Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Consistent stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

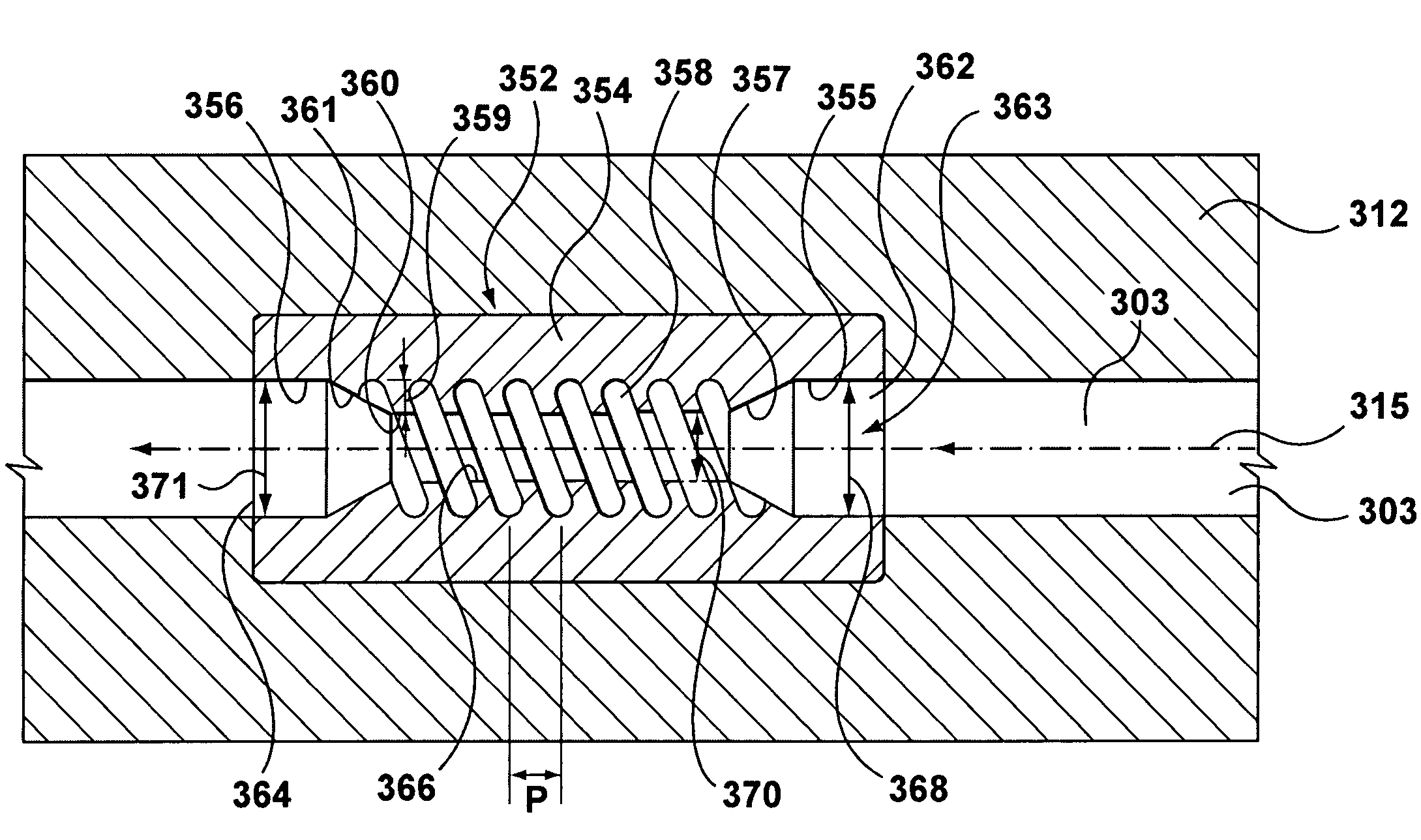

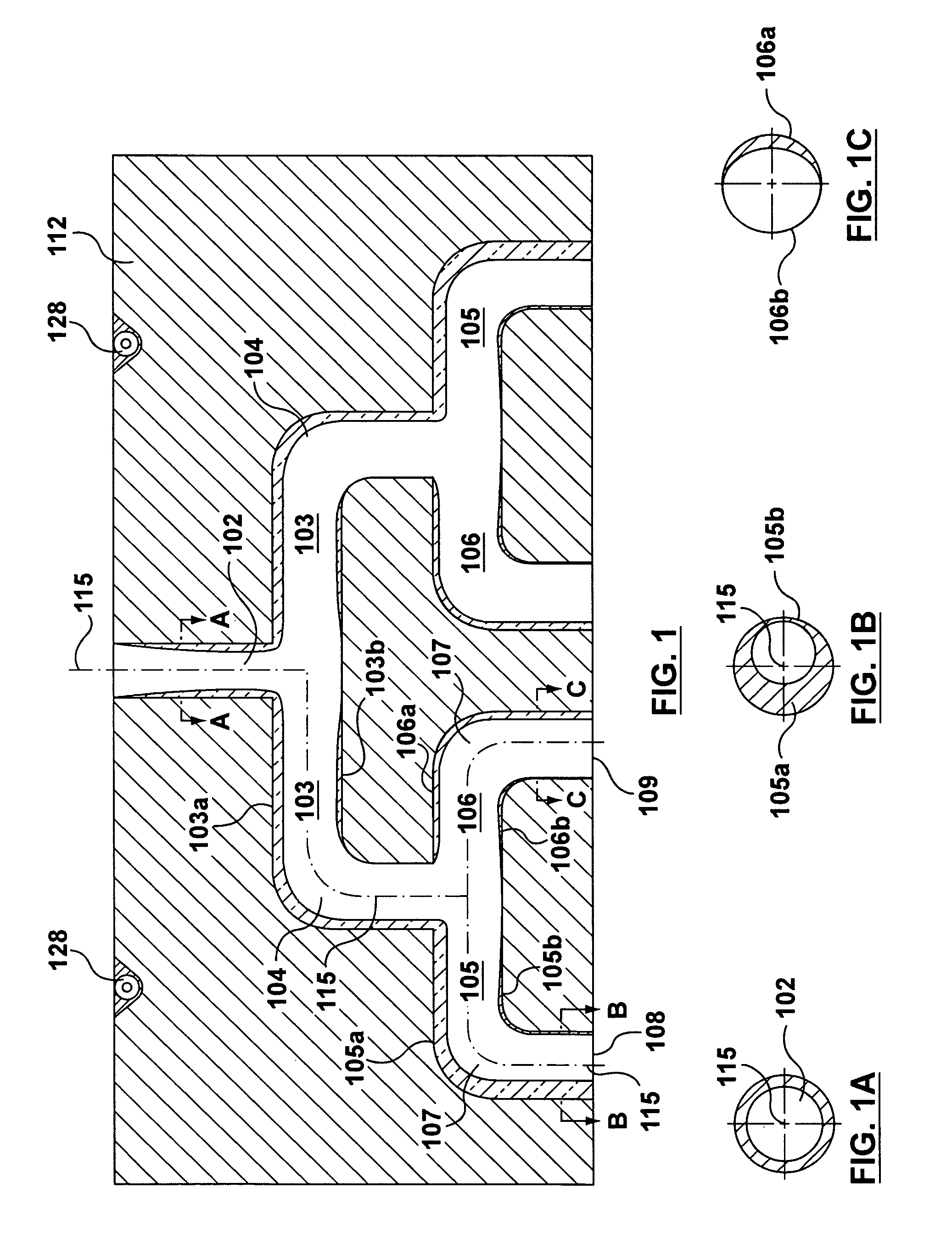

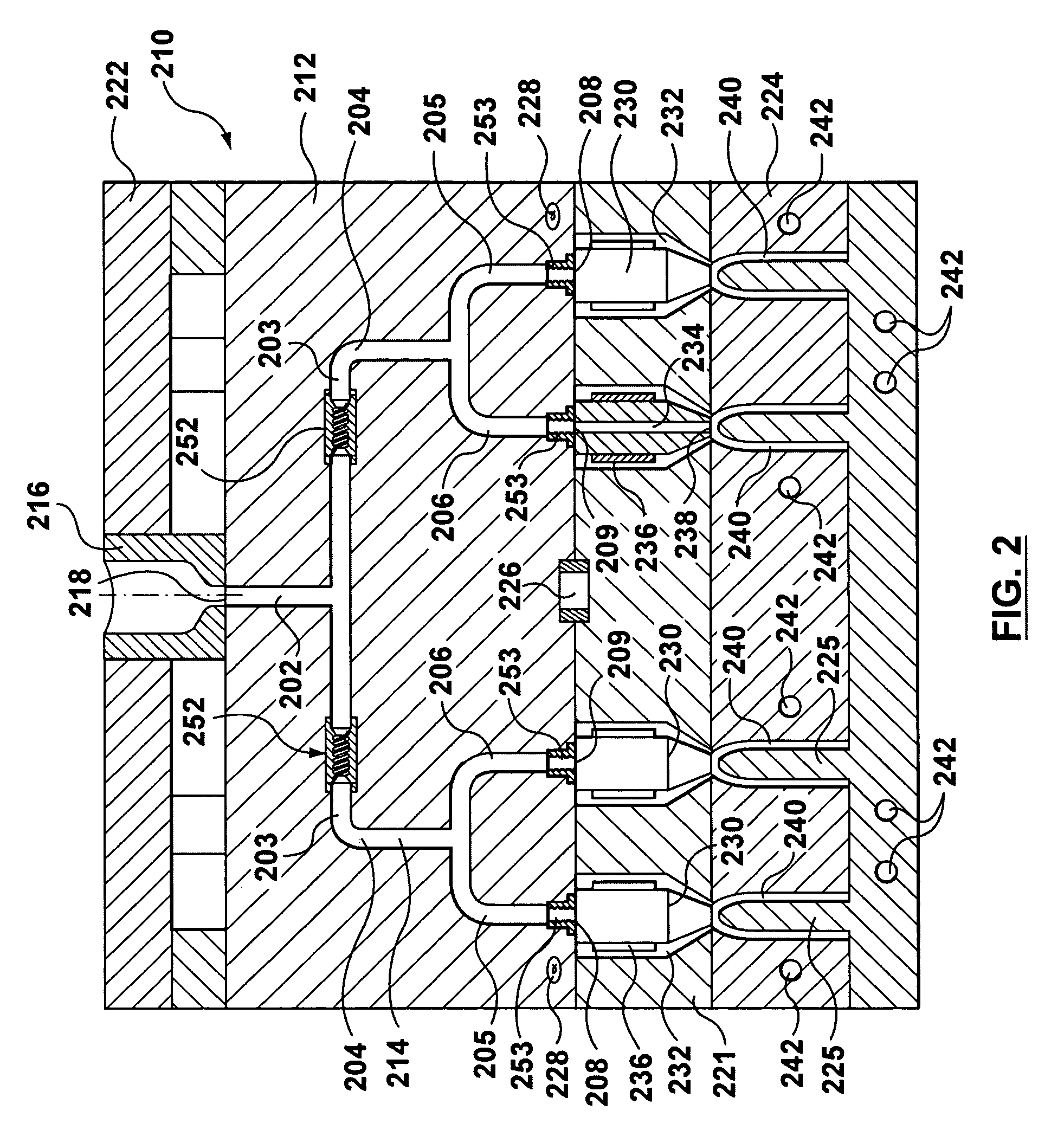

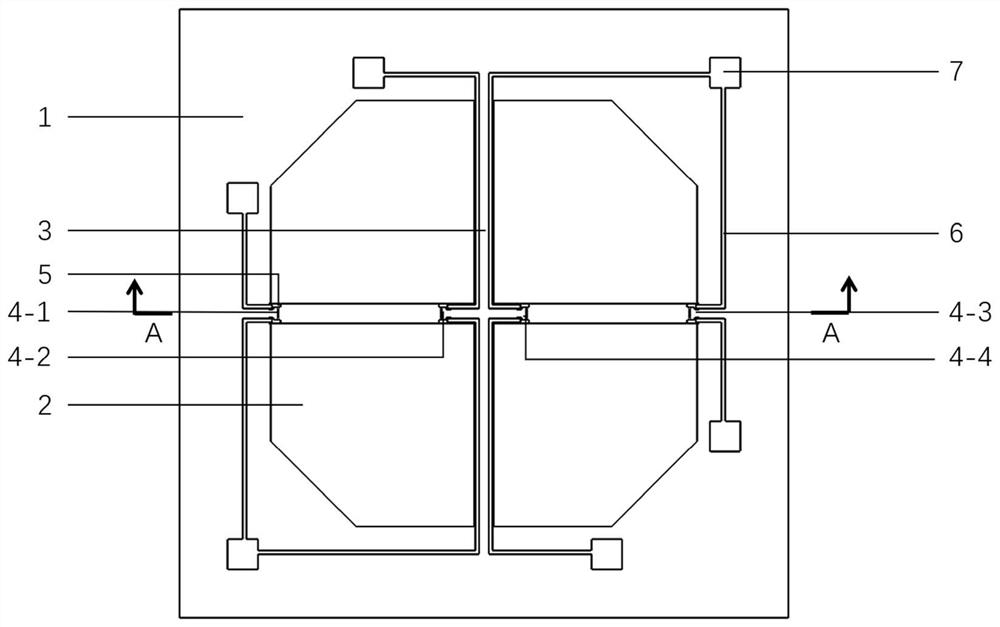

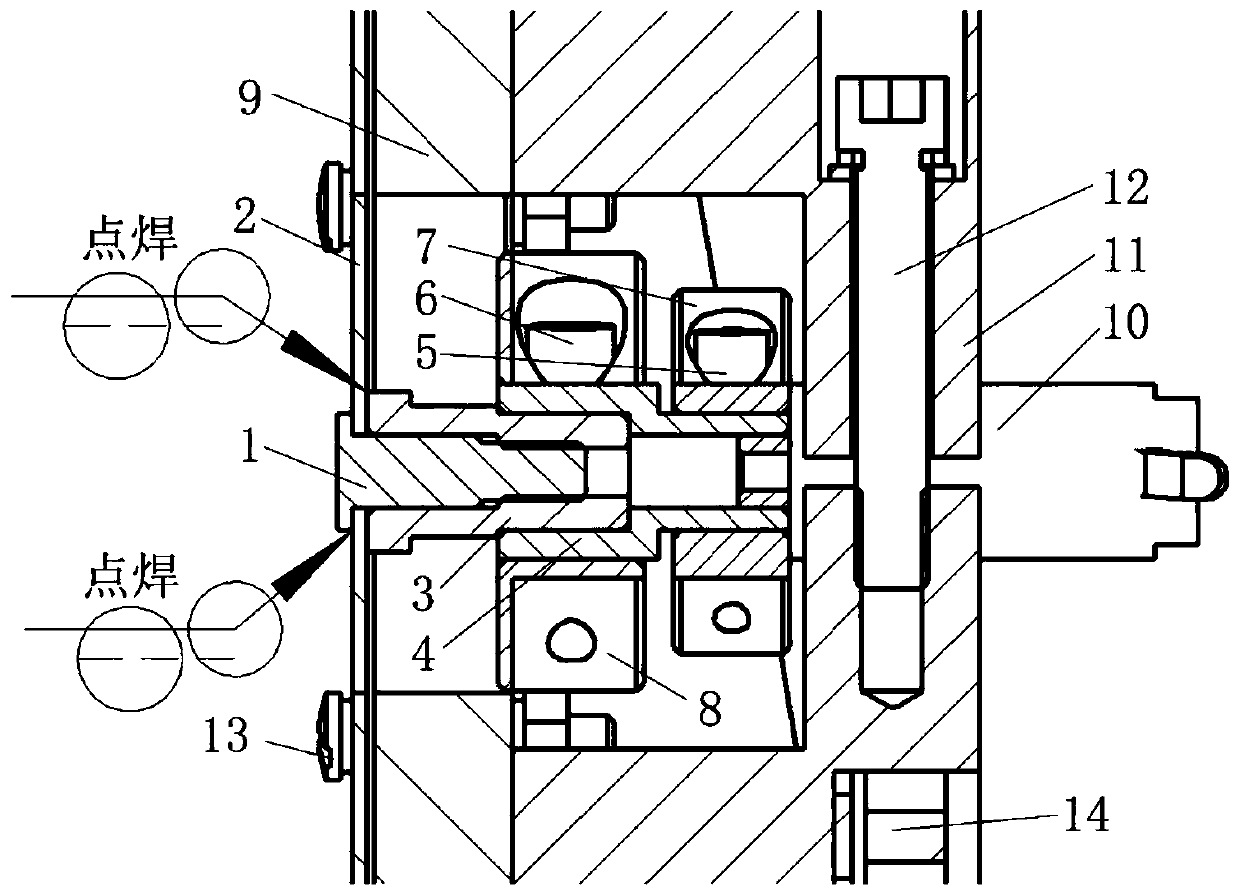

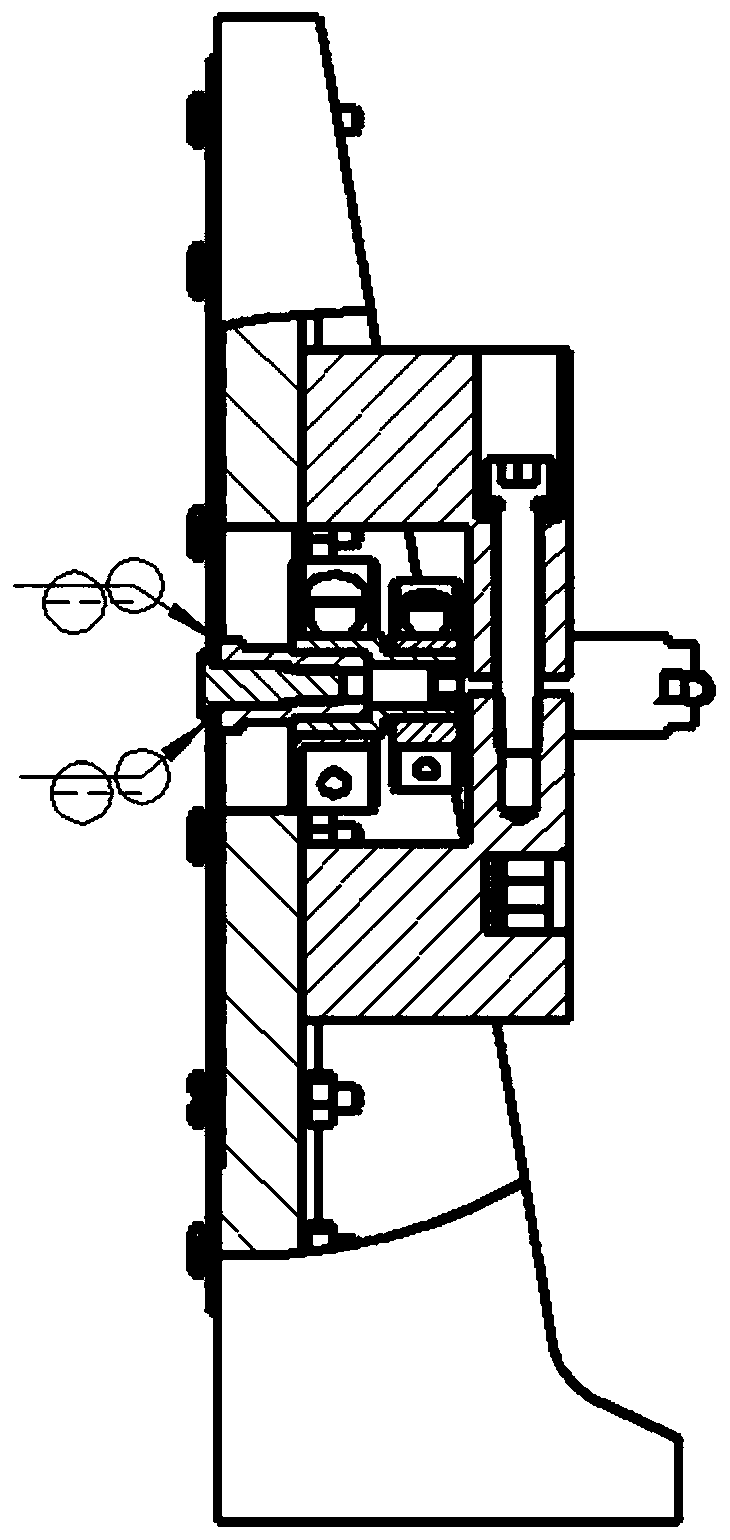

Melt redistribution element for an injection molding apparatus

ActiveUS20070077328A1Promote homogenizationReduce the overall diameterFlow mixersTransportation and packagingHot runnerShear stress

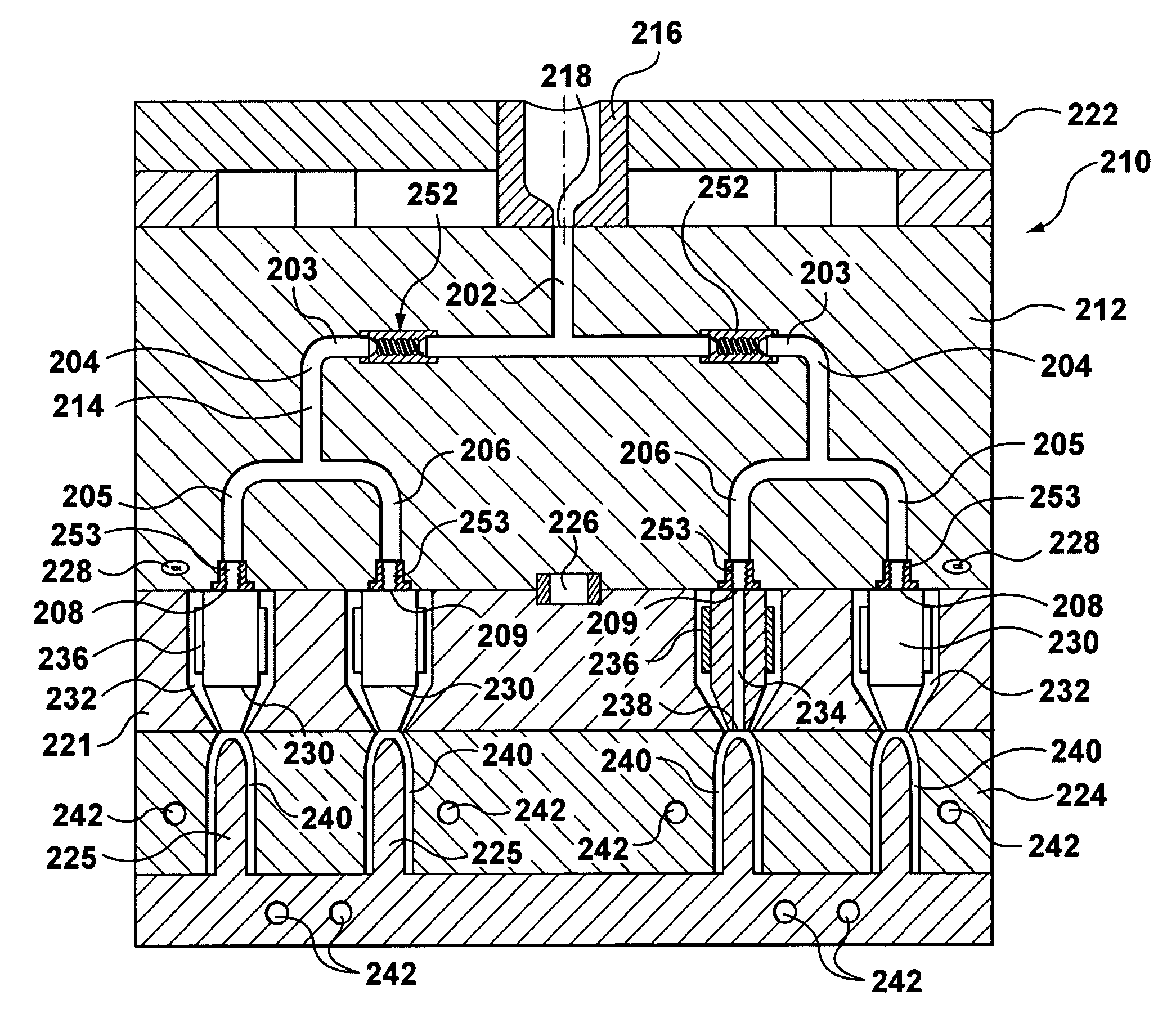

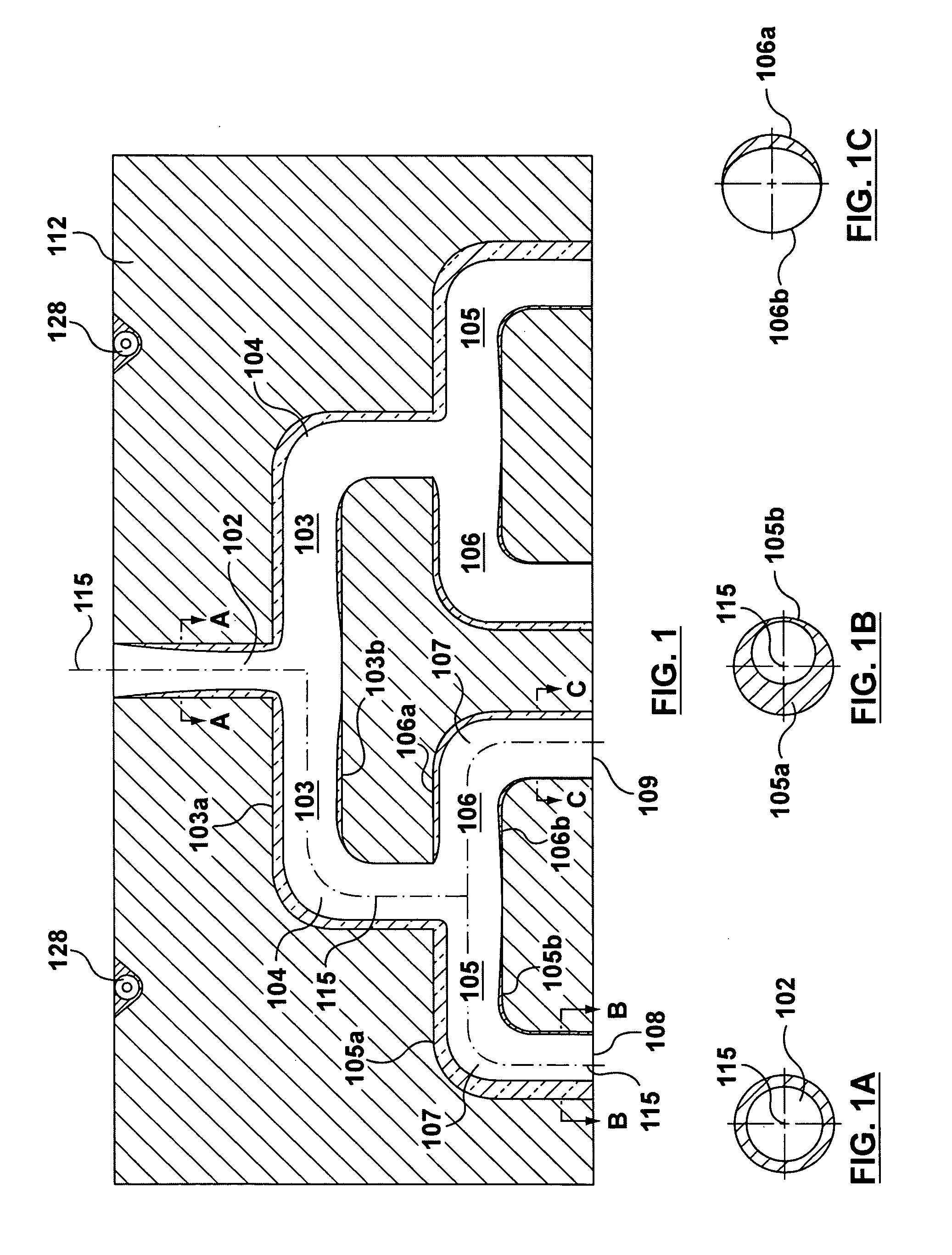

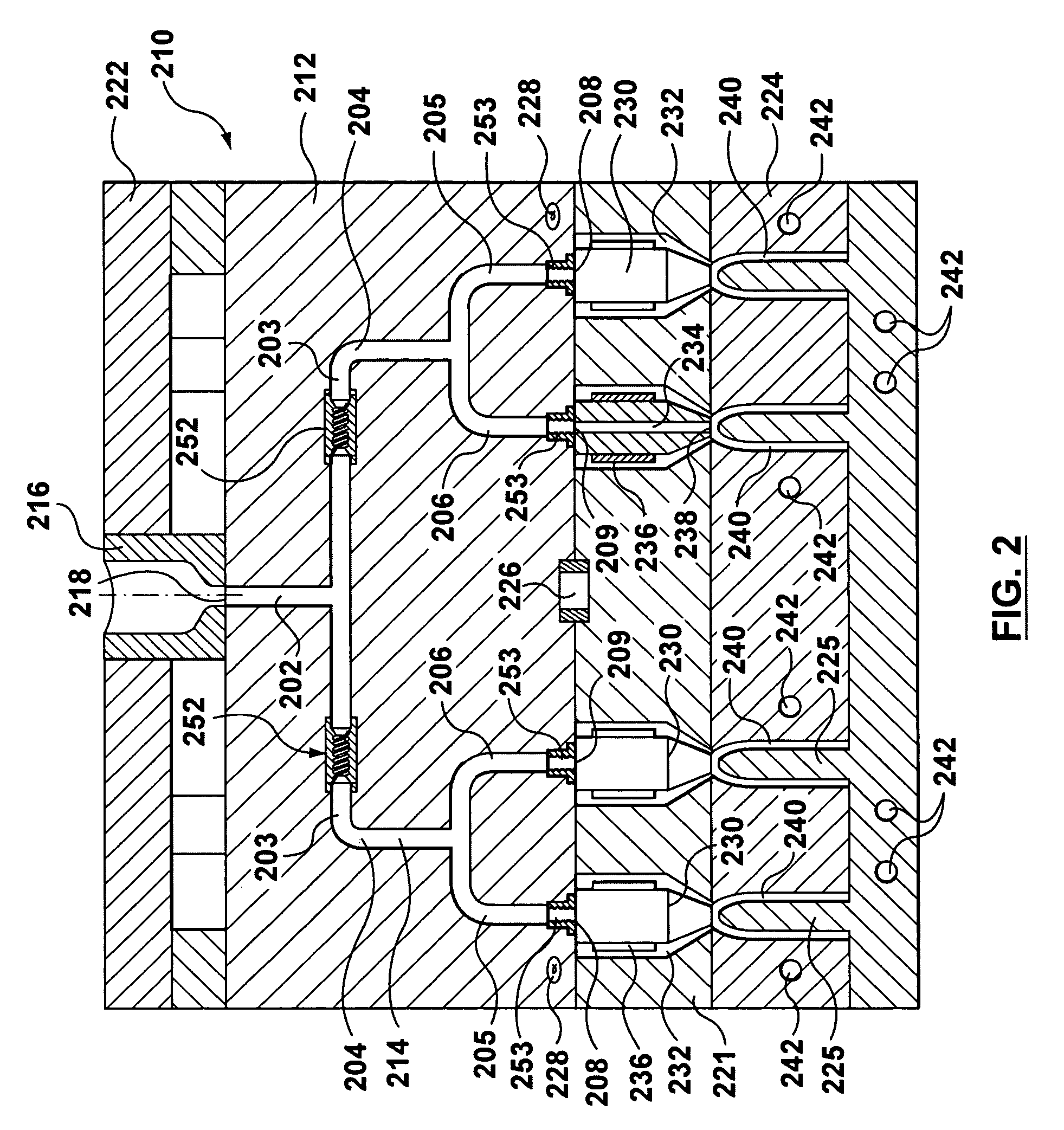

An injection molding apparatus having a manifold and several manifold melt channels communicating with several hot runner nozzles includes a melt redistribution element. The melt redistribution element is placed at specific locations along the melt channels to balance the uneven shear stress profile accumulated during the flow of a melt along the manifold channels. The melt redistribution element has an unobstructed central melt bore having at its inlet a narrowing tapered channel portion. The melt redistribution element also includes a helical melt pathway portion that surrounds the central melt bore. The incoming melt is first subjected to a pressure increase by the tapered portion that causes the melt to flow at a higher velocity through the central melt bore. The outer portion of the melt is forced to flow along the helical path and thus it changes direction multiple times and partially mixes with the melt flowing through the central melt bore. Accordingly, at the outlet of the melt redistribution element the shear stress profile is more evenly distributed than at the inlet of the redistribution element.

