Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about How to "Eliminate machining errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precise combined-machining equipment for complicated profiles made of hard and brittle materials

InactiveCN102069425AEliminate machining errorsImprove machining accuracyDriving apparatusMetal working apparatusUltrasonic sensorElectric machinery

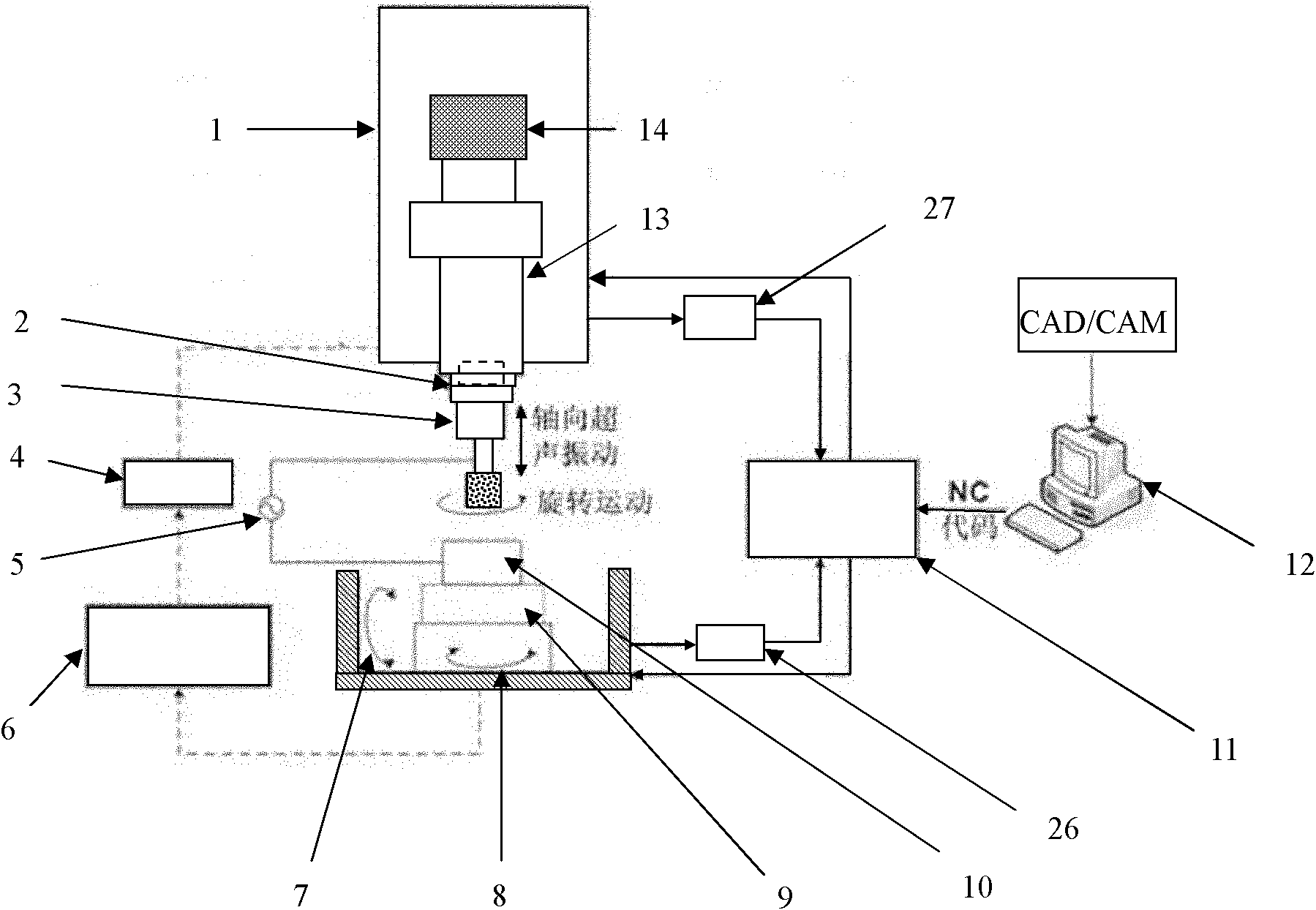

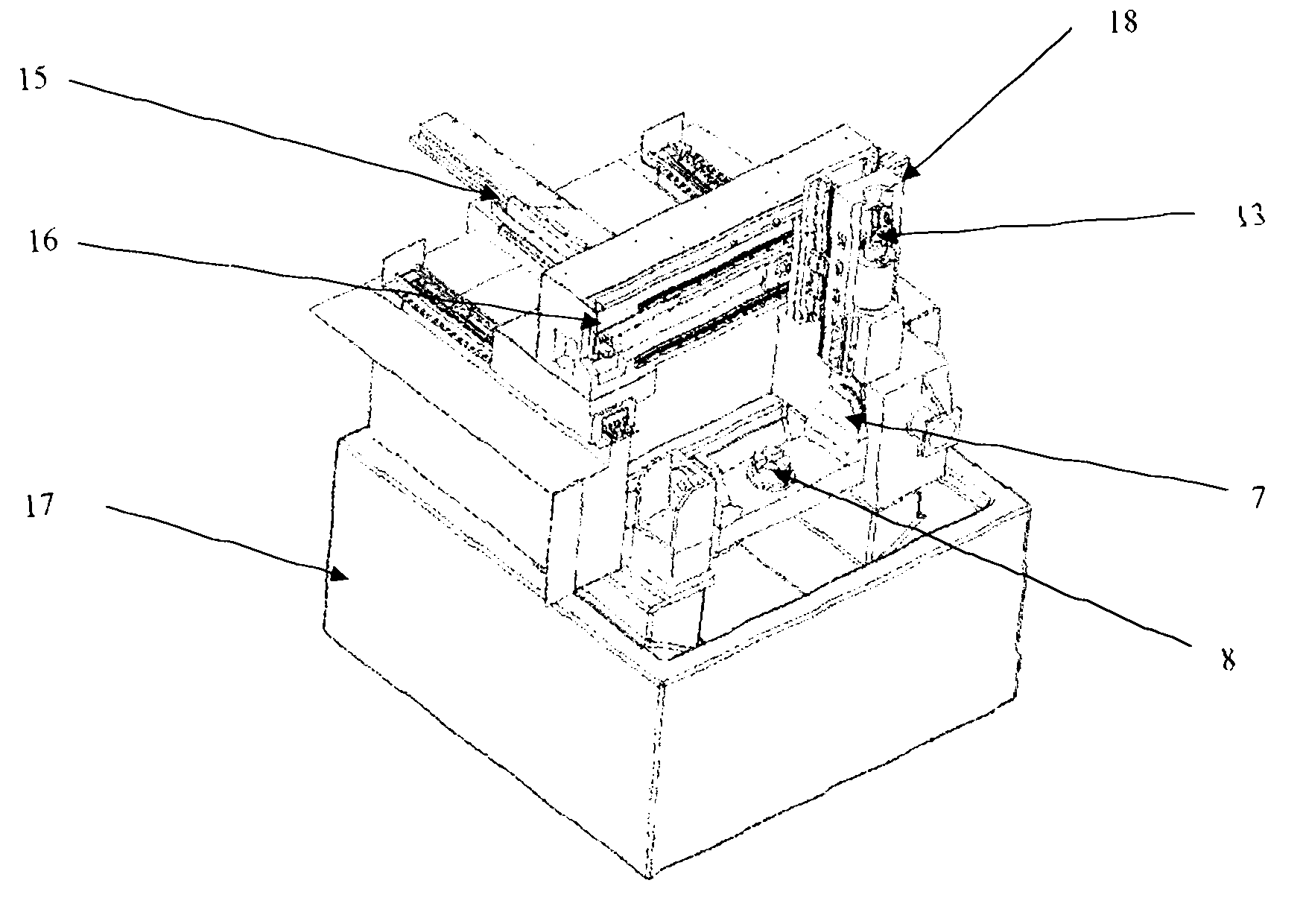

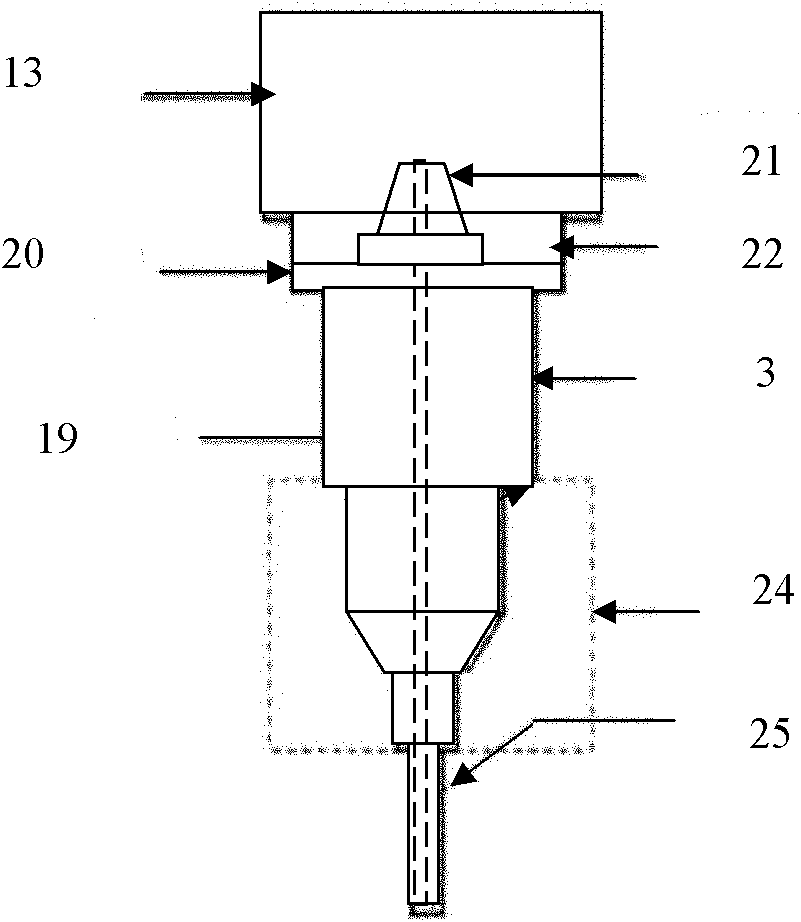

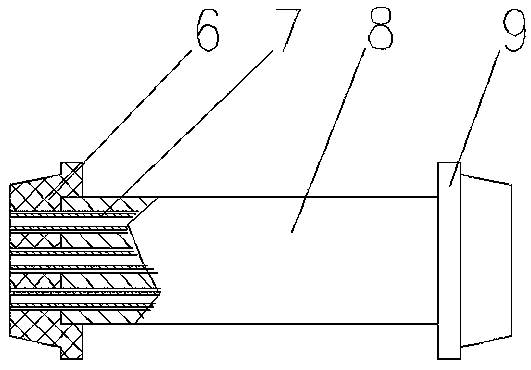

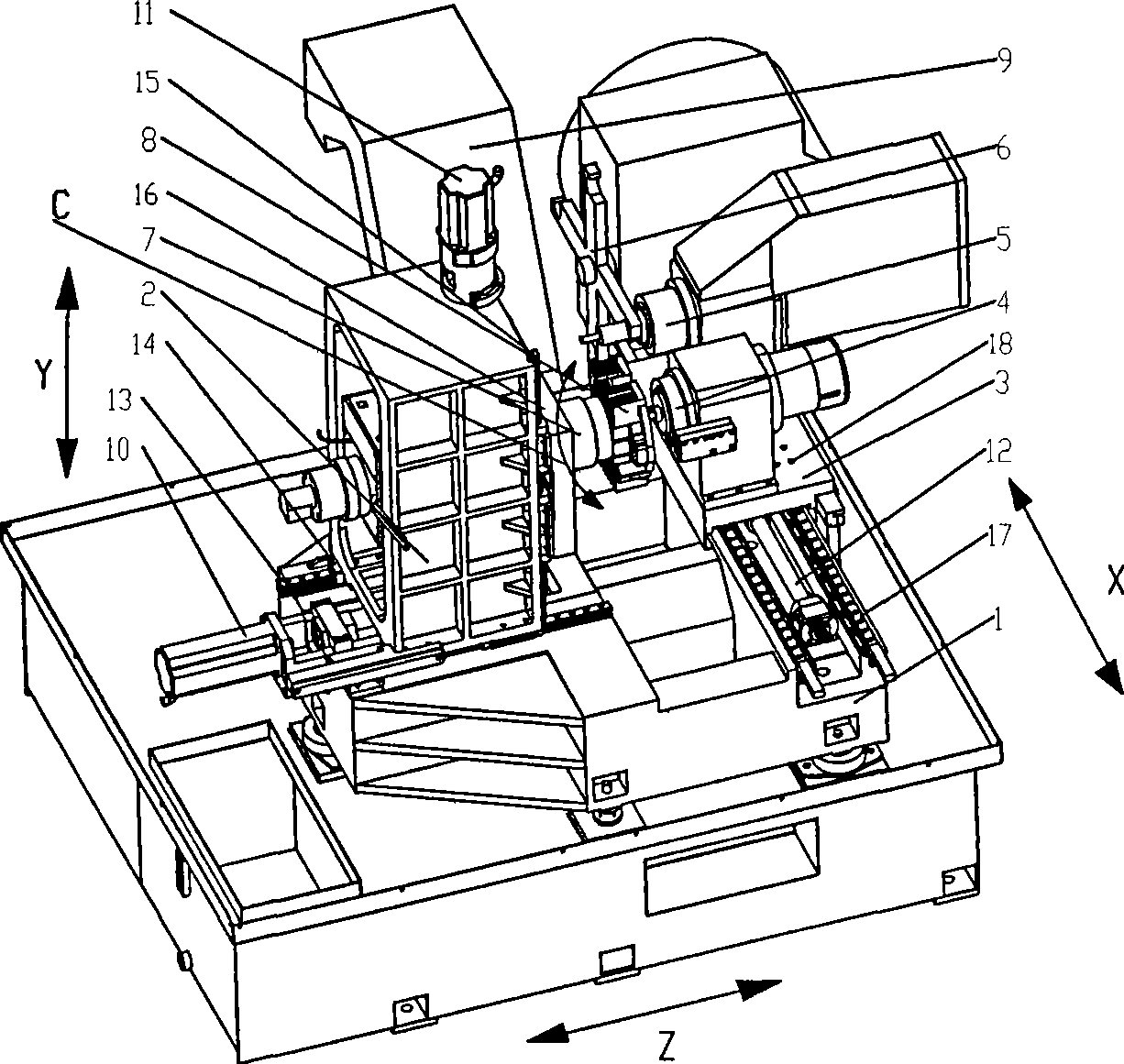

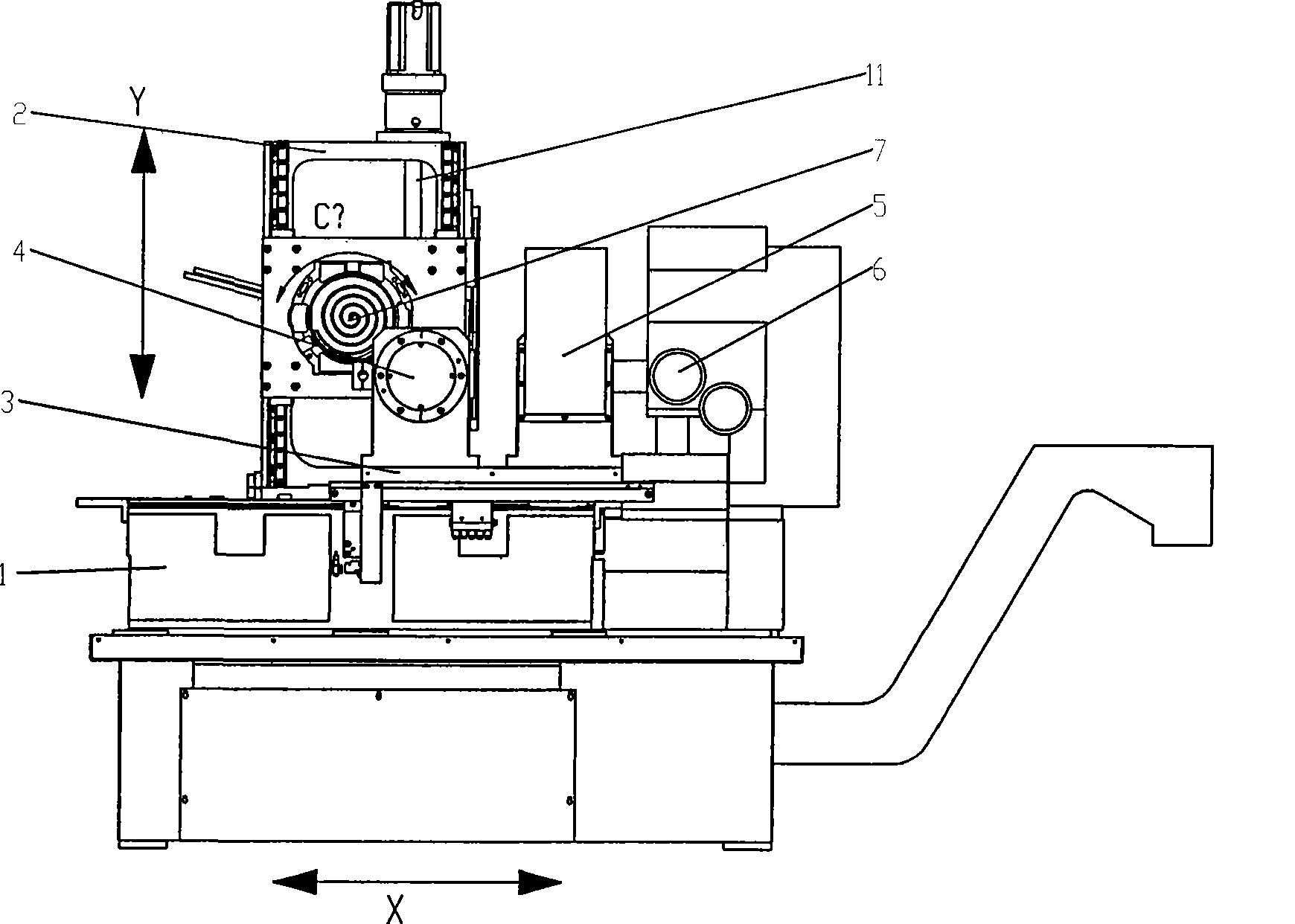

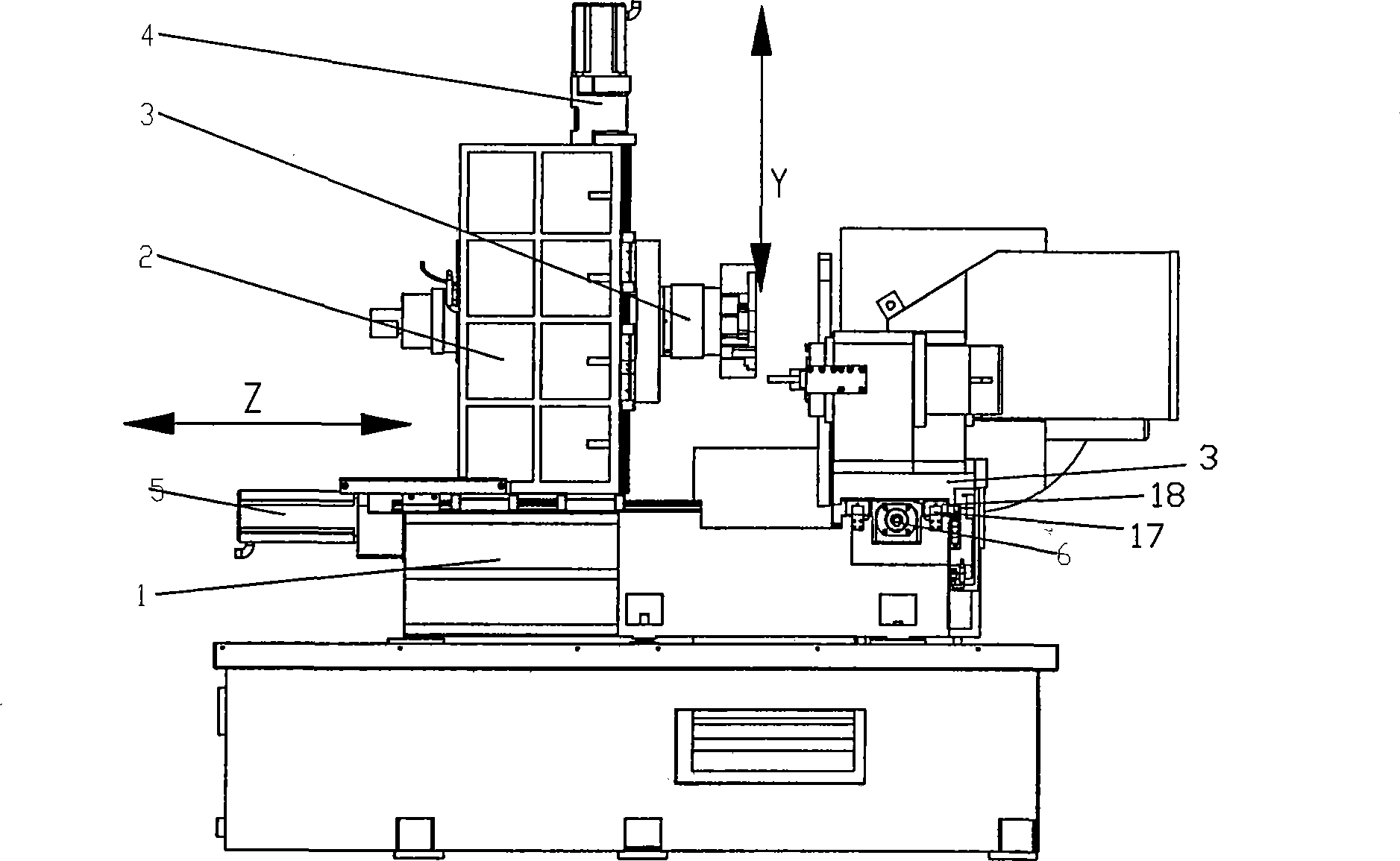

The invention discloses precise combined-machining equipment for complicated profiles made of hard and brittle materials. The equipment comprises a machine tool body which is provided with an X-Y-Z three-linkage workbench and an air float workbench bracket, wherein the moving output end of the three-linkage workbench is provided with a spindle which, driven by the X-Y-Z three-linkage workbench, can linearly move in the X, Y and Z directions; one end of the spindle is connected with an output shaft of a spindle rotating motor and the other end of the spindle is connected with a cutter handle through an interface; an ultrasonic transducer is mounted inside the cutter handle and is connected with a variable-amplitude rod; the air float workbench bracket is rotatably connected with an A-axis rotary workbench; the A-axis rotary workbench is provided with a C axis; the C axis is provided with an air float workbench; and the air float workbench can be arranged opposite to a machining tool. By adopting the equipment, integrated machining of various machining processes can be realized, and rough-semifinishing-finish multi-process machining can be implemented immediately after the workpieceis clamped once.

