Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Graph Layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pictorial representation of a graph on plane, for visualization of certain properties of the graph or of the data modeled by the graph.

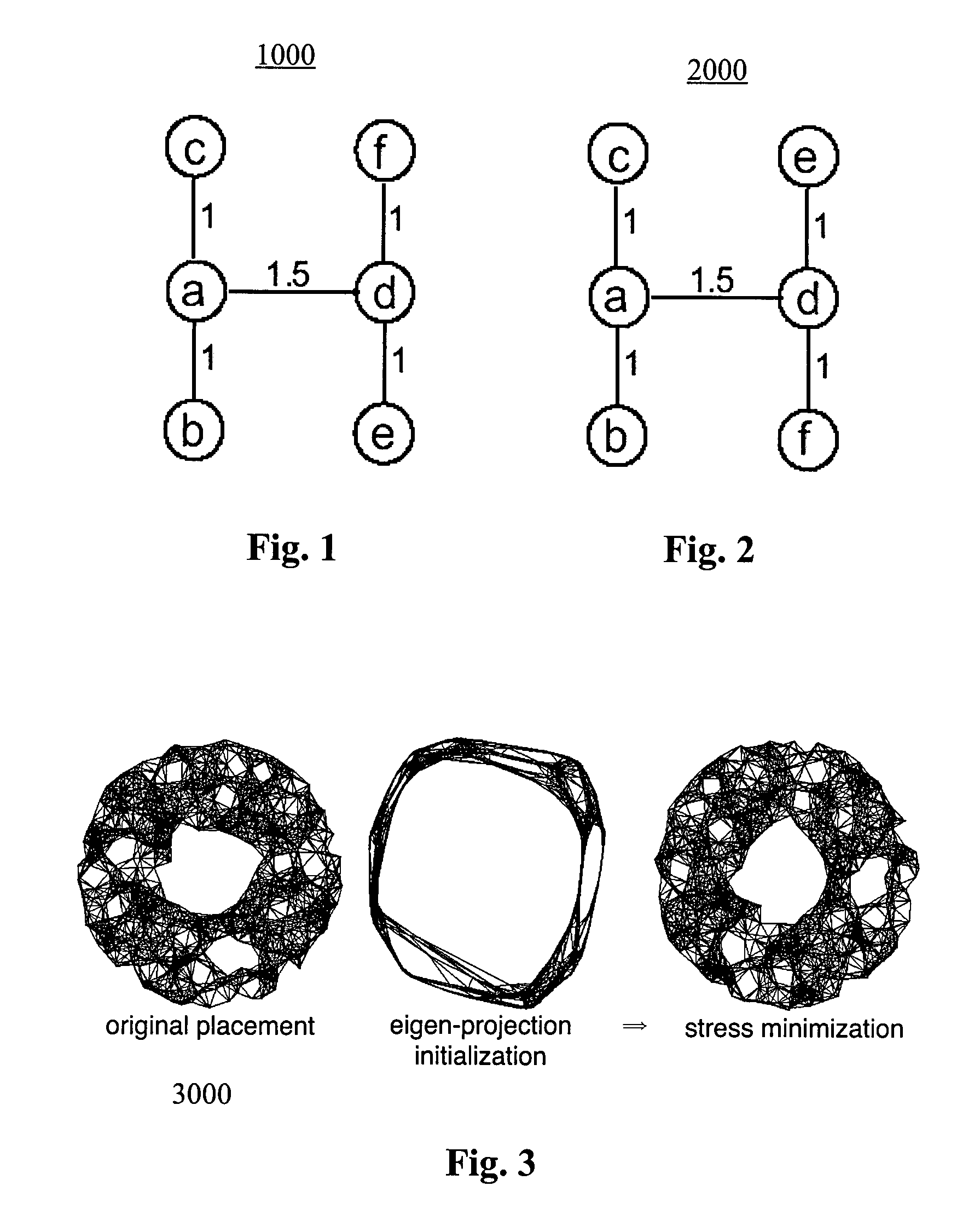

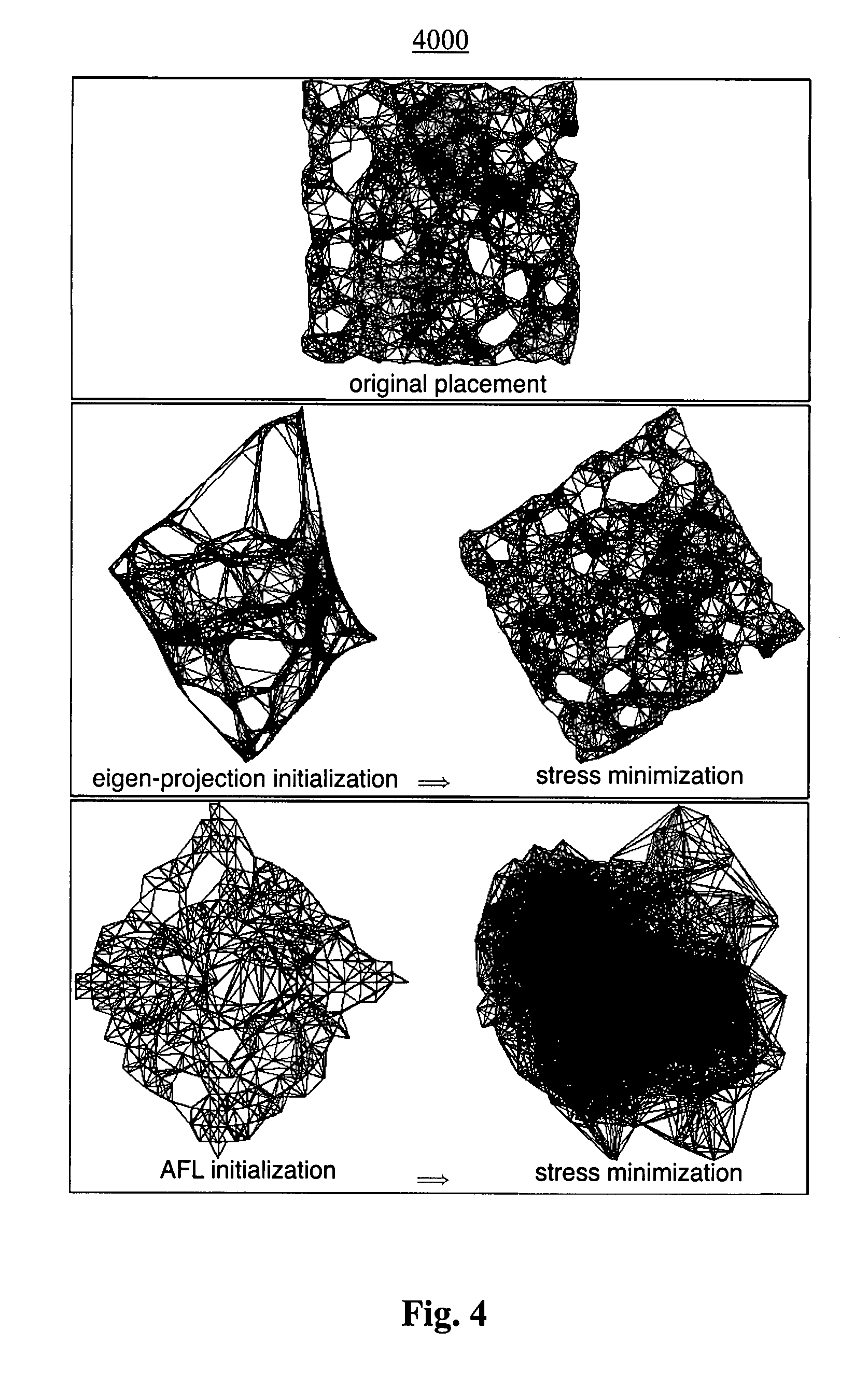

