Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130 results about "Sclerometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Sclerometer, also known as the Turner-Sclerometer (from Ancient Greek: σκληρός meaning "hard"), is an instrument used by metallurgists, material scientists and mineralogists to measure the scratch hardness of materials. It was invented in year 1896 by Thomas Turner (1861–1951), the first Professor of metallurgy in Britain, at the University of Birmingham.

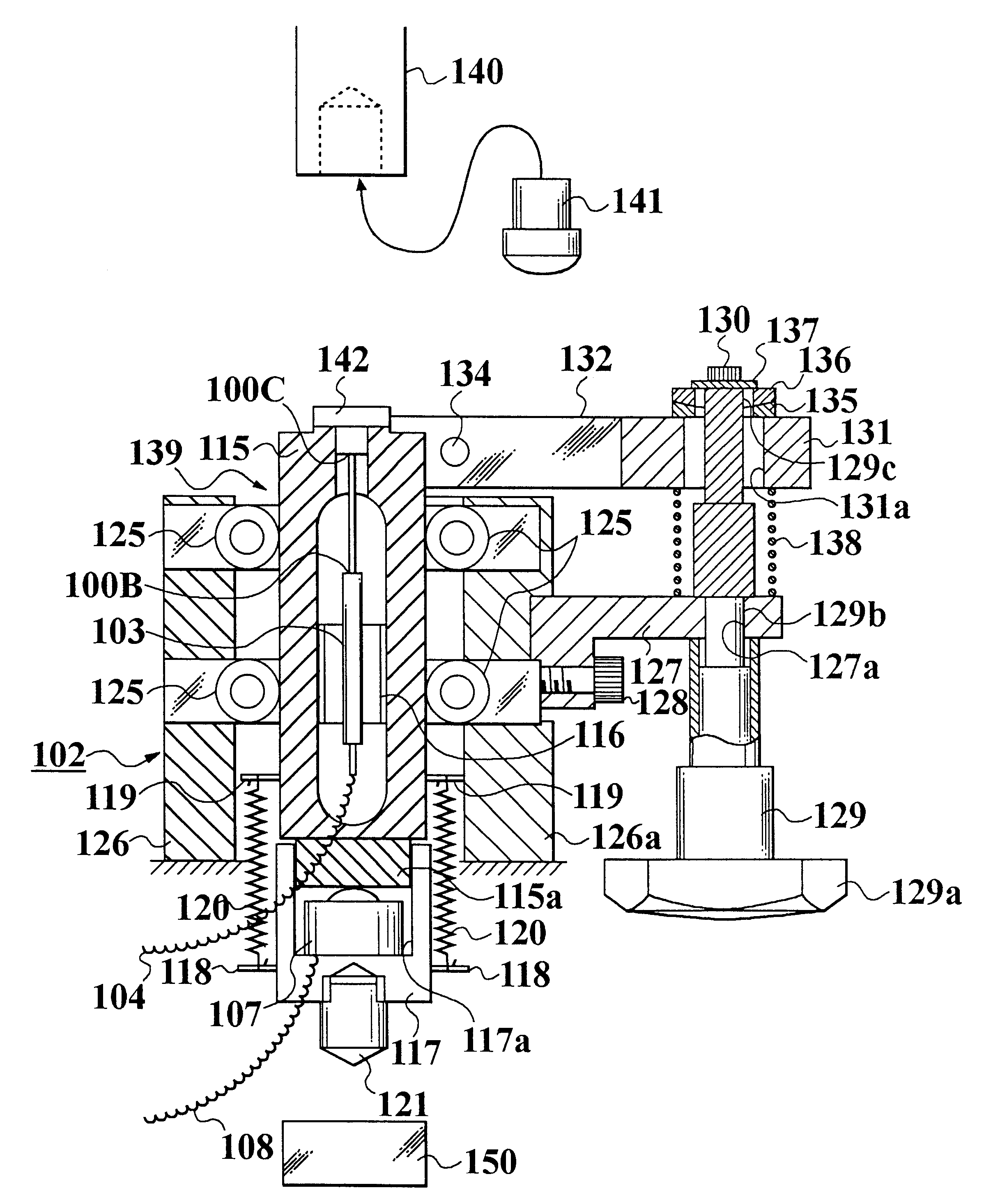

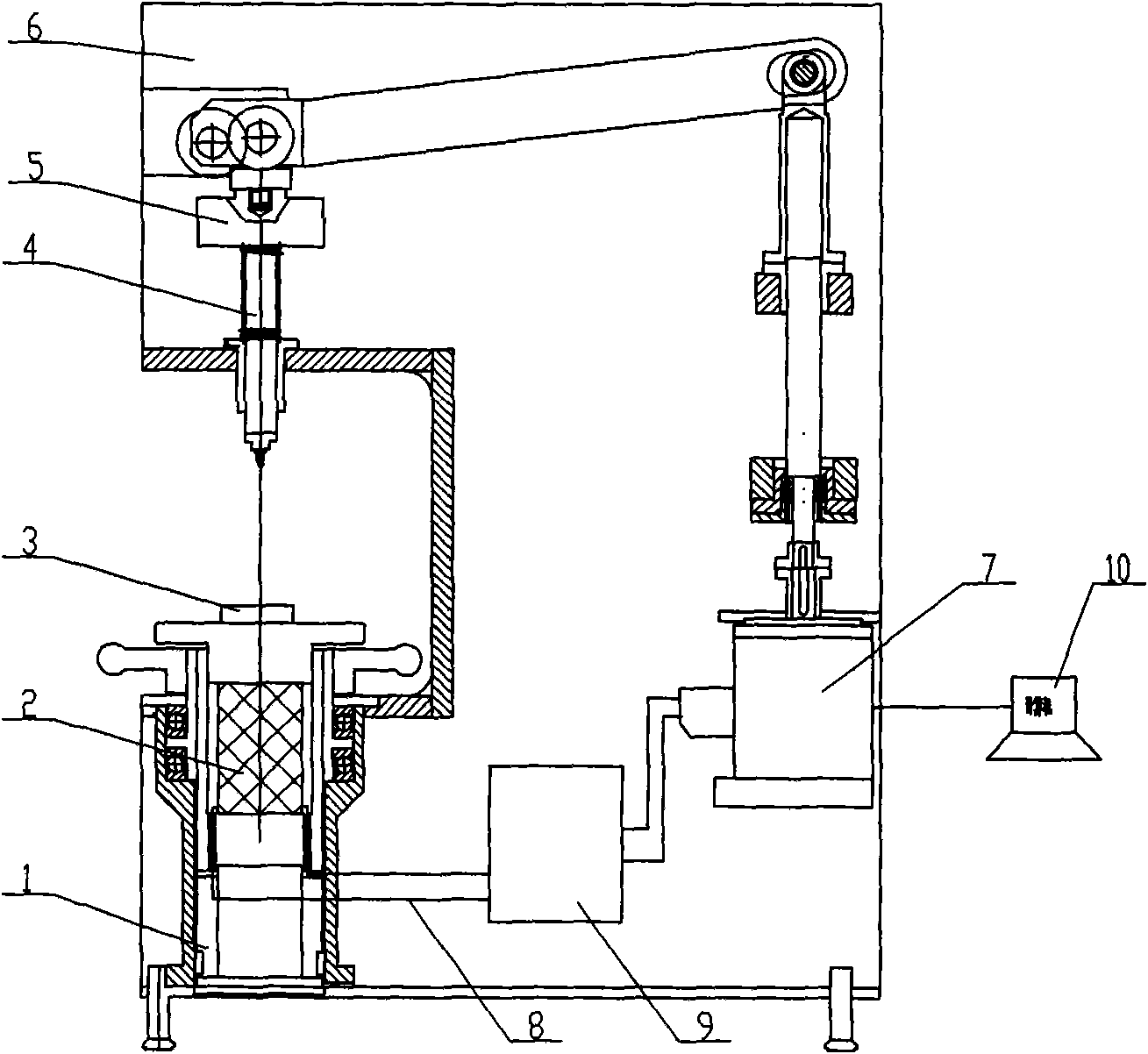

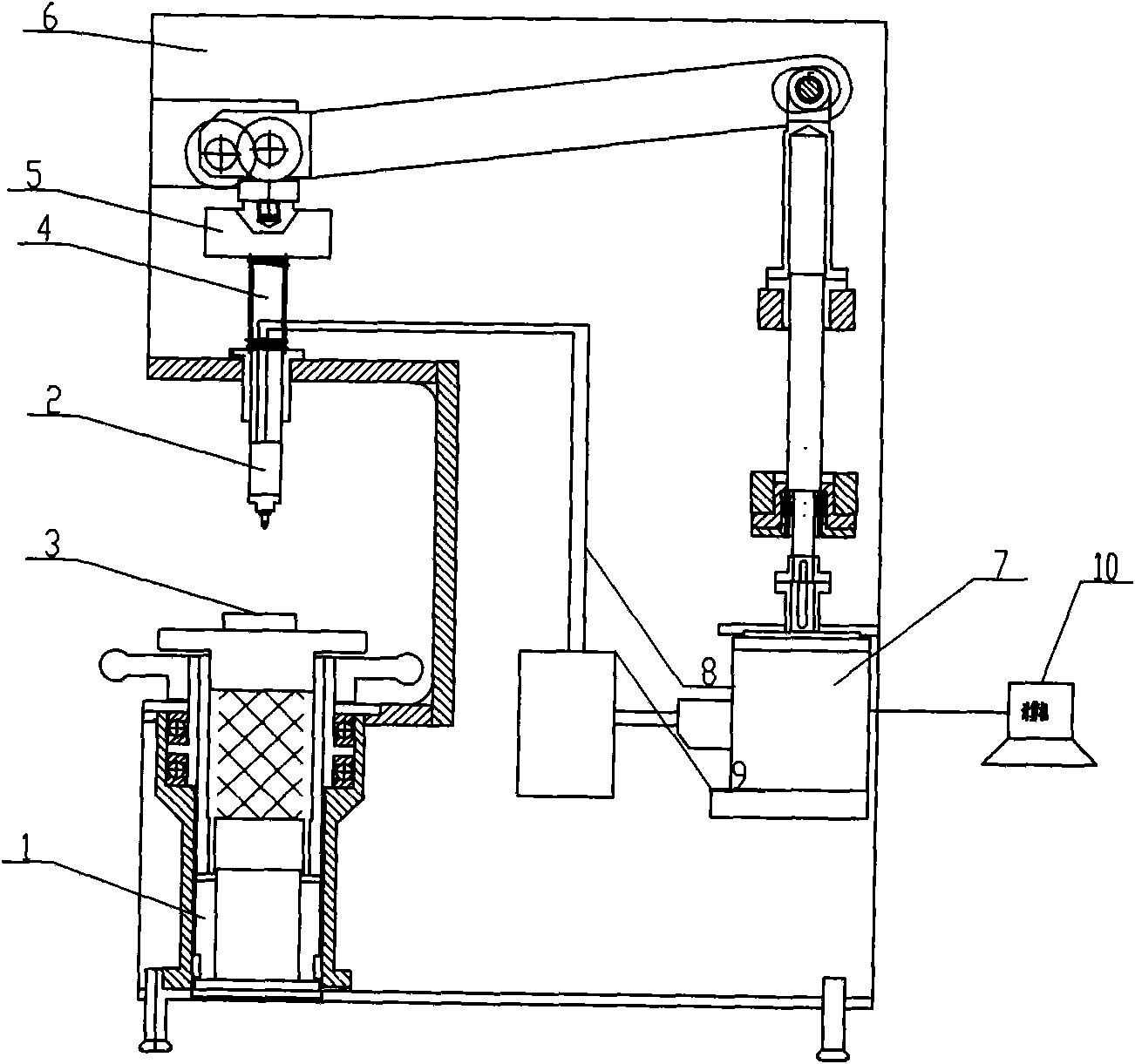

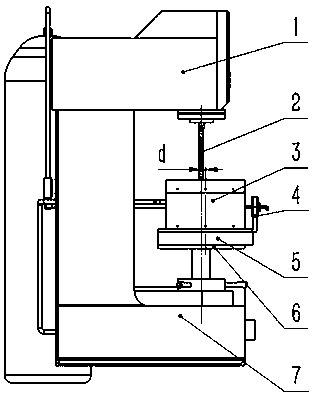

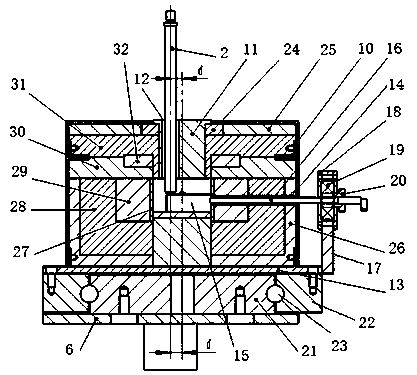

Portable full digital direct testing universal hardness meter

InactiveCN1556387AImprove general performanceHigh degree of digitizationInvestigating material hardnessData processing systemMagnetic tension force

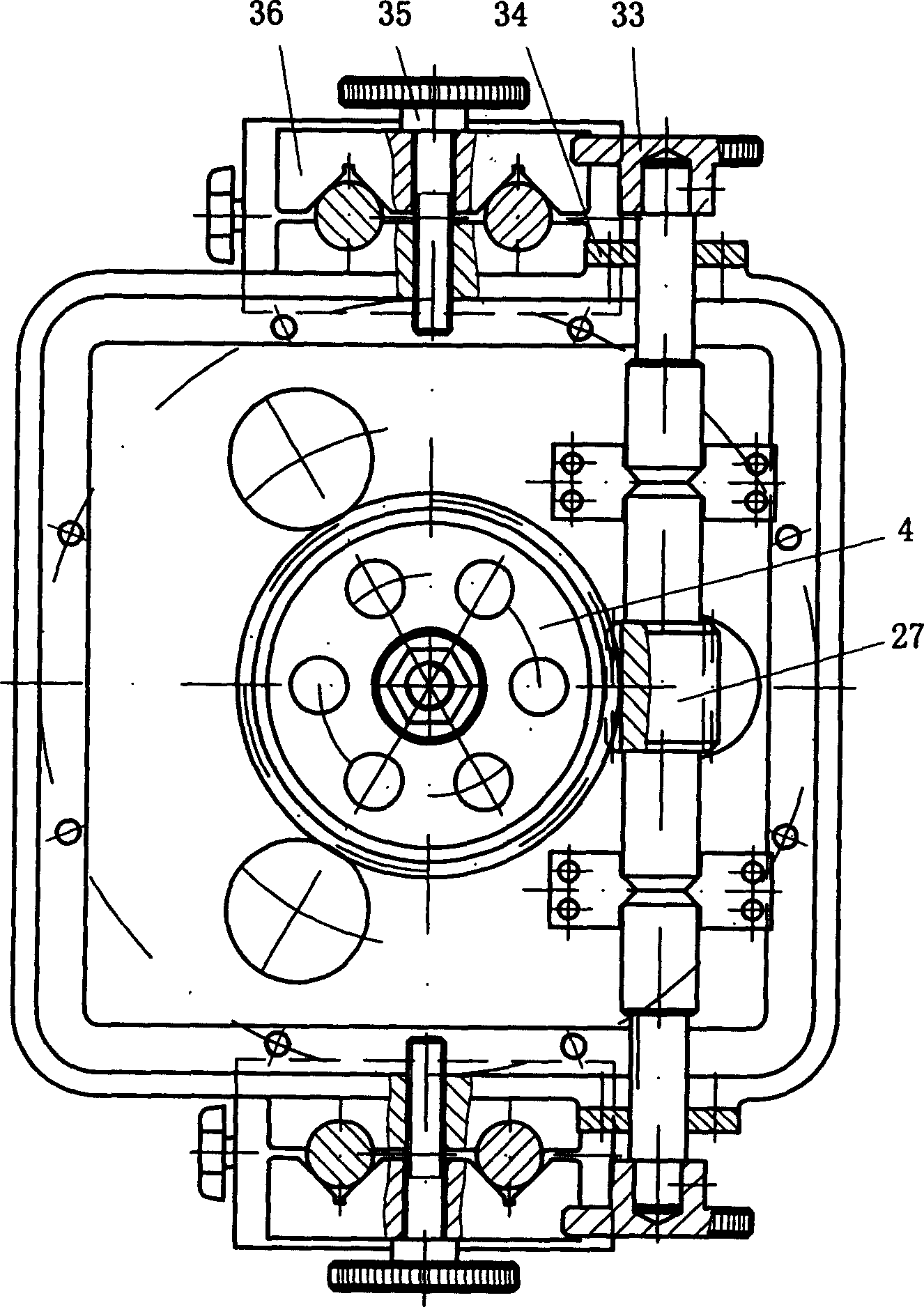

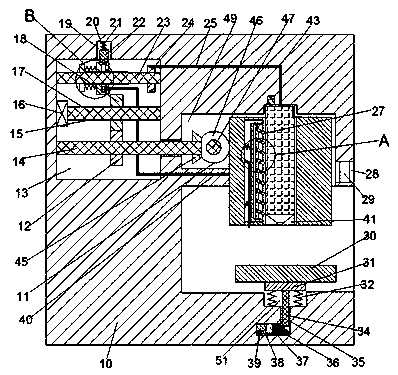

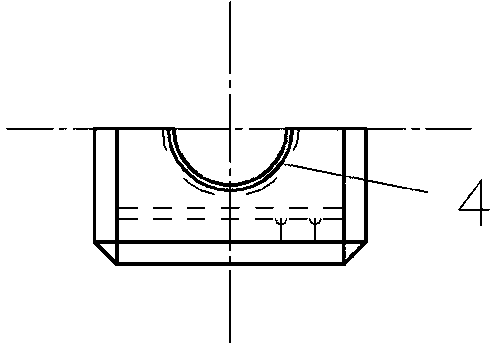

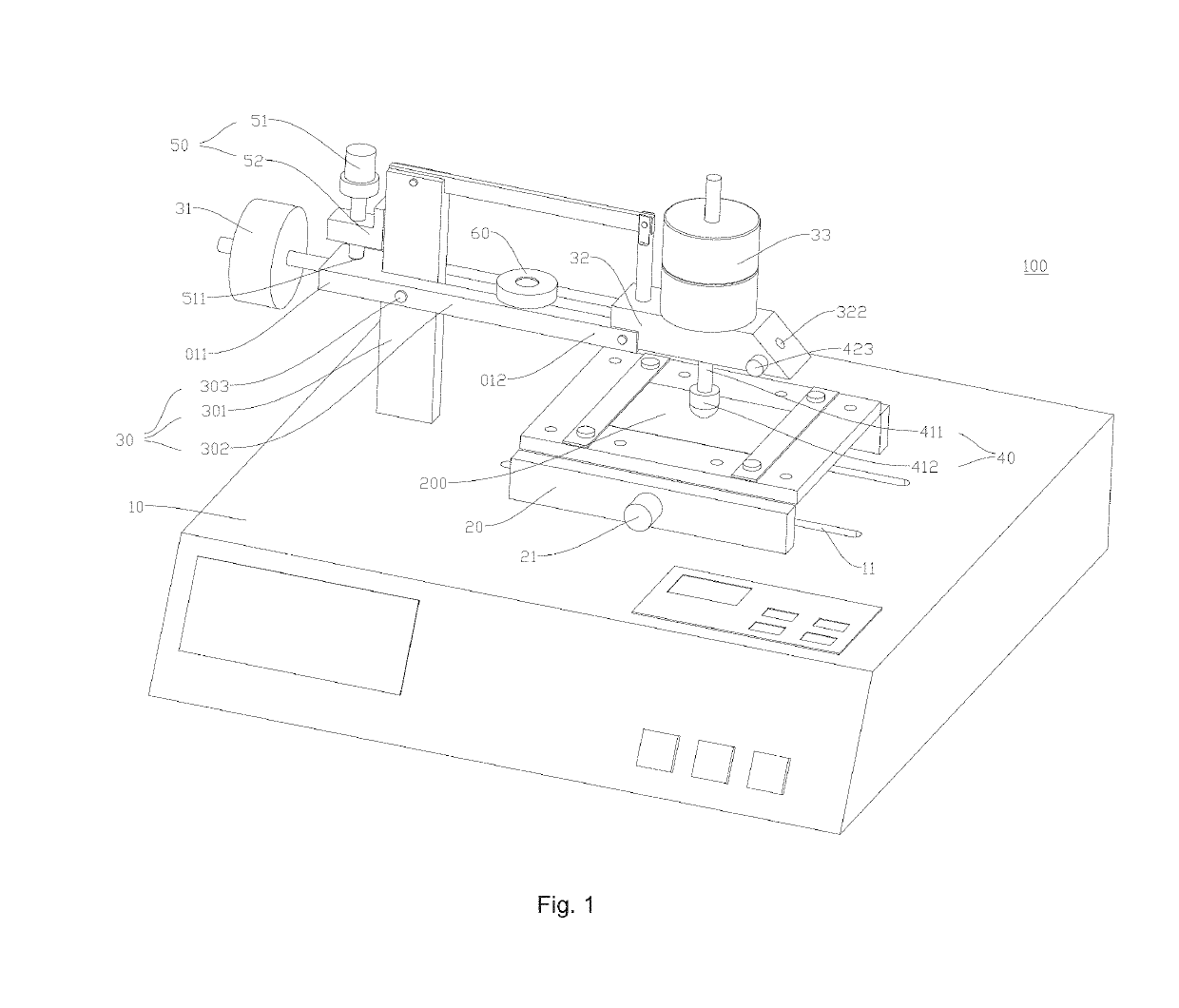

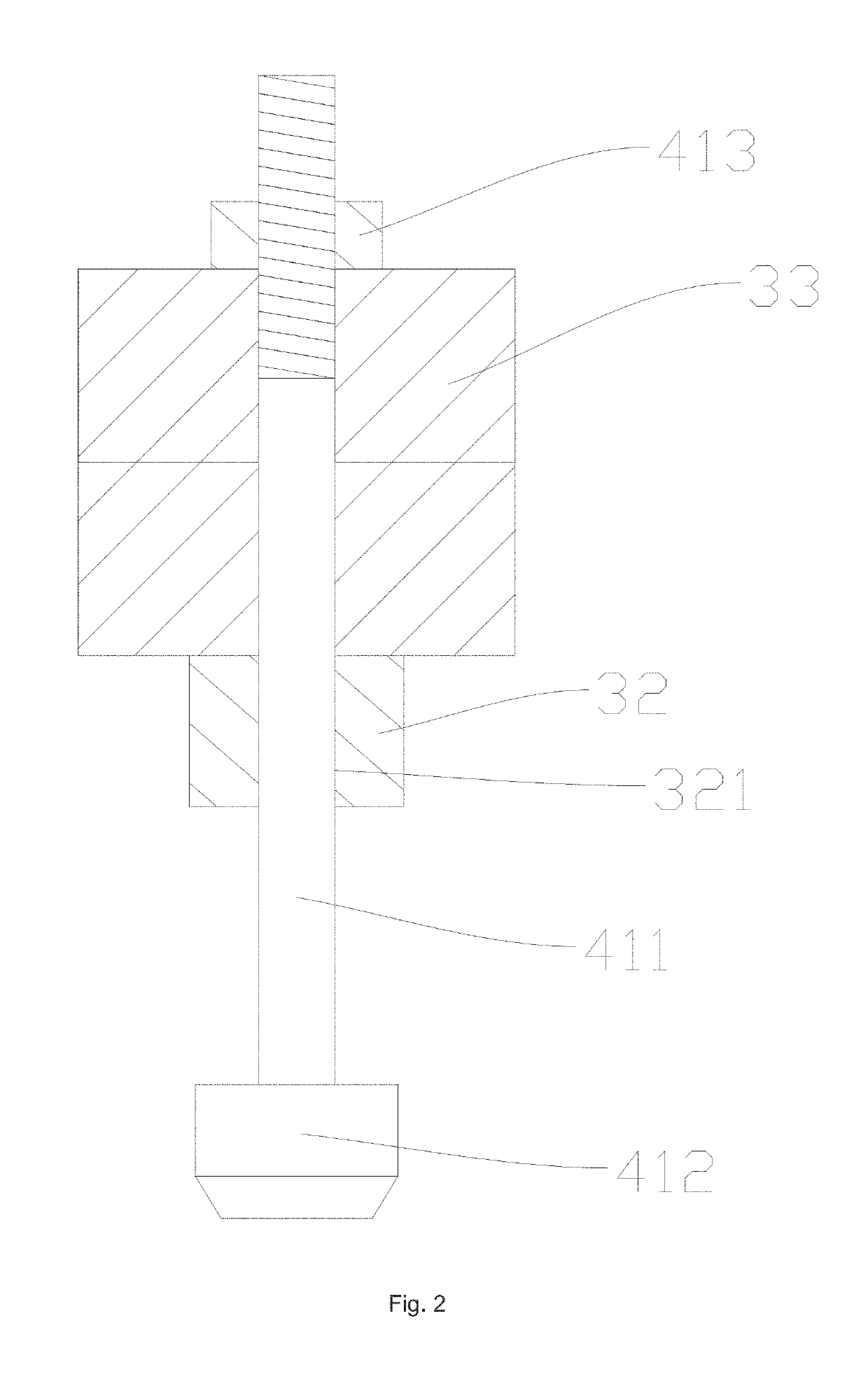

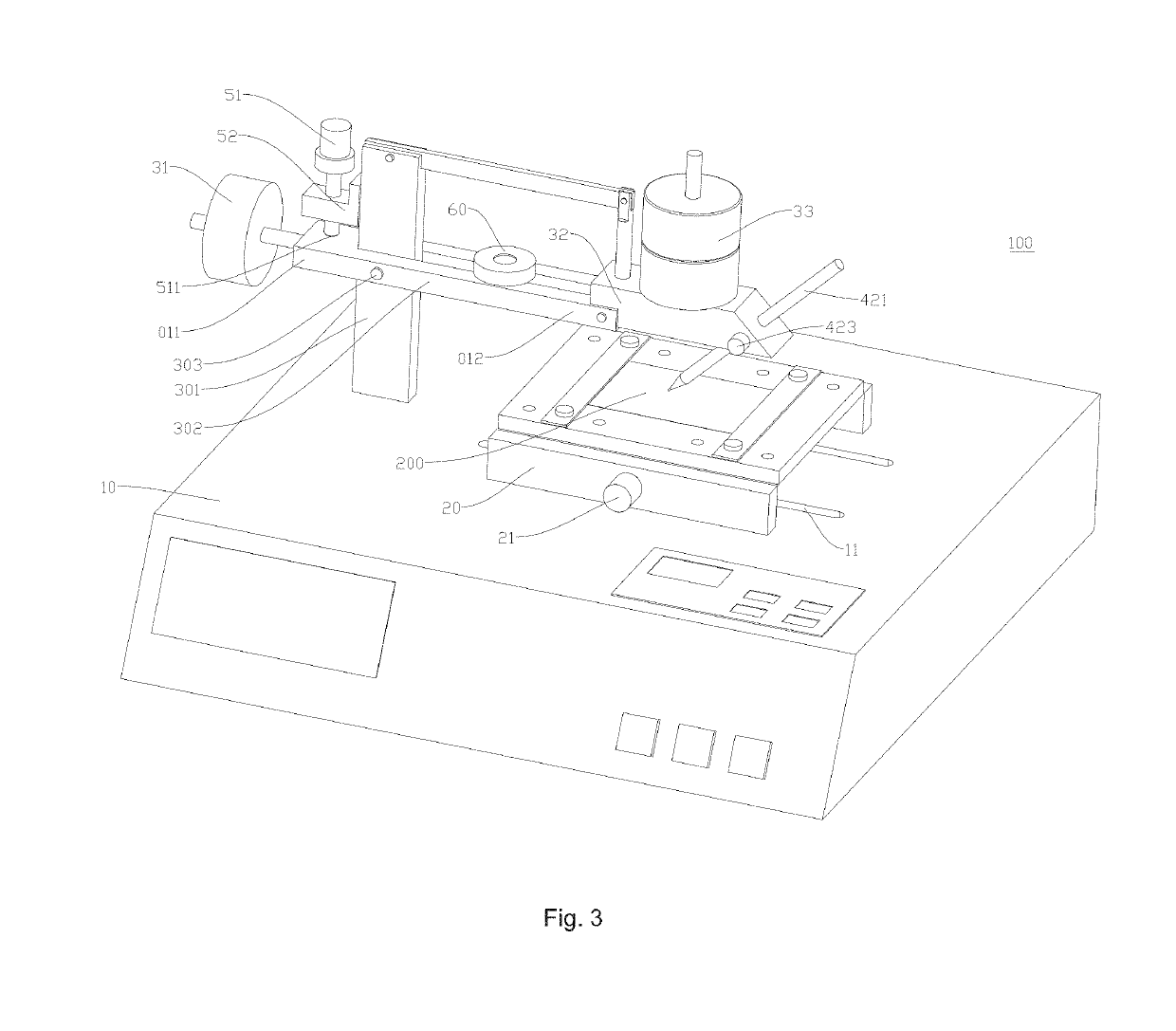

The sclerometer includes following parts: (1) cabinet rack; (2) frame in force-closed structure including at least two columns to support frame, and a magnetic holder for fixing a supporting bottom board or sample to be tested through magnetic connection; (3) unit for loading test force composed of worm, worm wheel, force sensor, replaceable press head etc; (4) displacement sensor for press head (5) processing system for treating signal and data of sensors. The invention possesses features: suitable to test hardness of sample in different shapes and situations on site; determining testing validity online; each general hardness test can be carried out after press head is replaced.

