A kind of preparation method of polyphenylene sulfide fiber

A polyphenylene sulfide fiber and fiber technology, applied in fiber treatment, fiber chemical characteristics, stretch spinning, etc., can solve the problem of poor mechanical properties of polyphenylene sulfide fiber, unfavorable linear molecular recrystallization, heat treatment temperature High-level problems, to achieve excellent comprehensive performance, suitable for post-processing and treatment, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

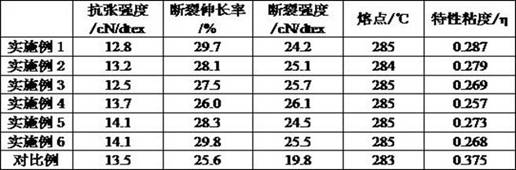

Examples

Embodiment 1

[0039] A preparation method of polyphenylene sulfide fiber, comprising the steps of:

[0040] (a) Raw material pretreatment

[0041] Select PPS slices with a melt index (MFR) of 220g / 10min, and place them in an electric blast drying oven for drying to reduce the moisture content of the PPS slices to below 50ppm. The drying temperature is 145°C and the drying time is 9h;

[0042] (b) spinning

[0043] Put the dried PPS chips into the screw extruder for spinning, and the spinning temperature is 310°C; firstly, the PPS chips are put into the barrel of the screw extruder, then they are transported and preheated in the feeding section, and then compressed compacted, exhausted and gradually melted in the metering section, then mixed and plasticized in the metering section, and quantitatively transported to the metering pump for spinning, the sprayed spinning is cooled and wound, and the primary fiber is obtained, wherein the draft ratio is 6. The drawing speed is 44m / min;

[0044...

Embodiment 2

[0049] A preparation method of polyphenylene sulfide fiber, comprising the steps of:

[0050] (a) Raw material pretreatment

[0051] Select PPS slices with a melt index (MFR) of 220g / 10min, and place them in an electric blast drying oven for drying to reduce the moisture content of the PPS slices to below 50ppm. The drying temperature is 145°C and the drying time is 9h;

[0052] (b) spinning

[0053] Put the dried PPS chips into the screw extruder for spinning, and the spinning temperature is 312°C; firstly, the PPS chips are put into the barrel of the screw extruder, then they are conveyed and preheated in the feeding section, and then compressed compacted, exhausted and gradually melted in the metering section, then mixed and plasticized in the metering section, and quantitatively transported to the metering pump for spinning, the sprayed spinning is cooled and wound, and the primary fiber is obtained, wherein the draft ratio is 8. The drawing speed is 52m / min;

[0054] (...

Embodiment 3

[0059] A preparation method of polyphenylene sulfide fiber, comprising the steps of:

[0060] (a) Raw material pretreatment

[0061] Select PPS slices with a melt index (MFR) of 220g / 10min, and place them in an electric blast drying oven for drying to reduce the moisture content of the PPS slices to below 50ppm. The drying temperature is 145°C and the drying time is 9h;

[0062] (b) spinning

[0063] Put the dried PPS slices into the screw extruder for spinning, and the spinning temperature is 314°C; firstly, the PPS slices are put into the barrel of the screw extruder, then they are transported and preheated in the feeding section, and then compressed compacted, exhausted and gradually melted in the metering section, then mixed and plasticized in the metering section, and quantitatively transported to the metering pump for spinning, the sprayed spinning is cooled and wound, and the primary fiber is obtained, wherein the draft ratio is 10. The drawing speed is 65m / min;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com