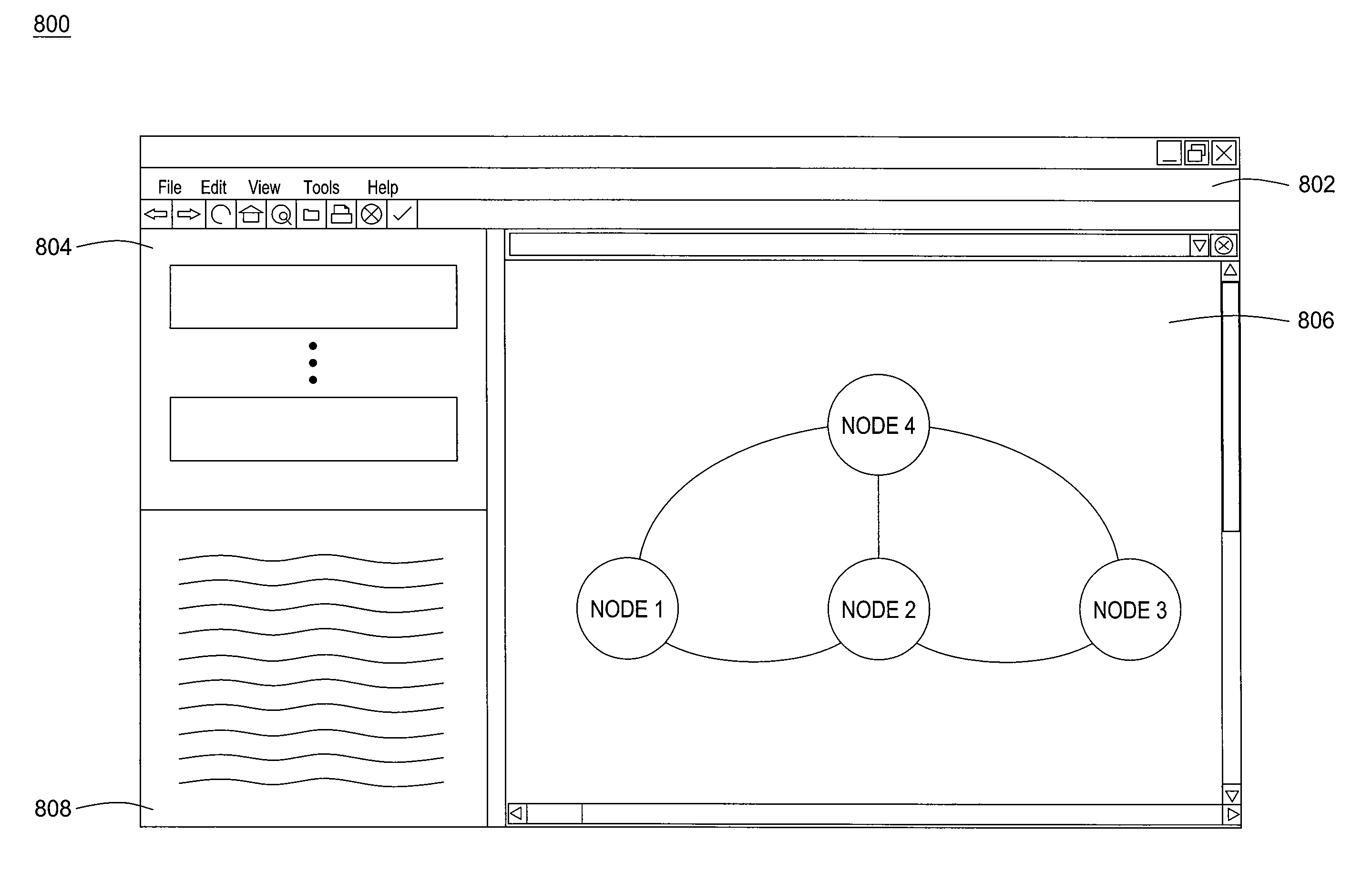

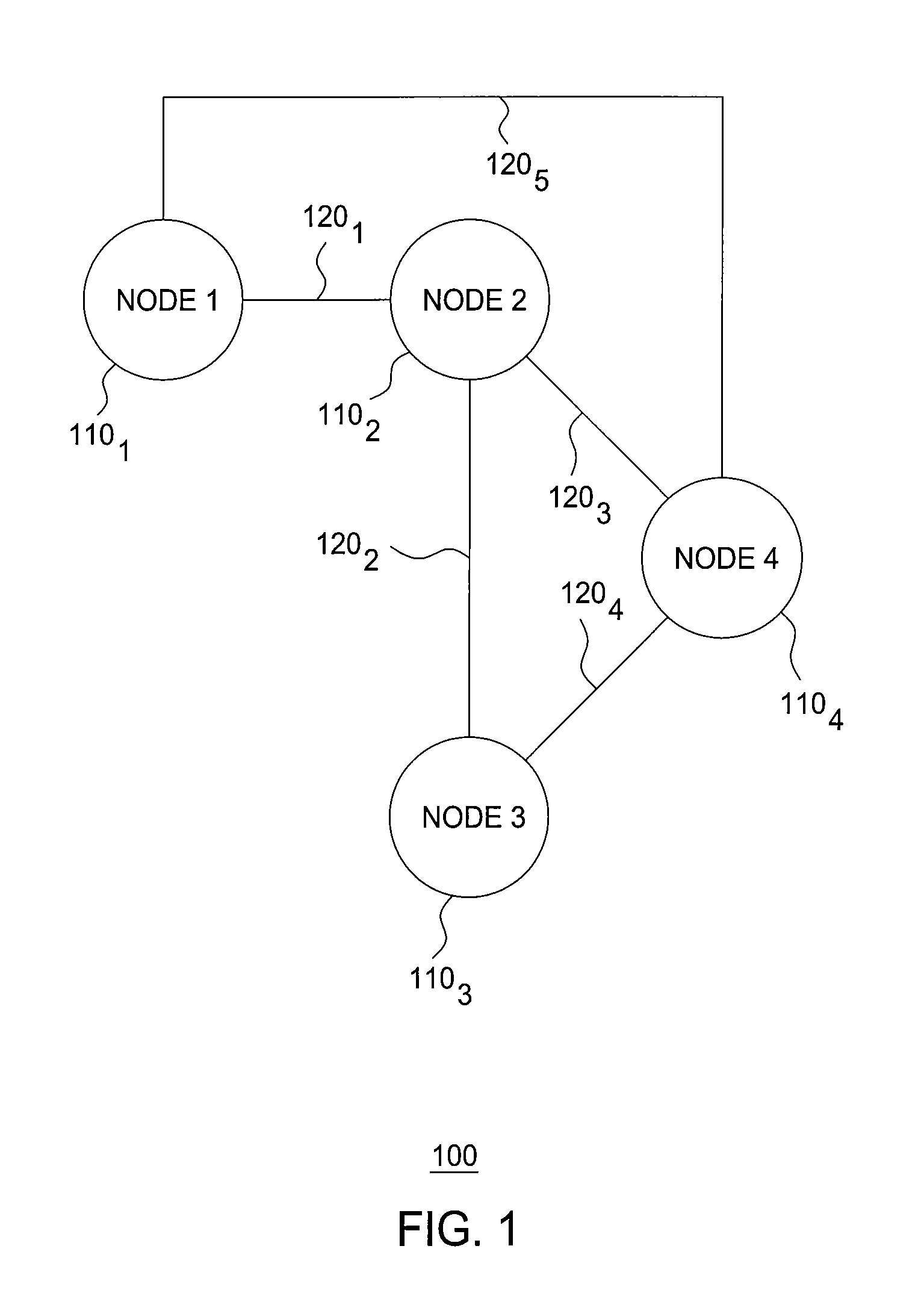

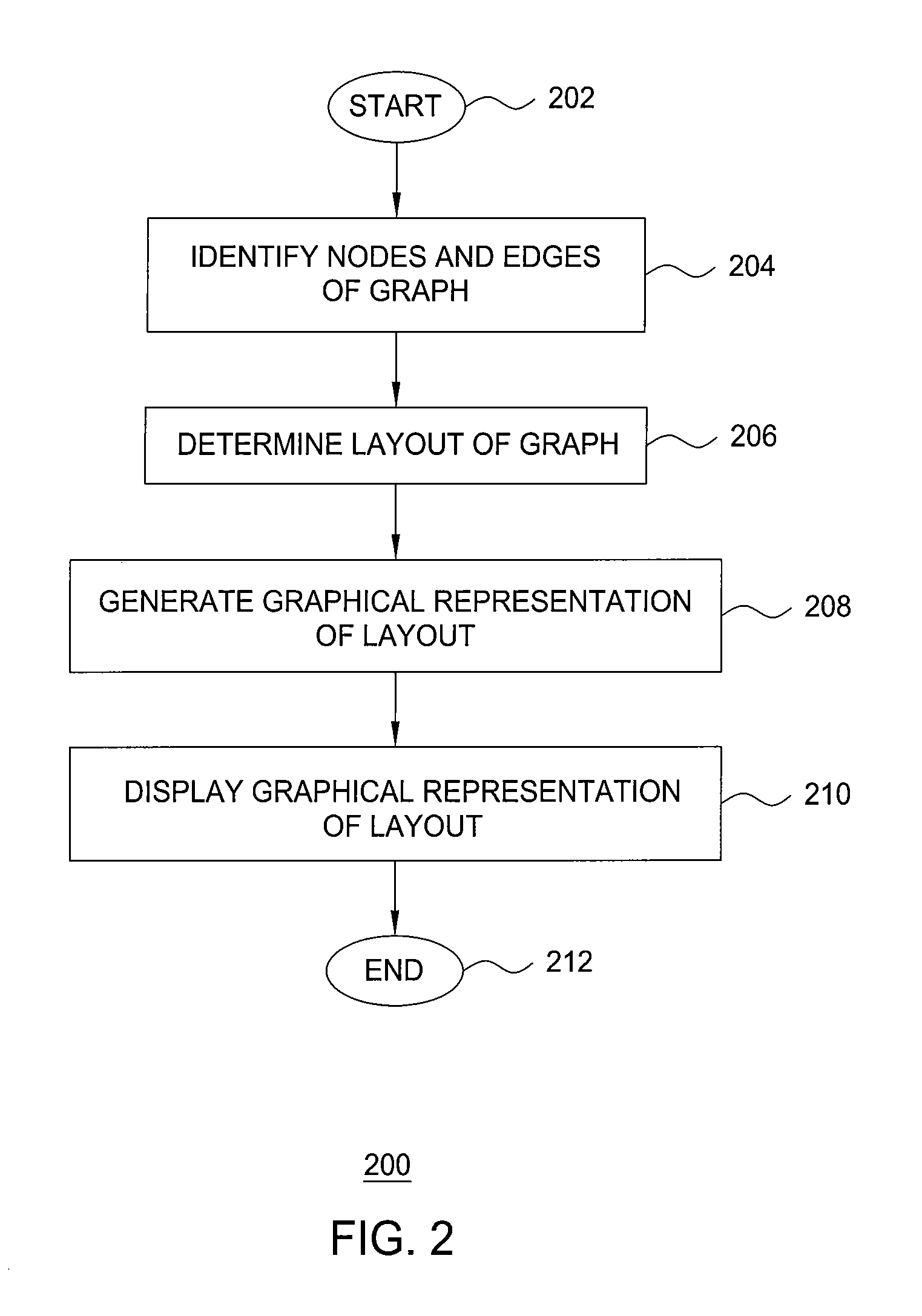

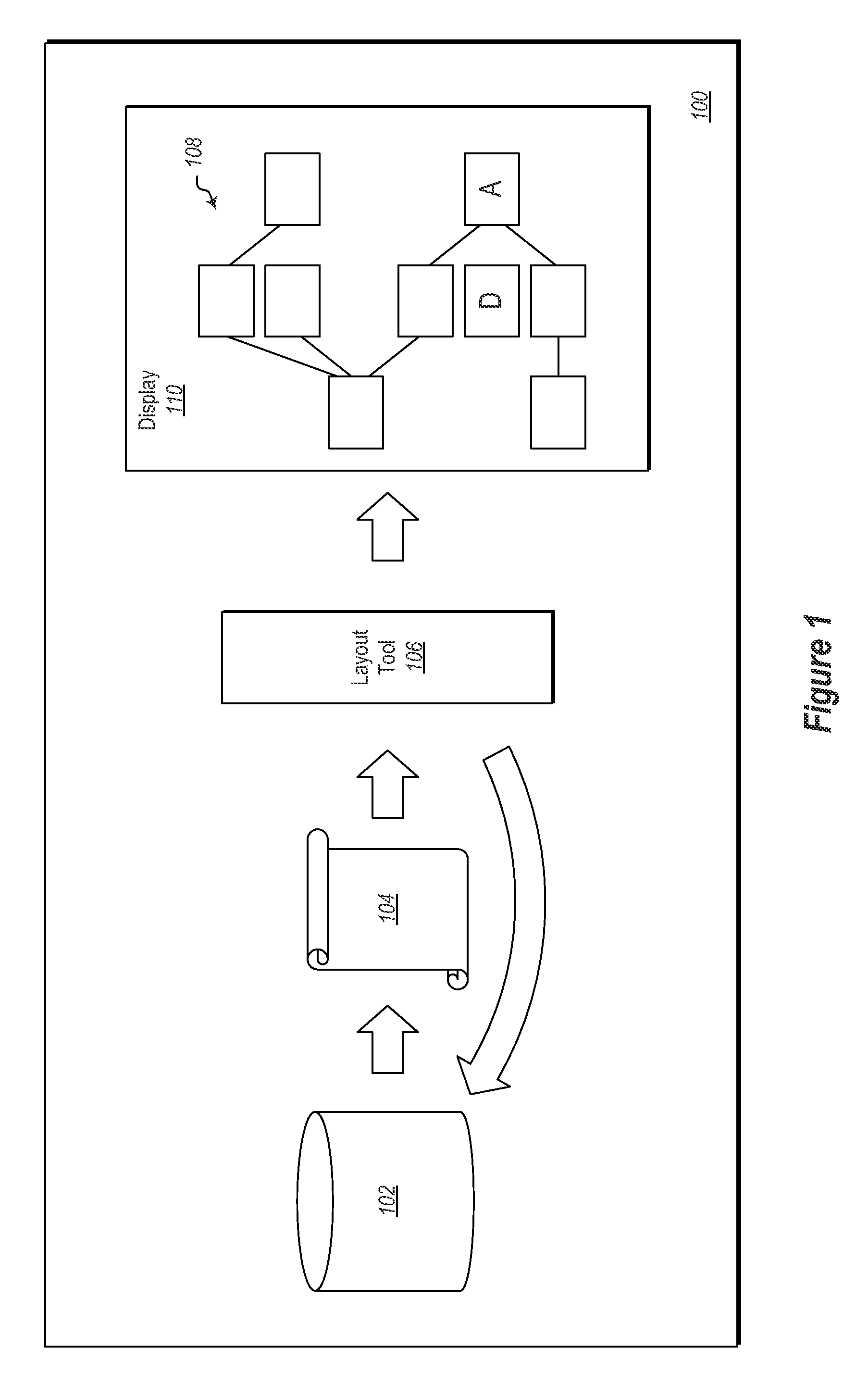

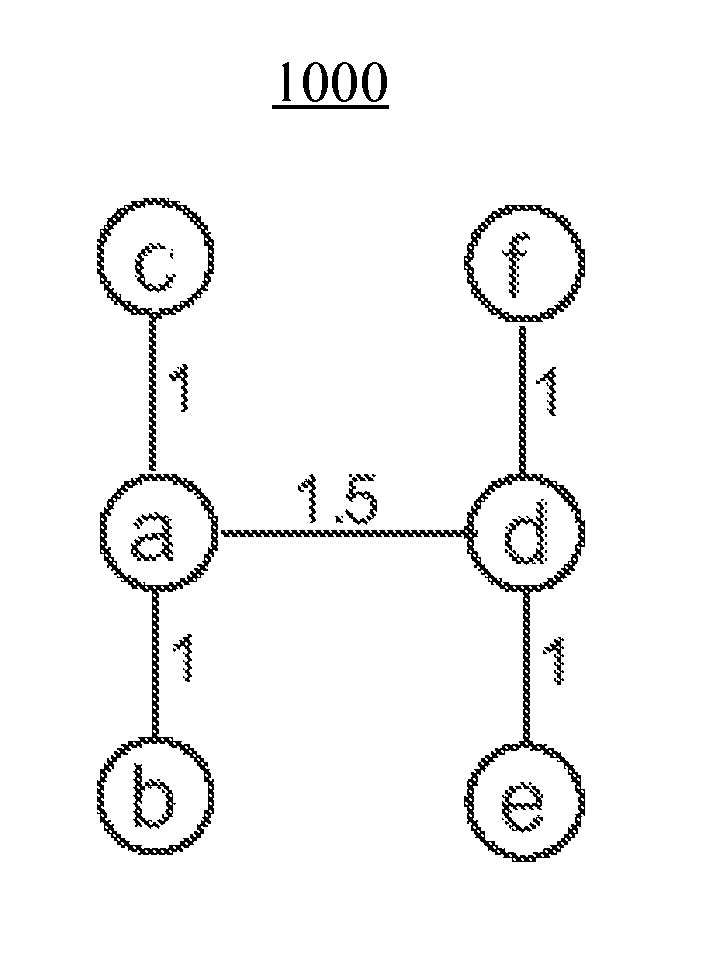

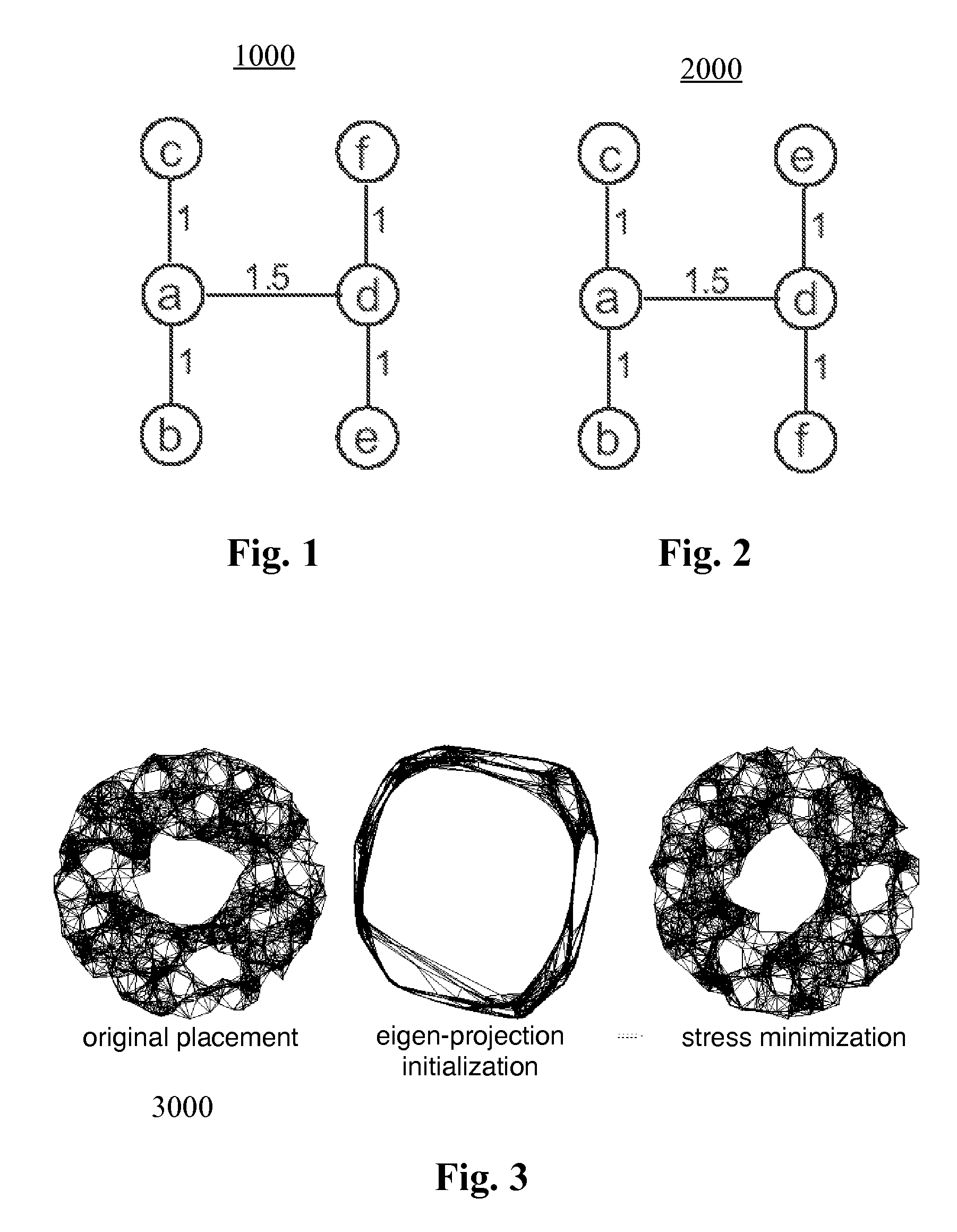

Method and apparatus for displaying graphical representations of graph layouts