Owner:WUHAN UNIV

Hardness test method

InactiveCN101893534AExpand the scope of detectionImprove detection accuracyInvestigating material hardnessSoftware engineeringSclerometer

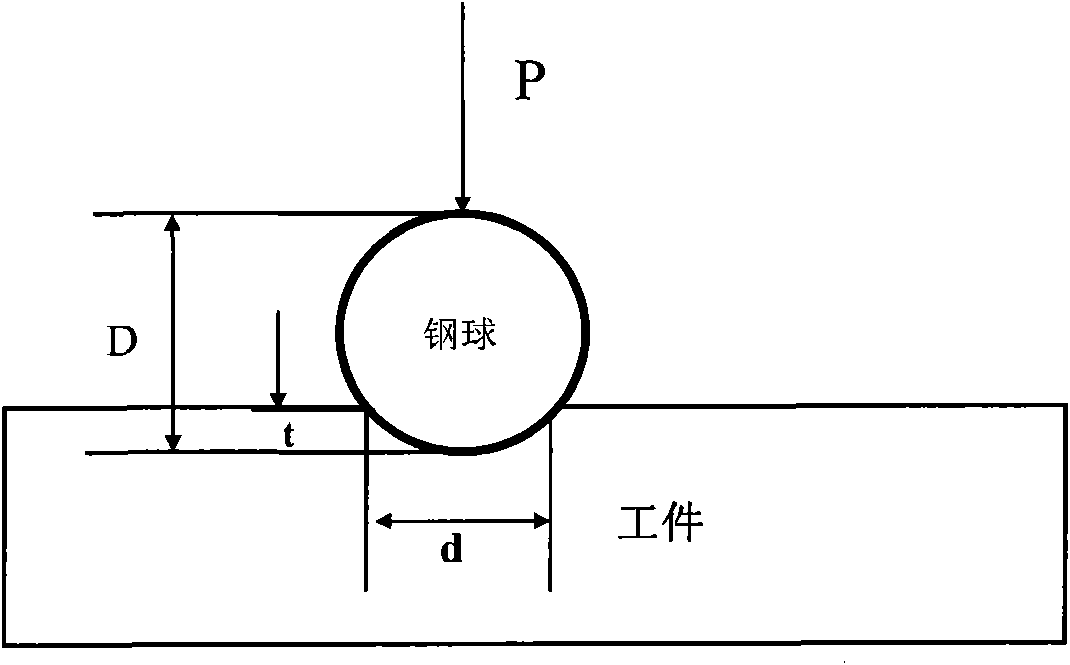

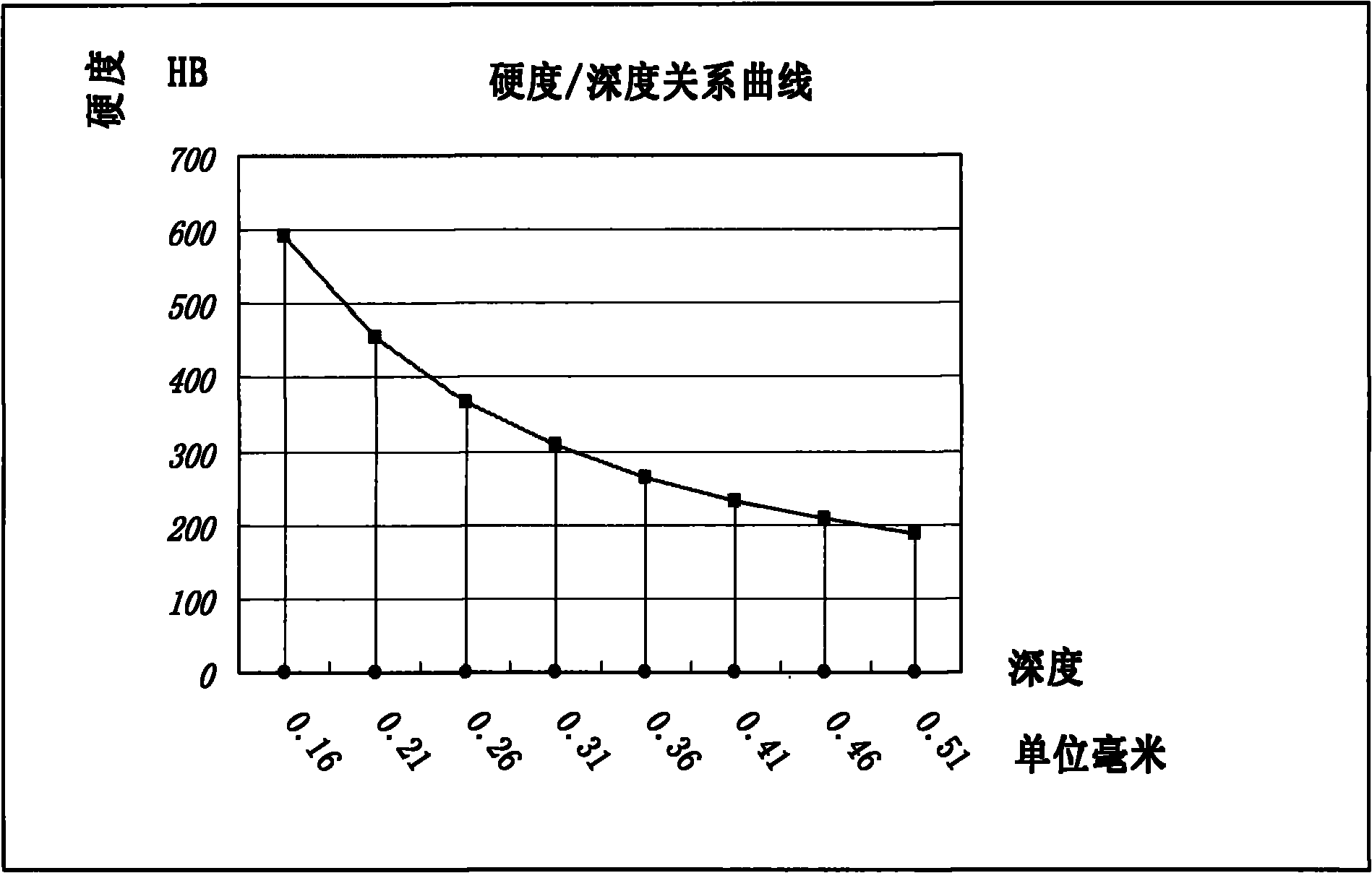

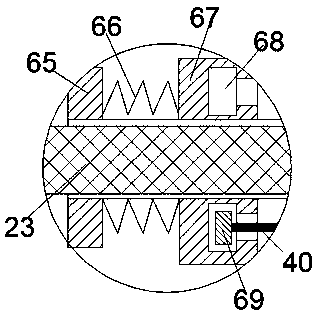

The invention discloses a hardness test method. The hardness test method comprises the following steps of: firstly, demarcating and drawing a hardometer working curve (namely an indentation depth-hardness value curve) by using test blocks with different hardness and using a VB software program; secondly, testing a workpiece to be tested; and substituting a tested indentation depth value into the hardometer working curve to obtain the hardness value of the workpiece to be tested. The technical scheme has the advantages of greatly improving the test precision and the stability, enlarging the test range and effectively monitoring the whole working process of equipment in a dynamic state to ensure that a hardometer can meet actual needs of automated large-scale production.

Owner:BAOSHAN IRON & STEEL CO LTD

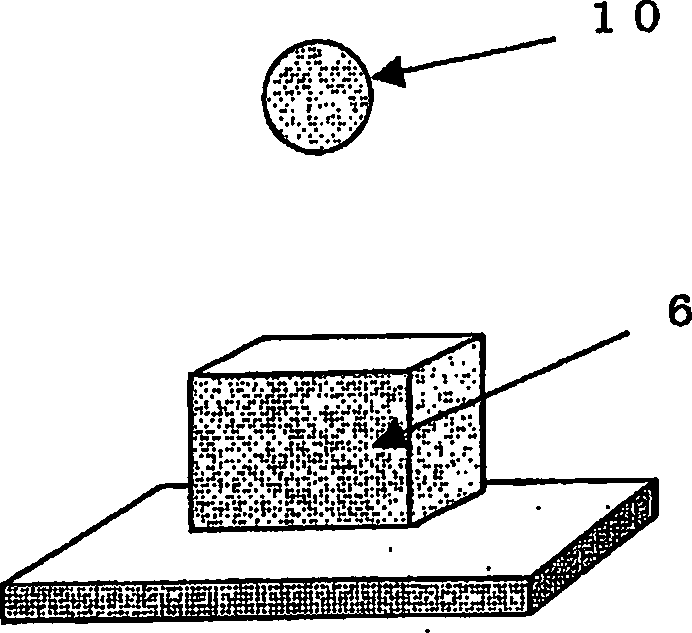

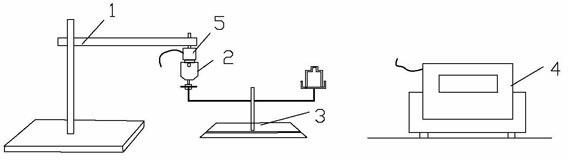

Device facilitating measurement of hardness of workpiece

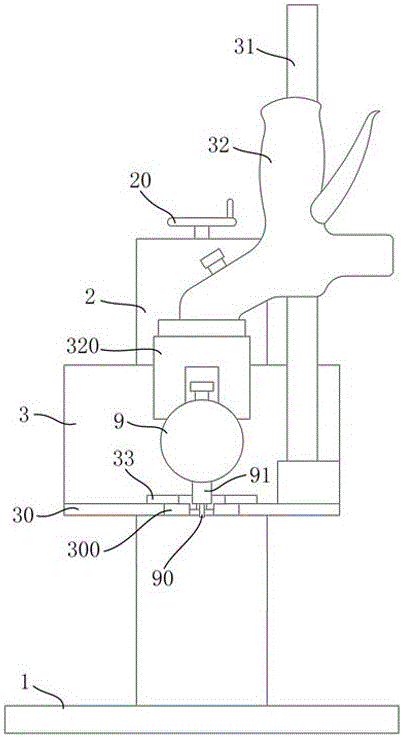

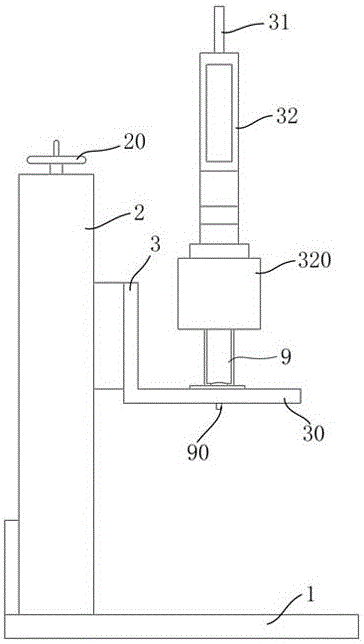

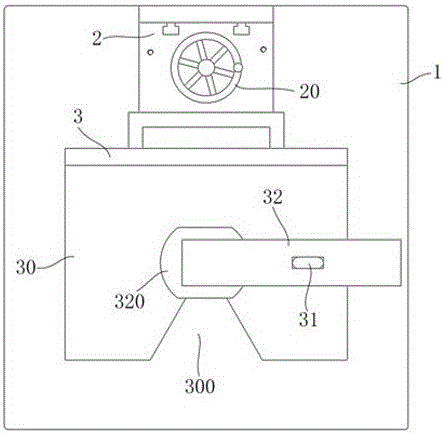

The invention relates to a device facilitating the measurement of the hardness of a workpiece. The device comprises a hardness meter and a base, wherein the base comprises a testing platform and a vertical column connected with the testing platform; the vertical column is of a cavity structure with an opening at one end; the hardness meter is arranged in the vertical column in a sliding manner and comprises a cylindrical cavity shell; a hardness converter is arranged in the cylindrical cavity shell; the hardness meter also comprises a guide pipe connected on the cylindrical cavity shell; a testing head is arranged in the guide pipe in a sliding manner; the bottom end of the guide pipe is provided with a hole; an electronic coil is wound above the hole; the hardness converter is electrically connected with the electronic coil; and the hardness meter also comprises a transmission device. The device has the beneficial effects that and height adjustment of the hardness meter can be realized by gear-rack meshing when a hand wheel rotates, and the distance between the testing head and the coil is shortest by directly winding the electronic coil on the guide pipe, so that the obtained final testing result is accurate.

Owner:四川富临集团成都机床有限责任公司

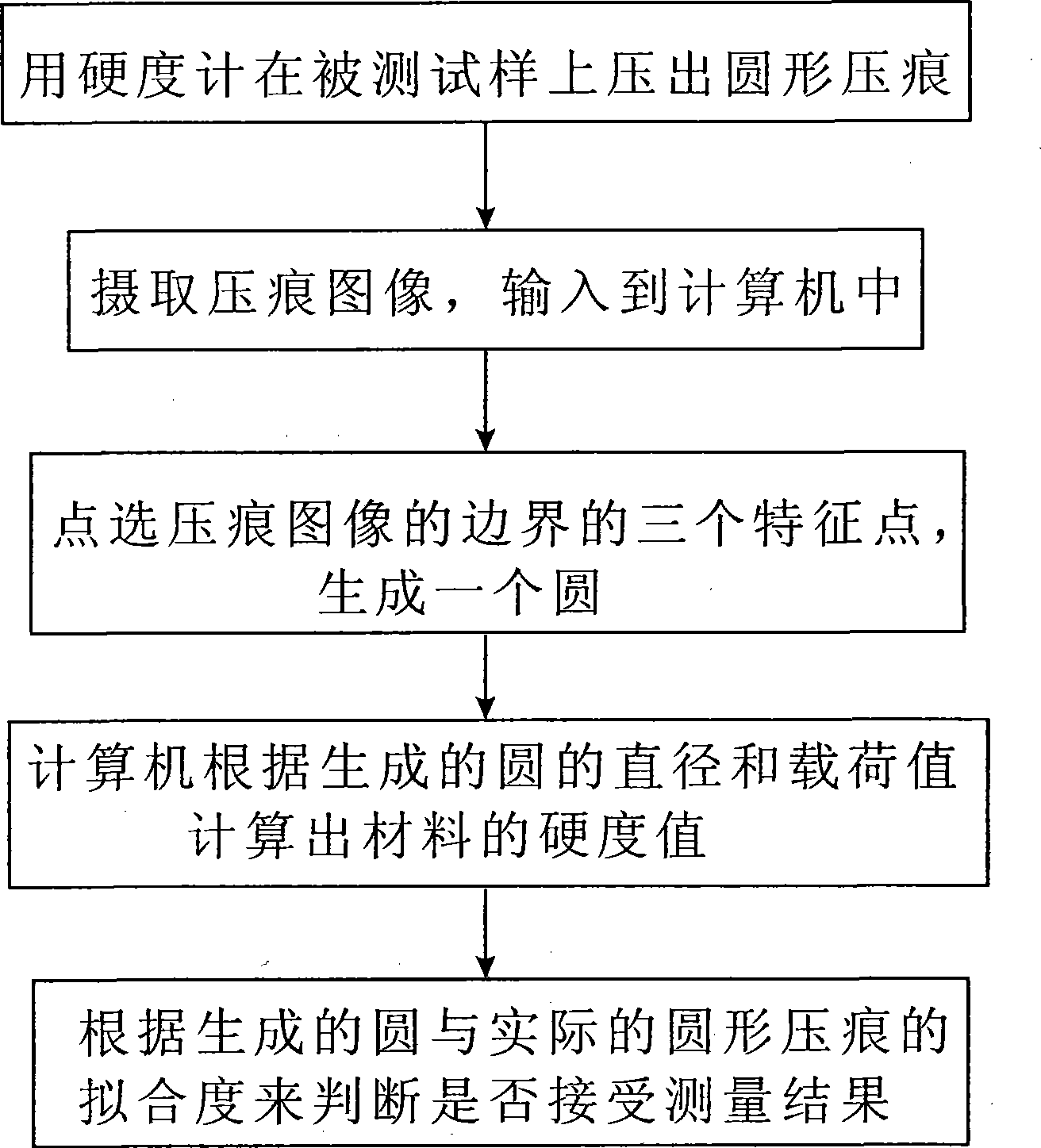

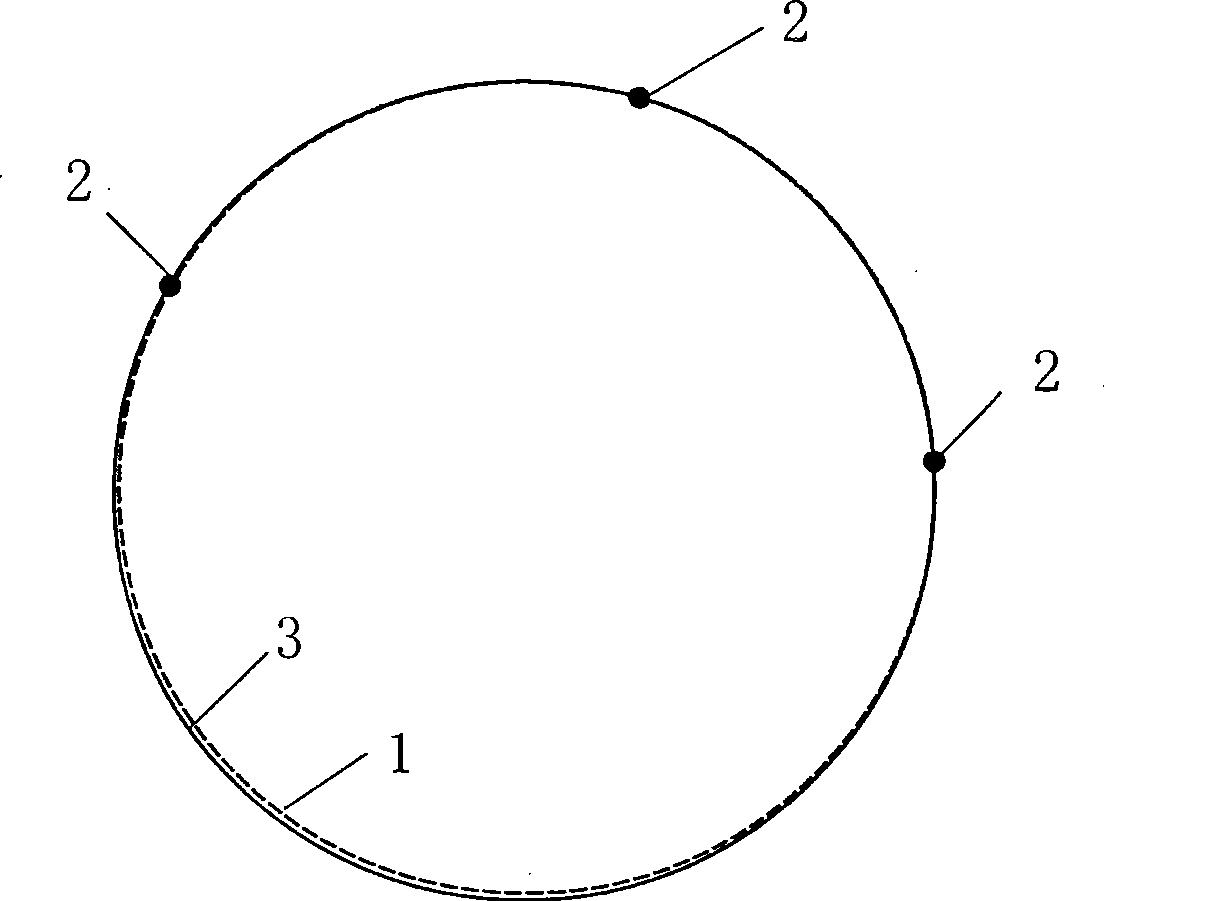

Method for measuring brinell hardness

InactiveCN101377457AEasy to operateReduce labor intensityInvestigating material hardnessFast measurementTest sample

The invention relates to a measurement method for Brinell hardness, comprising the following steps: firstly, applying load to the tested sample with a hardness tester to form circular impression on the tested sample; secondly, photographing the impression and inputting the photographed picture to a computer; thirdly, selecting three characteristic points along the boundary points of the impression picture to form a circle; and finally, computing the hardness according to the diameter of the circle generated by the computer and the input load value. With the technical proposal, the invention has convenient operation, precise and fast measurement, and low cost, can reduce the labor intensity, and does not occupy hours of the hardness tester.

Owner:上海电气集团上海电机厂有限公司

Decorating material for flooring

InactiveCN101397840AExcellent walking feelingGood dispersionSynthetic resin layered productsWood layered productsSclerometerEngineering

The present invention provides a floor decorating material which not only has caster resistance but also has excellent cullet cut resistance, impact resistance and walking effect. The floor decorating material can be stably produced with a large amount. The floor decorating material is composed through stacking decorating sheets on wood substrate. The surface hardness is lower than 60 when a D type sclerometer is used for measuring from one side of decorating sheet according to the prescription of JIS K 6253.

