Production technique for starch without waste matter

A starch and technology technology, applied in the field of starch production without waste, can solve the problems of high sewage treatment costs, large auxiliary water consumption, serious steam consumption, etc., and achieve the effects of significant energy saving, reduced water consumption, and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

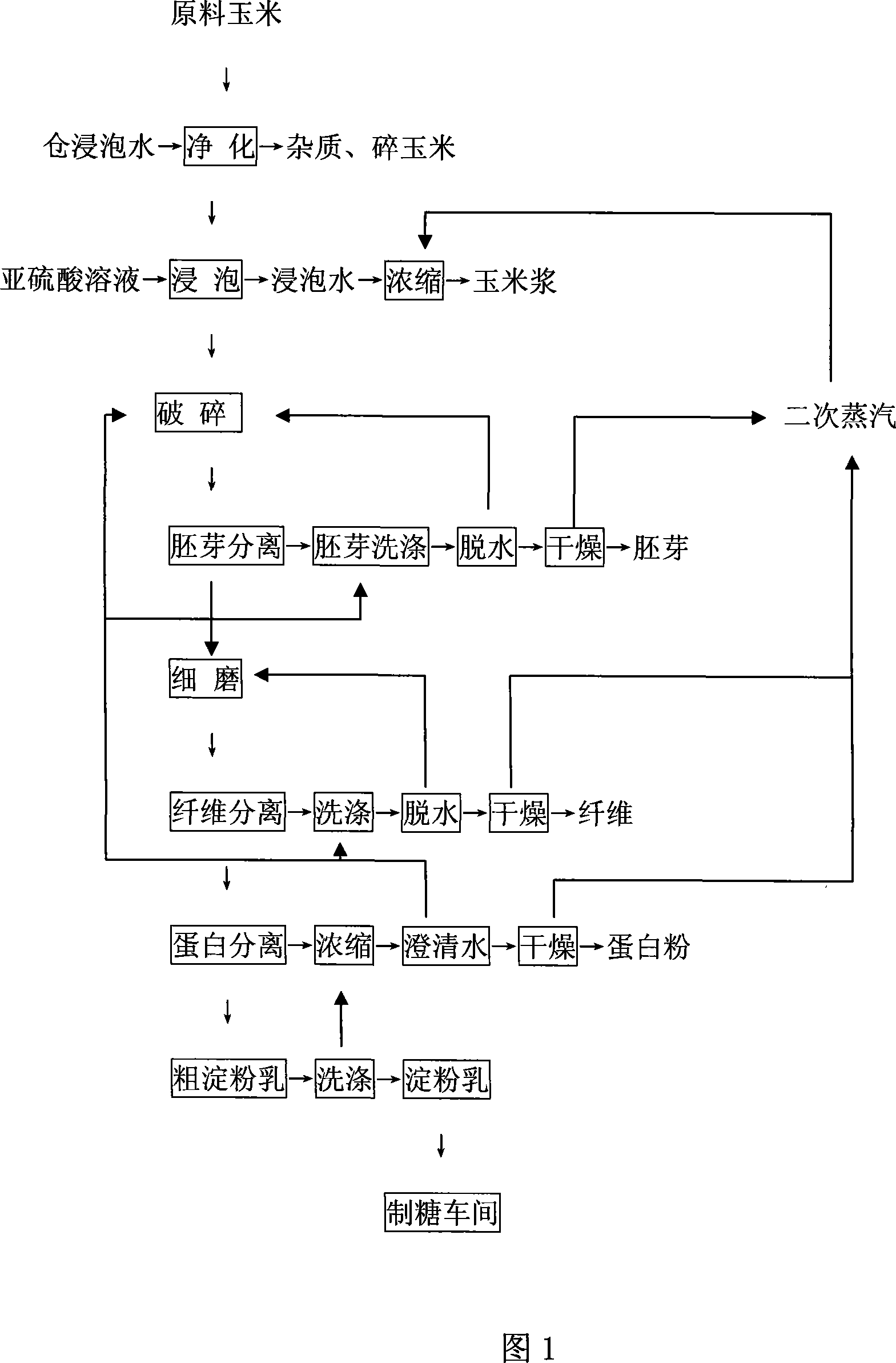

[0016] Its technical process of starch production without waste technology of the present invention is:

[0017] Corn→purification→transportation: use corn soaking water, that is, corn slurry to transport, the delivery speed is 0.9m / s, the delivery temperature is 35°C, the ratio of corn: thin corn slurry is 1:2.5→soaking: use 0.15% Sulfurous acid concentration soaking for 72 hours, soaking temperature 48°C → corn crushing: germ washing water and gluten clarified water, water temperature 35°C → germ separation: germ washing with gluten clarified water → fine grinding: fiber washing water → fiber separation : Gluten clarified water for fiber washing → protein separation: gluten water is separated, starch washing water also enters this post for protein separation → starch washing: 12-stage cyclone washing, with fresh water, the water temperature is 40 ℃) → starch Milk→Commercial starch.

Embodiment 2

[0019] Its technical process of starch production without waste technology of the present invention is:

[0020] Corn→purification→transportation: use corn soaking water, that is, corn slurry to transport, the delivery speed is 1.0m / s, the delivery temperature is 38°C, the ratio of corn: thin corn slurry is 1:2.8→soaking: use 0.25% Sulfurous acid concentration soaking for 65 hours, soaking temperature 49 ° C → corn crushing: germ washing water and gluten clarification water, water temperature 38 ° C → germ separation: germ washing with gluten clarification water → fine grinding: fiber washing water → fiber separation : Gluten clarified water for fiber washing → protein separation: gluten water is separated, starch washing water also enters this post for protein separation → starch washing: 12-stage cyclone washing, with fresh water, water temperature is 38 ℃) → starch Milk→Commercial starch.

Embodiment 3

[0022] Its technical process of starch production without waste technology of the present invention is:

[0023] Corn→purification→transportation: use corn soaking water, that is, corn slurry to transport, the delivery speed is 1.1m / s, the delivery temperature is 40°C, the ratio of corn: thin corn slurry is 1:3.0→soaking: use 0.35% Sulfurous acid concentration soaking for 60 hours, soaking temperature 50°C → corn crushing: germ washing water and gluten clarification water, water temperature 40°C → germ separation: germ washing with gluten clarification water → fine grinding: fiber washing water → fiber separation : Gluten clarified water for fiber washing → protein separation: gluten water is separated, starch washing water also enters this post for protein separation → starch washing: 12-stage cyclone washing, with fresh water, the water temperature is 42 ℃) → starch Milk→Commercial starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com