Steel wire tension control method and device for winding multi-strand helical spring

A helical spring and tension control technology, applied in the direction of mechanical pressure/force control, non-electric variable control, control/adjustment system, etc., can solve problems such as steel wire breakage, steel wire stress inconsistency, steel wire fatigue life difference, etc., to achieve reliable work, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

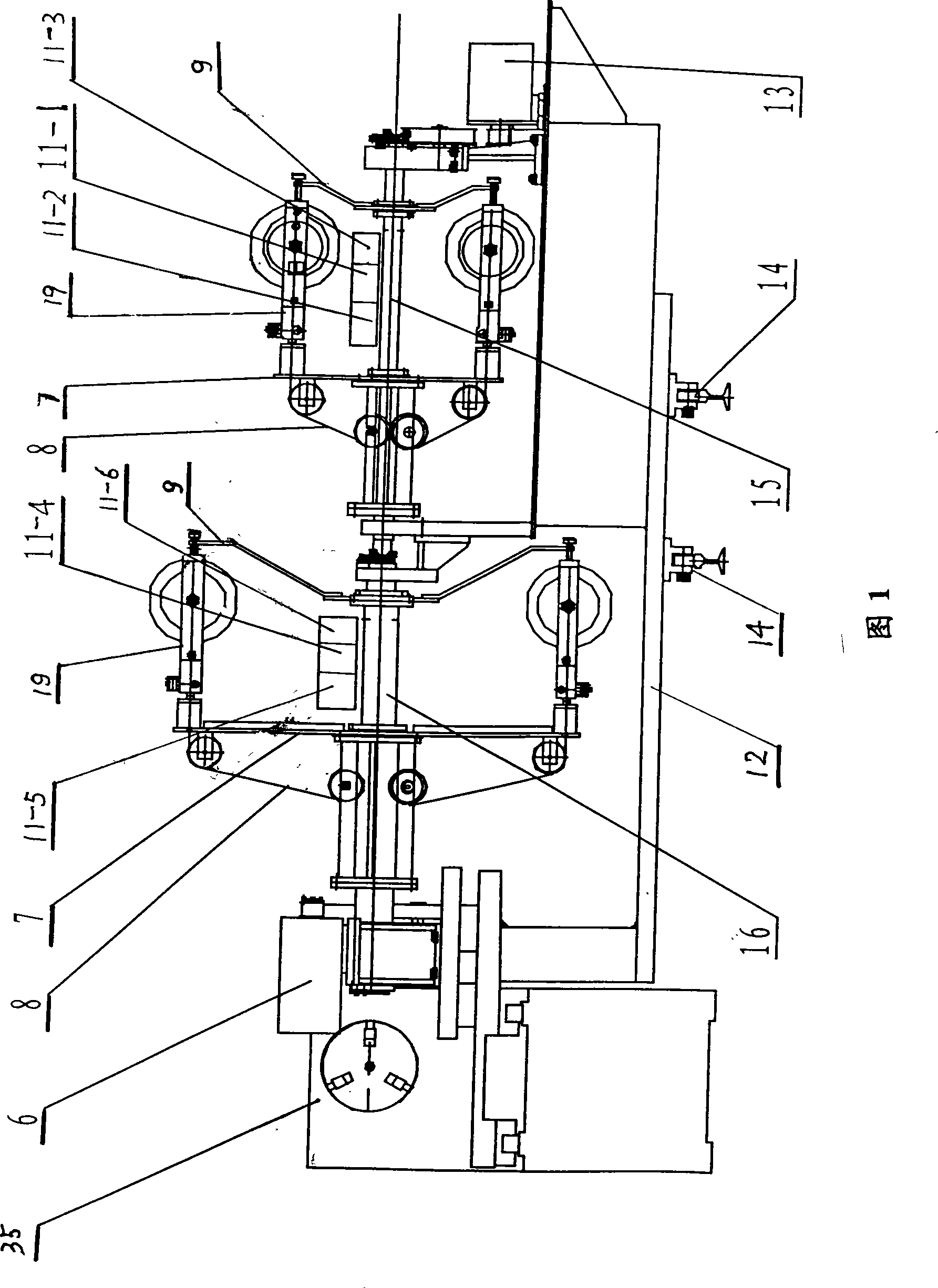