Owner:DAI NIPPON PRINTING CO LTD

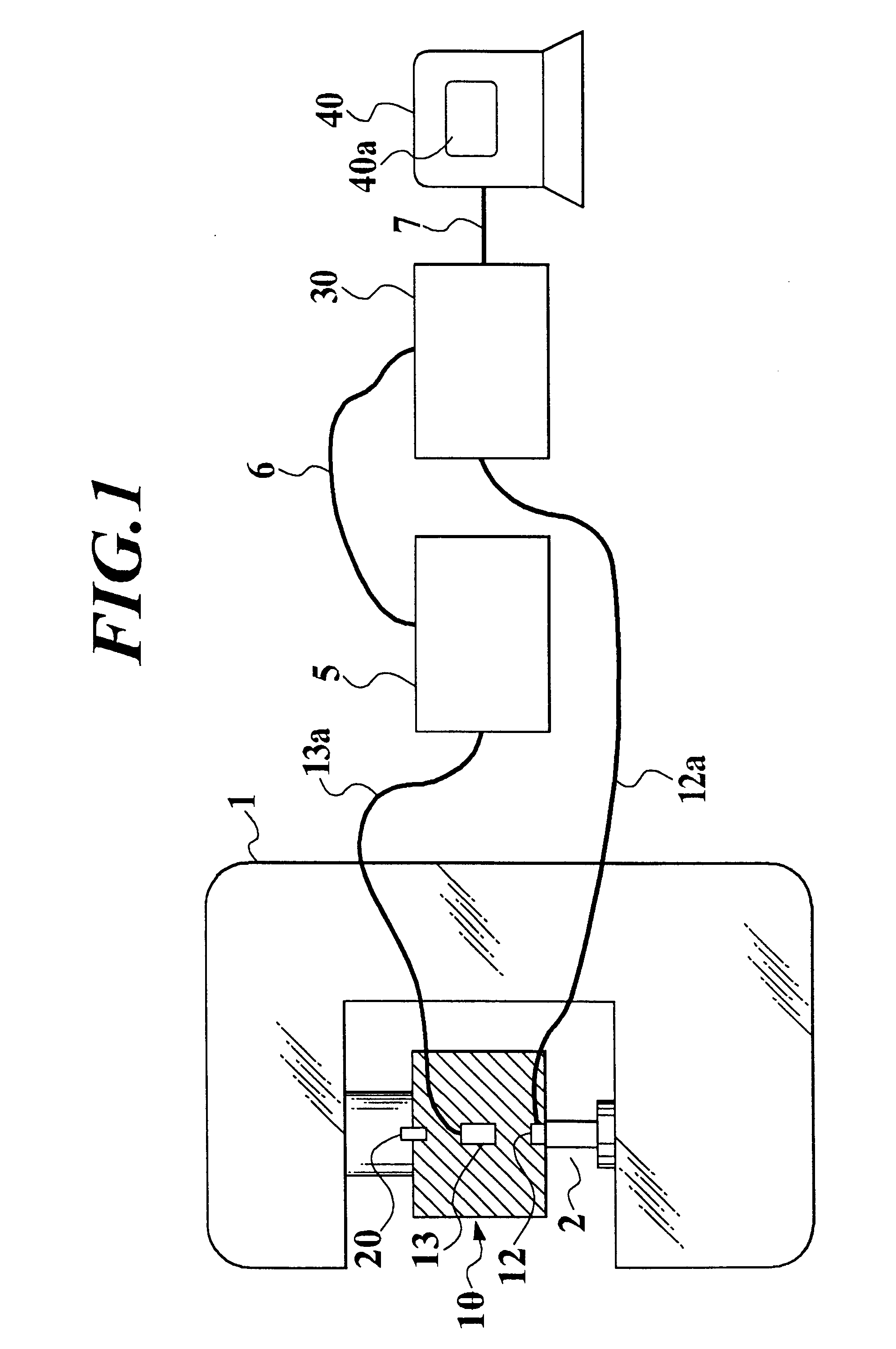

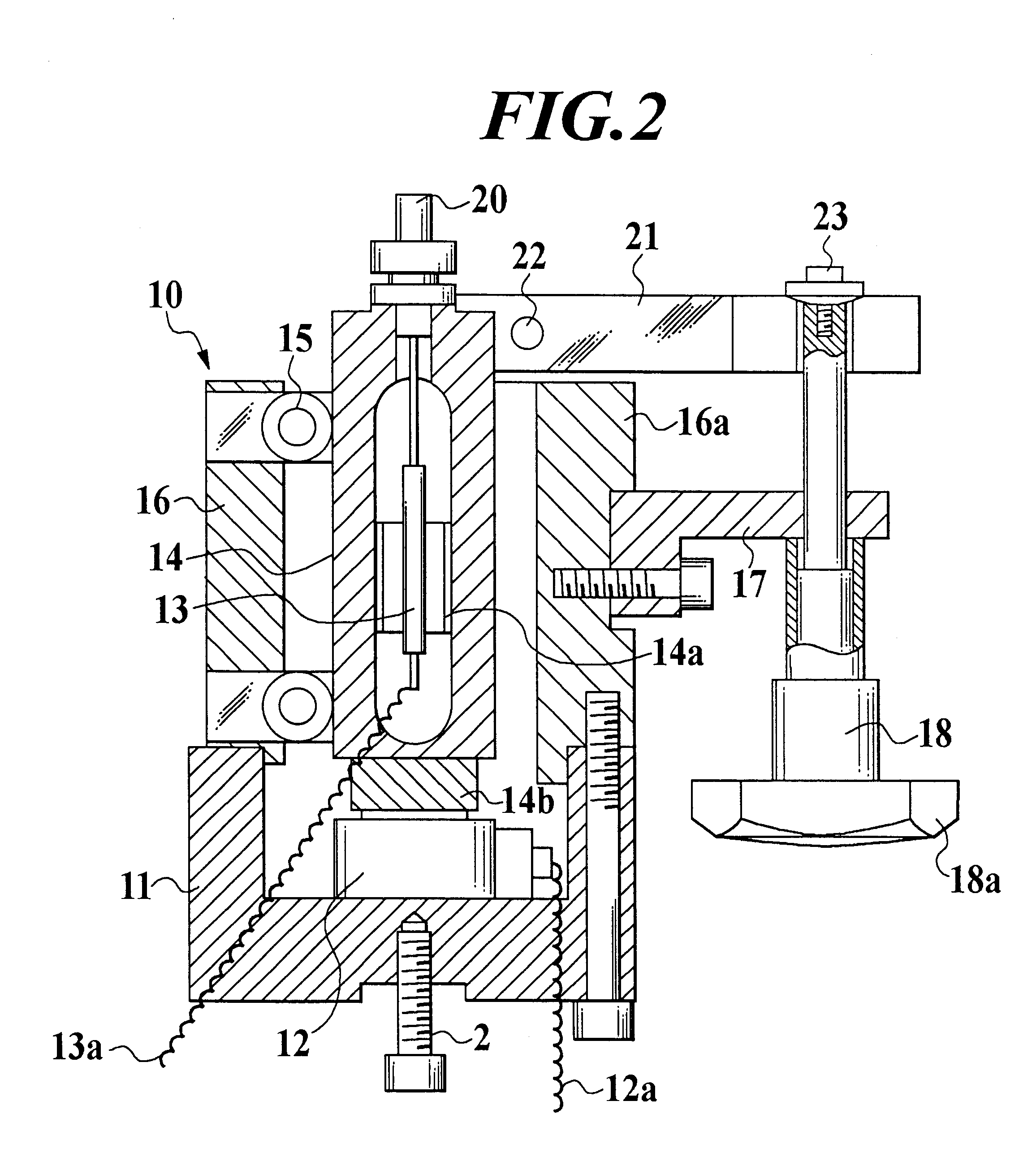

Apparatus for calibrating hardness tester, method for calibrating the same and apparatus for evaluating dynamic characteristic of specimen

InactiveUS6279388B1Avoid mistakesEasy to placeUsing optical meansInvestigating material hardnessMeasuring outputSclerometer

A method for calibrating an apparatus for calibrating a hardness tester, the method comprising the steps of: setting a plurality of calibration points between a rated force point at which a rated force of a force measuring member is applied and a zero point at which no-load is applied, for measuring outputs (mV / V) from the force measuring member according to test forces(N) applied to the force measuring member; and calculating a relation between the test forces(N) and the outputs(mV / V) as an approximation based on the test forces(N) and the outputs(mV / V) according to the test forces(N) at the calibration points. An apparatus for evaluating a dynamic characteristic of a specimen, which installed in a hardness tester, the apparatus comprising: a force measuring member; a force transmitting portion which is movable up and down; a distance measuring member incorporated in the force transmitting portion to be contacted with the force measuring member from above; and an indenter.

Owner:MITUTOYO CORP

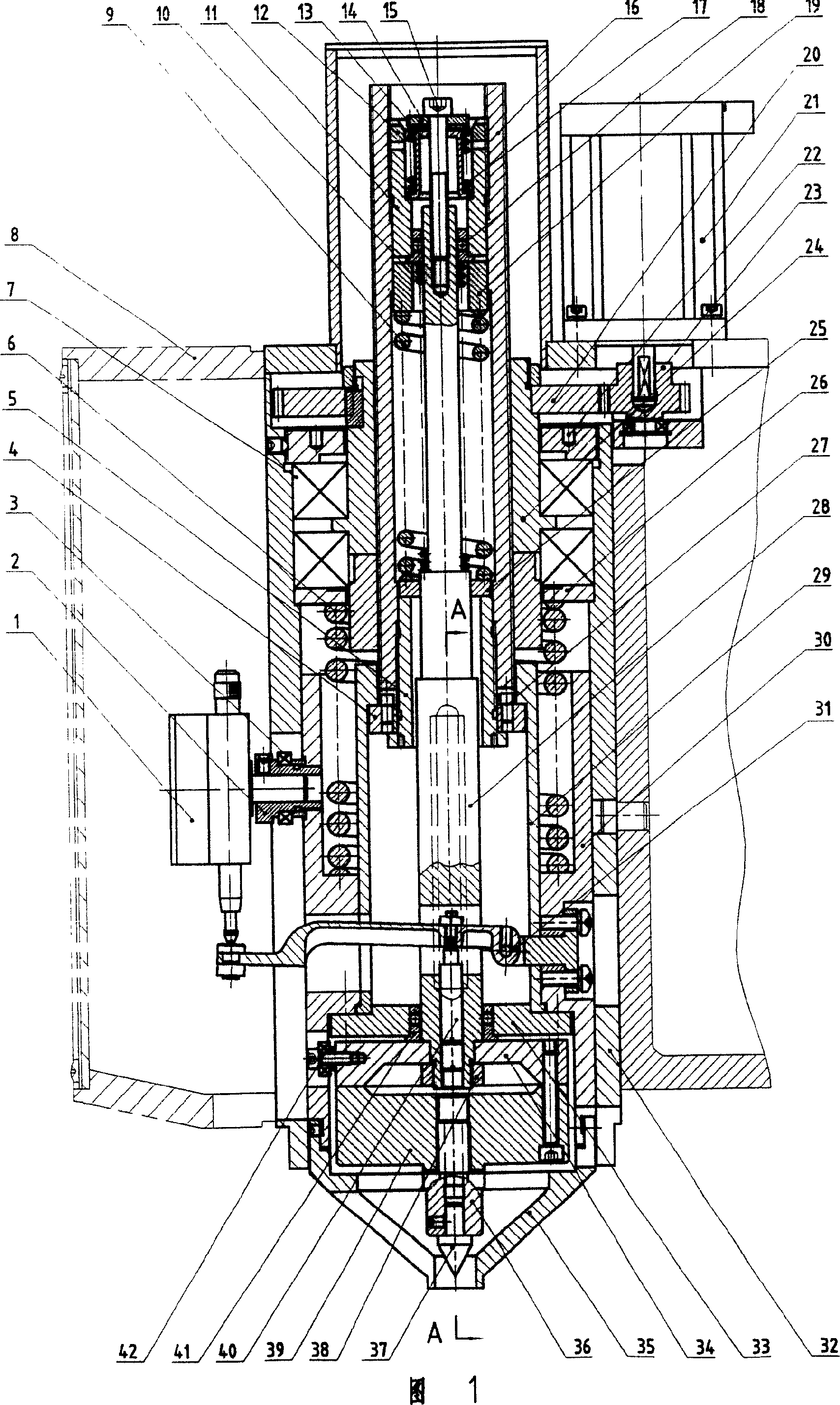

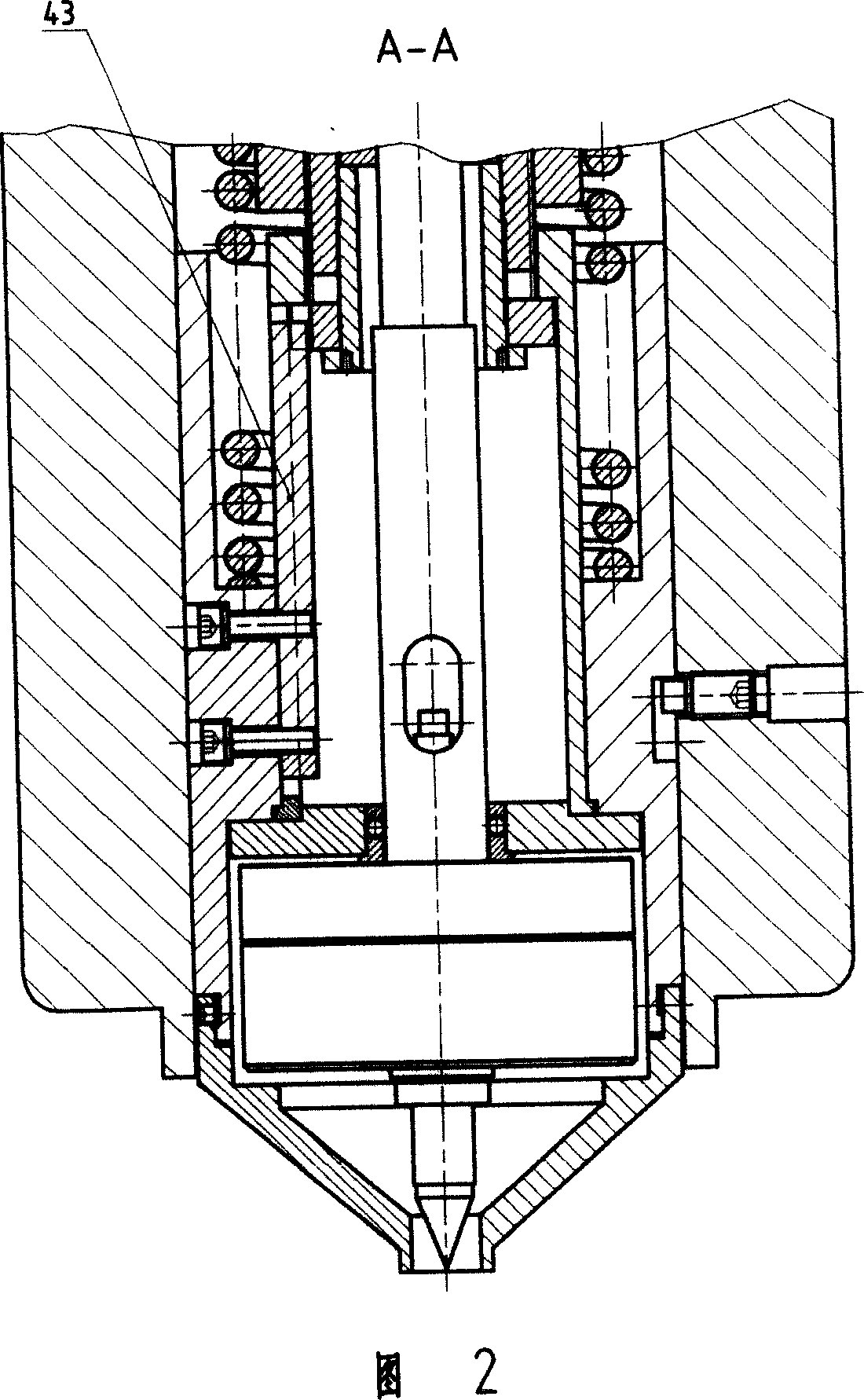

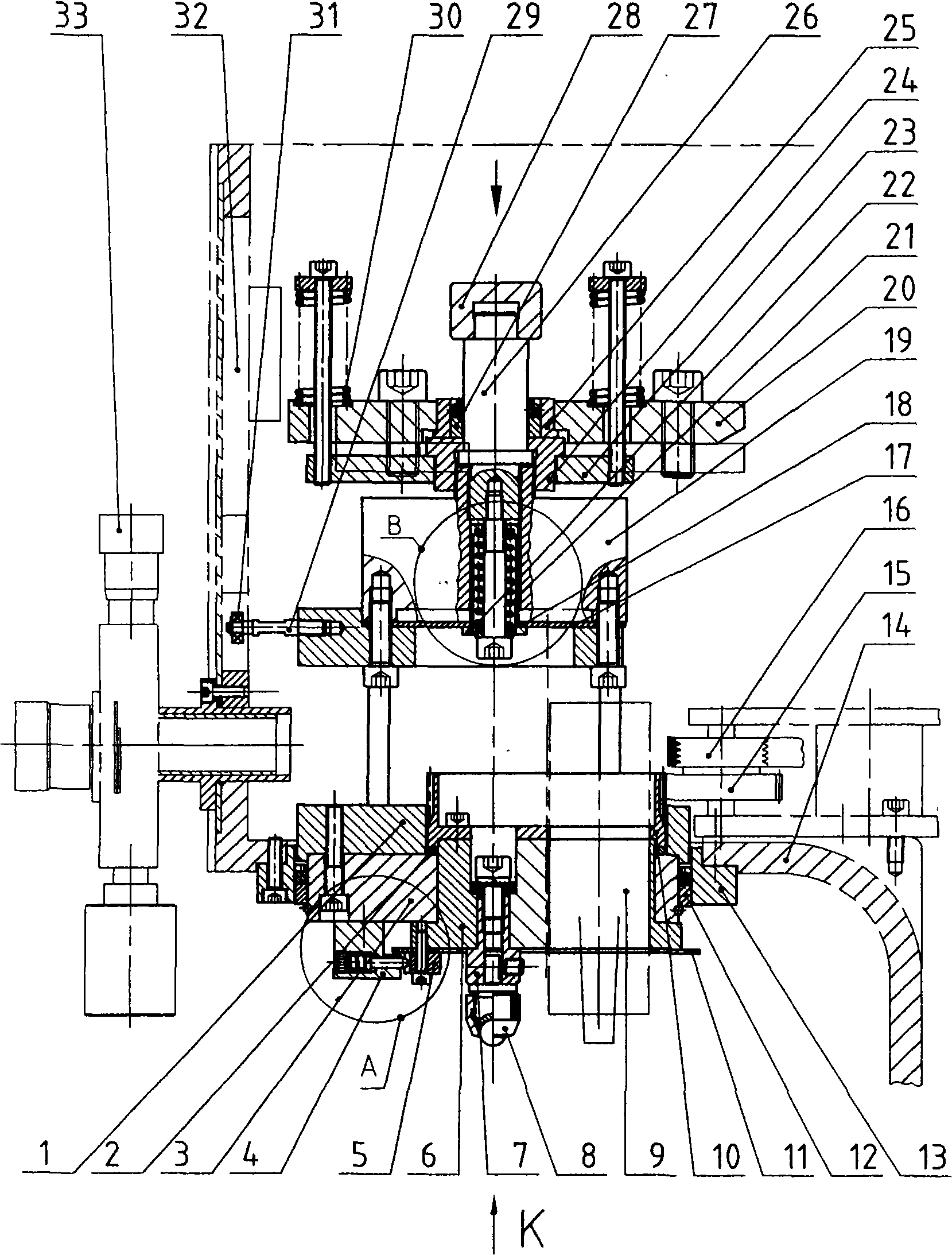

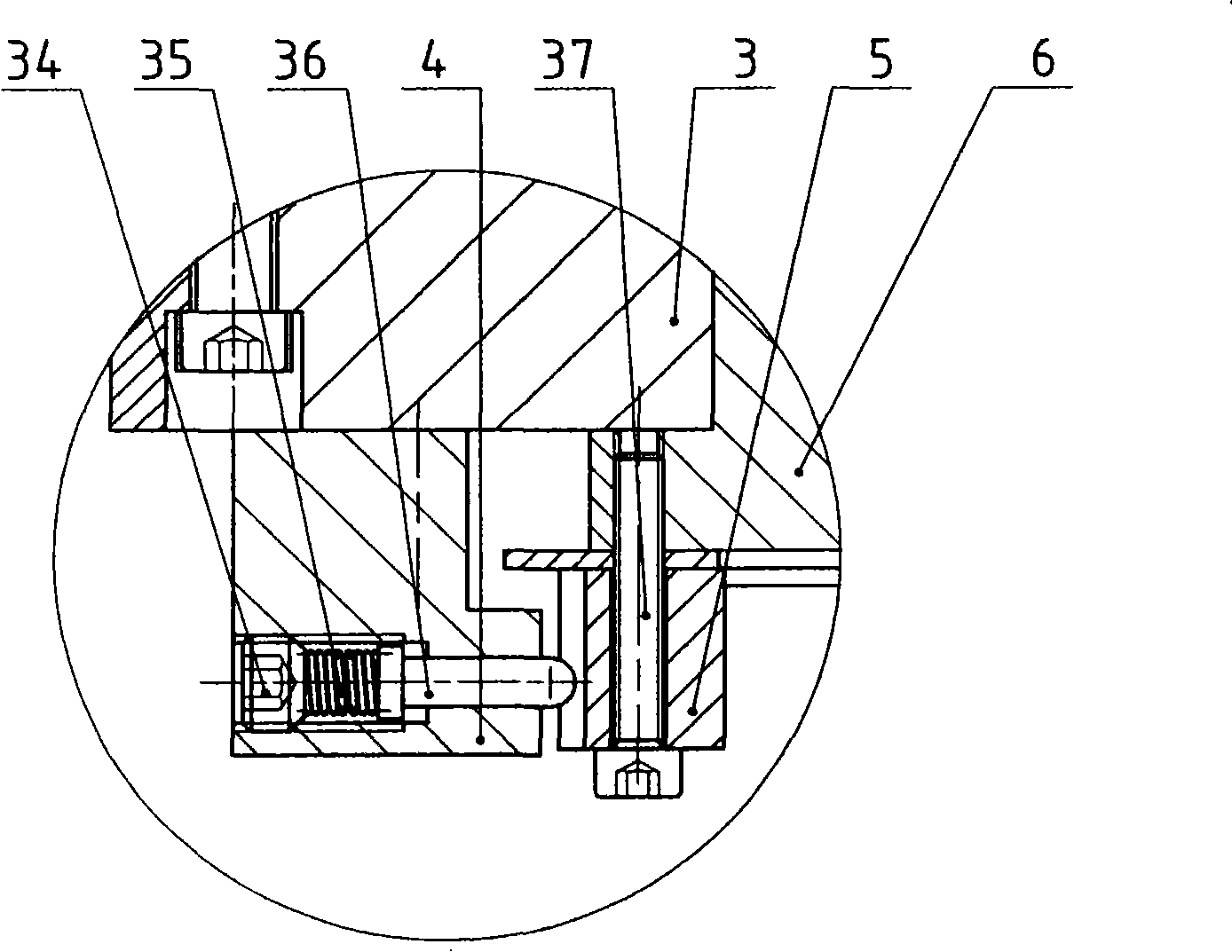

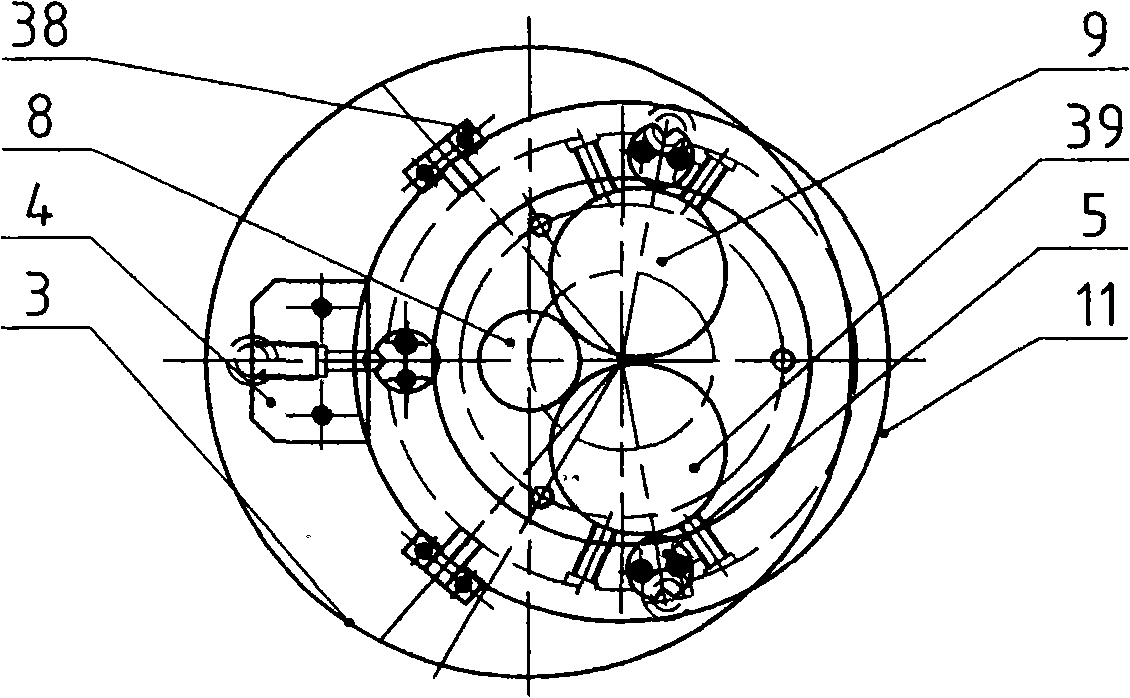

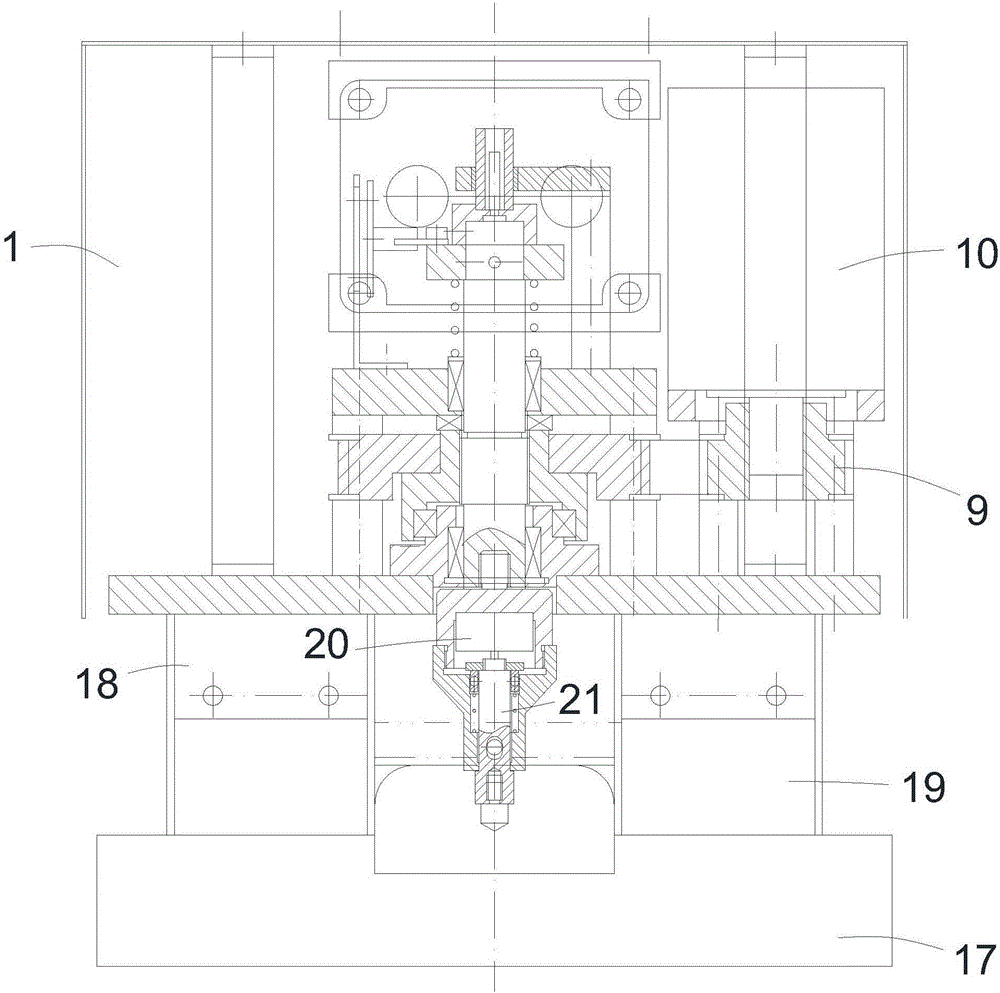

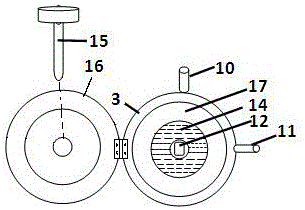

Automatic adding and discharging carrier of sclerometer and measuring cell

InactiveCN1963446ANotable featuresSignificant positive effectInvestigating material hardnessElectricitySclerometer

This invention discloses one metal and non metal hardness test and study meter automatic load and measurement unit, which comprises supportive rack, step drive structure, main axis loading structure, and main axis structure, clamping structure, print deepness measurement structure and electricity control structure. This invention can automatically trace print deepness to eliminate rack deformation and impact on test parts and can exert initial test force under slow impact status and can automatic clamp test parts free of size and weight impact.