Owner:TIANJIN UNIV

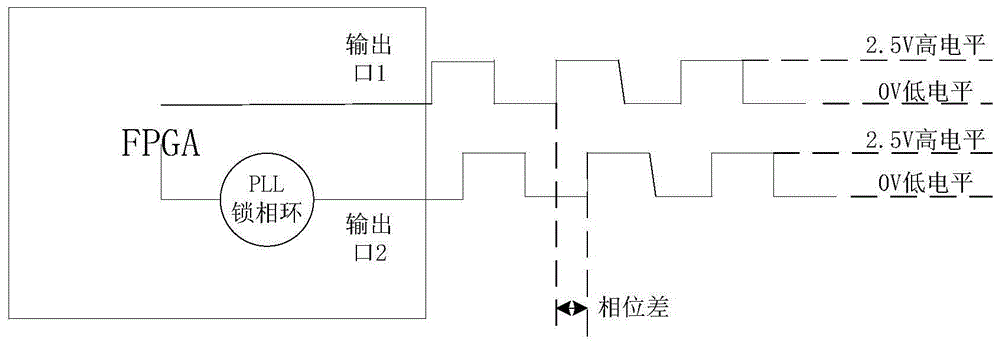

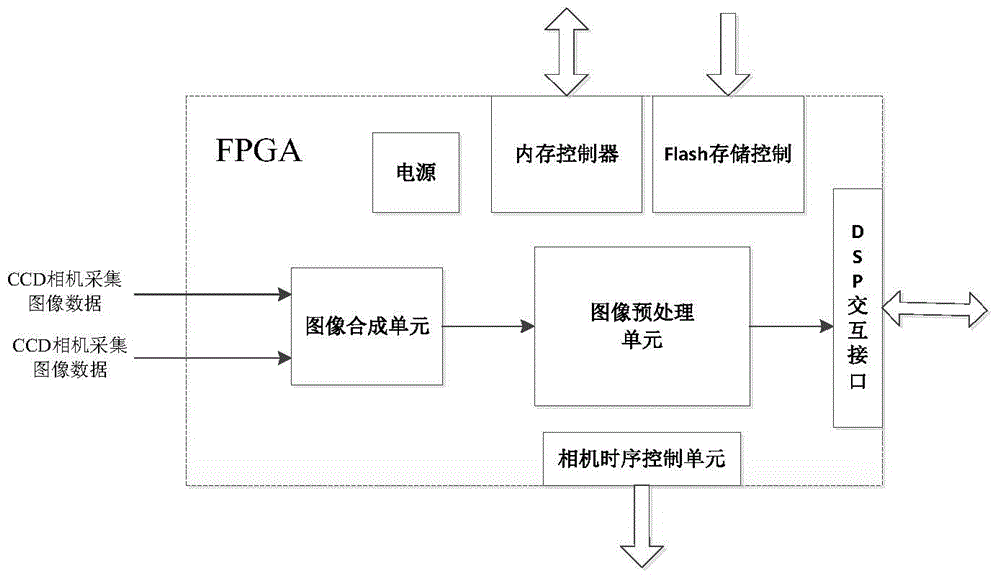

High-speed image acquisition and processing system

InactiveCN104902167ALow installation costEliminate spatial position errors and processing errorsTelevision system detailsColor television detailsCcd cameraImage synthesis

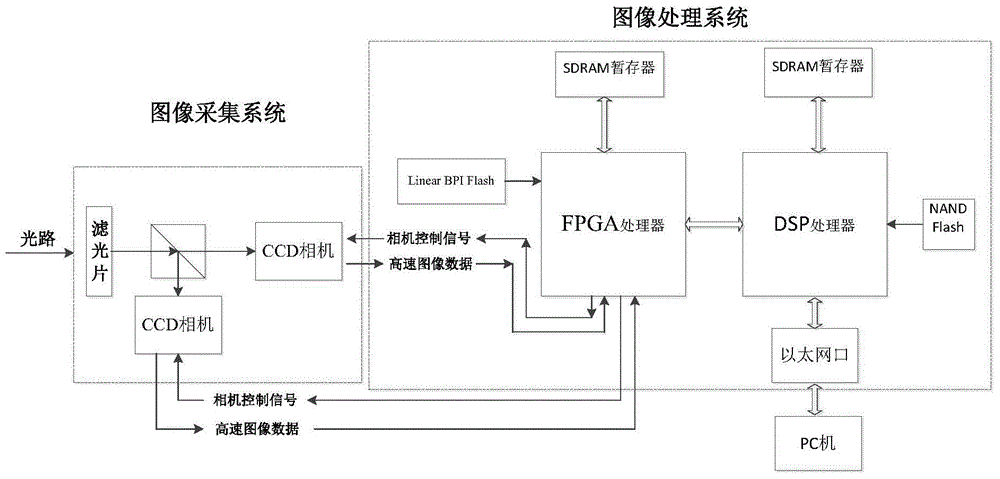

The present invention provides a high-speed image acquisition and processing system. The system comprises a beam splitter prism, two CCD cameras, a camera adjusting device and an FPGA. The beam splitter prism is used for splitting incident light into two sub light beams to respectively enter the two CCD cameras. The camera adjusting device is used for adjusting the spatial positions of the two CCD cameras. The FPGA includes a camera timing control unit, an image synthesis unit and an image pre-processing unit. The camera timing control unit is used for sending pulse control signals, via two triggering wires, to the two CCD cameras to control the two CCD cameras to be triggered by time and make exposures at different times for acquiring images. The image synthesis unit combines the images of the two CCD cameras into a continuous image. The image pre-processing unit is used to pre-process the image. The high-speed image acquisition and processing system of the present invention achieves high-frequency image acquisition with low-frequency image sensors, so that the device cost is significantly lowered, the image collection acquisition is increased, and the system is particularly suitable for image acquisition and processing of high-speed moving object measurement.

Owner:HUAZHONG UNIV OF SCI & TECH

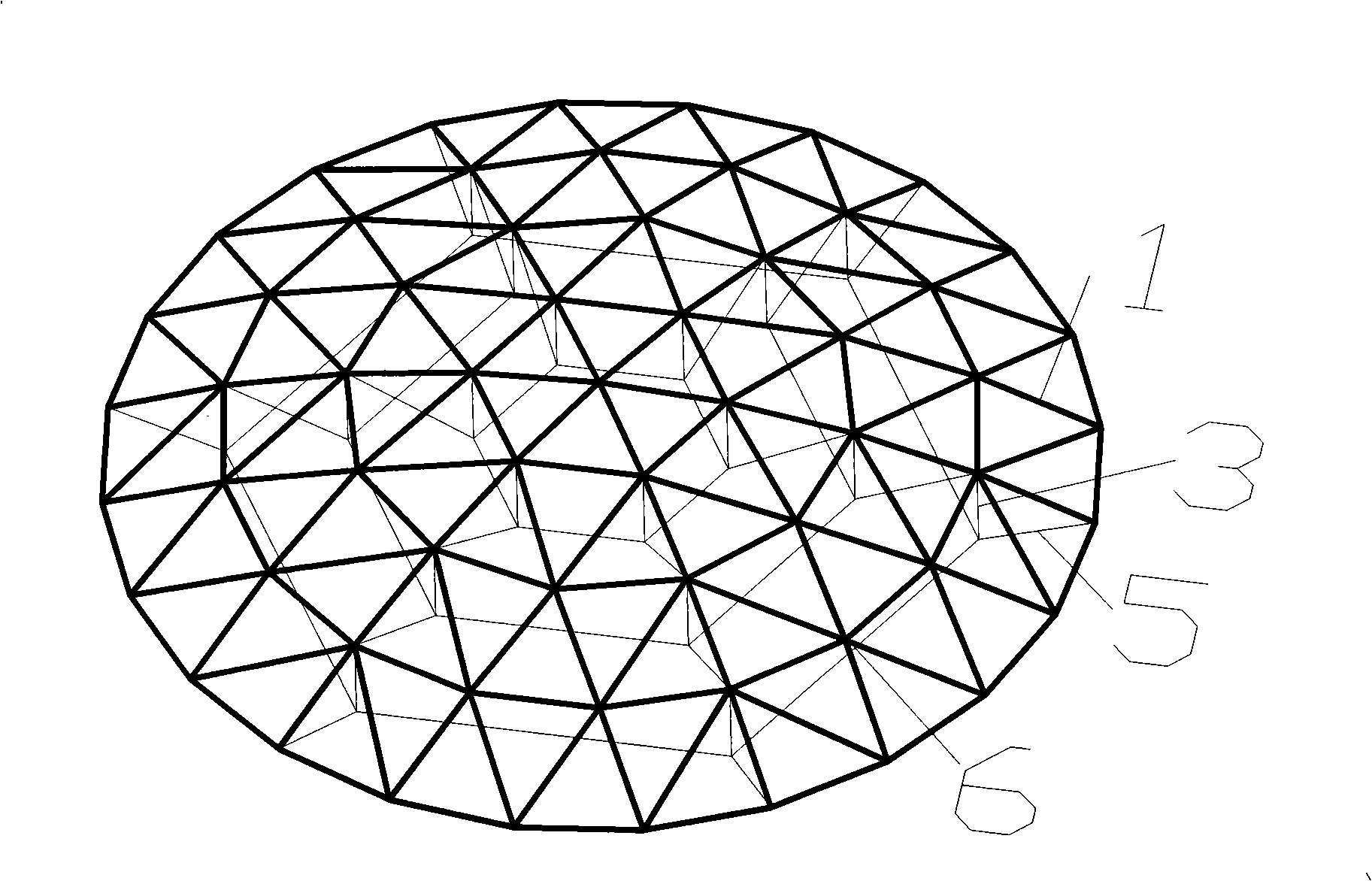

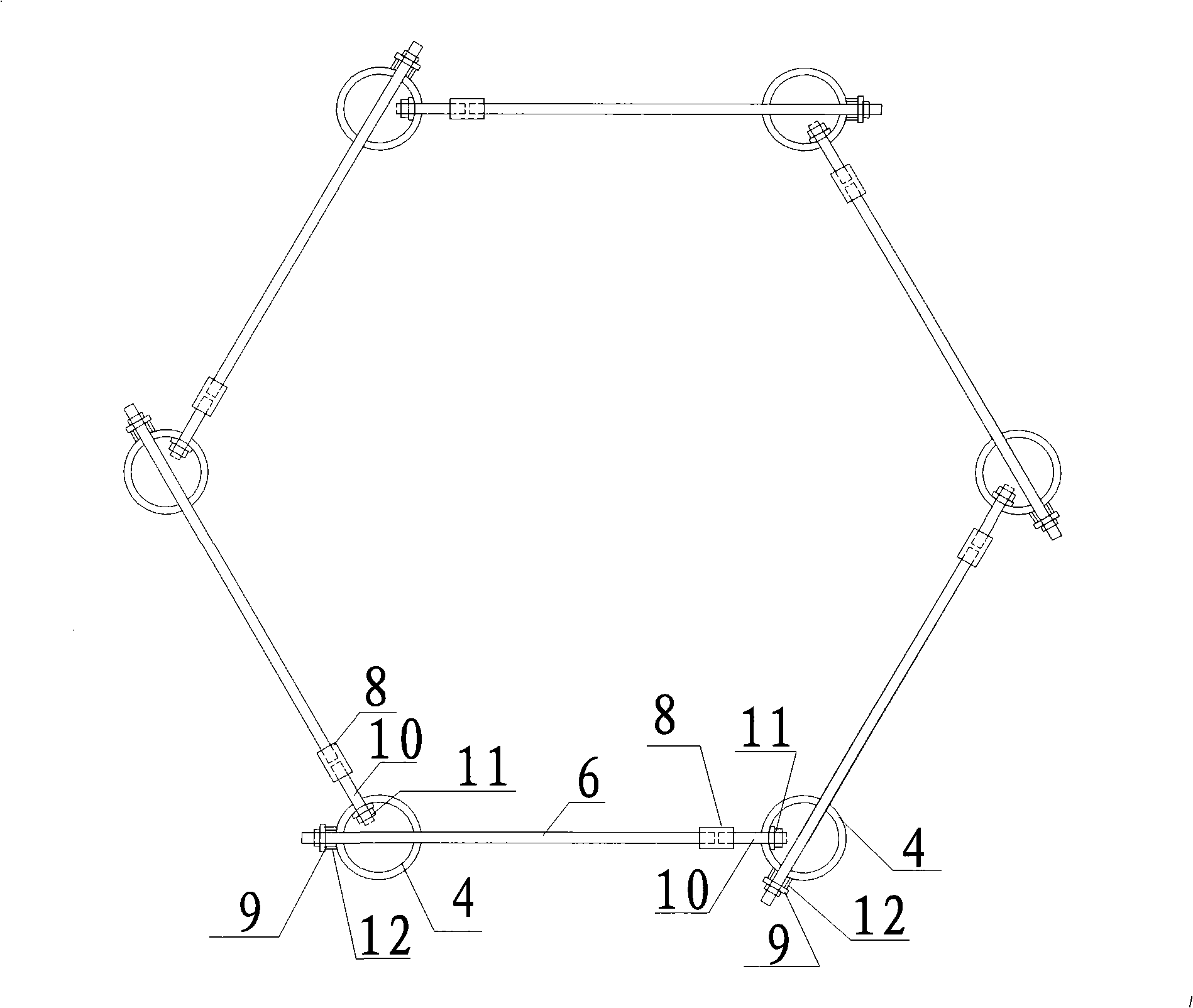

Connecting structure for suspendome

InactiveCN101314972AEasy to processEasy to installBuilding roofsArched structuresSpherical jointScrew thread

The invention discloses a connecting structure used for a suspend-dome structure. The suspend-dome structure is a structure formed by connecting an upper chord single-layer spherical reticulated shell, an oblique cable and hoop cables through a vertical compression rod. In the connecting structure, the oblique cable, the hoop cables and the vertical compression rod are connected with each other through a welded hollow spherical joint. The welded hollow spherical joint forms three holes in the horizontal hoop cable direction, wherein two holes allow one hoop cable to penetrate the welded hollow spherical joint and be anchored through a cast anchor, the other hole allows a washer inside the welded hollow spherical joint to be anchored with a screw cap to form a connecting cable head, and the connecting cable head is connected with a threaded sleeve through the other hoop cable; the welded hollow spherical joint forms the other hole in the oblique cable direction, the washer used inside the welded hollow spherical joint is anchored with the screw cap to form the other connecting cable head, and the connecting cable head is connected with the hoop cables through the threaded sleeve. After the connecting structure is adopted, the construction of the suspend-dome structure is very convenient, the cable force can be adjusted times and again, and the disadvantage that the cable force in the prior suspend-dome structure engineering is difficult to be consistent with the theoretical value can be overcome.

