Potato block cutter

A cutting machine and potato block technology, applied in metal processing, etc., can solve the problems of unable to meet production requirements, unable to complete raw material transportation, unable to pass through the delivery pump, etc., to improve production efficiency, save manpower, and avoid starch loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

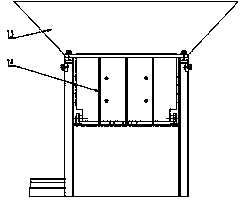

[0018] The present invention is further described below in conjunction with accompanying drawing:

[0019] like Figure 1-3 Shown: a large potato block cutting machine, including 2 machine frames and a cutting groove 12 fixed on the frame, the rear part of the cutting groove 12 is provided with a push plate 3, and a horizontal guide rod is fixed on the back of the push plate 6. The other end of the horizontal guide rod is connected with a crank rocker mechanism, which is composed of a turntable 8, a rocker 9 and a rocker fixing pin 10, and the two sides of the rocker fixing pin 10 are welded to prevent the rocker shaft from To the offset fixed plate 11. The crank rocker mechanism is driven by a motor to drive the horizontal guide rod and the push plate to reciprocate back and forth. The horizontal guide rod 6 is mounted on the guide rail 7 welded on the frame 2; The fixed knife device 14 of potato block is provided with receiving hopper 13 above the cutting groove 12, is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com