Owner:莱州华银试验仪器有限公司

High-precision hardness tester force value loading adjusting device

InactiveCN101587047AQuick responseCompact structureInvestigating material hardnessElectricitySclerometer

The invention provides a high-precision hardness tester force value loading adjusting device, comprising a high-rigidity body, a pressure head lifting device and a working platform coarse lifting device; the axle wire of force value loading of the device is mounted with a piezoelectric ceramic force value loading block composed by overlapping multiple piece of piezoelectric ceramics; the circuit connecting structure of the multiple piece of piezoelectric ceramics is in parallel connection, the excitation voltage thereof is supplied by driver through positive and negative electrode wires; the driver is controlled by computer; compared the technical proposal of the invention with the prior technical device, the device can cause the precision of the force loading to exceed more than + / - 0.1% and has the advantages of fast response, compact structure.

Owner:BEIJING CHANGCHENG METERING TEST TECH INST NO 1 GRP CO CHINA AVIATION IND

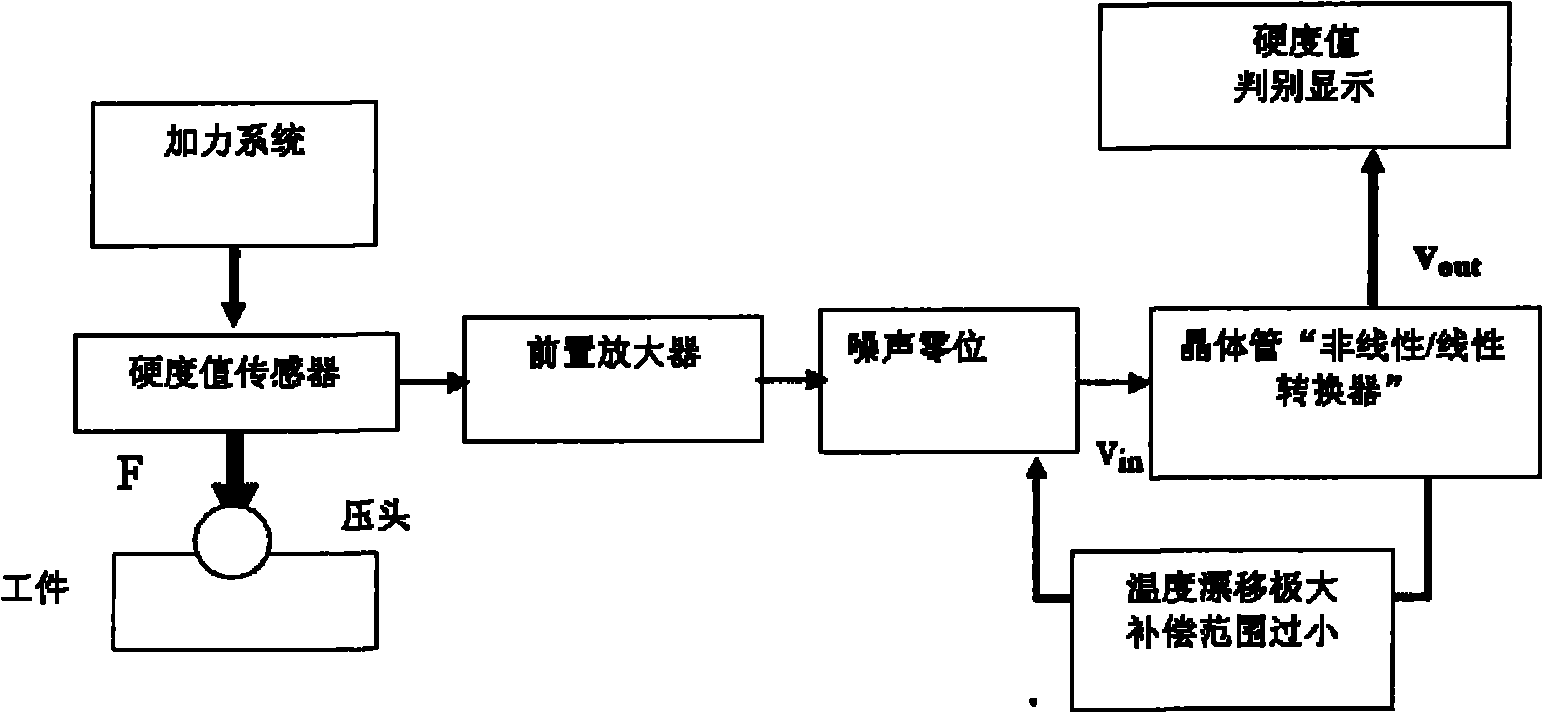

Metal material automatic identification hardness tester

InactiveCN110376083ASimple structureEasy to operateInvestigating material hardnessDisplay deviceSclerometer

The invention discloses a metal material automatic identification hardness tester which comprises a casing. A left side in the casing is provided with a transmission cavity, a right side in the casingis provided with a driven cavity, the transmission cavity is internally provided with a transmission mechanism for providing power to a device. The transmission cavity is further internally providedwith an impact mechanism for lifting a probe in a test. The driven cavity is internally provided with a clamping mechanism for fixing tested metal and a blocking mechanism for preventing the reverse impact of the probe. A lower end of the casing is provided with a display mechanism for starting a display function. When the device is working, a metal material to be tested is placed in the device, the device automatically clamps the metal material to perform an impact test on the metal and marks a hardness level scale according to a sinking depth on the surface of the impacted metal, and a result is automatically recorded in the display mechanism to facilitate reading.

Owner:JINYUN DUOTU INTELLIGENT TECH CO LTD

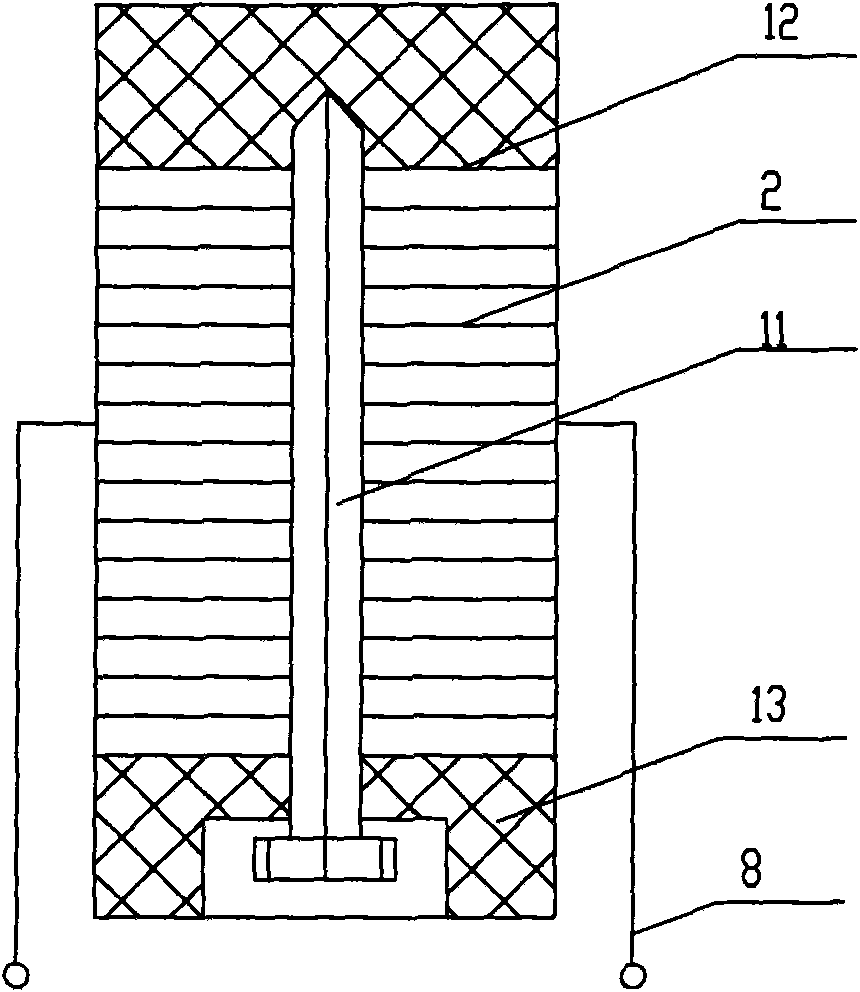

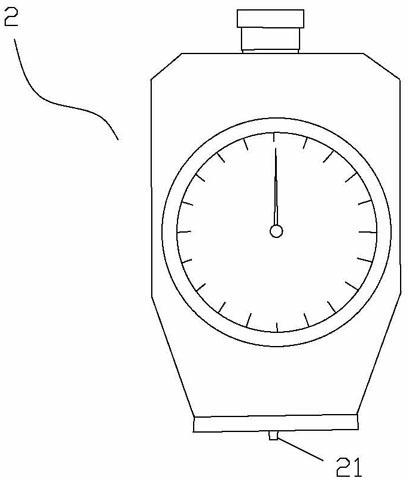

Portable hardometer

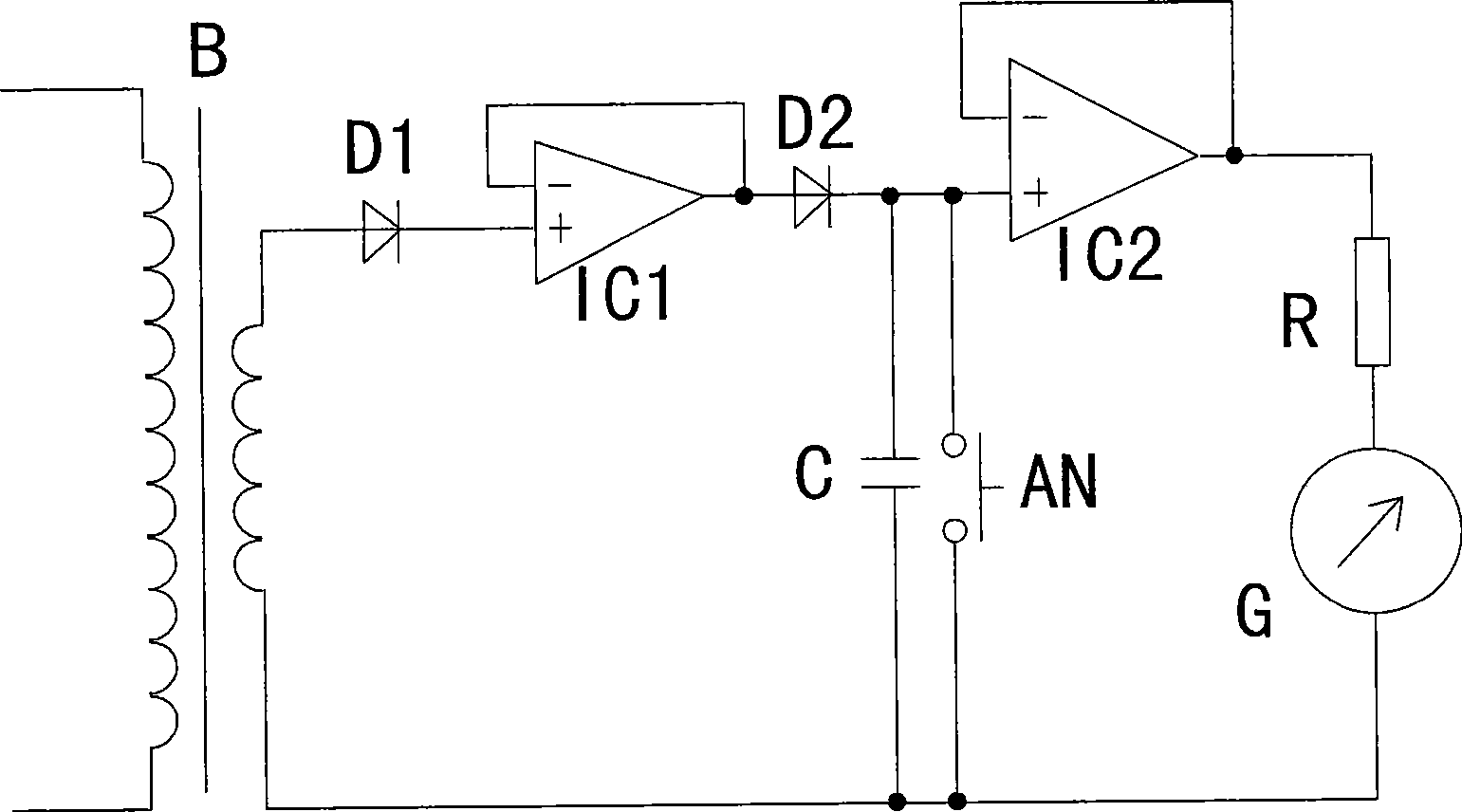

InactiveCN101451938AIncrease the output voltageHigh sensitivityInvestigating material hardnessCapacitanceElectricity

The invention relates to a portable sclerometer, comprising an impact microphone and a test signal processing circuit, wherein the impact microphone is composed of an engine base, a strike column, a power spring, a trigger and piezoelectric ceramic and a strike head tabled in the strike column, with the head clung with the strike head. In the test signal processing circuit, piezoelectric ceramic output lines are connected with a rectification circuit, a voltage follower, a capacitance storage circuit, an indicating circuit in turn through a transformer. The invention is suitable for testing of each type of bulk objects under the non-vertical state, in addition, the invention has the advantages of high sensitivity, correct testing and wide testing range.

Owner:李汀

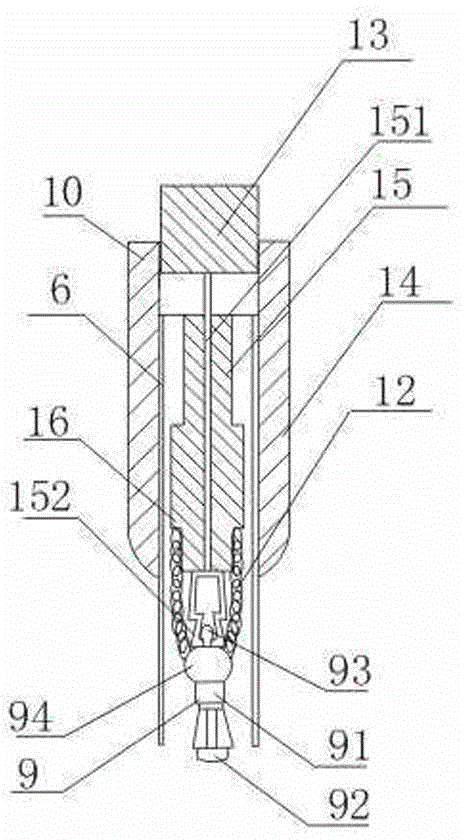

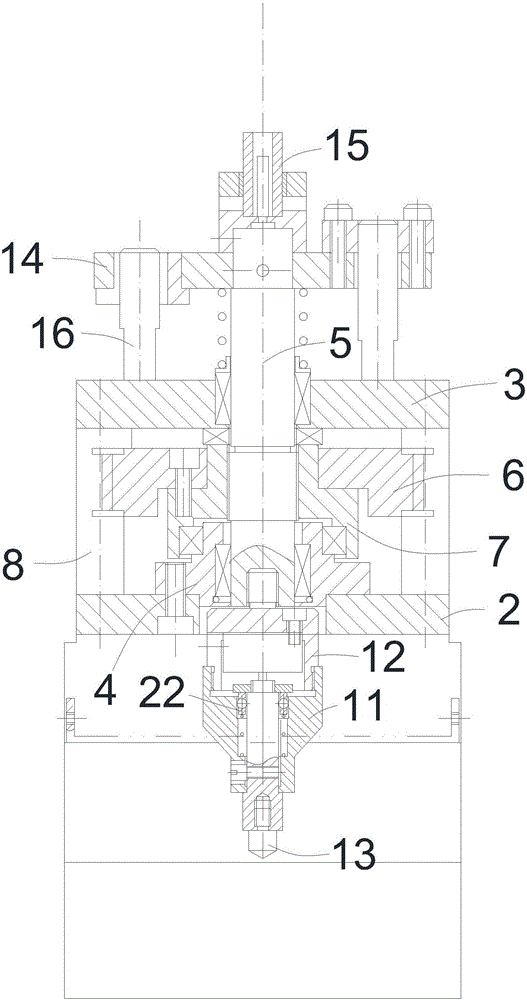

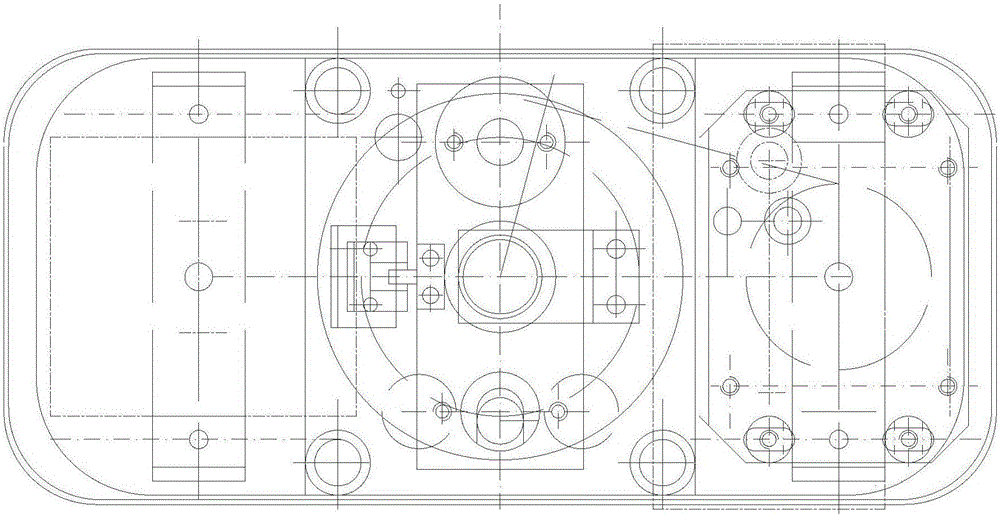

Automatic turret type electronic mainshaft measuring unit of Brinell hardness tester

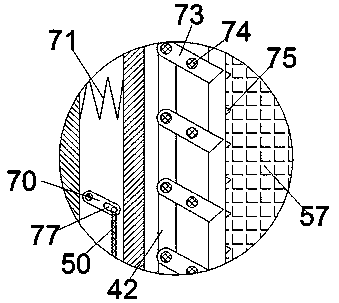

ActiveCN101526452ARealize integrationRealize closed-loop controlInvestigating material hardnessPhotoswitchMicrometer

The invention discloses an automatic turret type electronic mainshaft measuring unit of a Brinell hardness tester, which comprises an automatic turret mechanism, a weighing and force-measuring mechanism, a mainshaft anti-rotating mechanism, an accurate photoelectric measuring system and an electric control system; the lower end of an upper guide shaft is connected with the upper part of a force-transmission support seat by a weighting sensor; a turret is arranged in an inner cavity of a lower guide shaft which is fixedly arranged at the lower part of the force-transmission support seat, a turret gear connected with a turret driving mechanism is fixedly arranged at the upper end of the turret which is provided with a pressure head and two optical lenses, and a photoelectric switch and a turret locating block which is matched with a turret localizer arranged at the lower end of the lower guide shaft are arranged at the lower end of the turret; and a photoelectric micrometer and the two optical lenses form the accurate photoelectric measuring system. The automatic turret type electronic mainshaft measuring unit ensures that the hardness tester is integrated with the accurate photoelectric measuring system, realizes the accurate position conversion between the pressure head and the optical lenses and the accurate measurement of electronic stress application and indentation, can bear larger testing force and has simple operation, thereby being convenient for achieving the automation, lightening the labor intensity and improving the working efficiency.

Owner:莱州华银试验仪器有限公司

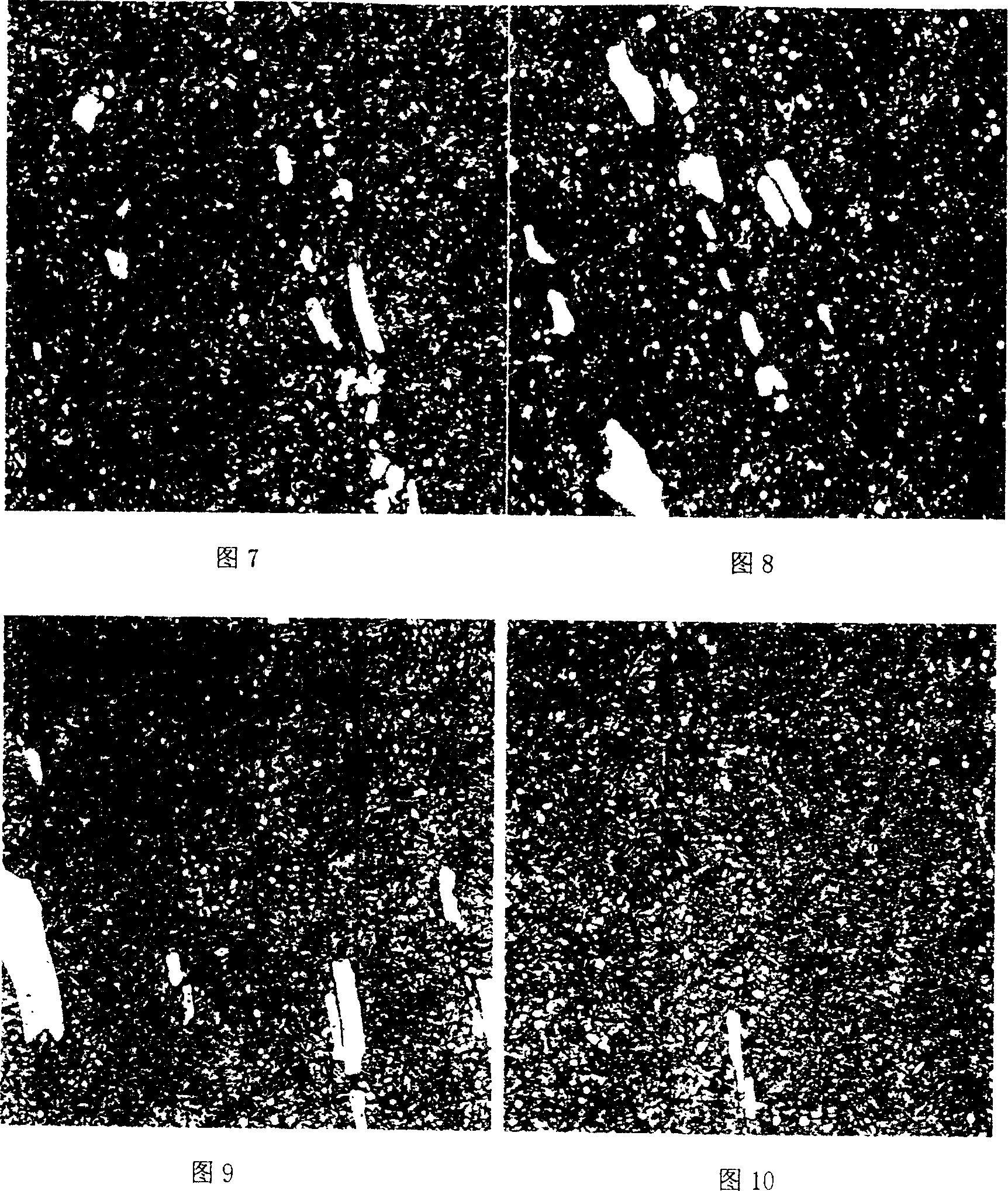

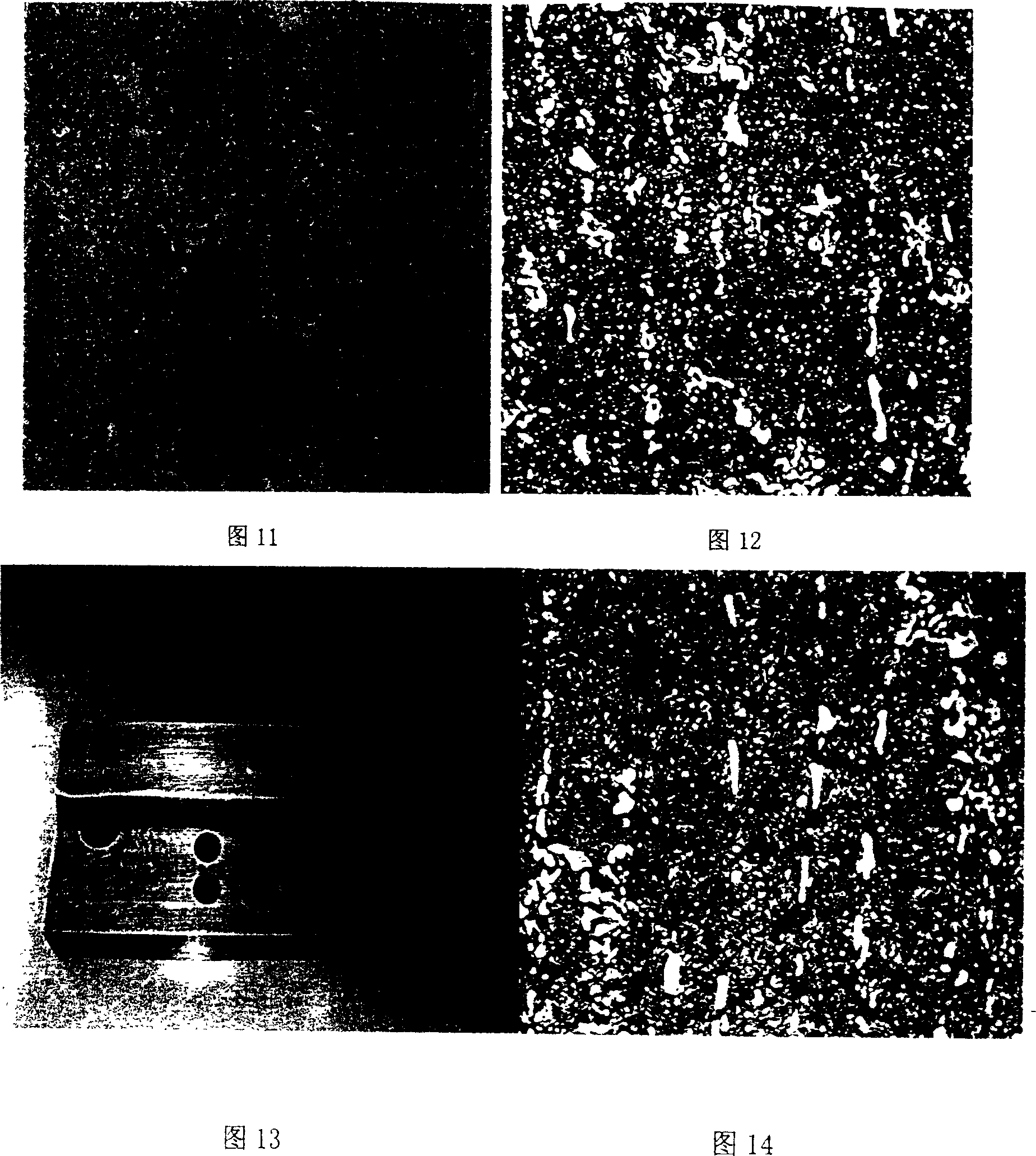

Method for calculating critical slitting stress of twin crystals through EBSD technology and Vickers hardness tester