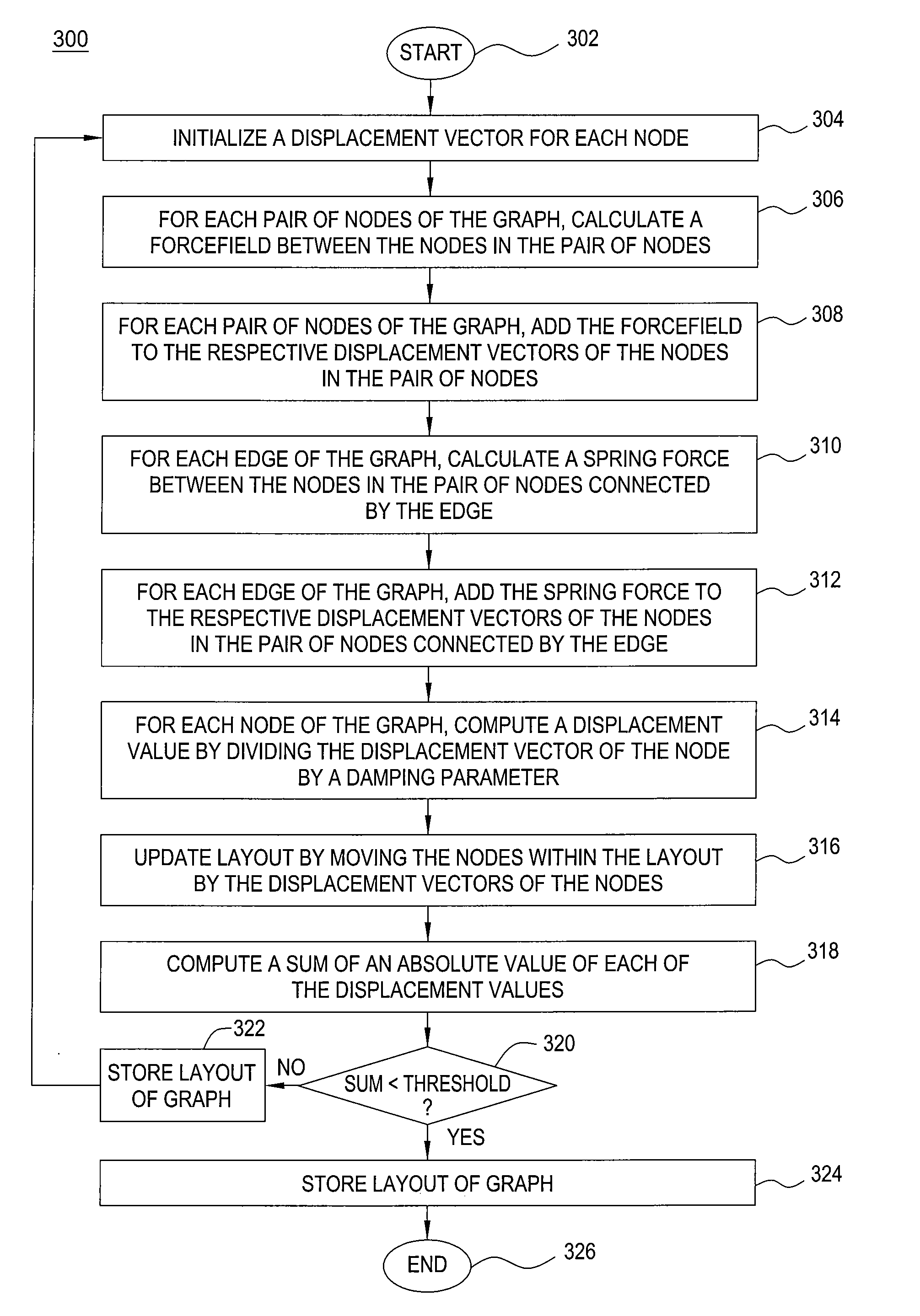

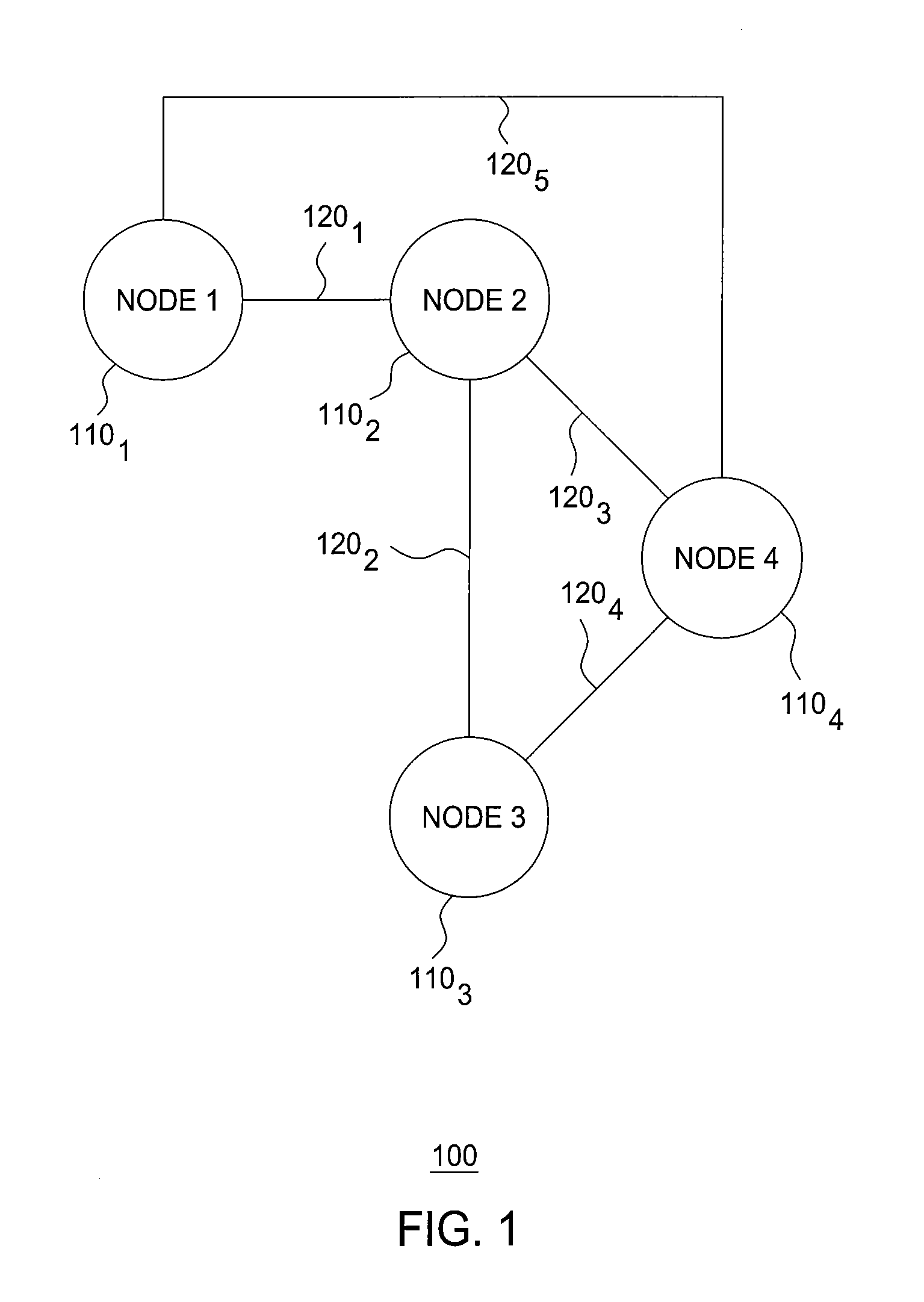

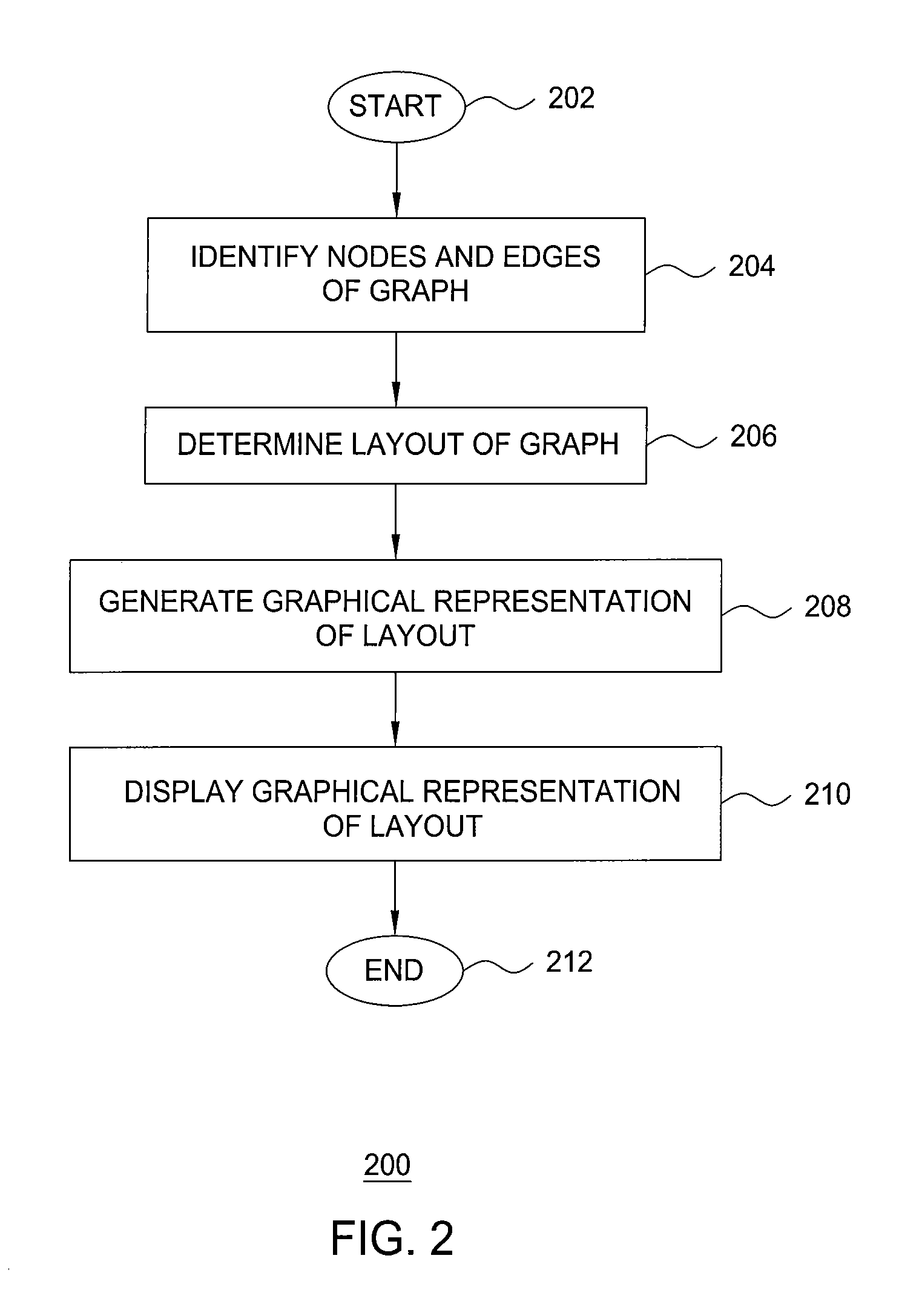

The invention includes a method and apparatus for displaying a graphical representation of a graph including nodes and edges. A layout of the graph is determined. The layout of the graph is determined by determining respective positions of each of the nodes and edges within the layout. The position of each node is determined using a first model and, optionally, a second force model, wherein the first force model comprises a substantially linear repulsive force in a first region, a substantially exponential repulsive force in a second region, and an attractive force in a third region. In one embodiment, the position of each edge may be determined using the first force model. A graphical representation of the layout is generated. The graphical representation of the layout is displayed to one or more users.