Owner:MOLD MASTERS 2007

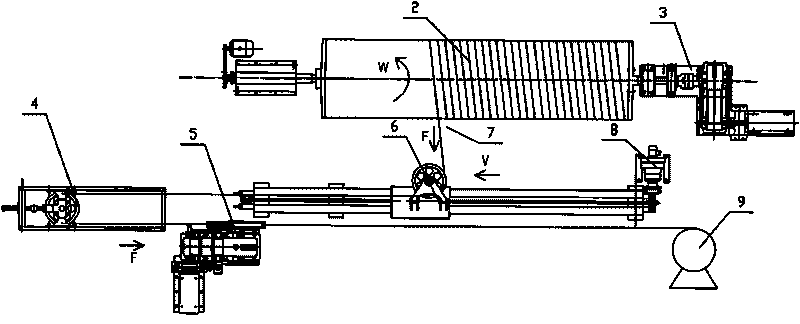

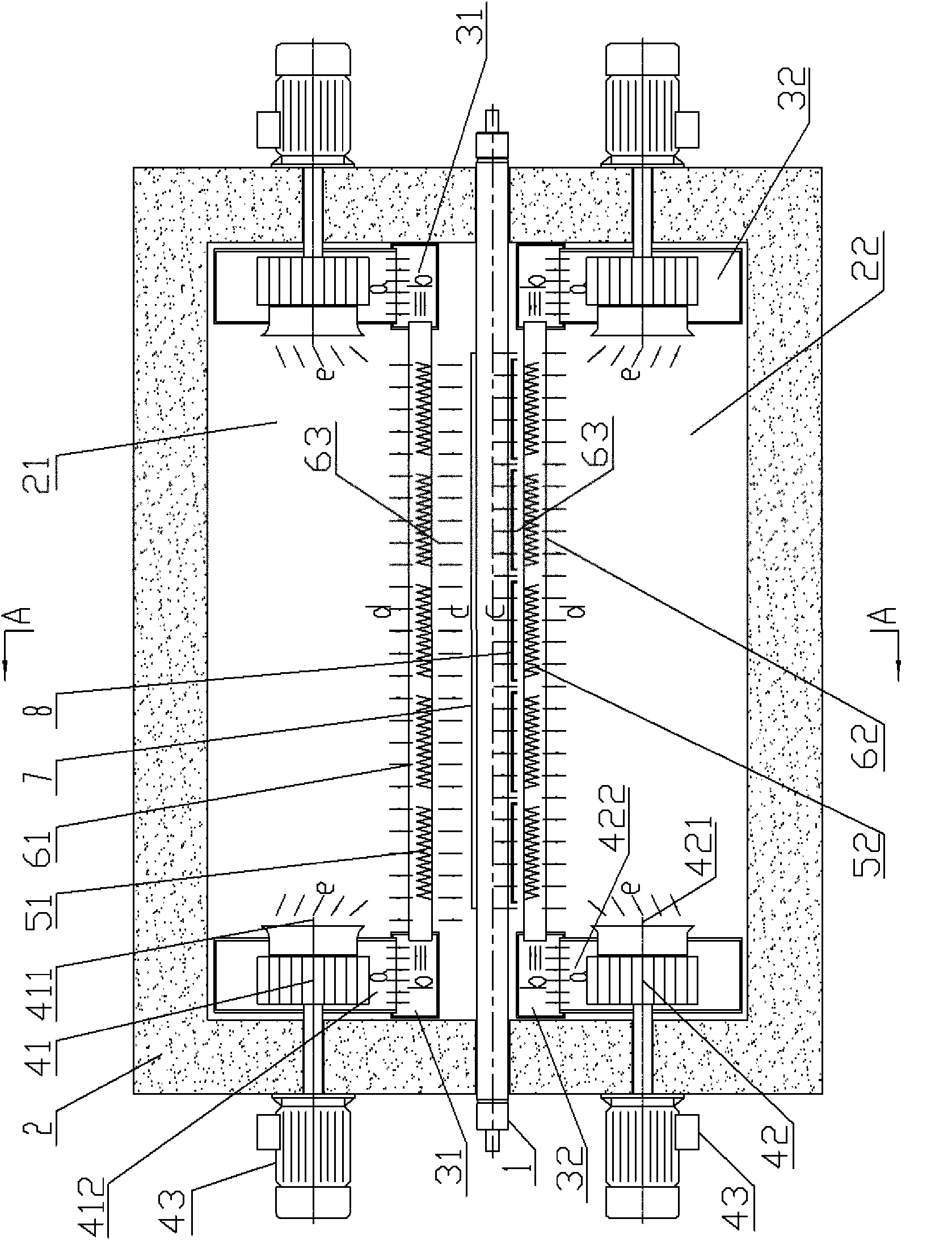

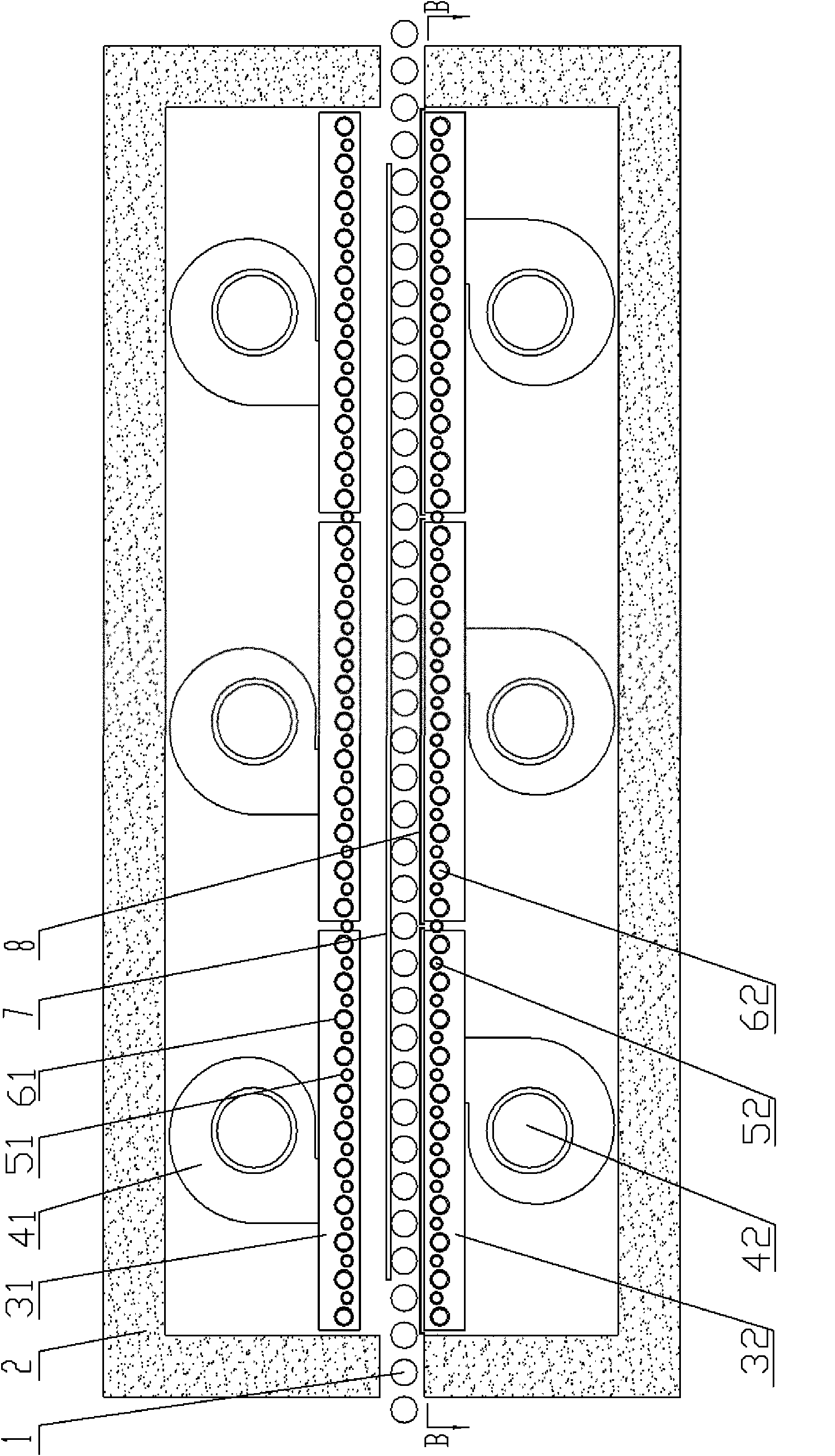

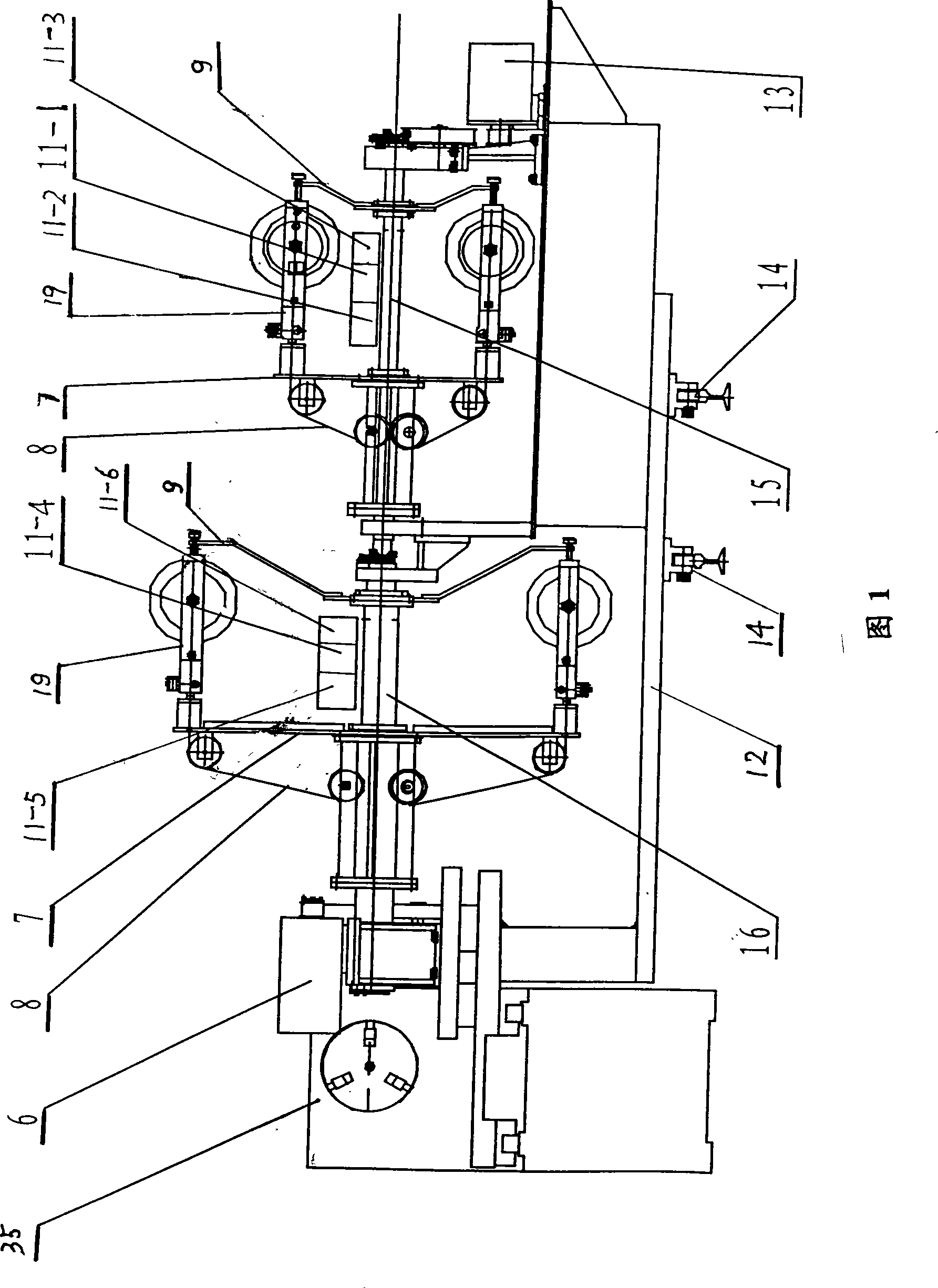

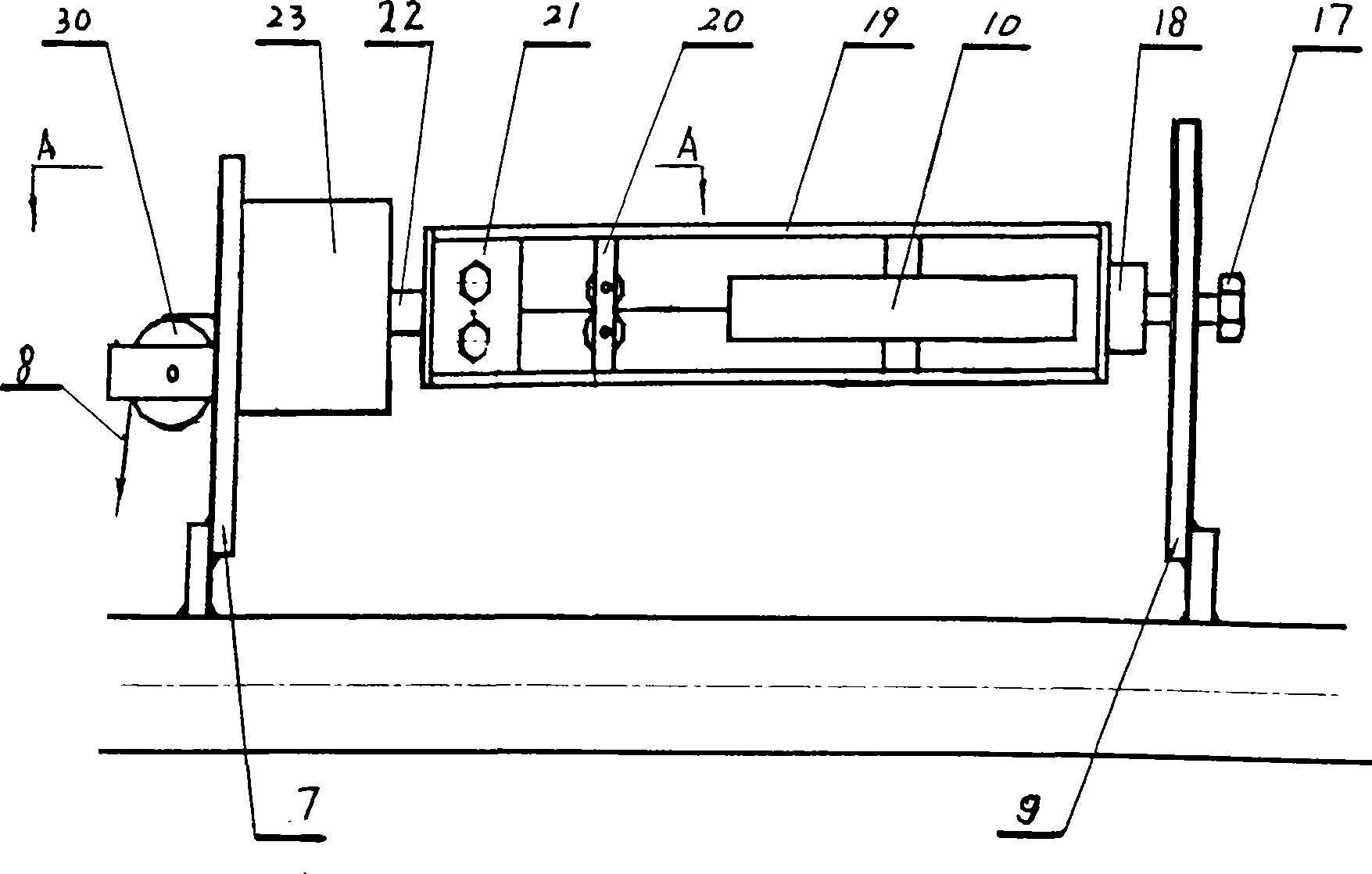

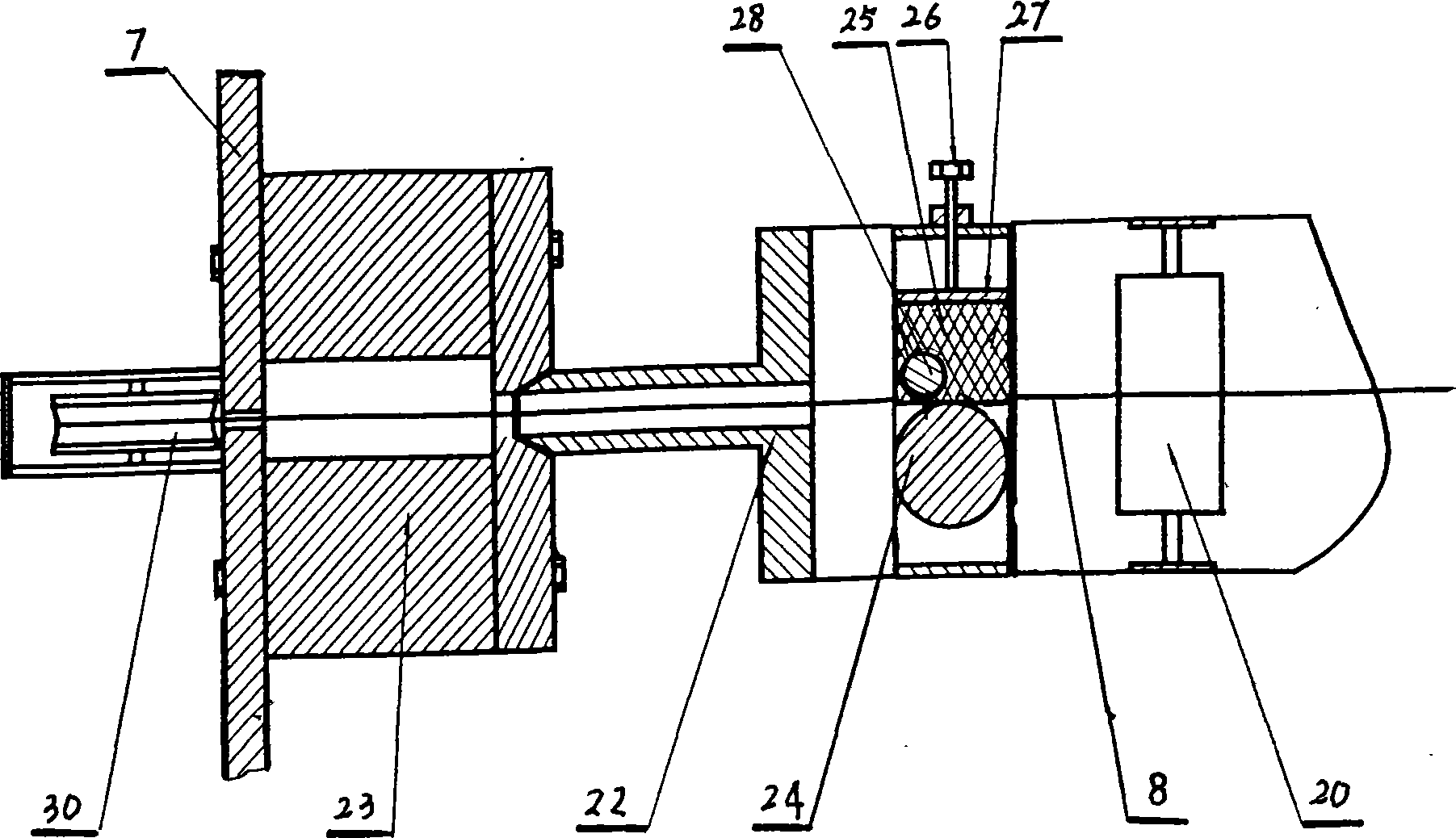

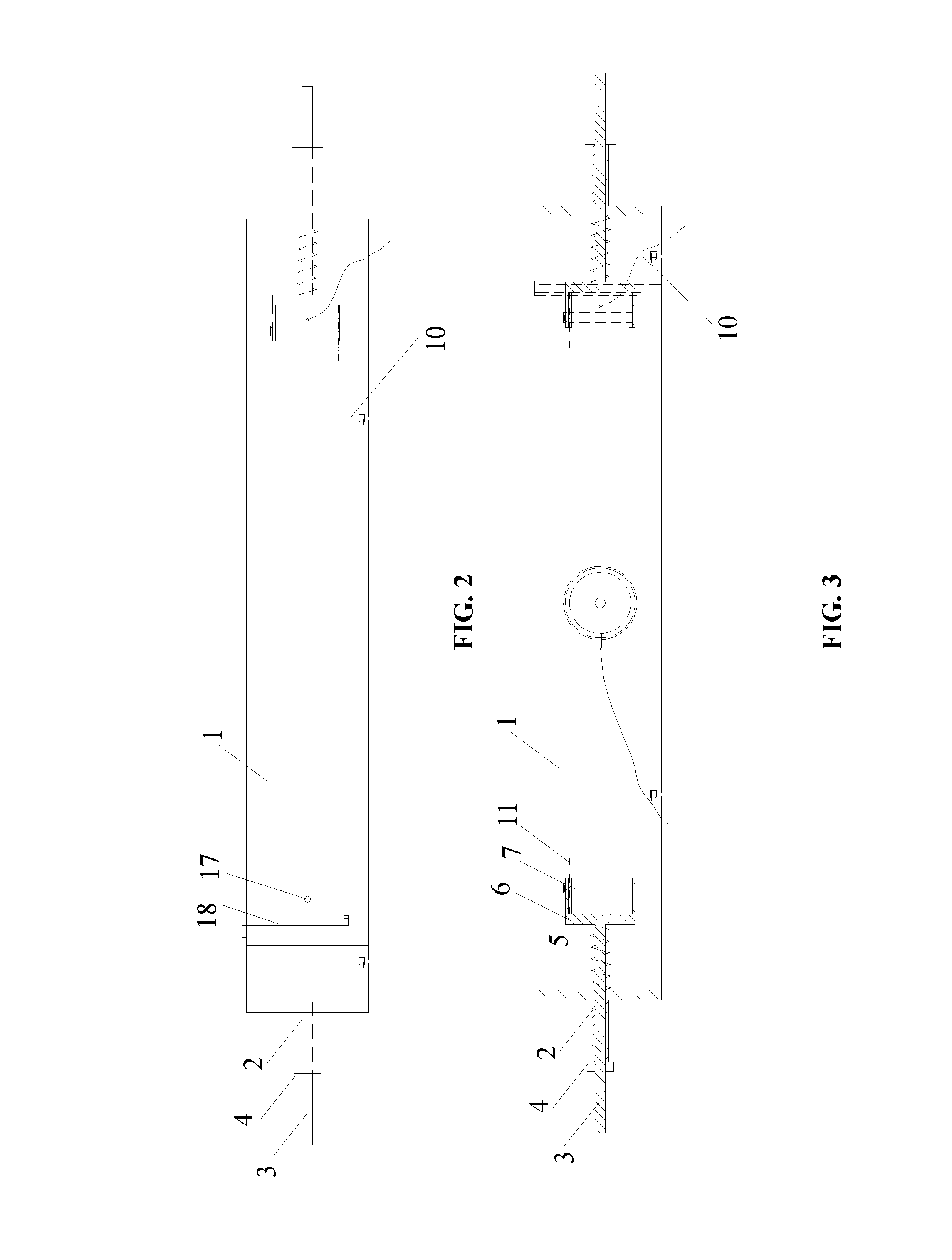

Control system of thread winding machine

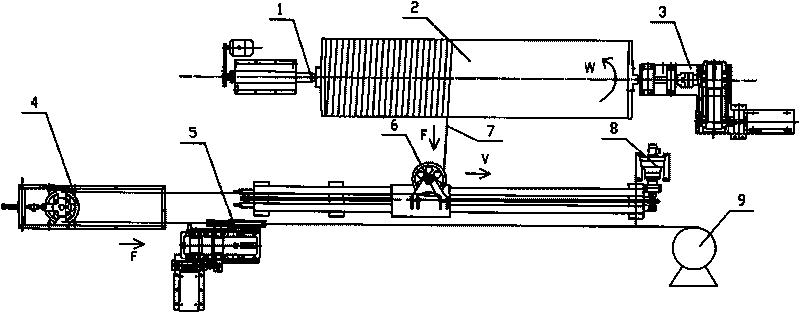

The invention relates to a thread winding machine used for producing prestressed concrete tubes and provides a control system of a thread winding machine, which not only can wind threads during feeding, but also can wind the threads during returning. The control system comprises a controller, a cement tube rotating drive device, a winding displacement device, winding displacement device running guide rails, a force measuring device and a stress device generating a set pull force on the threads, wherein the cement tube rotating drive device, the winding displacement device, the force measuring device and the stress device are connected with the controller; the winding displacement device comprises a thread-guide trolley and a driving motor for driving the thread-guiding trolley to reciprocate at the constant speed relative to the cement tube; the cement tube rotating drive device drives the cement tube to operate according to the set rotating speed to enable the threads to be wound on the cement tube according to the set thread pitch; and the controller is internally provided with an instruction stress device for changing the stress and a regulating circuit for ensuring that the stress of the thread-guiding trolley acted on the threads in the returning and feeding process is basically consistent.