Owner:ZHEJIANG UNIV

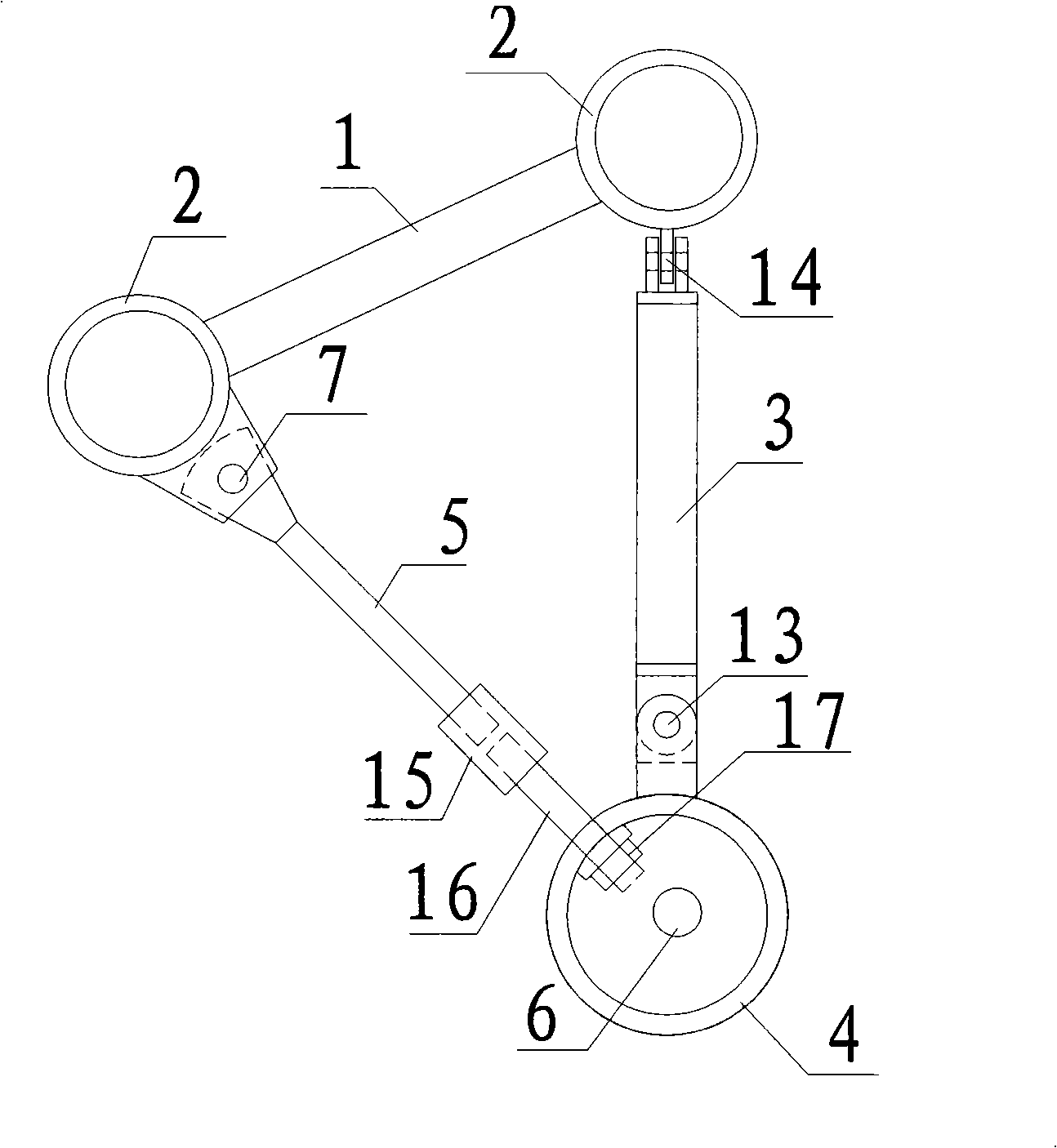

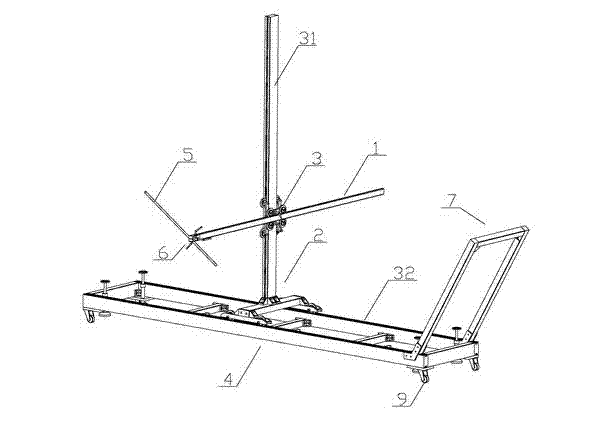

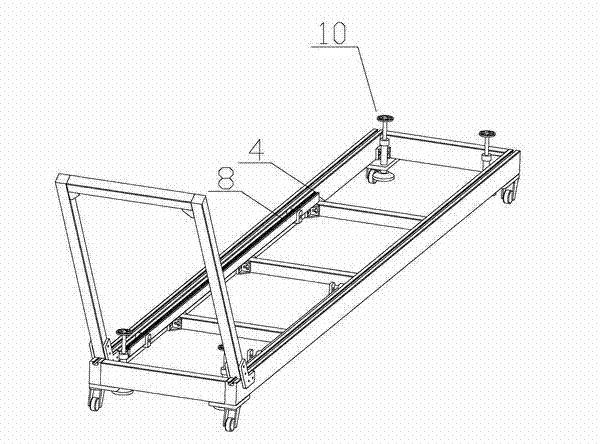

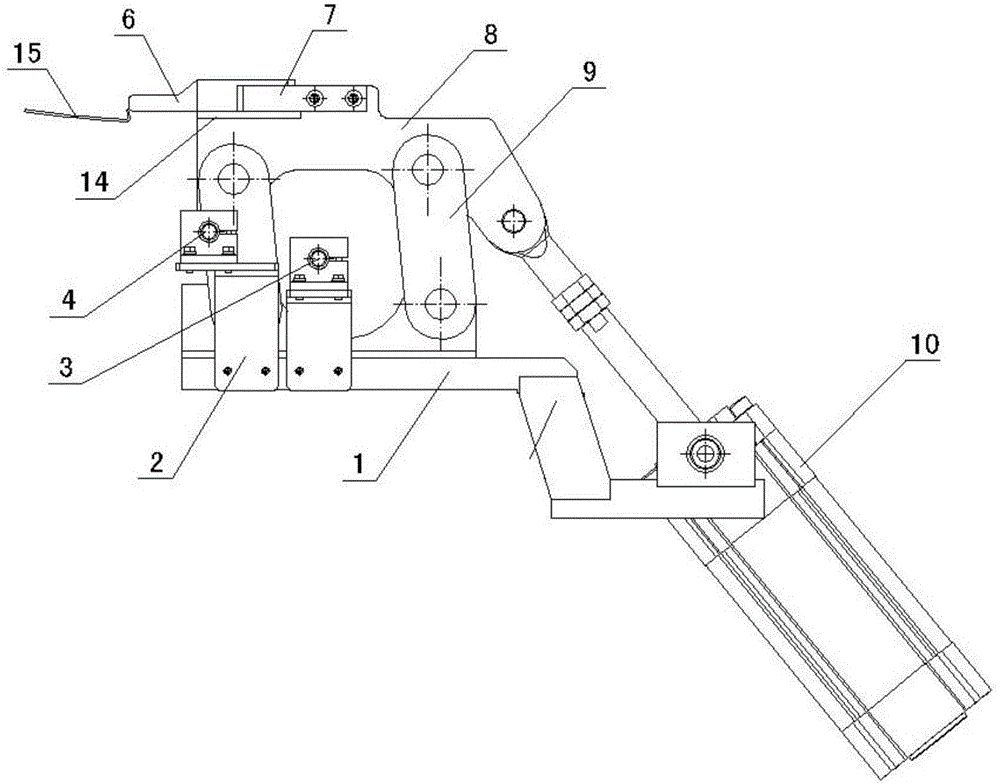

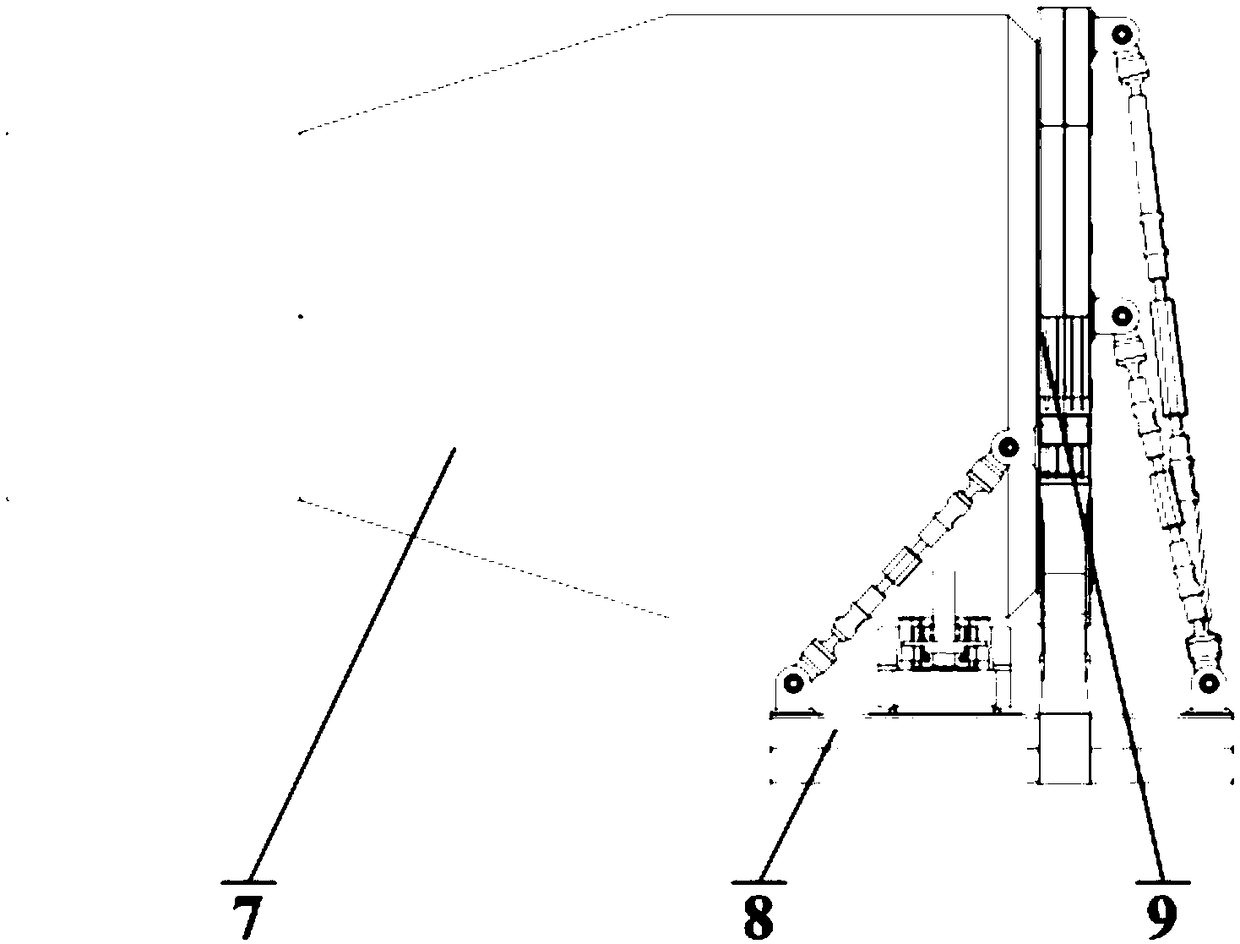

Pedestrian protecting vehicle scriber used for collision test

ActiveCN102501237AEasy to operateImprove marking efficiencyOther workshop equipmentUniversal jointScriber

The invention discloses a pedestrian protecting vehicle scriber used for a collision test, which comprises a movable base arranged in the Y direction, a horizontal moving rack, a longitudinal moving rod and a scribing rod, wherein the movable base is provided with a self-arranged leveling and fixing device; the horizontal moving rack and the movable base are in Y-direction sliding fit; a Z-direction extending vertical strut is fixed on the horizontal moving rack; the longitudinal moving rod is horizontally arranged on the vertical strut along the X direction; the longitudinal moving rod can horizontally slide along the X direction and the Z direction on the vertical strut and is locked and positioned; the scribing rod is arranged on one end of the longitudinal moving rod by a universal joint; and a space angle between the scribing rod and the longitudinal moving rod can be regulated at will. The pedestrian protecting vehicle scriber has the characteristics of low working intensity, high scribing efficiency and high scribing precision, is convenient and simple to operate, is convenient to move and saves space, can be made of belt trough aluminium profile, aluminium alloy plates and few steel materials to guarantee integral strength and have portability. The pedestrian protecting vehicle scriber is suitable for various vehicle collision test processes to serve as an auxiliary tool to carry out pedestrian protecting scribing operation.

Owner:长城汽车股份有限公司平湖分公司

Coil supporting device and plasma processing equipment

ActiveCN104299870AEliminate installation errorsEliminate machining errorsElectric discharge tubesRadio frequencyPlasma processing

The invention relates to a coil supporting device and plasma processing equipment. The coil supporting device is used for supporting a coil arranged above the top part of a reaction chamber. The coil supporting device comprises a shielding cover, a coil support and an elevating driving mechanism. The shielding cover is fixed at the top part of the reaction chamber. The coil and the coil support used for fixing the coil are arranged in the internal part of the shielding cover. The elevating driving mechanism is fixed above the top part of the shielding cover and used for driving the coil support and the coil fixedly connected with the coil support to move in an elevating way relative to the reaction chamber. According to the coil supporting device, height of the coil relative to the reaction chamber can be adjusted by driving the coil to move in the elevating way so that possible installing error and processing error of the coil can be eliminated, distribution of a radio frequency magnetic field in the reaction chamber can also be flexibly and accurately adjusted, and thus uniformity of the technology can be enhanced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

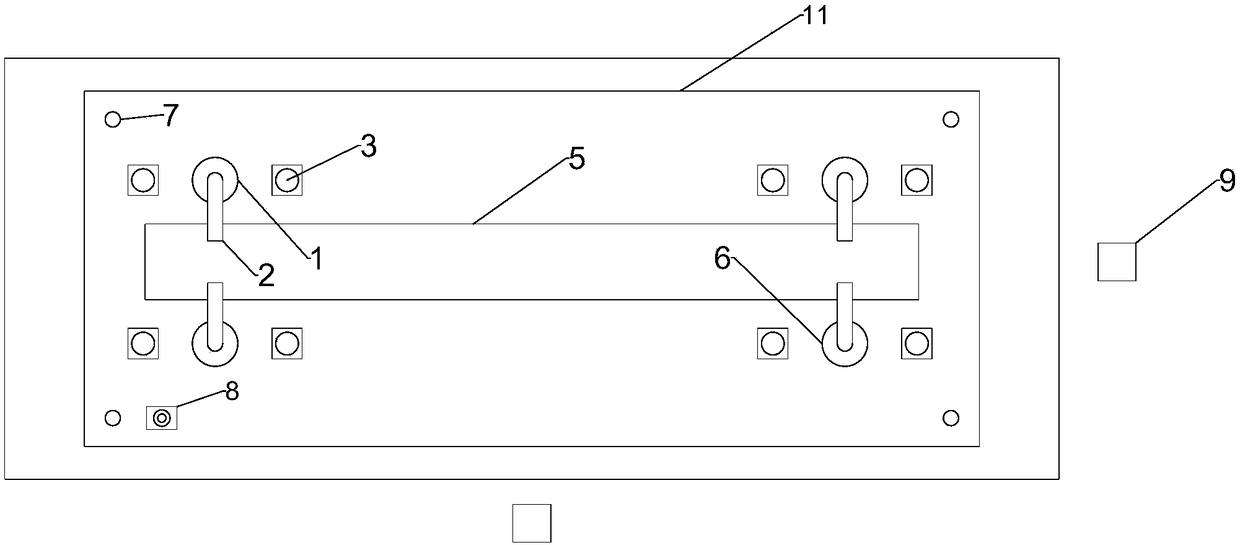

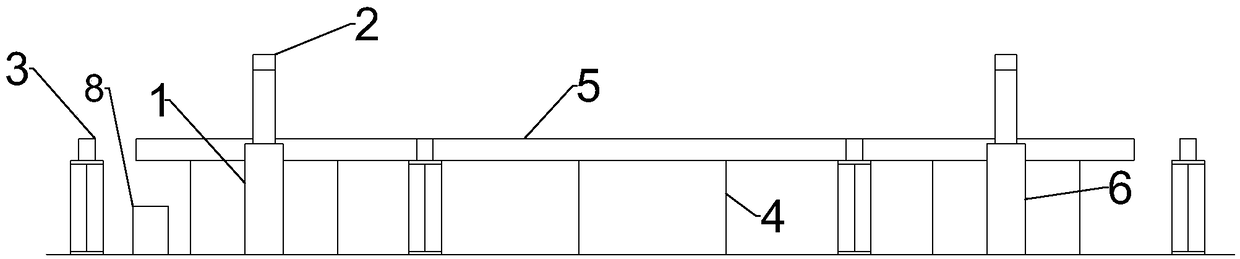

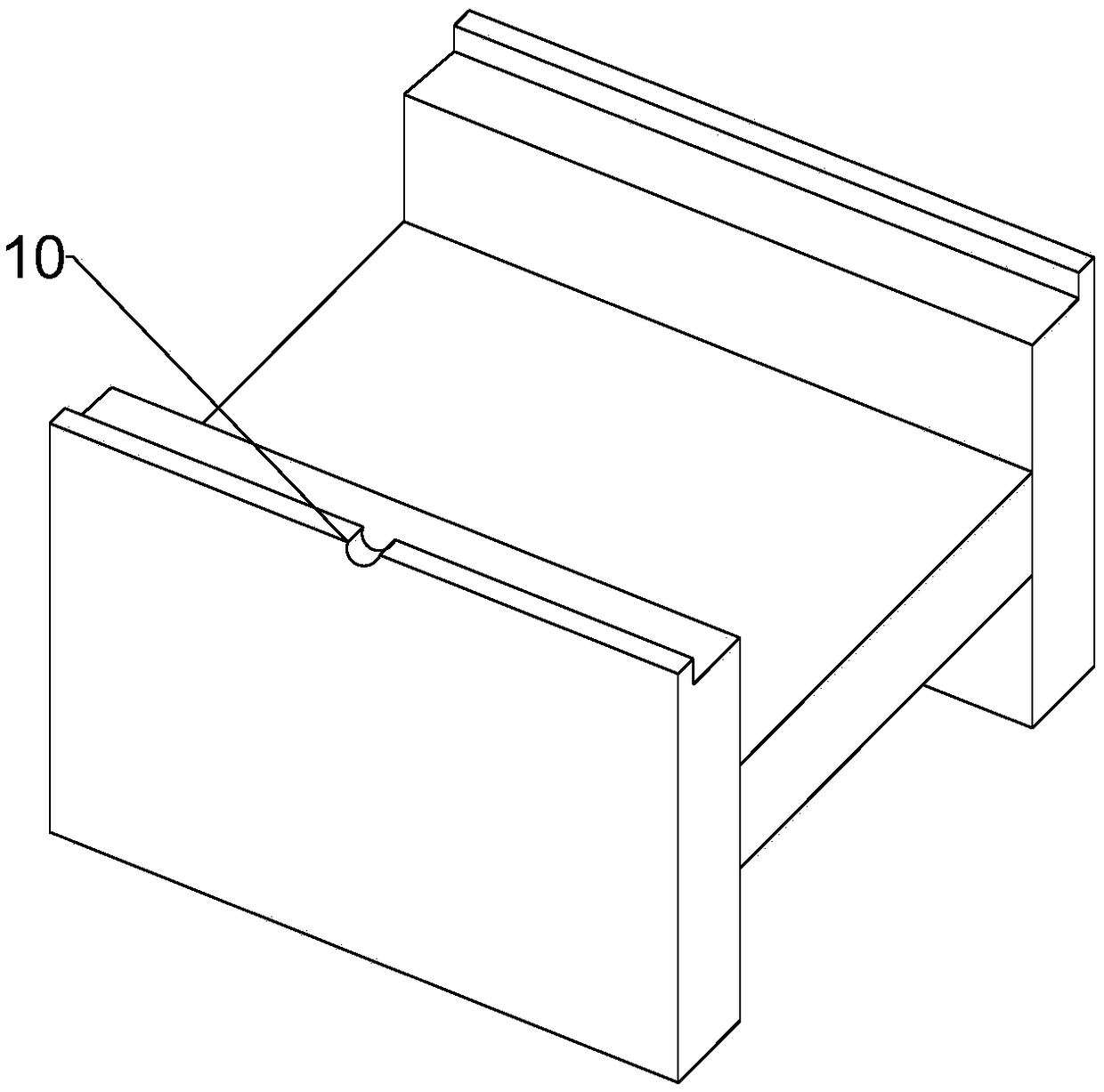

Aviation structural part automatic avoiding clamp device

InactiveCN108857506AImprove contactEliminate machining errorsWork clamping meansMeasurement/indication equipmentsAirplaneMachine tool

The invention discloses an aviation structural part automatic avoiding clamp device. The device comprises a bottom plate, a clamping unit, a detection unit, a supporting unit and a tool setting element. The clamping unit comprises four rotary clamping air cylinders, every two rotary clamping air cylinders form a group, and the rotary clamping air cylinders are divided into a first rotary clampingair cylinder group and a second rotary clamping air cylinder group. The supporting unit comprises at least three supporting plates which are arranged on the bottom plate, and a straight line is evenlydistributed under a clamped part. By means of multi-point clamping, the contact mode of a clamp and the part is improved, and machining errors caused by most of the clamping factors are effectively eliminated. A sensor is used for accurate positioning and pneumatic element control, so that a machining tool is automatically avoided, and machining efficiency and the machining errors caused by repeated clamping are greatly improved. According to the device, machining requirements of the whole structural part of an aircraft can be efficiently met at high quality, and the operation is convenient and fast.

Owner:四川铭利达科技有限公司

Eddy current displacement sensor array space geometry calibration method

ActiveCN107621220AAchieving Spatial Geometry CalibrationEliminate installation errorsUsing electrical meansSensor arrayEddy current

The invention belongs to the detection technical field and relates to a space geometry calibration method for any eddy current displacement sensor array by utilizing a common plane calibration board.The method is characterized by, to begin with, through rotation of the plane calibration board along one edge, realizing space geometry calibration in two directions between any two probes in an eddycurrent displacement sensor array; then, through rotation of the plane calibration board along the other edge, realizing space geometry calibration in the third direction of the any two probes; and finally, realizing space geometry calibration of the eddy current displacement sensor array, and obtaining space three-dimensional information of any probe in the array. The method realizes overall space geometry calibration of the eddy current displacement sensor array through two-axis rotation of the calibration board, thereby eliminating installation and processing errors, and improving calibration precision effectively; and the method is high in universality.

Owner:DALIAN UNIV OF TECH

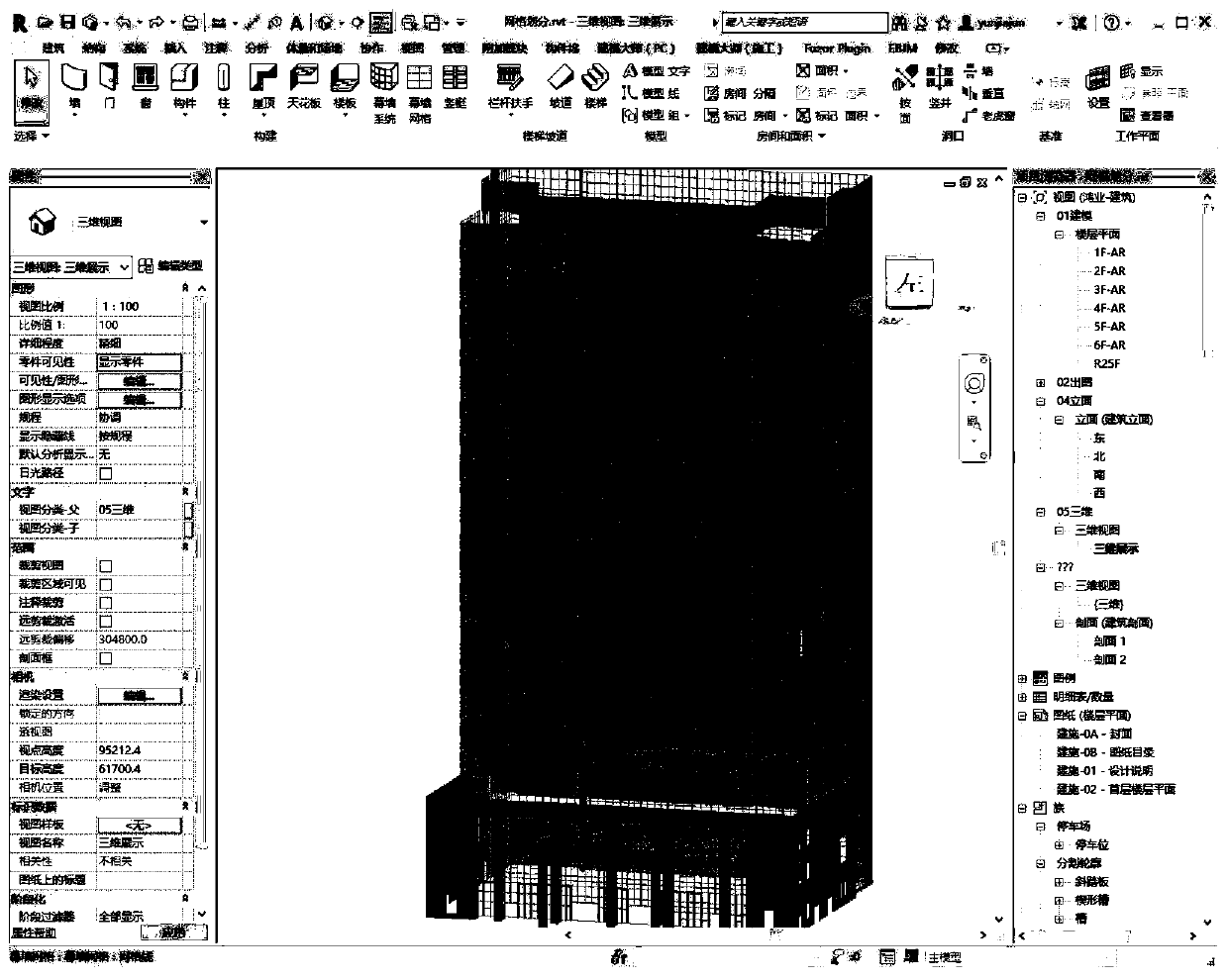

Curtain wall production and processing method based on BIM technology

The invention discloses a curtain wall production and processing method based on a BIM technology, and belongs to the technical field of curtain walls. The curtain wall production and processing method comprises the following steps of S1, designing a drawing; S2, performing statistics on shared parameters; S3, performing node deepening arrangement; S4, performing location optimization; S5, performing software programming; S6, performing information statistics; S7, providing a drawing; and S8, processing and installing. In the construction preparation stage, the BIM technology is adopted, a curtain wall three-dimensional model is established first, and an external wall in the design is divided and subjected to typesetting; before factory production and processing, early mounting simulationcontrol is carried out, and relevant content of a curtain wall discharging list is checked, so that the occasions that material models, sizes and quantities do not fit real on-site conditions during later mounting, so that manpower, materials, the construction period and other costs are increased invisibly are reduced. Meanwhile, the appearance and cost risks of the project are integrally controlled in advance.

Owner:方传斌 +3

Processing method of deep trough ball bearig ball sbaped pocket hole cage

InactiveCN1624348AImprove machining accuracyGuaranteed interchangeabilityBearing componentsEngineeringSpherical form

This holder process technology is once positioning, processing step of half-ball hole, rivet hole. It is ensuring the changable and raising processing precision.

