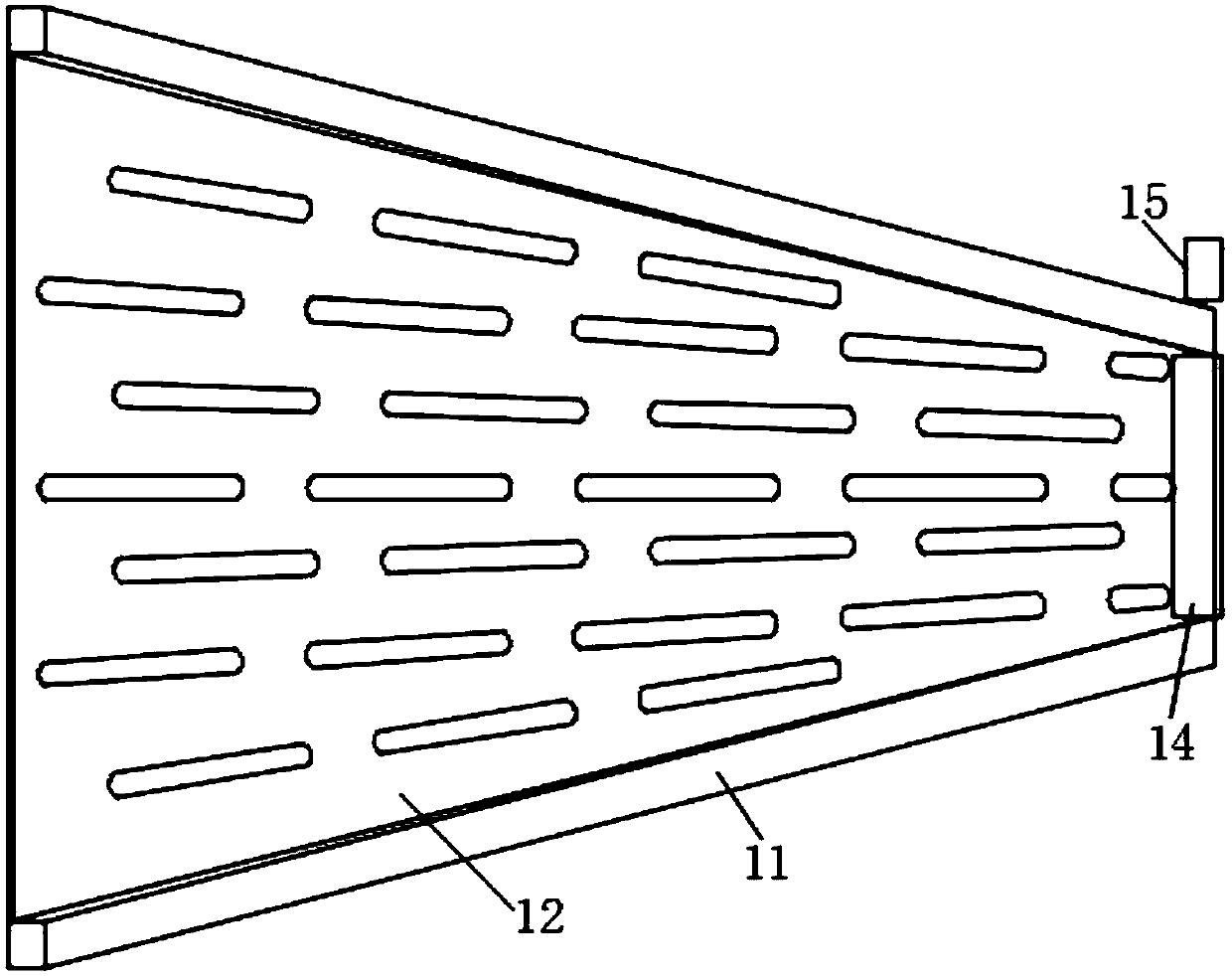

[0033] The discharge chute 1 includes two symmetrically arranged side plates 11 and a drainage grid plate 12 arranged between the lower ends of the two side plates 11 .

[0034] Before unloading aquatic products, adjust the height and angle of the entire unloading chute 1 through two sets of liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com