Concrete and masonry structure butting portion automatic net hanging device and method

A masonry structure and concrete technology, which is applied in building structure, covering/lining, construction, etc., can solve problems such as weak sense of responsibility of construction personnel, increased difficulty of decoration works, and lack of anti-cracking effect, reaching the scope of application Wide, prevent cement solidification, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

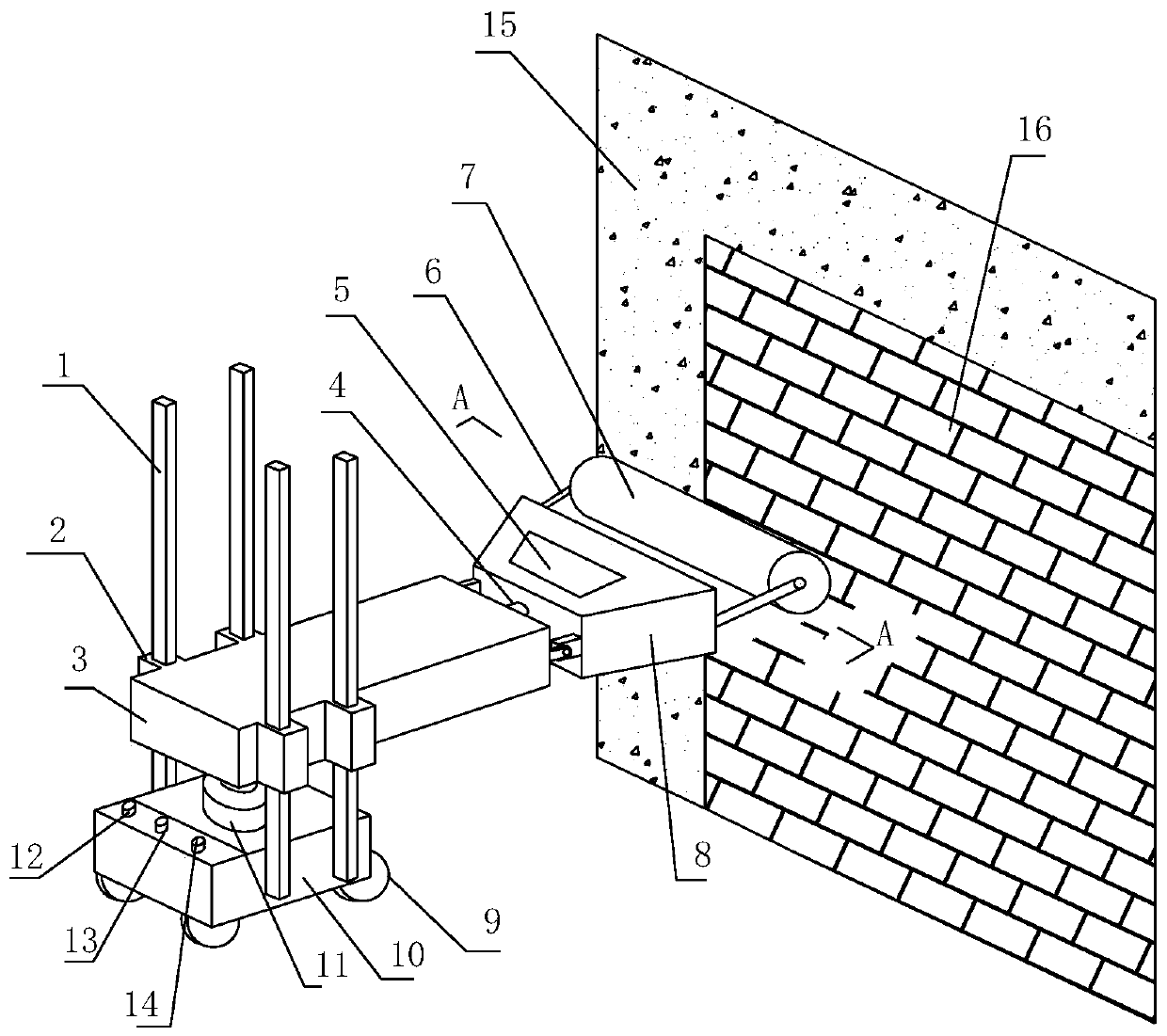

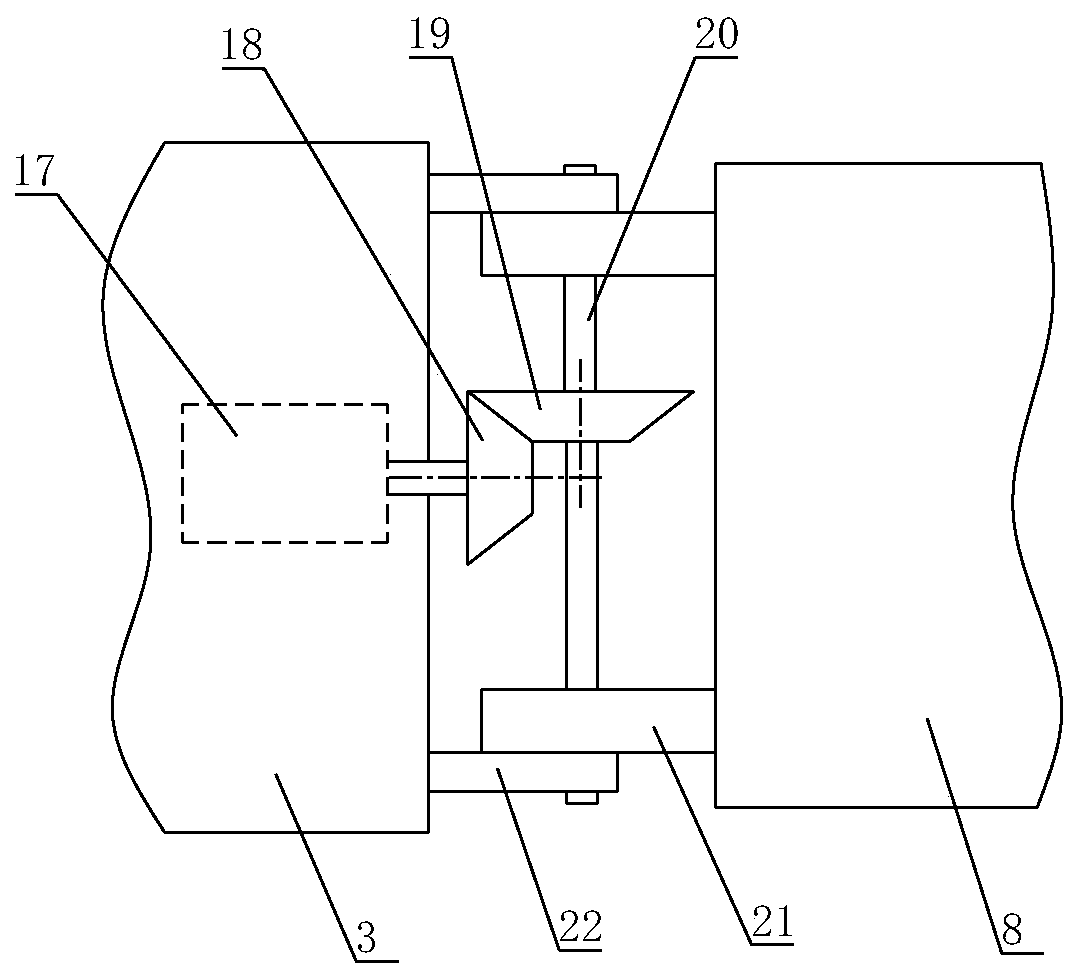

[0029] Such as figure 1 As shown, an automatic net hanging device for the stubble joint of concrete and masonry structure according to the present invention includes a mobile trolley, a lifting device 11, a cantilever 3, a machine head rotating device 4, a cement mixing extrusion box 8 and a glass fiber net laying frame The cantilever 3 is installed on the mobile trolley through the lifting device 11, and can be vertically lifted with the lifting device 11; the cement mixing and extruding box 8 is arranged at one end of the cantilever 3, and the mixing and extruding box 8 and the cantilever 3 are hinged structure and is connected by the head rotating device 44; the top of the cement mixing extrusion box 8 is provided with a cement inlet 5, the inside is provided with a stirring device, the bottom of the outer end is provided with a cement outlet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com