Low-coalification degree pulverized coal pyrolysis method and product prepared through the same

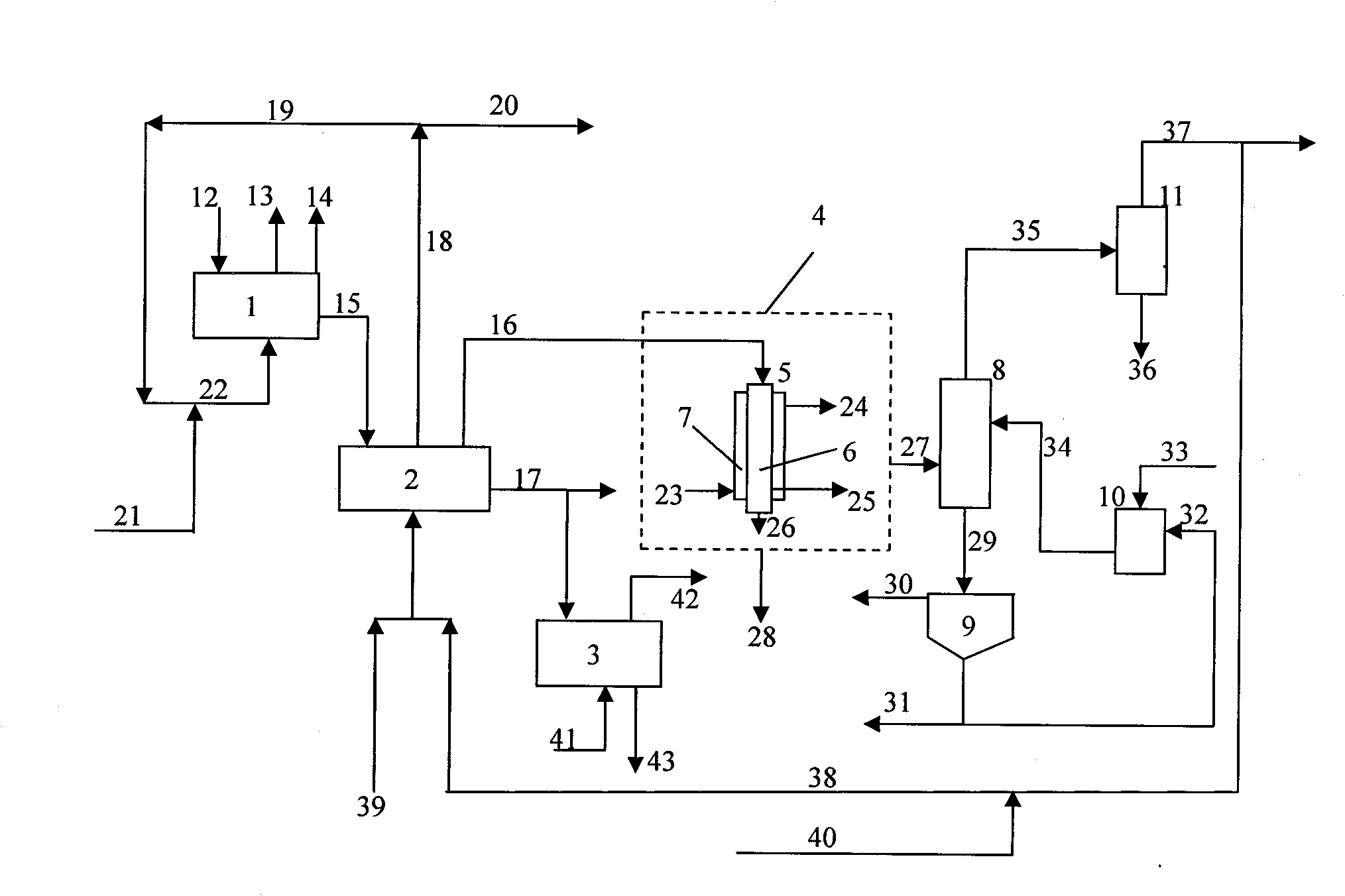

A low coalification degree, pulverized coal technology, applied in the cooling of coke, combustible gas purification, combustible gas purification/transformation, etc., can solve the problem of low yield and quality of product gas and tar, low heat transfer rate and comprehensive thermal efficiency, gas and low tar yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The method of the present invention is implemented by using pulverized coal with a low degree of coalification in northern Shaanxi.