Owner:PIECE FUTURE PTE LTD

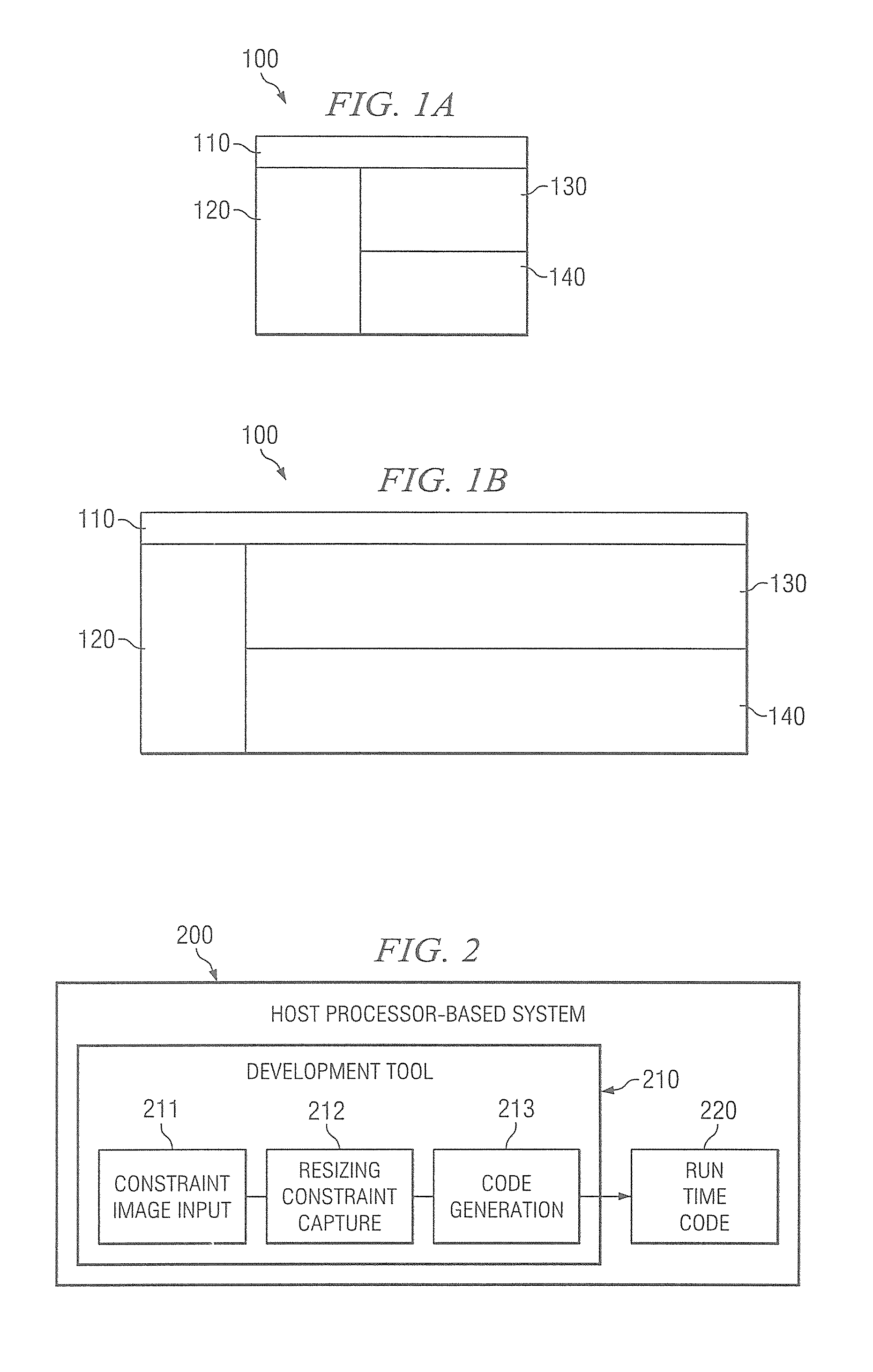

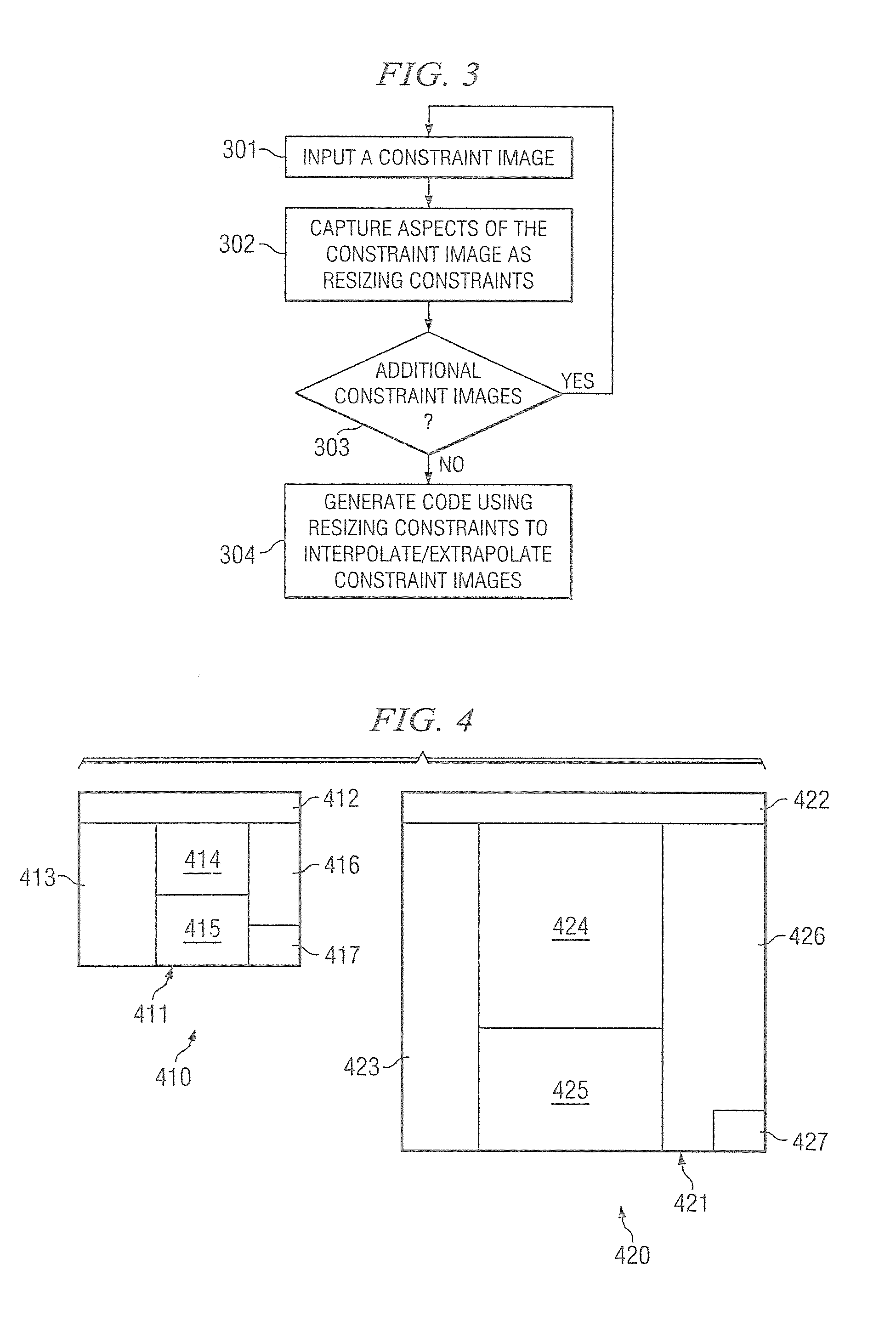

Rendition-based graphical layout management

ActiveUS7818684B1Digital computer detailsInput/output processes for data processingGraphicsComputer science