Owner:JIANGSU JIANGYANG BUILDING MATERIAL MACHINERY

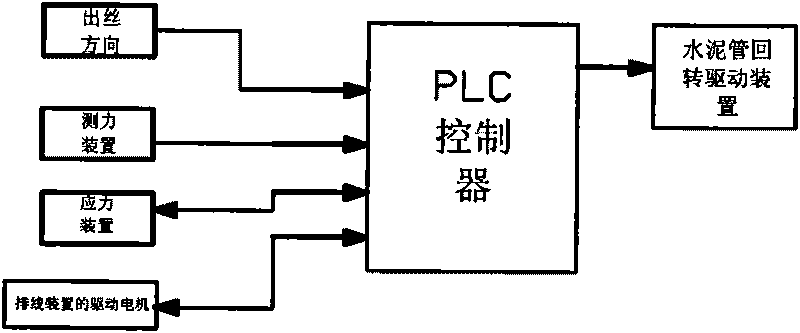

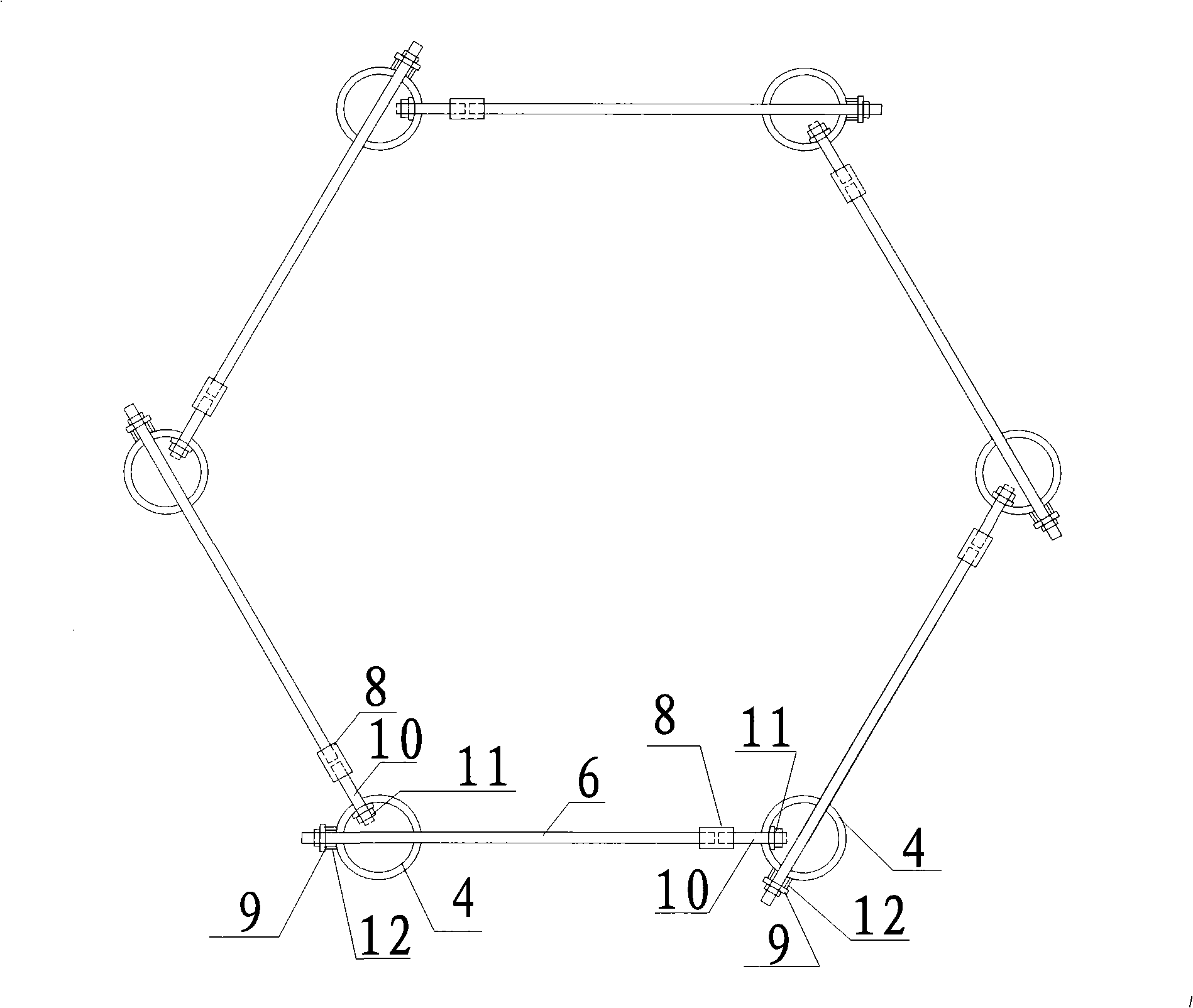

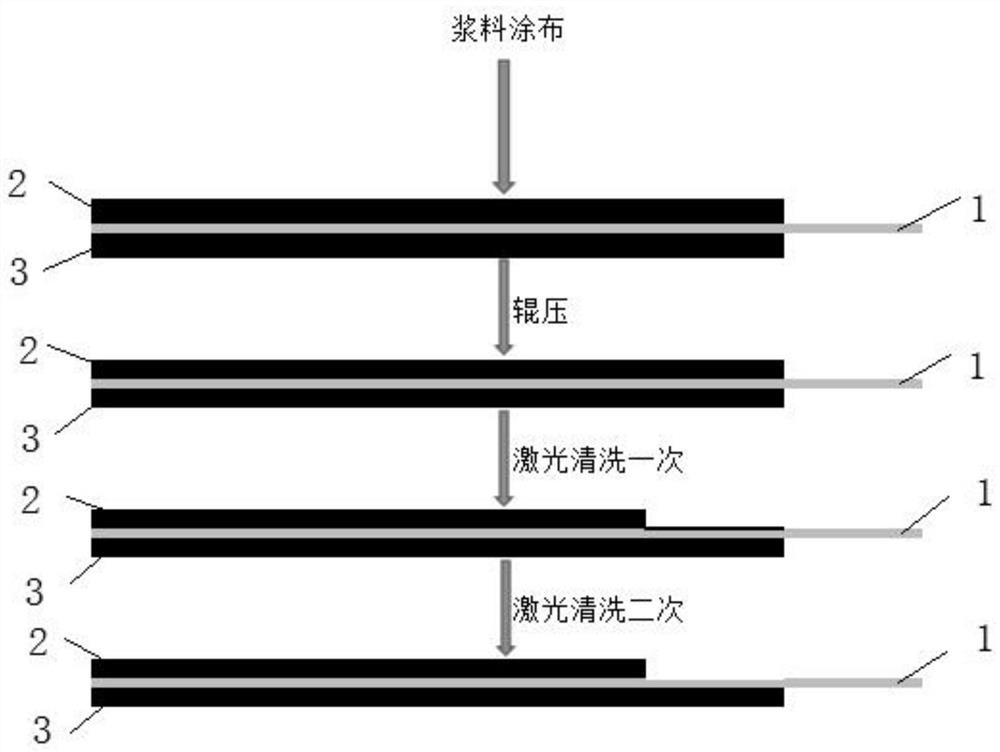

Connecting structure for suspendome

InactiveCN101314972AEasy to processEasy to installBuilding roofsArched structuresSpherical jointScrew thread

The invention discloses a connecting structure used for a suspend-dome structure. The suspend-dome structure is a structure formed by connecting an upper chord single-layer spherical reticulated shell, an oblique cable and hoop cables through a vertical compression rod. In the connecting structure, the oblique cable, the hoop cables and the vertical compression rod are connected with each other through a welded hollow spherical joint. The welded hollow spherical joint forms three holes in the horizontal hoop cable direction, wherein two holes allow one hoop cable to penetrate the welded hollow spherical joint and be anchored through a cast anchor, the other hole allows a washer inside the welded hollow spherical joint to be anchored with a screw cap to form a connecting cable head, and the connecting cable head is connected with a threaded sleeve through the other hoop cable; the welded hollow spherical joint forms the other hole in the oblique cable direction, the washer used inside the welded hollow spherical joint is anchored with the screw cap to form the other connecting cable head, and the connecting cable head is connected with the hoop cables through the threaded sleeve. After the connecting structure is adopted, the construction of the suspend-dome structure is very convenient, the cable force can be adjusted times and again, and the disadvantage that the cable force in the prior suspend-dome structure engineering is difficult to be consistent with the theoretical value can be overcome.

Owner:ZHEJIANG UNIV

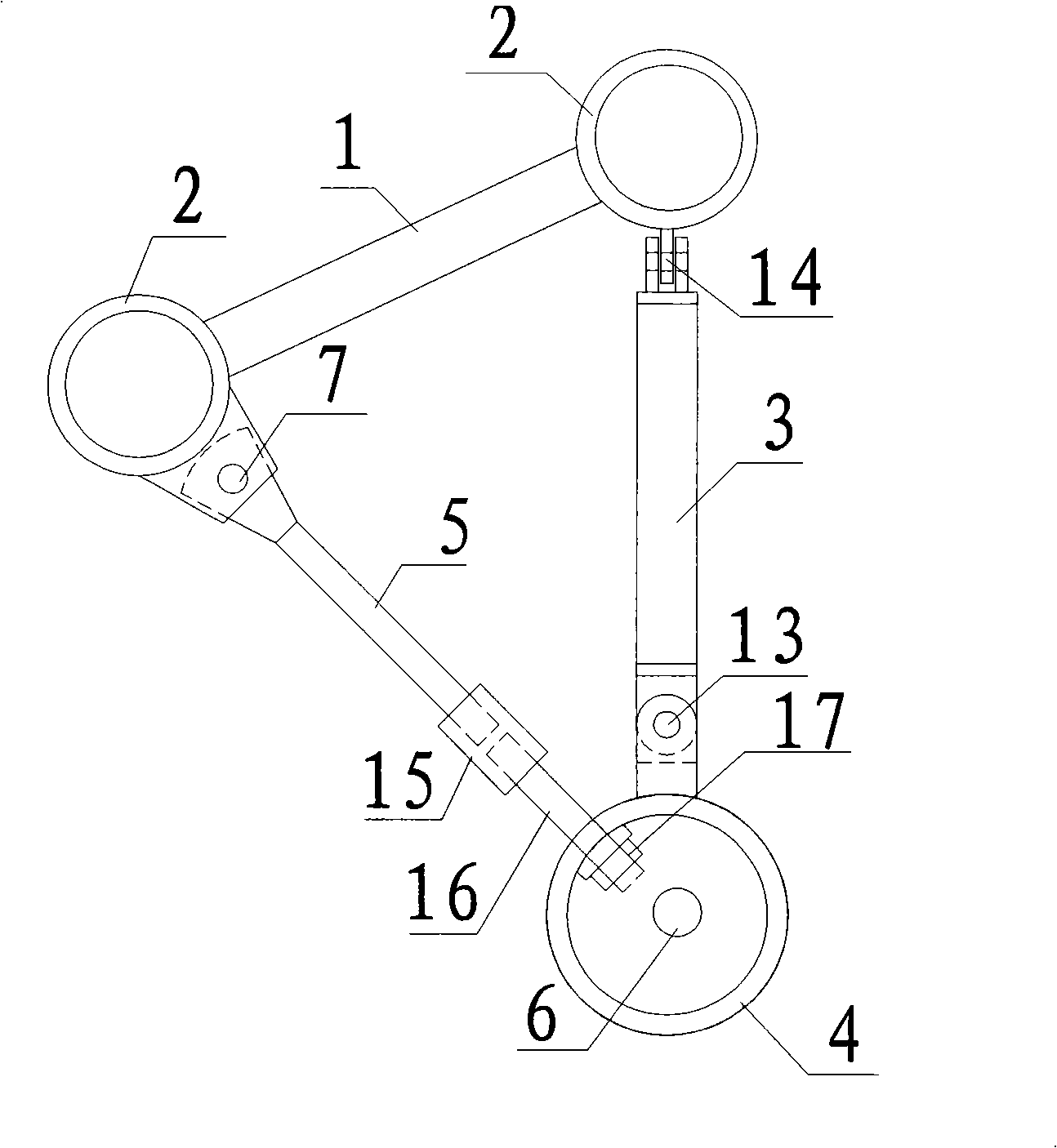

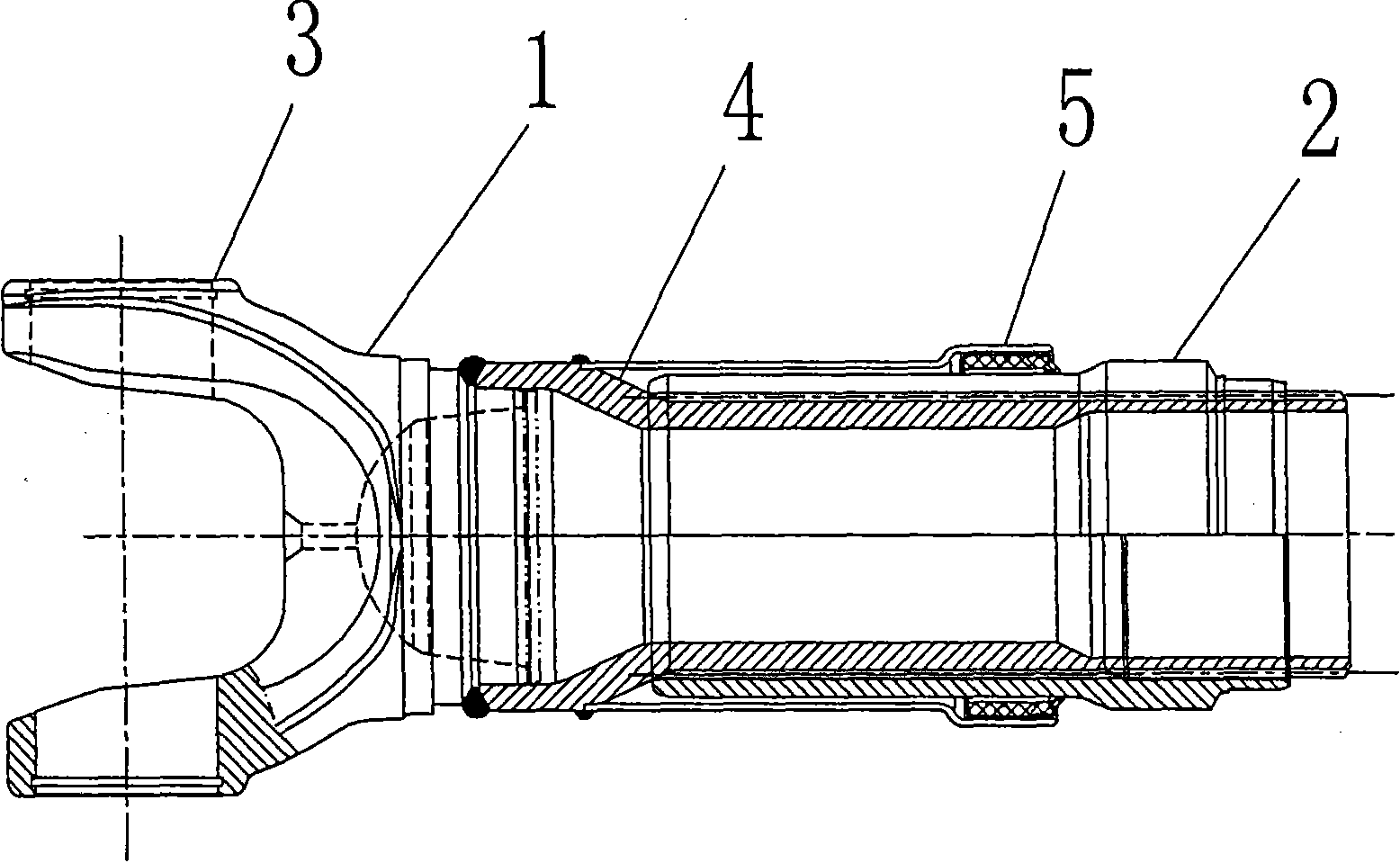

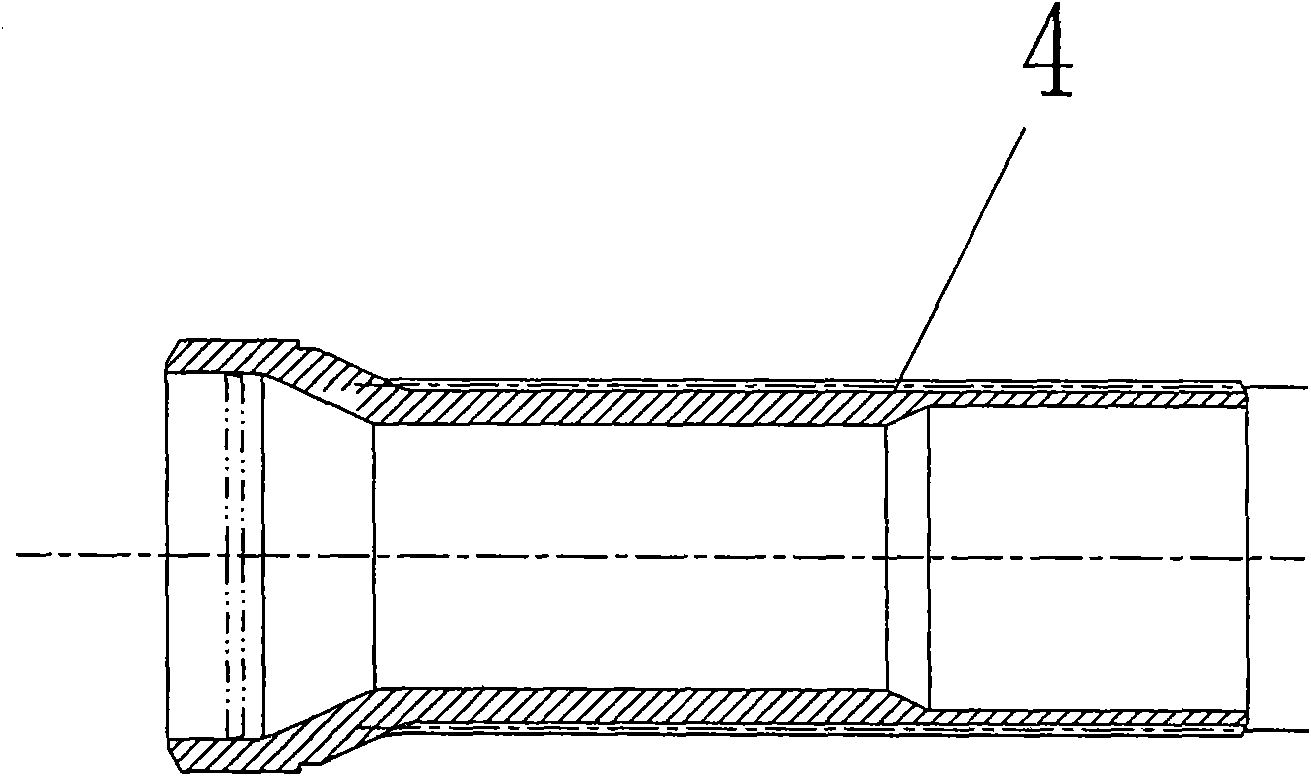

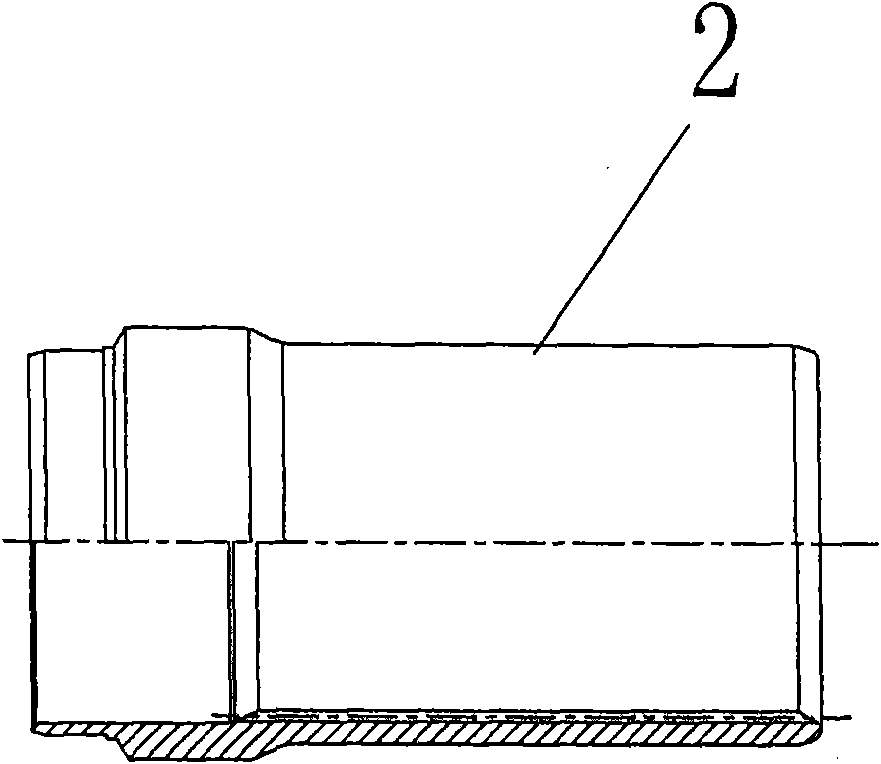

Spline pair of hollow shaft fork

InactiveCN101852251AReduce weightConsistent stressYielding couplingCouplings for rigid shaftsEngineeringMechanical engineering

The invention relates to a spline pair of a hollow shaft fork. The spline pair mainly comprises a spline shaft fork and an internal splined sleeve, wherein the spline shaft fork consists of a welding fork and an external splined sleeve; the internal splined sleeve is sleeved outside the external splined sleeve and matched with the external splined sleeve; and the external splined sleeve has a hollow structure. The spline pair has the advantages that: the weight for the raw materials of the spline fork can be reduced by 37.7 percent; and after a mathematical model is established to perform static stress analysis by using CAE software, the stress is only increased by about 5 percent while the weight of the hollow spline shaft is reduced by 37.7 percent. The fact shows that the strength of the hollow spline shaft fork is substantially the same as that of a solid spline shaft fork while the weight is greatly reduced, namely the hollow spline shaft fork has higher comprehensive performance; and meanwhile, the structure ensures higher working performance for the spline pair.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

Method and device for decreasing offset voltage of Hall integrated circuit

InactiveCN101290946AReduce the impactManufacturing process variations affect consistentSolid-state devicesSemiconductor devicesElectrical conductorEngineering

The invention relates to a method for reducing the misalignment voltage of a hall integrated circuit. The method is as follows: a hall unit array is positioned on the central part of a chip and other circuit devices which serve hall units are arranged on the circumference of the hall unit array and in parallel connection with the hall units; the circumference of each hall unit is enclosed by an isolation belt and an epitaxial layer which are formed by heavy doping; involved devices comprise a semiconductor P type substrate and a light-dope semiconductor N type epitaxial layer which is grown on the semiconductor P type substrate; a heavy-dope semiconductor P type isolation belt is also arranged on the semiconductor N type epitaxial layer; and the isolation belt divides the semiconductor N type epitaxial layer into at least three isolated hall units which are centrally symmetrically arranged arrays. The method can make affection of stress, pressure and so on of the chip edge on the hall devices be consistent, make affection of other devices on the circumference of the hall units on the misalignment voltage of the hall units smaller, make affection of deviation of the manufacturing technique on the hall units be consistent, and have better matching property.

Owner:WUXI POWERSILICON TECH

Heating method of heating furnace for glass tempering

ActiveCN102690048AShorten the radiation distanceHeating fastGlass tempering apparatusGlass productionEngineeringHeating furnace

The invention provides a heating method of a heating furnace for glass tempering; air in the heating furnace is driven by a high temperature blower fan to flow circularly so as to take away heat generated by an electric heating element; the air is pressurized and injected onto a surface of glass to be processed; and thus heating in a convection heating manner is realized; the heat generated by the electric heating element is also transmitted to the surface of the glass to be processed through radiation heating; during the heating process, the glass to be processed is heated in a main manner of convection heating; when the glass to be processed is heated to a temperature near a glass softening temperature, the glass to be processed is heated in a main manner of radiation heating till the glass to be processed reaches a temperature at which tempering can be completed. With the heating method, using the characteristic that convection heating is faster than radiation heating, the temperature of the glass to be processed is increased quickly; and with the characteristic that matrix radiation heating of a device allows regional temperature adjustment, each part of the glass to be processed can be heated to the temperature at which glass tempering can be completed.

Owner:LUOYANG NORTHGLASS TECH +2

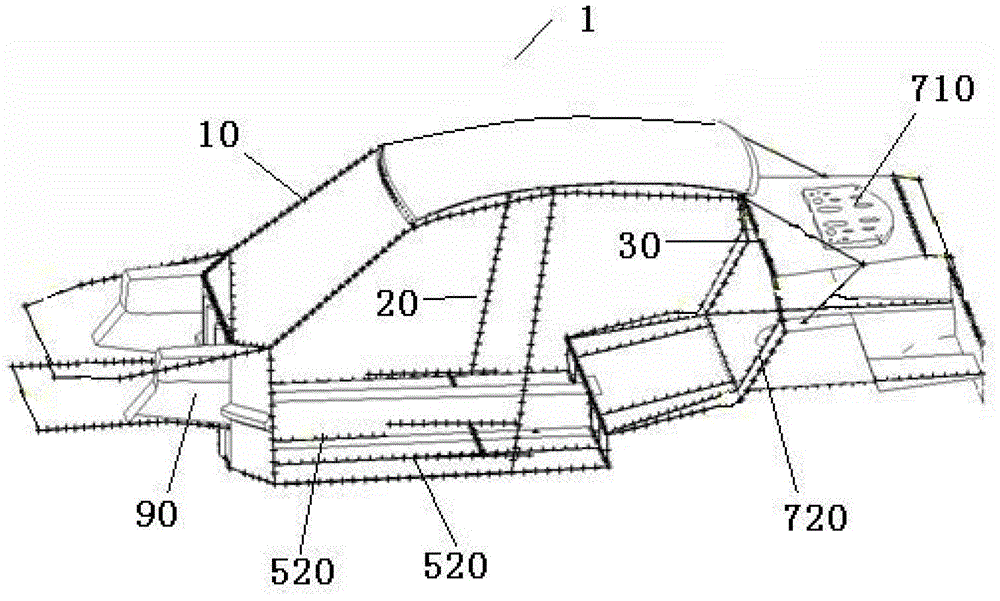

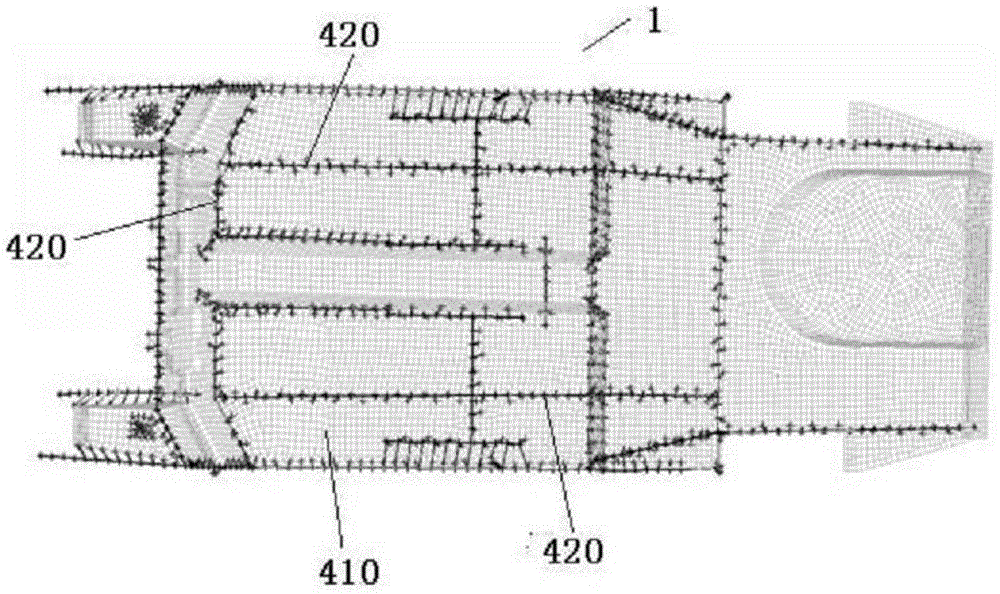

Method for building conceptual design model of white automobile body

InactiveCN104424371AReduce gapConsistent stressInternal combustion piston enginesSpecial data processing applicationsAutomotive engineeringConceptual design

The invention discloses a method for building a conceptual design model of a white automobile body. The method comprises the following steps: building conceptual models of corresponding structures of an upper automobile body by using a beam unit sequence, a plate shell unit and a rigid rod unit; building conceptual models of corresponding structures of lower automobile body by using the beam unit sequence, the plate shell unit and the rigid rod unit; building a conceptual model of a joint part by using a rigid rod unit and beam unit sequence connection mixing structure; building a conceptual model of a front coaming assembly by using topology optimization and topography optimization. According to the conceptual model which is built by the method for building the conceptual design model of the white automobile body, the corresponding rigidity and the corresponding stress distribution of the white automobile body can be more precisely simulated, and meanwhile, cross section and truncation databases are more easily constructed, and responses of the while automobile body to subsequent modifications on a cross section, a typical truncation, a model and the like can be reflected in more details.

