Method for preparing and abstracting lycopene

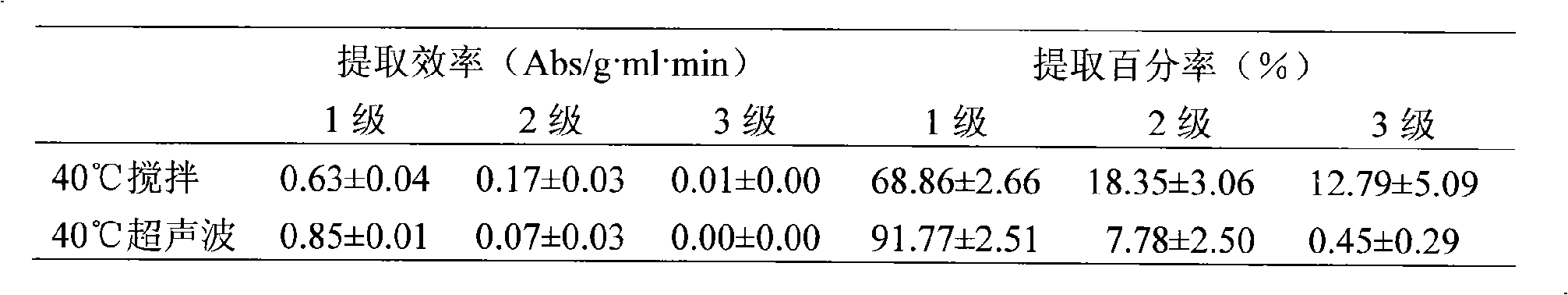

A technology for lycopene and tomato, applied in chemical instruments and methods, purification/separation of hydrocarbons, organic chemistry, etc., can solve the problems of high energy consumption, many extraction stages, large amount of solvent, etc., and achieve simplified extraction procedures, Avoid mutual pollution and improve the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

