High-precision hardness tester force value loading adjusting device

A technology of adjusting device and hardness tester, which is applied in the direction of measuring device, testing material hardness and strength characteristics, etc., can solve problems such as difficulty in achieving maximum loading force value, inability to meet accuracy requirements, and large mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] The device of the present invention will be further described in detail according to the accompanying drawings and embodiments:

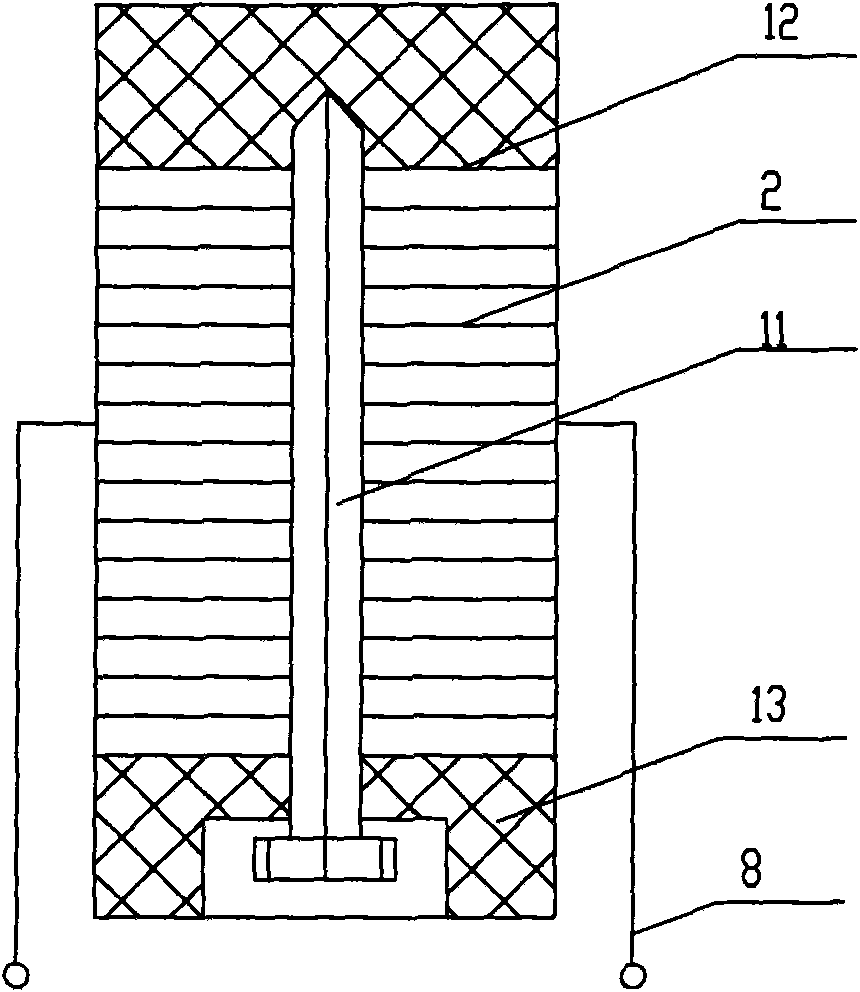

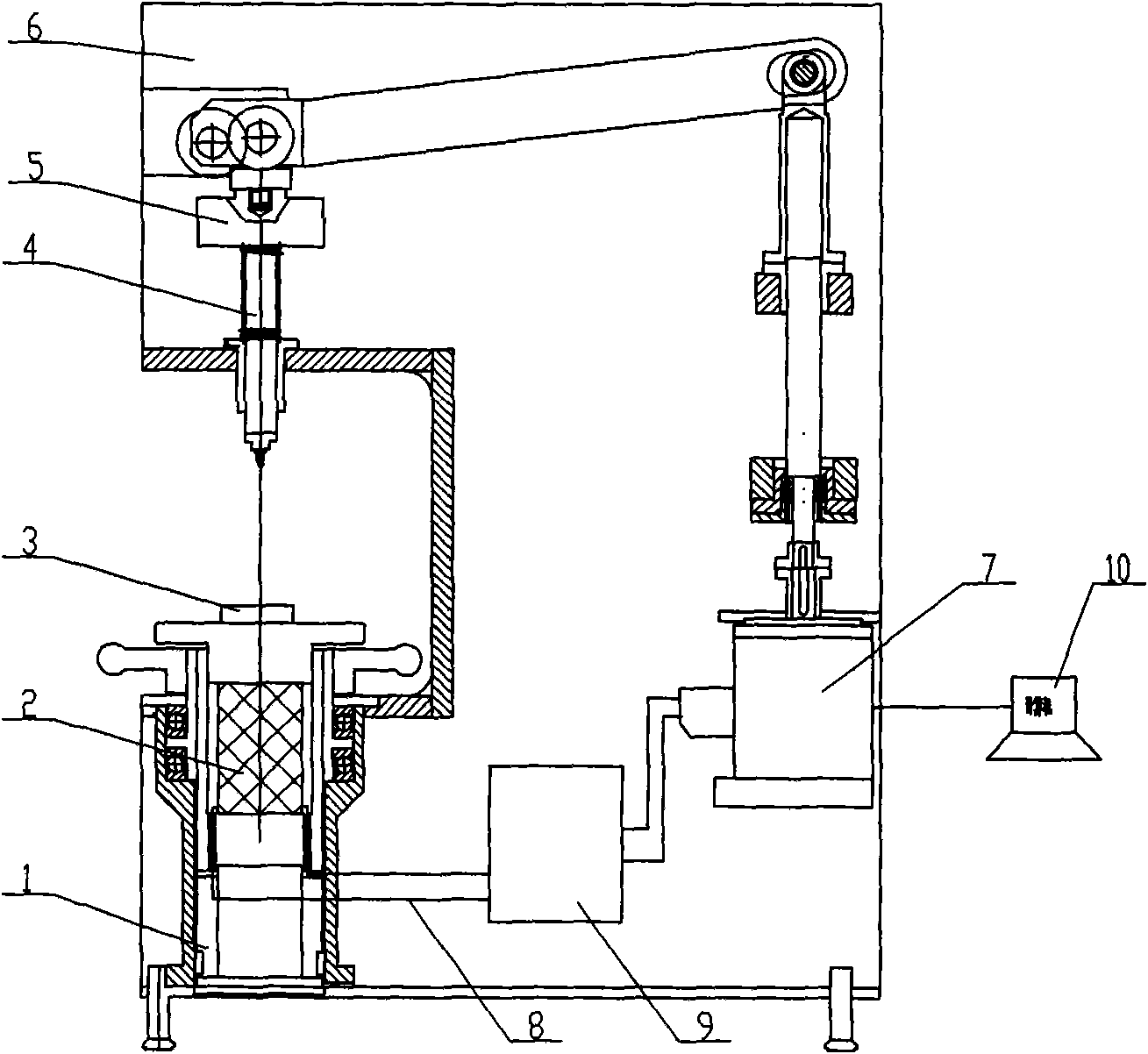

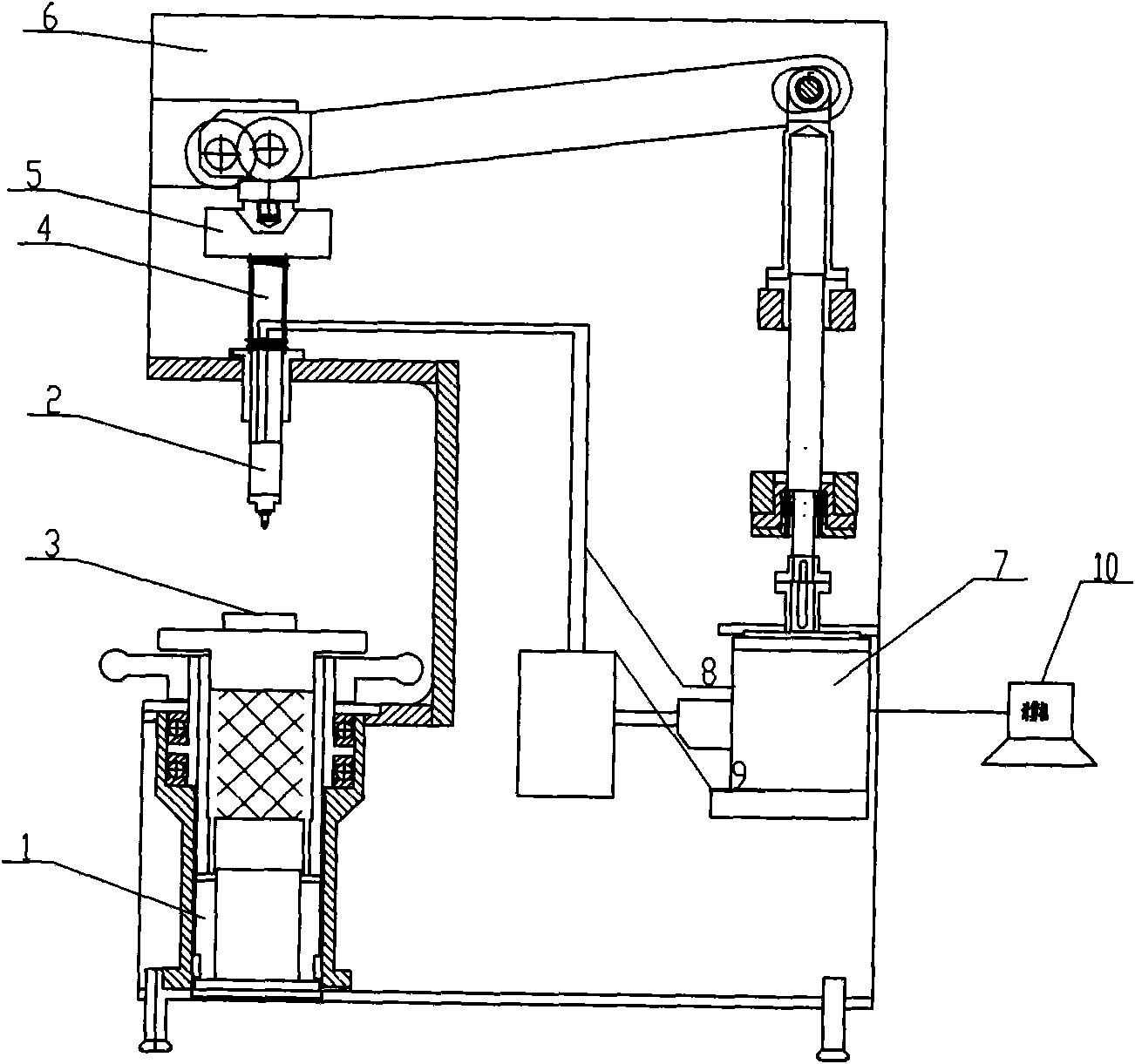

[0017] See attached Figure 1~3 As shown, this kind of high-precision hardness tester force value loading adjustment device includes a body 6, an indenter lifting device 4, a working platform 8, a working platform lifting device 1 and a motor 7, and the upper part of the indenter lifting device 4 is connected to a force sensor 5 A piezoelectric ceramic force loading block 2 formed by stacking multiple piezoelectric ceramics 2 is installed on the central axis of the force loading of the device. The piezoelectric ceramic force loading block 2 can be installed under the working platform 3, or It can be installed above the pressure head lifting device 4. The piezoelectric ceramic force value loading block 2 fixes the upper cover plate 12, the lower cover plate 13 and the multi-layer piezoelectric ceramic she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com