Method for producing refining sugar

A technology for refining sugar and syrup, applied in sugar production, sucrose production, sugar products, etc., can solve problems such as extra energy consumption, increased product production costs, and high cost of production plant equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

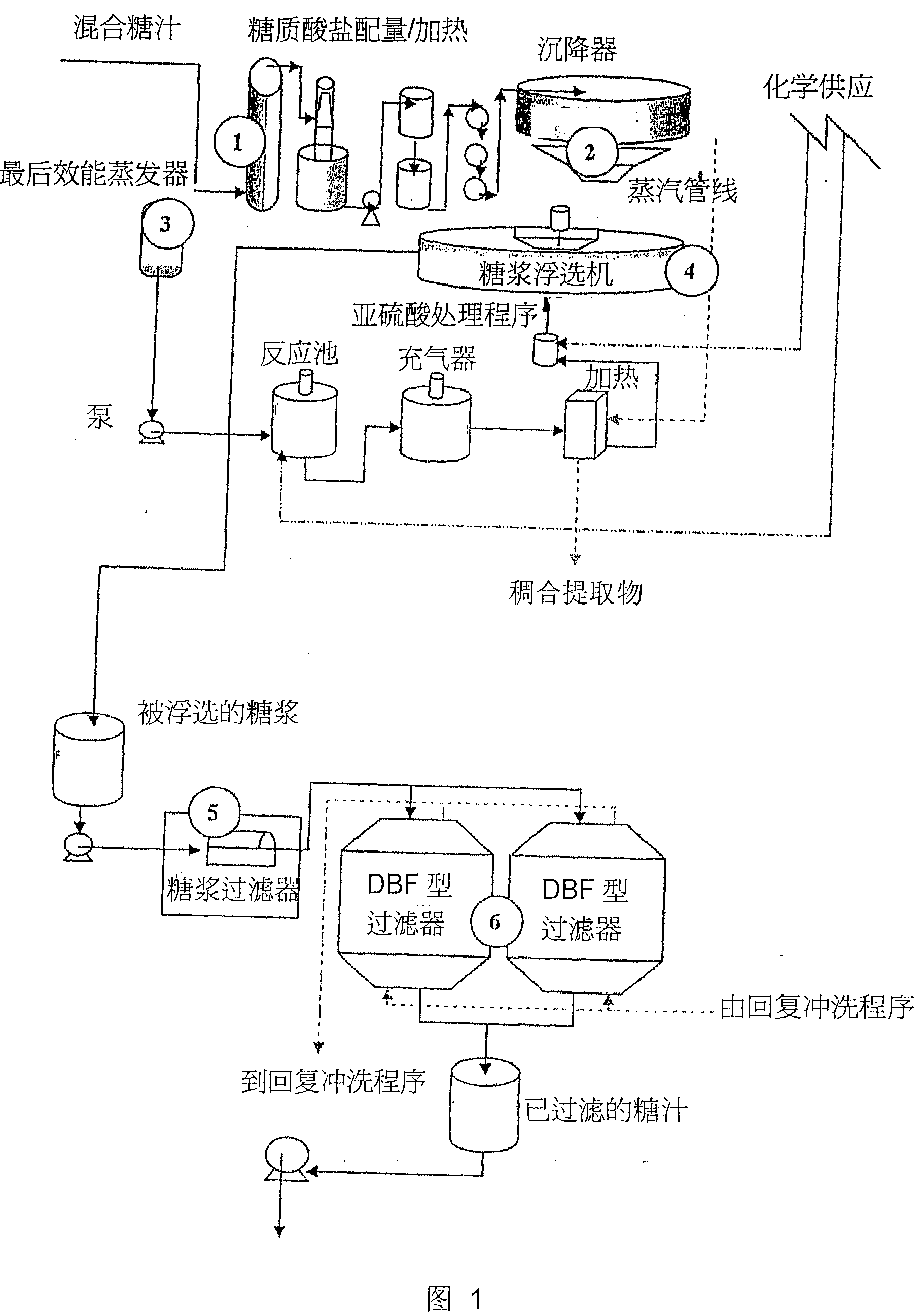

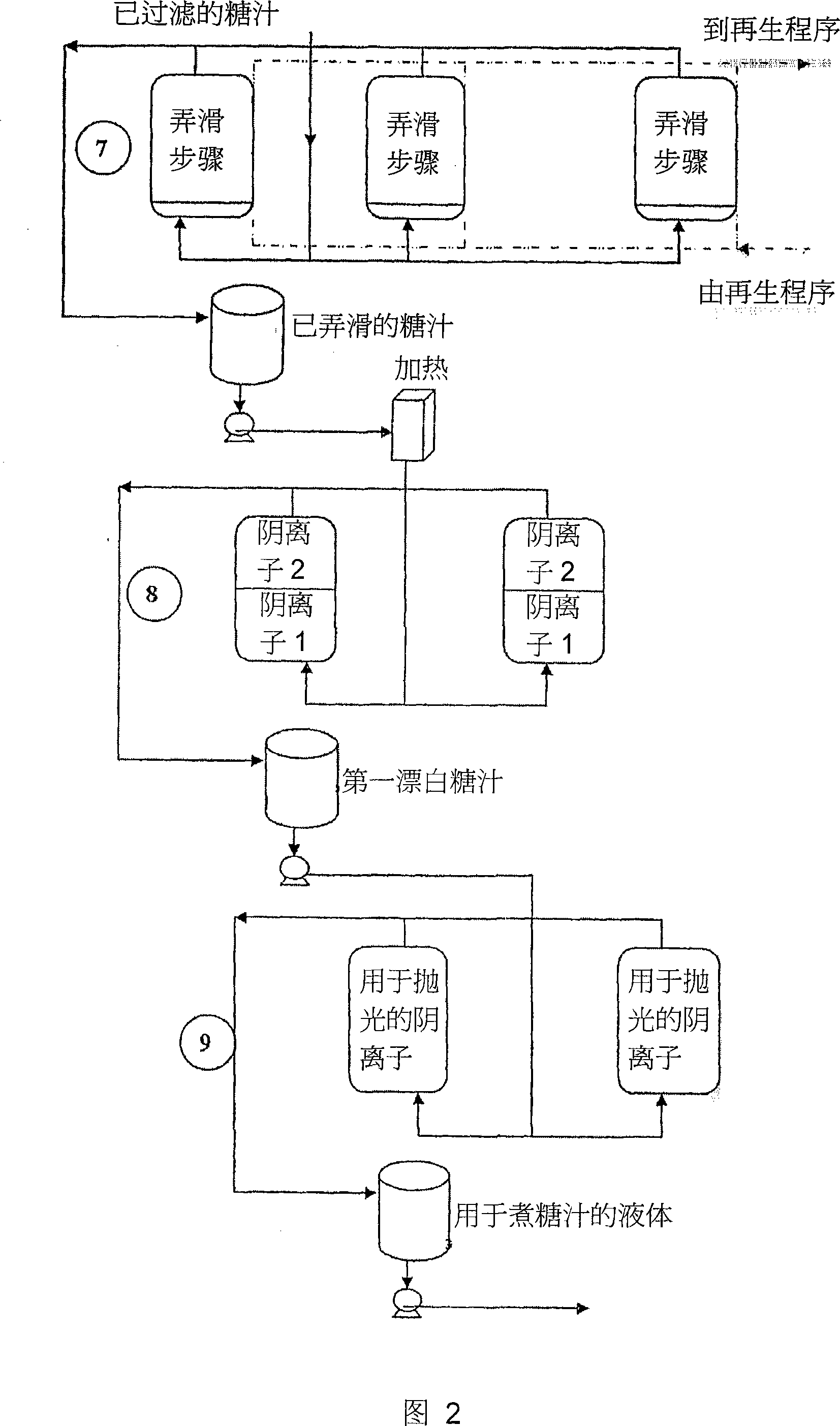

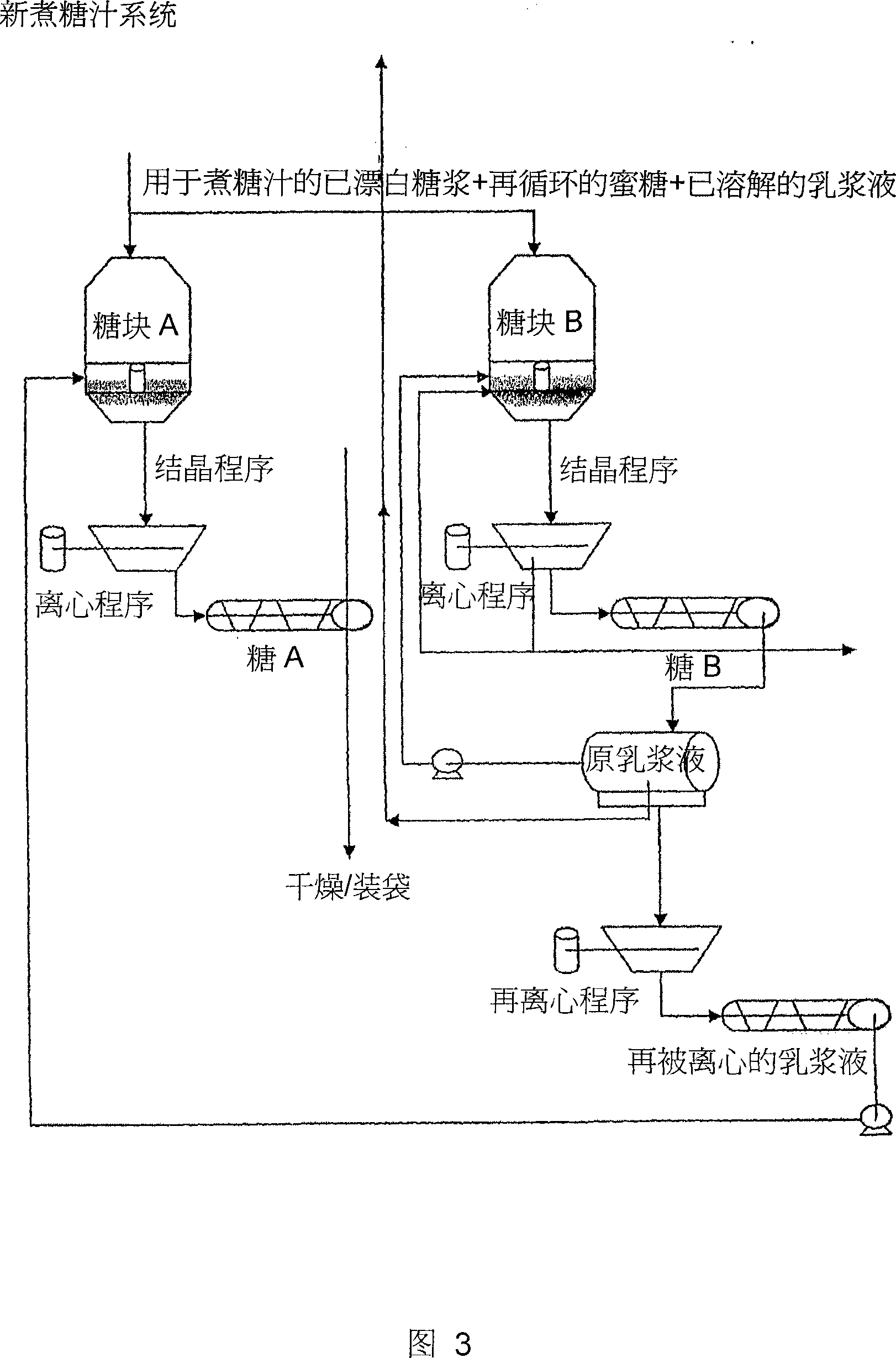

[0034] As shown in the accompanying drawings, the method for directly producing refined sugar of the present invention includes a method for producing refined granulated sugar using syrup as a raw material, which does not require recrystallization of sugar after dissolving sugar.

[0035] When processing sugar cane, a juice rich in saccharosis is expressed at a concentration of 13% to 17% total soluble solids. After heating, the juice is clarified by a sulphiting procedure (item 1 in Figure 1 ) and a settling procedure (item 2 in Figure 1 ).

[0036] The juice is clarified and sent to a multiple effect evaporator where the concentration of the juice rises to 60 to 65 Brix and forms the specified syrup.

[0037] After leaving the designated last effect evaporator (item 3 in Figure 1 ), the syrup begins its flotation procedure using phosphoric acid, cationic bleach, calcium glucarate and a flocculant medium.

[0038] Leaving the flotation machine (item 4 in Figure 1), the syrup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com