ActiveCN110940686AAccurate size determinationEasy to measureMaterial analysis using wave/particle radiationPreparing sample for investigationCrystal orientationSclerometer

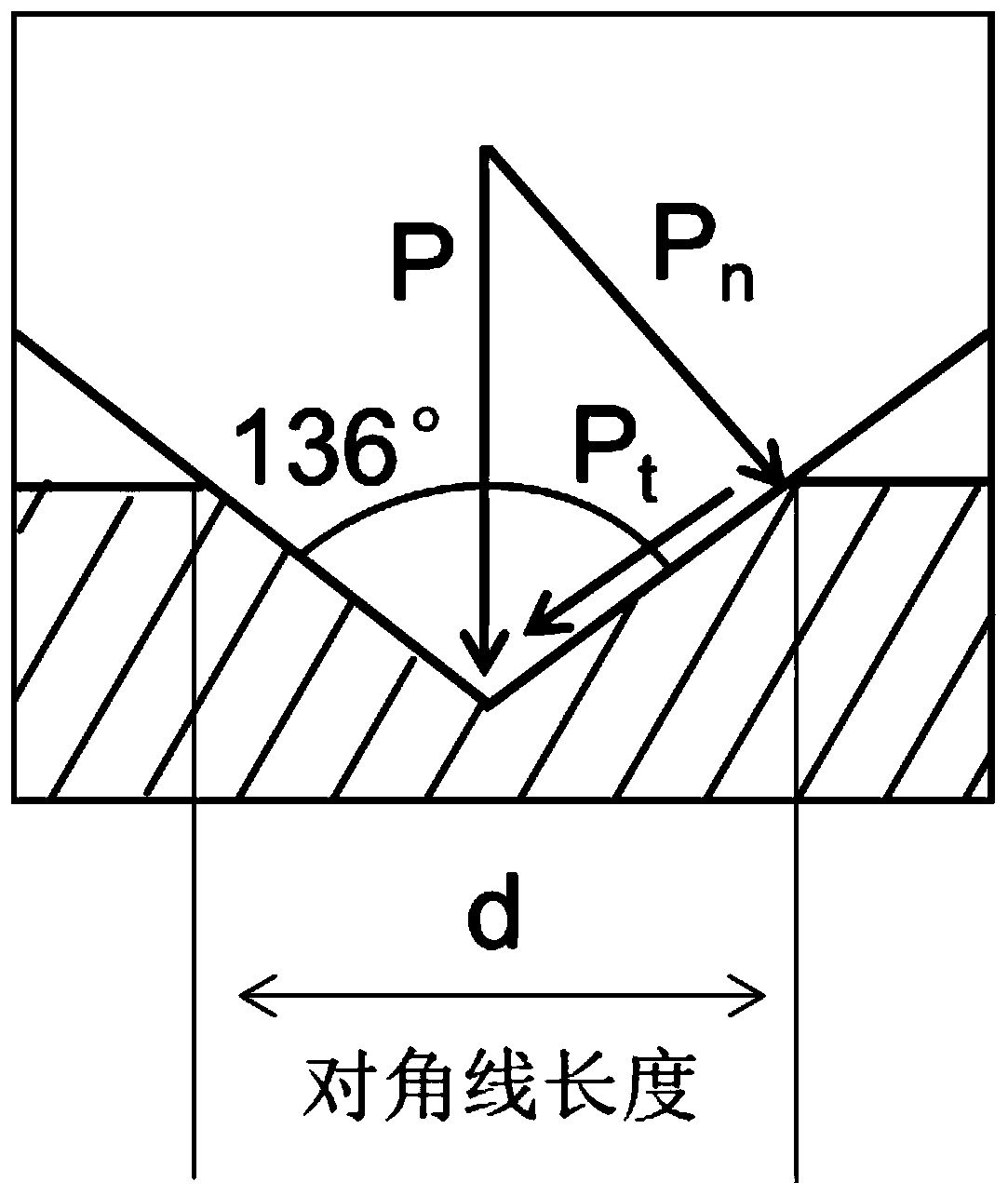

The invention discloses a method for calculating critical slitting stress of twin crystals through an EBSD technology and a Vickers hardness tester. According to the method, the critical slitting stress of twin crystals is finally obtained mainly by geometrically analyzing and calculating Vickers hardness indentations with different loads and combining the functions of EBSD calibration crystal orientation and twin crystals. The calculation process of the method comprises the following steps: firstly, preparing an EBSD blocky sample, and ensuring the flatness of the surface of the sample through chemical wiping corrosion or mechanical vibration polishing; measuring a certain area of the sample by using a metallographic microscope and EBSD, and marking the position by using Vickers hardness;then carrying out hardness testing on the area through Vickers hardness of different loads until twin crystals appear beside the hardness indentation under a certain load, and recording the diagonalsize and the hardness value of the hardness indentation; and then calibrating the type of the twin crystal by using EBSD, and finally obtaining the critical slitting stress of the twin crystal by combining hardness indentation geometric analysis calculation under the load with Schmid factor calculation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

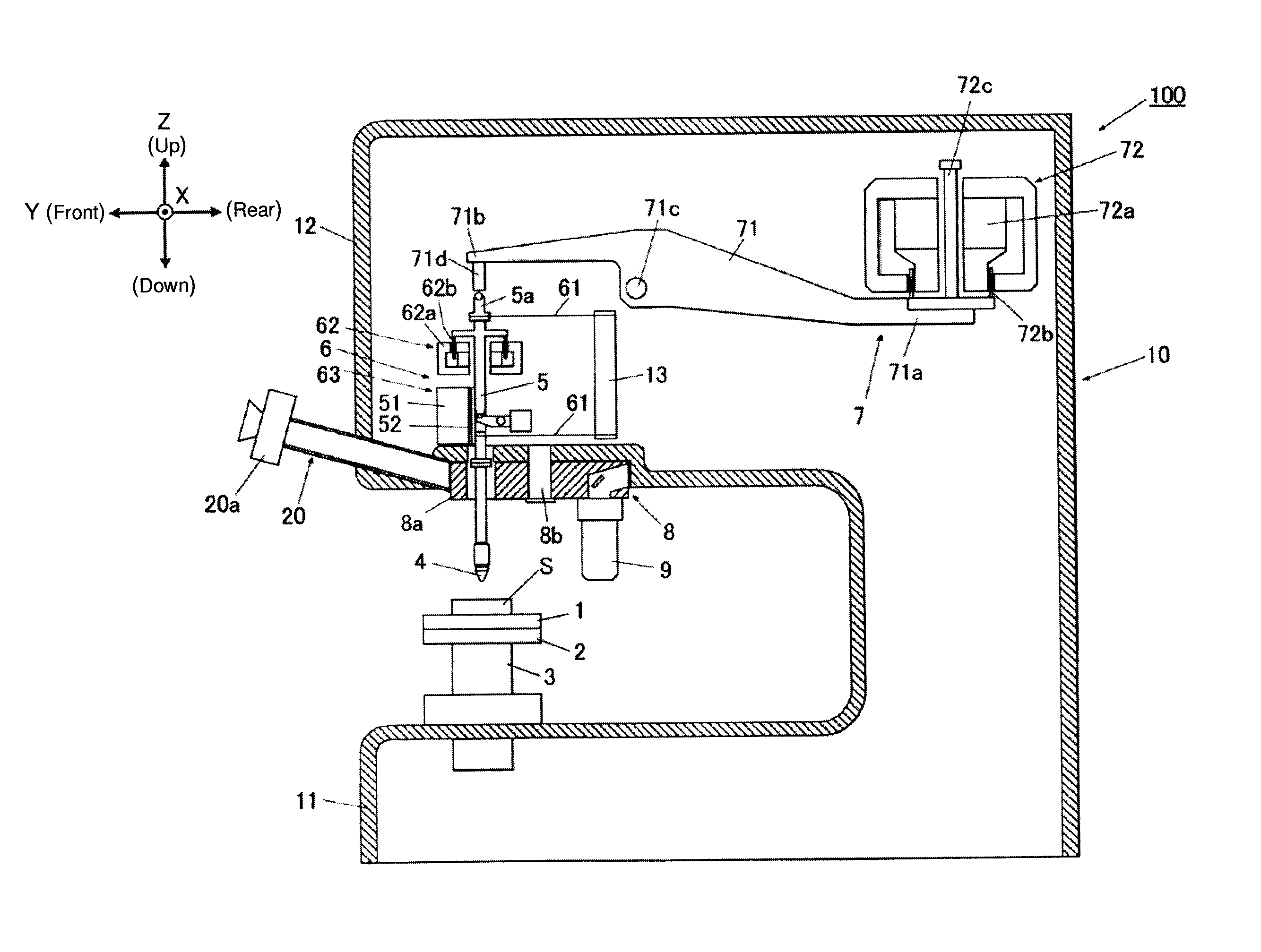

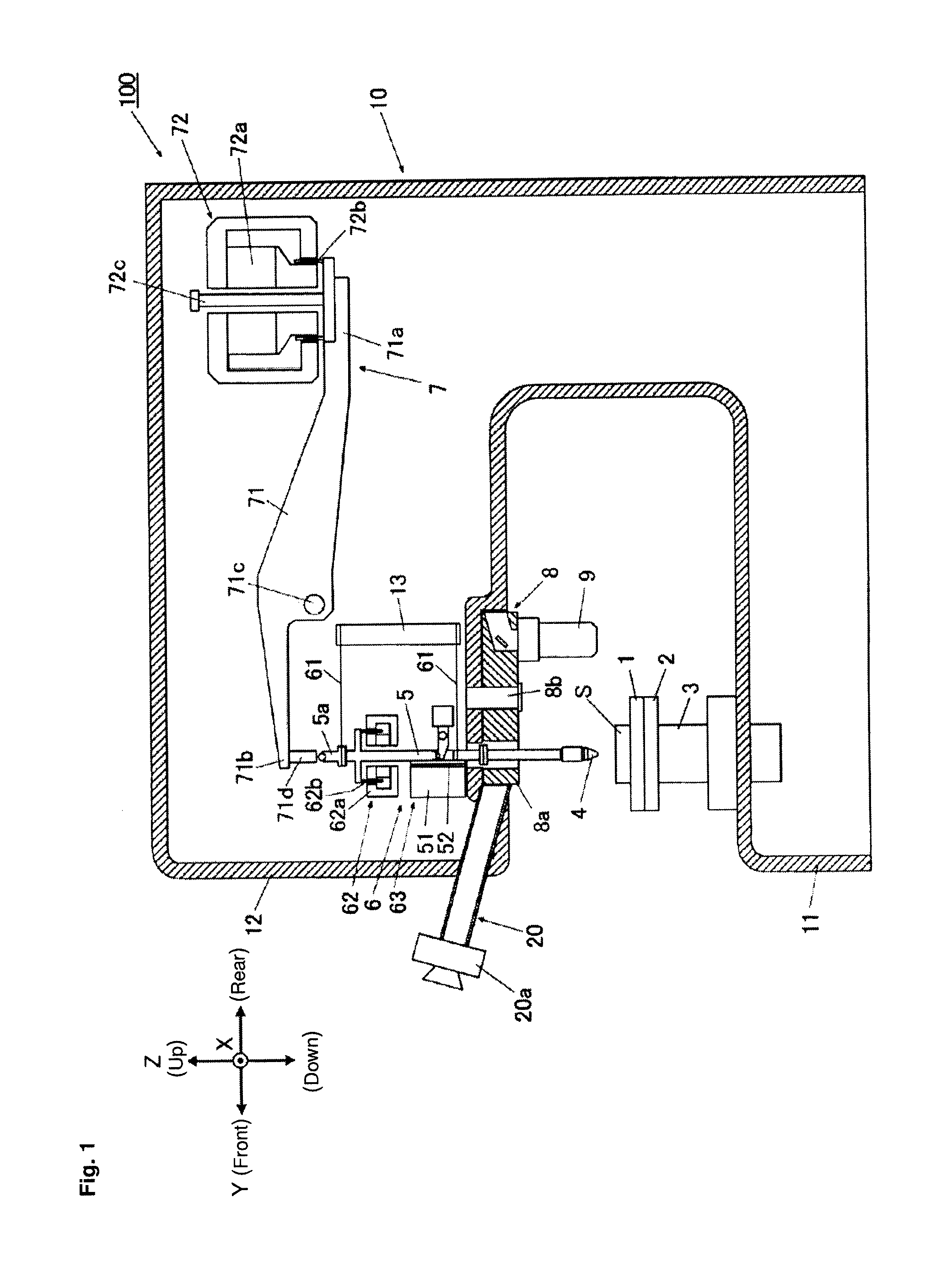

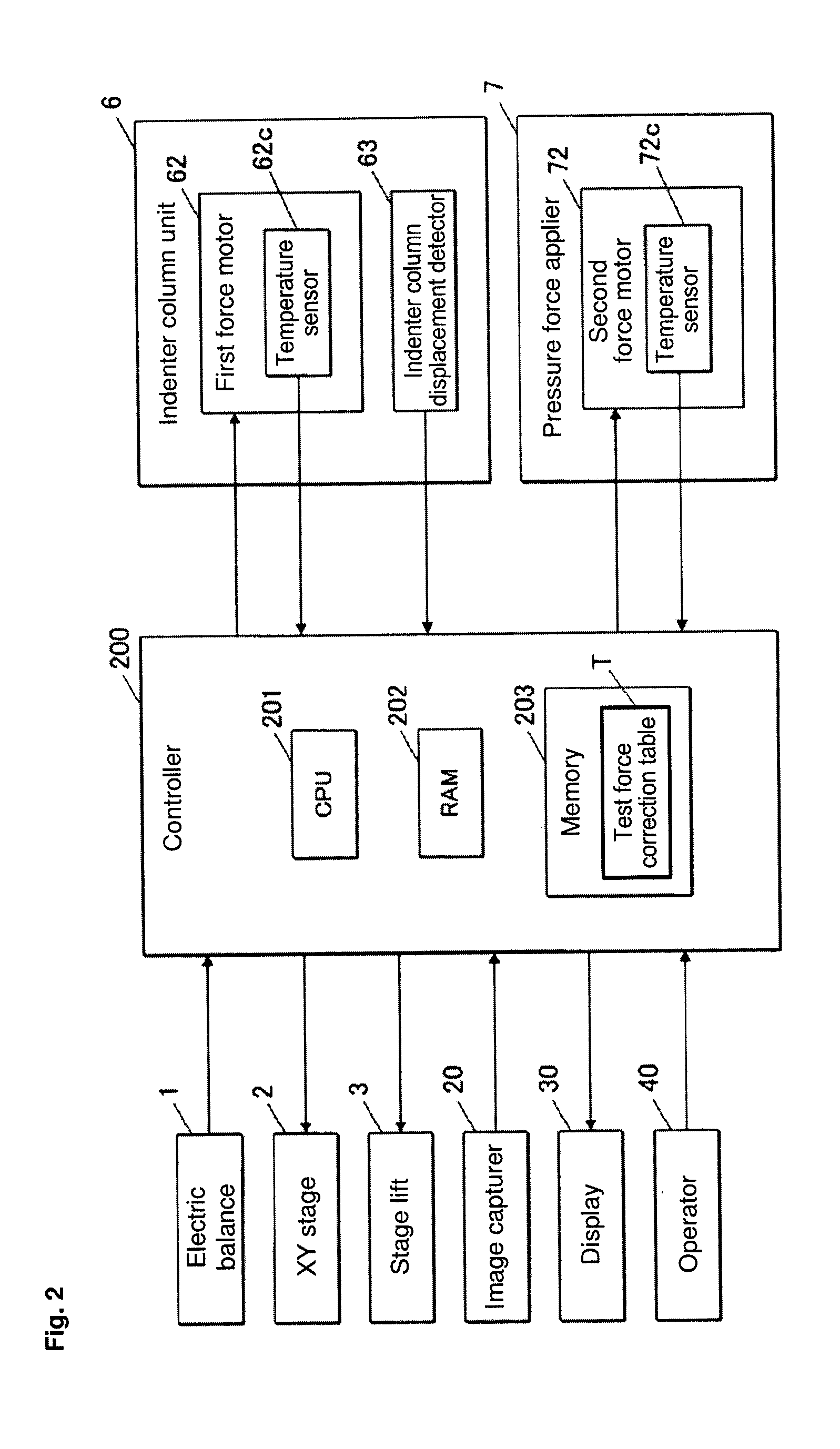

Hardness tester

ActiveUS20140250989A1Achieve correctionAccurate forceInvestigating material hardnessTester deviceSclerometer

A hardness tester has a test force applier generating a test force using an electromagnetic force generated by supplying a current to a drive coil provided in a magnetic field and applies the test force to an indenter to press the indenter into a surface of a sample; a temperature detector detecting a temperature of the test force applier; and a test force corrector correcting the test force generated from the test force applier based on the temperature detected by the temperature detector.

Owner:MITUTOYO CORP

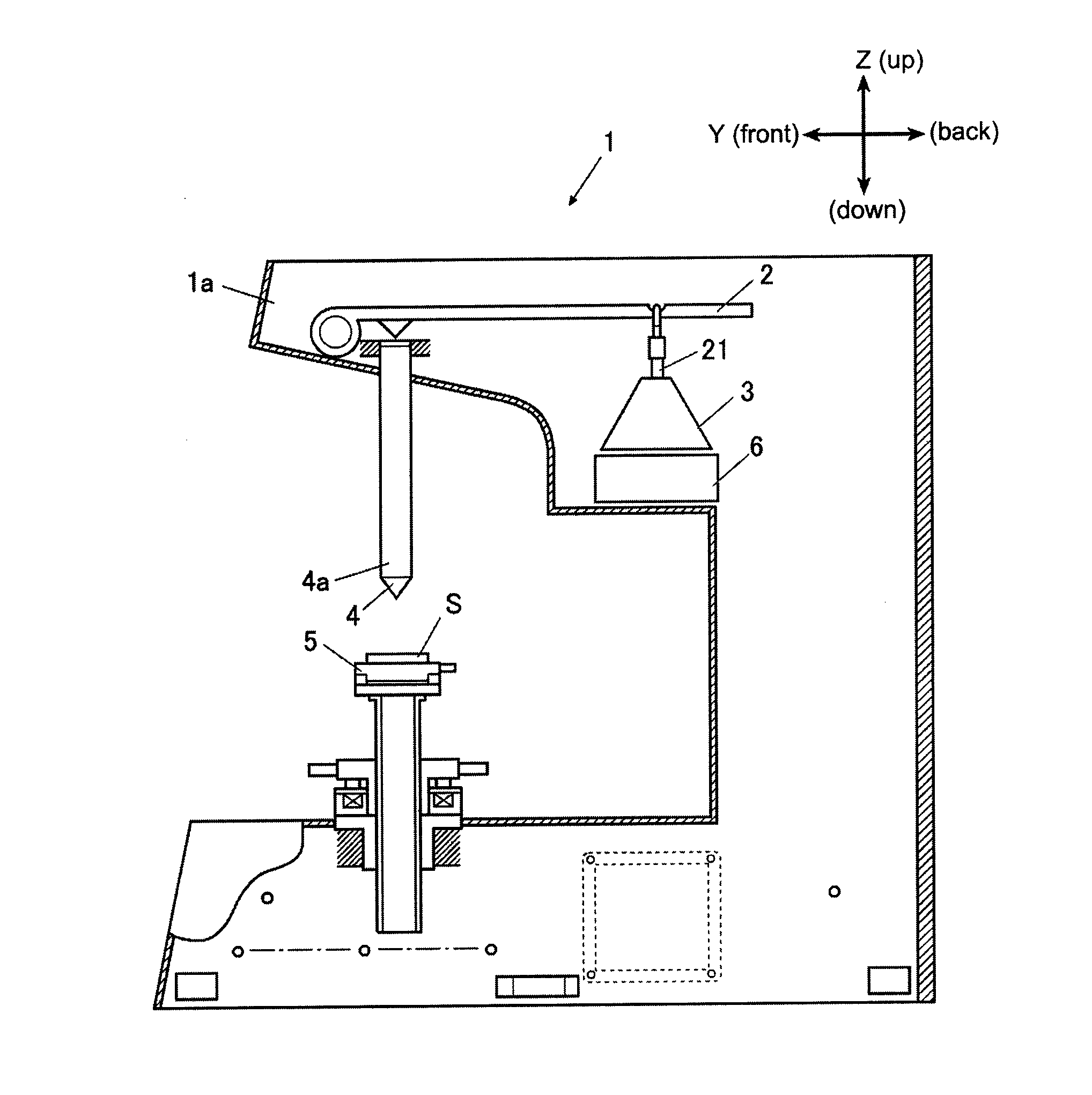

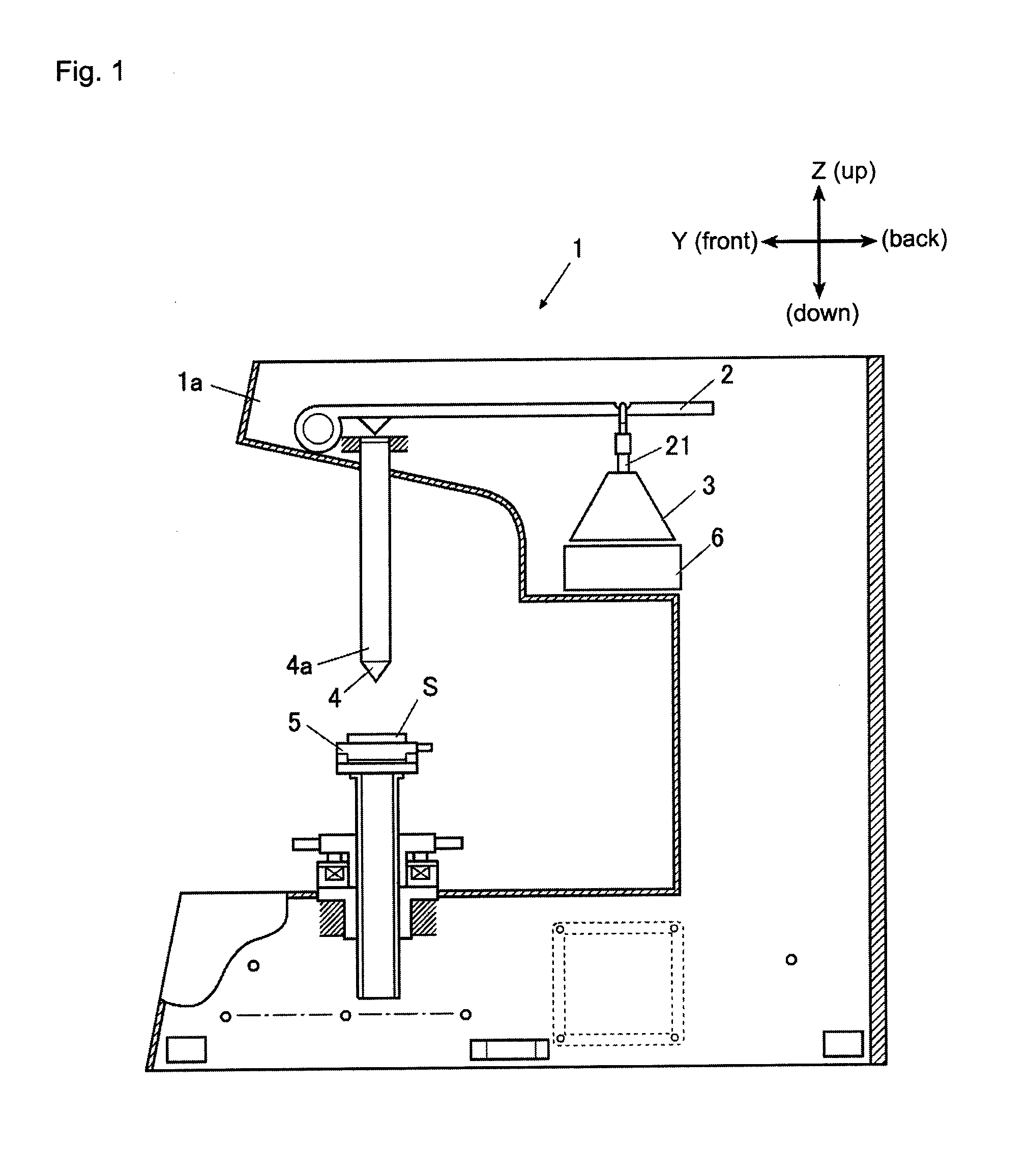

Hardness tester

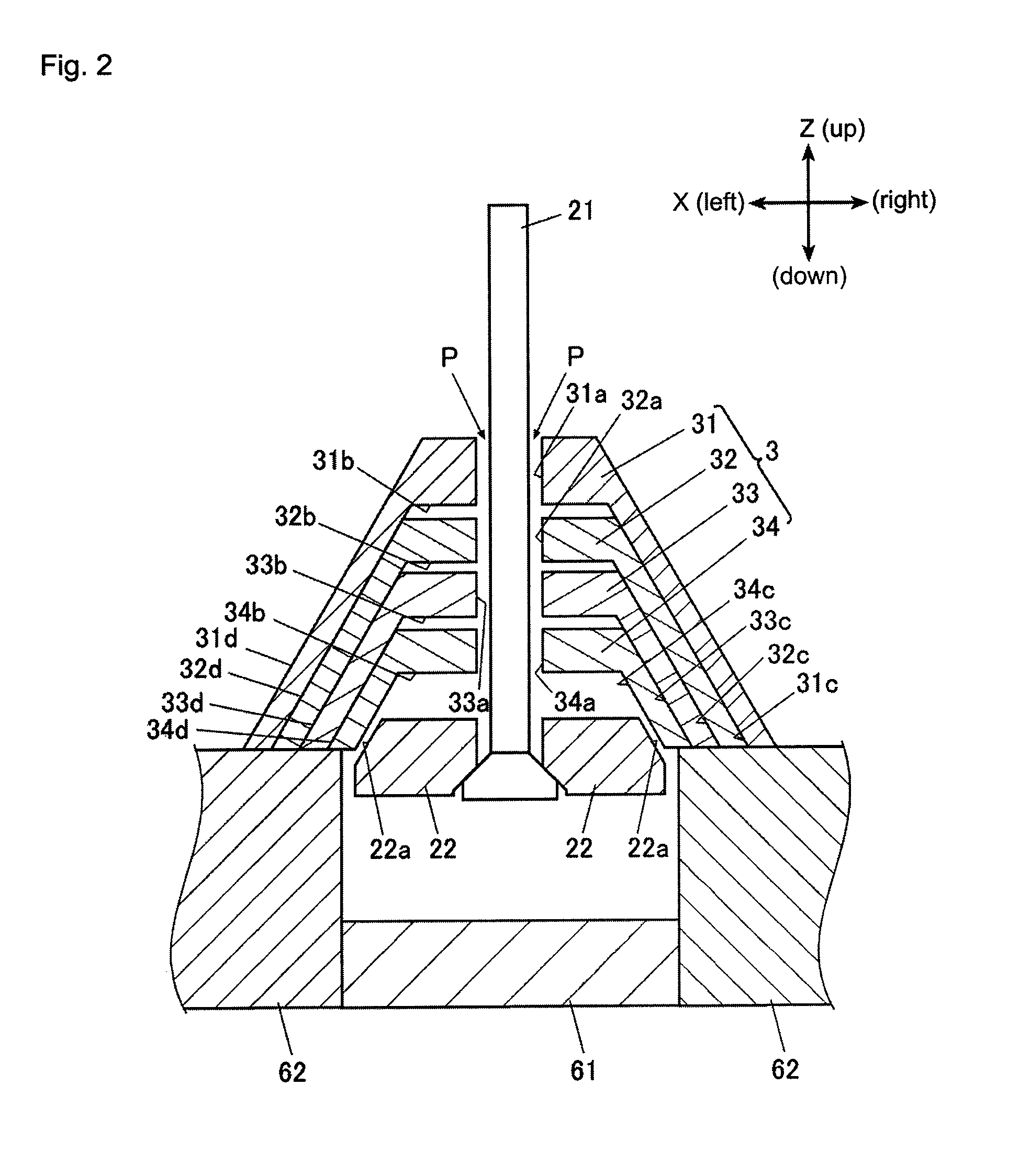

ActiveUS20140182364A1Accurate test forceAccurate forceInvestigating material hardnessSclerometerEngineering

