Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

A high-temperature-resistant coating and silicone technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

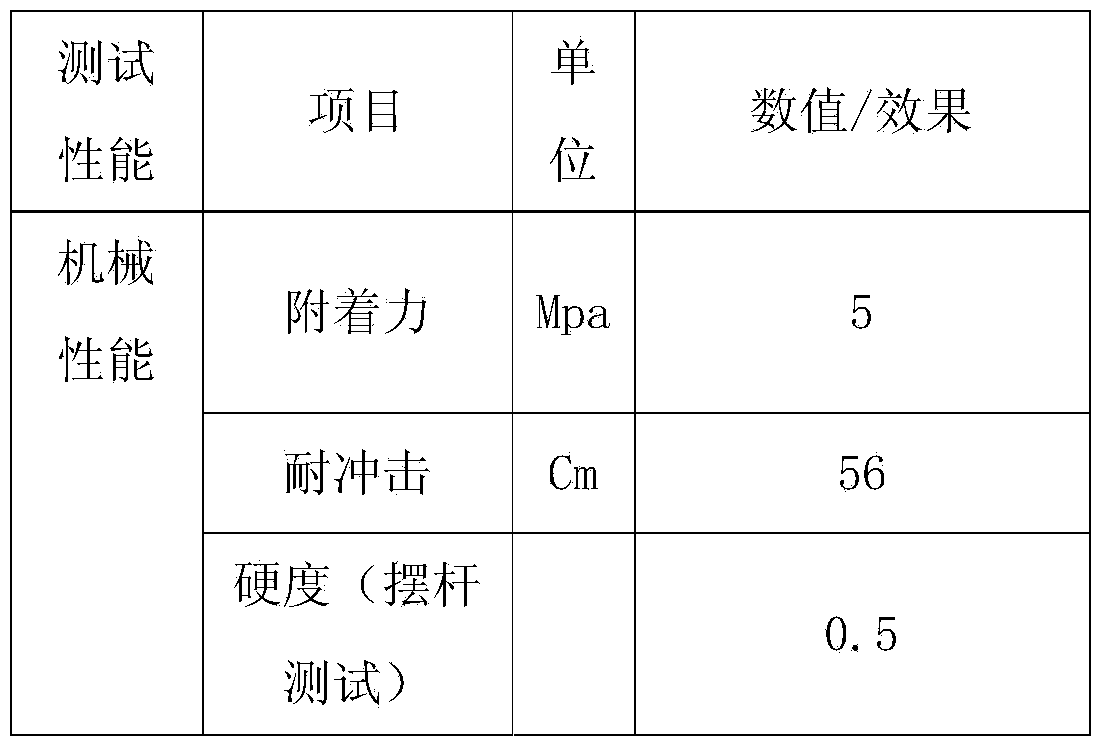

Embodiment 1

[0031] A boron-modified silicone resin high-temperature-resistant coating provided in this example, the mass percentages of each component are: boron-modified silicone resin: 45%, heat-resistant pigments and fillers: 35%, additives: 2% , wherein the boron-modified silicone resin is boric acid-modified silicone resin or epoxy-modified silicon boron resin;

[0032] Heat-resistant pigments and fillers include:

[0033] Nano silicon dioxide, barrier type functional filler and aluminum powder and the mass ratio of nano silicon dioxide, barrier type functional filler and aluminum powder is 1.5:1:1;

[0034] Barrier functional fillers include the following components in parts by mass:

[0035] Hollow glass microspheres: 3 parts, graphite: 10 parts, black silicon carbide: 25 parts, fine-grained alumina: 24 parts, molybdenum disulfide: 5 parts, zinc oxide: 2 parts, talcum powder: 3 parts;

[0036] Auxiliaries include the following components in parts by mass:

[0037] Dispersant: 10...

