Automatic turret type electronic mainshaft measuring unit of Brinell hardness tester

A measuring unit and turret-type technology, applied in the field of automatic turret-type electronic Brinell hardness tester spindle measuring units, can solve the problem of optical measuring mechanism that cannot be installed with indentation diameter, separation of hardness tester and optical measuring mechanism, and test operation. Cumbersome and other problems, to achieve the effect of high rigidity, stable and reliable performance, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

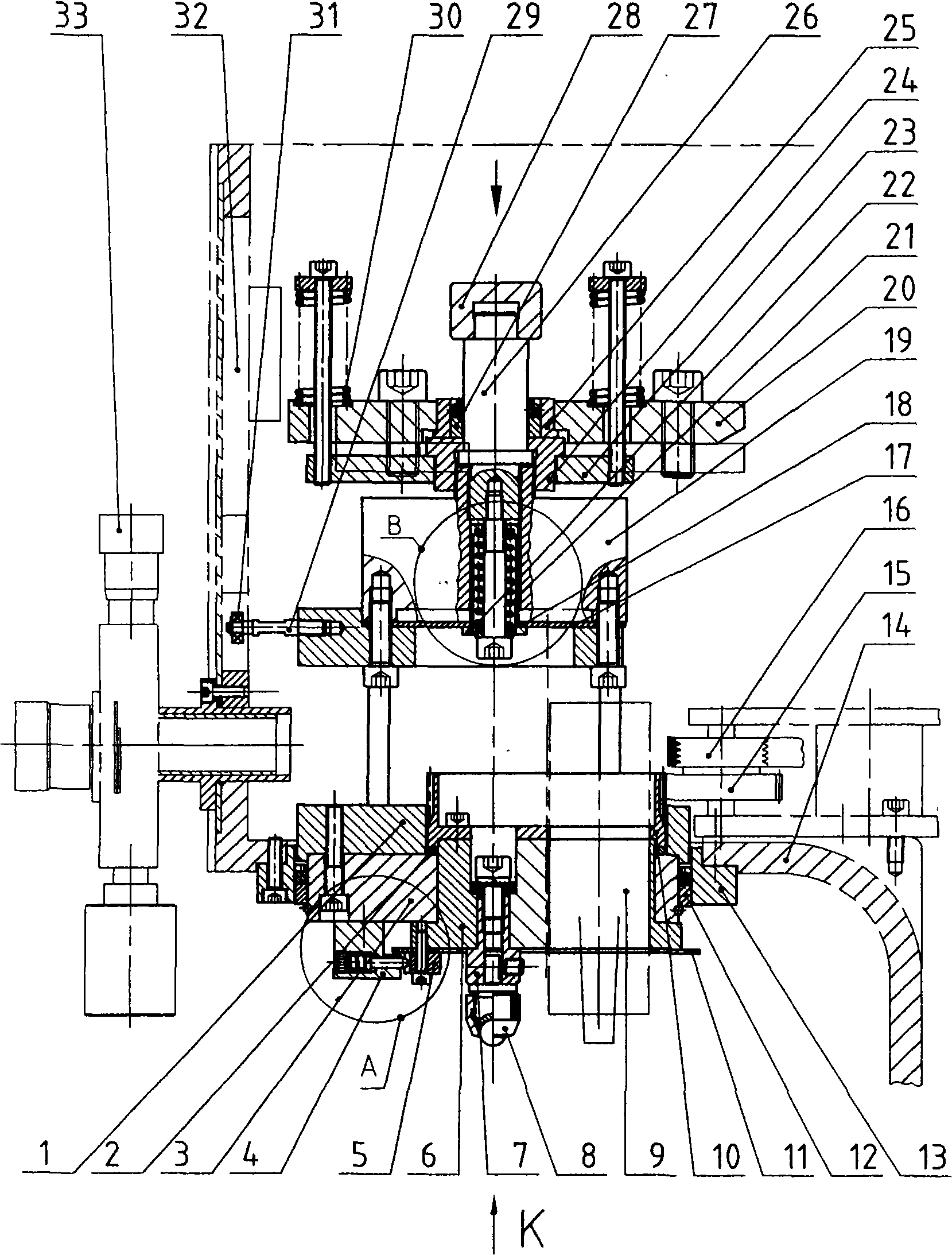

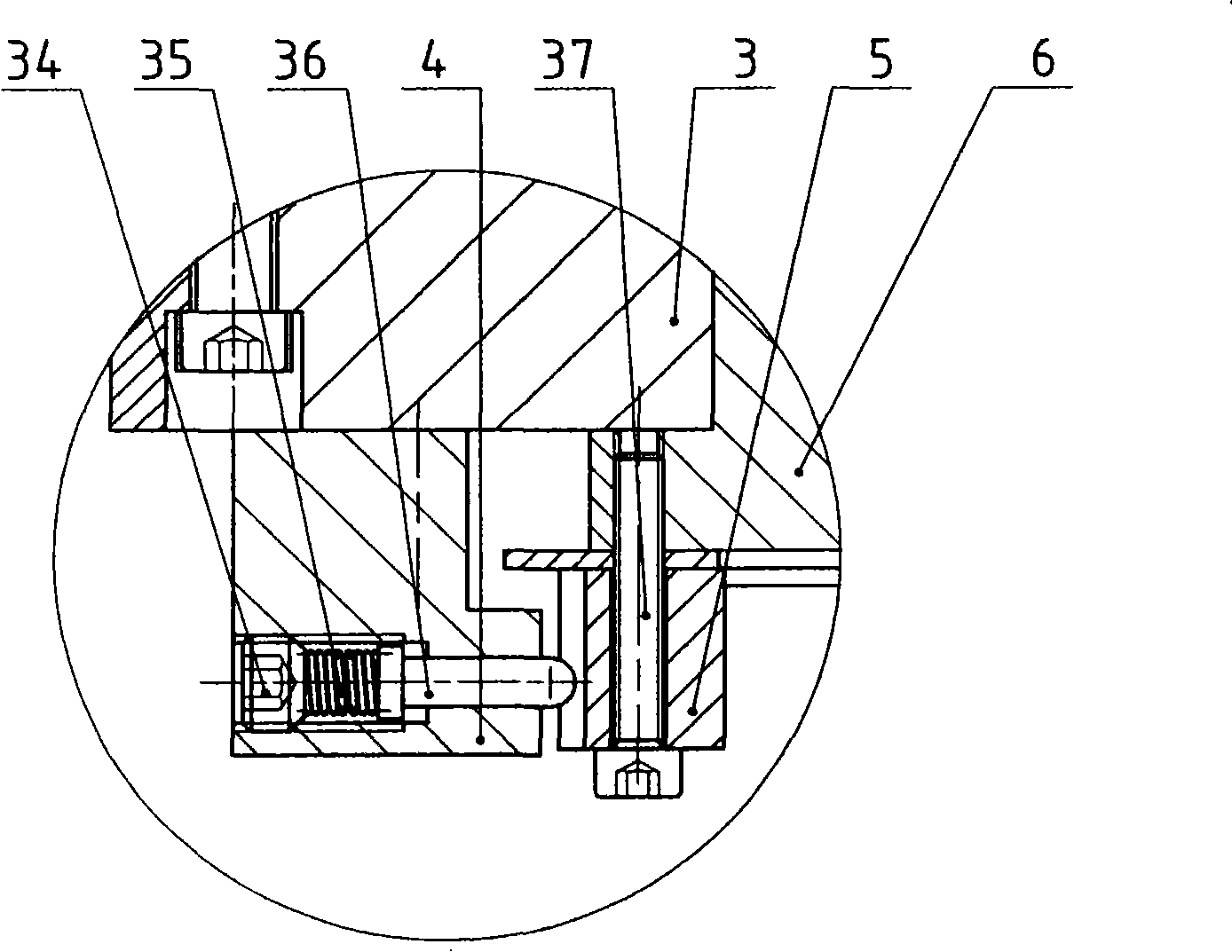

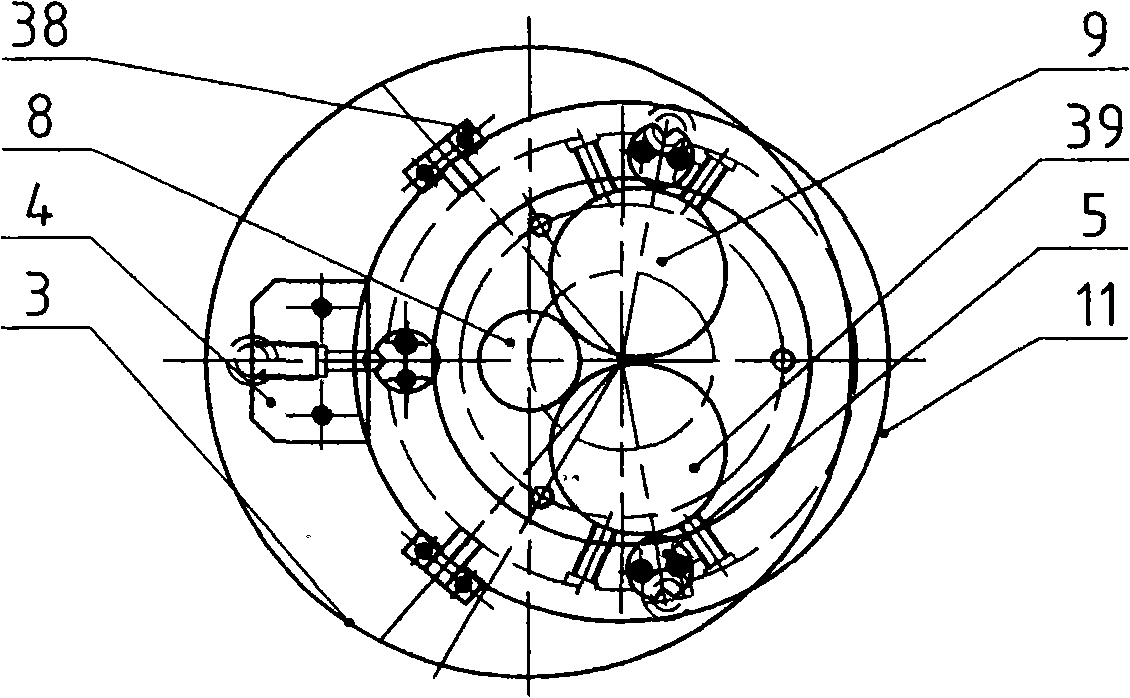

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Figure 1-Figure 4 Middle: 1. Force transmission support; 2. Wave washer; 3. Lower guide shaft; 4. Turret positioner; 5. Turret positioning block; 6. Turret; 7. Pressure head rod; 8. Pressure head ; 9, optical lens; 10, turret gear; 11, photoelectric switch board; 12, lower guide frame; 13, lower guide sleeve; 14, hardness tester frame; 15, driving gear; , force transmission plate; 18, zero-crossing spring seat; 19, load cell; 20, mounting seat on the main shaft; 21, zero-crossing spring; 22, zero-crossing spring force transmission support; 23, main shaft holding plate; 24, Upper guide shaft fixing cap; 25, upper guide sleeve; 26, upper guide shaft; 27, upper guide frame; 28, test force transmission pad; 29, main shaft anti-rotation guide rod; 30, main shaft reset spring; 31, bearing ;32, control display panel; 33, photoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com