Owner:BEIQI FOTON MOTOR CO LTD

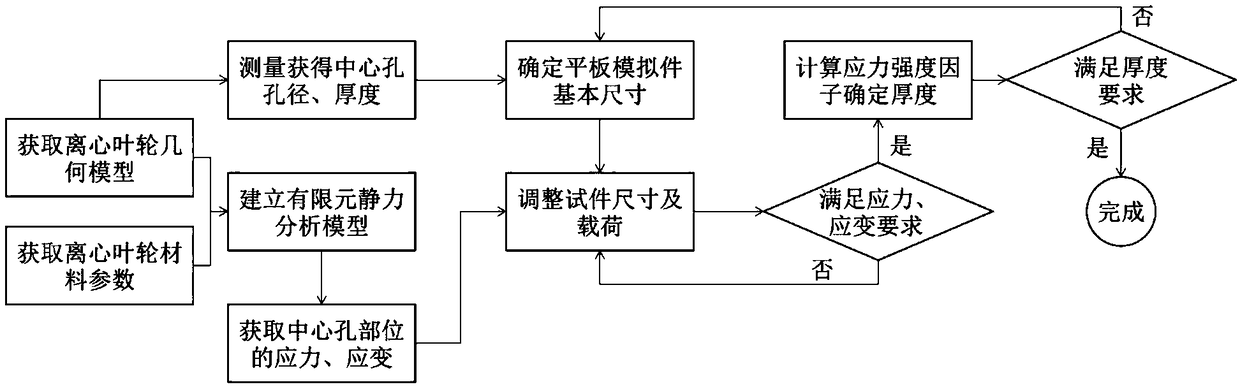

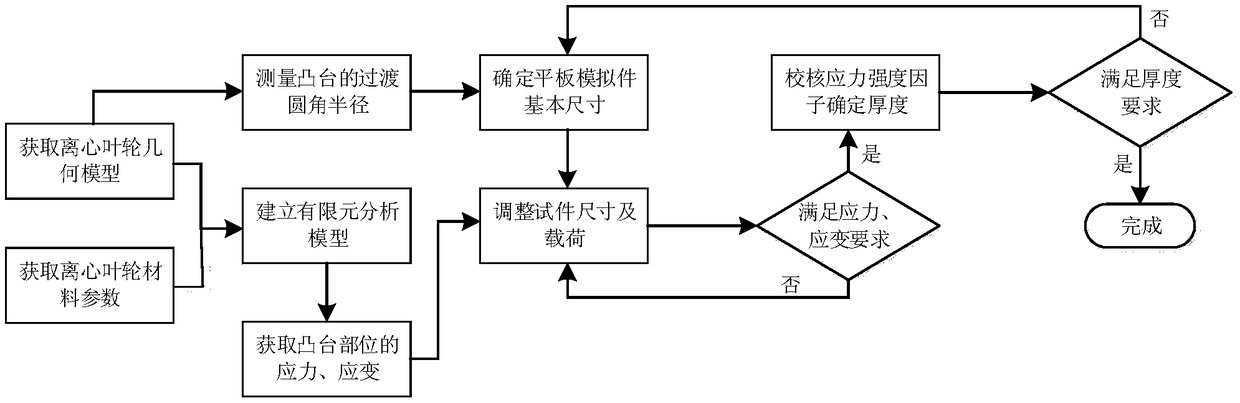

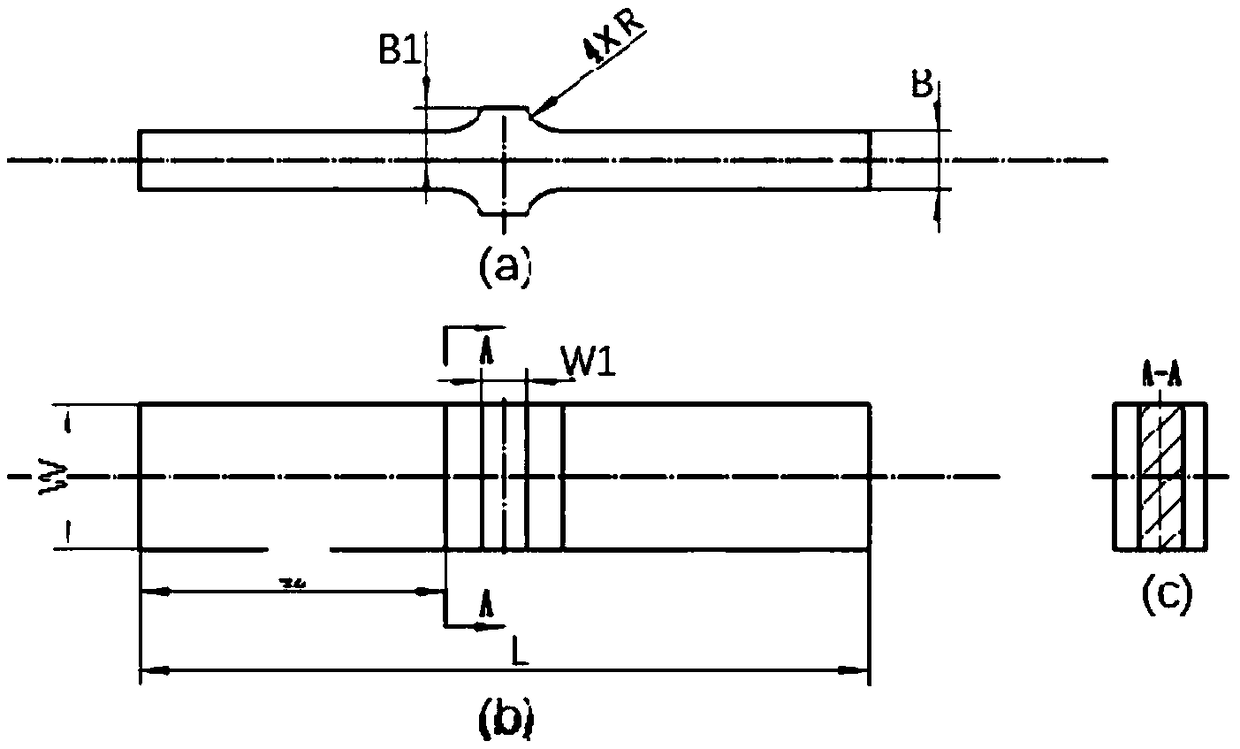

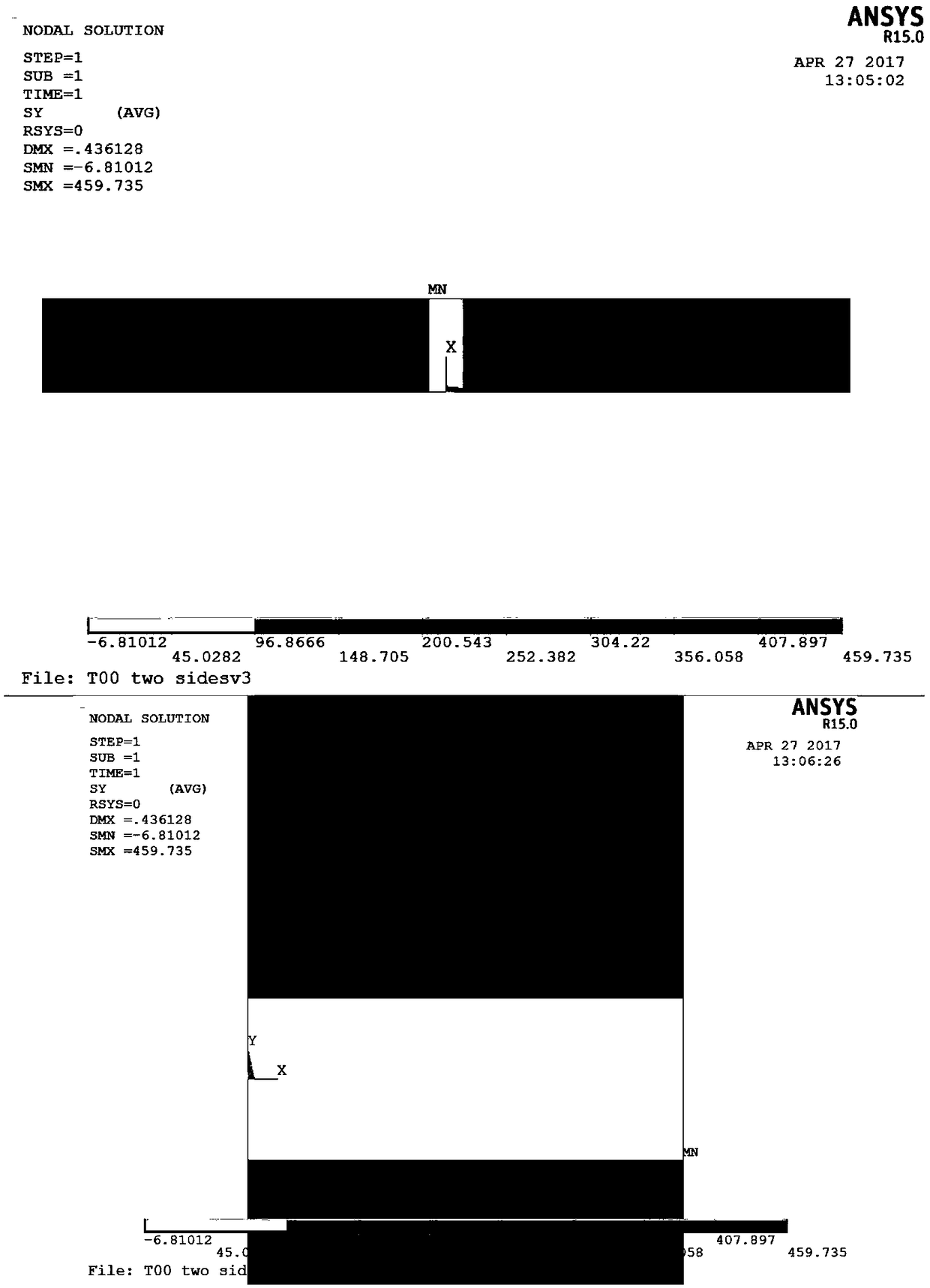

Method for designing crack propagation characteristic simulator of centrifugal impeller central hole

ActiveCN109063287AGuaranteed maximum pulling forceConsistent maximum pullGeometric CADDesign optimisation/simulationStress concentrationImpeller

A method for designing a crack propagation characteristic simulator of a central hole of a centrifugal impeller include such steps as obtaining a geometric model of that centrifugal impeller, measurea diameter and a thickness of the central hole structure, measuring the diameter and the thickness of the centrifugal impeller, measuring the diameter and the thickness of the centrifugal impeller, measuring the diameter and the thickness of the centrifugal impeller, measuring the diameter and the thickness of the centrifugal impeller, (2) obtaining the working conditions of the centrifugal impeller and the material performance parameters under the working conditions, including load, temperature, elastic modulus, yield strength and so on; (3) Establishing the finite element static analysis model of centrifugal impeller, calculating and obtaining the maximum circumferential stress point at the center hole of centrifugal impeller, and obtaining the circumferential stress value and the circumferential stress gradient of the point; (4) Based on the basic shape of the plate simulator with symmetrical circular notch, the central hole structure simulator is designed, so that the maximum stress along the direction of tensile loading on the stress concentration point of the simulator is equal to the maximum circumferential stress in the actual central hole structure, and the stress gradientis ensured to be the same; (5) Calculate the stress intensity factor of the simulator and determine the thickness of the simulator.

Owner:BEIHANG UNIV +1

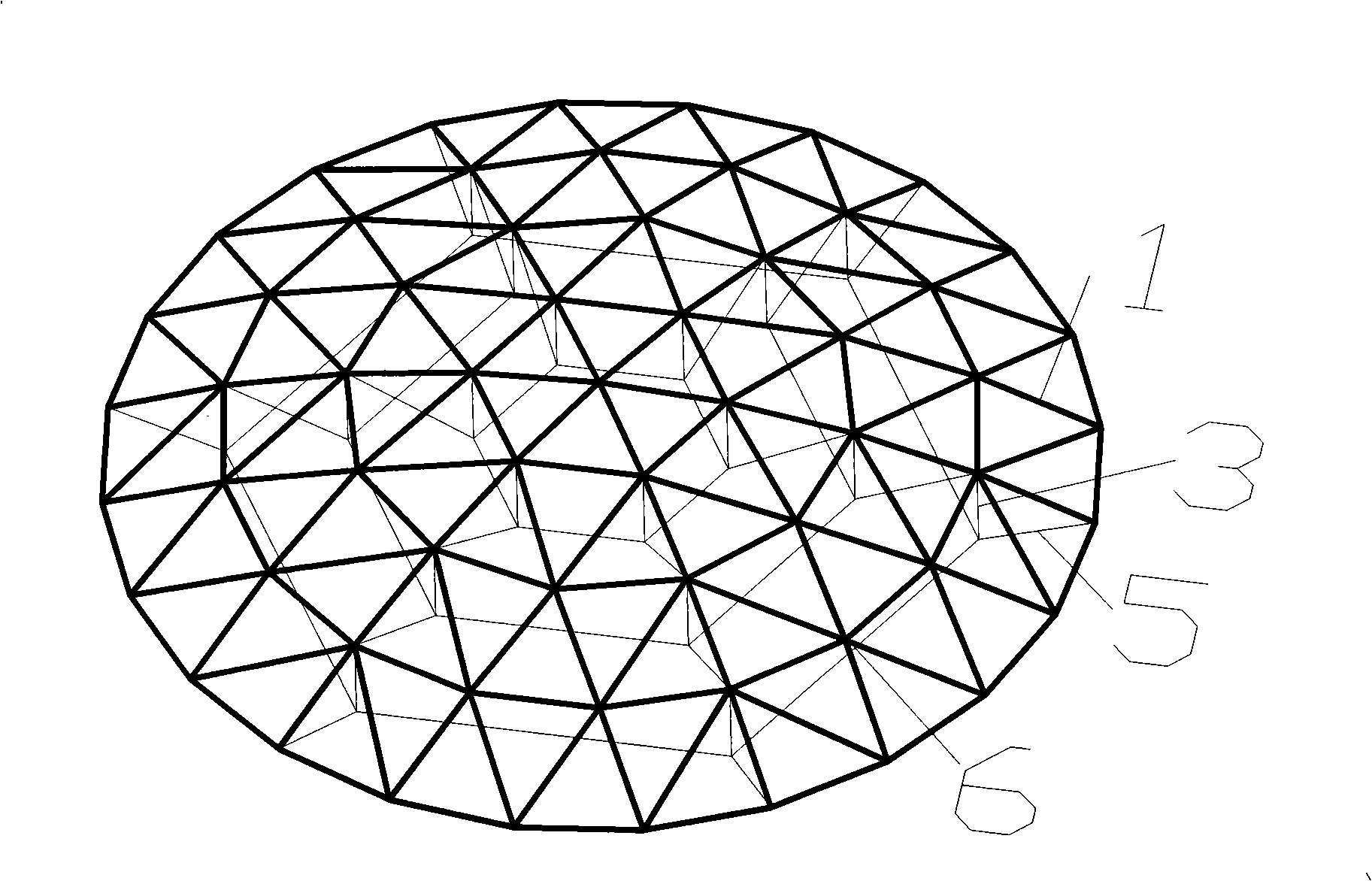

Steel wire tension control method and device for winding multi-strand helical spring

InactiveCN101458533AWork reliablyEasy passTransmission systemsMechanical pressure/force controlRadio receptionWire tension

The invention relates to a tension control device of wrapping manufacturing multi-strand coil spring steel wire which includes a steel wire tension adjusting and signal radiation part, a steel wire tension signal receiving displaying part; the steel wire tension adjusting and signal radiation part includes an inner layer steel wire rotary rack and an outside layer rotary rack, the inner / outside layer steel wire rotary racks are equipped with an individual rack; the individual rack inside is equipped with a force sensor, the steel wire is educed from a third directive wheel through the force sensor; the force sensor on each individual rack of the inner / outside layer steel wire connects with a tension measuring plate circuit and a radio sending circuit through lead; the steel wire tension signal receiving displaying part includes a radio receiving plate, a computer and a display. The device has advantages that each steel wire of wrapped spring has basic coincident tension by controlling each steel wire tension of multi-strand coil spring, spring working is reliable and working life is prolonged.

Owner:CHONGQING WANGJIANG IND

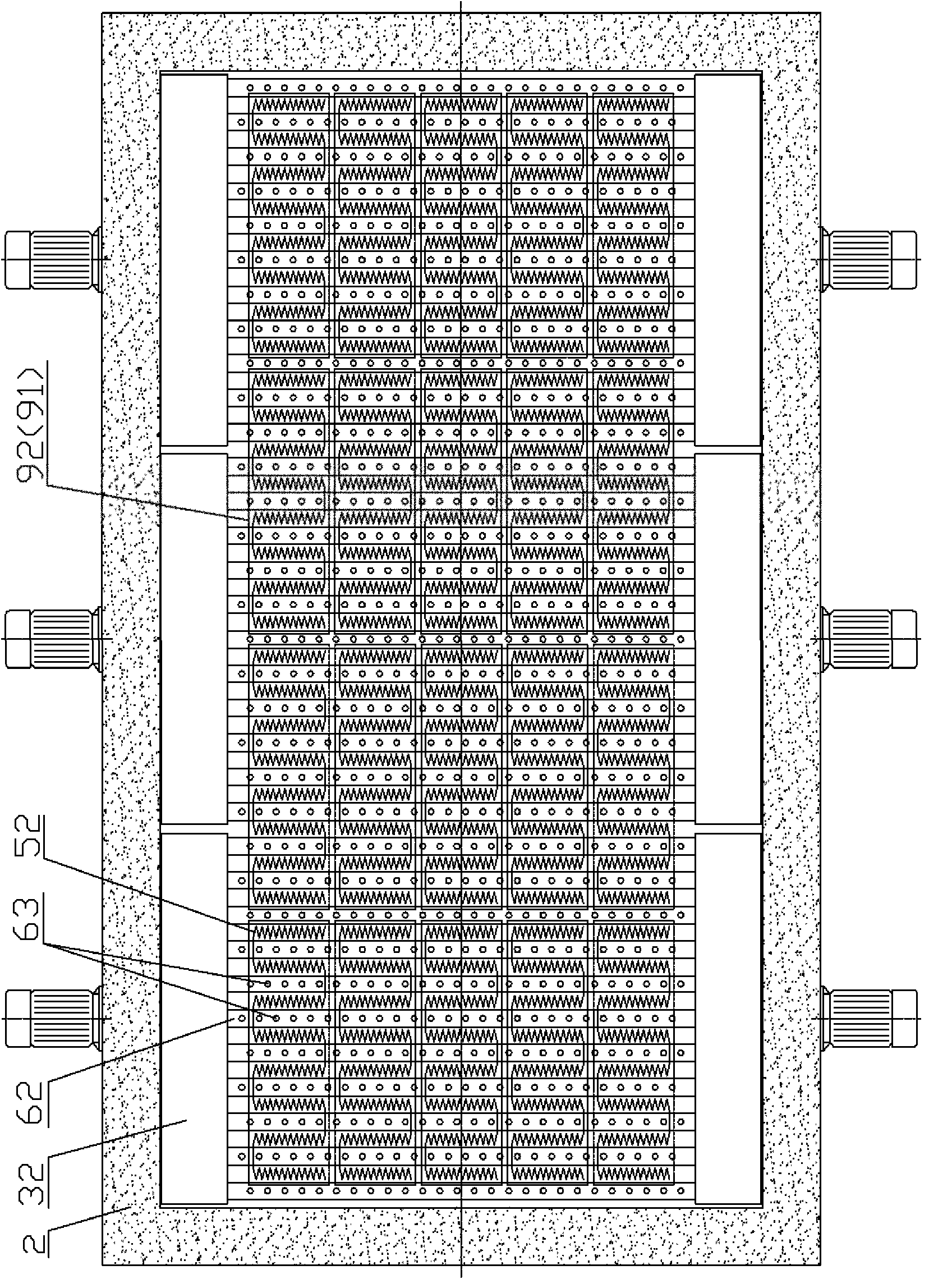

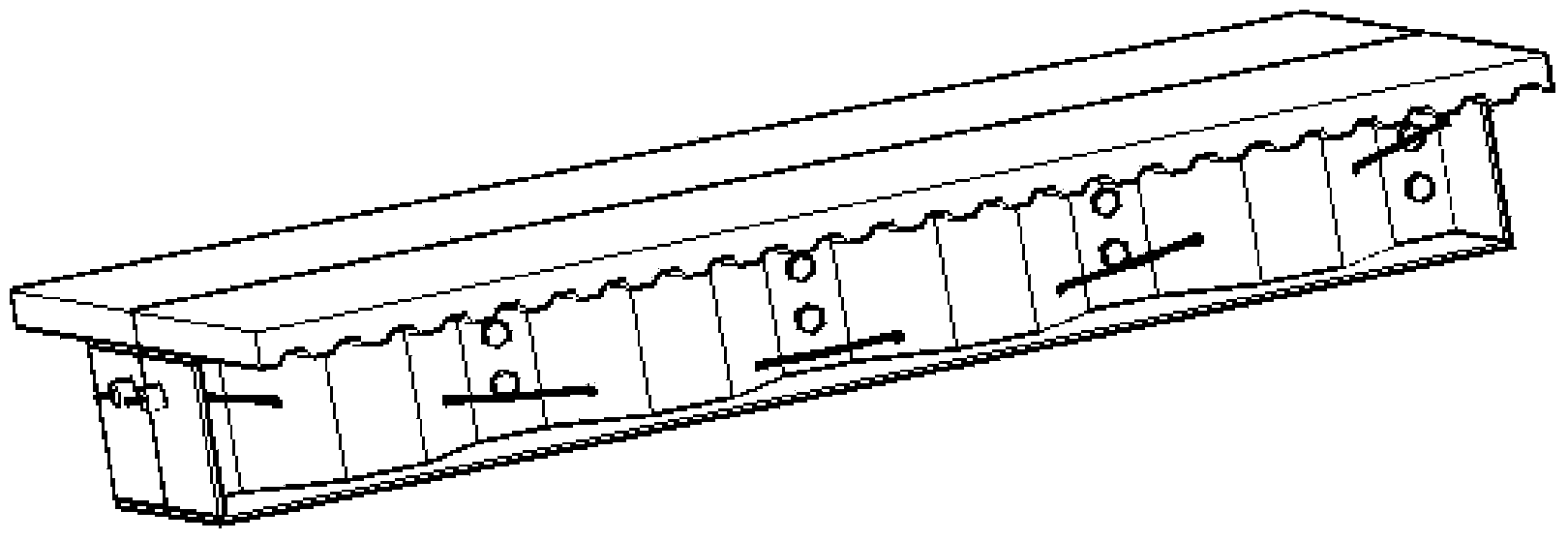

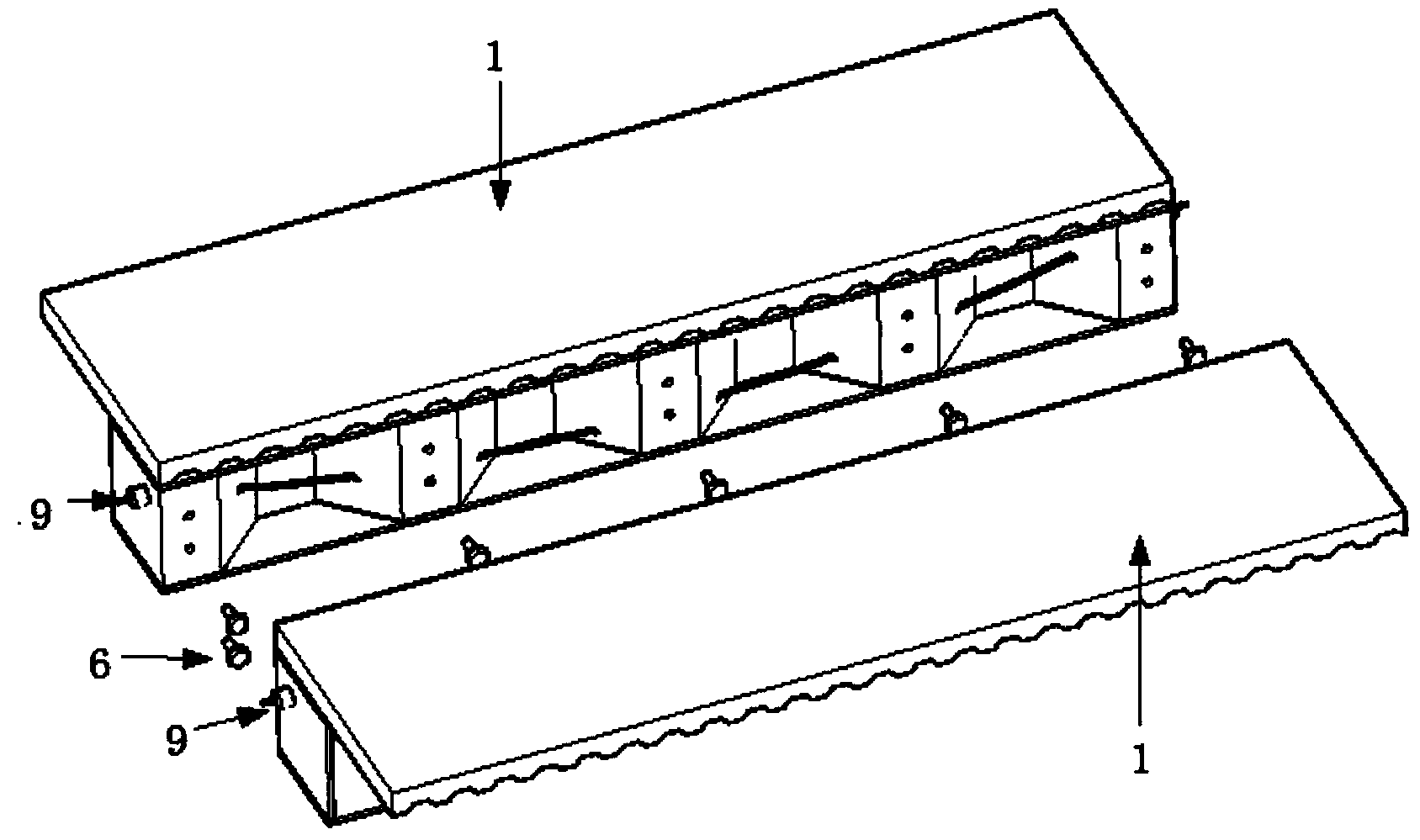

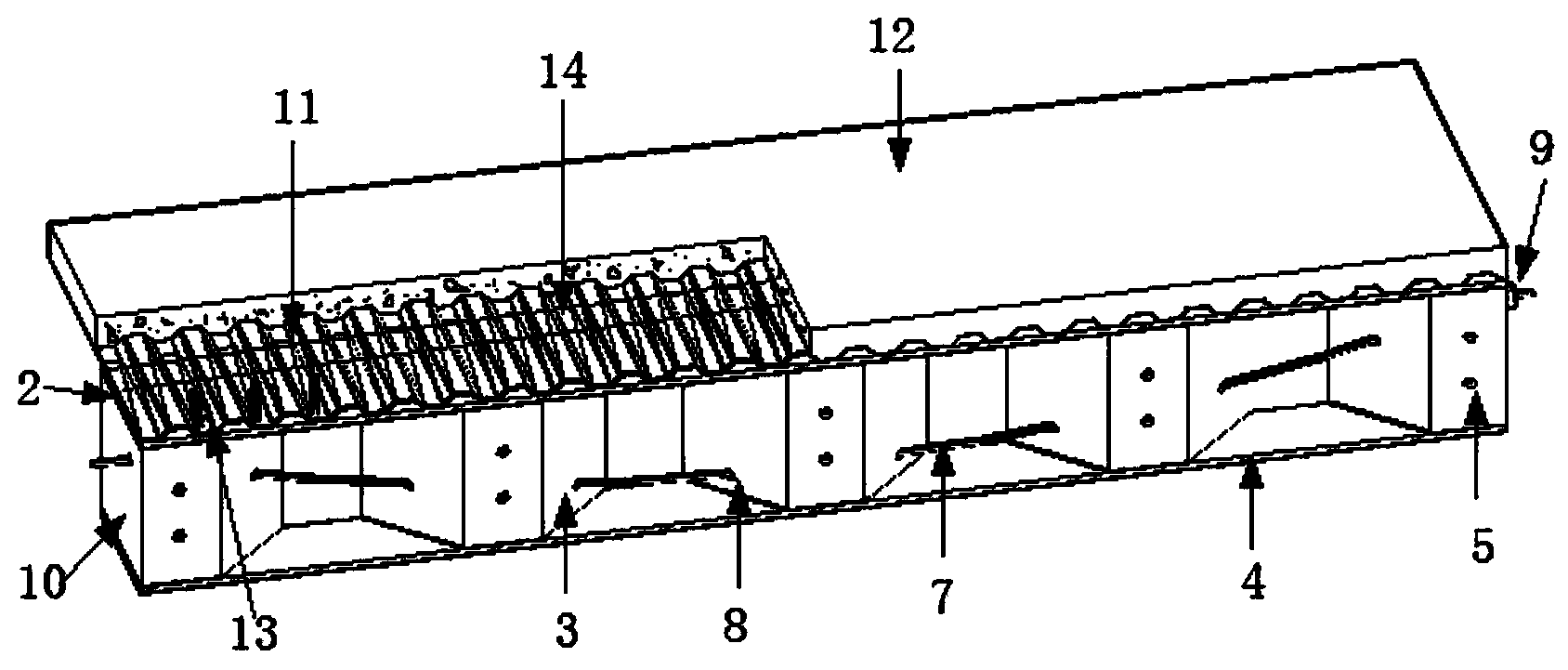

Assembly type prestress honeycombed web composite beam

The invention relates to an assembly type prestress honeycombed web composite beam. The assembly type prestress honeycombed web composite beam is assembled by two prestress corrugated web steel channel composite beam bodies through bolts. Each prestress corrugated web steel channel composite beam body is composed of a reinforced concrete wing plate, a profiled steel plate, an upper flange, one web, a lower flange, a prestressed cable, an anchor and a beam end plate. The fracture surface of each prestress corrugated steel channel composite beam body is composed of the reinforced concrete wing plate, the profiled steel plate, the upper flange, the lower flange and the webs. The fracture surface of each web is in even or uneven wave shape repeated periodically, and each prestressed cable penetrates through the webs and the beam end plate and is tensioned and then fixed to the beam end plate through the anchor. The plane of each web is arranged to be honeycombed to obtain the optimum effect in overall bearing capacity of the component, and the assembly type prestress honeycombed web composite beam is an innovation-type assembly type prestress section steel composite beam which is suitable for an assembly type steel structural system and particularly suitable for a large-span multi-story or high-rise assembly type steel structural system. Compared with a traditional assembly type beam, the assembly type prestress honeycombed web composite beam has the advantages of being light in self weight, high in bearing capacity, large in span and the like.

Owner:BEIJING UNIV OF TECH

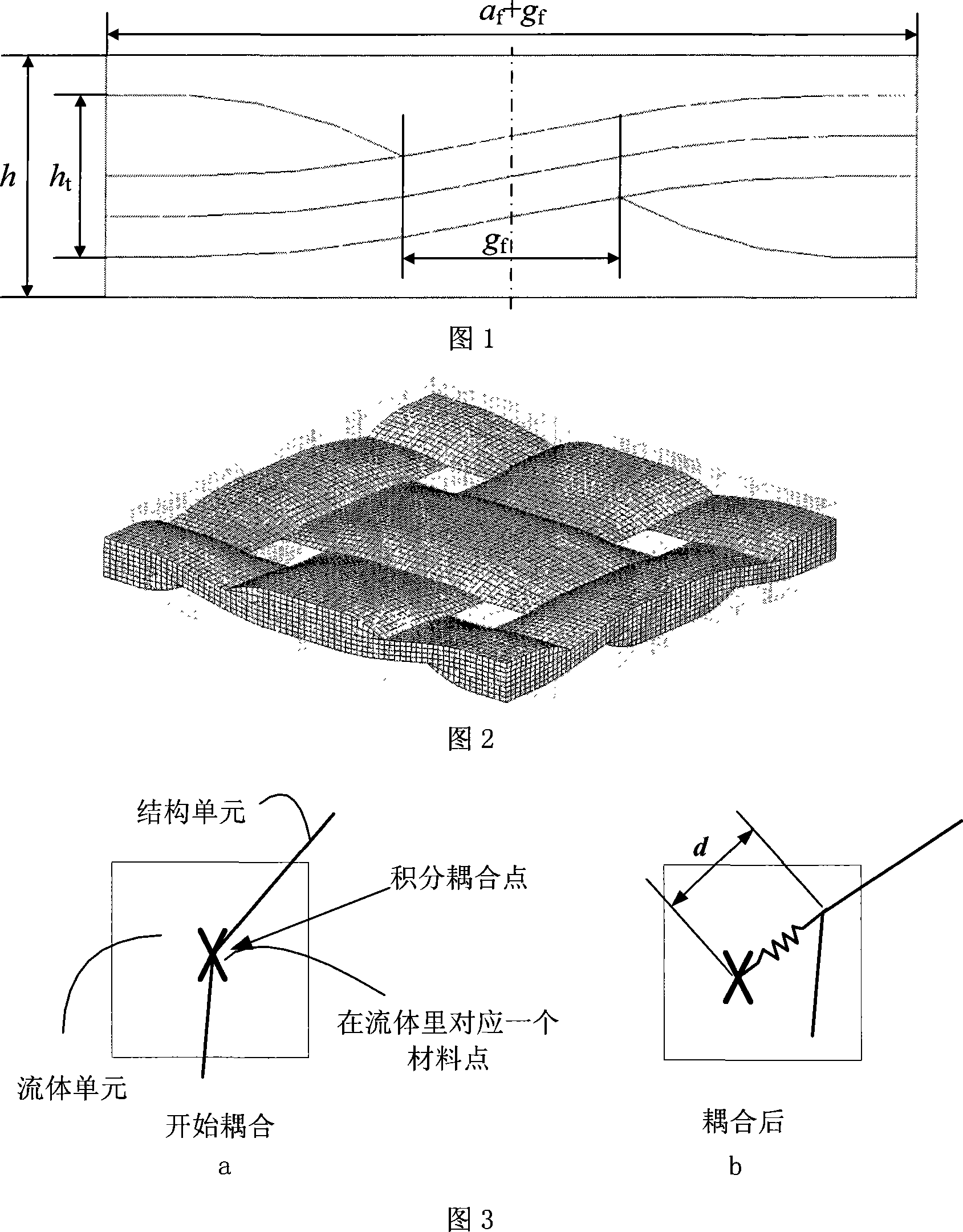

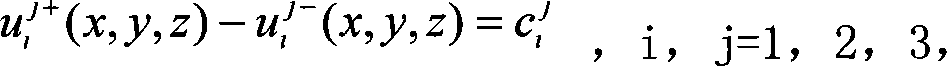

Compound material liquid storage container performance multi-dimension testing method

InactiveCN101178341AReliable macro performance test resultsGuaranteed accuracyComplex mathematical operationsStrength propertiesImaging processingDrop tests

The invention relates to a method for multi-scale detection of a composite material liquid storage container. The steps are: obtaining the mesoscopic geometric shape of the material through optical equipment, using image processing technology to extract the mesoscopic geometric parameters of the material; The three-dimensional reconstruction method is used to establish the material unit cell, and the comprehensive performance parameters of the material are predicted by loading the periodic boundary conditions; the composite material liquid storage container model is established by using the material comprehensive performance parameters and the design size of the liquid storage container. The fluid-solid coupling is realized in the form of a function, and the safety detection of the collision impact of the liquid storage container is carried out with the numerical reproduction of the airdrop test; for the damaged area of the liquid storage container, the microscopic damage behavior of the material is detected through the unit cell model, and the macroscopic damage behavior of the composite material is obtained. performance parameters. The invention solves the performance detection problem of the composite material liquid storage container, greatly shortens the equipment development time, and reduces the randomness of experiments and capital investment.