The hardness tester includes a plurality of weights; a transmission mechanism transmitting to an indenter a force of gravity acting on the weights; and a test force switching mechanism switching between magnitudes of a test force. The weights include hollow portions running through the weights in a vertical direction; and accommodation portions formed so as to be capable of accommodating the weight directly below. Outside tapered portions are provided to an exterior surface of the weights and inside tapered portions are provided to an interior surface of the accommodation portions. The transmission mechanism includes a shaft member and a weight engagement portion capable of being accommodated by the bottom-most accommodation portion to engage a weight. The weight engagement portion includes a tapered portion engaging the weight to regulate horizontal-direction displacement. A predetermined gap is reserved between the hollow portions and the shaft member.

Owner:MITUTOYO CORP

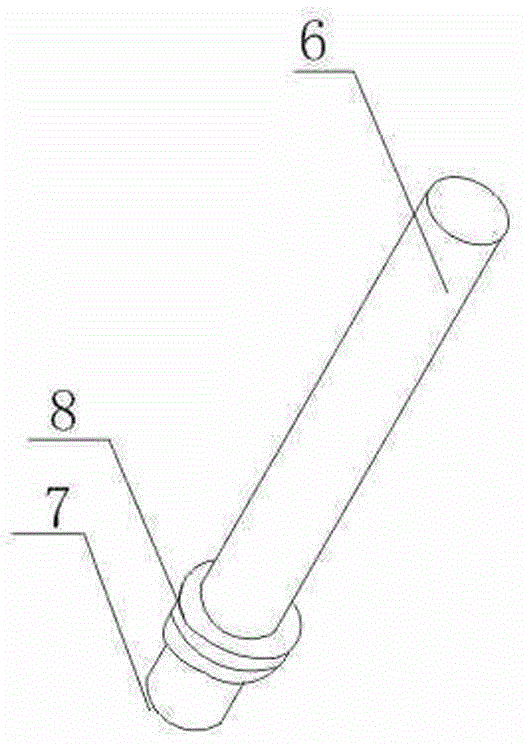

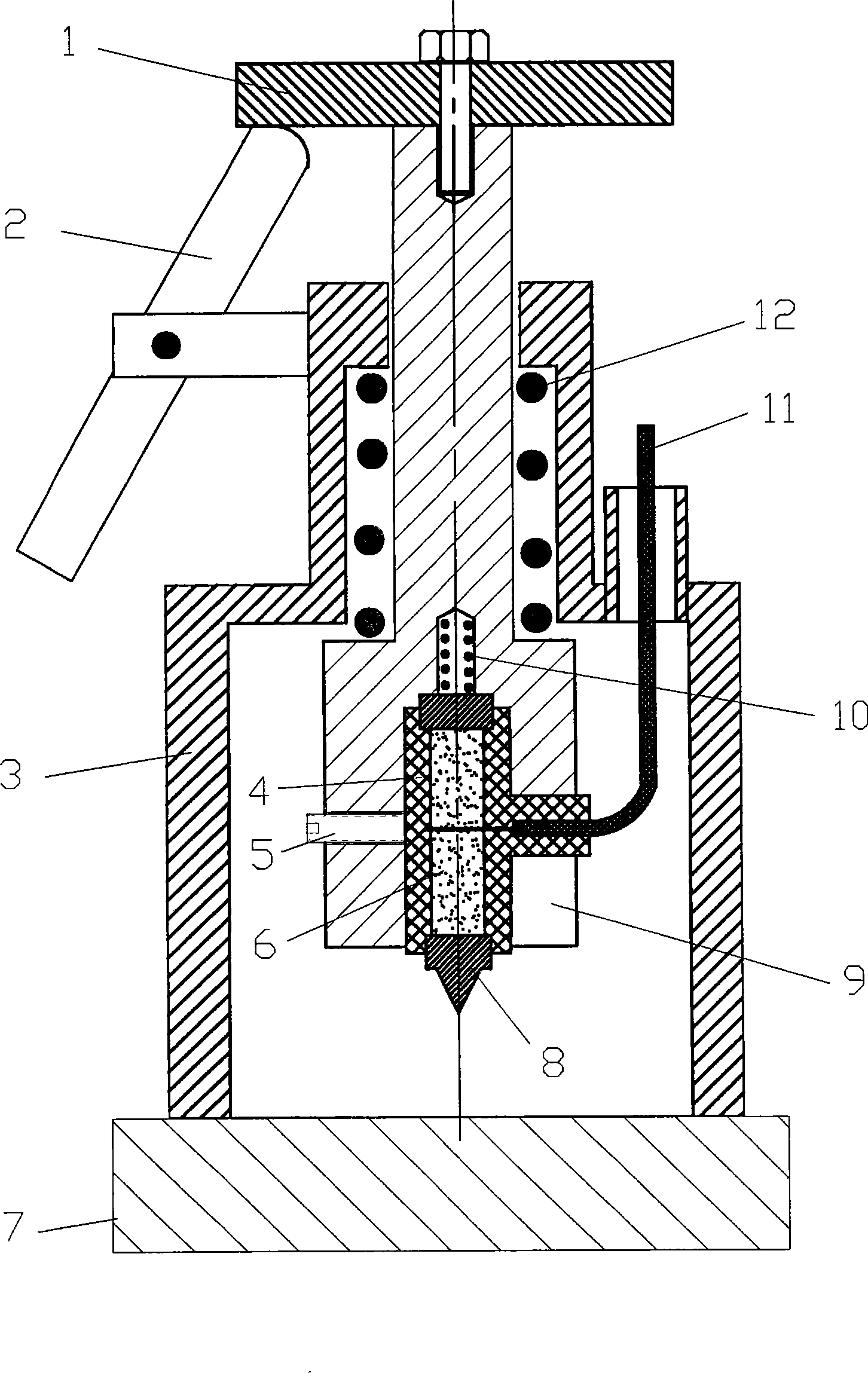

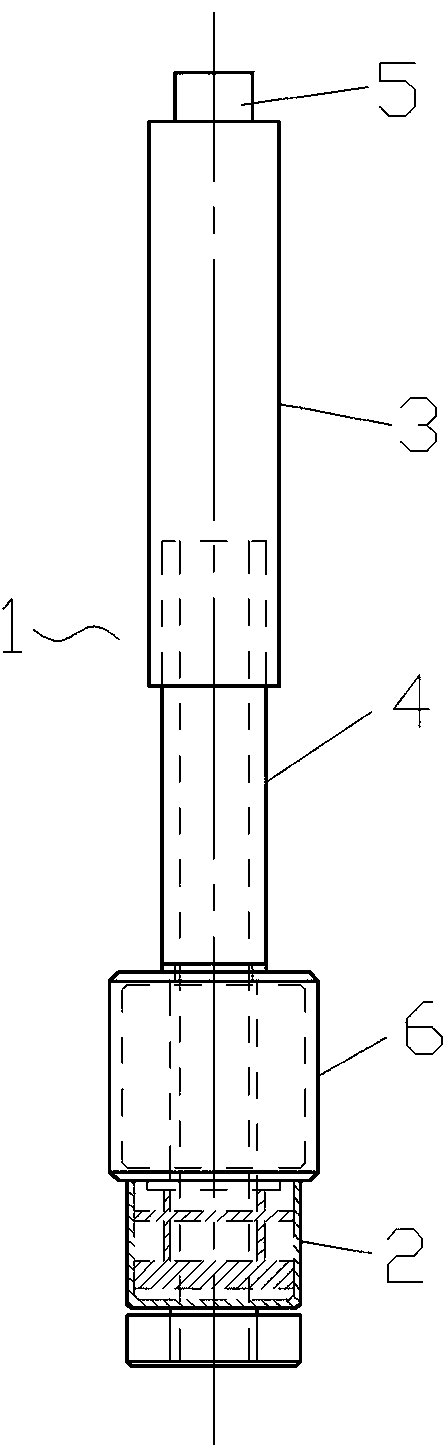

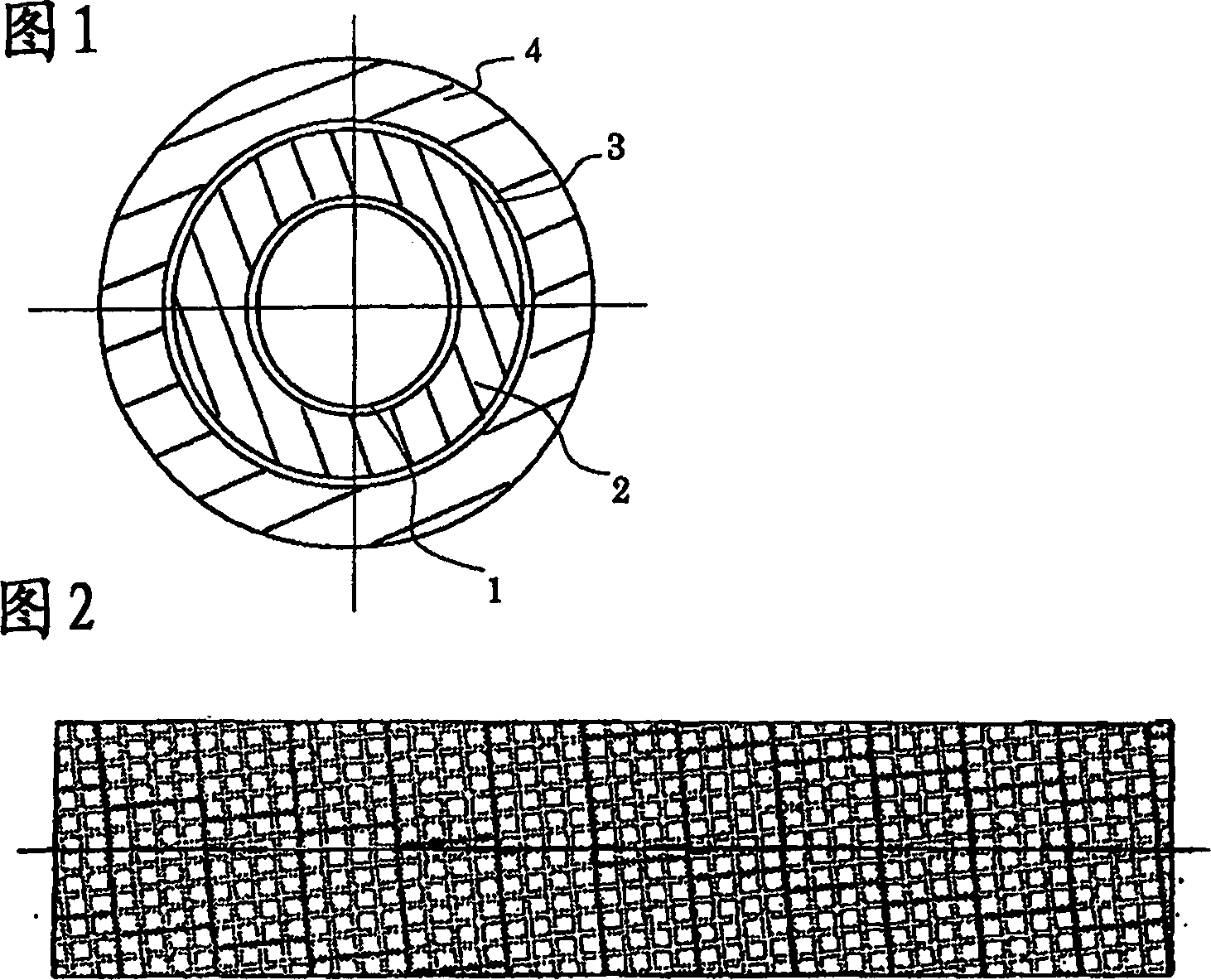

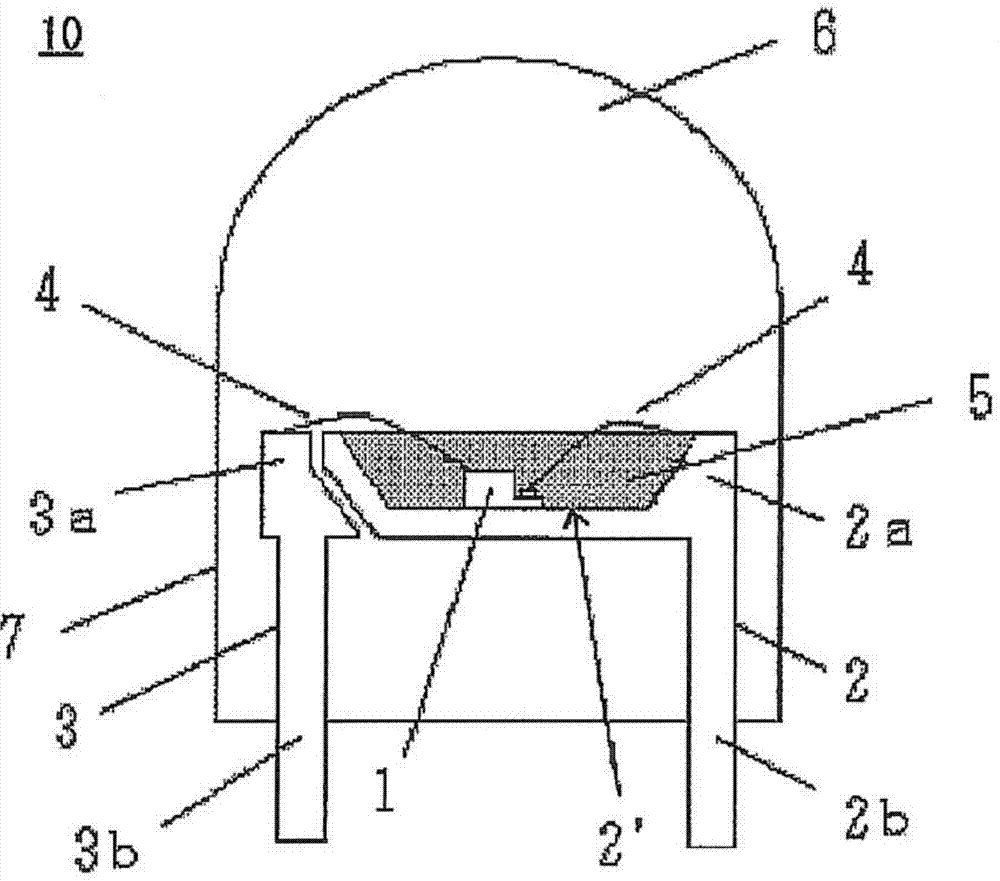

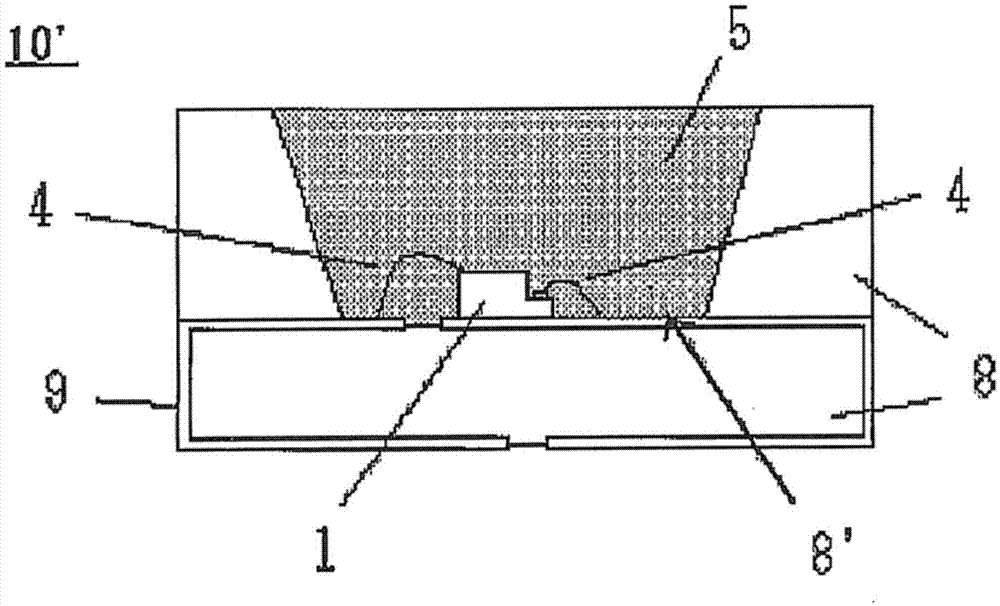

One portable Rockwell sclerometer

The invention discloses one portable Rockwell sclerometer, includes the external shell with opening on the one side, support structure is set in the shell, including baseboard and collar bush connected by the strutting piece, cavity is formed in the middle, the baseboard is connected to the opening of the shell, spindle seat, inner and outer bearings are set on the surface; and the pushing mechanism is placed in the cavity, including principal axis fixed on the spindle seat and running through the collar bush and baseboard, and nuts of big pulleys having mesh on the top set on the surface, the mentioned nuts are convex, the bottom is concave, the sheath is fixed on the outer bearing of the spindle seat, the big pulleys are installed on the strutting piece, and assist rotation with small pulleys on one side of the cavity, the small pulleys connect the stepping motor; Portable effect is reached.

Owner:JIASHAN NAIBO PRECISION INSTR

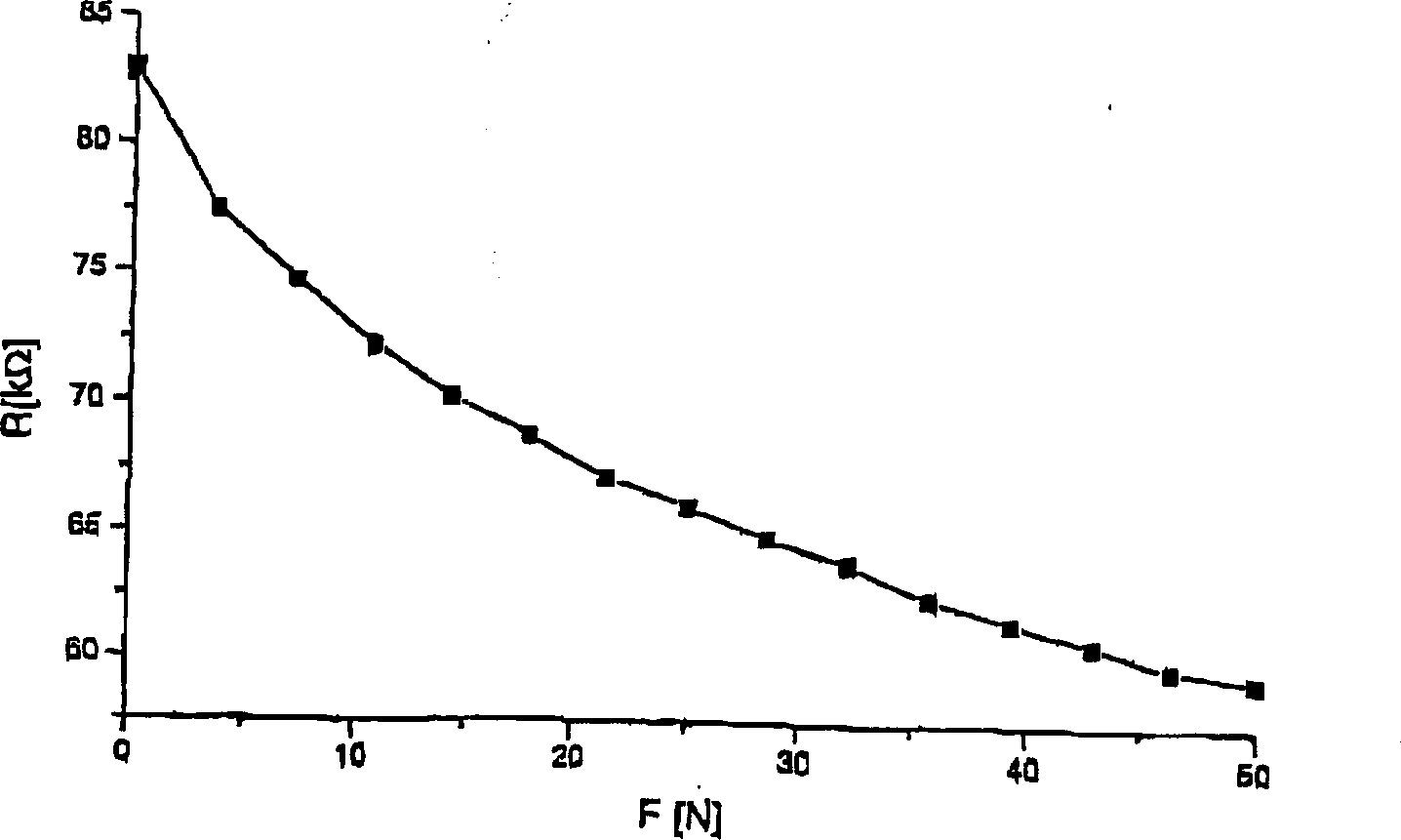

Cereal particle hardness measurement method and its hardness measurement instrument

ActiveCN101487782ATo overcome the deficiency in hardness judgmentIndividual particle analysisInvestigating material hardnessSclerometerHardness