Owner:LUOYANG BEARING GROUP

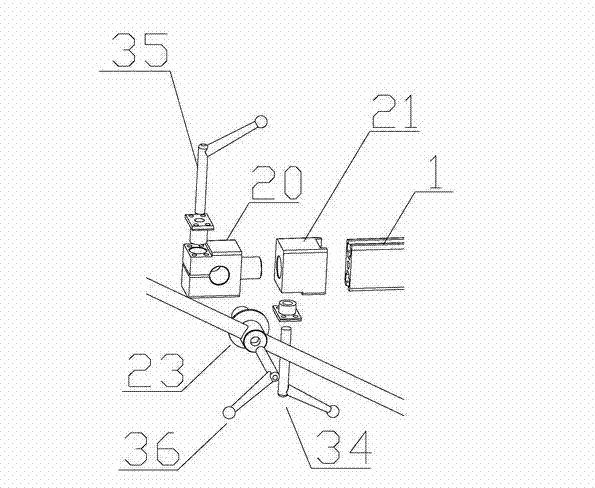

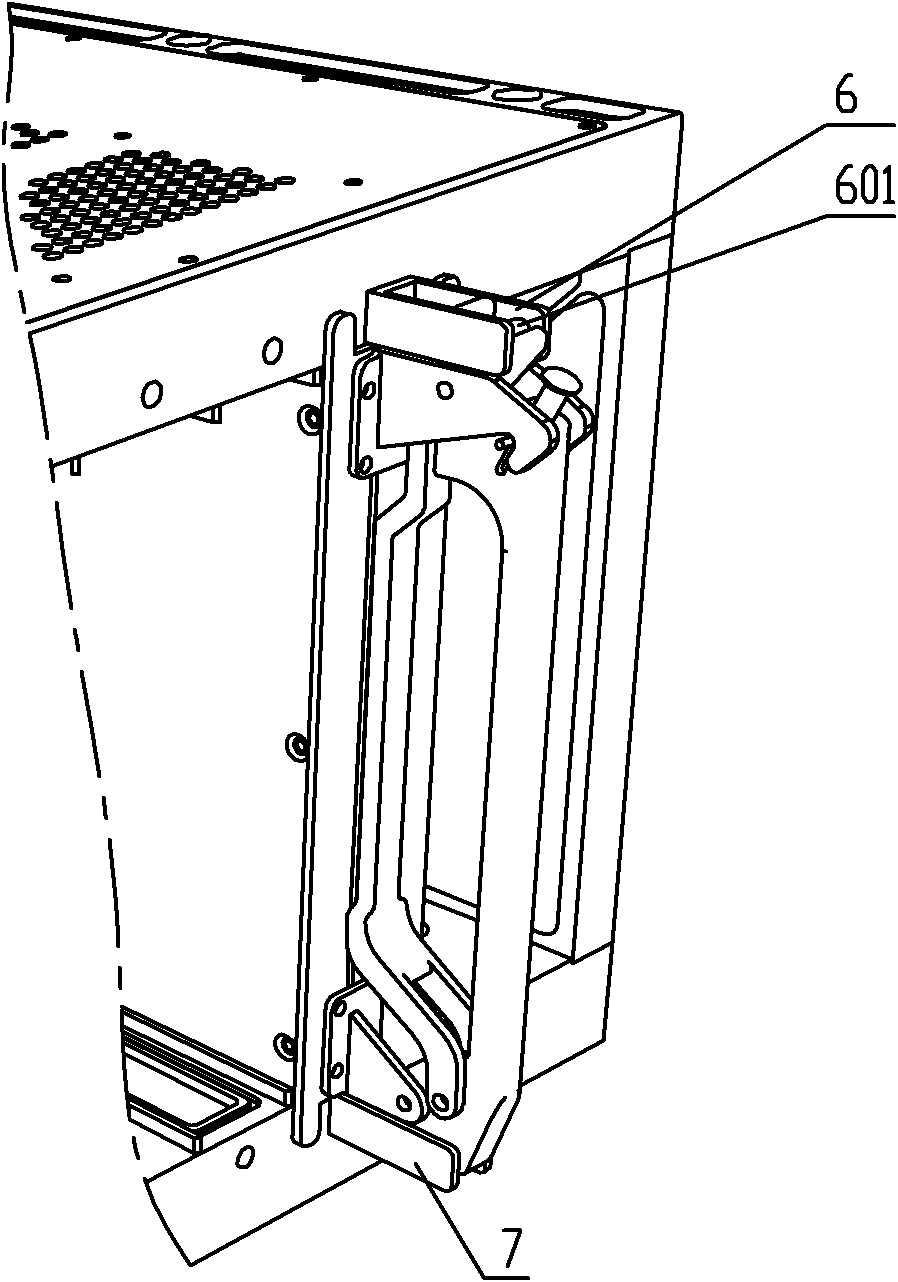

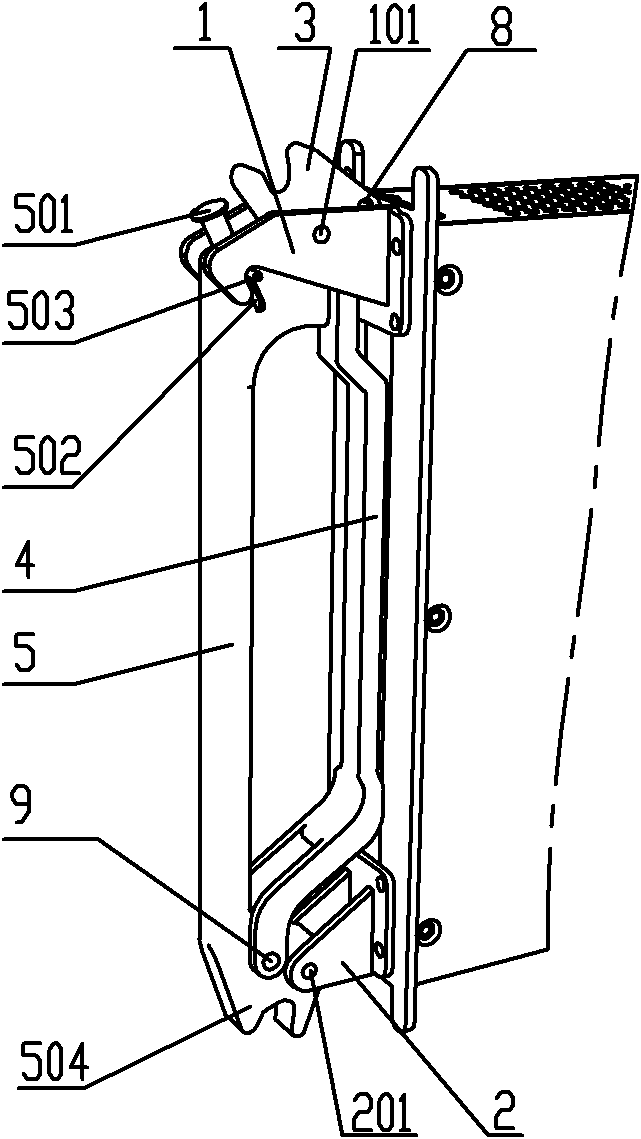

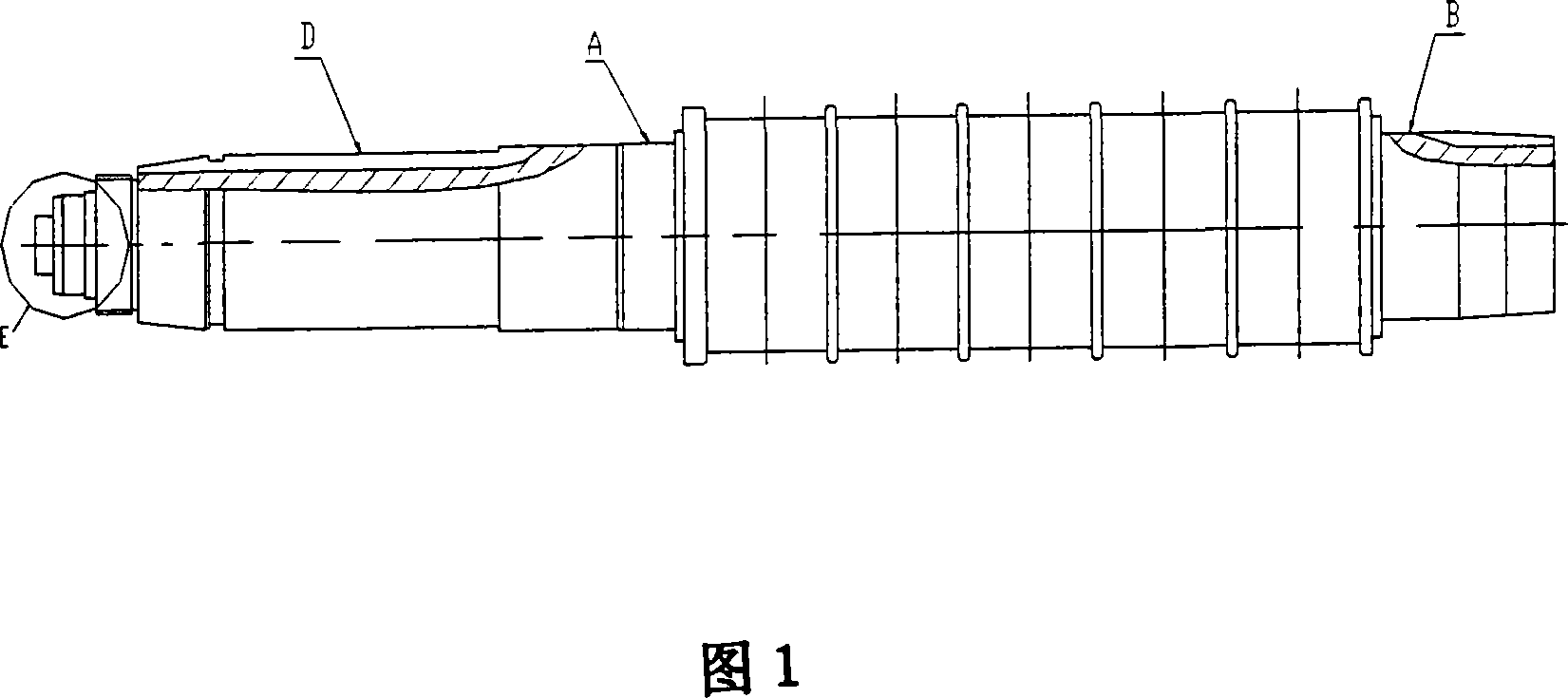

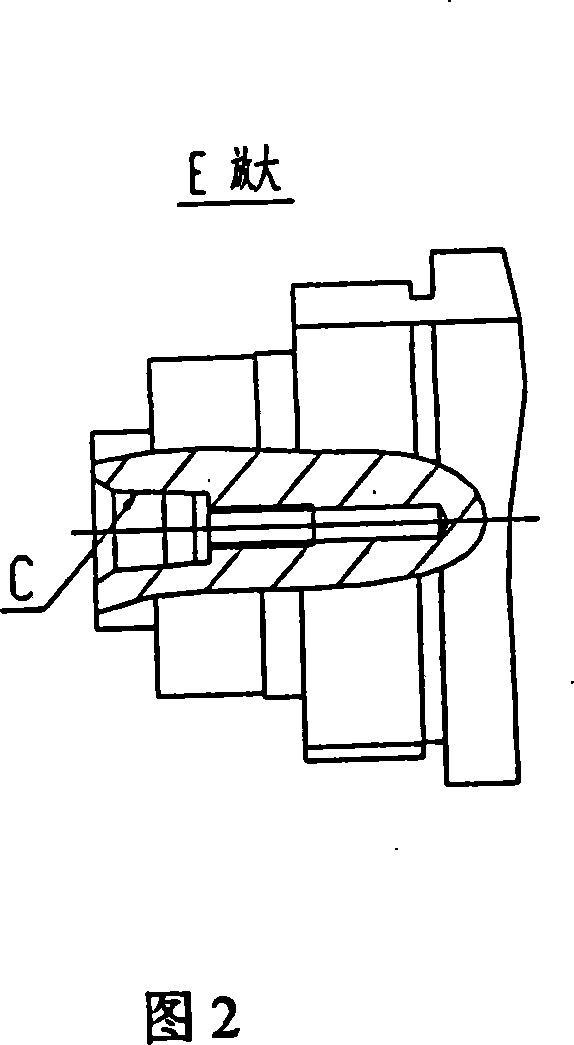

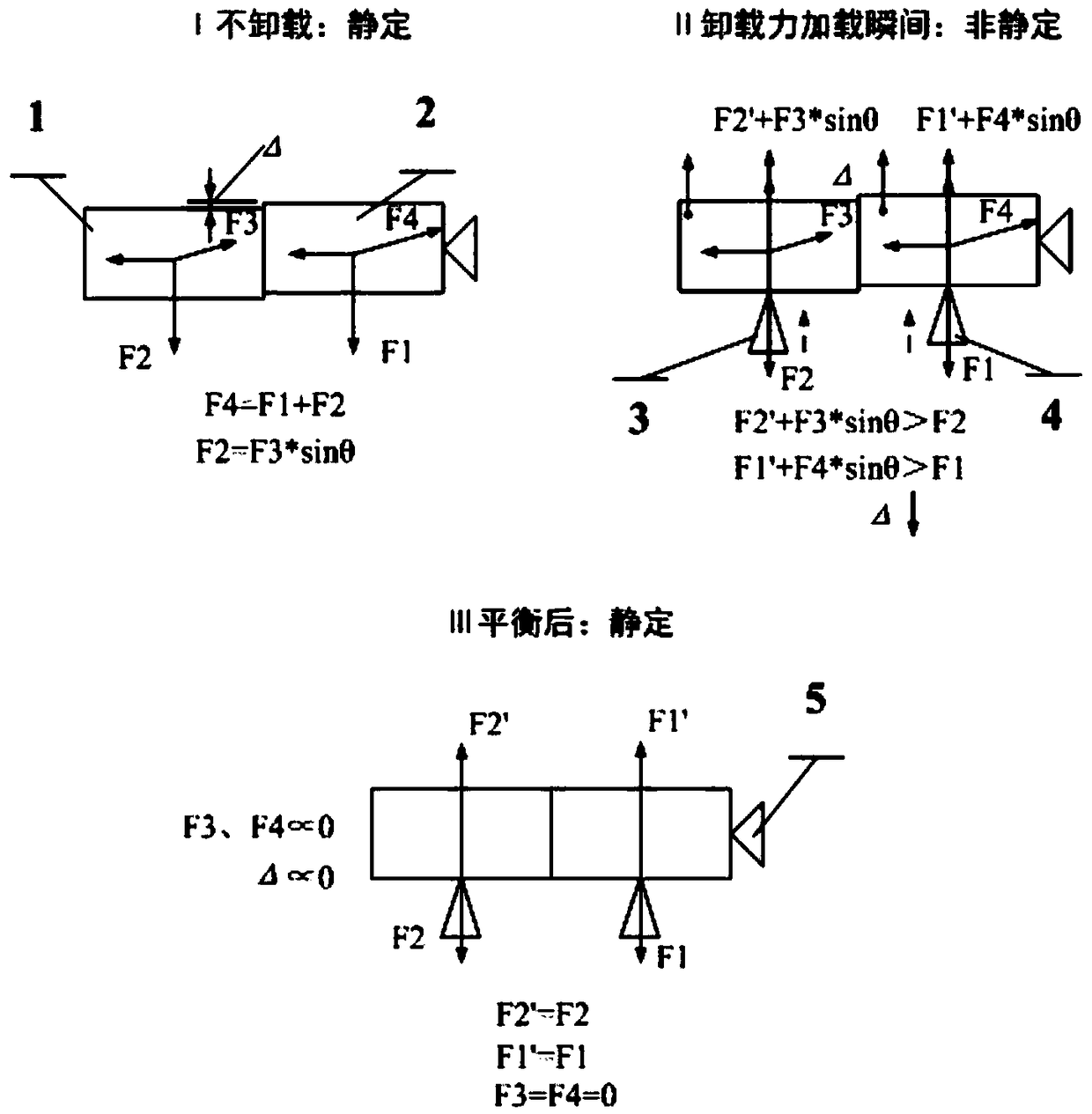

LRM (Line Replaceable Module) module locking and plugging device

ActiveCN102083288ARealize the locking functionQuick changeComponent plug-in assemblagesResilient/clamping meansEngineeringMechanical engineering

The invention provides an LRM (Line Replaceable Module) module locking and plugging device, which settles the problems of complex structure, poor stability and reliability and inconvenient locking and plugging operations in traditional products. The device is composed of a fork lever component fixed on a frame and a plugging component fixed on an LRM module, wherein the plugging component is designed in such a manner that double concave wheels are in elastic tight fit with a four-link movement mechanism, pressure is applied to a pin in the fork lever by pulling a push rod in order to lock or plug out the LRM module. The LRM module locking and plugging device realizes the onsite hand plugging and locking function for the first time on the premise of conforming to the ARINC650 standard, the entire mechanism achieves the automatic adjustment for tightening distance, eliminates processing and assembling errors and has predetermined pretightening force, thereby guaranteeing the reliable tightening of equipment under various harsh vibratory conditions.

Owner:AVIC NO 631 RES INST

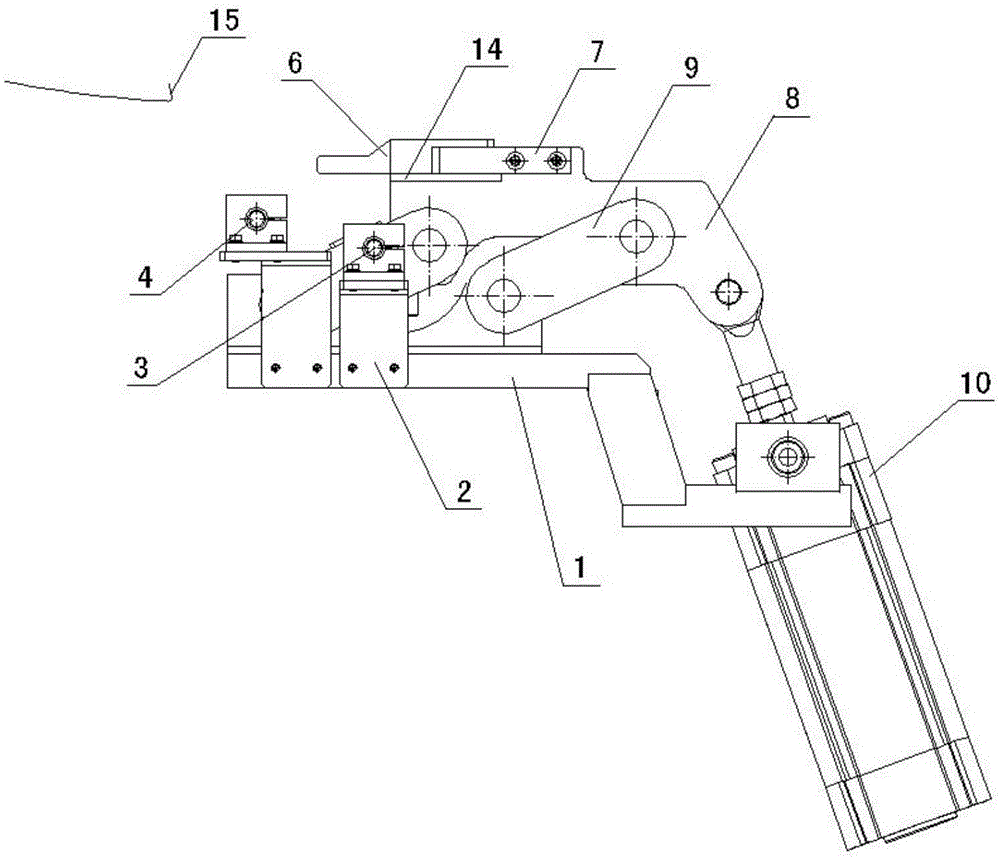

Automobile door closure corner edge covering mechanism

The invention discloses an automobile door closure corner edge covering mechanism. The automobile door closure corner edge covering mechanism is characterized in that a lower step face is arranged at one end of a base, and lug shaft supporting blocks are arranged on the two sides of the lower step face respectively; an air cylinder base of an air cylinder is hinged to the lug shaft supporting blocks through pin shafts and can swing around the lug shaft supporting blocks to provide drive force; a pressing cutter is fixedly installed on the front end face of a pressing cutter installing block through a bolt, and the tail of the pressing cutter installing block is hinged to the end of a piston rod of the air cylinder through a pin shaft; the work face of the pressing cutter is provided with a profile matched with the workpiece corner closing digital analogy; and parallel four-bar mechanisms are symmetrically arranged on the two sides of the base and composed of two pairs of parallel connecting rods, the pressing cutter installing block and the base, the bottom ends of the connecting rods are hinged to the sides of the base, and the upper ends of the connecting rods are hinged to the sides of the pressing cutter installing blocks. The pressing cutter is driven through pushing of the air cylinder to carry out the edge covering action. The automobile door closure corner edge covering mechanism is stable in edge covering effect and good in forming performance.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

