Internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis method and device

A technology of solid heat carrier and moving bed, applied in the field of coal chemical industry, can solve the problems of complex equipment process and large energy consumption, and achieve the effects of good separation effect, low investment cost and good thermal expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

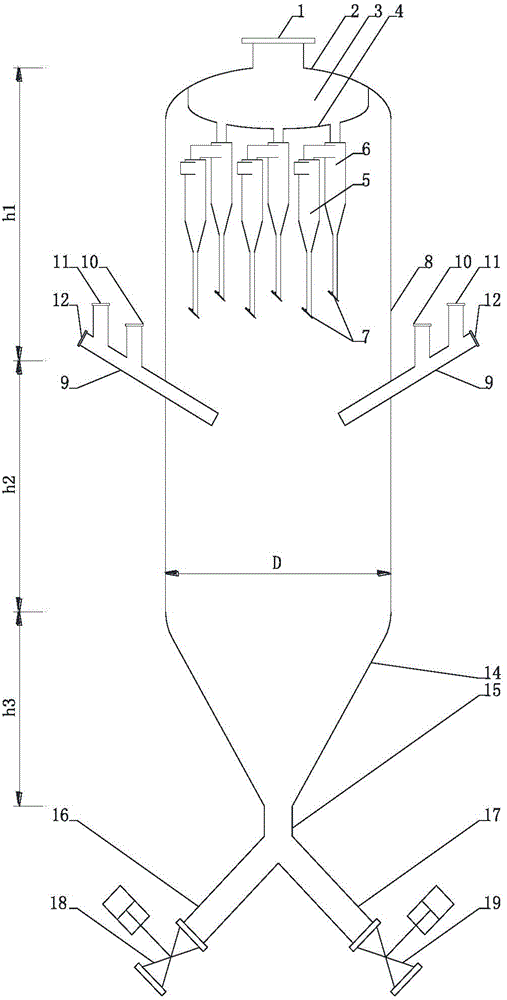

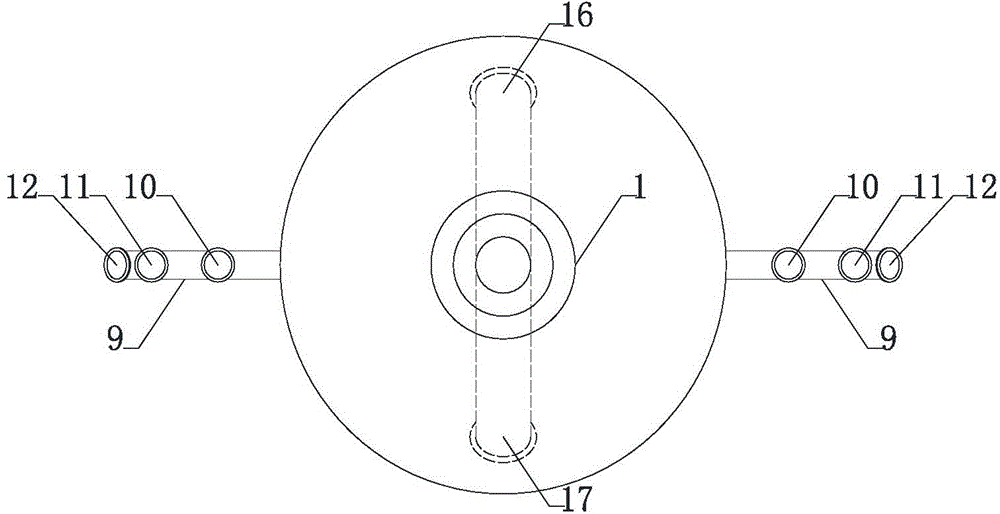

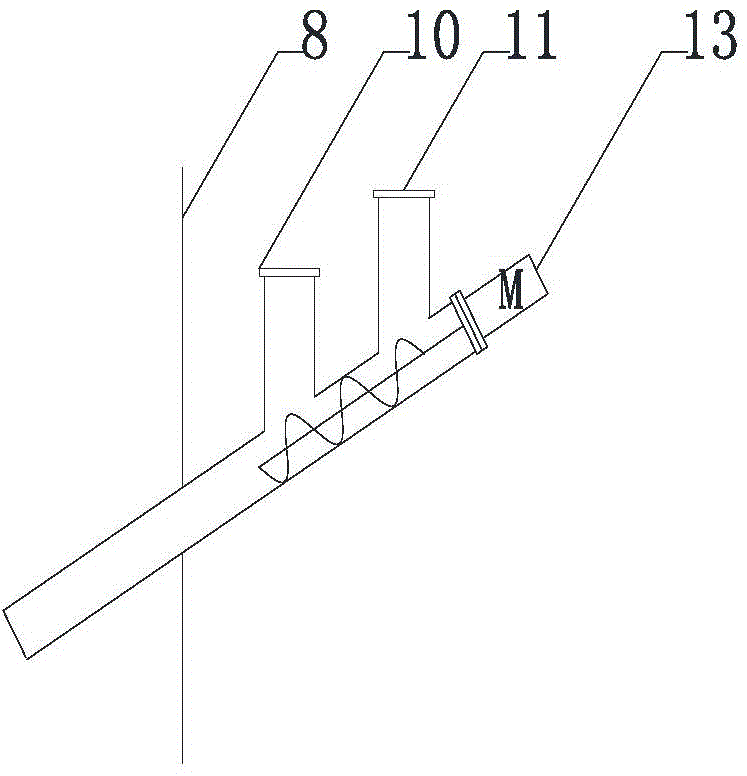

[0042] The pulverized coal of Xigou in Shenmu County is used as raw material, and the particle size distribution (mass percentage) of the pulverized coal is 8-6mm23%, 4-6mm45%, 4-2mm18%, <2mm14%. The pulverized coal is fed from the pulverized coal inlet 11 of the mixing tube 9, and the circulating semi-coke (temperature 750°C) enters from the heat carrier inlet 10 of the mixing tube 9, and the volume ratio of pulverized coal to high-temperature semi-coke is 1:3.5. The gas is fed into the gas inlet 12 of the mixing tube 9. Under the action of the gas thrust, the high-temperature hot semi-coke and pulverized coal are fully mixed in the mixing tube 9 and then enter the pyrolysis section h2. As the pulverized coal is heated by the high-temperature hot semi-coke, the temperature of the pulverized coal entering the pyrolysis section h2 reaches 550°C, and the pyrolysis gas generated by the heating of the pulverized coal rises into the cyclone separation section h1, and the pyrolysis g...

Embodiment 2

[0045] The pulverized coal of Inner Mongolia Pingzhuang lignite is used as the raw material, and the particle size distribution (mass percentage) of the pulverized coal is 8-6mm 19%, 4-6mm 48%, 4-2mm 18%, <2mm 15%. The pulverized coal is fed in from the pulverized coal inlet 11 of the mixing tube 9, and the high-temperature hot ash (temperature 850°C) is fed in from the heat carrier inlet 10 of the mixing tube 9, and the volume ratio of the pulverized coal to the high-temperature hot ash is 1:3.7. Under the action of the screw propeller 13, the solid heat-loaded high-temperature hot ash and pulverized coal are fully mixed in the mixing tube 9 and then sent to the pyrolysis section h2. As the pulverized coal is heated by high-temperature hot ash, the temperature of the pulverized coal entering the pyrolysis section h2 reaches 600°C, and the pyrolysis gas generated by the heating of the pulverized coal rises into the cyclone separation section h1, and the pyrolysis gas enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com