Method for co-producing crystalline fructose and fructose corn syrup by taking wheat as raw material, and preparation method of wheat starch

A fructose syrup and crystallized fructose technology, applied in fructose production, sugar production, sugar production, etc., can solve the problems that the glucose component and crystallized fructose separation mother liquor cannot be effectively used, and the production cost of crystallized fructose is high, and achieve Improve the utilization rate of raw materials, improve the separation effect, and expand the effect of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

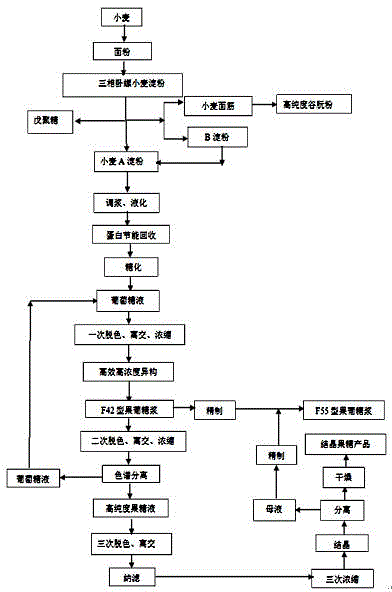

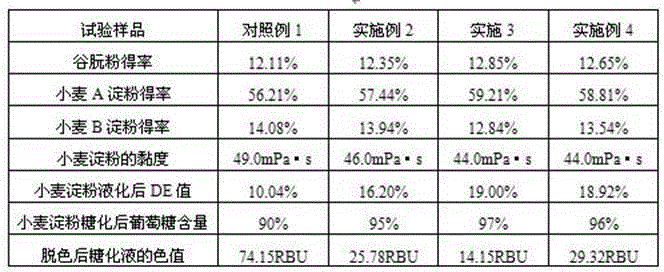

[0063] 1. Preparation of wheat flour from wheat: Wheat is used as raw material, wheat grains are crushed by wheat flour milling equipment, and gradually ground, the endosperm part on the bran sheet is scraped off, and the endosperm is ground into flour of a certain fineness.

[0064] 2 Composite enzyme preparation assists in the production of wheat starch: Wheat flour is separated into wheat starch and gluten powder through pulping, three-phase decanter centrifugal separation, circular sieve and centrifugal sieve extraction and drying processes. Add a compound enzyme composed of lipase, Spezyme CP viscosity reducing enzyme and glutamine transaminase to the pulping process water, and the components of the compound enzyme in parts by weight are composed as follows: lipase, 10 parts; Spezyme CP viscosity reducing enzyme, 60 parts; transglutaminase, 30 parts. The compound enzyme is added in an amount of 0.4g / kg flour when the flour is mixed with water, the temperature is controlle...

Embodiment 3

[0079] 1. Preparation of wheat flour from wheat: Wheat is used as raw material, wheat grains are crushed by wheat flour milling equipment, and gradually ground, the endosperm part on the bran sheet is scraped off, and the endosperm is ground into flour of a certain fineness.

[0080] 2 Composite enzyme preparation assists in the production of wheat starch: Wheat flour is separated into wheat starch and gluten powder through pulping, three-phase decanter centrifugal separation, circular sieve and centrifugal sieve extraction and drying processes. Add the compound enzyme that is made up of lipase, Spezyme CP viscosity-reducing enzyme and glutamine transaminase in pulping process water, each component composition of compound enzyme is as follows in parts by weight: Lipase, 17 parts; Spezyme CP viscosity-reducing enzyme, 50 parts; transglutaminase, 33 parts. The compound enzyme is added in an amount of 0.10g / kg flour when flour is mixed with water, the temperature is controlled at...

Embodiment 4

[0095] 1. Preparation of wheat flour from wheat: Wheat is used as raw material, wheat grains are crushed by wheat flour milling equipment, and gradually ground, the endosperm part on the bran sheet is scraped off, and the endosperm is ground into flour of a certain fineness.

[0096] 2 Composite enzyme preparation assists in the production of wheat starch: Wheat flour is separated into wheat starch and gluten powder through pulping, three-phase decanter centrifugal separation, circular sieve and centrifugal sieve extraction and drying processes. Add the compound enzyme that is made up of lipase, Spezyme CP viscosity-reducing enzyme and glutamine transaminase in pulping process water, each component composition of compound enzyme is as follows in parts by weight: lipase, 25 parts; Spezyme CP viscosity-reducing enzyme, 40 parts; transglutaminase, 35 parts. The compound enzyme is added in an amount of 0.05g / kg flour when flour is mixed with water, the temperature is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com