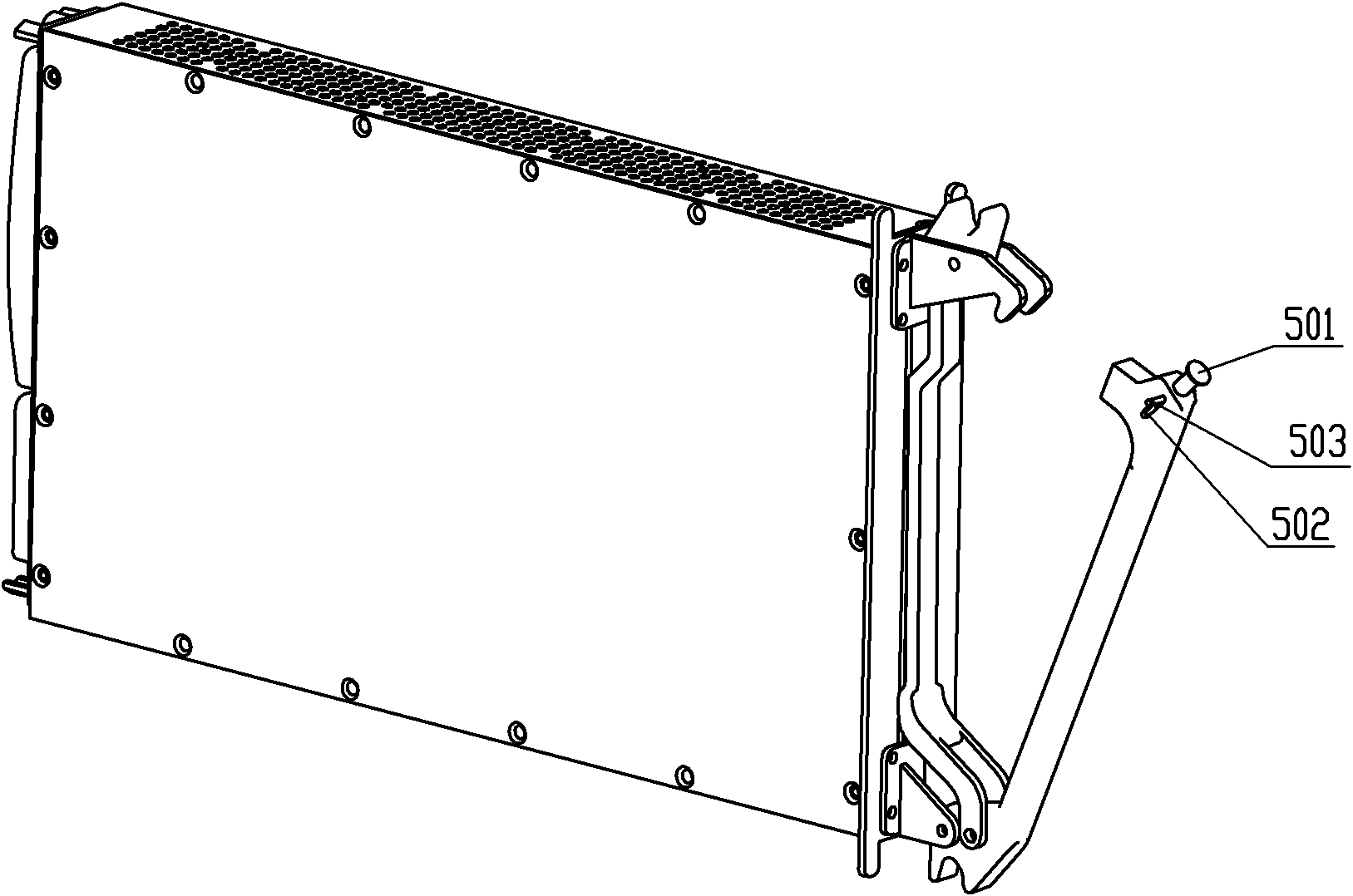

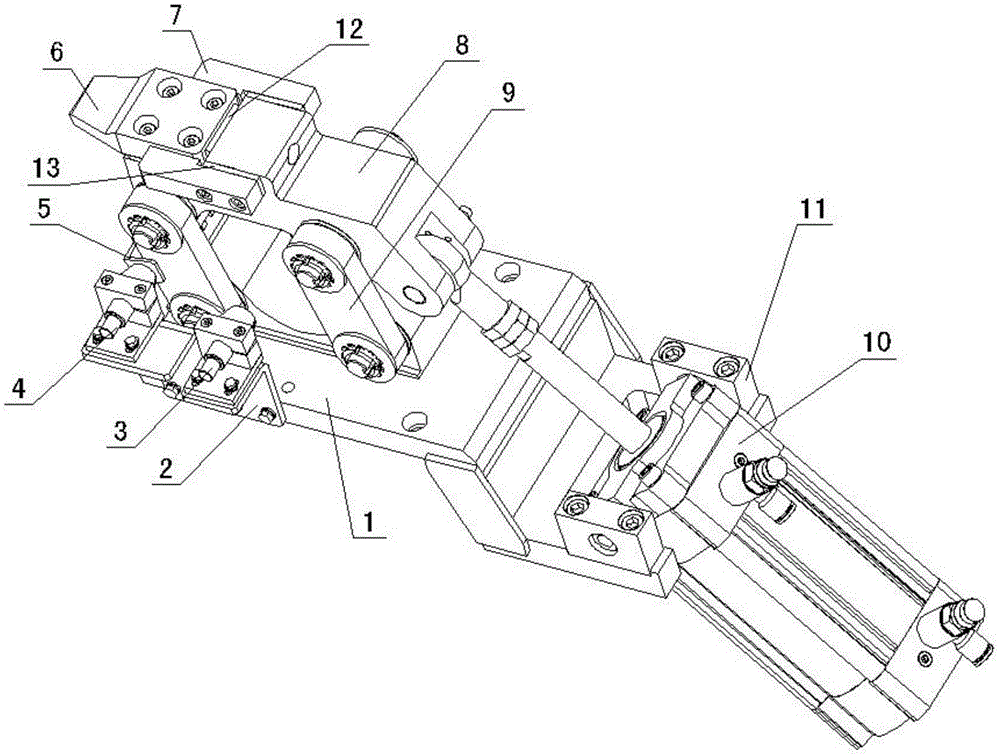

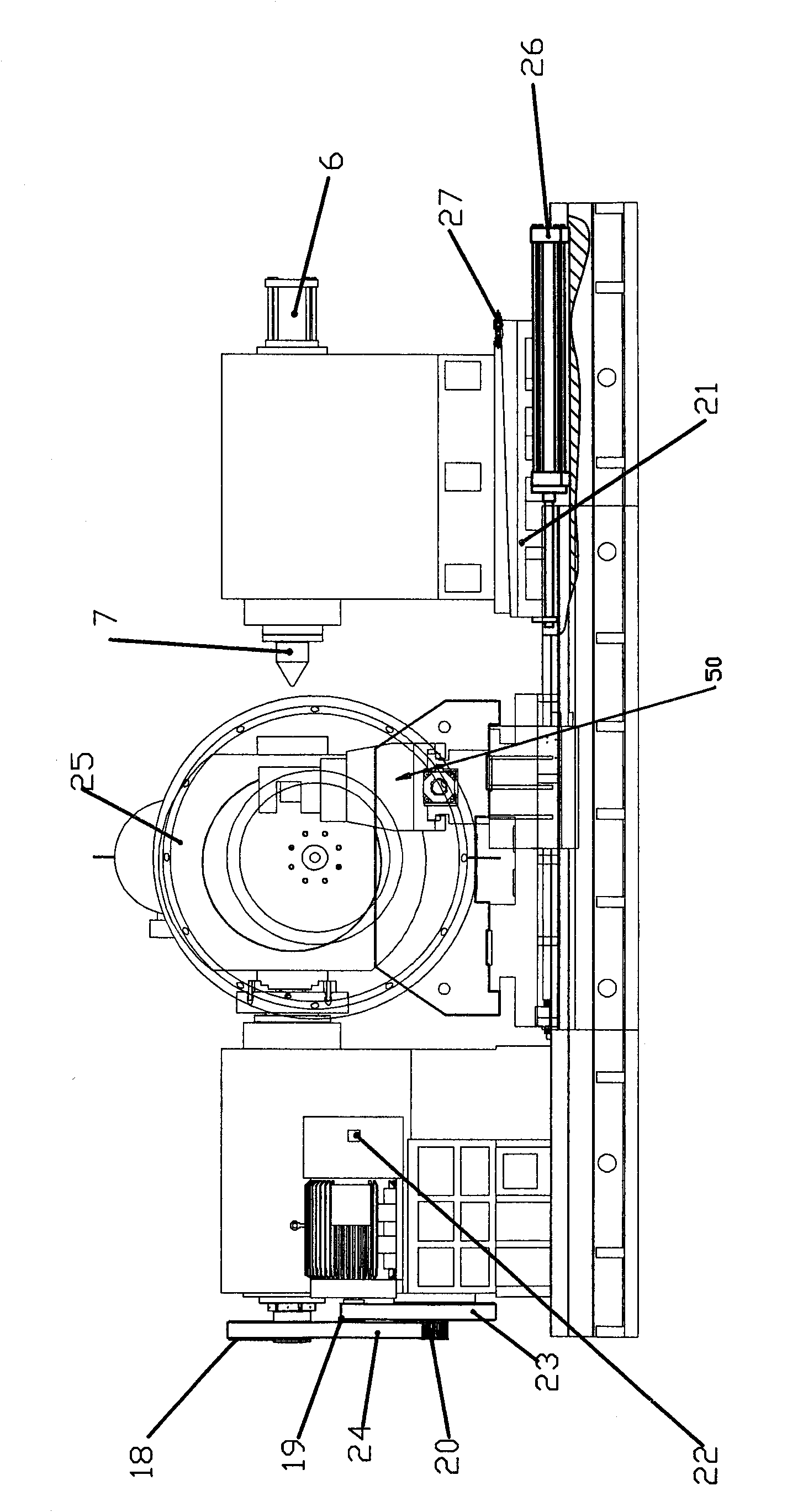

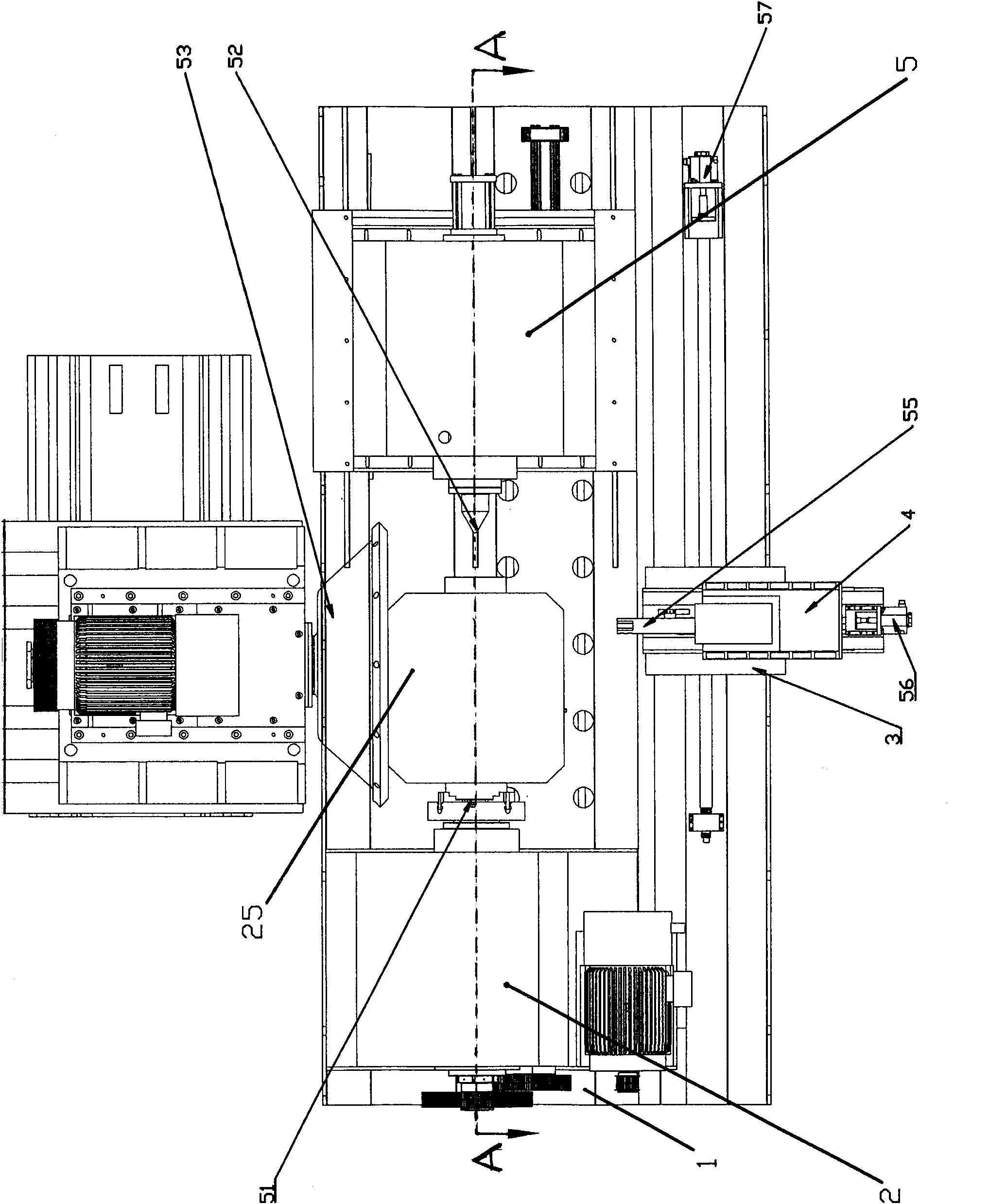

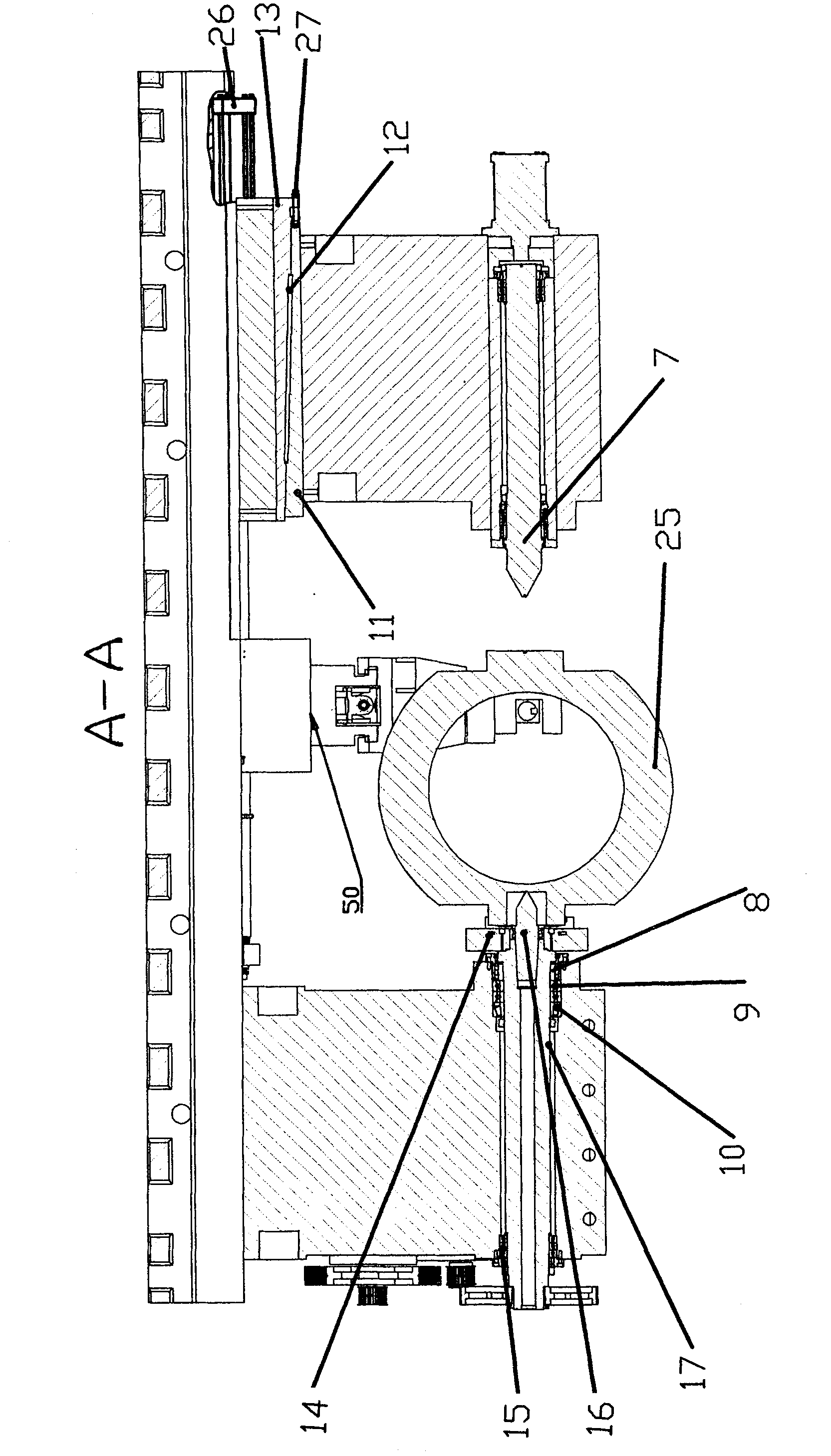

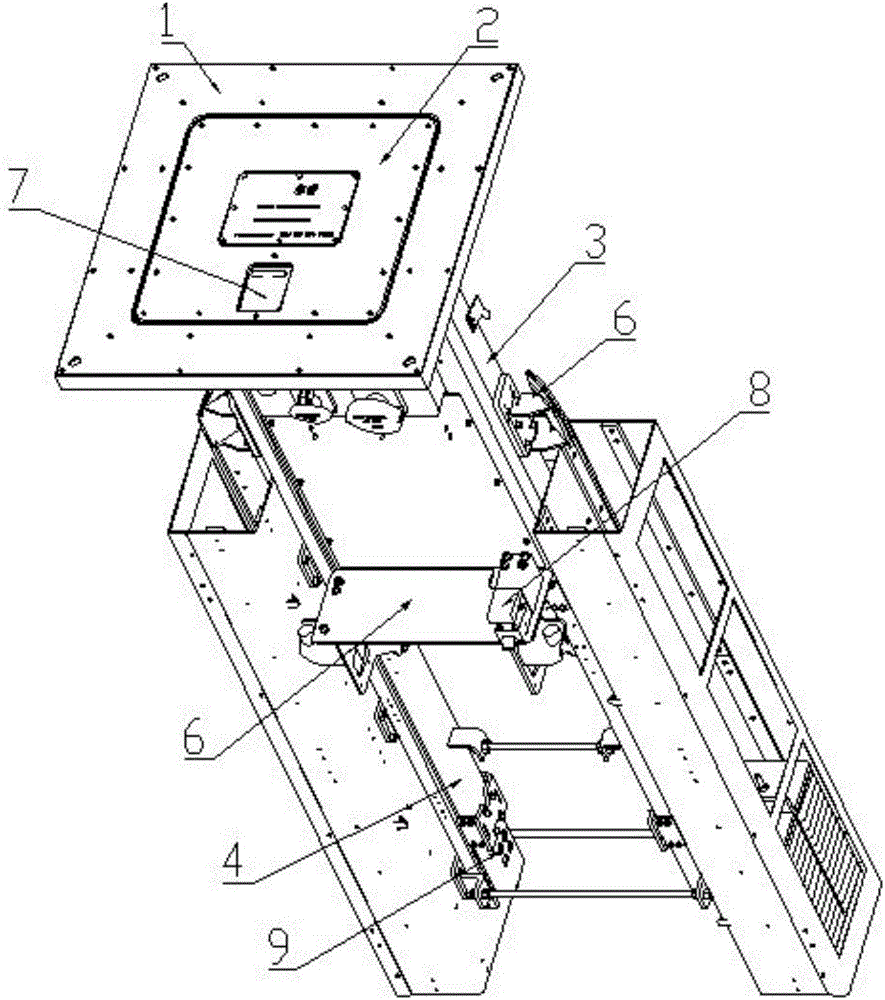

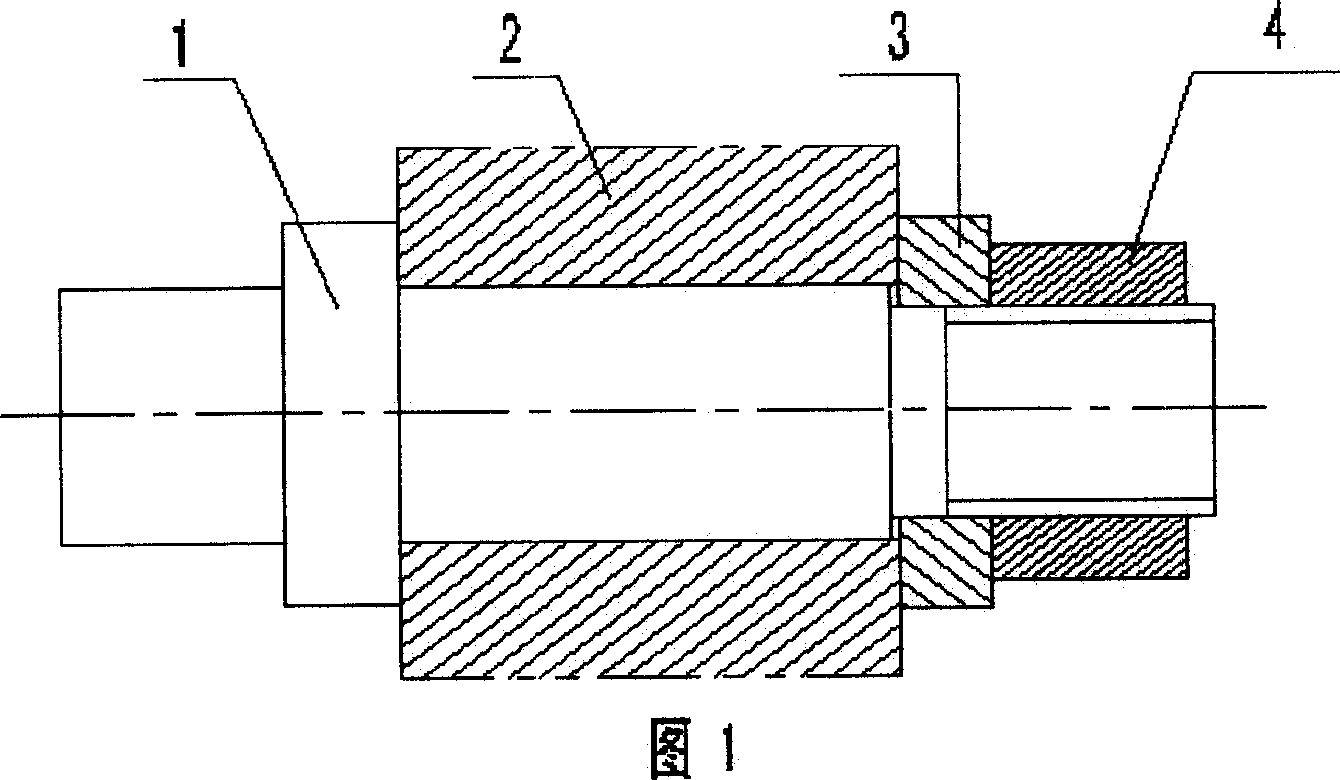

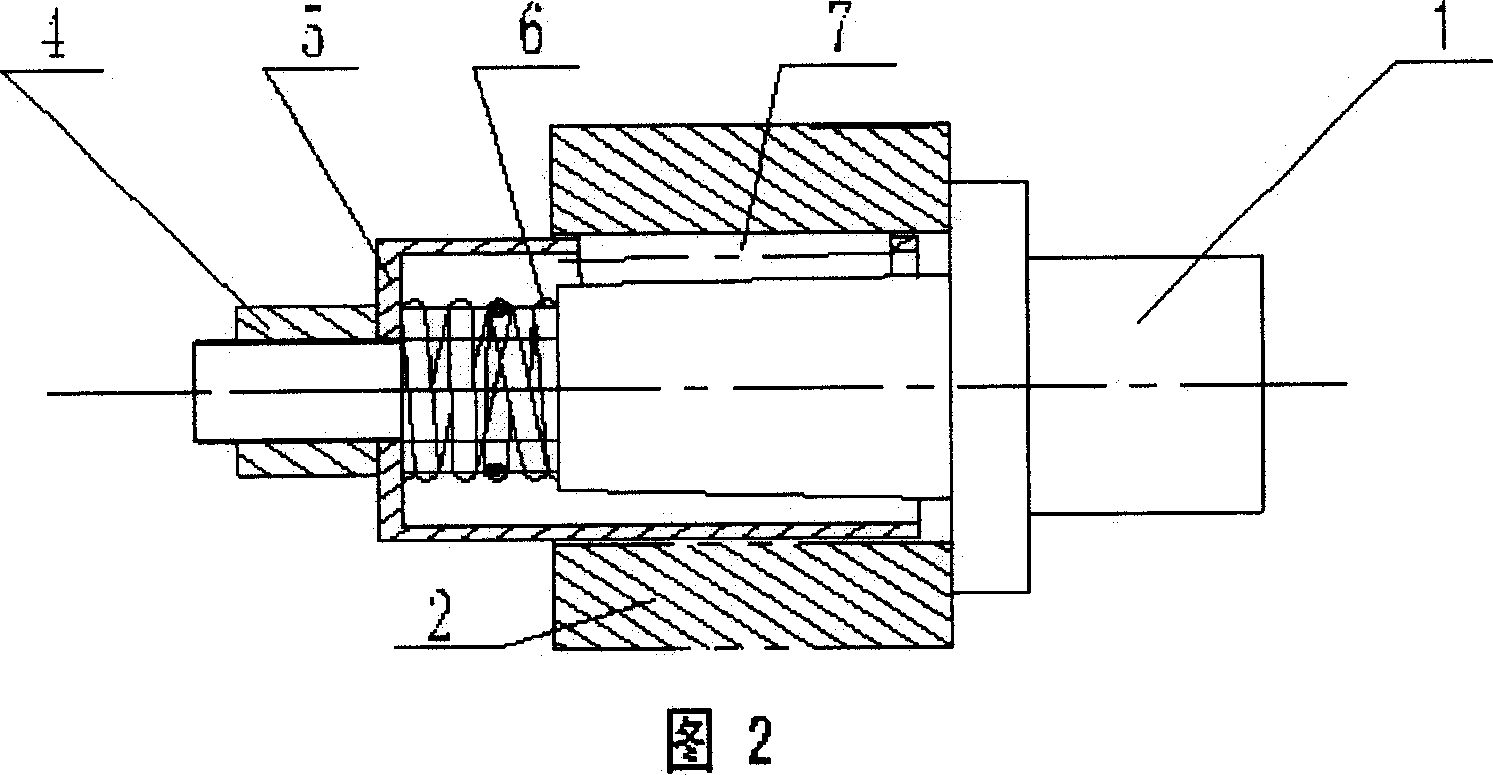

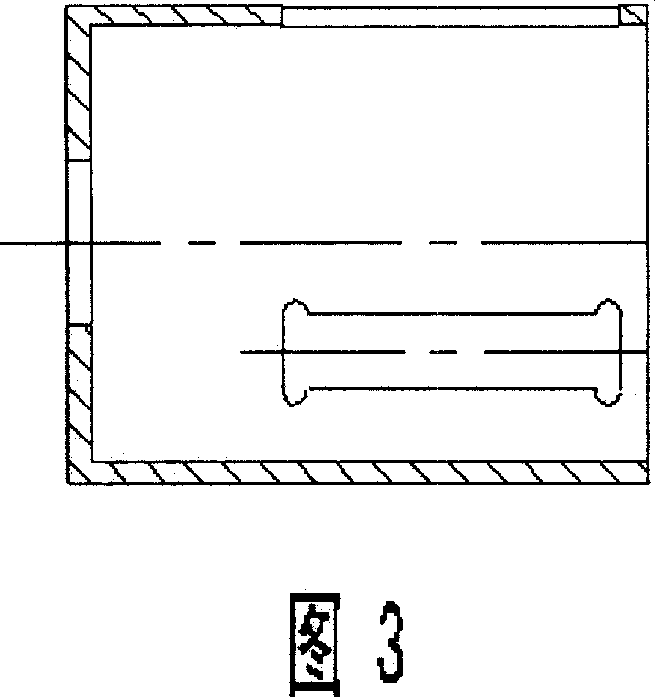

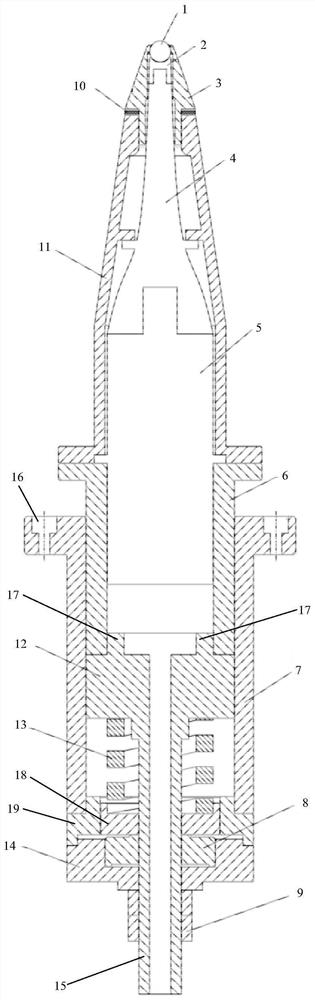

Integrated grinding/turning mechanism of grinding lathe for ball valve bodies

InactiveCN102069382AHigh precisionQuality improvementOther manufacturing equipments/toolsMachine partsSlide plate

The invention discloses an integrated grinding / turning mechanism of a grinding lathe for ball valve bodies, which comprises a lathe base (1), a ball-clamping device (51), a ball-jacking device (52) and a grinding-disc rotating control device (53), wherein the lathe base, the opposite surface of the grinding-disc rotating control device and the side edge of the ball-clamping device are respectively provided with a turning device (50); and the turning device is composed of a ball-turning saddle, a ball-turning sliding plate, a turning head assembly, a sliding-plate longitudinal movement control assembly and a saddle horizontal movement control assembly. By using the integrated grinding / turning mechanism disclosed by the invention, the head part of a machined part is clamped by the ball-clamping device, the tail part of the machined part is jacked by the ball-jacking device, the surface of the machined part is ground by the grinding-disc rotating control device, and the surface of the machined part is turned on a same machine by the turning device, thereby eliminating the processing errors caused by respectively carrying out grinding and turning on different machines, improving the surface grinding machining precision and quality of a workpiece (in particular to a ball valve body), and improving the operating efficiency.