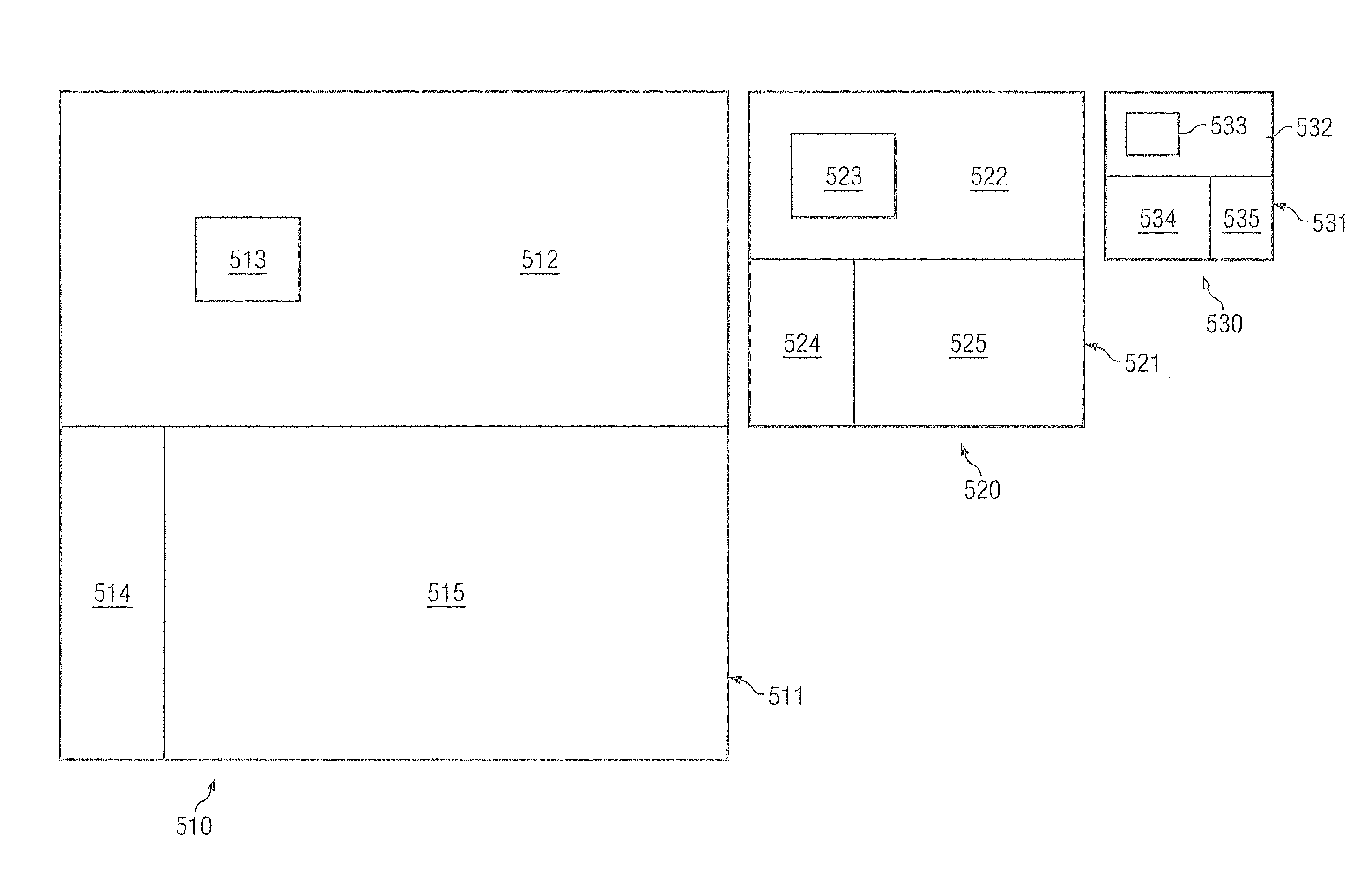

Systems and methods which implement rendition-based graphical layout management techniques are shown. According to an embodiment, desired resizing of items within a program's user interface is managed through a developer graphically describing a plurality of different sized renditions of a desired user interface and other different sized renditions of the user interface being dynamically interpolated and / or extrapolated through operation of the program. According to embodiments, linear interpolation and / or extrapolation is provided with respect to windows sized differently than constraint images provided by a developer. In embodiments where more than two constraint images are provided, piece-wise liner interpolation and / or extrapolation may be provided. Non-linear interpolation and / or extrapolation may be implemented according to embodiments of the present teachings.

Owner:ADOBE SYST INC

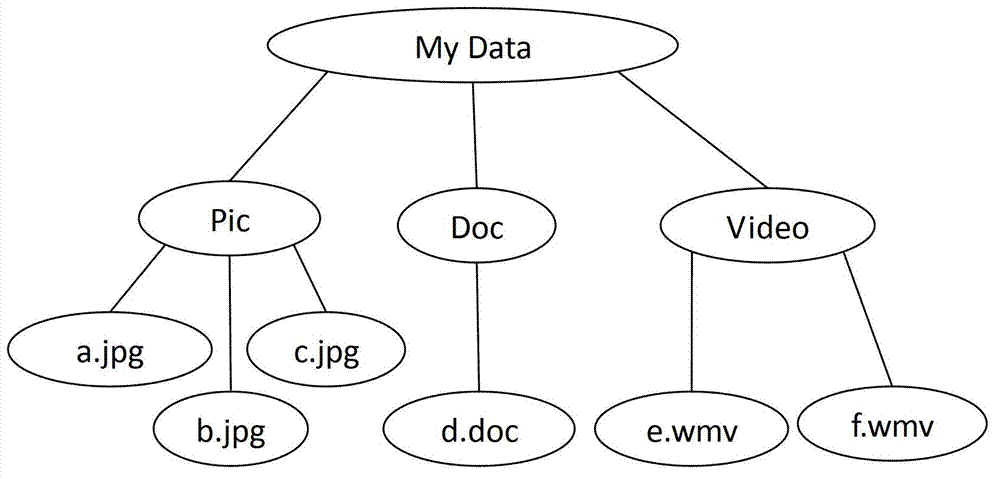

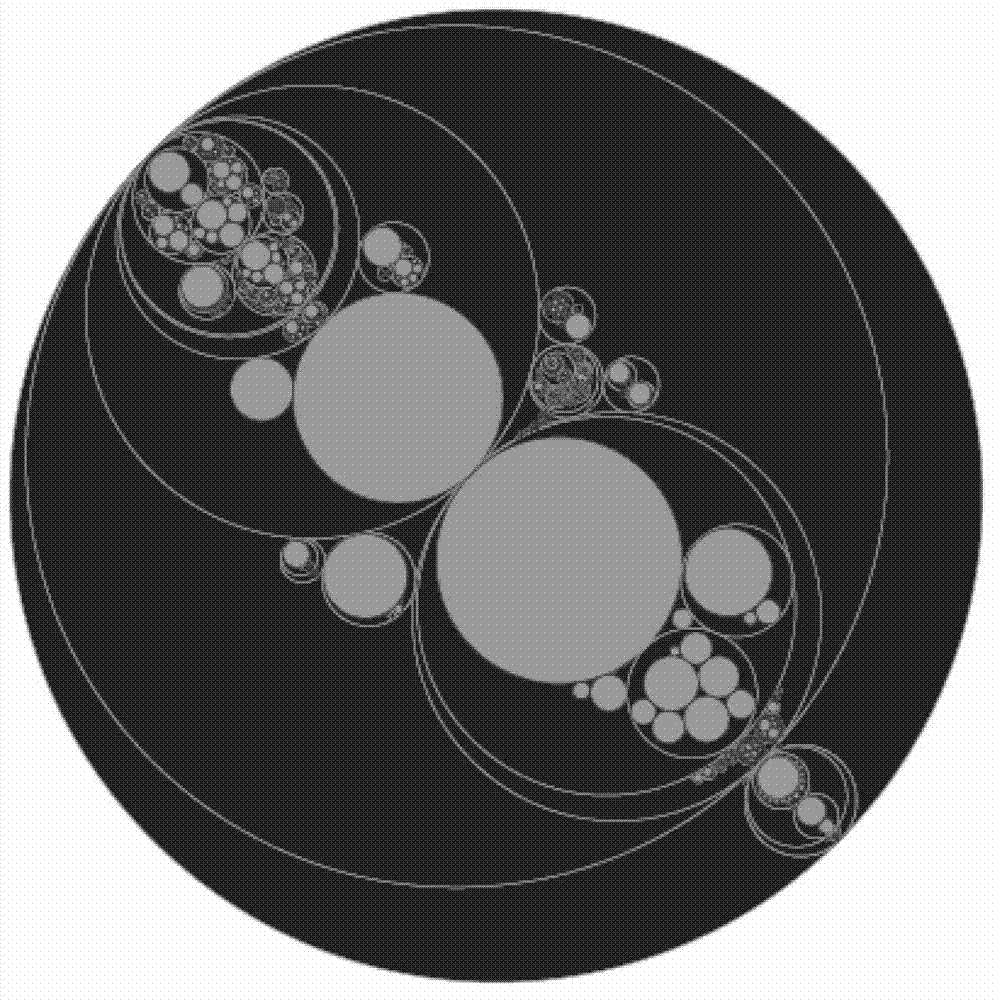

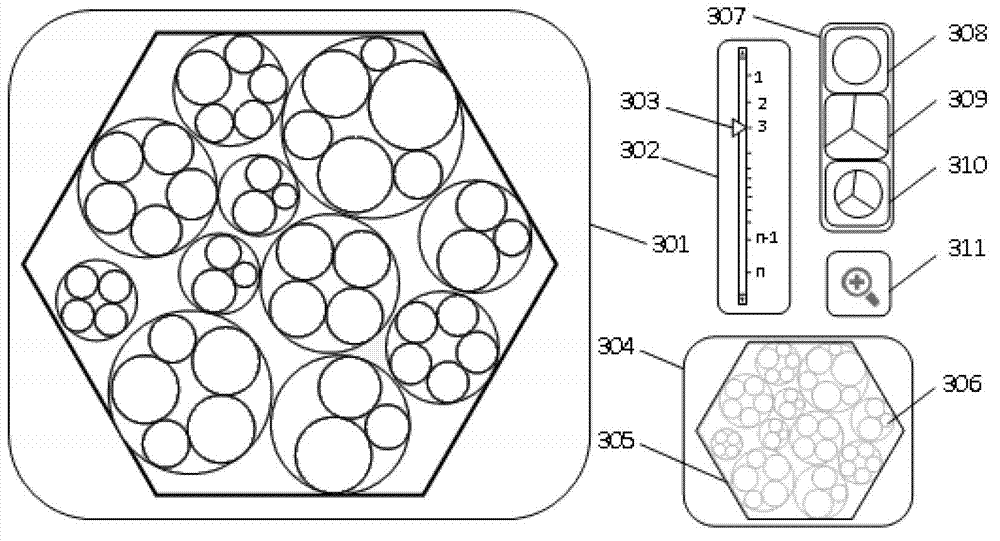

Interactive visual method and device facing layering data

InactiveCN103164520AClear presentation hierarchySame aspect ratioSpecial data processing applicationsLarge scale dataComputer science