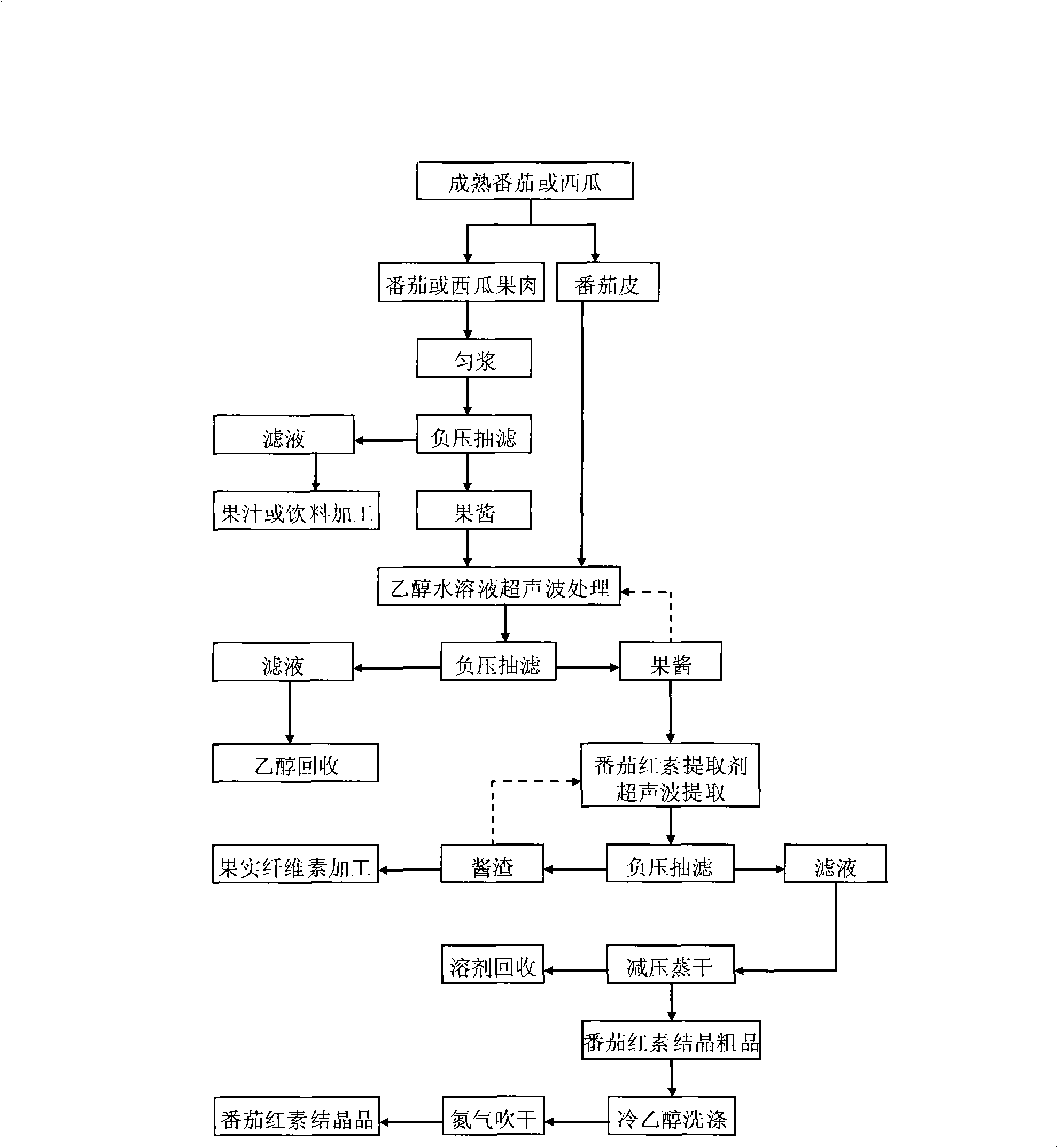

[0036] Embodiment 1: (extract from tomato, prepare lycopene)

