Portable hardometer

A hardness tester, a portable technology, applied in the field of improvement of the hardness tester, can solve the problems of inconvenient portability, large size, and can only be used for the detection of horizontal objects, etc., and achieve the effect of high output voltage, wide detection range and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

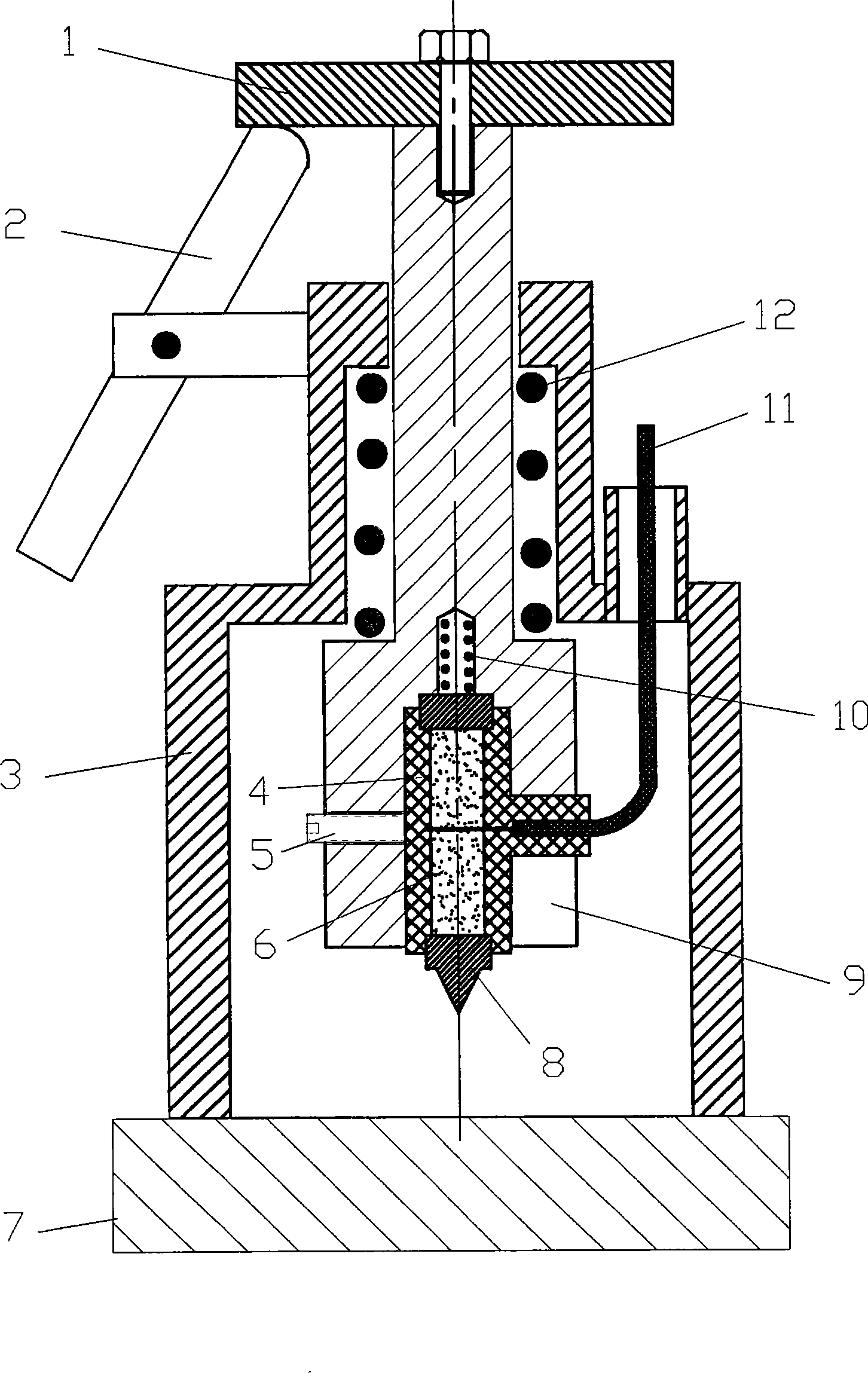

[0011] The hardness tester of the embodiment is composed of an impact sensor and a host including a detection signal processing circuit.

[0012] The structure of the impact sensor is as figure 1 As shown, it is made up of a base 3, an impact column 9, an energy storage spring 12, a trigger 2, a piezoelectric ceramic 6 and an impact head 8.

[0013] Support 3 is the seat of a two-section cylindrical structure, and a through hole is a guide hole in the center of the first half, and a cavity is in the lower half.

[0014] Collision post 9 is movably worn in the guide hole of support 3, and can be telescopically moved. Collision post 9 is covered with energy storage spring 12, which is located between the bottom of guide hole and 9 front ends of percussion post.

[0015] The base 3 is provided with a trigger 2 and a controllable release device composed of the trigger 2 and the energy storage spring 12 .

[0016] When the impact column 9 moves up, the trigger 2 is stuck on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com