Owner:SHANGHAI JIAO TONG UNIV

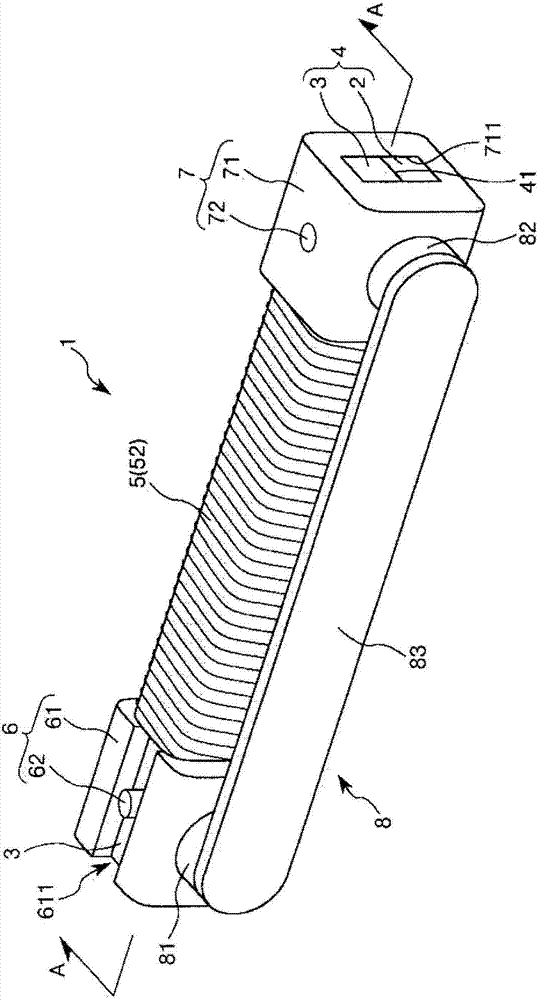

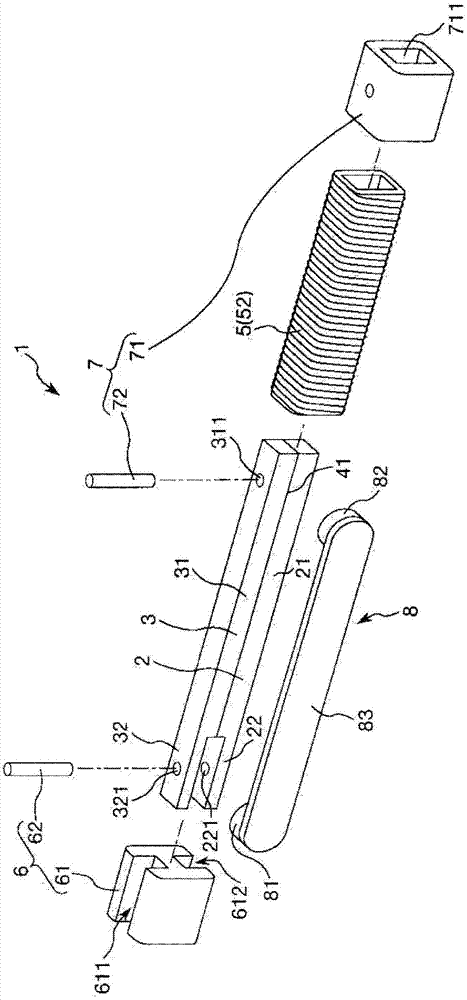

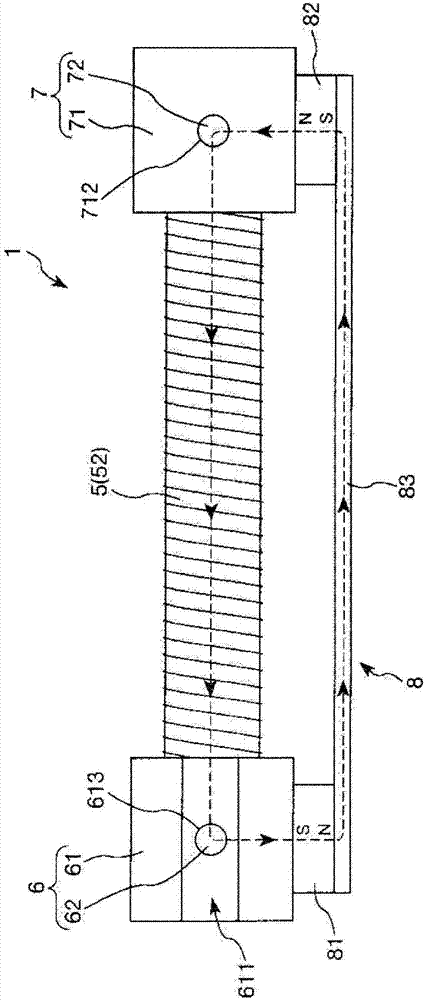

Power generating element

InactiveCN104508968AConsistent stressImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive device detailsEngineeringNon magnetic

Owner:MITSUMI ELECTRIC CO LTD

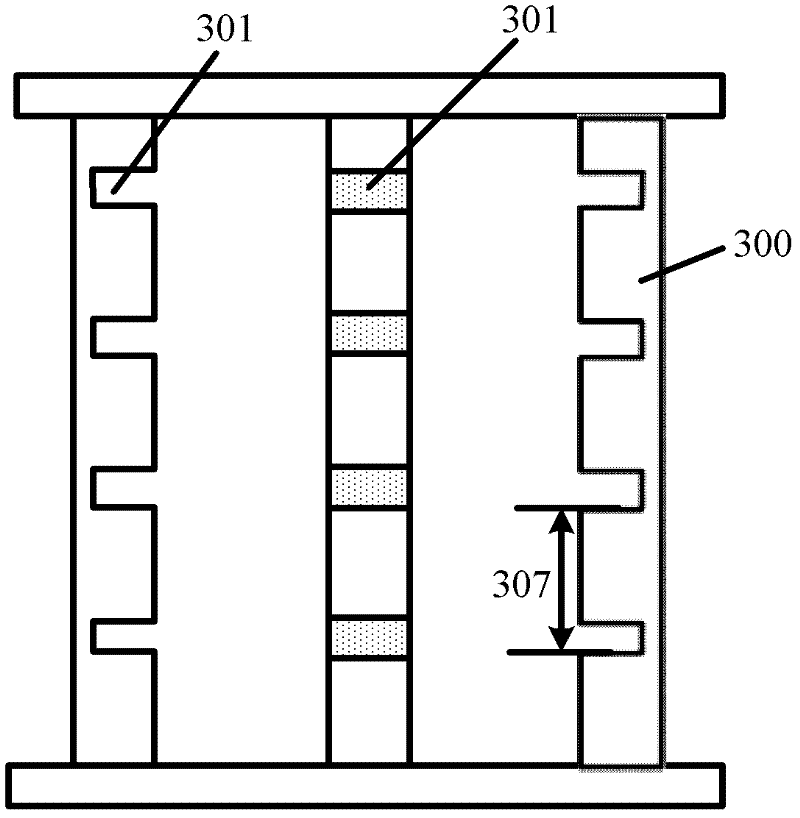

Integrated water tank type crystallizer used for casting 7 series extra super duralumin alloy

The invention provides an integrated water tank type crystallizer used for casting 7 series extra super duralumin alloy, relating to a crystallizer. The invention solves the problem that cast ingot produces cracks caused by stress concentration as the existing crystallizer is not even in water-cooling distribution. The cross section contour of the flat through hole is composed of two arc sections and two straight line sections, each arc section is formed by butt joint of two arcs in different diameters; the lower end face of all the side walls of crystallizer tank body is opened with an annular groove, the lower end face of the annular water feeding hole wall body between the annular groove and the flat through hole is opened with a plurality of osculums in uniform distribution, the lower end of each osculum is inclined toward the central axis of the flat through hole; and four clapboards are respectively arranged at the two ends of the annular groove and divide the annular groove into four regions. The crystallizer of the invention adopts four-section design and different diameters of osculums to control water flow, so that cooling of cast ingot is even, temperature is ensured to be consistent with stress field distribution, and cast ingot crack tendency is greatly reduced.

Owner:NORTHEAST LIGHT ALLOY CO LTD

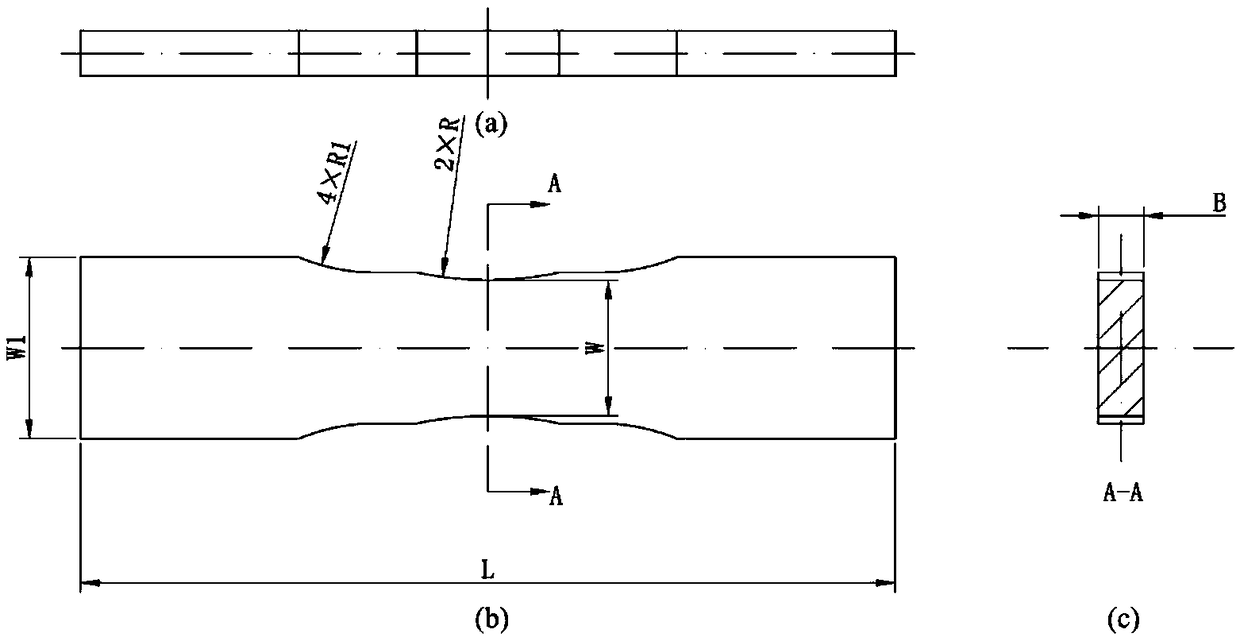

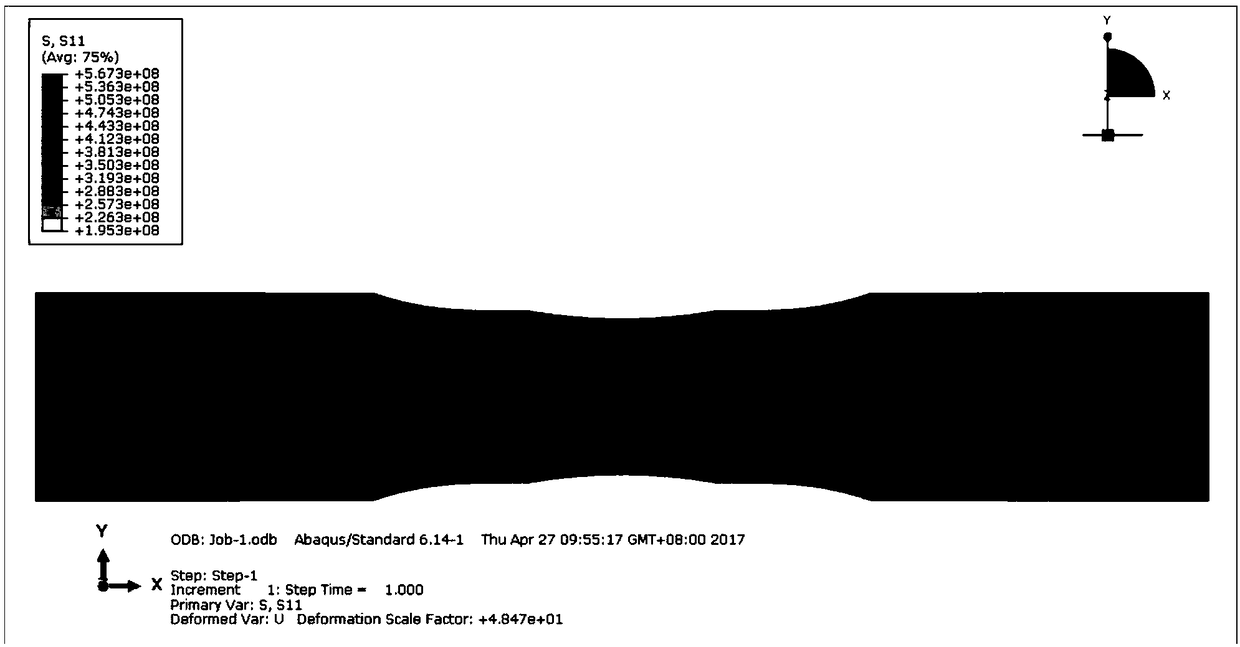

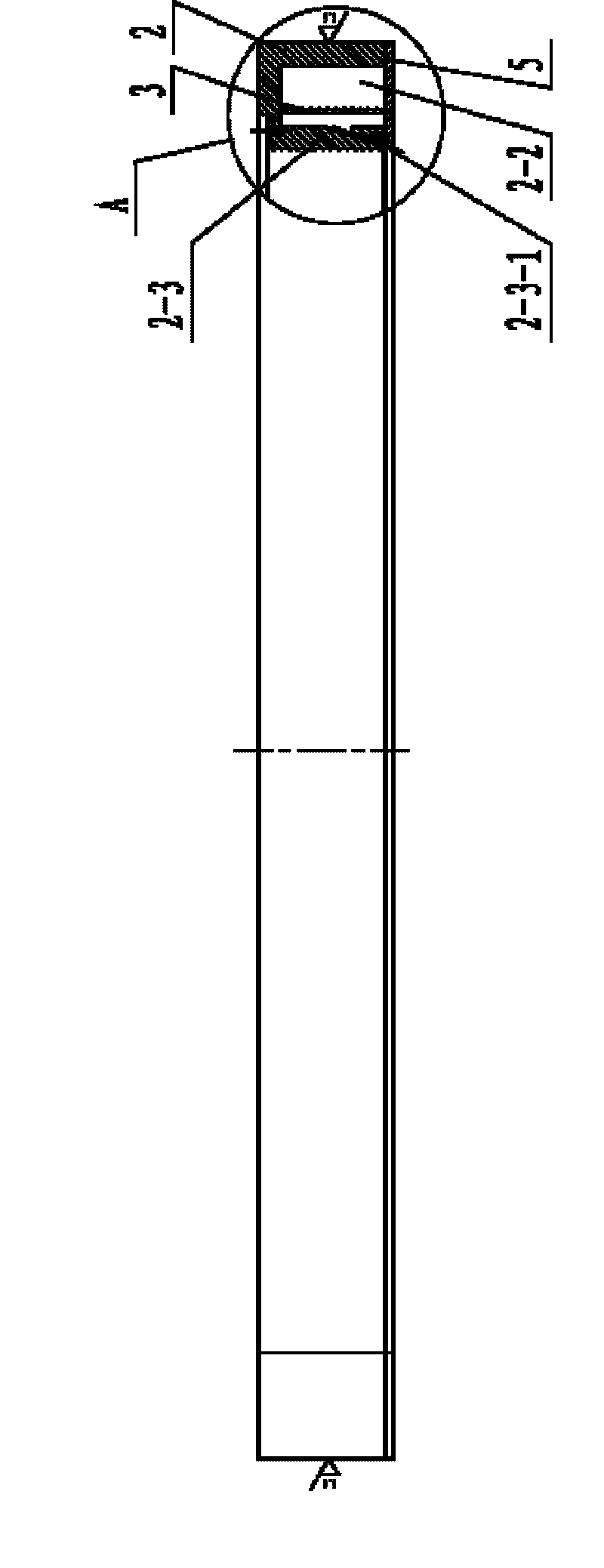

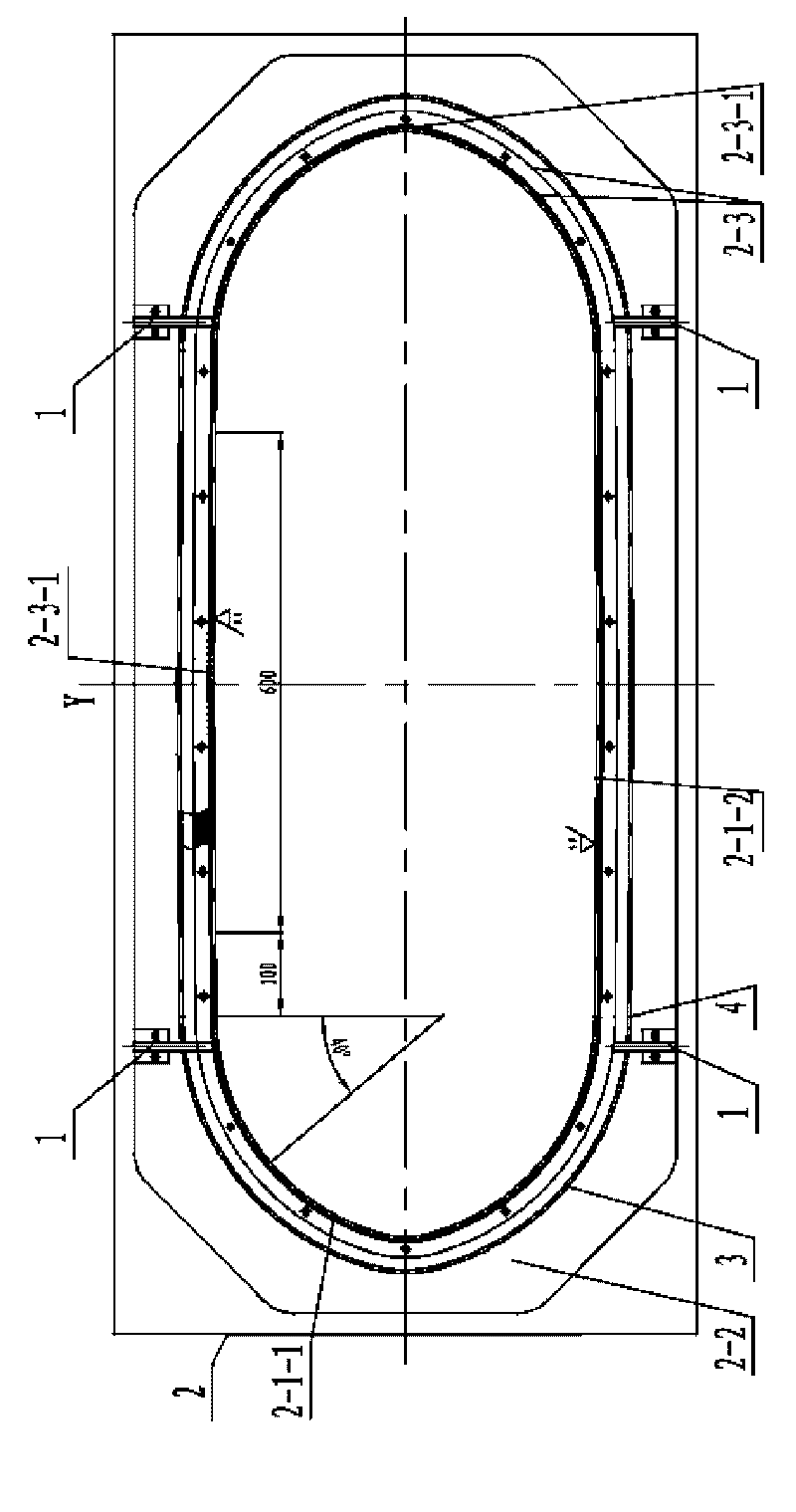

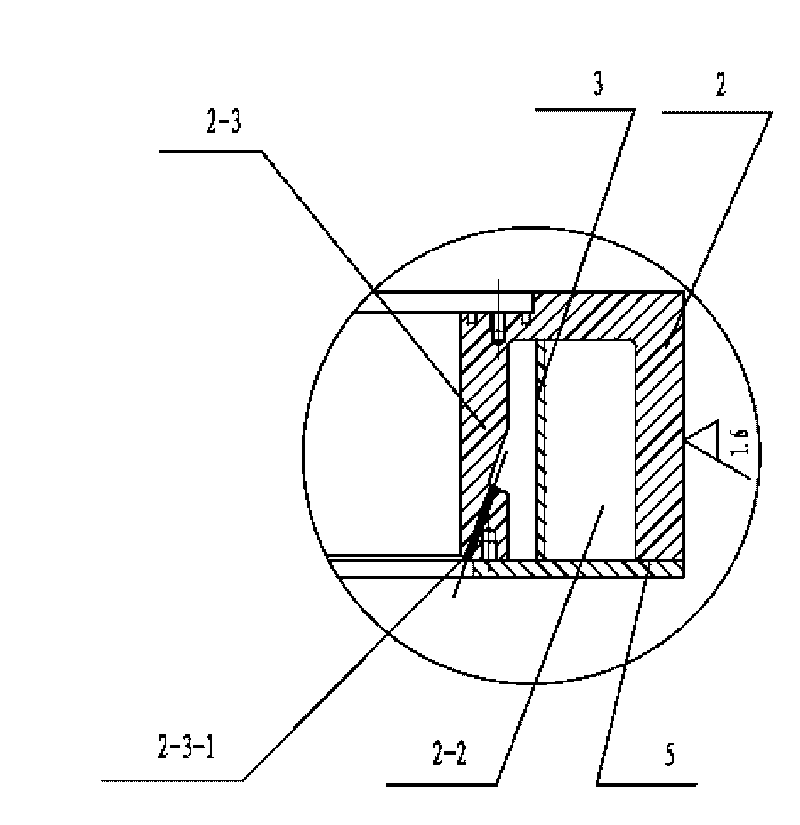

Centrifugal impeller boss crack propagation feature simulator design method

ActiveCN108763839AGuaranteed maximum pulling forceConsistent maximum pullGeometric CADDesign optimisation/simulationImpellerStress intensity factor

The invention relates to a centrifugal impeller boss crack propagation feature simulator design method. The method comprises the following steps: acquiring a geometric model of a centrifugal impeller,measuring a transition fillet semi-diameter of a boss structure and a boss radial length; acquiring a working condition of the centrifugal impeller and the material performance parameter under the working condition; establishing a centrifugal impeller finite element analysis model, computing to acquire the stress maximum point of the boss part of the centrifugal impeller; taking the rectangular slab test piece as the basic shape, wherein boss structures are arranged on symmetric locations at two sides of the slab, and the transition fillet semi-diameters of the boss and the rectangular slab and the boss radial length and the actual structure are consistent; enabling the maximum stress at the stretching direction of the simulator close to the boss location is consistent with the actual structure by adjusting the test piece length method, and guaranteeing that the stress gradient is same; checking the relation of the stress strength factor of the simulator and the test piece thickness,determining the thickness of the test piece, wherein the obtained simulator can simulate the stress strain field of the centrifugal impeller boss structure and can be used for developing crack extension test.

Owner:BEIHANG UNIV +1

Melt redistribution element for an injection molding apparatus

ActiveUS7614872B2Improved profileReduce generationFlow mixersTransportation and packagingHot runnerShear stress

An injection molding apparatus having a manifold and several manifold melt channels communicating with several hot runner nozzles includes a melt redistribution element. The melt redistribution element is placed at specific locations along the melt channels to balance the uneven shear stress profile accumulated during the flow of a melt along the manifold channels. The melt redistribution element has an unobstructed central melt bore having at its inlet a narrowing tapered channel portion. The melt redistribution element also includes a helical melt pathway portion that surrounds the central melt bore. The incoming melt is first subjected to a pressure increase by the tapered portion that causes the melt to flow at a higher velocity through the central melt bore. The outer portion of the melt is forced to flow along the helical path and thus it changes direction multiple times and partially mixes with the melt flowing through the central melt bore. Accordingly, at the outlet of the melt redistribution element the shear stress profile is more evenly distributed than at the inlet of the redistribution element.

Owner:MOLD MASTERS 2007

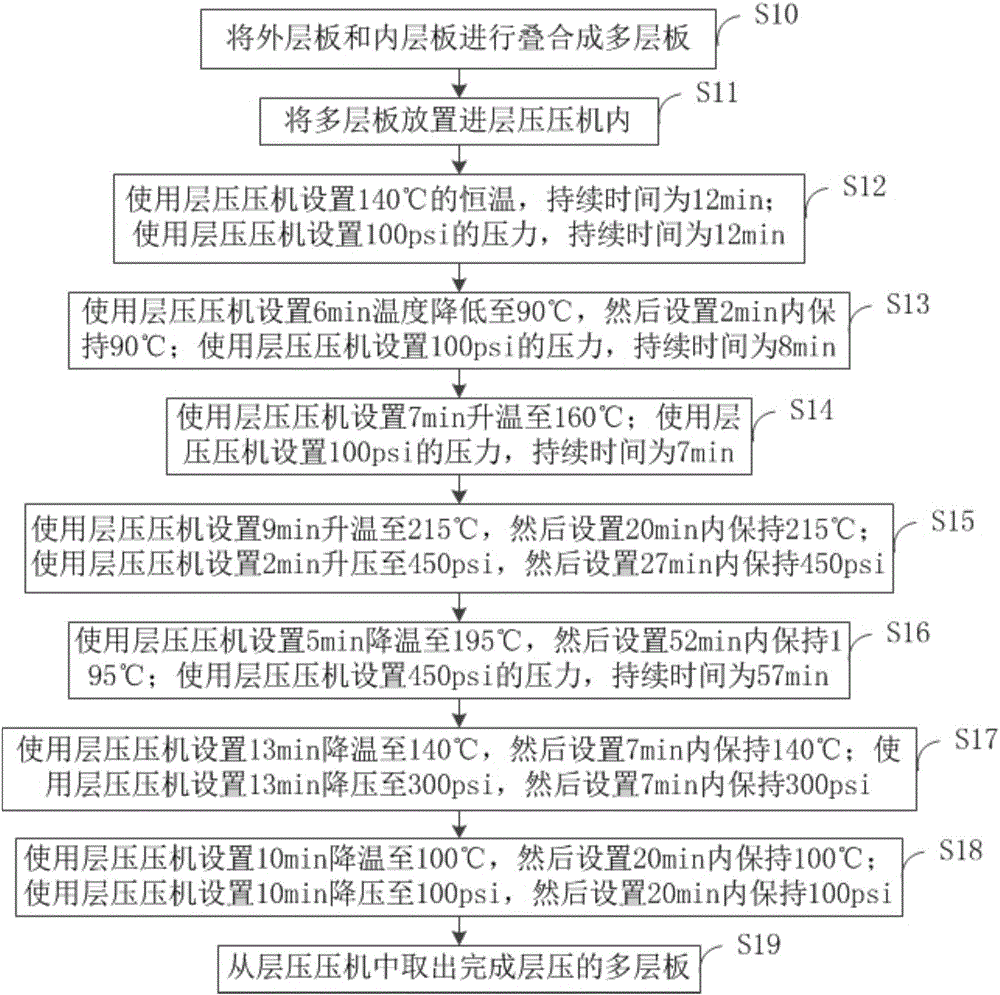

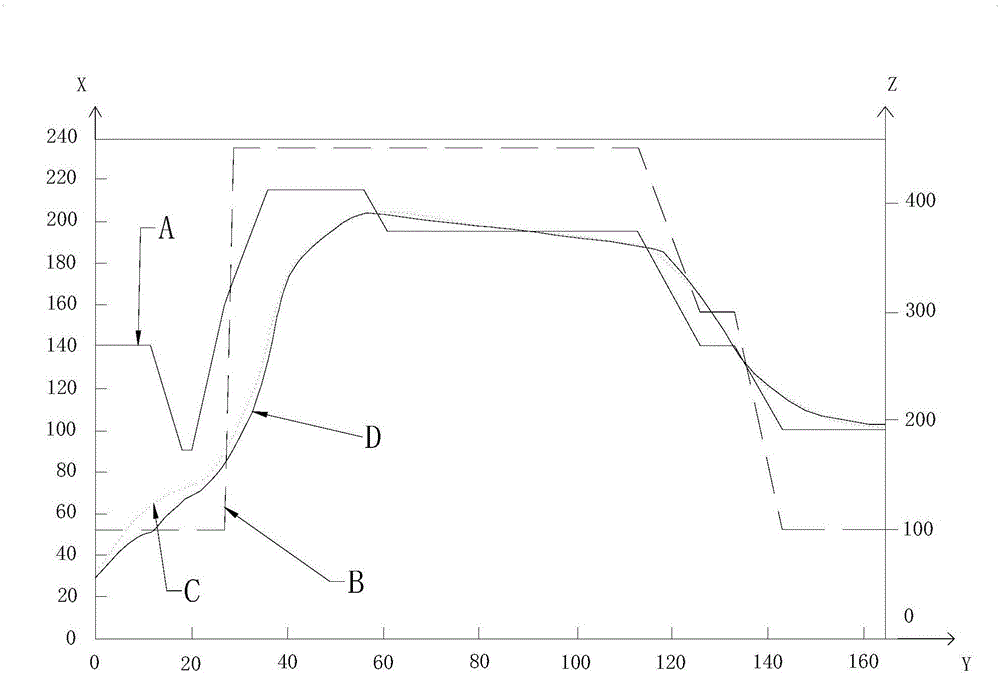

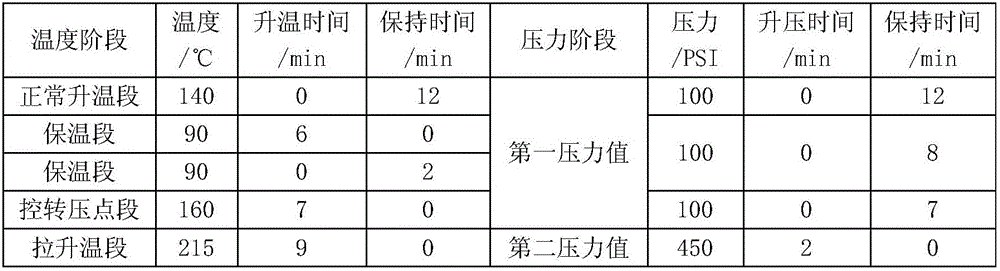

PCB (printed circuit board) laminating process and PCB

ActiveCN106476405AImprove actual material temperature differenceConsistent lamination stateLaminationLamination apparatusEngineeringPrinted circuit board

The invention discloses a PCB (printed circuit board) laminating process, comprising the steps of heating multiple boards that are stacked under first temperature and first pressure constantly; decreasing the temperature to second temperature that is less than the first temperature such that the multiple boards are heated under the second temperature and pressure constantly; increasing the temperature and pressure to laminate the multiple boards. The invention also discloses a PCB manufactured by using the laminating process. By using the PCB laminating process and the PCB, an actual material temperature difference between inner and outer boards of the PCB can be significantly improved, lamination states of the inner and outer boards are consistent, quality stability of batched boards is guaranteed, and consistent stress, namely, surface warping degree, of the inner and outer boards after laminating is ensured.