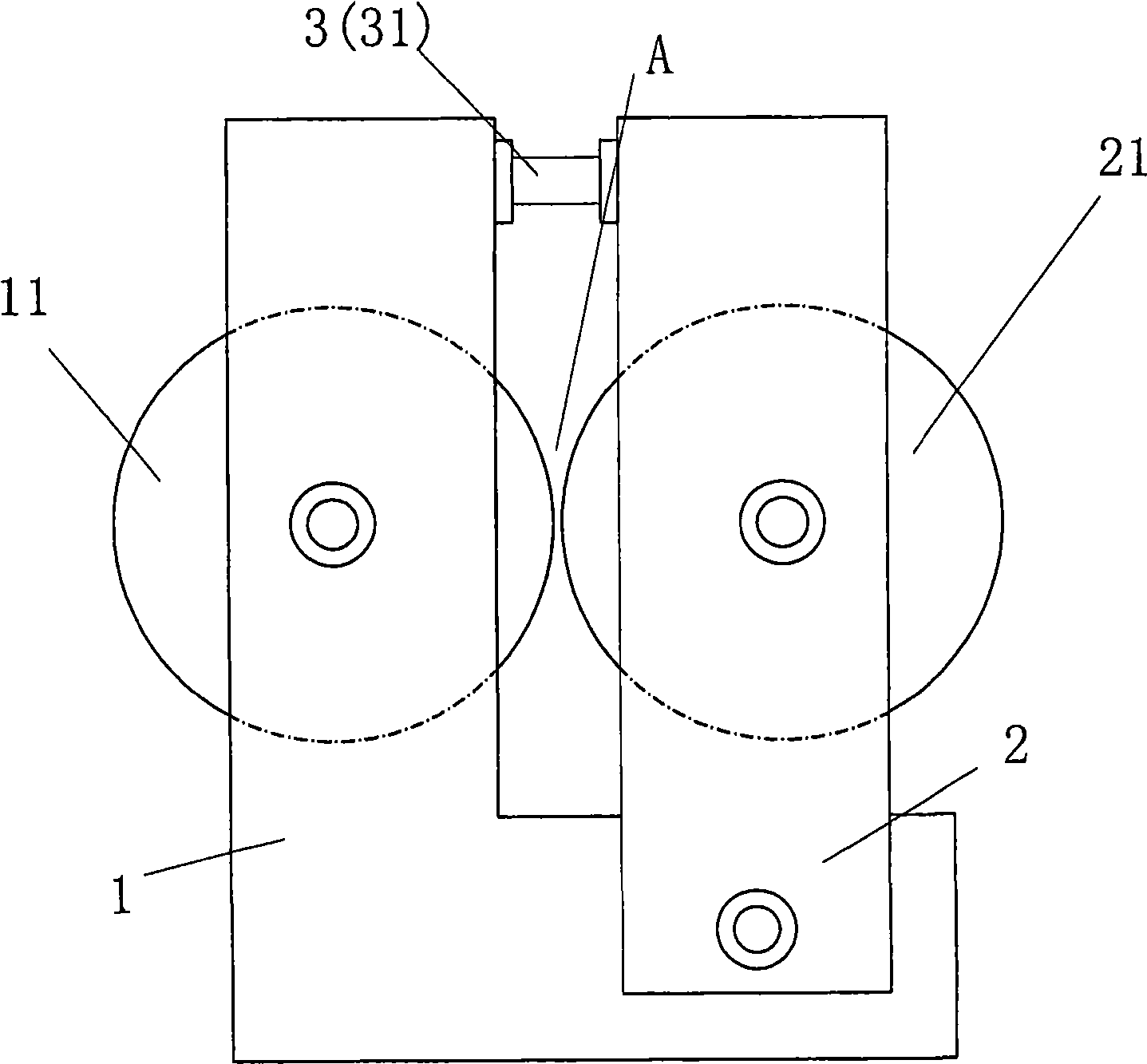

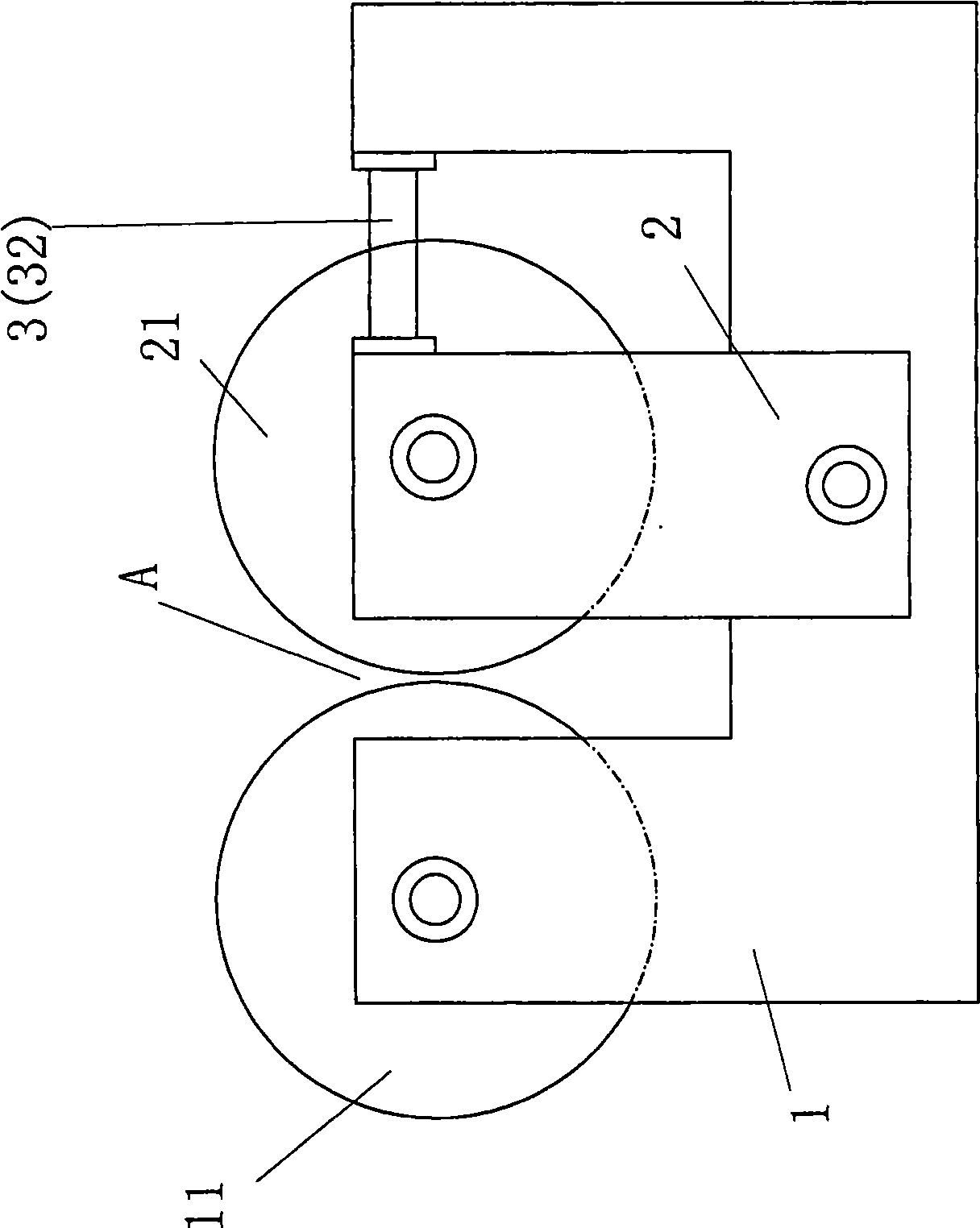

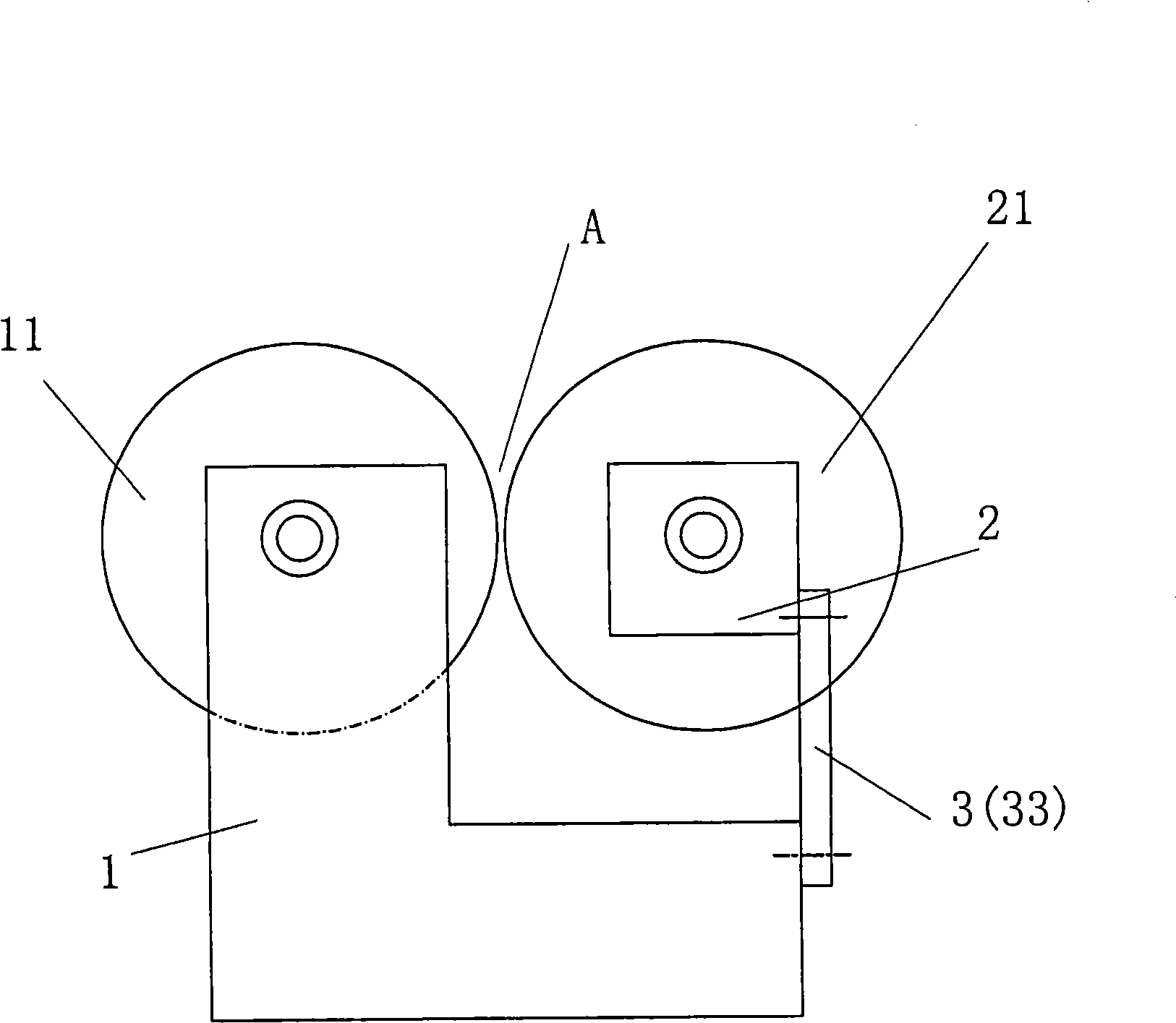

The invention relates to a meter for measuring the hardness of grains. The hardness measuring meter comprises: a base on which a first roll is arranged; and a support base arranged on the base. A second roll is arranged on the support base opposite to the first roll, the two rolls rotate in opposite directions, and a gap is arranged between the two rolls; and at least one force sensor is arranged between the base and the support base. The meter for measuring the hardness of grains is characterized in that the hardness of a plurality of single grains can be measured continuously between the two rolls as the two rolls rotate continuously in opposite directions, that is, a plurality of single grains can be fed into the gap between the first roll and the second roll by a feeding device so that the detection process of the grain group can be carried out continuously. The meter for measuring the hardness of grains quickly measures the grains in mass and overcomes the defect of the existing grain hardness meter in the aspect of the grain group hardness measurement.

Owner:BEIJING DONGFU JIUHENG INSTR TECH

Method for detecting retained austenite and under-tempering by using Rockwell and Leeb hardness contrast method

The invention uses Rockwell and Brinell hardness tester to inspect each hardness value after heat treatment tempering, with bigger difference of the values, more residue of austenite inside the working piece. The insufficient tempering standard is when the Rockwell and Brinell hardness value difference bigger or equal to 3HRC, otherwise, the qualified tempering. It is quick, simple, and convenient with on site inspection for each part together with high accuracy and free from pollution. It not only applies to Cr12MoV steel tempering insufficiency inspection of quenching status, also applies to secondary hardening of high alloy steel tempering insufficiency.

Owner:DONGFENG MOTOR CO LTD

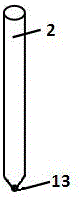

Hardometer

InactiveCN103954515ASolve the fragileImprove accuracyInvestigating material hardnessExternal dataMagnetic testing

The invention discloses a hardometer which comprises a supporting pipe, a hardness sensor, a magnetic testing body which is arranged in the supporting pipe in a sliding mode, and a transmission device arranged in the supporting pipe, wherein the transmission device drives the magnetic testing body to impact the surface of a workpiece so as to generate impact speed and rebound speed; a data processing transmitter is arranged on the hardness sensor; the data processing transmitter comprises a shell, and a data processing unit, a data emission and transmission unit and a battery which are fixedly arranged in the shell; data measured by the hardness sensor is directly transmitted to the data processing unit for processing and is wirelessly transmitted to an external receiver through the data emission and transmission unit. The data processing transmitter is directly arranged on the hardness sensor, so that the data processing transmitter is directly combined to the hardometer, and the problem that a transmission line of an external data processor is easily damaged is solved. Meanwhile, the inclination angle of the hardometer is detected through a triaxial sensor, so that data compensation is calculated, and the measurement accuracy is improved.

Owner:DRAGON ELECTRONICS

Indentor and method for producing the same

InactiveCN1365443AElectric/magnetic roughness/irregularity measurementsInvestigating material hardnessComposite filmGas phase

The invention discloses a new electronic hardometer indenter which is applicable for measuring material microhardness and binding strength between a film and a base. This indenter is form by steps of vapor phase growing boron doped conductive diamond films, diamond / carbides composite films or amorphous carbon films on the diamond indenter surface. The invention innovates the traditional material hardness measuring method with advantages of easy operation, accurate measuring and possibility of on-line measuring for complex geometry workpiece.

Owner:姜辛

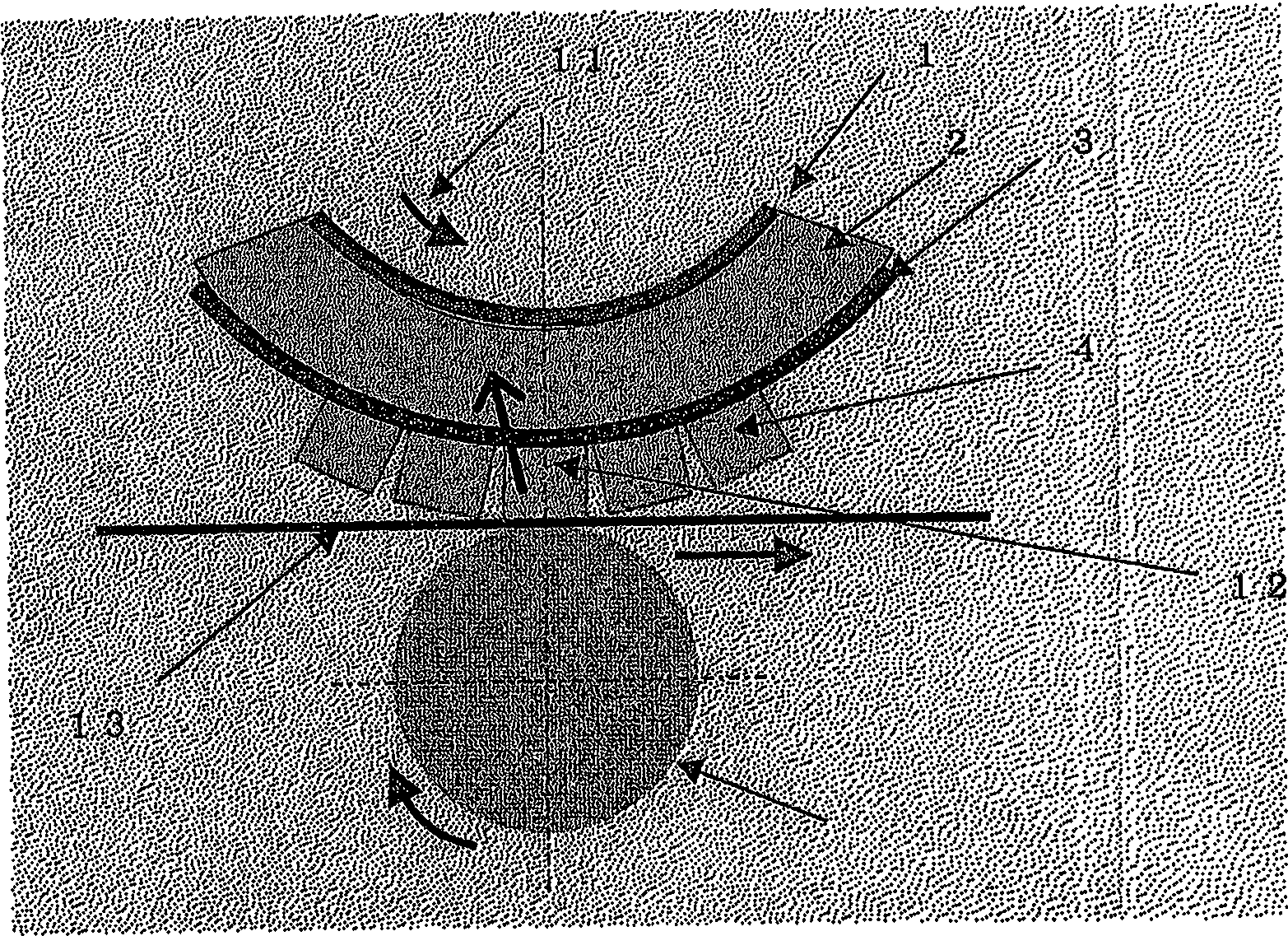

Grinding machine for rubbing

InactiveCN1872497AEliminate grinding unevennessImprove grinding responsivenessFlexible-parts wheelsSclerometerHardness

The invention provides a grinding device for plate-like clipped material, which is characterized by even grinding and good pressure responsibility. The cylinder chip material (1) is equipped with porous elastic material (2), the outer of which is provided with grinding layer (4), and said porous elastic material is rubber sponge. The hardness of rubber sponge is 5-40 when test by rubber hardness gage C graduation, and the best elastic rate is 50-90%, while the best 25% compress loading value regulated by JIS K 6767 is 0.010- 0.200 Mpa.

Owner:KURE GRINDING WHEEL

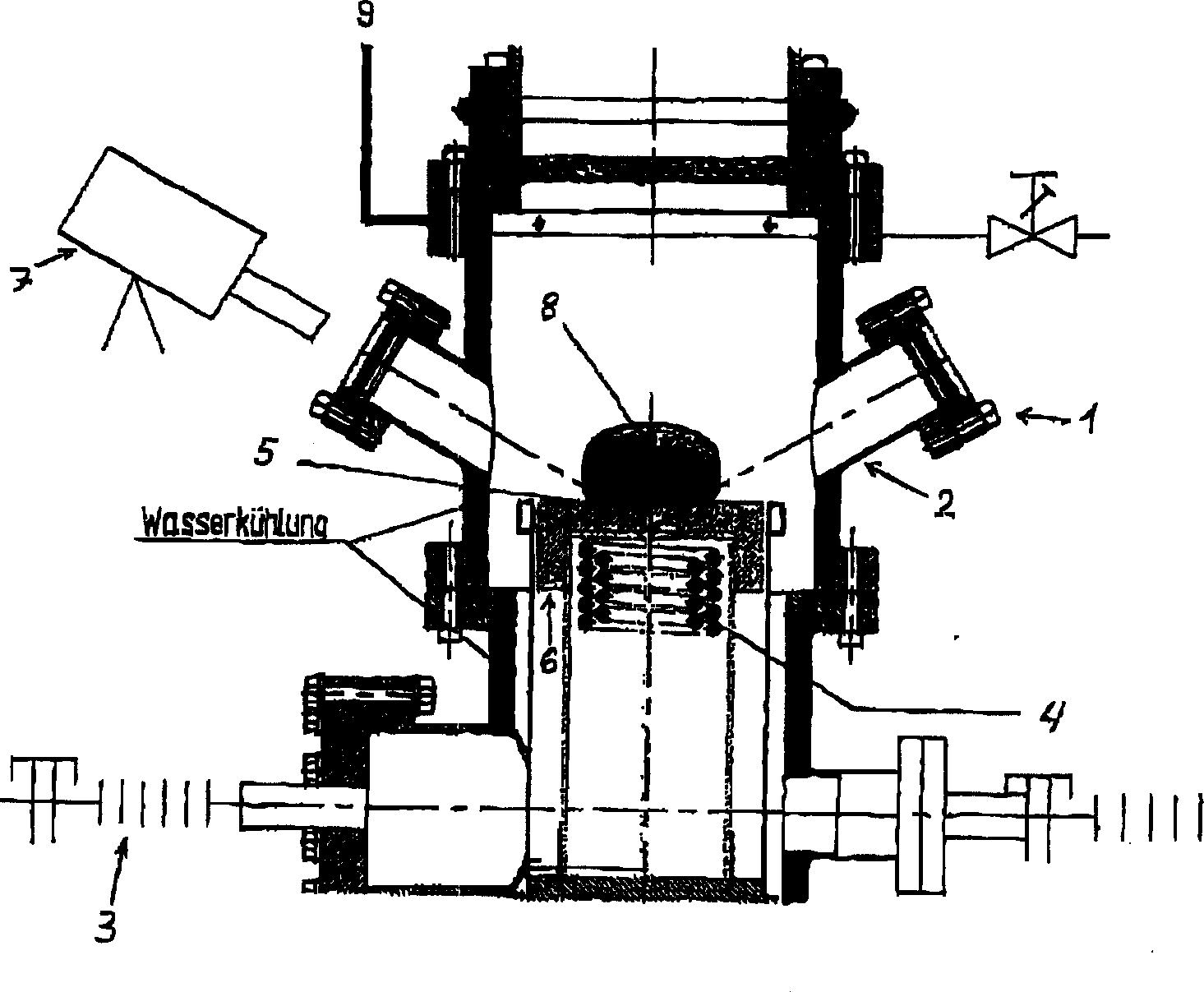

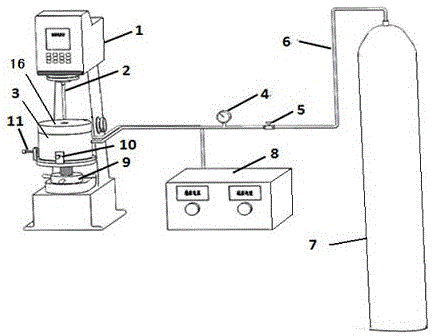

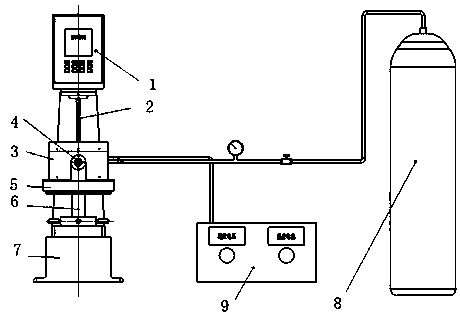

Durometer for measuring variable-temperature hardness of metal material

InactiveCN105891033APrevent oxidationSimple structureInvestigating material hardnessSclerometerMetallic materials

The invention discloses a durometer for measuring the variable-temperature hardness of a metal material, and belongs to the technical field of metal material mechanical property testing instruments. The durometer is used for measuring the hardness of the metal material under the variable temperature environment. According to the technical scheme, an embedded heating body is adopted as a heating source, the embedded heating body and a heating furnace shell are isolated and insulated by nanometer heat insulation materials, water-cooling pipelines do not need to be installed, the structure is simple, operation is convenient, and the service life is long; high-purity nitrogen or argon is adopted as the protective atmosphere, and the sample surface is prevented from being oxidized; a thermocouple and a temperature controller are adopted for controlling the heating temperature, and the highest heating temperature of a hearth can reach 1000 DEG C. The durometer is the initiation for measuring the hardness of the metal material under the variable temperature environment, the problem that the variable temperature hardness of the metal material cannot be measured continuously is solved, the new testing means is provided for online measurement of the material variable temperature mechanical performance, the durometer has the advantages of being convenient to operate and accurate in measurement, and hardness value determination under various metal material variable temperature environments can be achieved.

Owner:HEBEI IRON AND STEEL

Method for calibrating hardness indicating value of rubber hardness gauge and standard blocks

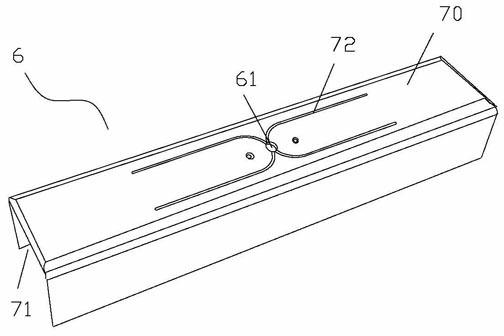

The invention discloses a method for calibrating the hardness indicating value of a rubber hardness gauge and standard blocks, relating to a metering calibration technology. The calibrating method comprises the following step of: calibrating the standard blocks for the hardness indicating value of the rubber hardness gauge, wherein the standard blocks for the hardness indicating value of the rubber hardness gauge comprise an A-type standard block group, a C-type standard block group, a D-type standard block group and an F-type standard block group; the standard block group of each type comprises at least six individual standard blocks of different hardness values; each individual standard block comprises a metal inverted long groove body; a groove is formed at the groove bottom; or each individual standard block comprises a base block, an elastic sheet and a cover plate; the elastic sheet is arranged at the convex cutting edge position of the base block in the form of flat plate; and the profile body of a cover body is covered on the base block in cooperation with the base block, and is contacted with the elastic sheet. The calibrating method is quick, and the artificial errors are fewer; and the standard blocks have skillful and simple structures, easily-stored calibration value and low cost, are convenient to manufacture and carry, are quick for grasping relevant calibrating technologies and are convenient for plant inspection.