Owner:NANYANG AUTOMOBILE & CYCLE GROUP CHINA

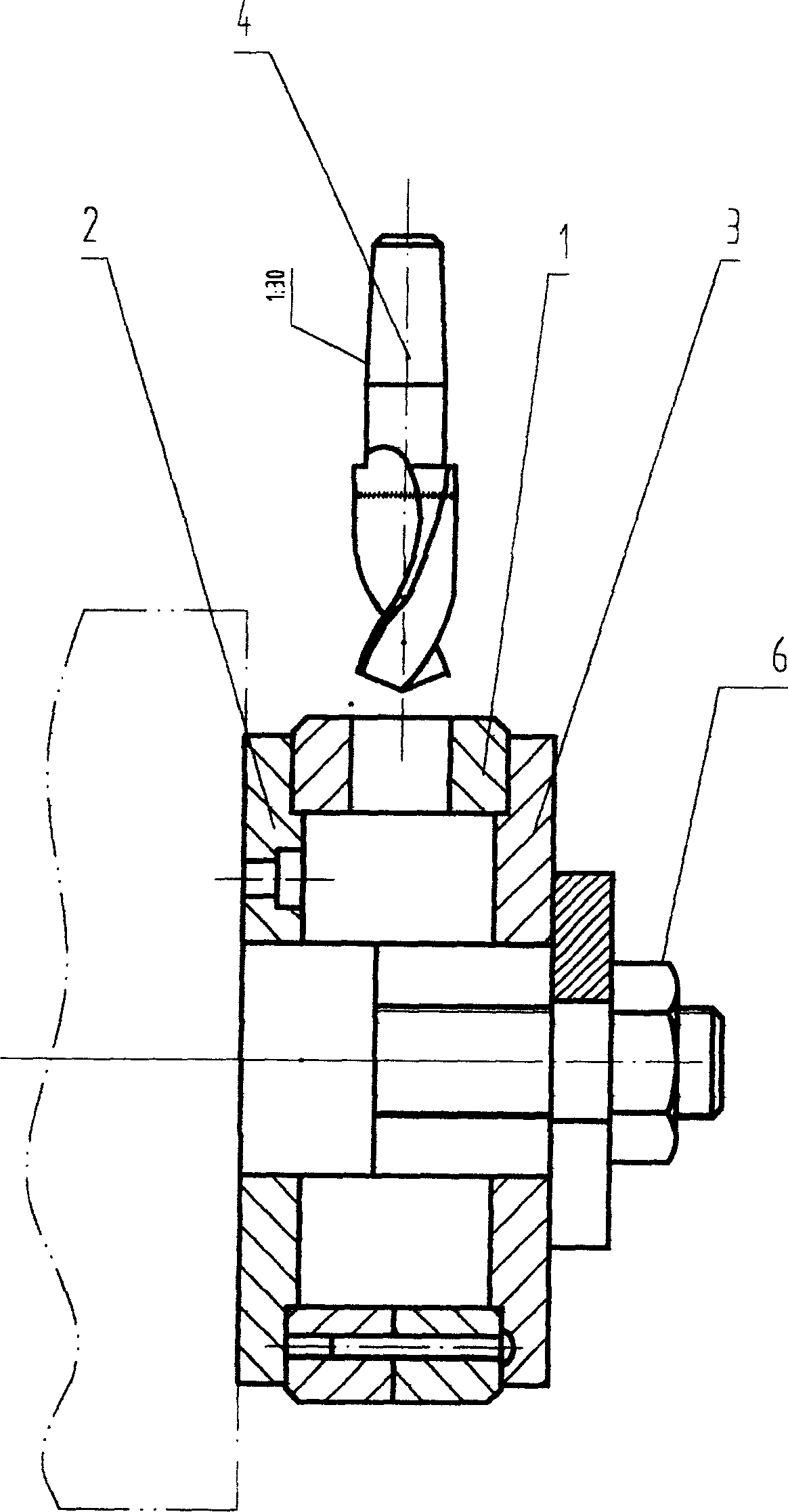

Universal elevator axis processing technique

It relates to the processing of electric lift that comprises the normalizing rough turning, fine turning, milling slot, calibration, fine grinding shaft radius, featuring in the rough turning before the fine one, with the processing of the small tapering hole C processing with the A and B end central hole, with pass rate reaching over 98%.

Owner:SHANGHAI NO 1 AUTOMOBILE GEAR FACTORY

Floating support device for on-ground gravity unloading of aerospace optical load

ActiveCN109188648AImprove application accuracyReduce volumeMountingsImaging qualityOptical correction

The invention relates to the field of precision machinery and aerospace optical technology, and in particular discloses a floating support device for on-ground gravity unloading of aerospace optical load, comprising an unloading base, and multiple sets of gravity unloading devices arranged on the unloading base. The gravity unloading devices are fixedly arranged under the optical load. The floating support device also comprises multiple sets of fixed support devices arranged on the back of the optical load. Gravity unloading in the direction of the gravity vector can be achieved by the gravityunloading devices, thereby offsetting the maximum deformation introduced by the gravity of the large optomechanical structure, and significantly alleviating the effect brought by the inconsistency ofsky-earth mechanics on the accuracy of on-ground installation and alignment as well as the quality of on-orbit imaging of aerospace optical loading. Therefore, the invention provides basic image quality for on-ground pre-installation and alignment as well as active optical correction for high-sensitivity optical components. In addition, through on-ground gravity unloading, the unnecessary designof the large aperture optical load optomechanical structure and the launching cost can be greatly reduced, and the use efficiency of the aerospace vehicle can be improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Testing table for detecting the relaxation of high voltage breaker closing spring stress

ActiveCN106370402ATest for stress relaxationQuantitative description of stress relaxationMachine part testingPull forceEngineering

The invention discloses a testing table for detecting the relaxation of high voltage breaker closing spring stress, which comprises a substrate, a spring fixing plate, a spring moving platform, a screw rod fixing plate, a hand wheel and a speed reducer. The spring fixing plate and the screw rod fixing plate are fixedly arranged on the substrate; the spring moving platform is capable of sliding in the track of the T shaped groove arranged on the substrate through a T shaped sliding block. The spring fixing plate is provided with a plurality of pressure pulling sensors. The spring moving platform is provided with corresponding suspension ring screw nails. The to-be-tested springs are placed between the suspension ring screw nails and the pressure pulling sensors. The spring moving platform is connected with the screw rod fixing plate through a leading screw and nut mechanism; the screw rod fixing plate is provided with a clamping groove. The transmission screw rod of the leading screw and nut mechanism is provided with a clamping ring cooperating with the clamping groove. The hand wheel is connected to the end part of the transmission screw rod through the speed reducer. Through the hand wheel and the speed reducer, great torque is provided to the transmission screw rod so that the leading screw and nut mechanism can provide strong pulling force to the spring moving platform and that a plurality of the to-be-tested springs are tested at the same time.

Owner:WUHAN UNIV

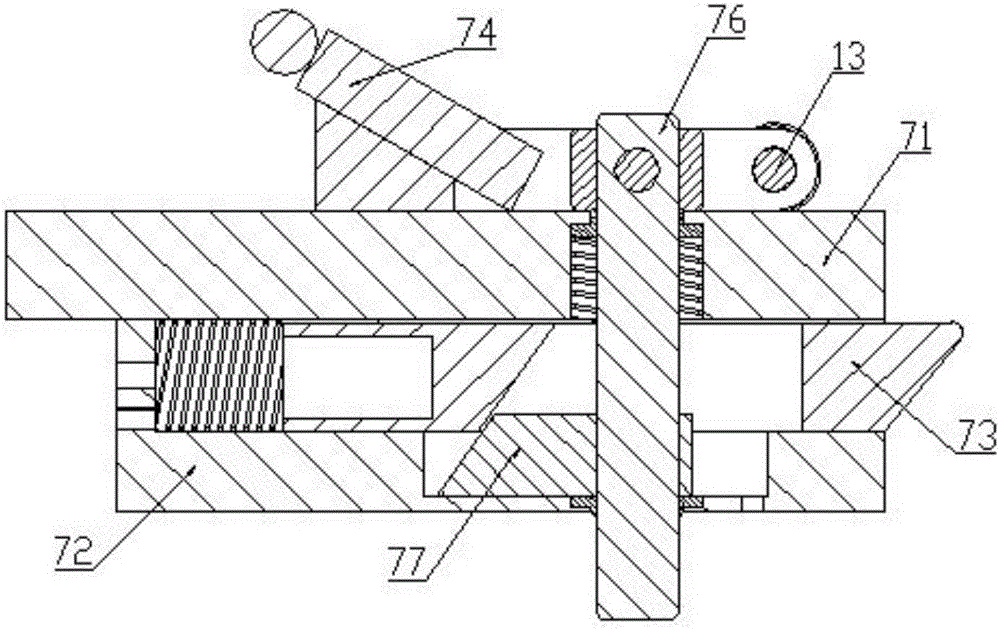

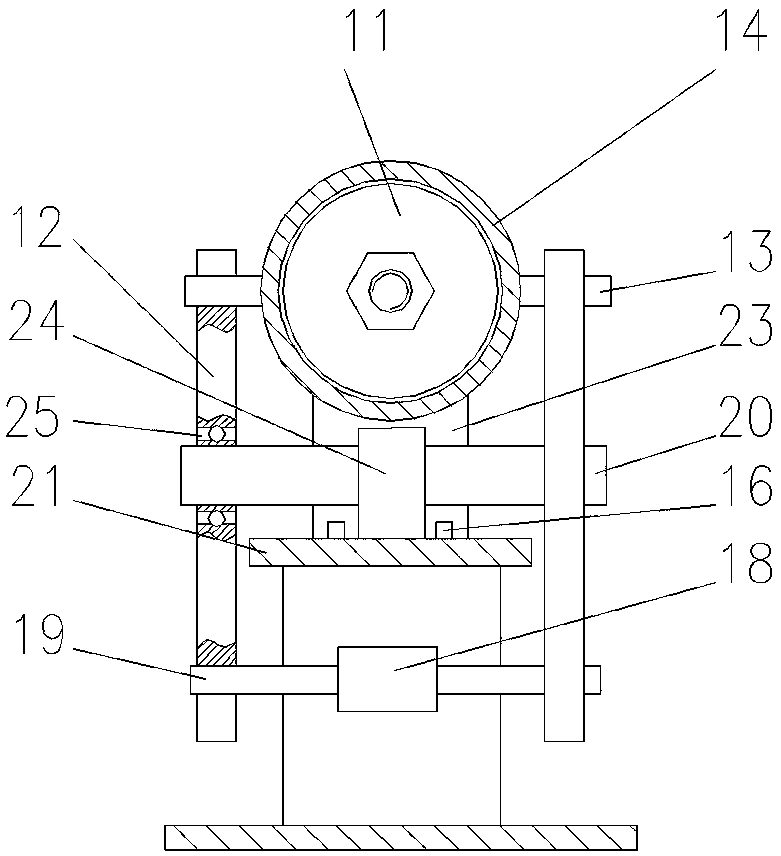

Centering measurement apparatus for measuring center distance of two intersecting holes in intersecting hole system

ActiveCN105841587AEliminate machining errorsEliminate the effects of detectionMechanical clearance measurementsEngineeringCam

The invention discloses a centering measurement apparatus for measuring the center distance of two intersecting holes in an intersecting hole system. The centering measurement apparatus comprises a two-hole positioning and centering device including an elastic centering expanding sleeve, a centering pull bar, a centering pressure bar, an eccentric wheel compacting mechanism and a positioning pin, a variable-pitch cam mechanism including a handle, a servo-actuated eccentric cam, a bearing positioning circular section and a cooperative column, and an auxiliary centering mechanism, wherein the two-hole positioning and centering device is inserted in a first hole system of a part to be measured, the eccentric wheel compacting mechanism is rotated to move the centering pull bar and centering pressure bar and open the elastic centering expanding sleeve to center the first hole system, and the variable-pitch cam mechanism and the auxiliary centering mechanism are inserted in two sides of a second hole system of the part to be measured. The handle is rotated to drive the cam to rotate, so that the rim of the cam is tangent to the excircle of the elastic centering expanding sleeve, and angle scales corresponding to different center distances of the first hole system and the second hole system are radially marked on the end face of the servo-actuated eccentric cam. The actual center distance of the intersecting holes of the part to be measured can be rapidly obtained by observing the angle graduation lines, and rapid and accurate measurement is realized.

Owner:CHONGQING JIANSHE IND GRP

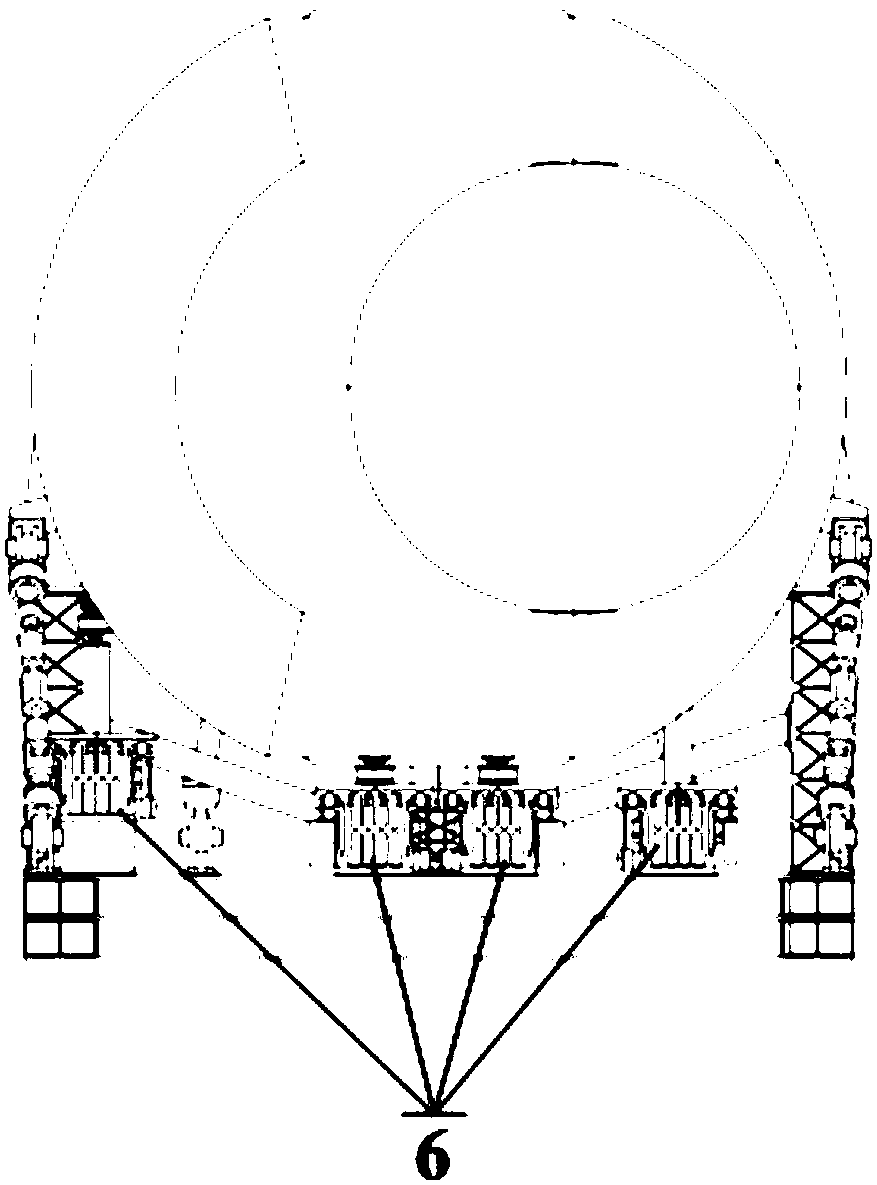

Mechanical balance weight type airplane service support lifting platform

ActiveCN106144946AEasy to operateImprove safety and reliabilitySafety devices for lifting equipmentsLifting framesAviationEngineering

The invention relates to the technical field of the aviation product manufacturing process and aircraft daily maintenance and guarantees, and particularly discloses a mechanical balance weight type airplane service support lifting platform. The mechanical balance weight type airplane service support lifting platform comprises an outer well lid assembly, an inner well lid assembly, a hand-lifting lock assembly, a foot-stepping lock assembly and a sliding bearing assembly. The outer well lid assembly comprises an outer well lid, fixed guide rails and a pulley assembly. The pulley assembly is installed on the outer sides of the fixed guide rails. The inner well lid assembly comprises an inner well lid, movable guide rails and a connection beam. The connection beam is installed on the inner sides of the two movable guide rails. The hand-lifting lock assembly is installed on the inner well lid. The foot-stepping lock assembly is installed on the connection beam. The sliding bearing assembly is installed on the movable guide rails. The movable guide rails slide along the fixed guide rails through the sliding bearing assembly. The mechanical balance weight type airplane service support lifting platform has the beneficial effects that the inner well lid is controlled to move and stop through mechanical locks, and the safety reliability is high; the sliding bearing assembly ensures that the inner well lid part operates stably, and the cable abrasion is relieved; and the pulley assembly prevents a balance weight assembly from interfering with other parts, and noise is reduced.

