Preparation method of fast charging type lithium ion battery pole piece, pole piece and lithium ion battery

A lithium-ion battery, pole piece technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of shortened cycle life, low compaction density of single-sided coating area, poor conductivity, etc. Long cycle life, taking into account the effects of energy density and fast charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

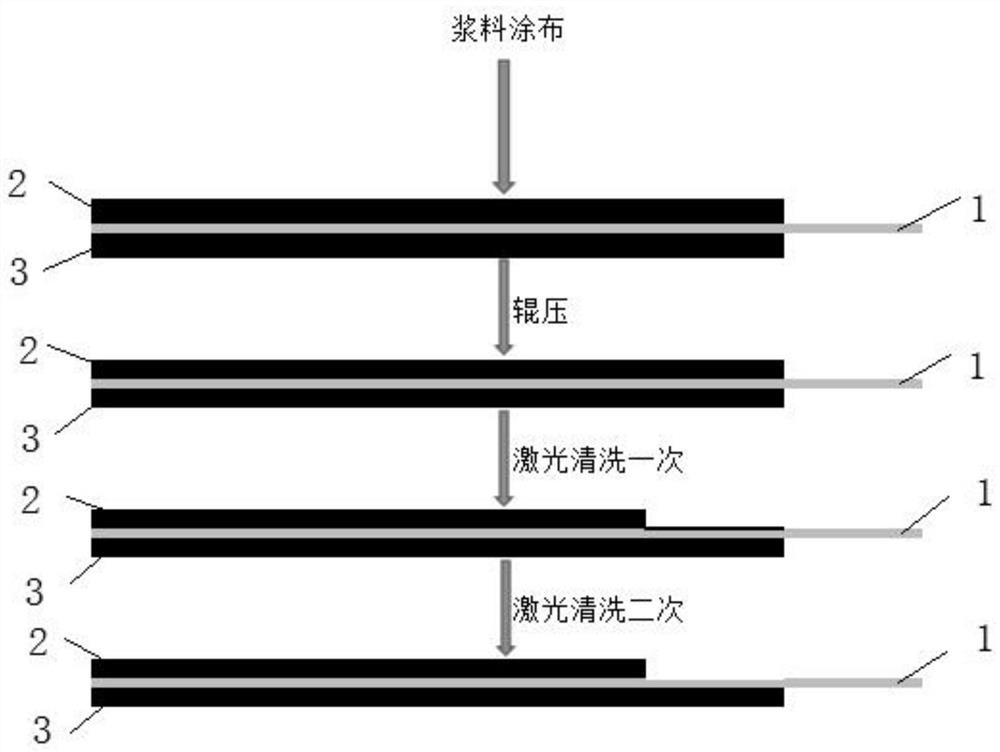

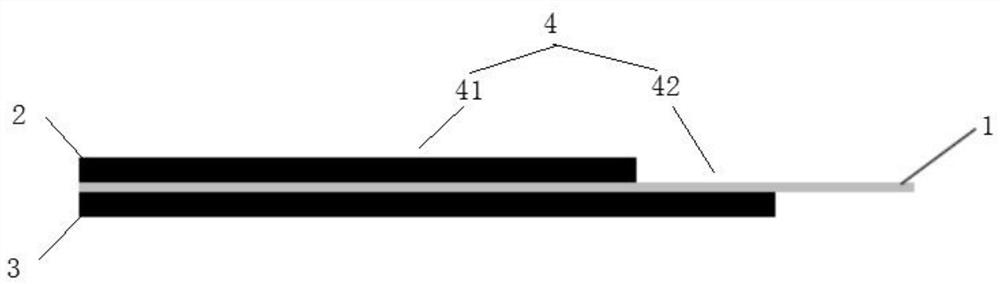

[0035] Such as Figure 1~2 Shown, a kind of preparation method of fast charging type lithium ion battery pole piece comprises the following operations:

[0036] Coating the slurry with the active material on both surfaces of the current collector 1 to obtain a pole piece with a symmetrically arranged first active material layer 2 and a second active material layer 3;

[0037] rolling the two surfaces of the pole piece;

[0038] The redundant first active material layer is cleaned to obtain a fast-charging lithium-ion battery pole piece 4 having a double-side coating area 41 and a single-side coating area 42 .

Embodiment 1

[0040] This embodiment provides a method for preparing a positive electrode sheet of a fast-charging lithium-ion battery, including the following operations:

[0041] (1) Add lithium cobaltate, conductive carbon black (SuperP), carbon nanotubes (CNT) and polyvinylidene fluoride (PVDF) with a particle size D50 of 10 μm to N-methyl In pyrrolidone (NMP), after stirring evenly, positive electrode slurry is obtained;

[0042] (2) The positive electrode slurry is coated on both surfaces of an aluminum foil with a thickness of 10 μm to obtain a positive electrode sheet with a symmetrically arranged first active material layer and a second active material layer; the positive electrode sheet is rolled after drying, and the test surface density is 18.9 mg / cm 2 , the compacted density is 4.15g / cm 3 ;

[0043] (3) Laser burning and cleaning the redundant first active material layer, and cleaning off the coating in this area to obtain a fast-charging lithium-ion battery positive electro...

Embodiment 2

[0045] This embodiment provides a method for preparing a negative electrode sheet of a fast-charging lithium-ion battery, which includes the following operations:

[0046] (1) Graphite, conductive carbon black (SuperP), single-walled carbon nanotubes (SWCNT), sodium hydroxymethylcellulose, and binder (SBR) are used in a mass ratio of 97:0.95:0.05:1:1 Feeding: First, add fast-filling graphite, conductive carbon black (SuperP), single-walled carbon nanotubes (SWCNT), and sodium hydroxymethyl cellulose to an appropriate amount of deionized water, and stir well to form a slurry with a solid content of 46%. 1; Then add the binder (SBR) aqueous solution to the slurry 1, and continue to stir for 0.5 hours to obtain the slurry 2;

[0047] (2) Slurry 2 is coated on the 8 μm thick negative electrode current collector copper foil, obtains the negative electrode sheet that has the first active material layer and the second active material layer that are arranged symmetrically, and the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com