Ultrapure quartz sand and purification process thereof

A quartz sand and process technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of limited diffusion and dissolution of impurity ions, long leaching time, low product purity, etc., achieve obvious economic and practical application value, improve purification Efficiency and purity, the effect of a simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

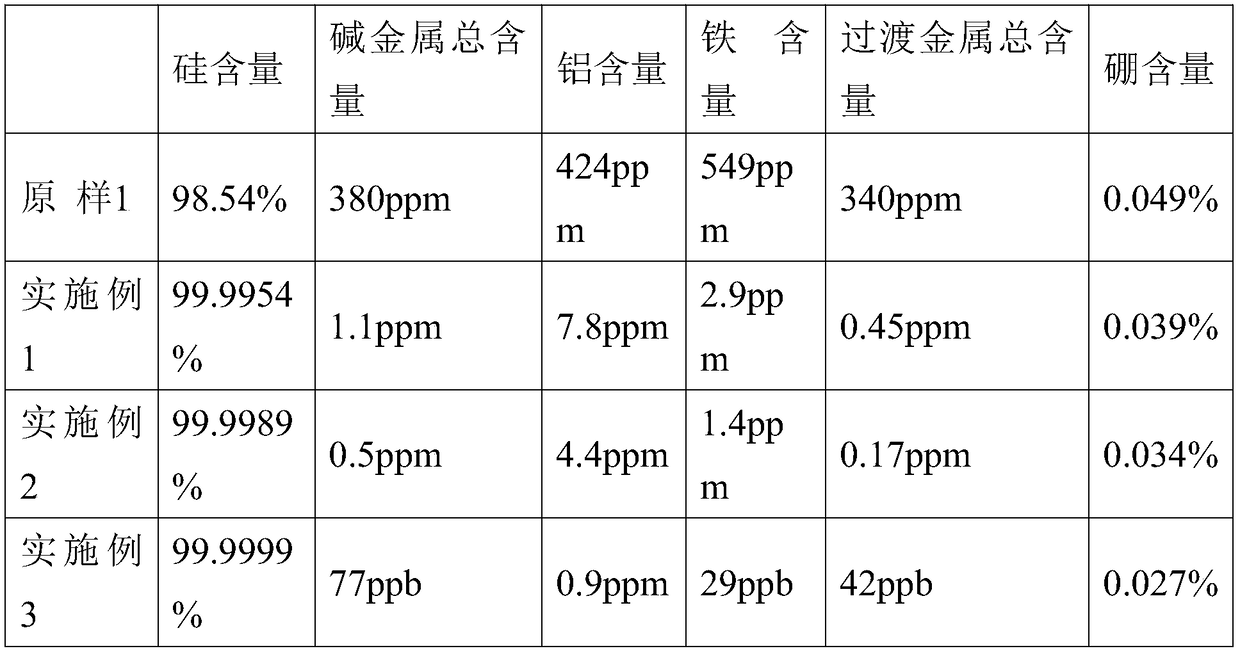

Embodiment 1

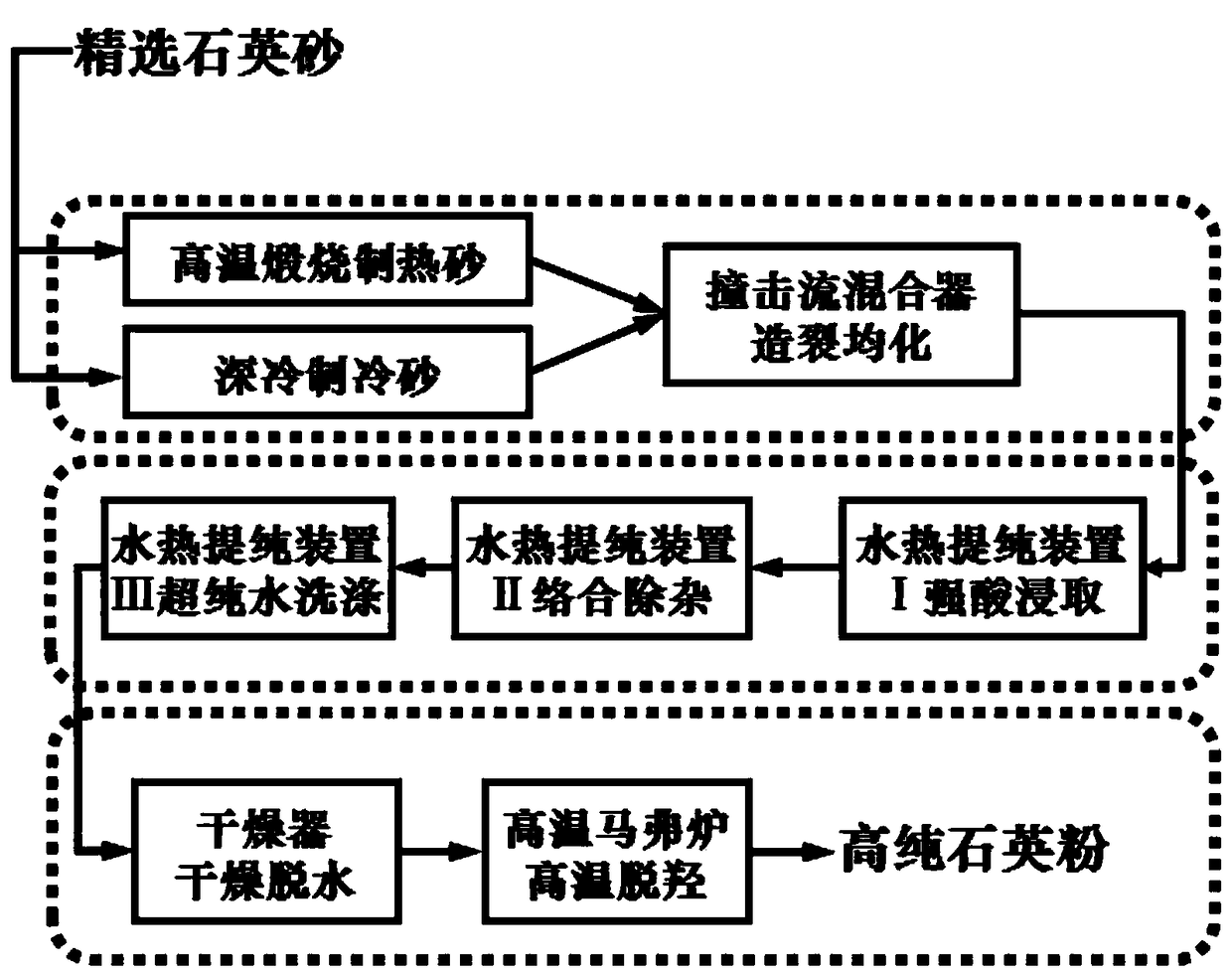

[0023] Embodiment 1: as figure 1

[0024]The method for purifying quartz sand comprises the steps of:

[0025] 1) Using quartz sand with a silica content of 98.2% as raw material, add a 4mol / L inorganic mixed acid solution, place it in an impingement flow mixer and heat it to 80°C, and perform repeated impact cleaning for 4 hours. The pickled quartz sand in the mixer is subjected to solid-liquid separation to obtain primary washed sand.

[0026] The inorganic mixed acid is composed of hydrofluoric acid and hydrochloric acid, the concentration of the mixed acid is 4mol / L, the concentration of hydrofluoric acid is 0.5mol / L, and the concentration of hydrochloric acid is 3.5mol / L.

[0027] 2) Divide the initial washing sand into two parts, and heat and cool them separately. One part of the initial washing sand is heated to 600 °C for crushing, and the other part is cryogenically cooled to -180 °C. The prepared cold sand and hot sand are sent to the high temperature resistant im...

Embodiment 2

[0033] Embodiment 2: as figure 1

[0034] The method for purifying quartz sand comprises the steps of:

[0035] 1) Using quartz sand with a silica content of 98.4% as raw material, add a 9mol / L inorganic mixed acid solution, place it in an impingement flow mixer and heat it to 80°C, and perform repeated impact cleaning for 4 hours. The pickled quartz sand in the mixer is subjected to solid-liquid separation to obtain primary washed sand.

[0036] The inorganic mixed acid is composed of fluorosulfuric acid and hydrochloric acid, the concentration of the mixed acid is 4mol / L, wherein the concentration of fluorosulfuric acid is 0.5mol / L, and the concentration of hydrochloric acid is 3.5mol / L.

[0037] 2) Divide the initial washing sand into two parts, and heat and cool them separately. One part of the initial washing sand is heated to 800 °C for crushing, and the other part is cryogenically cooled to -200 °C. The prepared cold sand and hot sand are sent to the high temperature...

Embodiment 3

[0043] Embodiment 3: as figure 1

[0044] The method for purifying quartz sand comprises the steps of:

[0045] 1) Using quartz sand with a silica content of 98.9% as raw material, add a 15mol / L inorganic mixed acid solution, place it in an impingement flow mixer and heat it to 100°C, and perform repeated impact cleaning for 6 hours. The pickled quartz sand in the mixer is subjected to solid-liquid separation to obtain primary washed sand.

[0046] The inorganic mixed acid is composed of fluorosulfuric acid, nitric acid and hydrochloric acid. The concentration of the mixed acid is 15mol / L, of which the concentration of fluorosulfuric acid is 3mol / L, the concentration of nitric acid is 2mol / L, and the concentration of hydrochloric acid is 10mol / L.

[0047] 2) Divide the initial washing sand into two parts, and carry out heating and cooling treatment respectively. One part of the initial washing sand is heated to 1000 °C for crushing, and the other part is cryogenically cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com