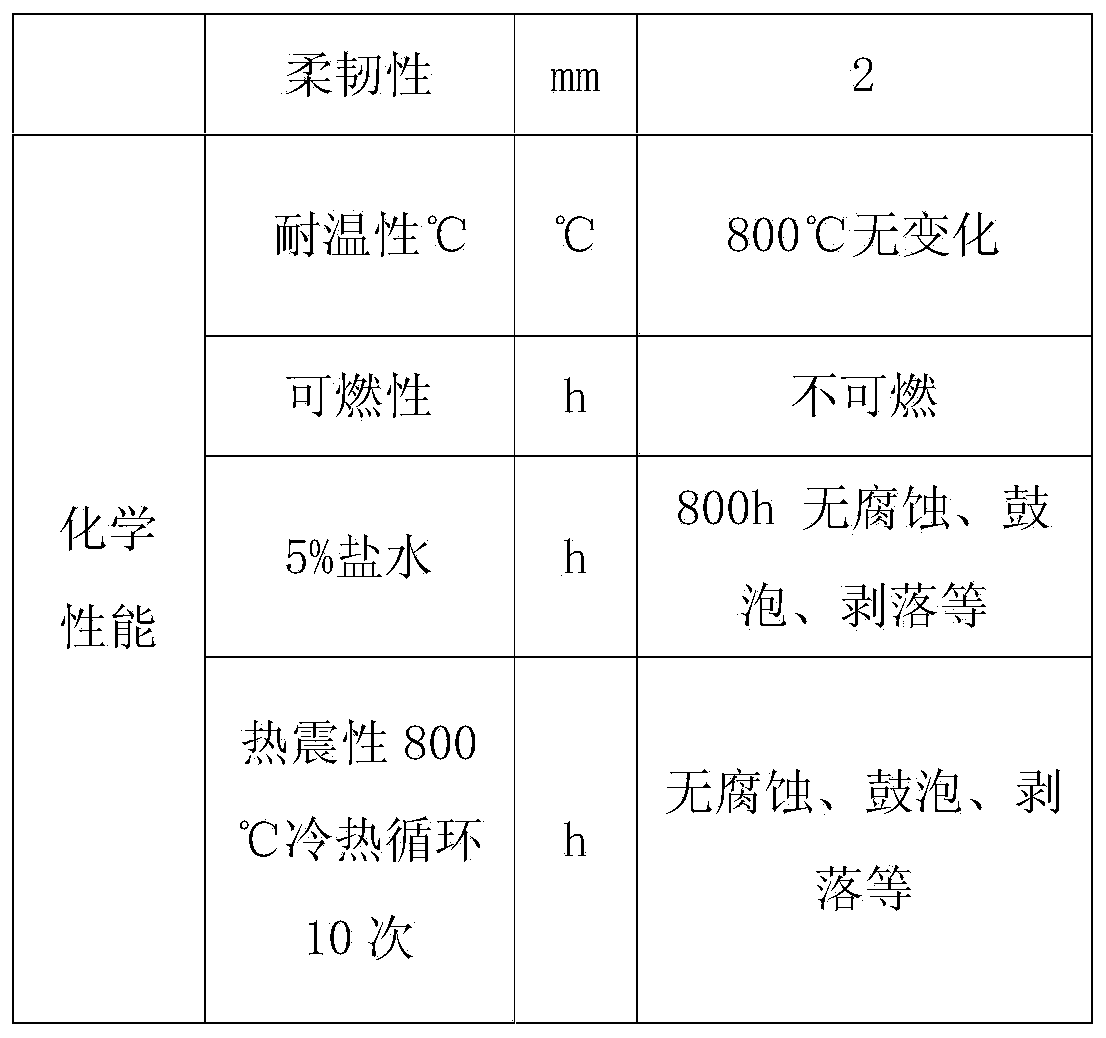

Embodiment 2

[0043] A boron-modified silicone resin high-temperature-resistant coating provided in this example, the percentages by mass of each component are: boron-modified silicone resin: 48%, heat-resistant pigments and fillers: 38%, additives: 4% , wherein the boron-modified silicone resin is boric acid-modified silicone resin or epoxy-modified silicon boron resin;

[0044] Heat-resistant pigments and fillers include:

[0045] Nano silicon dioxide, barrier type functional filler and aluminum powder and the mass ratio of nano silicon dioxide, barrier type functional filler and aluminum powder is 1.5:1:1;

[0046] Barrier functional fillers include the following components in parts by mass:

[0047] Hollow glass microspheres: 3 parts, graphite: 13 parts, black silicon carbide: 29 parts, fine-grained alumina: 28 parts, molybdenum disulfide: 6 parts, zinc oxide: 4 parts, talcum powder: 5 parts;

[0048] Auxiliaries include the following components in parts by mass:

[0049] Dispersant: 1...