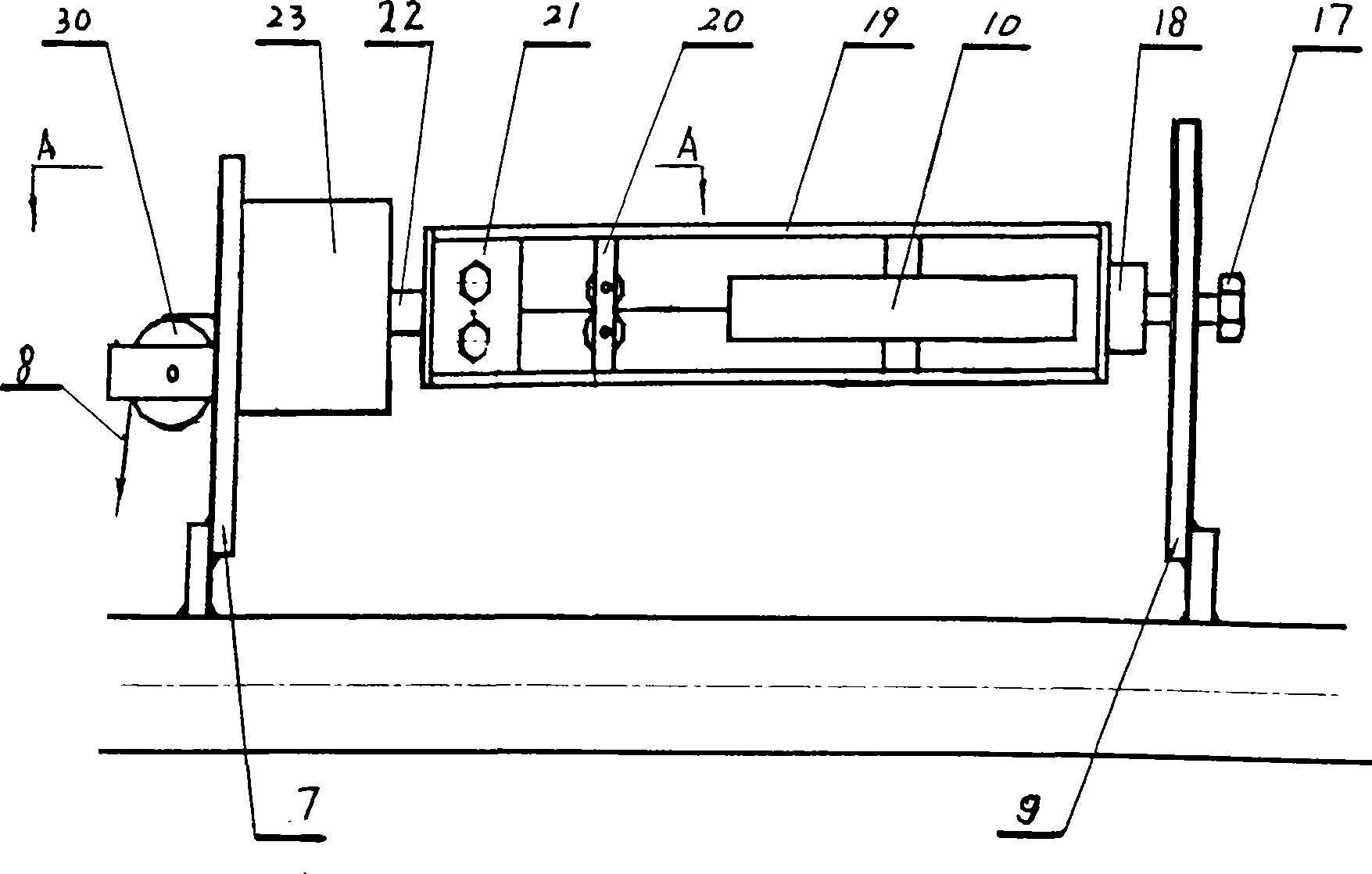

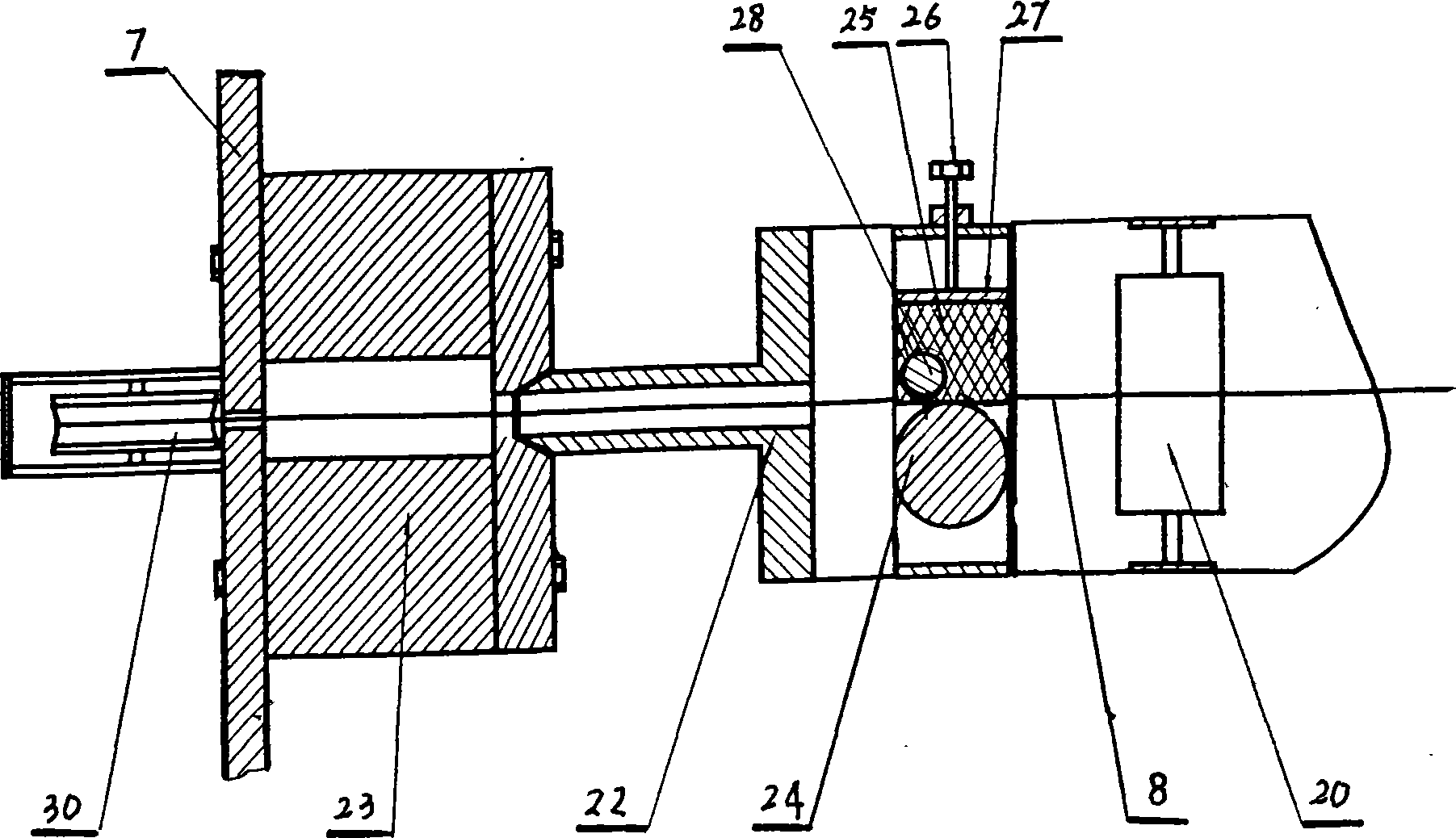

[0027] Referring to Fig. 1, the multi-strand helical spring steel wire tension control device is produced by winding, including the steel wire tension adjustment and signal transmission part and the steel wire tension signal receiving and display part; The inner layer steel wire rotating frame composed of independent supports on the upper layer and the outer layer steel wire rotating frame composed of 12 independent supports that are positioned and connected on the outer layer rotating shaft 16;

[0028] The inner layer rotating shaft 15 is installed on the right part of the wire rope winding device 12, driven by the first motor 13; the outer layer rotating shaft 16 is installed on the left part of the wire rope winding device 12, driven by the second motor 6; the wire rope winding device 12 moves along the track 14, and the multi-strand spring winding equipment 35 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com