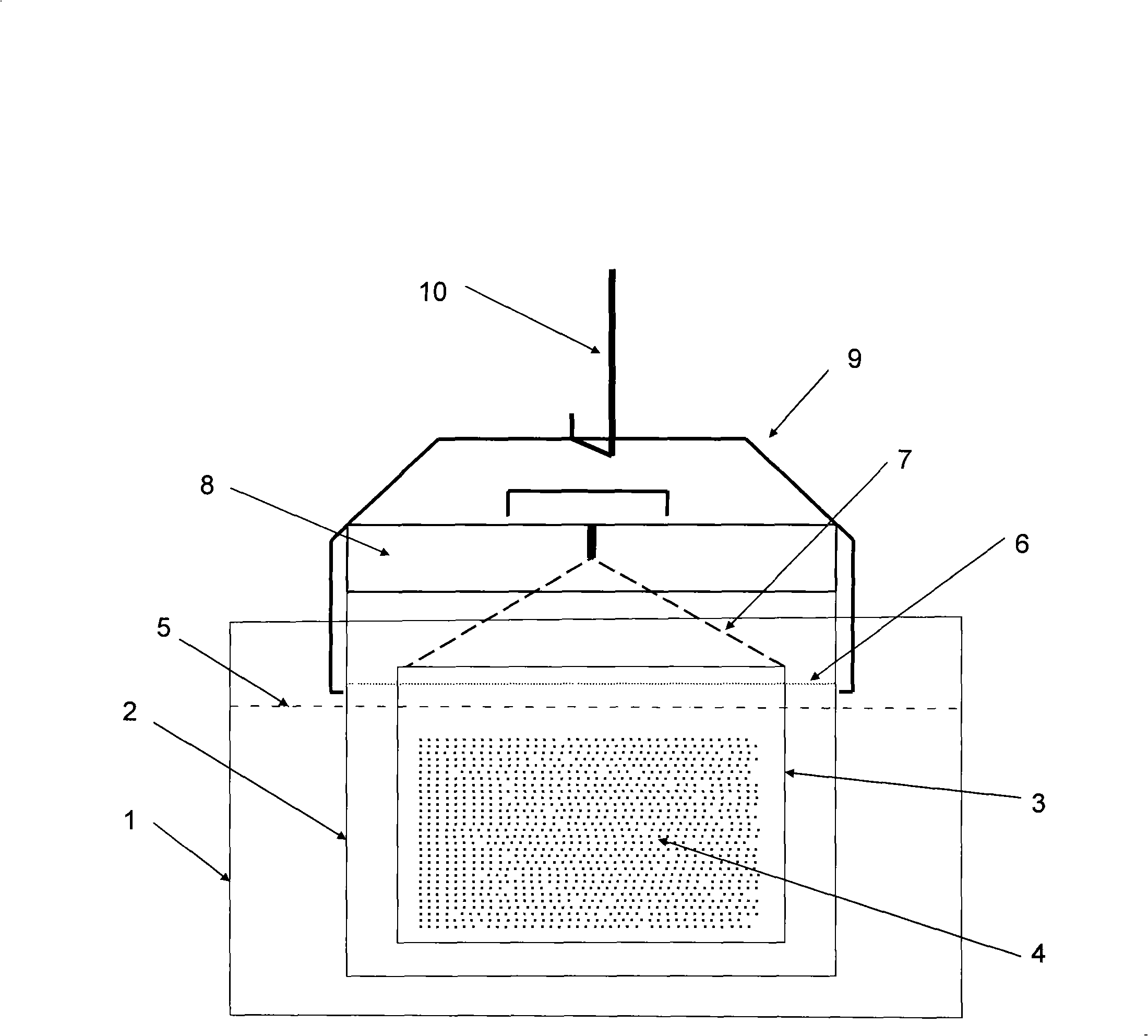

[0037] Weigh 100kg of mature tomatoes without disease or damage, wash the surface with water; rinse with hot water at 90°C for 6 minutes, then quickly rinse with cold water at 20°C for 4 minutes, and complete the peeling with the assistance of mechanical rolling and hydraulic impact; cut the peeled tomatoes into two rings Half, manually complete the seed removal; the pulp is mechanically crushed and then pulped with a beating mechanism; the pulp is packed into a 150-mesh polyester sieve silk extraction bag 3, tied, and the filtrate 1 is separated by -30Kpa negative pressure suction filtration (can be used for processing fruit juice or beverage), retain 20kg of jam 1 in the extraction bag 3; put the extraction bag 3 containing jam 1 into the extraction tank 2-1, add 200L of 80% ethanol aqueous solution to the tank, and ultrasonically 1 treatment for 4 minutes, take out the extraction bag 3 from the extraction tank 2...

Embodiment 2

[0038] Embodiment 2: (extracting and preparing lycopene from watermelon)

[0039] Weigh 100kg of disease-free, non-damaged, mature red watermelon pulp, make pulp and put it into 200-mesh nylon sieve silk extraction bag 3; after negative pressure filtration at -20Kpa, put the remaining jam 1 (22kg) into extraction bag 3 Put it into the extraction tank 2-1, add 250L of 70% ethanol aqueous solution to the extraction tank 2-1, extract it with ultrasonic wave 1 at 80°C and 50KHz for 2min, and after it is separated by negative pressure suction filtration at -55Kpa, keep the jam 2 in the extraction bag 3 ;Jam 2 was repeatedly extracted and filtered once in the same way to obtain 15kg of jam 3; the extraction bag 3 containing jam 3 was placed in the extraction tank 2-2, and 400L tetrahydrofuran was added to the extraction tank 2-2 at 50°C and 50KHz Under the condition of ultrasonic 1 extraction for 2 minutes, and then -60Kpa negative pressure suction filtration to separate the sauce r...

Embodiment 3

[0040] Embodiment 3: (extract and prepare lycopene from watermelon sauce)

[0041] Weigh 1Kg of watermelon sauce, put it into a 300-mesh nylon sieve silk extraction bag 3, add 40L of diethyl ether, and extract by ultrasonic wave 1 at 30°C and 80KHz for 5min, and the extract is rotatably evaporated at 35°C to obtain a crude crystal, which is then rinsed with ethanol. Wash and dry with nitrogen to prepare about 0.15 g of 76% lycopene crystals. Processes, steps such as the preparation of watermelon sauce, ethanol treatment are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com