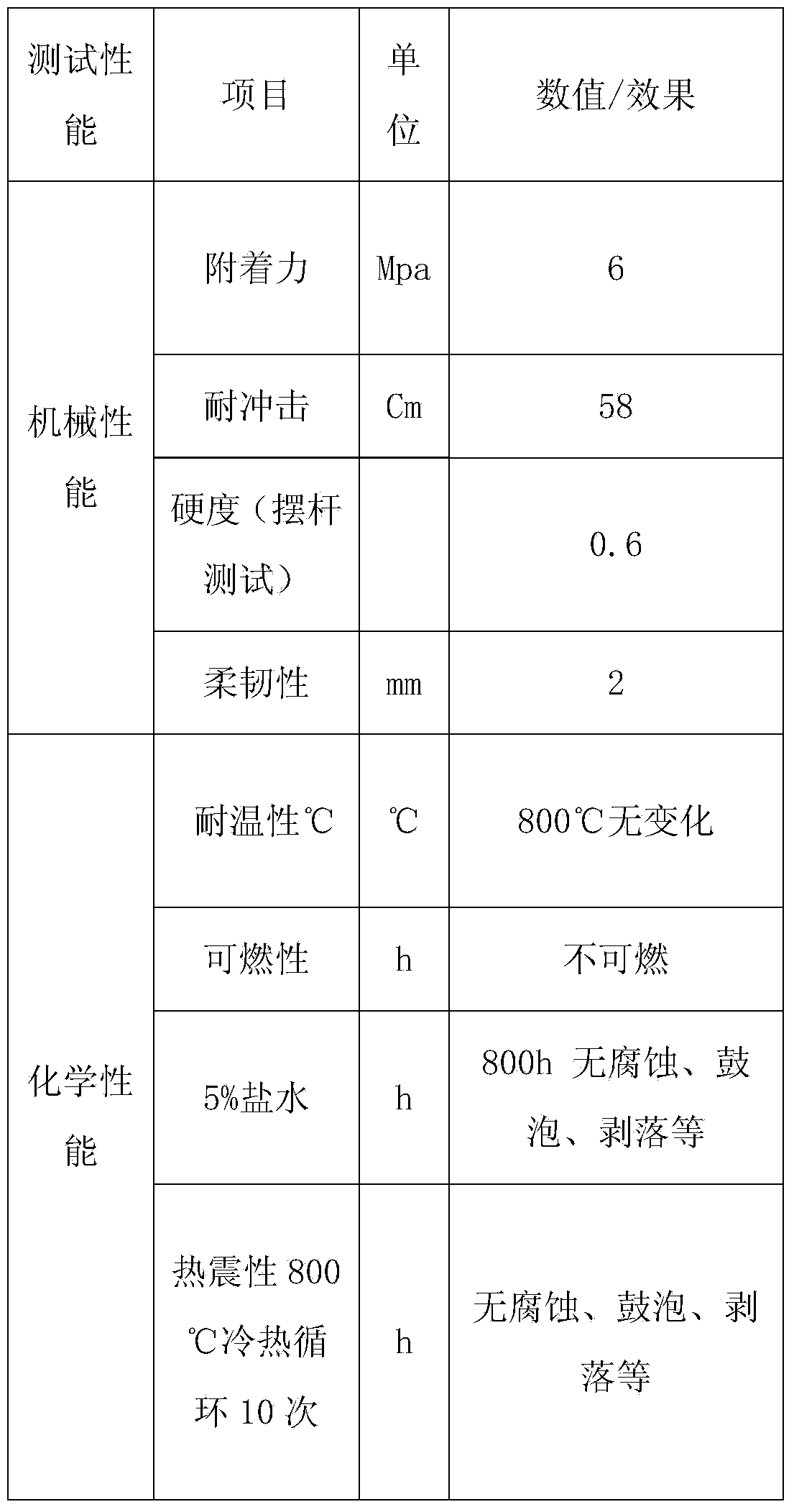

Embodiment 3

[0054] A boron-modified silicone resin high-temperature-resistant coating and its preparation method provided in this example can be realized on the existing coating production line without increasing investment in equipment, and the prepared high-temperature-resistant silicone coating can It is constructed by spraying, brushing and rolling, which can withstand high temperature of 800 degrees for a long time and has corrosion resistance.

[0055] In order to solve the above technical problems, the present invention provides a boron-modified silicone resin high-temperature-resistant coating, the mass percentages of each component are: boron-modified silicone resin: 52%, heat-resistant pigments and fillers: 40%, helping Agent: 3%, wherein the boron-modified silicone resin is boric acid-modified silicone resin or epoxy-modified silicon-boron resin;

[0056] Heat-resistant pigments and fillers include:

[0057] Nano silicon dioxide, barrier type functional filler and aluminum pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com