Owner:DONGGUAN SHENGYI ELECTRONICS

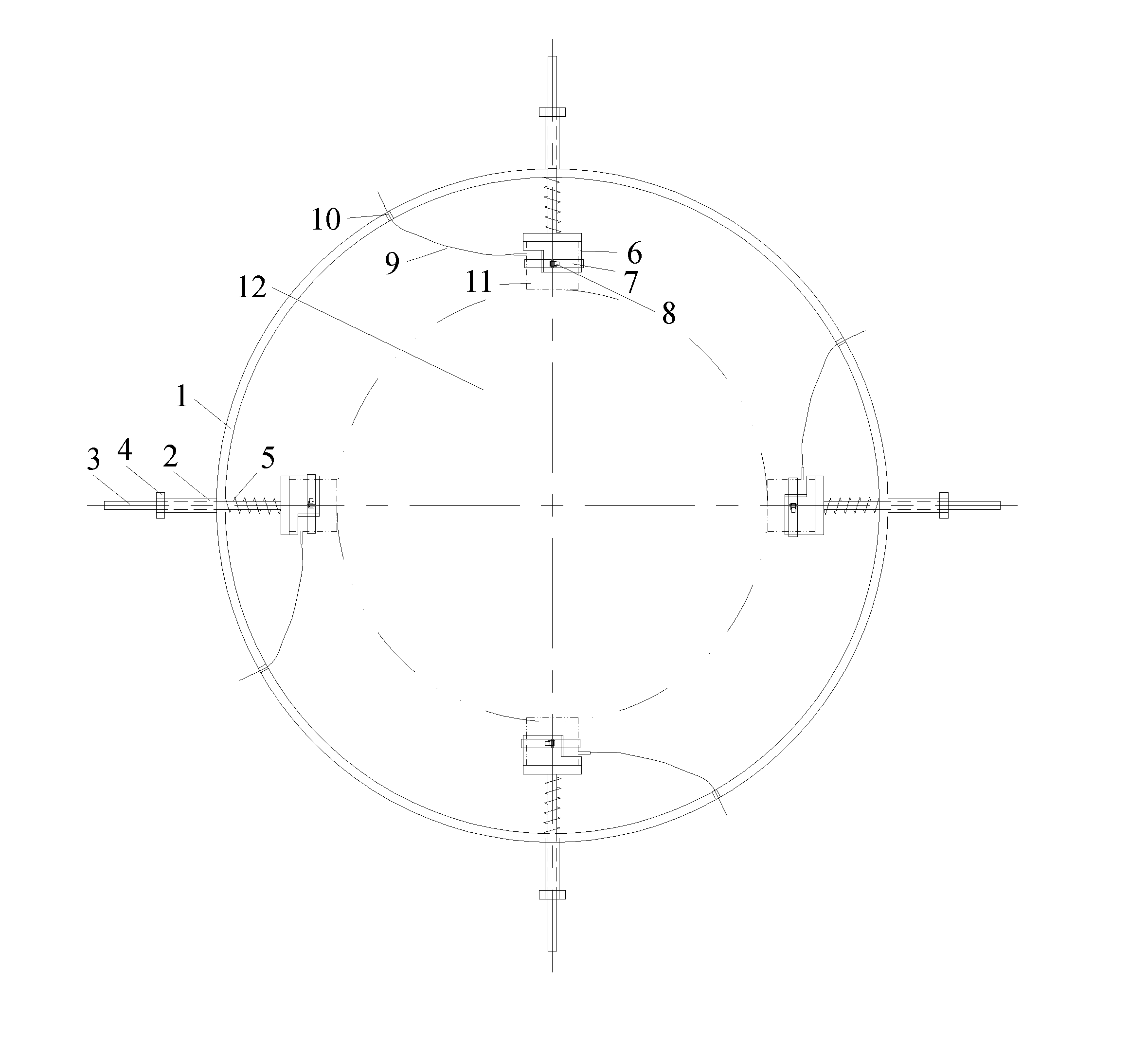

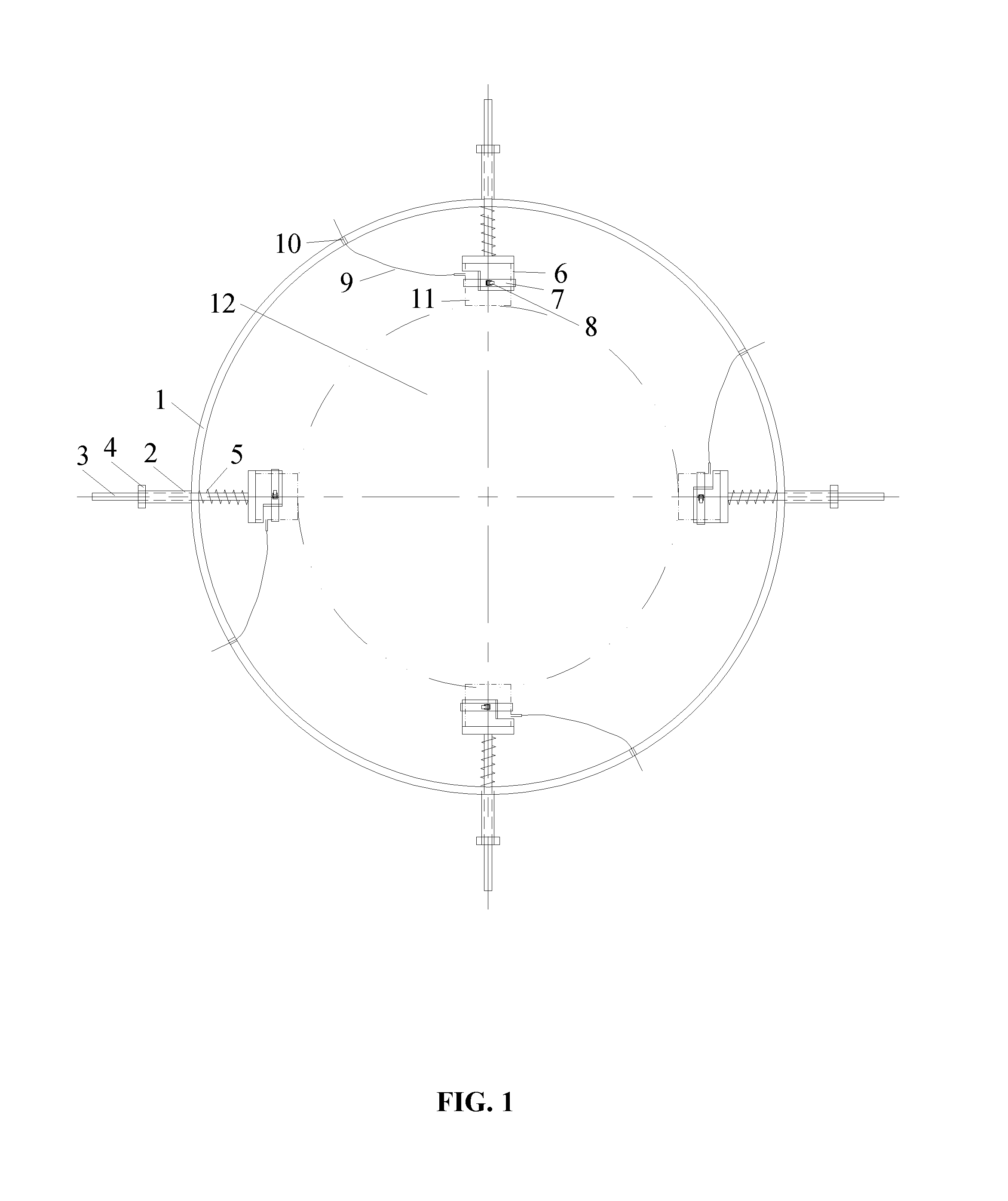

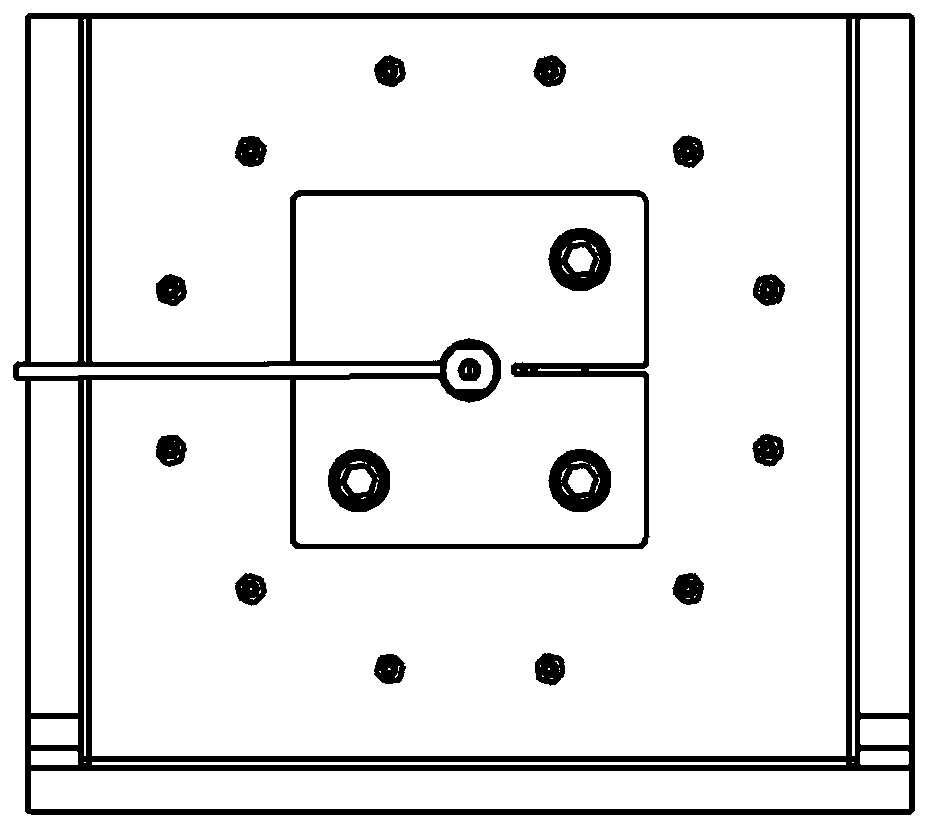

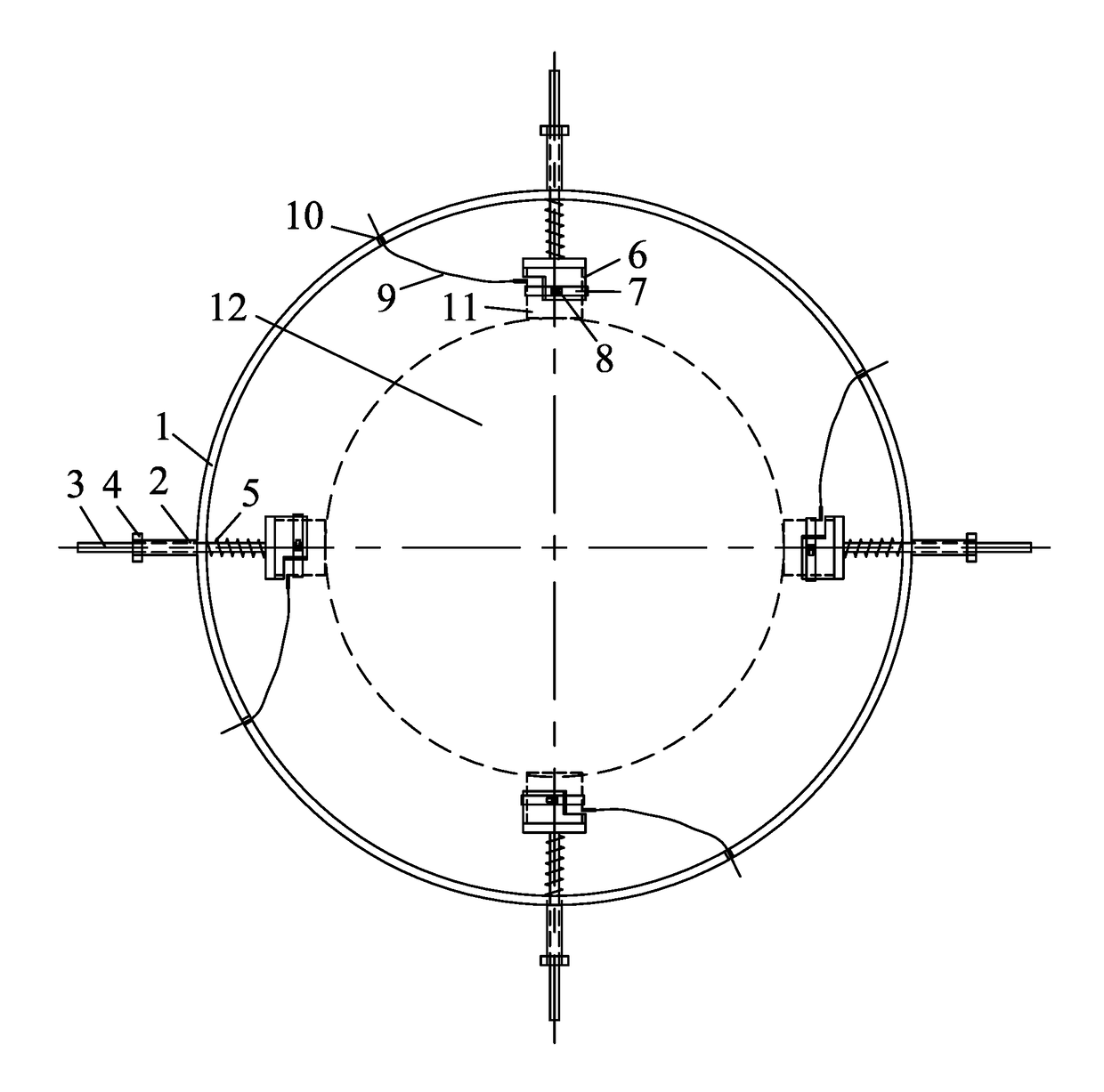

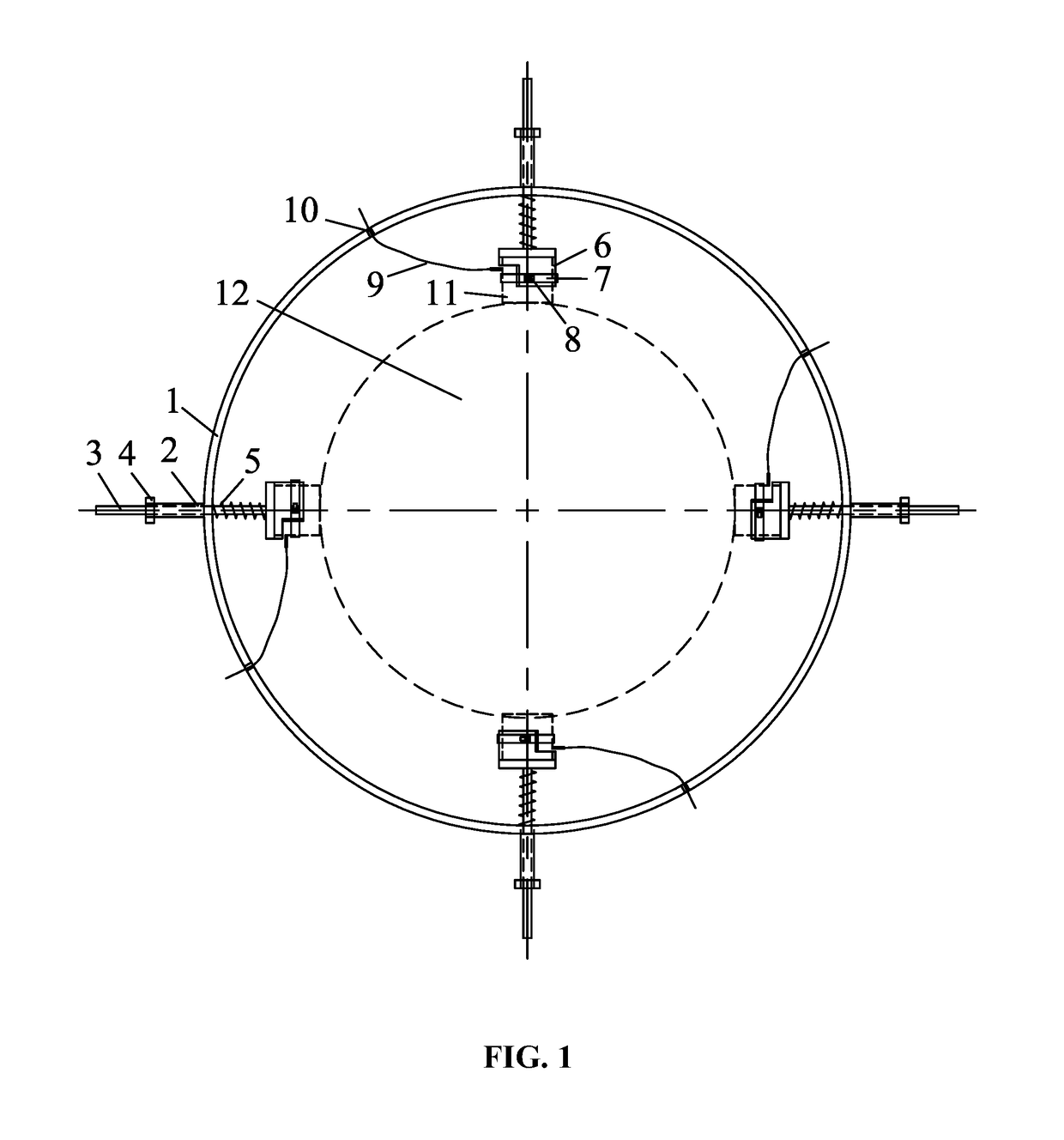

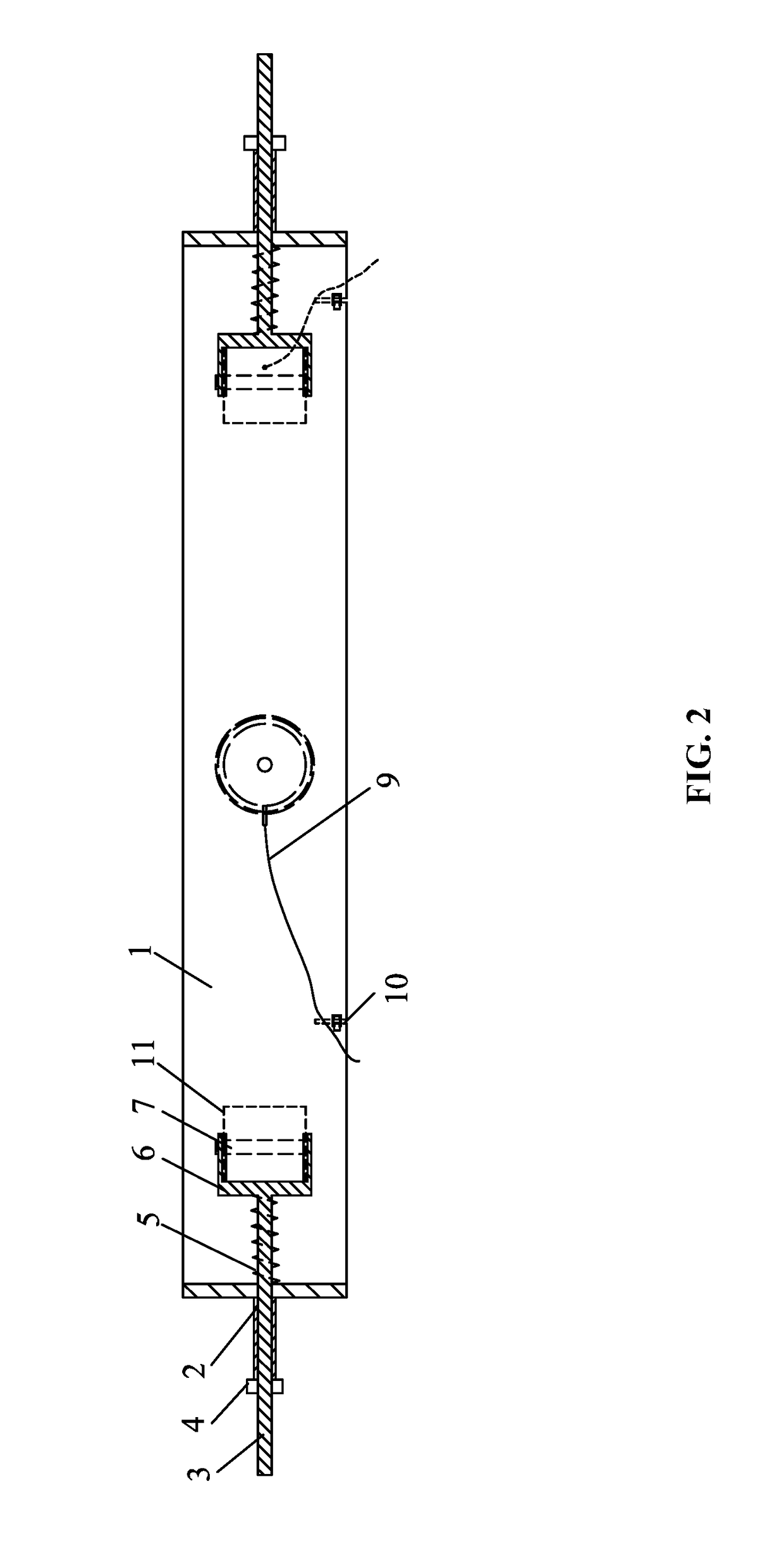

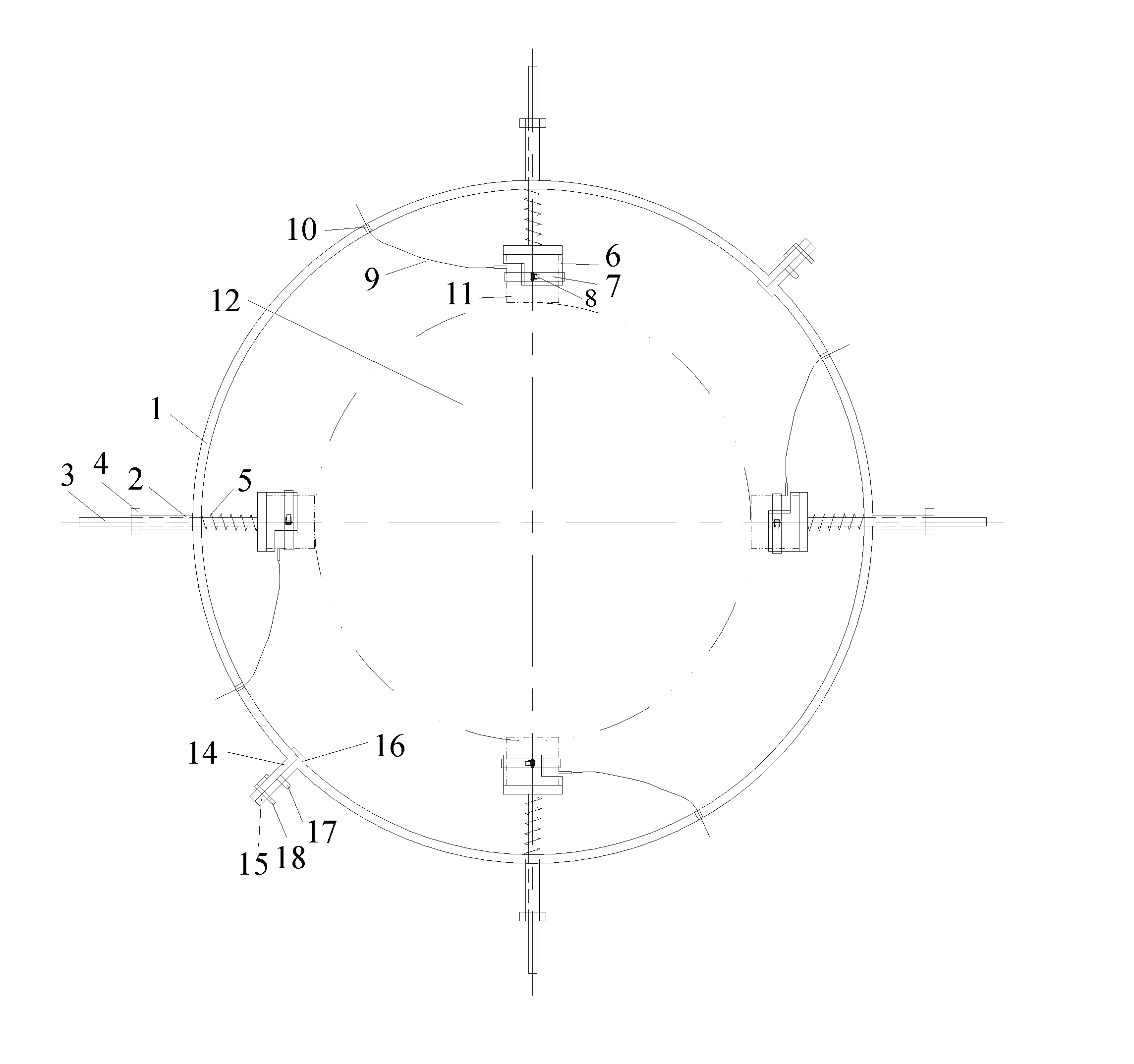

Fixing device for acoustic emission test sensors for rock damage testing

ActiveUS20160231285A1Improve efficiencyImprove accuracyMaterial analysis using acoustic emission techniquesSection planeFixed frame

A fixing device for acoustic emission test sensors for rock damage testing, the device including: a fixing frame, installation bases operating to accommodate the acoustic emission test sensors, respectively, fixing assemblies operating to fix the acoustic emission test sensors in the installation bases, and installation mechanisms operating to install the installation bases on the fixing frame. The fixing frame is an integrated loop-shaped frame. Each of the installation bases is a cylinder structure which includes: a cavity corresponding to an outer edge of each of the acoustic emission test sensors, and a wall including a gap for leading out wires of each sensor. The installation mechanisms are adapted to automatically and axially adjust positions of the installation bases. The installation mechanisms are four in number. The four installation mechanisms are disposed on a same section plane of the fixing frame and every two installation mechanisms are oppositely disposed.

