Preparation method and use of medicinal pregelatinized hydroxypropyl starch

A technology of pregelatinizing hydroxypropyl and hydroxypropyl starches, which is applied in pharmaceutical formulations, medical preparations of non-active ingredients, capsule delivery, etc. It can solve the problem of uneven mixing of starch and modifiers, uncontrollable reaction degree Various problems such as product performance, to achieve the effect of good catalytic activity and stability, high controllability of product quality, and consistent technical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

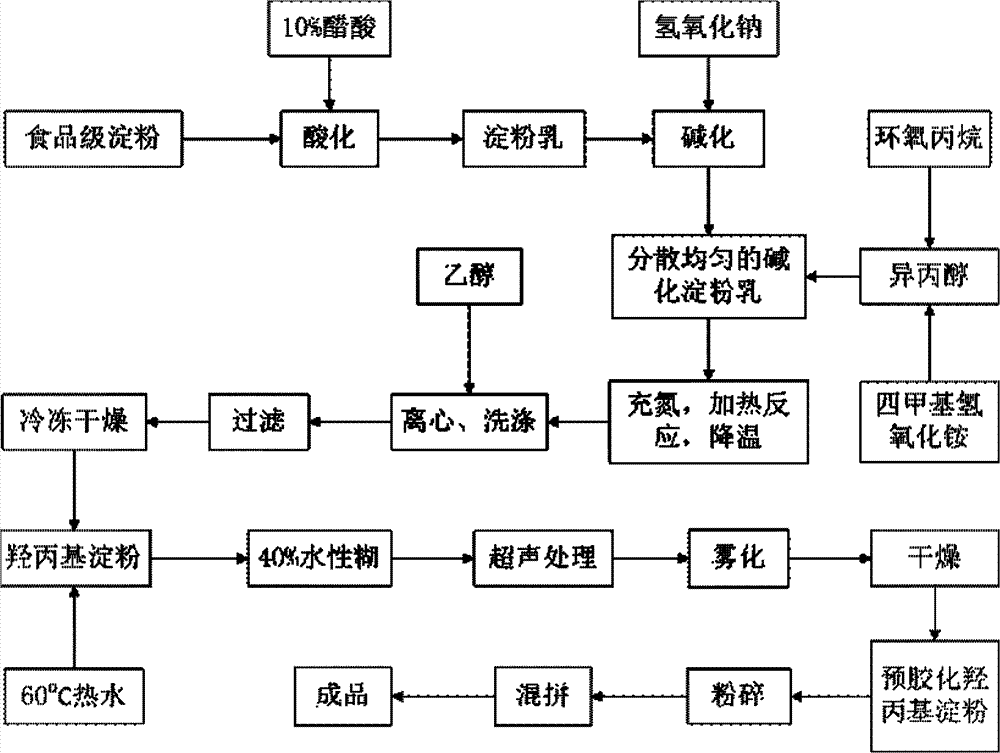

Method used

Image

Examples

Embodiment 1

[0053] Weigh 100g of food-grade cassava starch and place it in a pressure-resistant reactor, add 5ml of acetic acid with a mass fraction of 10%, acidify for 4 hours, and obtain starch milk after fully stirring, then add sodium hydroxide to adjust the pH to 11.0; Dissolve propylene oxide solution and 6ml 25% tetramethylammonium hydroxide solution in 400mL isopropanol, disperse evenly, add to alkalized starch milk, and heat to 45°C under normal pressure under the protection of high-purity nitrogen , stirring and reacting for 7 hours, after cooling to room temperature, adding 3 times the amount of ethanol to stand for a period of time, centrifuging and washing 3 times, then filtering and freeze-drying to obtain hydroxypropyl starch; the prepared hydroxypropyl starch Dissolve in hot water at a temperature of 65°C to make a water-based paste with a concentration of 45%. After 300W ultrasonic treatment for 20 minutes, the water-based paste solution is atomized through an air-flow spr...

Embodiment 2

[0055] Weigh 500g of food-grade cassava starch and place it in a pressure-resistant reactor, add 50ml of acetic acid with a mass fraction of 10%, acidify for 3 hours, and obtain starch milk after fully stirring, then add sodium hydroxide to adjust the pH to 9.0; Propylene oxide solution and 25ml of 25% tetramethylammonium hydroxide solution were dissolved in 2.5L of isopropanol, dispersed evenly, added to the alkalized starch milk, under the protection of high-purity nitrogen, heated to 55 ℃, stirred and reacted for 8 hours, poured out the crude hydroxypropyl starch after cooling to room temperature, added 3 times the amount of ethanol to stand for a period of time, centrifuged and washed 3 times, then filtered and freeze-dried to obtain hydroxypropyl starch Dissolve the prepared hydroxypropyl starch in hot water at a temperature of 60°C to make a water-based paste with a concentration of 42%. After 200W ultrasonic treatment for 30 minutes, the water-based paste solution is ato...

Embodiment 3

[0057] Weigh 1000g of food-grade cassava starch and place it in a pressure-resistant reactor, add 80ml of acetic acid with a mass fraction of 10%, acidify for 1.5 hours, and stir thoroughly to obtain starch milk, then add sodium hydroxide to adjust the pH to 10.0; Dissolve propylene oxide solution and 40ml 25% tetramethylammonium hydroxide solution in 3L of isopropanol, disperse evenly, add to alkalized starch milk, and heat to 50°C under normal pressure under the protection of high-purity nitrogen , stirring and reacting for 6 hours, after cooling to room temperature, adding 2 times the amount of ethanol to stand for a period of time, centrifuging and washing 3 times, then filtering and freeze-drying to obtain hydroxypropyl starch; the prepared hydroxypropyl starch Dissolve in hot water at a temperature of 60°C to make a water-based paste with a concentration of 48%. After 250W ultrasonic treatment for 25 minutes, the water-based paste solution is atomized through an air-flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com