Owner:XIAN RVNUO NEW ENERGY

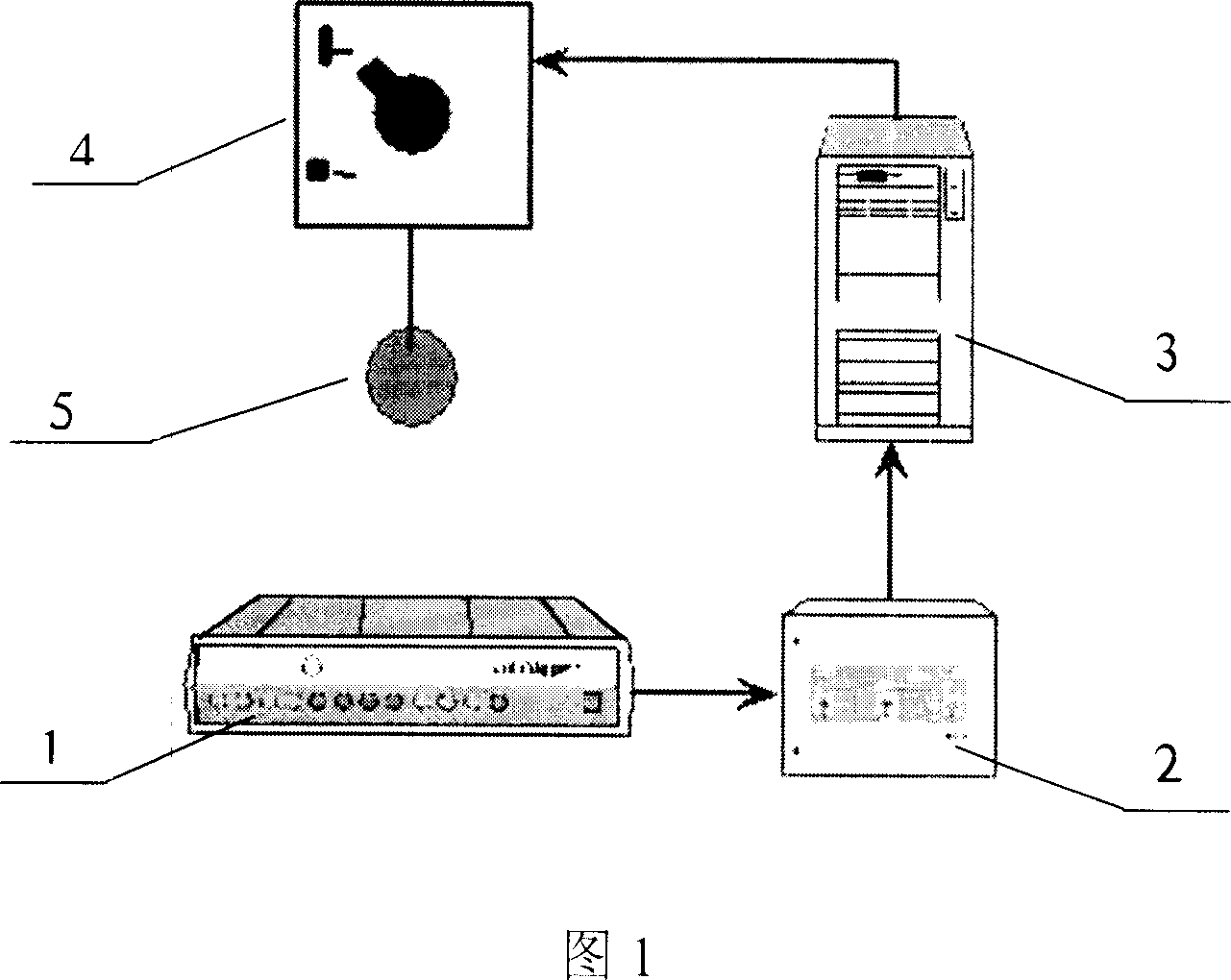

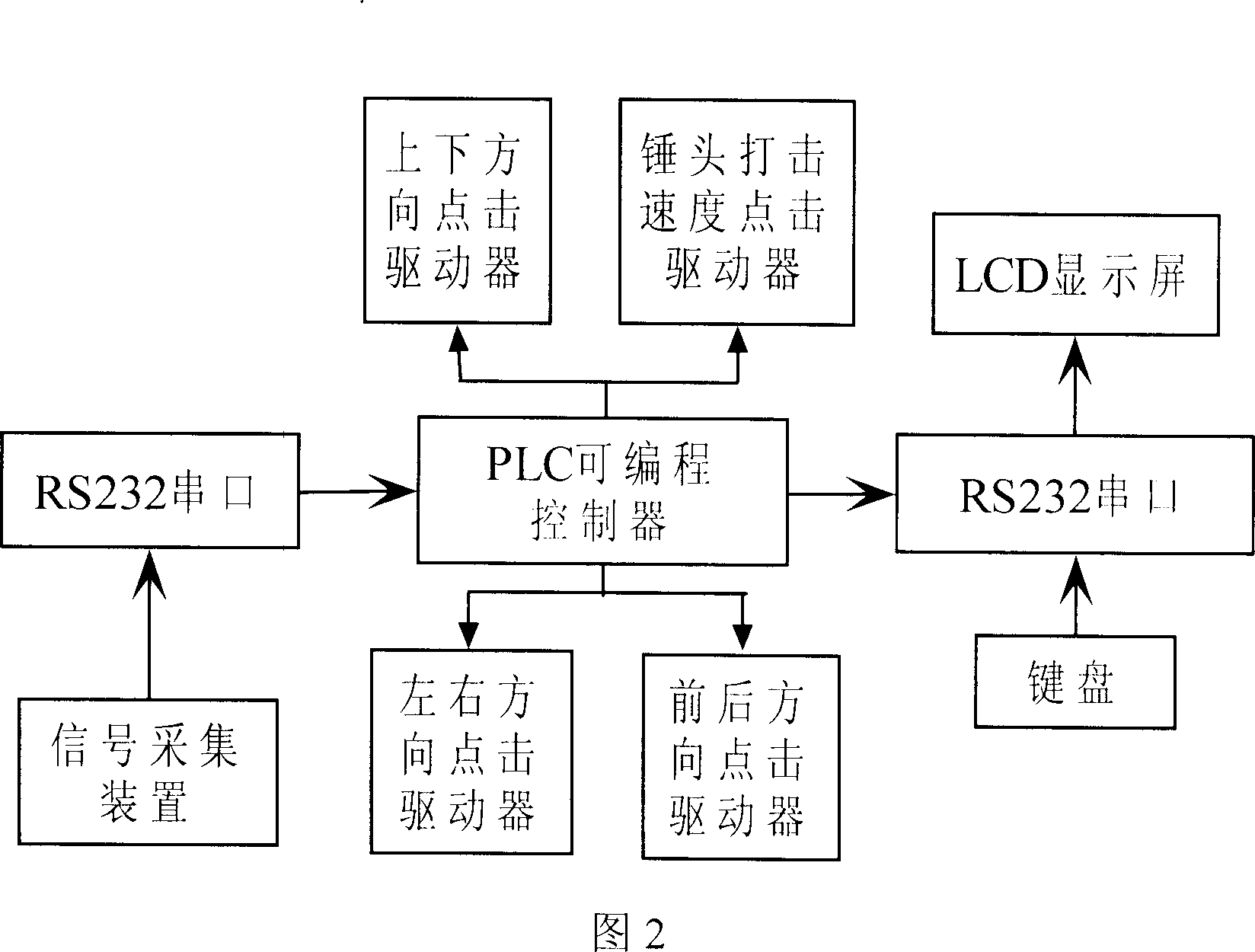

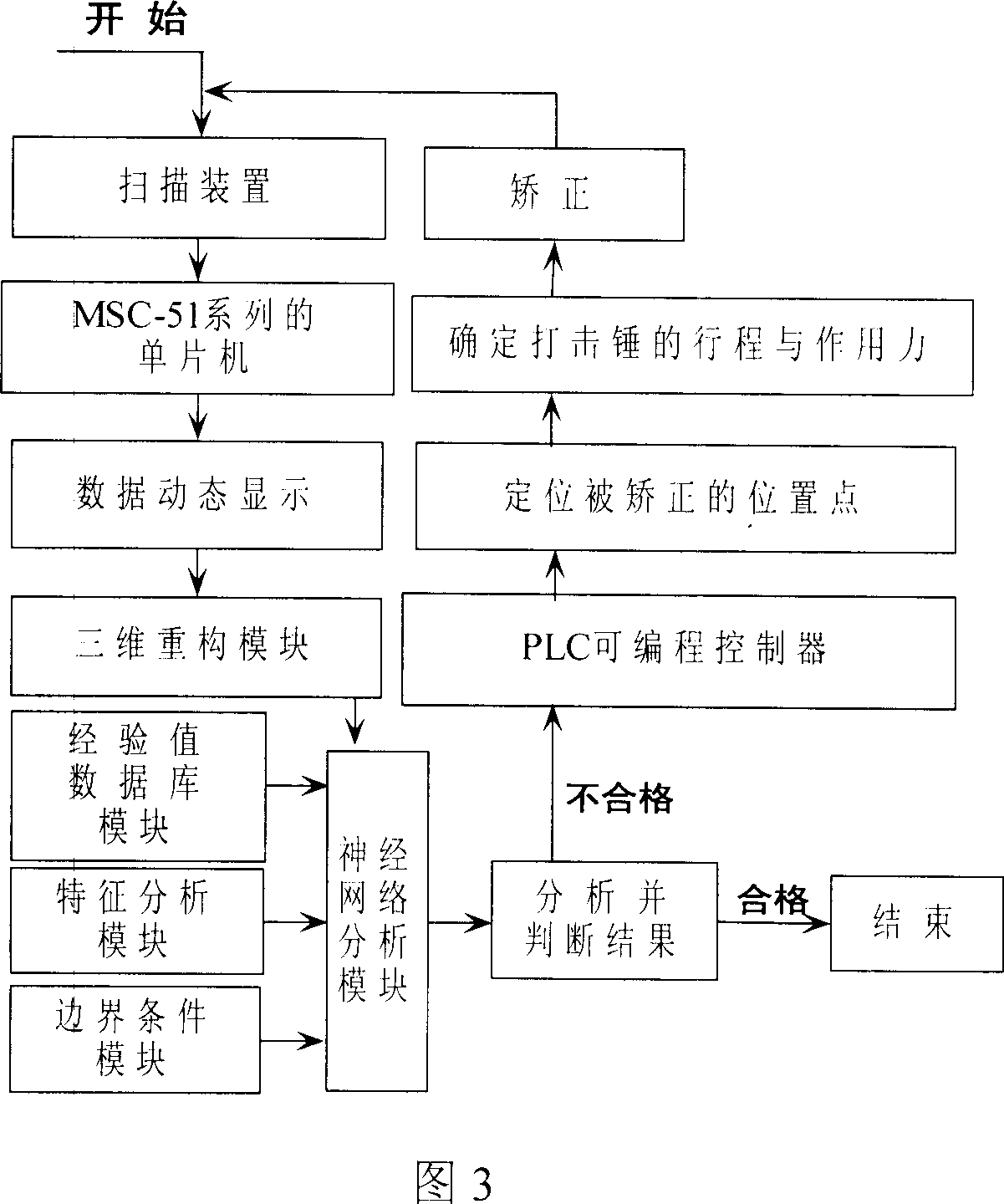

Intelligent work piece correcting system and correcting method thereof

InactiveCN1975618AReduce the number of correctionsFix orthoticsTotal factory controlProgramme control in sequence/logic controllersHuman bodyEngineering

This invention relates to a kind of intelligence workpiece corrective system and its correcting method , includes the working table, PC machine, controller, strike hammer, one end of the said working table sets up signal collection device, the said signal collection device includes the scan device and processor connected mutually, PC machine links with the processor of the said signal collection device, the controller includes actuating mechanism and treatment element connected mutually, the treatment element of the controller links with the said PC machine, the actuating mechanism of the said controller links the strike hammer. And this system has adopt automation treating , has resolved the correcting problem of the cosh material and specially appointed stick type workpiece geared to the needs of medium-sized and small enterprises, has improved the production efficacy, and the system has decreased the correcting number of the workpiece on maximal degree, has removed various unnecessary treating error; On the other hand, has changed the tradition work manner that the scene work of the worker, has realized the long-range supervisory control to deformation workpiece, has kept away the noise and other bad factor's damage effect to the human body.

Owner:SOUTH CHINA UNIV OF TECH

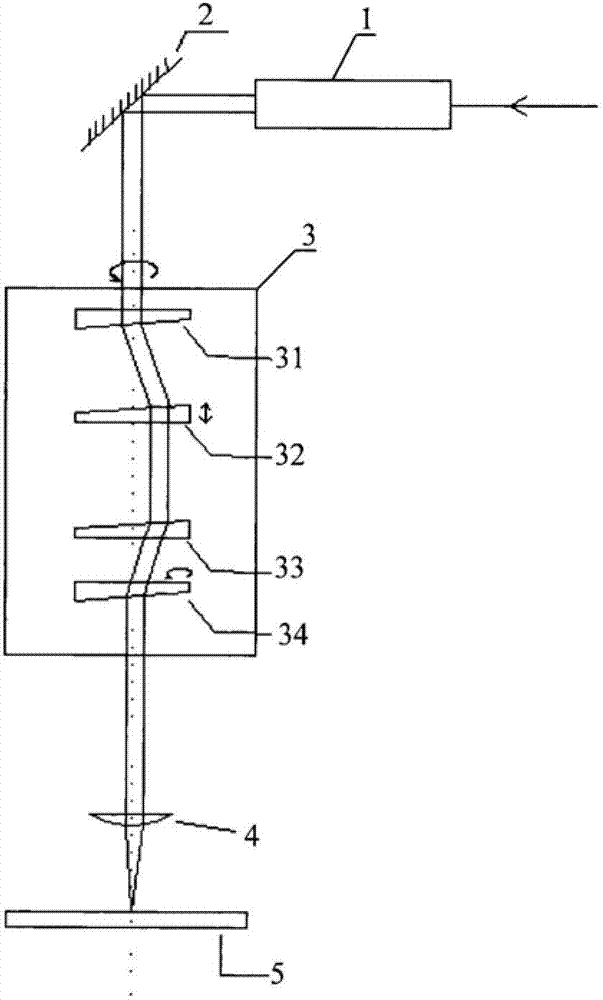

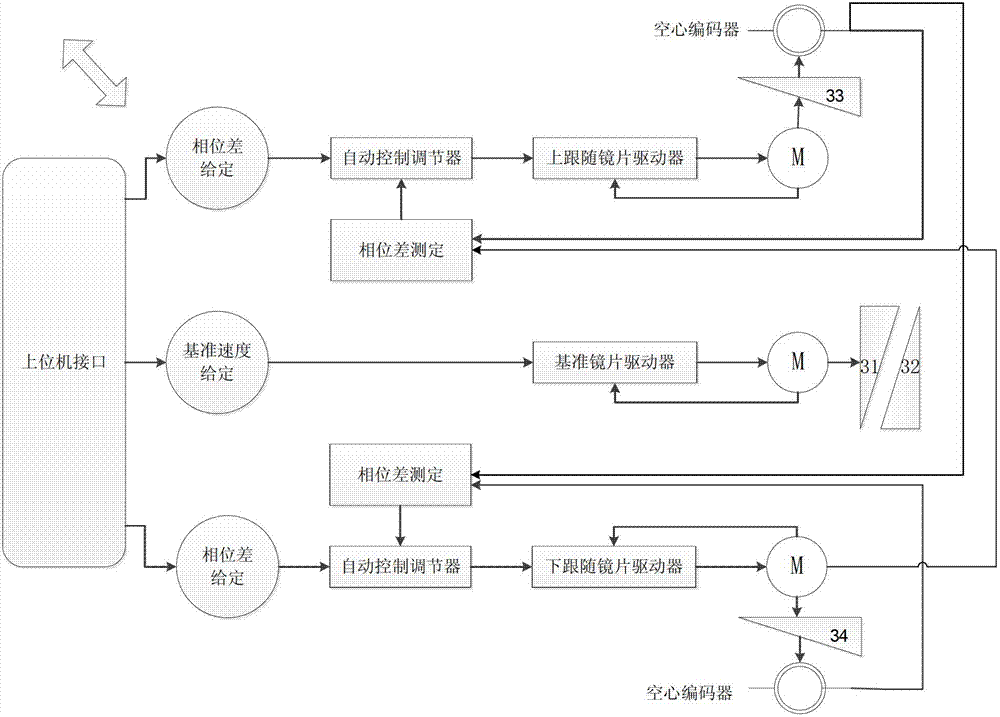

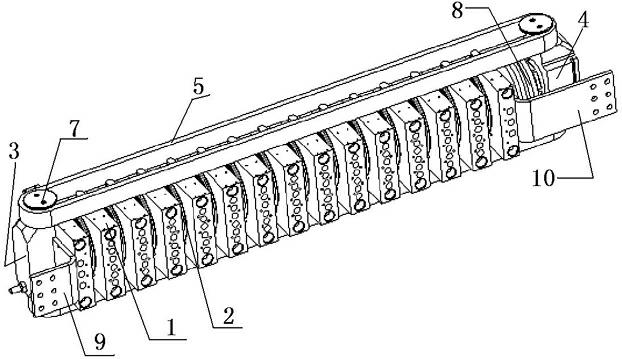

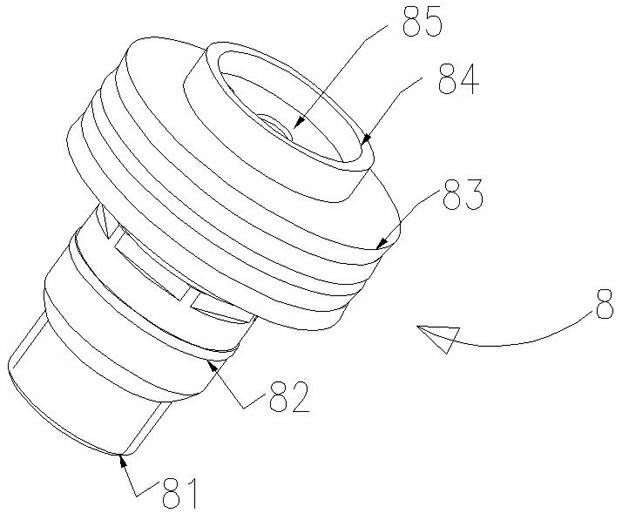

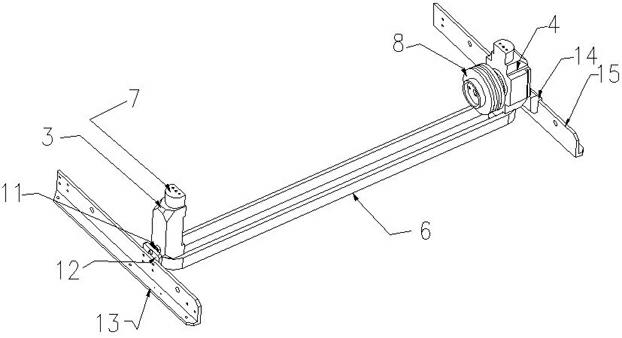

Optical scanning head drive control system based on hollow encoder and phase difference

ActiveCN103091836AImprove errorEliminate machining errorsOptical elementsAutomatic controlControl signal

A drive control system of an optical scanning head comprises an upper following lens drive module, a benchmark lens drive module and a lower following lens drive module. The upper following lens drive module drives an upper following optical wedge to rotate, the lower following lens drive module drives a lower following optical wedge to rotate, and the benchmark lens drive module drives a benchmark optical wedge to rotate at a benchmark speed. The upper following lens drive module and the lower following lens drive module comprise an even automatic control adjuster, a phase difference measurement module, an upper following lens driver and a lower following lens. Locating signals of the optical wedges are collected by a hollow encoder, given phase difference signals are compared with phase difference signals collected between the upper following optical wedge and the lower following optical wedge, an error amount is obtained, a motor is driven to move according to motor rotation speed control signals newly generated by the error amount, rotation speed of the upper following optical wedge and the lower following optical wedge is changed until the error amount is in a permissible range.

Owner:CHINA KEHAN LASER FUJIAN

Laser etching preparation method for surface array microstructure on basis of curved surface workpiece appearance

ActiveCN104741794AEliminate layoutEliminate machining errorsLaser beam welding apparatusLaser etchingSpatial Orientations

The invention provides a laser etching preparation method for a surface array microstructure on the basis of a curved surface workpiece appearance. The method includes the steps that the free curved surface workpiece appearance to be processed is measured by the adoption of a reverse engineering method in a modeling mode, and design graph layout of the surface array microstructure is conducted on the basis of a reconstructed curved surface model; then, laser etching processing path planning is conducted on a design graph, the spatial orientation of a laser processing head relative to a free curved surface workpiece is adjusted according to a tangent plane where a processing path is located, a geometric center point and a corresponding outer-normal vector, laser beams are reflected to the free curved surface workpiece in the normal direction, and laser etching processing is conducted on geometric lines one by one. According to the method, it can be effectively guaranteed that the focus of the laser beams is located on the surface of the free curved surface workpiece all the time in the processing procedure or a certain defocusing distance exists between the focus of the laser beams and the surface of the free curved surface workpiece, a brand new accurate focusing laser processing method is provided, layout and processing errors of the surface array microstructure graph are completely eliminated, and accuracy and stability of laser etching processing technical quality are ensured.

Owner:WENZHOU UNIVERSITY

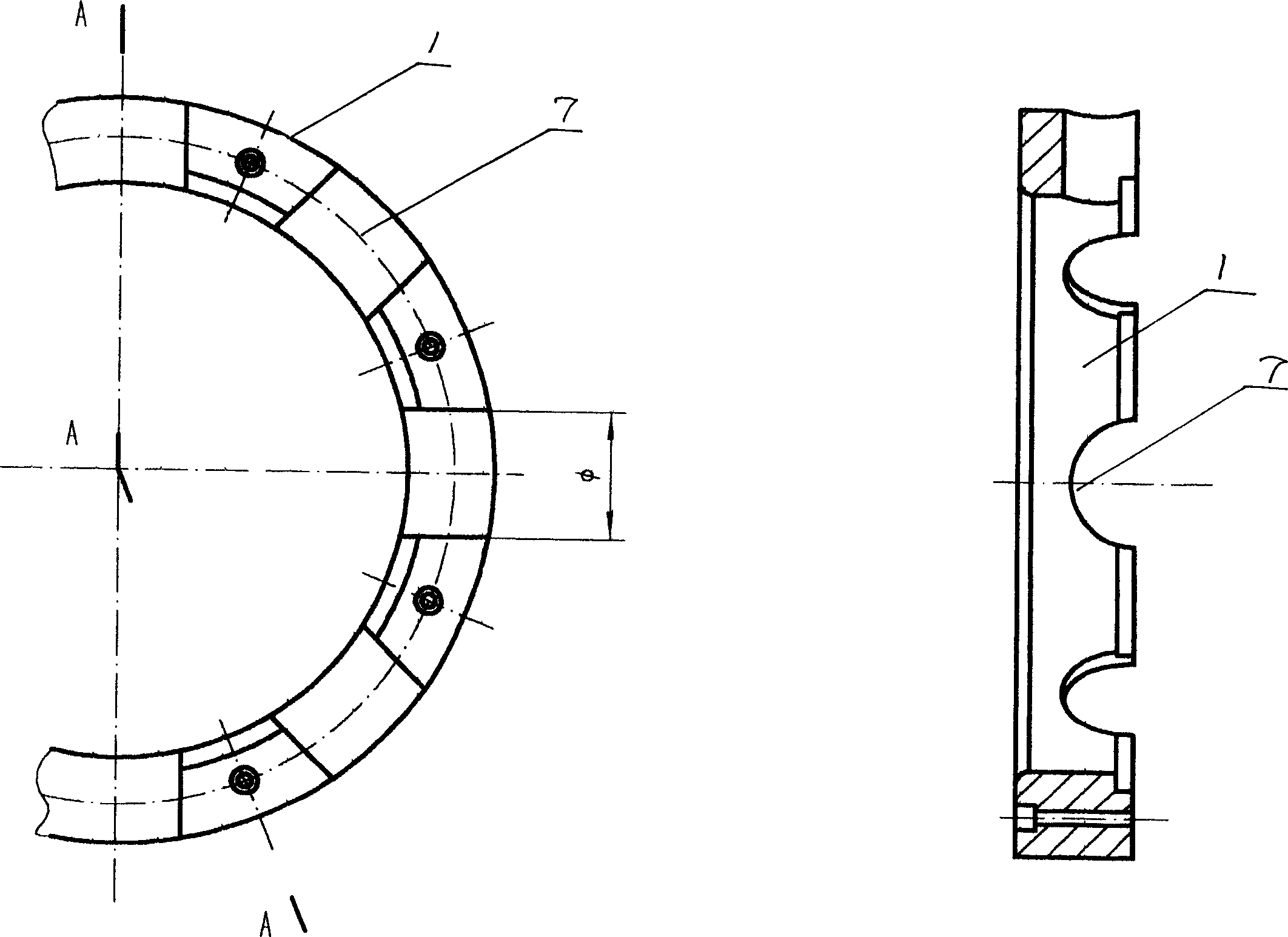

Thyristor valve section and crimping method thereof

ActiveCN102136468AGuaranteed uniformitySolve the technical bottleneck that cannot crimp the six-inch thyristorSemiconductor/solid-state device detailsSolid-state devicesHeat spreaderWater cool

The invention relates to a thyristor valve section and a crimping method thereof. The thyristor valve section comprises a valve group consisting of water cooling radiators and thyristors which are arranged alternately, wherein the left and right ends of the valve group are provided with a left end plate and a right end plate of the valve section respectively; the upper and lower end parts of the left and right end plates of the valve section are provided with a boss respectively, and an upper clamping ring and a lower clamping ring are sleeved on the bosses; the valve group is clamped between the upper clamping ring and the lower clamping ring; a disc spring top-pressing device is clamped at an end of the right end plate of the valve section in contact with the valve section; the water cooling radiators of the valve group of the thyristor valve section are directly mounted on the lower clamping ring so as to ensure that the centers of the water cooling radiators are collinear, thus ensuring uniform thyristor crimping force; and moreover, as the crimping force is provided for the valve section by the disc spring top-pressing device, the upper and lower clamping rings and the left and right end plates of the valve section together without involving a bolt, the crimping reliability and stability of the system are greatly improved.