Owner:SICHUAN UNIV

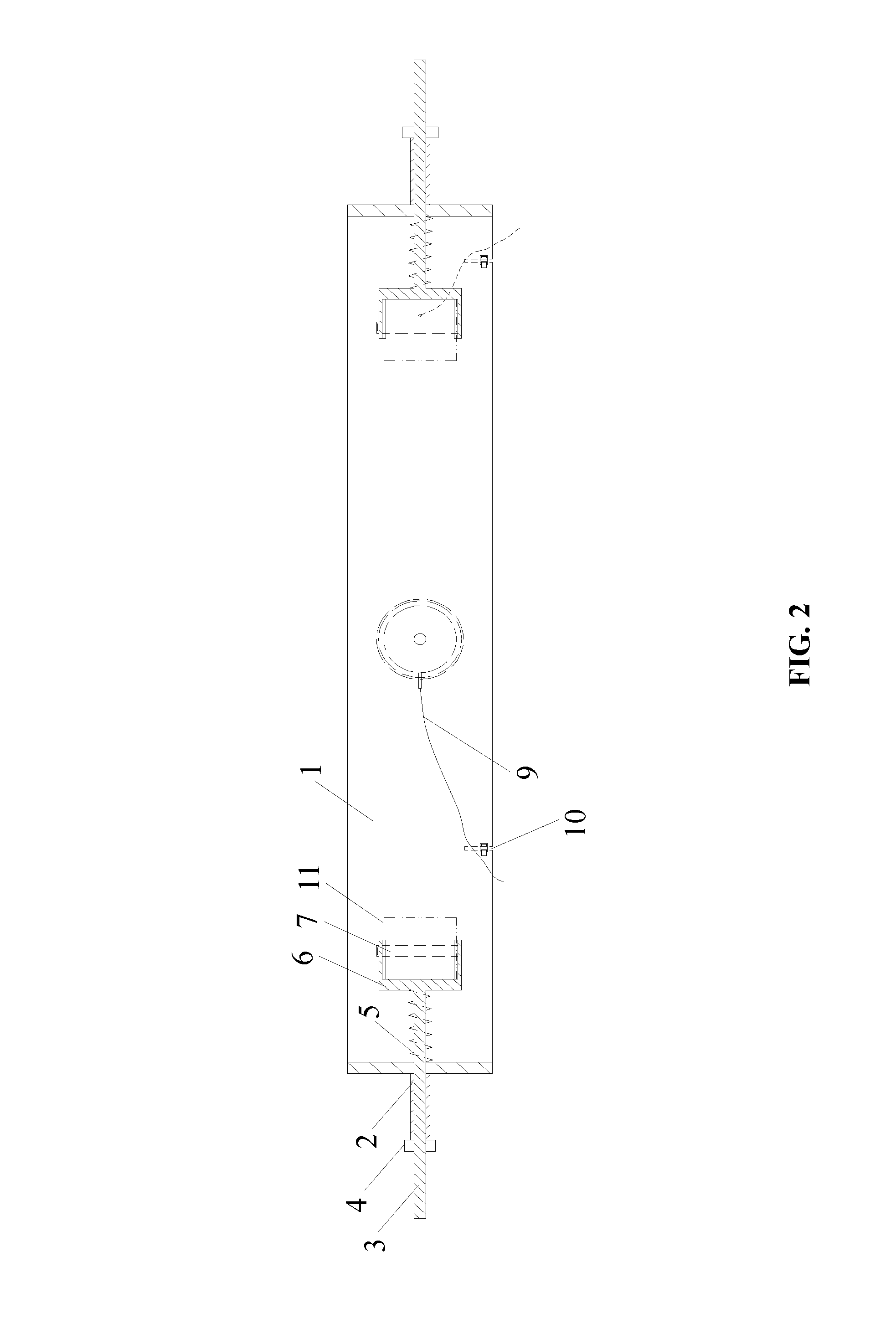

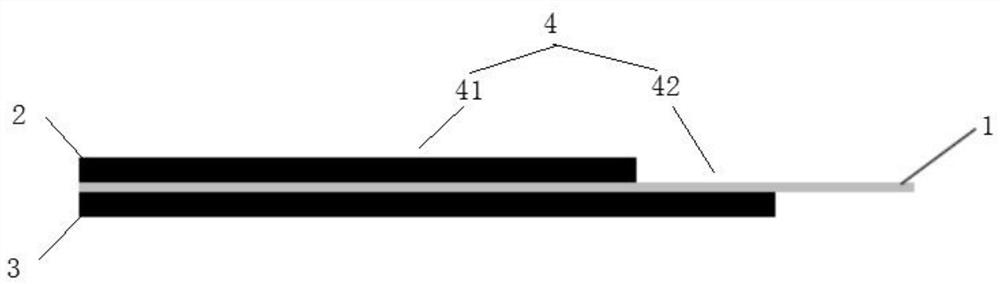

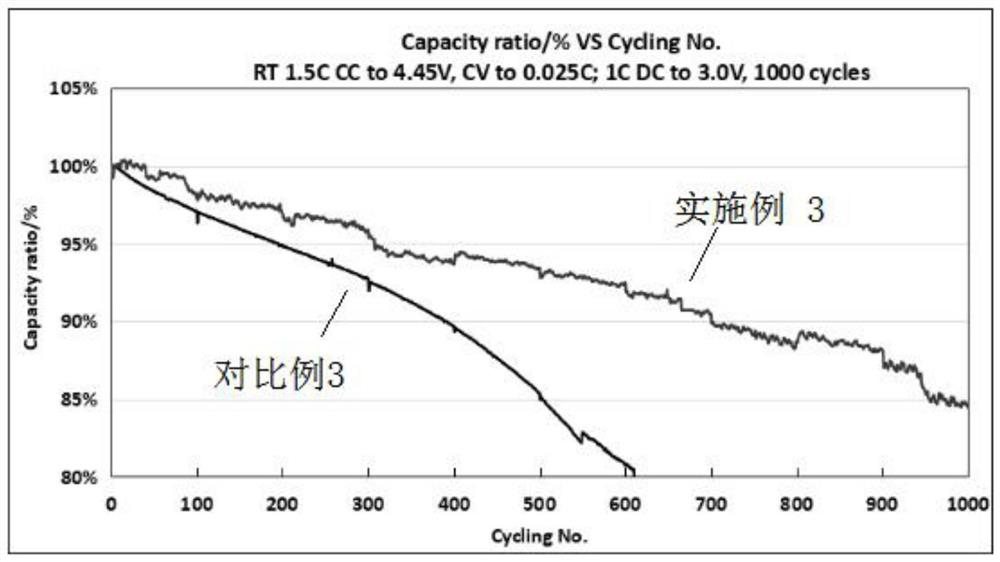

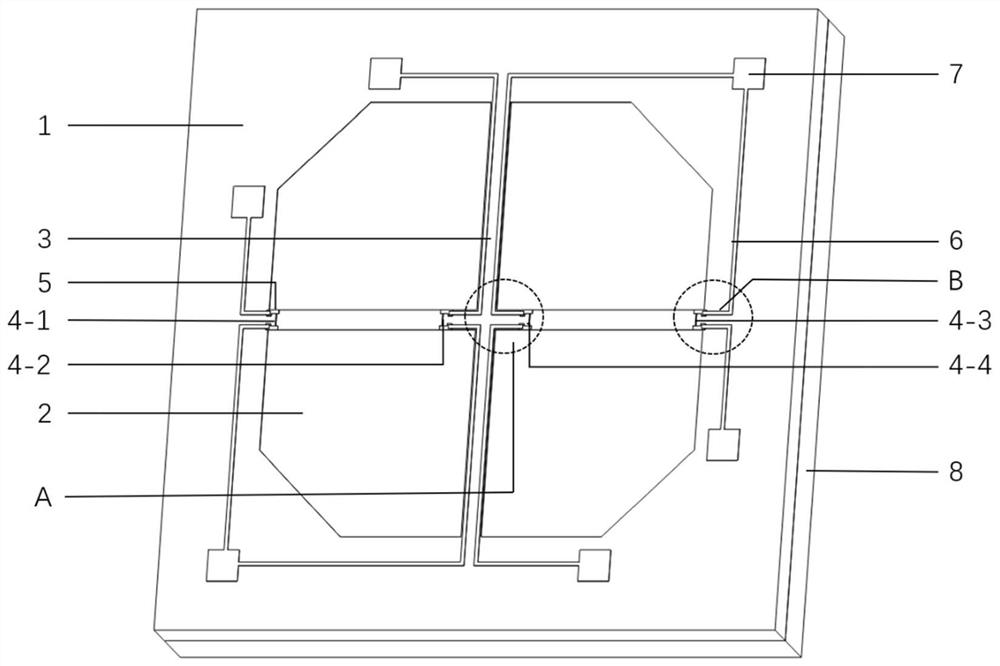

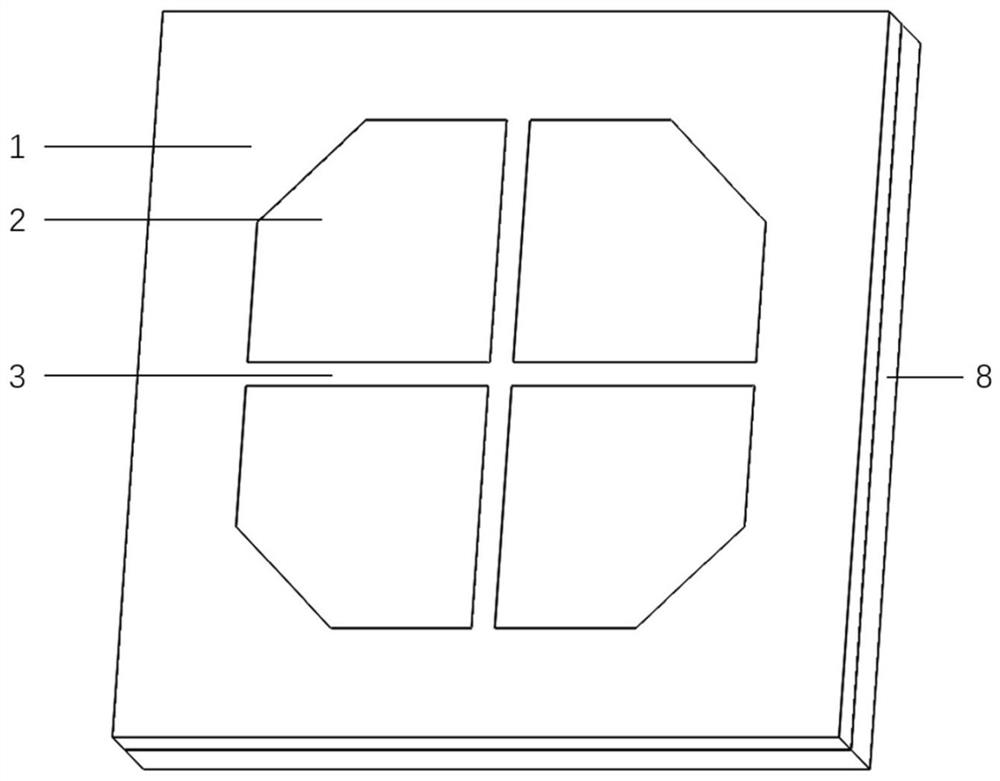

Preparation method of fast charging type lithium ion battery pole piece, pole piece and lithium ion battery

InactiveCN112582583AConsistent thicknessConsistent stressElectrode rolling/calenderingSecondary cellsFast chargingPhysical chemistry

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a fast charging type lithium ion battery pole piece. The method comprises thefollowing steps of coating slurry with active substances on the two surfaces of a current collector to obtain the pole piece with a first active substance layer and a second active substance layer which are symmetrically arranged; rolling the two surfaces of the pole piece; and cleaning the redundant first active material layer to obtain the fast charging type lithium ion battery pole piece witha double-sided coating area and a single-sided coating area. According to the preparation method of the fast charging type lithium ion battery pole piece, the rolling thickness of the single-side coating area of the pole piece after rolling is consistent with that of the double-side coating area, and the compression degree of active substance layers at the two sides of the pole piece can be effectively ensured to be consistent during rolling; and the failure problems of powder falling, lithium precipitation and the like of the single-side coating area in the subsequent charging and dischargingprocess due to different thicknesses of the single-side coating area and the double-side coating area of the pole piece and different compression degrees when the pole piece is rolled to pass througha roll gap in the traditional process, are effectively avoided.

Owner:东莞维科电池有限公司

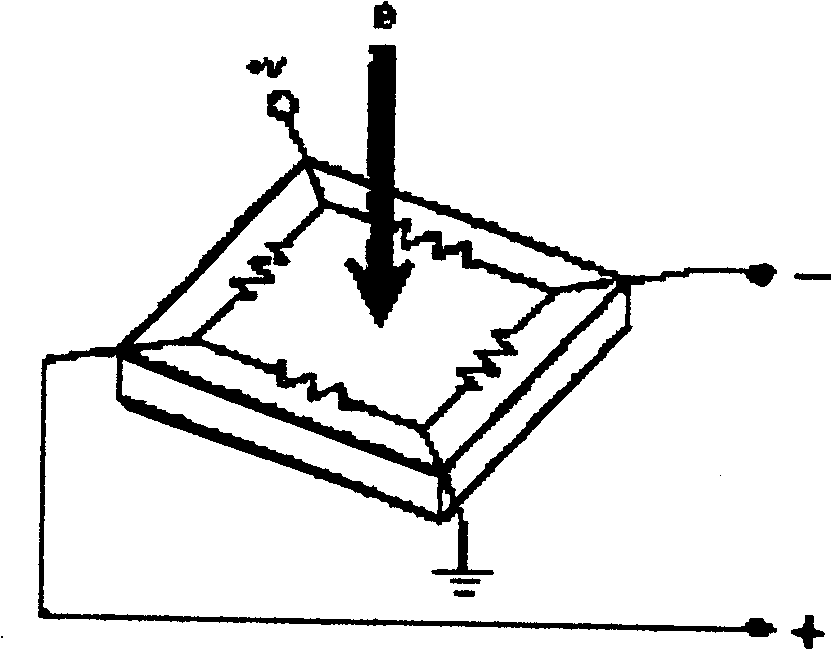

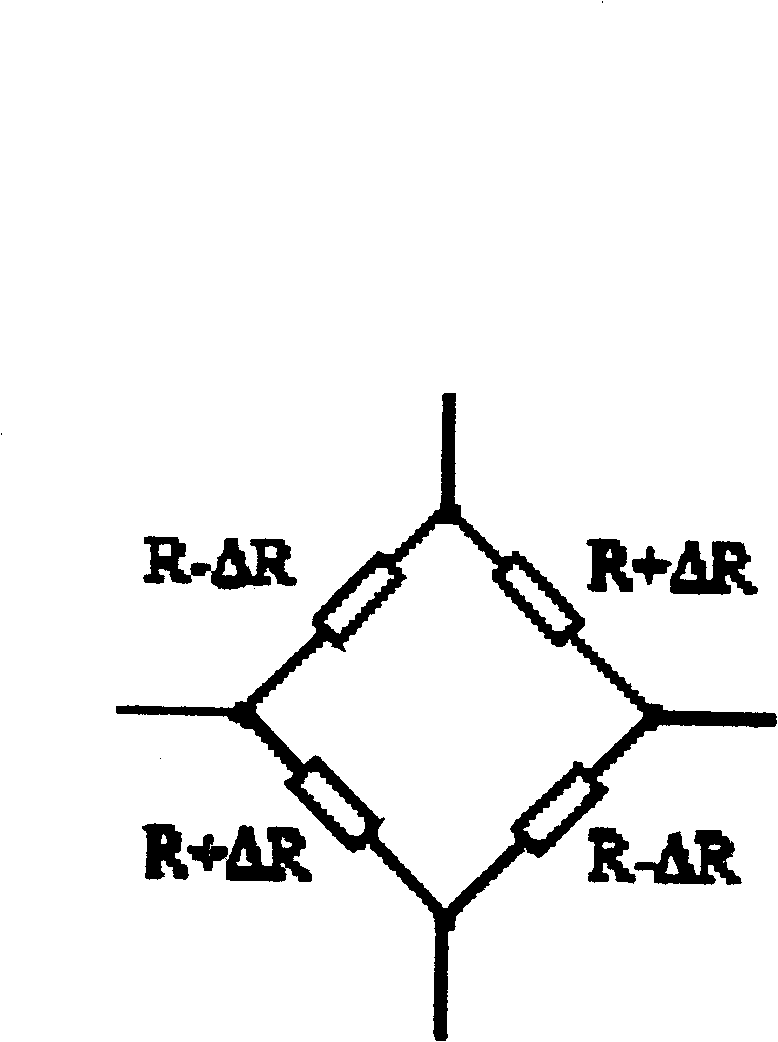

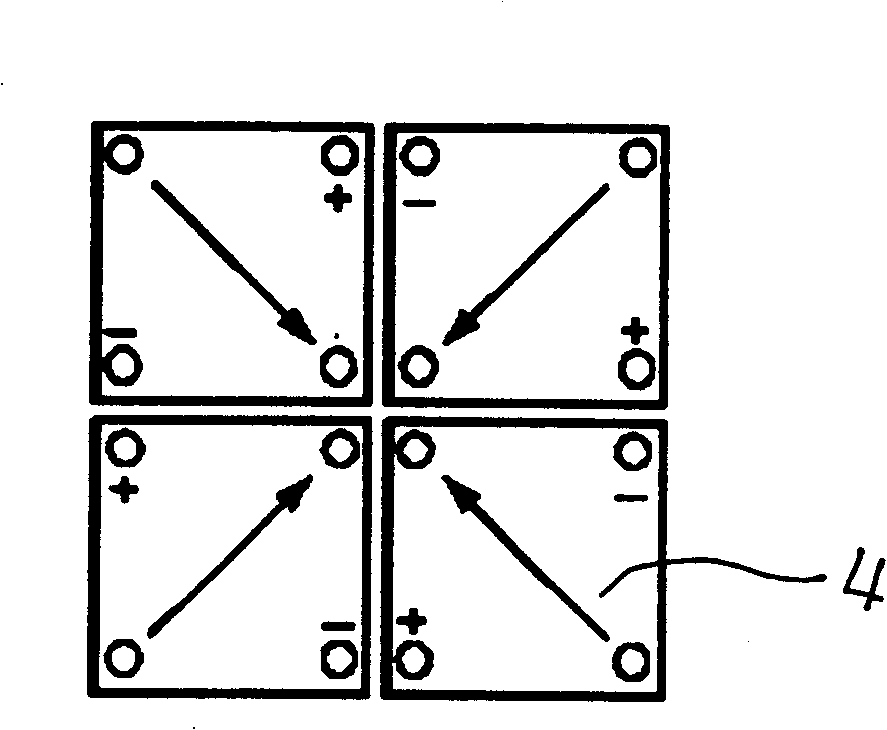

Cross beam film stress concentration micro-pressure sensor chip and preparation method thereof

ActiveCN113551812AHigh sensitivityImprove linearityFluid pressure measurement using ohmic-resistance variationFinal product manufactureOhmic contactThin membrane

The invention discloses a cross beam film stress concentration micro-pressure sensor chip and a preparation method thereof. The sensor chip comprises a pressure-bearing film, a silicon substrate, a piezoresistor strip, a metal lead, an anti-overload glass substrate and the like. According to the specific structure, the back face of a silicon substrate is etched to form a pressure-bearing film and a peninsular and island structure, and four diamond-shaped areas are etched on the front face of the silicon substrate to form a cross beam. Stress concentration areas are formed on the front face of the chip corresponding to gaps between islands adjacent to a chip back cavity and between the islands and peninsula, the four piezoresistor strips are arranged on the stress concentration areas, and the piezoresistor strips are connected to form a Wheatstone bridge through heavily-doped ohmic contact areas, metal leads and metal bonding pads. The existence of the cross beam can further improve the stress concentration effect at the piezoresistor strip.

Owner:陕西省计量科学研究院 +1

Method and device for improving micro-deformation loading precision

ActiveCN110987677AUniform deformation loading throughout the fieldSmall elastic aftereffect hysteresisPreparing sample for investigationMaterial strength using repeated/pulsating forcesThin walledMachining process

The invention discloses a method for improving the precision of a micro-deformation loading device. A test piece made of a constant-elasticity alloy material is divided into a central displacement area, a middle ring elastic deformation area and a peripheral fastening area, the test piece is designed and assembled in a split manner to form a test piece assembly so as to eliminate the influence ofthe deformation caused by machining of a disc-shaped thin-wall area of the test piece and the deformation of a cutting residual stress deformation area generated in the machining process, and displacement errors caused by threaded connection gaps or contact force deformation at the joint of a high-precision driving device and the test piece are reduced through the connection mode of an outer circle at the output interface of a radial enclasping driving device and an outer circle of the cylindrical extending end of the test piece. According to the method and the device, the deformation hysteresis caused by internal stress after the elastic deformation area of the test piece is deformed is reduced, and the displacement errors caused by connection contact force deformation or connection clearance between the driving device and the test piece is reduced, so that the uncertainty of the micro-deformation loading device can be greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV

Method for wet drawing Al-enclosing steel wires for electrotechnics

InactiveCN1452185ANo stayWill not affect productionBridge structural detailsCable/conductor manufactureProduction lineWork in process

A wet drawing method for manufacturing the aluminium clad steel wire used for electric engineering is characterized by that the semi-finished aluminium clad steel wire is drawn through multi-pass drawing die by drawing machine while the lubricating oil is applied.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

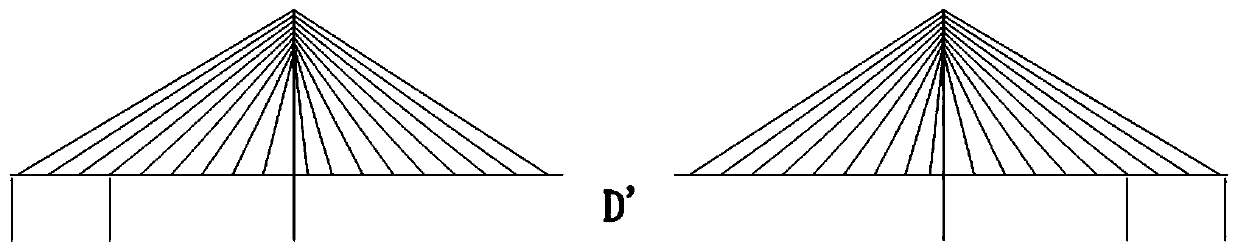

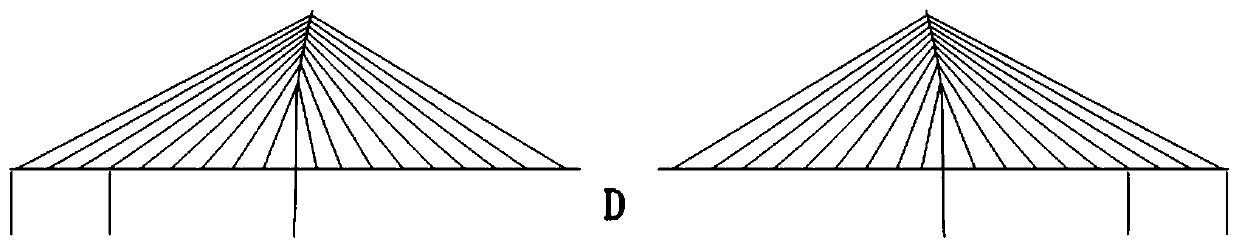

Kilometer-level hybrid beam cable-stayed bridge closure method

ActiveCN111335168AReduce dependenceSimplify the tedious processCable-stayed bridgeBridge erection/assemblyTowerControl theory

The invention discloses a closing method for a kilometer-level hybrid beam cable-stayed bridge. The closing method comprises the steps that the pushing direction of main beams on the two sides of thekilometer-level hybrid beam cable-stayed bridge is determined according to the single-side displacement amount; enabling the two-side line shapes of the closure gap to accord with the two-side line shapes of the closure gap in the reference model; after the actual length of the closure opening is equal to the reference length of the closure opening, the closure opening is locked, and pushing is removed; after the closure section beam is hoisted, the unstressed length of the first set inhaul cable is adjusted to a reference value, and the length of the closure section beam is the reference length of a closure opening; calculating a main span steel structure linear relative error, a bridge axis relative error, a tower deviation relative error and a cable force error after the bridge is formed; whether the errors meet corresponding set errors or not is judged, if yes, closure is completed, If not, adjustment is conducted till all the errors meet the corresponding set errors; the relativeerror of the main span steel structure line shape is set to be L / 4000, the relative error of the bridge axis is set to be L / 40000, the relative error of tower deviation is set to be L / 10000, and L isthe main span length.

Owner:SOUTHWEST JIAOTONG UNIV

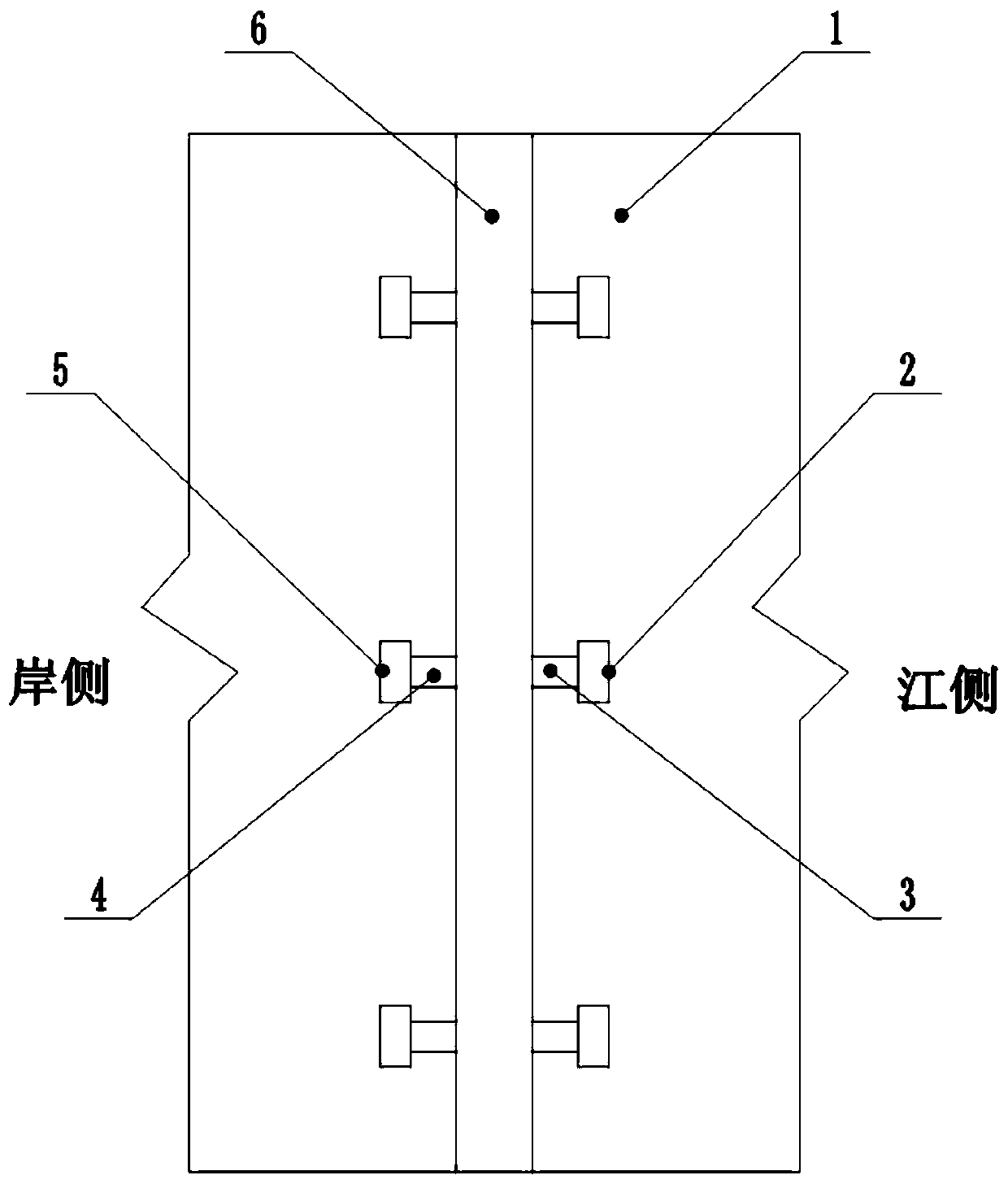

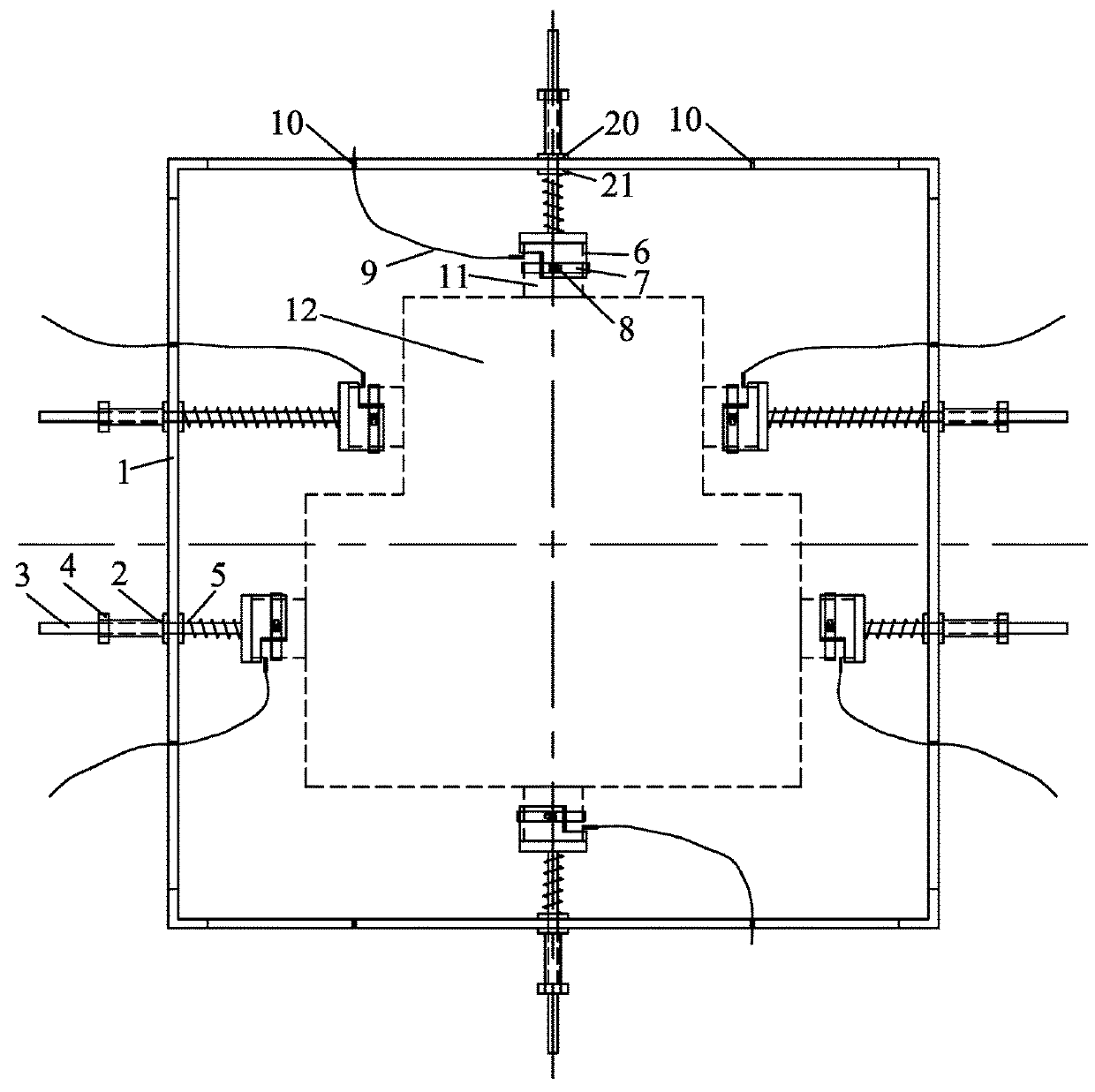

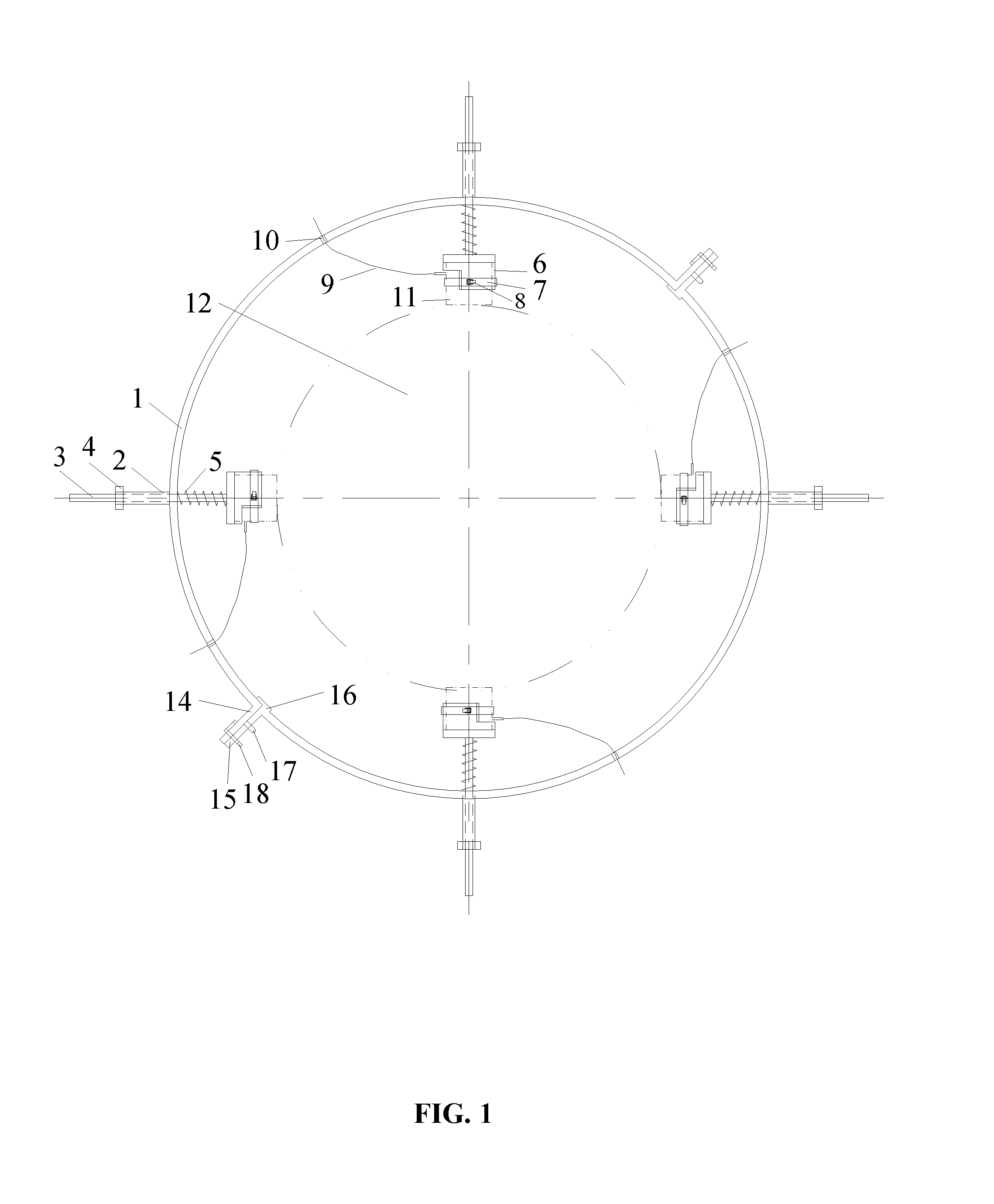

Adjustable fixing device for acoustic emission test sensors for rock damage testing