Owner:东莞市高品计量技术服务有限公司

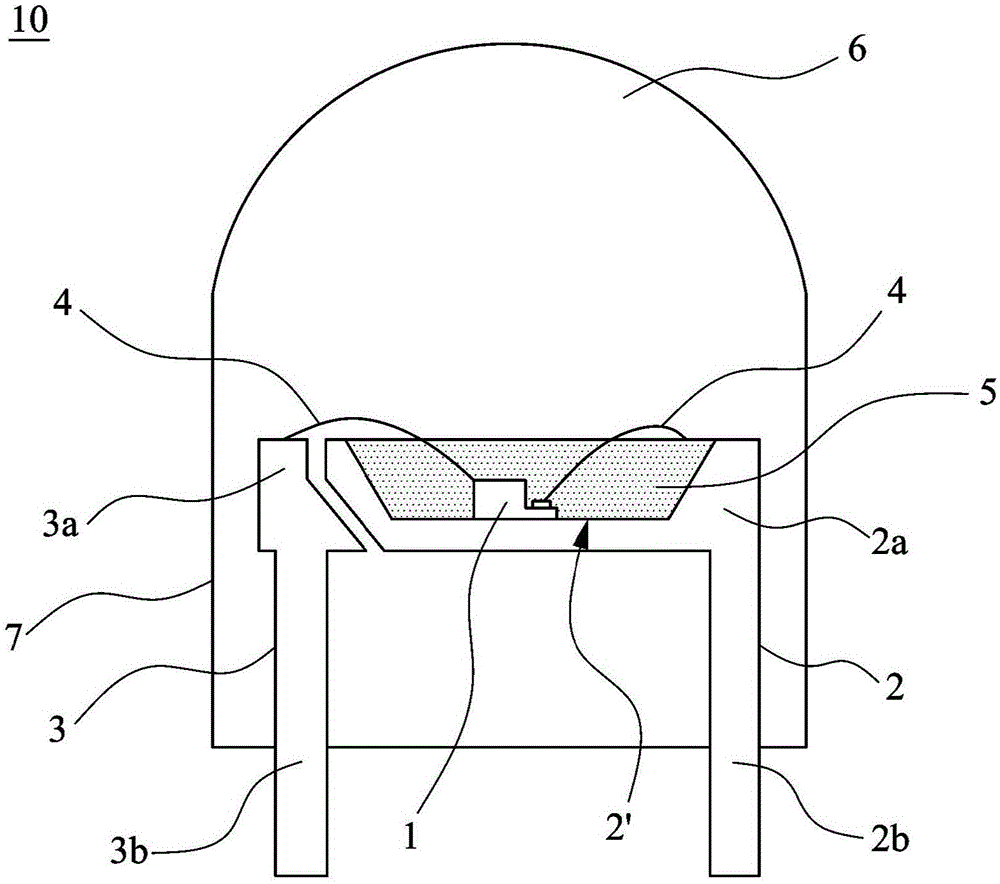

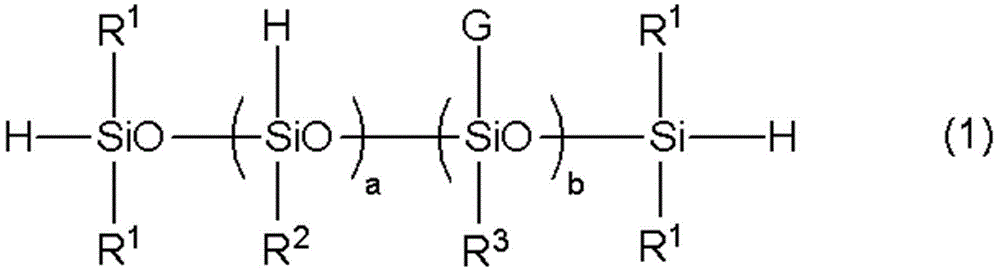

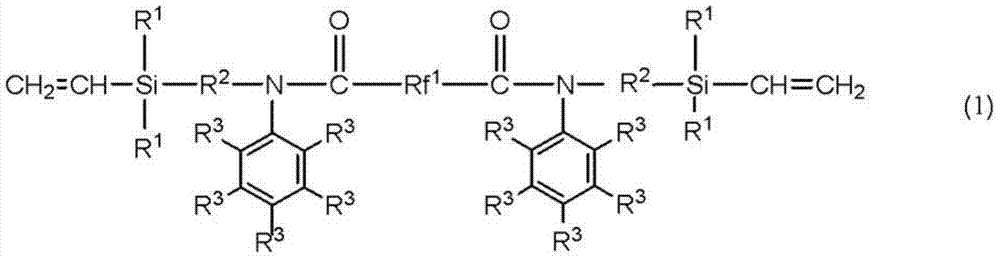

Curable composition for sealing optical semiconductor and optical semiconductor device using the same

ActiveCN105482429AImprove impact resistanceImprove crack resistanceSolid-state devicesSemiconductor devicesCrack resistanceSilanes

The invention provides a curable composition for sealing an optical semiconductor and an optical semiconductor device. The composite can obtain a cured product which have excellent impact resistance and crack resistance and low gas penetrability and whose hardness is 30 to 70, the hardness is measured by using an A type sclerometer, a waver vapor penetration rate of the 1-millimeter-thick cured product of the abovementioned composition is below 10.0g / m2*day, and the optical semiconductor device has the cured product of the composition. The composition contains the following components: (A) a straight-chain polyfluorinated compound having more than two alkenyl groups in a molecule and having a perfluoropolyether structure in a main chain; (B) organohydrogenpolysiloxane represented by the following general formula (1); (C) a platinum group metal catalyst; and (D) organopolysiloxane having hydrogen atoms directly bonded to silicon atom, a monovalent perfluoroalkyl group or a monovalent perfluorinated oxyalkyl group, and an epoxy group or trialkoxy silane group or both.

Owner:SHIN ETSU CHEM IND CO LTD

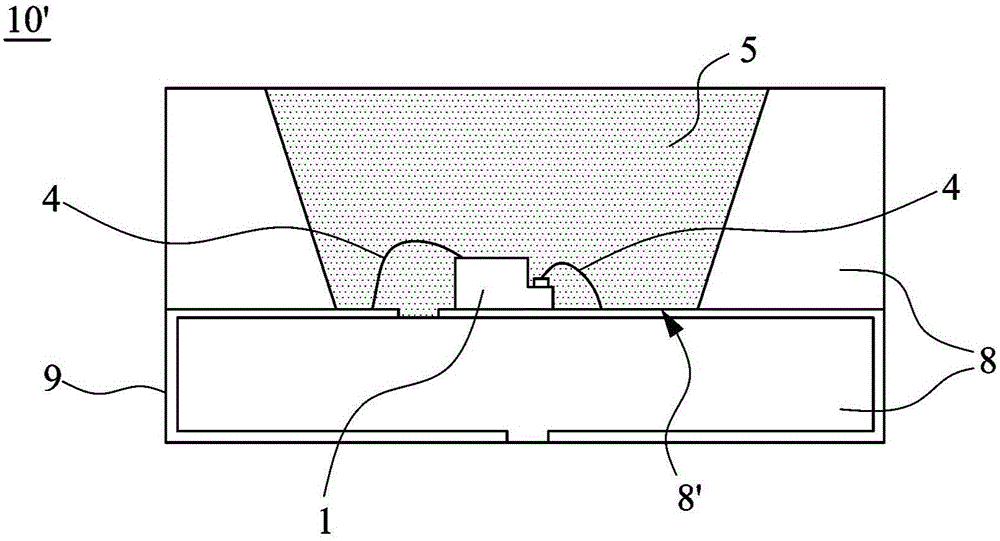

Curable composition for sealing optical semiconductor and optical semiconductor device using the same

ActiveCN103804880ANot easy to peel offLess prone to damageSemiconductor/solid-state device detailsSolid-state devicesMetal catalystSclerometer

The invention provides a curable composition for a sealing optical semiconductor, which can form cured products with high impact resistance and adhesion properties, and an optical semiconductor device having optical semiconductor elements sealed by the cured products formed by the curable composition for the sealing optical semiconductor. The curable composition for the sealing optical semiconductor is characterized by containing a (A) linear chain fluoro polymer, a (B) fluorine-containing organic hydrogenated siloxane with an SiH group and a fluorine-containing organic group, a (C) platinum group metal catalyst, an (D) annular organic siloxane with an SiH group, a fluorine-containing organic group, and an epoxy group, the hardness of the cured products through the curing measured by an A type sclerometer regulated by JIS K6253-3 is in the range of 30-80.

Owner:SHIN ETSU CHEM IND CO LTD

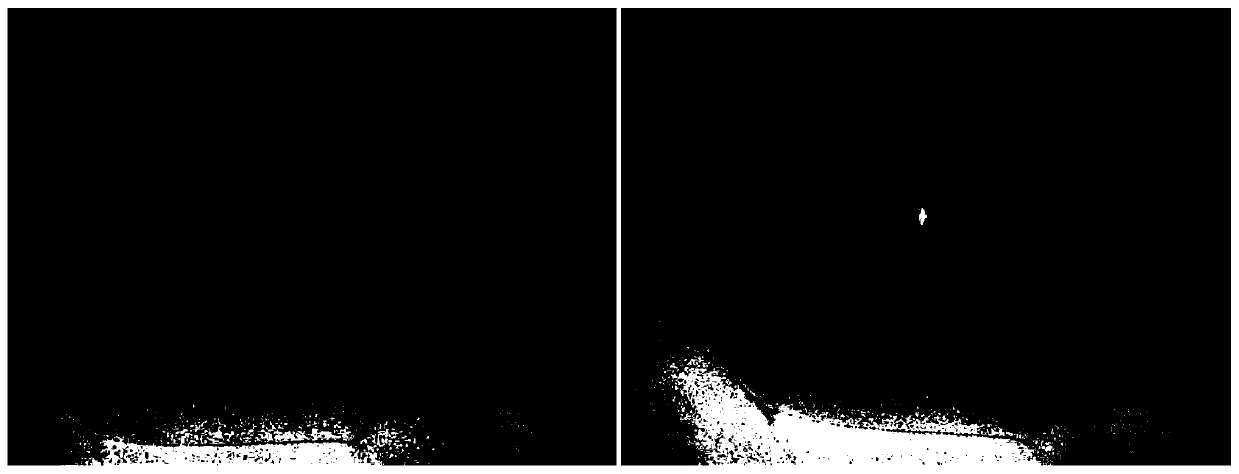

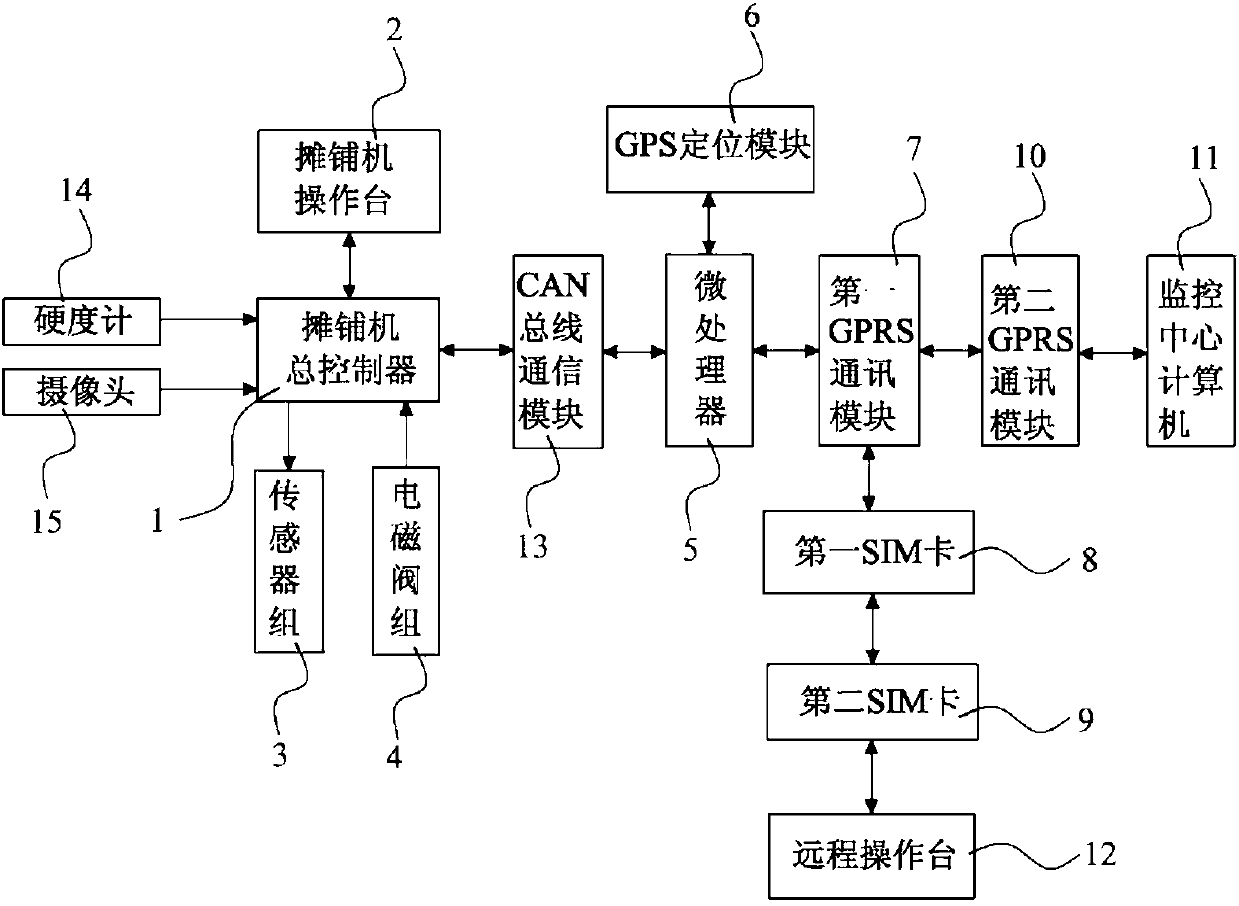

Remote brinell compactness image analysis and measuring system in paving process

InactiveCN103345225AImprove reliabilityImprove stabilityProgramme total factory controlCamera lensControl system

The invention discloses a remote brinell compactness image analysis and measuring system in a paving process. The system comprises a paver control system and a monitoring center computer in wireless connection with the paver control system remotely through a telecommunication system, and a remote operating table. The paver control system comprises a paver total controller and a paver operating table, and an input end of the paver total controller is connected with a sclerometer used for exerting loads on a tested construction road surface and a camera lens used for shooting indentation images. The system is simple in structure, novel and reasonable in design, convenient to achieve, high in operating reliability, high in stability, capable of assisting an on-site operator in completing adjustment of reasonability of an operating state of a paver and guaranteeing safe and effective proceeding of after-sales maintenance operation, complete in function, high in practicability and popularization and application value, and especially capable of achieving remote brinell compactness image analysis and measuring in the paving process through matching of the sclerometer and the camera lens in use, and brings convenience to monitoring of engineering quality.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

Sclerometer calibrating apparatus

ActiveCN105716984AEasy to observeSolve the problem of large error in test resultsStrength propertiesSclerometerEngineering

The invention provides a sclerometer calibrating apparatus. The sclerometer calibrating apparatus comprises a base, wherein a sclerometer fixing base is assembled on the base in the longitudinal direction in a directed moving manner, a supporting part used for upwards supporting the lower end surface of a lower casing of a sclerometer and allowing an ejection pin of the lower casing of the sclerometer to extend downwards is arranged on the sclerometer fixing base, and a pressing mechanism used for vertically pressing the sclerometer onto the supporting part is further arranged on the sclerometer fixing base. When the sclerometer calibrating apparatus is used, the sclerometer is upwards supported by the supporting part, the pressing mechanism presses the sclerometer downwards, accordingly, the sclerometer is fixed, the problem of displacement of the sclerometer in the longitudinal direction cannot occur in the calibration process, and the accuracy of a detection result is guaranteed.

Owner:HENAN PROVINCE INST OF METROLOGY +1

High temperature sclerometer capable of conducting continuous temperature changing multi-point testing

PendingCN108982268ASimple structureEasy to operateInvestigating material hardnessSclerometerMetallic materials

The invention discloses a high temperature sclerometer capable of conducting continuous temperature changing multi-point testing, and belongs to the technical field of metal material mechanics detection equipment. The high temperature sclerometer is used for conducting multi-point high temperature hardness detection on metal materials. The high temperature sclerometer is characterized in that a penetrator is connected with a sclerometer body, a heating furnace is mounted on a heating furnace rotary mechanism, the heating furnace rotary mechanism is fixed to a heating furnace lifting platform,the heating furnace lifting platform is fixed to a sclerometer lower supporting structure, one side of the sclerometer lower supporting structure is connected with the sclerometer body, the penetratoris perpendicularly inserted into the heating furnace, a sample moving mechanism is connected to one side of the heating furnace, the heating furnace and the heating furnace rotary mechanism are co-axial cylinders, and eccentric distance exists between the central axes of the heating furnace and the heating furnace rotary mechanism and the axis of the penetrator. The high temperature sclerometer achieves the purpose that a furnace type high temperature sclerometer conducts continuous temperature changing hardness testing by randomly selecting points on the whole surface under the premise thatthe furnace is not turned on to adjust the sample, and the hardness testing quantity of the same sample is greatly improved.

Owner:HEBEI IRON AND STEEL

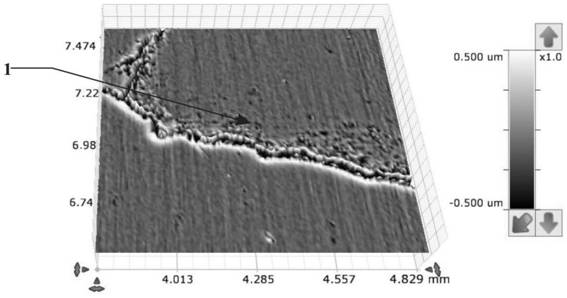

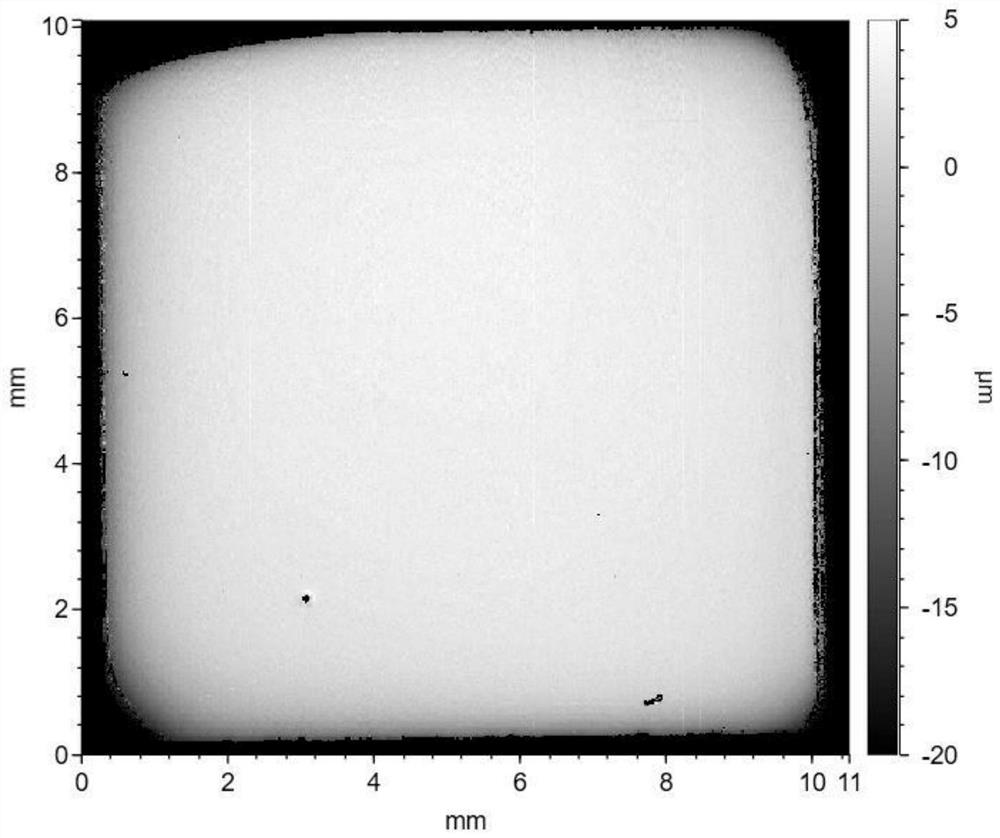

Metal micromechanical property high-flux statistical characterization method

ActiveCN112665931AEnable high-throughput screeningHigh micromechanical propertiesMaterial analysis using wave/particle radiationPreparing sample for investigationMirror reflectionHigh flux

The invention discloses a metal micromechanical property high-flux statistical characterization method which comprises the following steps of grinding and polishing a metal sample until the mirror reflection finish meets the test requirement, marking the position coordinates of the to-be-detected areas on the metal sample by using a microhardness tester to ensure the comparison of the same to-be-detected areas, carrying out isostatic pressing strain test on the to-be-tested area by utilizing an isostatic pressing technology, and comparing high-flux characterization of components, tissue structures, microdefects and surface three-dimensional shapes of the metal samples before and after isostatic pressing strain to obtain full-view-field cross-scale high-flux statistical characterization of the micromechanical property uniformity of the metal samples. According to the metal micromechanical property high-flux statistical characterization method, high-flux characterization of sample components, tissue structures, microdefects and surface three-dimensional morphology is combined, screening and characterization of weak areas of the mechanical properties of the material are facilitated, and accurate quantitative data are provided for material quality evaluation and service safety evaluation.

Owner:NCS TESTING TECH

Tester

Discloses is a pressure and hardness tester of a planar material, comprising a base, a stage, a test frame and a test device. The test piece is flatly extended and fixed on the stage. The test frame comprises a floor stand and a cross bar hinged by a rotating shaft. The floor stand and the stage are fixedly connected with the base. One end of the cross bar is provided with a balance weight and the other end of the cross bar is provided with a counterweight and a connecting part. The connecting part is used to connect the test device including a pressure test assembly or a hardness test assembly and make the test device right opposite to the stage. After the cross bar rotates about the rotating shaft, the test device contacts with the test piece for testing a pressure resistance or a hardness of the test piece.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

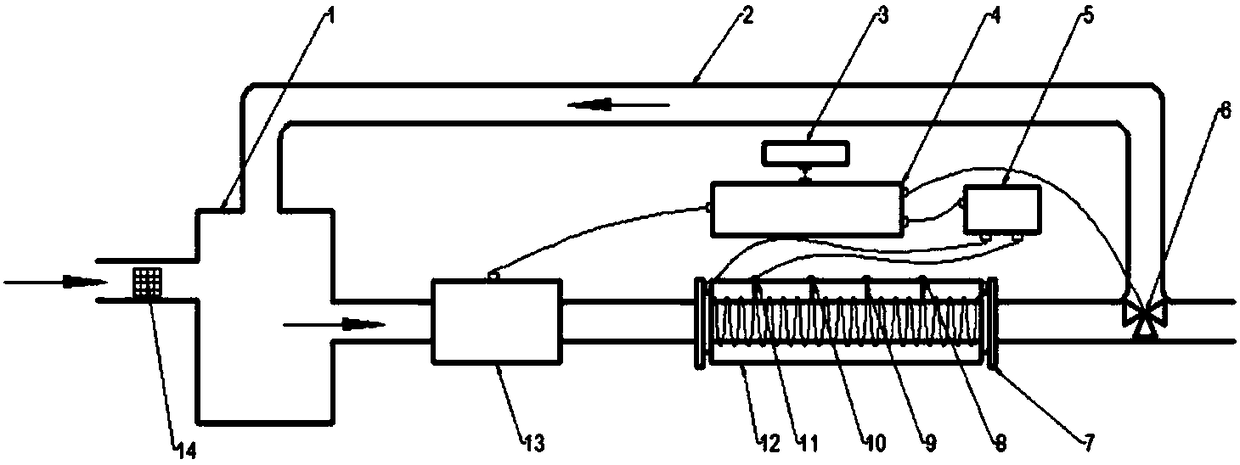

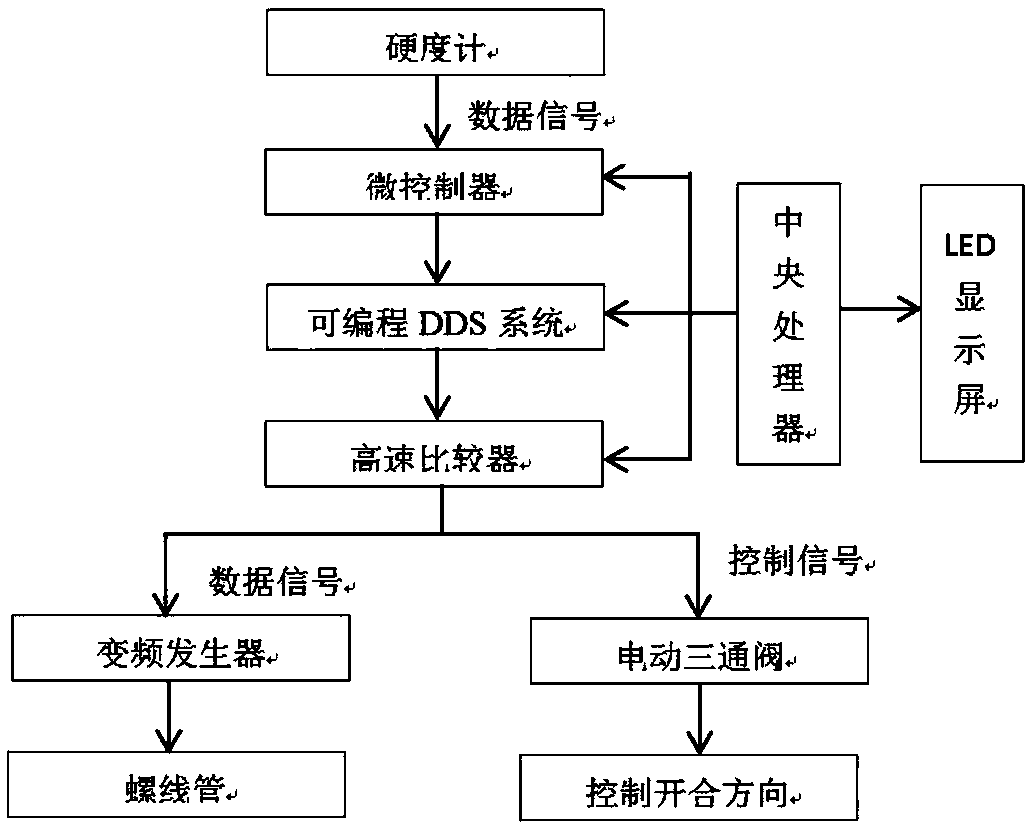

Intelligent electromagnetic scale inhibition device and design method

InactiveCN108503049AControl accessEffective scale inhibitionWater treatment parameter controlScale removal and water softeningWater sourceIndustrial equipment

The invention discloses an intelligent electromagnetic scale inhibition device and a design method thereof. The intelligent electromagnetic scale inhibition device is connected between a water sourceand a water inlet of industrial equipment and is composed of a water tank 1, a PVC pipeline 2, a display screen 3, a central processor 4, a power source 5, an electric three-way valve 6, a water treatment cavity 12, a water quality sclerometer 13 and a filtering screen 14. An electric wire is closely wound around the outer pipe wall of the PVC pipeline in the water treatment cavity 12, and the inner wall of the water treatment cavity 12 and the electric wire 4 wound around the PVC pipeline in the cavity have four equidistant contact points, namely, the first contact point 8, the second contactpoint 9, the third contact point 10 and the fourth contact point 11 in sequence. The display screen 3 is connected with the central processor 4, and the power source 5 is connected with the central processor 4 and the water treatment cavity 12. The electromagnetic three-way valve 6 is located at a forked opening of the PVC pipeline 2, and the water quality sclerometer 13 is connected with the central processor 4, the water quality sclerometer 13 is located between the water tank 1 and the water treatment cavity 12, and the filtering screen 14 is located on a water inlet in the left side of the water tank. According to the intelligent electromagnetic scale inhibition device, the concentration of calcium ions and magnesium ions in a water sample is reduced through an electromagnetic field in a wound coil, and therefore the aim of scale inhibition is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com