[0084] The maximum particle size of raw pulverized coal is 12mm, and the average particle size is 8mm. The main coal quality analysis results are described in the table below:

[0085] Table 1: Coal quality analysis results

[0086]

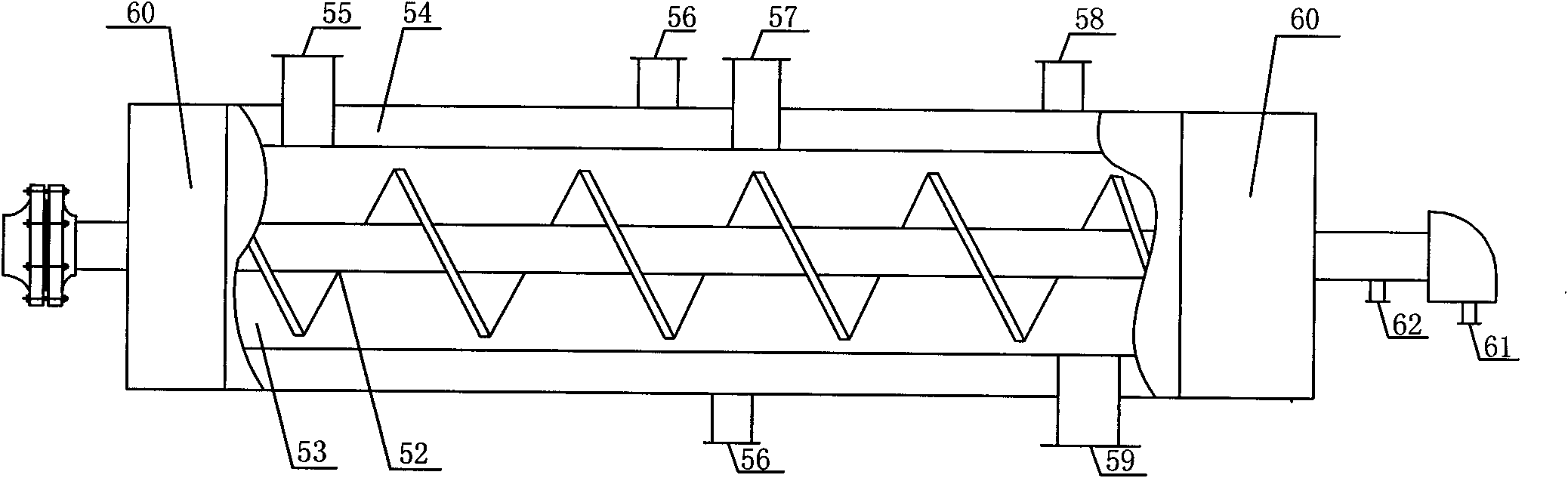

[0087]The specific operating conditions are as follows: the pyrolysis furnace 2 adopts the first structural form, and the pulverized coal with low coalification degree in northern Shaanxi is added to the inner cylinder 46 of the drying furnace 1 through the pipeline 12, and the pyrolysis furnace 2 coming out of the outer cylinder 44 is adjusted. The flow of combustion waste gas heats the pulverized coal in the inner cylinder 46 to 190° C., and the residence time of the pulverized coal with low coalification degree in the drying furnace reaches 30 minutes by adjusting the rotating speed of the hinge 45 in...

Embodiment 2

[0095] Example 2: The method of the present invention is implemented with Inner Mongolia lignite powder as a raw material. The maximum particle size of the raw material is 10mm, and the average particle size is 3mm. The main coal quality analysis data are as described in Table 3.

[0096] Table 3: Analysis data of lignite coal quality in Inner Mongolia

[0097]

[0098] The specific operating conditions are as follows: the method of this embodiment is the same as the process of Example 1, except that the pyrolysis furnace 2 adopts the second structural form, the operating process conditions of the drying furnace 1 and the pyrolysis furnace 2 are different, and the semi-coke cooling furnace 3 is removed, and the The raw coal types are different. Inner Mongolia lignite powder enters the inner cylinder 46 of the drying furnace 1 through the pipeline 12, and the pulverized coal in the inner cylinder 46 is heated to 140°C by adjusting the flow rate of the drying medium in the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com