Producing method of pharmaceutic adjuvant cane sugar by carbonic acid method process

A technology of pharmaceutical excipients and carbonic acid method, which is applied in sucrose production, sugar production, application, etc., can solve the problem that sucrose cannot meet the standard of pharmaceutical sugar, and achieve the solution of difficult large-scale production, simple process, and improved cleanliness level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

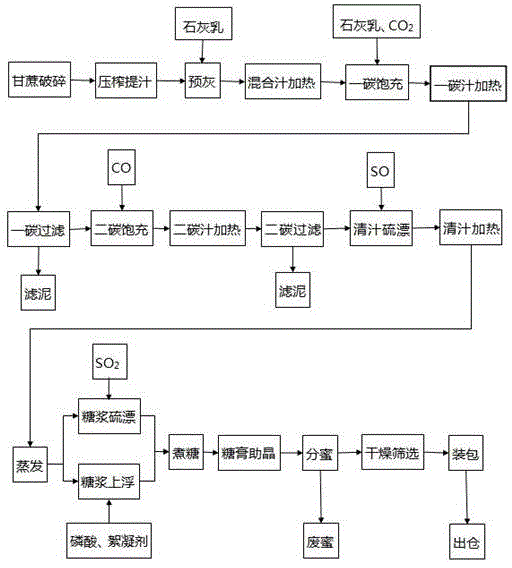

[0039] The method for producing medicinal auxiliary material sucrose by using the carbonic acid process of the present invention adopts the steps of crushing-squeezing-cleaning-evaporating-sulfur bleaching-floating-boiling sugar-dividing honey-drying sugarcane to obtain medicinal sucrose.

[0040] The combined process of sulfur bleaching and floating: sugar syrup is floated after sulfur bleaching, wherein phosphoric acid and flocculant are added during the floating process, and the clear juice is obtained after sulfur bleaching. Obtained sucrose, residue on ignition% <0.09, calcium salt% <0.02, heavy metal PPM <4.

[0041] The comparison between the production of sucrose as a pharmaceutical excipient by the carbonic acid method of the present invention and the 2010 edition of the Chinese Pharmacopoeia.

[0042] project Products of the invention Medicinal sucrose Sucrose content (%)≥99.7 99.6 (converted according to specific curl) Reducing sugar content (%)≤ 0.080.10 Sulfate% <...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com