ActiveUS10006887B2Improve efficiency and accuracy and authenticityEnsuring efficiency and accuracy and authenticityAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesFixed frameAcoustic emission

An adjustable fixing device for acoustic emission test sensors for rock damage testing, the device including: a fixing frame; installation bases operating to accommodate the acoustic emission test sensors, respectively; fixing assemblies operating to fix the acoustic emission test sensors in the installation bases; and installation mechanisms operating to install the installation bases on the fixing frame. The fixing frame is a rectangular frame, and at least a pair of opposite frame walls of four frame walls is provided with installation slots adapted to install the installation mechanisms. The installation slots positioned at different frame walls are in a same cross section of the rectangular frame. Each of the installation bases is a cylinder structure. The cylinder structure includes: a cavity corresponding to an outer edge of each of the acoustic emission test sensors, and a wall including a gap for leading out wires of each sensor.

Owner:SICHUAN UNIV

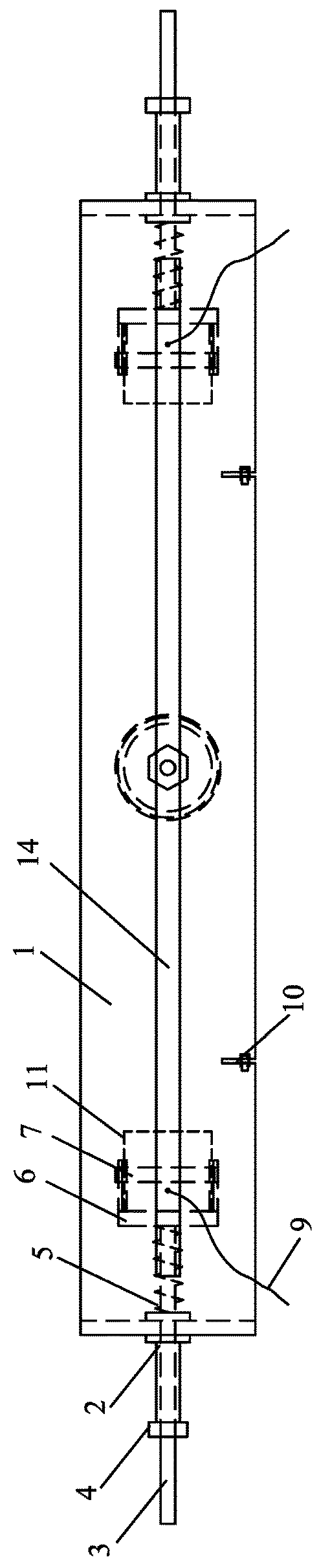

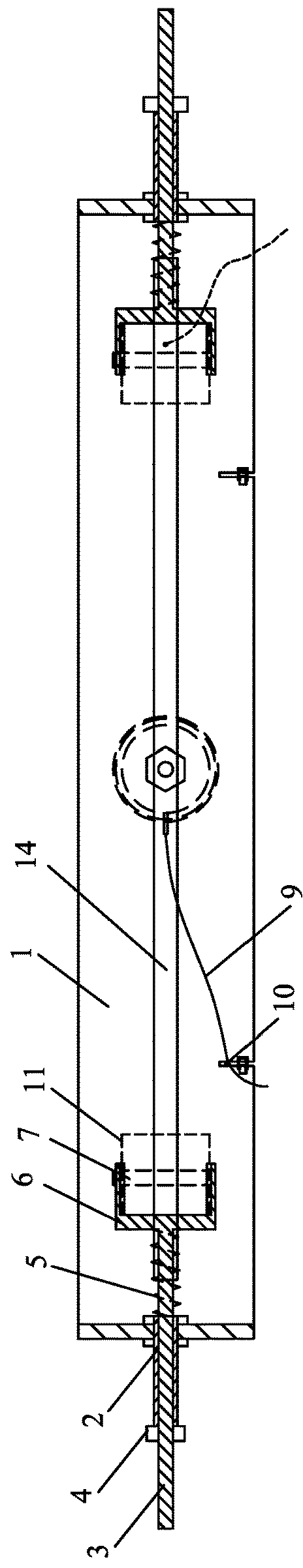

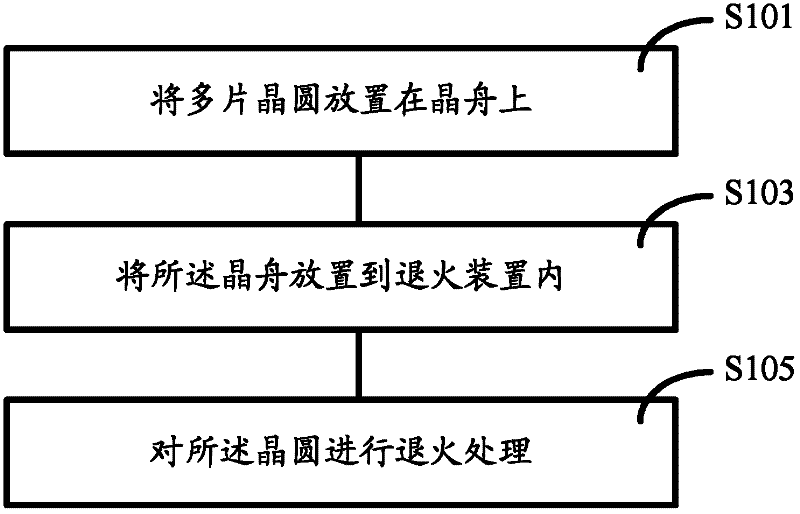

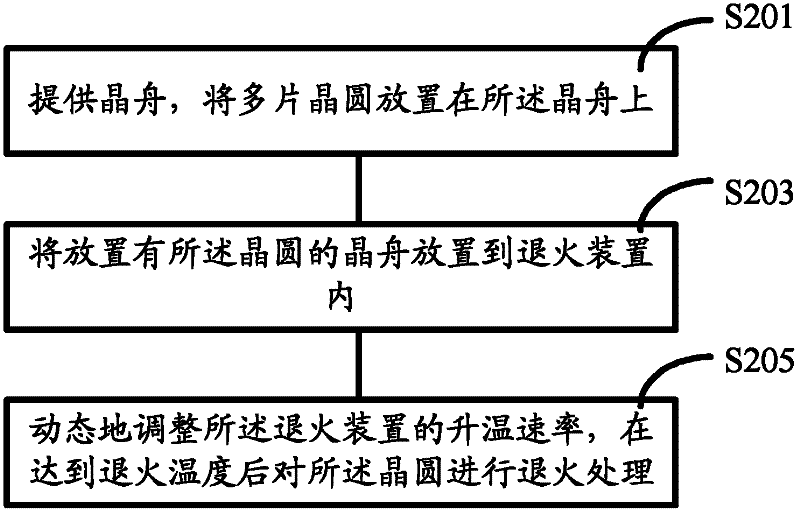

Wafer Formation Method

ActiveCN102263028AAvoid deformationUniform stress distributionSemiconductor/solid-state device manufacturingEngineeringDislocation

An embodiment of the present invention provides a method for forming a wafer, comprising: providing a wafer boat, placing a plurality of wafers on the wafer boat; placing the wafer boat on which the wafers are placed in an annealing device; The heating rate of the annealing device is dynamically adjusted, and the wafer is annealed after reaching the annealing temperature. By adopting the method of the embodiment of the present invention, the quality of the formed wafer is good, it is not easy to be deformed, and the crystal lattice inside the wafer is not easy to slip or dislocate.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Energy-saving doorbell based on piezoelectric principle

InactiveCN107093297AImprove work efficiencyImprove performancePiezoelectric/electrostriction/magnetostriction machinesElectric/electromagnetic audible signallingDoorbellElectricity

The invention discloses an energy-saving doorbell based on the piezoelectric principle, and the doorbell comprises a button device and a loudspeaker device of the doorbell. The button device consists of two piezoelectric pieces with the consistent polarization direction, and a flexible insulating material layer which is used for separating the two piezoelectric pieces. The two surfaces, backing on to each other, of the two piezoelectric pieces are connected through a first wire, and the opposite surfaces of the two piezoelectric pieces are connected through a second wire. The first and second wires are respectively connected with a current limiting resistor, an inductor and a loudspeaker device. The doorbell employs the piezoelectric effect of a piezoelectric material, does not need a power supply, and saves the energy. Moreover, the piezoelectric material is stable in performance, and is long in service life, is low in cost, and can be widely used in life.

Owner:吴冕

Fixing device for acoustic emission test sensors for rock damage testing

ActiveUS10018594B2Improve efficiency and accuracy and authenticityEnsuring efficiency and accuracy and authenticityMaterial analysis using acoustic emission techniquesSection planeAcoustic emission

Owner:SICHUAN UNIV

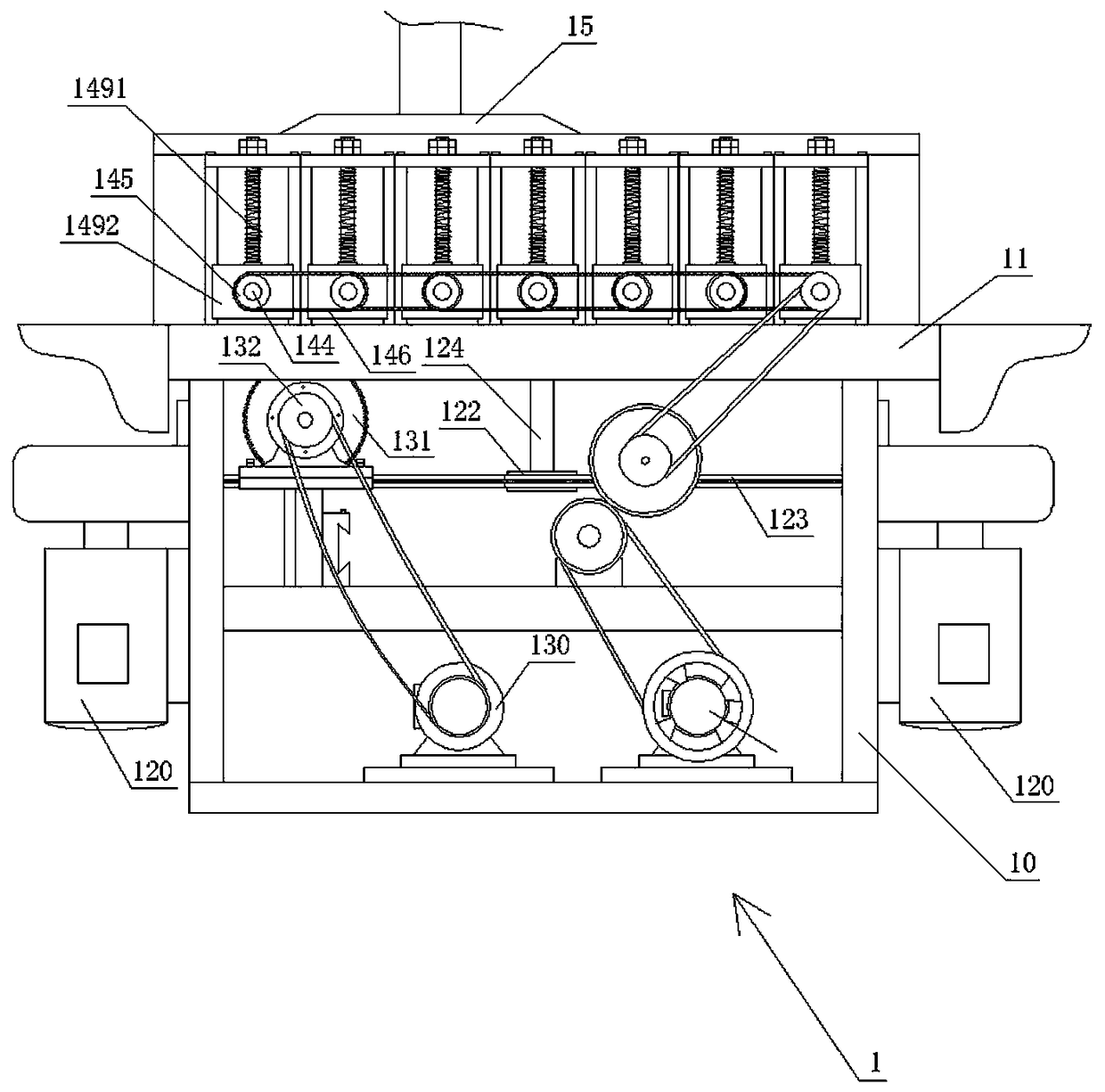

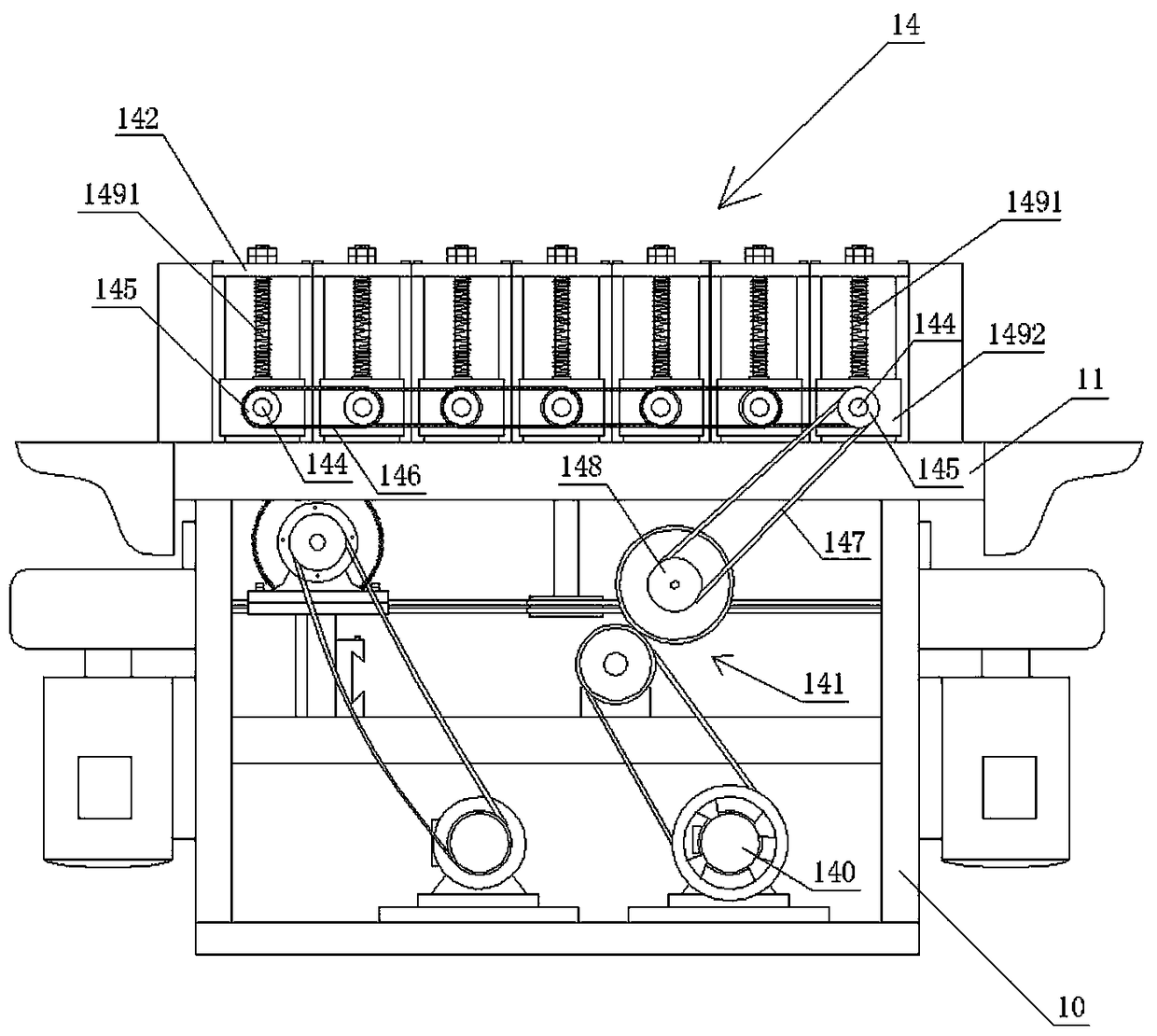

Slicer for door frame board quick forming

ActiveCN108274539AIdeal structural designCompact designFeeding devicesCircular sawsLateral bendingEngineering

The invention discloses a slicer for door frame board quick forming. The slicer for door frame board quick forming comprises a rack, a working platform, a transverse cutting tool, a lengthways cuttingtool and a push device, wherein the transverse cutting tool is used for transversely cutting the side part of a short material, the lengthways cutting tool is installed on the working platform and used for lengthways cutting the same side part of the short material, and the push device is installed on the rack and used for pushing the short material to move forwards on the working platform. The slicer for door frame board quick forming is ideal and compact in structural design, can achieve the very good quality benefit and economic benefit while the pollution caused by glue to the environmentis reduced; it is adopted that the short material is transversely cut by the transverse cutting tool and is lengthways cut by the lengthways cutting tool in sequence in the length direction of the short material, and then a door frame short material with the integrated large border and small border can be formed by removing excess materials; according to the running form cutting mode, operation is carried out in one step, the traditional mode of keeping to the edge, and the traditional mode of splicing a large border and a small border are changed, it is guaranteed that the internal stress ofthe door frame short material formed by the large border and the small border keeps consistent, a door frame board made through finger joint later is consistent in internal stress, and it is guaranteed that the forward lateral bending of a product is not out of limits, so that the straightness is guaranteed.

Owner:福建省尤溪县红树林木业有限公司

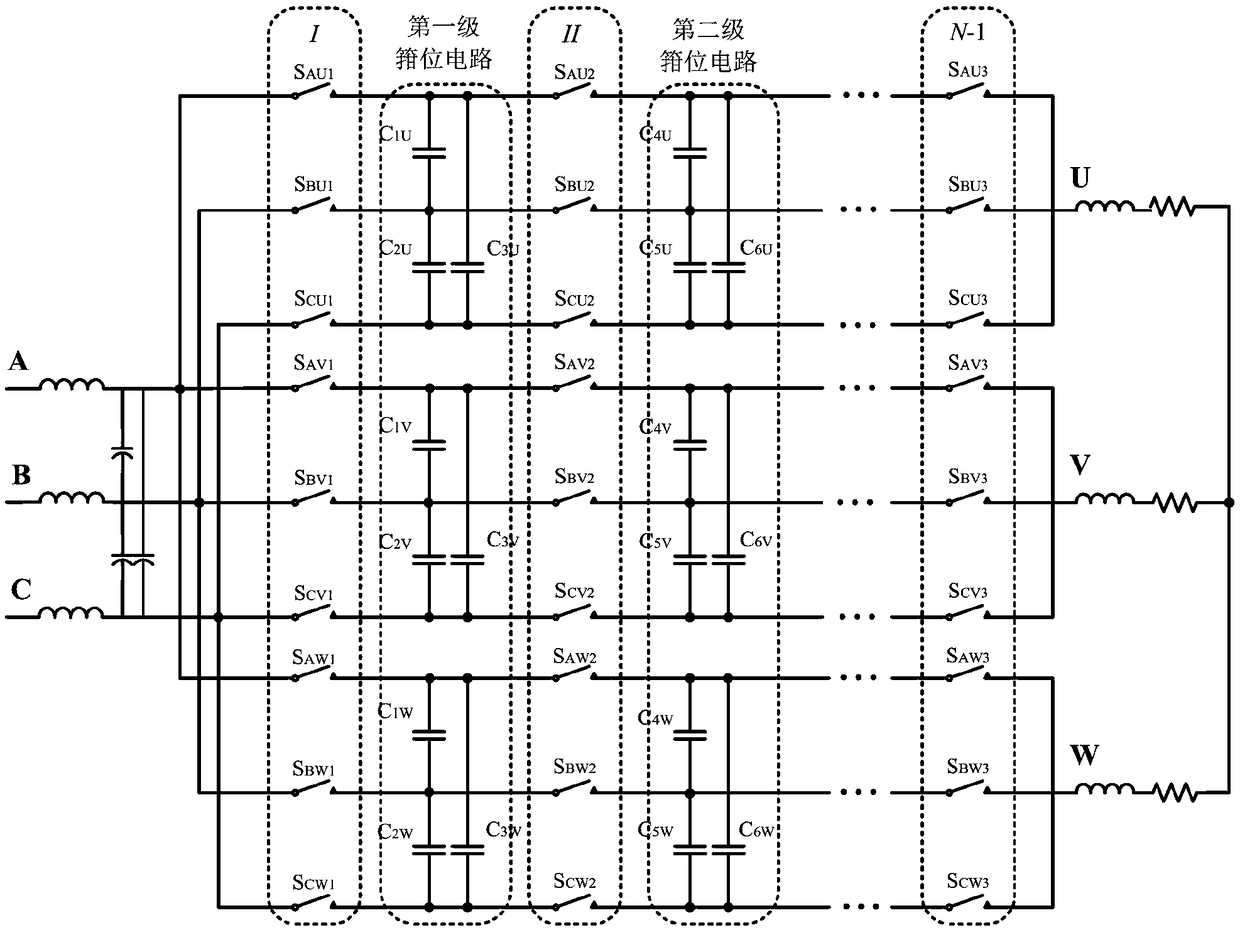

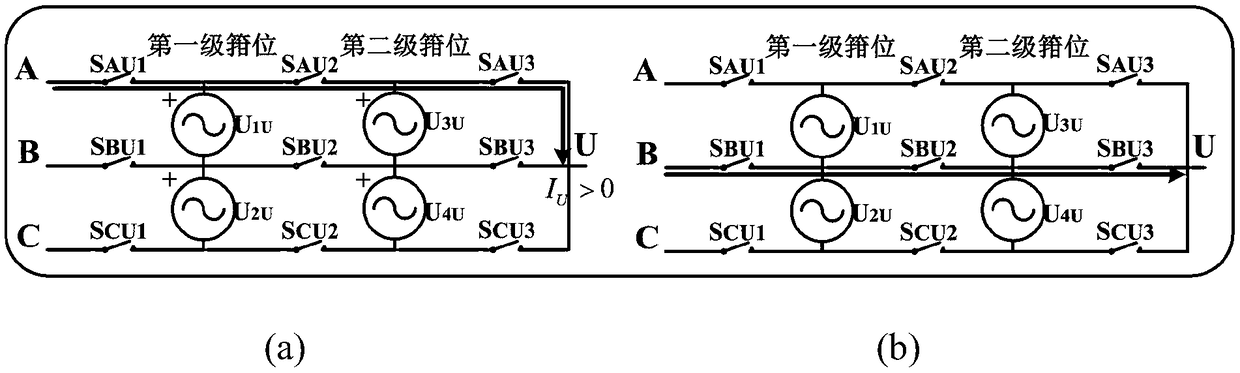

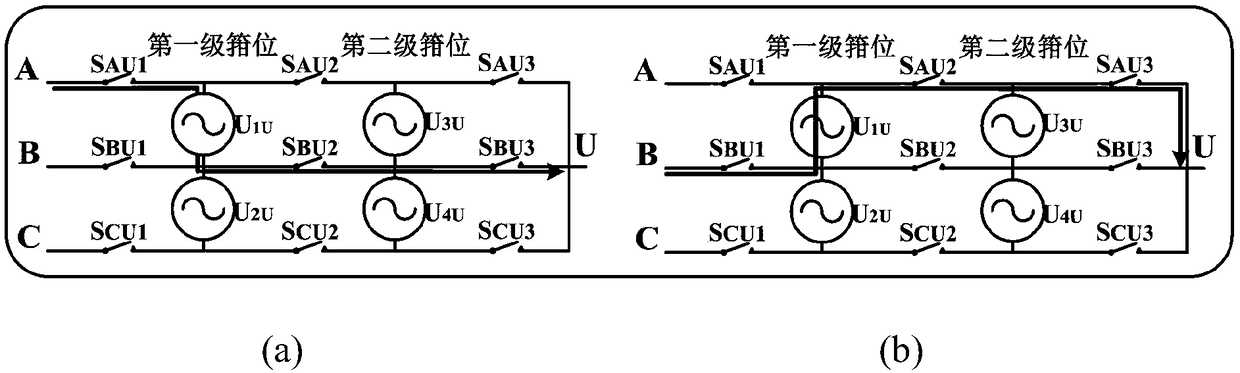

Multi-level matrix converter suitable for high-power density occasion and clamp capacitor voltage control method thereof

The invention discloses a multi-level matrix converter suitable for a high-power density occasion and a clamp capacitor voltage control method thereof. The converter can be suitable for the direct AC-AC conversion occasion with high power density and reliability requirement. The converter topology structure can realize the output of multi-level, and the withstand voltage of the single-device is lower than the traditional two-level topology, the output end harmonic wave can be effectively reduced, and the voltage step is smaller; and the proportion of the clamp circuit voltages at different levels can be 1: 2: 3: ...N-1. Compared with the prior art, all devices in the converter are consistent in stress, maximum withstand voltages born by various bidirectional switches are consistent, the modularity is strong, the device model selection and maintenance are convenient, and the later cost is effectively reduced; furthermore, the capacitor balancing region is increased, the capacitor voltage controllable range is greatly increased, the capacitor can be completely controlled at a low-modulation region (low in voltage utilization efficiency), and the capacitance balancing computation complexity is reduced.

Owner:ZHEJIANG UNIV

Fixing device for acoustic emission test sensors for rock damage testing

ActiveUS20160231287A1Improve convenienceImprove efficiency and accuracy and authenticityMaterial analysis using acoustic emission techniquesFixed frameAcoustic emission

A fixing device for acoustic emission test sensors for rock damage testing, the device including: a fixing frame; installation bases operating to accommodate the acoustic emission test sensors, respectively; fixing assemblies operating to fix the acoustic emission test sensors in the installation bases; and installation mechanisms operating to arrange the installation bases on the fixing frame. The fixing frame is an assembled loop-shaped frame and includes between two and four frame members and corresponding fixing structures; and the frame members are assembled into an integrated loop-shaped frame by the fixing structures. Each of the installation bases is a cylinder structure. The cylinder structure includes: a cavity corresponding to an outer edge of each of the acoustic emission test sensors, and a wall including a gap for leading out wires of each sensor.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com