Connecting structure for suspendome

A technique for a chord-supported dome and a connecting structure, which is applied in the field of construction, can solve the problems of large deviation between the measured value of prestress and the design value, increase the index of steel used, and less engineering application, so as to ensure the construction quality, eliminate the processing error, and facilitate the construction site. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

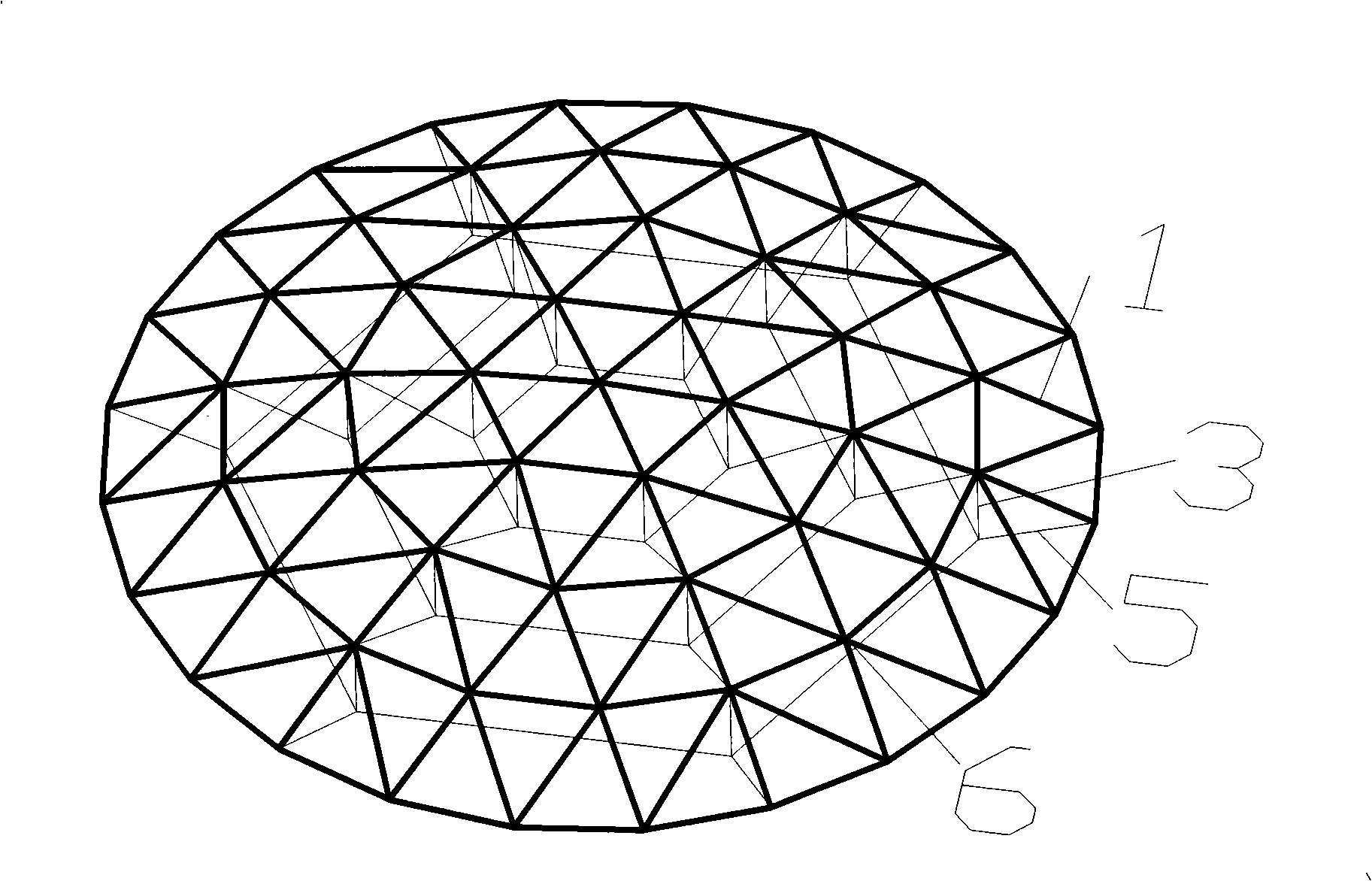

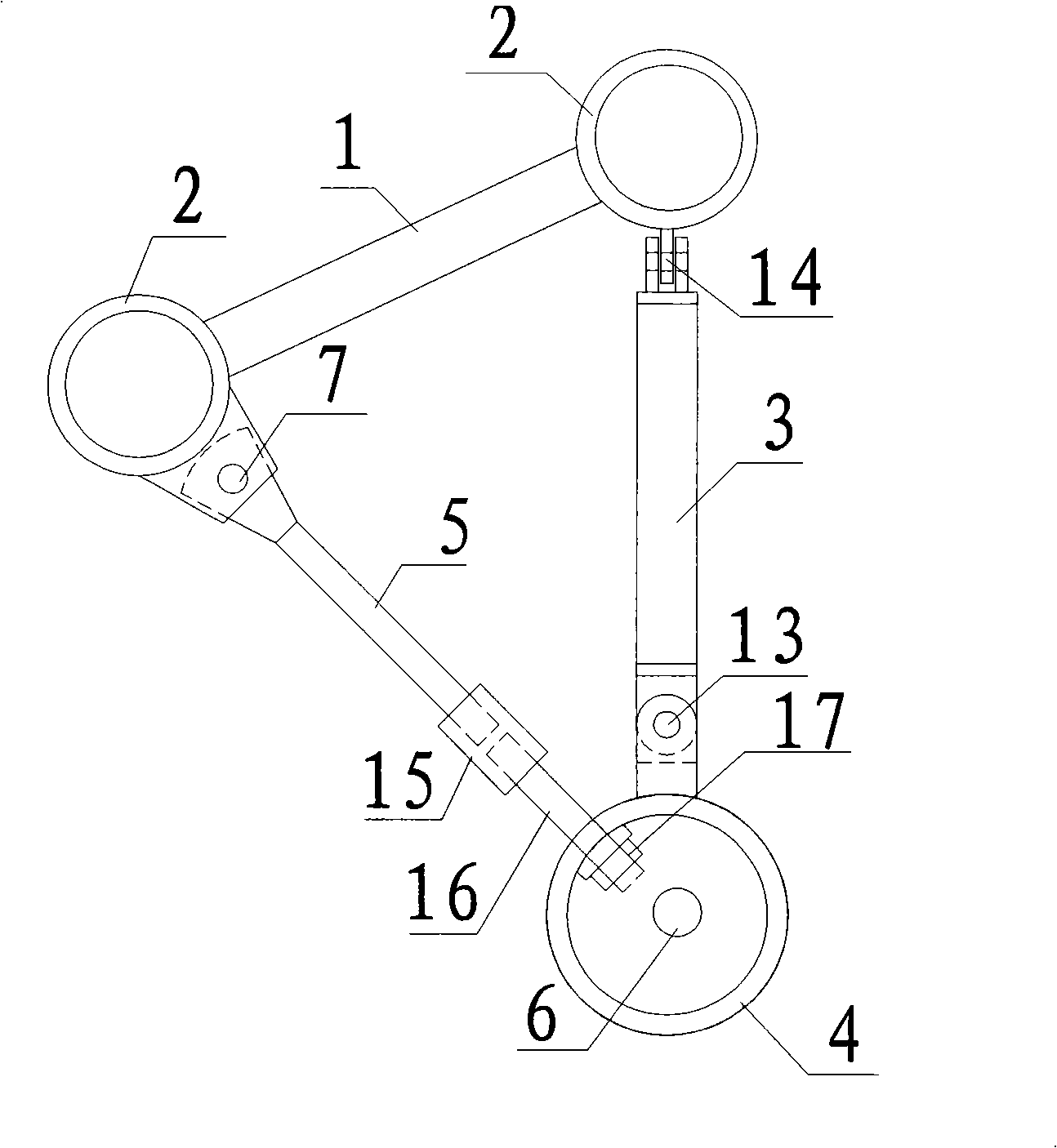

