Biological selenium-rich aromatic peanut oil and production method thereof

A production method and peanut oil technology, applied in the direction of fat oil/fat production, fat production, food science, etc., can solve the problems that it is not suitable for the production of selenium-enriched fragrant peanut oil, the repeatability of the ultrasonic extraction method is poor, and it is not suitable for large-scale industrial production. To achieve the effect of changing the phenomenon of selenium deficiency, meeting the demand and removing the harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Obtaining Selenium-enriched Peanuts:

[0028] 30 days after the emergence of peanuts, apply 100 milliliters of "Sefeng 5118" liquid selenium-enriched fertilizer per acre, dilute 200 times with water and then spray on the leaves; apply "Selenium 5118" liquid selenium-enriched fertilizer per acre 200 milliliters, dilute 200 times with clear water and spray on the leaves; apply 200 milliliters of "Sefeng 5118" liquid selenium-enriched fertilizer per acre during the fruit-full stage, dilute 180 times with clear water and spray on the leaves. When spraying, pay attention to avoid strong sunlight and rainy days. If it rains within 8 hours of spraying, it should be sprayed again. A total of 500 ml was applied per mu. "Selenium 5118" liquid selenium-enriched fertilizer was purchased from Dongying Yingyuan Fertilizer Technology Co., Ltd.

[0029] After testing, the organic selenium content of peanut kernels reaches 0.490 (mg / kg), while the organic selenium content of ordinary ...

Embodiment 2

[0031] A kind of production technology of biological selenium-enriched strong fragrance peanut oil, it carries out according to the following steps:

[0032] 1) Selection of peanut raw materials: peanut raw materials come from selenium-enriched peanut planting bases, and the selenium content is more than 30 times that of ordinary peanuts;

[0033] 2) Cleaning: remove immature, damaged, moldy, stones and metals, etc. Stones and metals will damage machinery and equipment, and mildewed and immature peanuts will seriously affect the quality of oil; fresh peanuts and full grains are required , no damage, no mildew, no insects, less impurity, and no aging period;

[0034] 3) Step 2) obtains peanuts and carries out grading process:

[0035] a) Break 90% of the peanuts, remove the red coat, break the peanut kernels into 4-6 petals, control the water content at 10%, and then steam and fry the peanuts at a temperature of 80°C for 15 minutes to obtain material A;

[0036] b) 10% of the...

Embodiment 3

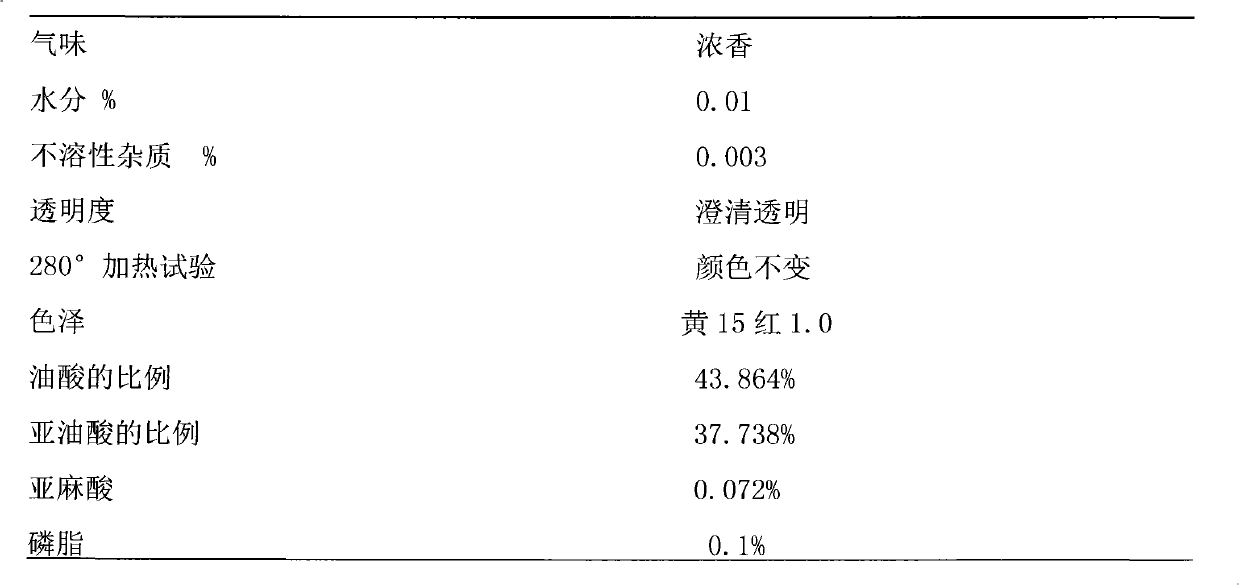

[0043] The quality detection of selenium-enriched peanut oil of the present invention: table 1

[0044]

[0045]

[0046] Control group: the raw material and the hot-air roasted material were used at a ratio of 3:1; no effective method was used to remove phospholipids; no ethanol treatment was used; other processes were similar to the experimental group of Example 2 of the present invention. See Table 2 for specific parameters.

[0047] Table 2

[0048]

[0049] Test summary:

[0050] Compared with the experimental group of the present invention (table 1), the degree of strong fragrance does not change, but the content of linoleic acid, linolenic acid and oleic acid reduces, and the output of selenium also obviously reduces, while the ratio of phospholipids increases greatly, and meets high temperature ( 280°C) the oil becomes darker and turbid. It can be seen that the process for preparing selenium-enriched peanut oil in the present invention is obviously better t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com