Owner:XJ ELECTRIC +1

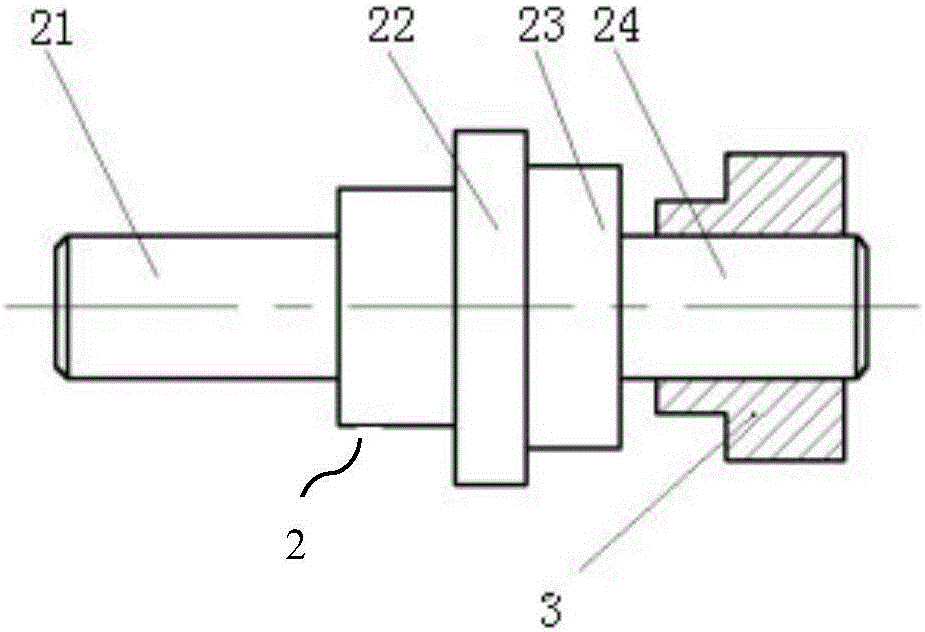

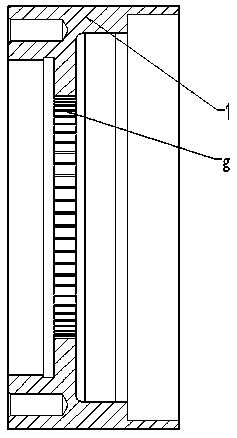

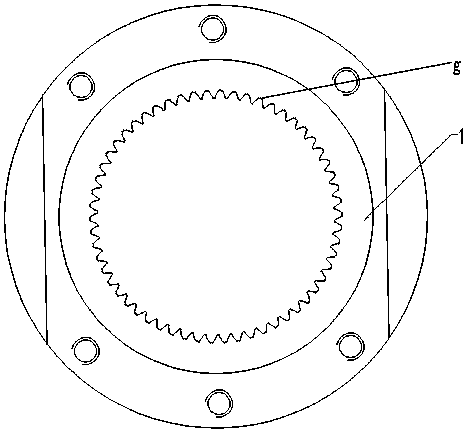

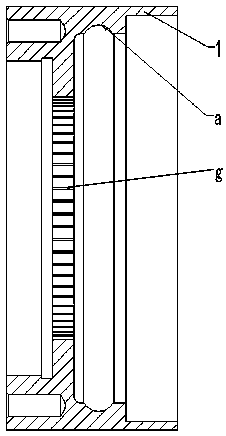

Dabber clamp for processing disc type gear

InactiveCN1943948AEliminate machining errorsQuality assurancePositioning apparatusGear-cutting machinesGear wheelEngineering

The spindle clamp for machining disc type gear includes rigid spindle, clamping nut, needle roller holder, compression spring and conic needle roller. Between the rigid spindle and the workpiece, are the conic needle rollers taper contacting the rigid spindle and inside the needle roller holder; the needle roller holder covers the rigid spindle and has outer end is contacted with the clamping nut connected to the rigid spindle; and the compression spring covers the rigid spindle and has two ends supporting the needle roller holder and the rigid spindle separately. The present invention is superior to available spindle clamp and has lowered production cost.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

Tubular workpiece fluid abrasive finishing device and finishing method thereof

ActiveCN111531462AEliminate end effectReduce processing timeEdge grinding machinesPolishing machinesHydraulic cylinderReciprocating motion

The invention relates to a tubular workpiece fluid abrasive finishing device and a finishing method thereof, belongs to the technical field of part inner surface polishing, and solves the technical problem that abrasive enters a gap between a workpiece and a clamp. The device comprises a rack, a hydraulic cylinder, a pushing cylinder and a tubular workpiece clamp, and a guide rail is arranged on the right side of the upper surface of the rack; a left supporting frame is arranged above the left side of the rack, a right supporting frame horizontally reciprocates along the guide rail, and a lower hydraulic cylinder is fixedly installed on the rack below the right supporting frame in the horizontal direction; and a tubular workpiece is clamped in an inner cavity of the tubular workpiece clamp, rubber pads are oppositely arranged at the left end and the right end of the tubular workpiece clamp, the left end of the left rubber pad is installed in a left material extruding pipe, the left endof the right rubber pad is installed in a right material extruding pipe, the left end of the tubular workpiece is installed in the left rubber pad, and the right end of the tubular workpiece is installed in the right rubber pad. According to the device, all grinding materials can enter a to-be-machined tubular workpiece, the machining effect is obvious, and the end face effect cannot be generatedat the two ends of the tubular workpiece.

Owner:TAIYUAN UNIV OF TECH

Machining method of glass mold

ActiveCN104384879AEliminate machining errorsHigh matching precisionImaging processingCircular surface

The invention provides a machining method of a glass mold. The machining method comprises the following steps of parison casting, parison outer circular surface turning, mold matched surface milling, side surface positioning benchmark milling, spray welding, matched surface refining, machining of other mold parts and finished product forming. In the parison outer circular surface turning step, a correction outer circular molded line corresponding to the parison outer circular surface is obtained by utilizing an image processing technology, then a positioning hole is formed by adopting the correction outer circular molded line as the benchmark, the distance between the correction outer circular molded line and the parison outer circular surface is used as the turning removal, so that the irregular problem of the outer circular molded surface can be primarily solved. By adopting the machining method, the matching precision of the glass mold matched surface can be further improved, and the qualification rate of products can be effectively increased.

Owner:ZHEJIANG JINGTAI GLASS TECH

Horizontal type swirl machining center

InactiveCN101434038AGuaranteed accuracyGuaranteed position control accuracyLarge fixed membersMetal working apparatusNumerical controlEngineering

The invention relates to a horizontal vortex machining center, which relates to a high-grade digital control machine tool product for processing a key component of a vortex compressor. The horizontal vortex machining center consists of a lathe bed, an upright post, a precise milling electrical main shaft, a machining center main shaft, a machining center tool magazine, a workpiece moment motor main shaft, a Z-axis guide rail, a Z-axis slider, a Y-axis guide rail, a Y-axis slider, an X-axis guide rail, an X-axis slider, etc., wherein the X-axis guide rail is arranged on the lathe bed; the precise milling electrical main shaft is arranged on the X-axis slider; the Z-axis guide rail is arranged on the lathe bed; the upright post is arranged on the Z-axis slider; the Y-axis guide rail is arranged on the upright post; the workpiece moment motor main shaft is arranged on the Y-axis slider; the machining center main shaft is arranged on the X-axis slider; the workpiece moment motor main shaft is a C gyro shaft and horizontally arranged on the Y-axis slider. The horizontal vortex machining center guarantees the precision requirement of workpieces, is easy to remove scrap iron, and avoids influence on the surface quality of the workpieces due to accumulation of the scrap iron.

Owner:GUANGZHOU CITY AGILE MFG

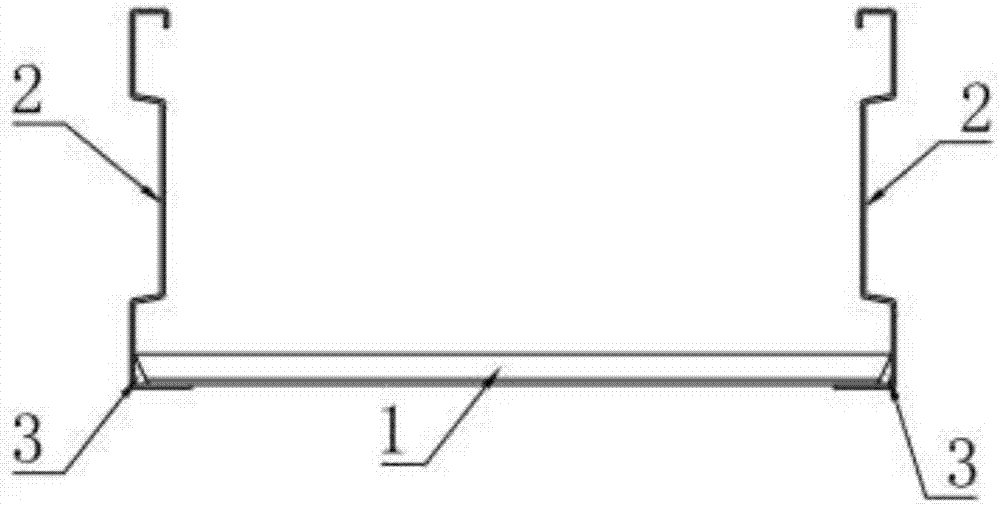

Light enhanced tray type bridge stand

InactiveCN106972429AHigh strengthGuaranteed assembly accuracyElectrical apparatusResource utilizationStructural engineering

The invention provides a light enhanced tray type bridge stand. The bridge stand is composed of two side plates (2) and multiple baseplates (1). The baseplates (1) are arranged between the two side plates (2), and multiple baseplates (1) are continuously spliced along the length direction of the internal side of the side plates (2) to form the bridge stand. The width of the baseplates (1) is cut according to the specification of the bridge stand. The cutting angle of the baseplates (1) is inclined, i.e. the width of the transverse upper plane of the baseplates (1) is greater than the width of the lower plane so that the transverse width of bottom grooves (12) is enabled to be less than the width of protrusions (11), a certain gap (3) can be reserved between the bottom connecting part of the baseplates (1) and the side plates (2) and finally the baseplates (1) and the side plates (2) are spliced and welded into an organic whole. Compared with the bridge stands in the prior art, the bridge stand is low in weight, high in strength and easy to process, the cumulative error is eliminated and the splicing part is not liable to deform so that the problem of zinc liquid deposition in the baseplate grooves in hot-dip galvanizing can be solved, water accumulation of the bottom part is not liable to occur and the resource utilization rate is high.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

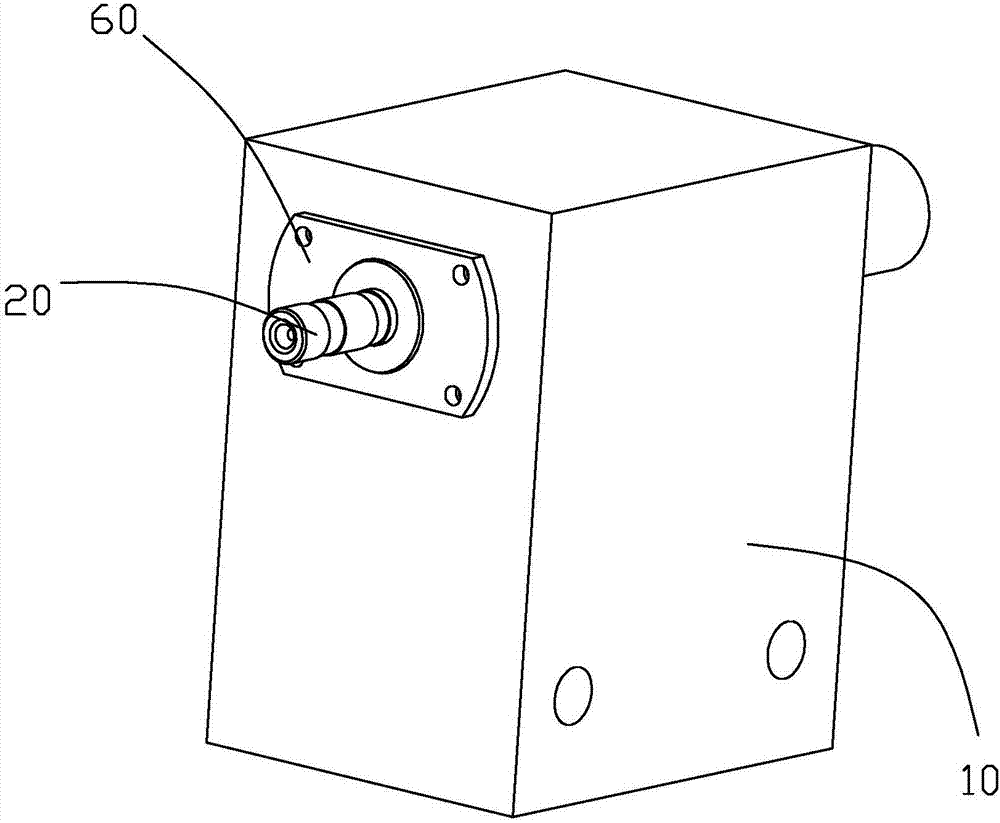

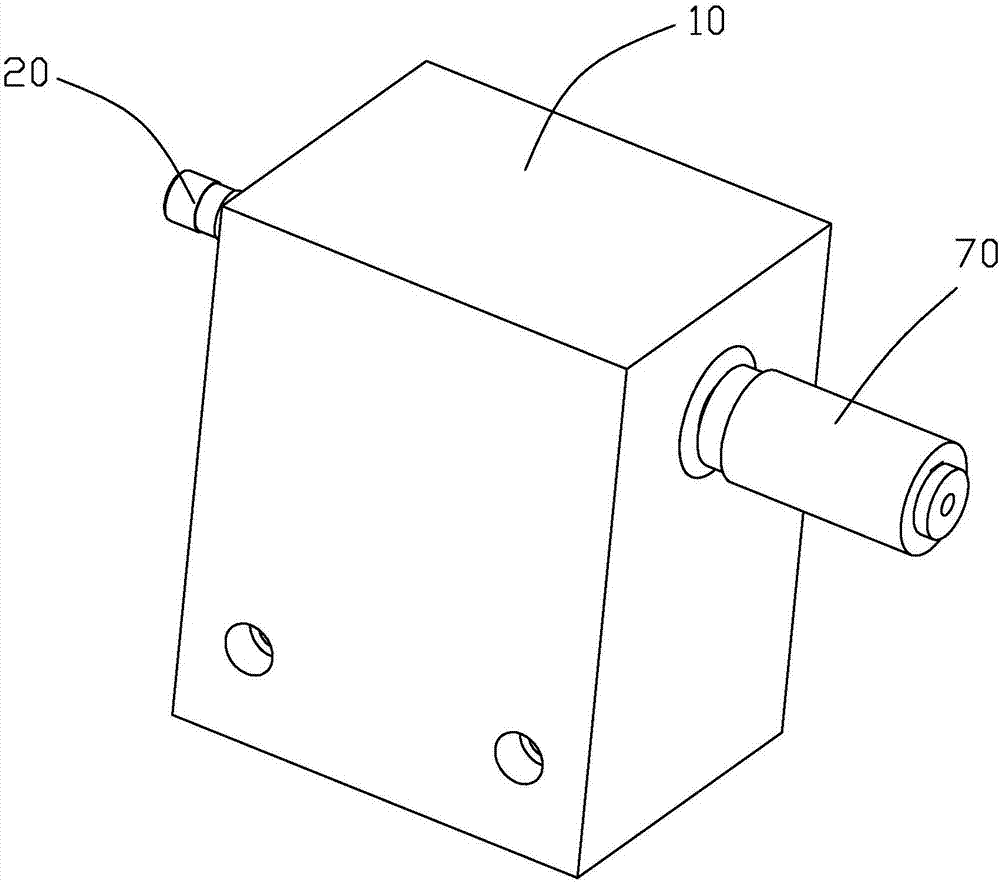

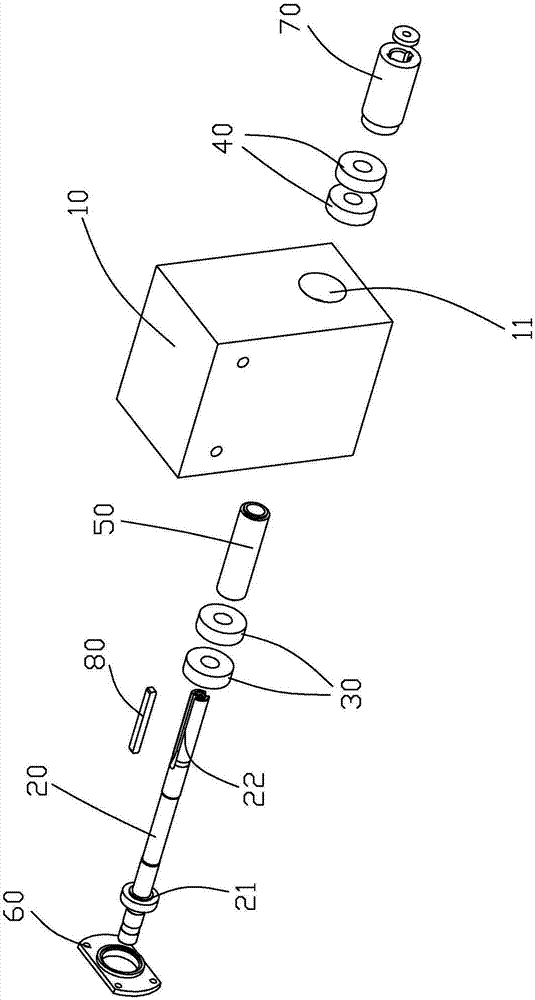

Spindle mechanism of winding machine

ActiveCN107381220AEven by forceIncrease speedFilament handlingCoils manufactureWinding machineFree state

The invention provides a spindle mechanism of a winding machine. The spindle mechanism comprises a spindle box, a spindle and bearings, a mounting hole is formed in the spindle box, the spindle is penetratingly arranged in the mounting hole of the spindle box and rotatably arranged on the spindle box through the bearings, the bearings are arranged at two ends of the mounting hole of the spindle box to form a front-end bearing and a rear-end bearing respectively, the front-end bearing and the rear-end bearing are identical in number, and an outer ring of each bearing at least at one end is unlimited axially to form a free end. Through arrangement in this way, the spindle is more uniform in front and rear stress, and a foundation is laid for high-speed running; the outer ring of each bearing is in a free state axially, so that thermal expansion and cold contraction of parts caused by heat release of the bearings running at a high speed, and rotating speed of the spindle can be increased while frequency of being damaged can be reduced. In addition, the outer ring of each bearing is in the free state axially, so that processing errors can be eliminated, and assembling and disassembling are simpler.

Owner:XIAMEN HONGFA IND ROBOT CO LTD

Machining process of steel wheel of robot reducer

The invention discloses a machining process of a steel wheel of a robot reducer. The machining process of the steel wheel of the robot reducer comprises the following steps of precision casting or forging of a blank of a first steel wheel; rough machining of the blank of the first steel wheel; heat treatment on the rough machined first steel wheel; finish machining of the first steel wheel; heat treatment on the finished first steel wheel; superfinish machining of the first steel wheel by adopting one-time clamping; and detecting various indexes of the superfinished first steel wheel until therequirements of a finished product are met.

Owner:SHANDONG SHKE MACHINERY MFG +1

Photoelectric number-carrying method for photoelectric direct-reading remote water meter

InactiveCN105387905AEliminate machining errorsAvoid Carry Data ErrorsVolume meteringPosition errorDirect reading

The invention discloses a photoelectric number-carrying method for a photoelectric direct-reading remote water meter. The method comprises the steps that when character wheel code tracks are arranged, the position of a photoelectric geminate transistor on a photoelectric emission small plate remains unchanged, the high-order code track is lagged by 5-10 degrees compared with the adjacent low-order code track, then a software algorithm is adopted for correcting high-order lagging, the software algorithm is that when the unit and the decade are both in the number carrying state, 10 is added to the hundred place; when neither the unit nor the decade is in the number carrying state, 5 is added to each of all other places except the unit; when the unit is in the number carrying state and the decade is not in the number carrying state, 5 is added to each of all other places except the unit and the decade; when all low-order places sequentially adjacent to high-order places are all in the number carrying state, 10 is added to each of the high-order places. By means of the photoelectric number-carrying method, when the character wheel code tracks are arranged, the high-order places of the character wheel code tracks are lagged, then the software algorithm is adopted for correcting high-order lagging, the situation that in the character wheel number carrying process, the situation that high-order character wheel number carrying is lagged behind low-order character wheel number carrying due to character wheel code track processing errors and photoelectric geminate transistor position errors is avoided, and a number carrying data error is avoided.

Owner:CHENGDU XINGLIANYI TECH CO LTD

Gap-adjustable ultrasonic rolling device capable of stably outputting

The invention relates to a gap-adjustable ultrasonic rolling device capable of stably outputting. The gap-adjustable ultrasonic rolling device capable of stably outputting comprises a pressing cap, anadjusting ring, a fixing cover, a sliding sleeve and a tool seat, wherein the pressing cap, the adjusting ring, the fixing cover and the sliding sleeve are hollow and sequentially connected in the axial direction, the tool seat is arranged on the outer side of the sliding sleeve in a sleeving mode, and the sliding sleeve is in sliding fit with the tool seat; inner cavities of the pressing cap, the fixing cover and the sliding sleeve are communicated with each other to form an installation chamber, the installation chamber is internally provided with a ball, a top cap, an amplitude-change lever and a transducer which are sequentially connected, the ball partially extends out of the outer wall of the pressing cap, and the amplitude-change lever is connected with the fixing cover; and the adjusting ring is arranged between the pressing cap and the fixing cover. According to the ultrasonic rolling device, the adjusting ring is additionally arranged between the pressing cap and the fixingcover, so that the ball clearance is controllable, the amplitude-change lever with a flange is adopted, the flange is arranged at the node position of the amplitude-change lever, the output effect ofthe amplitude-change lever is not influenced, and the amplitude-change lever is fixed at the same time, so that the output of the amplitude-change lever is more stable; and a spring is arranged at thelower end of the device to play a buffering and protecting role.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com