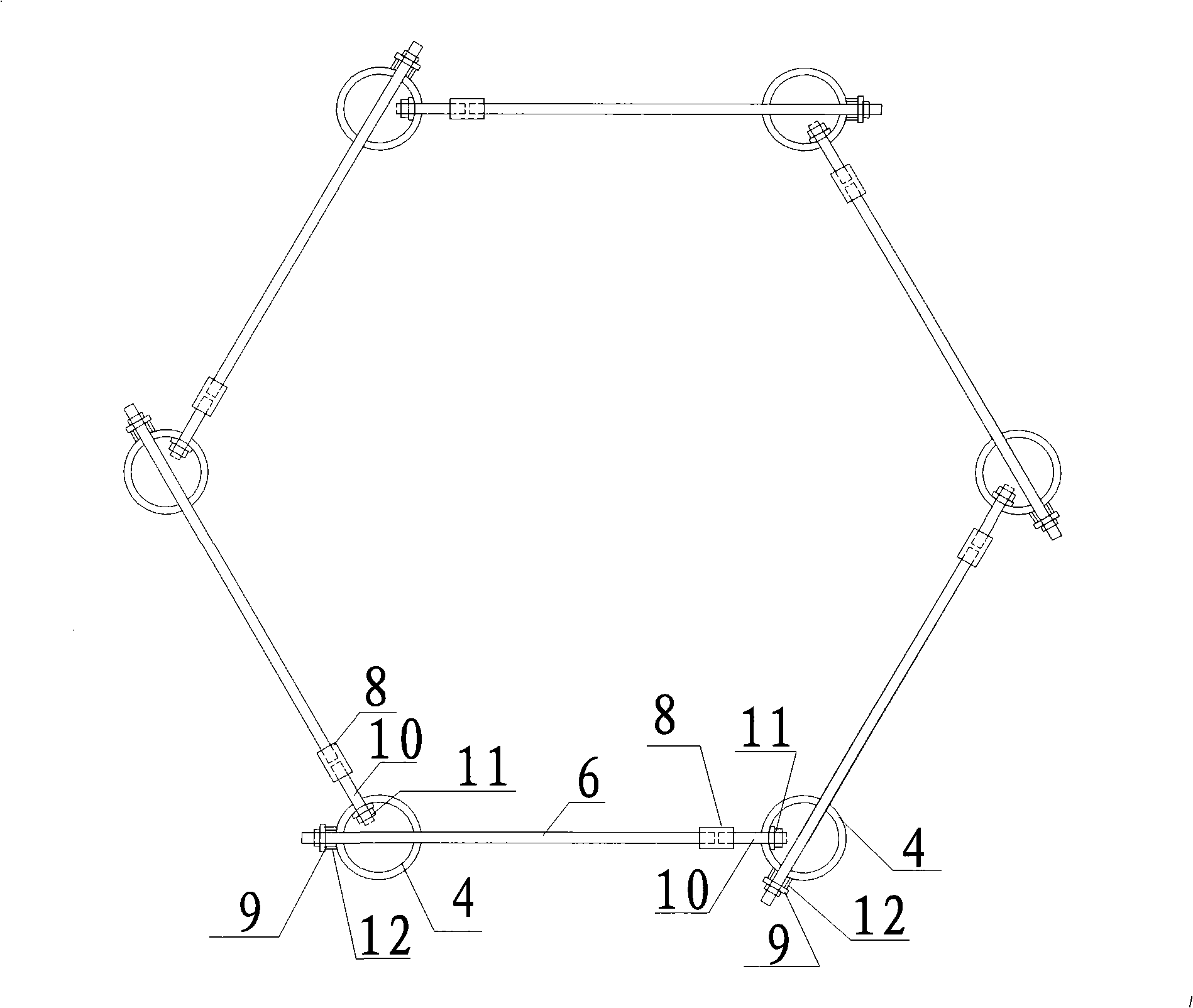

[0021] The connection structure for the suspendome structure includes upper chord reticulated shell rods 1, upper chord reticulated shell nodes 2, vertical compression bars 3, welded hollow spherical nodes 4, oblique cables 5, ring cables 6, first pin bolt connection joints 7, First threaded sleeve 8, first nut and backing plate 9, first cable head 10, second nut and backing plate 11, support pipe 12, second pin connection joint 13, third pin connection joint 14 , the second threaded sleeve 15, the second cable head 16, the third nut and the backing plate 17; the rod 1 and the node 2 form the reticulated shell structure part of the suspensive dome structure, the oblique cable 5, the ring cable 6 and the vertical pressure Rods 3 are connected by welded hollow ball joints 4; welded ball joints 4 have three holes in the direction of the horizontal hoops, two of which allow a hoop 6 to pass through the welded ball joints 4 and pass through the first nut and backing plate 9 Anchori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com