The invention discloses an interactive visual method and a device facing layering data. The method comprises the flowing special steps: step1, a layering data object is acquired, and a suitable weight mapping function is set according to characteristics of the layering data, characteristics of application scenarios and special requirements of a user; step2, the weight of each node of the layering data is defined through the mapping function; step3, a root node of the layering data is expressed by selecting round space or arbitrary polygonal space; step 4, other nodes are expressed to be circles with specific radiuses according to the weight of each node of the layering data; step5, the arrangement of layering circles is produced due to the adoption of a circular layout method; and step 6, an interactive visual interface is generated. The layering circular layout generated through the method corresponds to a Voronoi tree graph layout, various visual coding modes are provided, the circular layout is optimized and adjusted in real time, various interactive modes are provided, and the layering circular layout can be applied to multi-point touch control equipment. The method and the device not only can be used for processing layering data of ordinary data sizes but also can be used for processing large-scale data sets.

Owner:SHANDONG UNIV

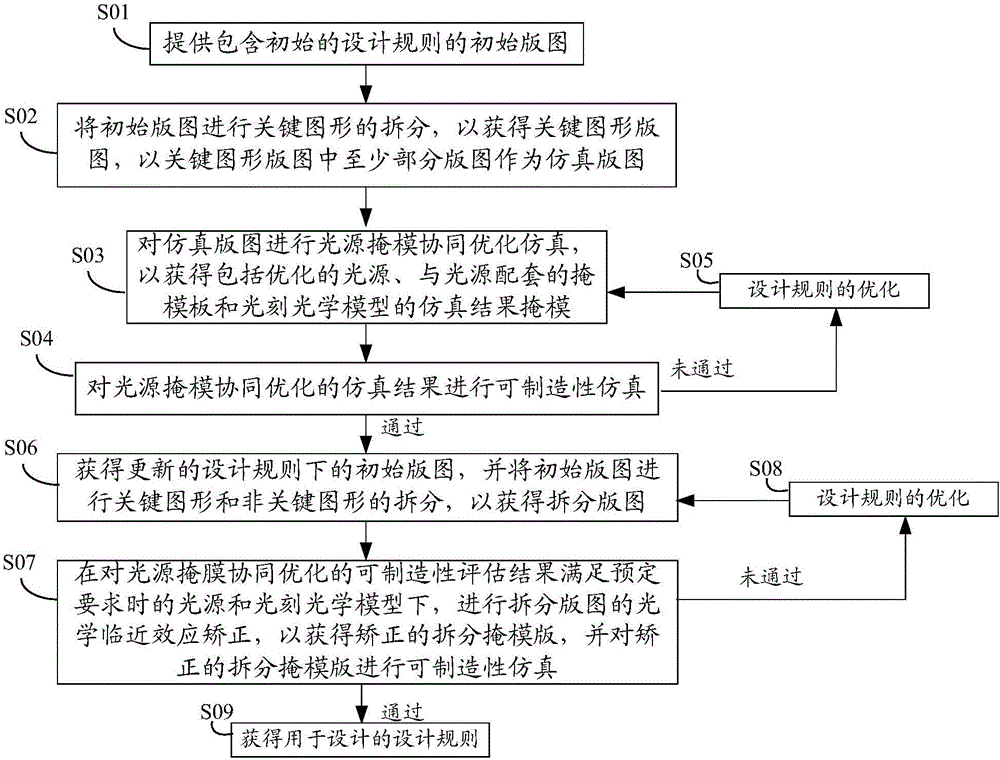

Method and system for optimizing layout design rules

ActiveCN105825036ADesign Rule OptimizationHigh feasibilityDesign optimisation/simulationCAD circuit designGraphicsComputer architecture

The invention provides a method for optimizing layout design rules, wherein aiming at research and development of advanced technological nodes, an initial layout is split from an initial layout, and the key graph is taken as a layout for subsequent simulation optimization; during the optimization, through combination of a light source masking and optimization simulation, a rational light source, a matched masking template and an optimized photo-etching optical model are determined; then, under the photo-etching optical model, manufacturability of the optimized light source and the optimized masking template is simulated; the design rules are optimized according to hotspot output of the manufacturability simulation; and the optimized design rules are obtained through repeated iterations. During the optimization, the key graph layout is optimized, so that feasibility and optimization efficiency are high. Through adjustment of the design rules, the quantity of iterations in the layout simulation can be reduced and the optimization efficiency can be increased on one side; and on the other side, the more optimal design rules can be obtained, design courses are simplified, and design duration is shortened.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

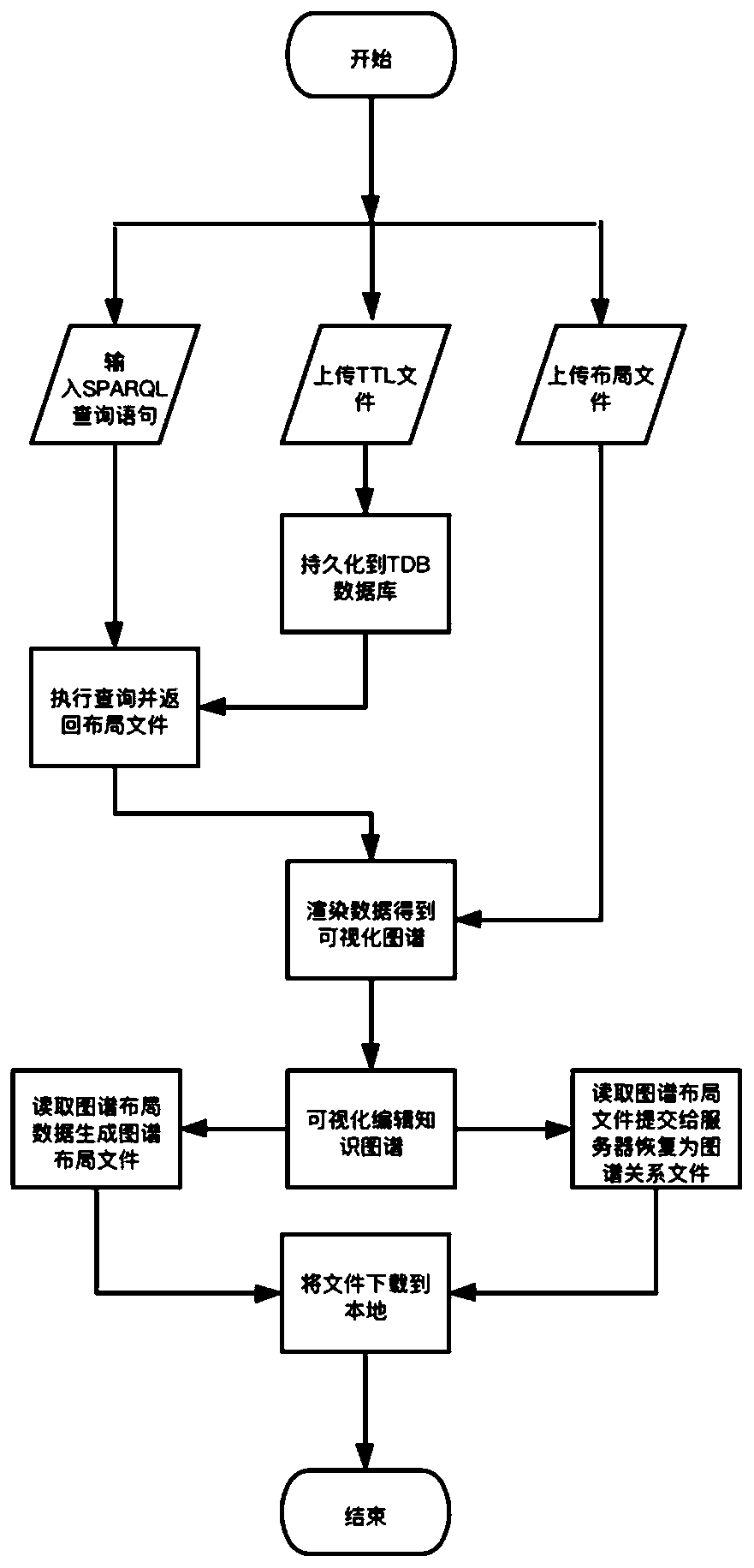

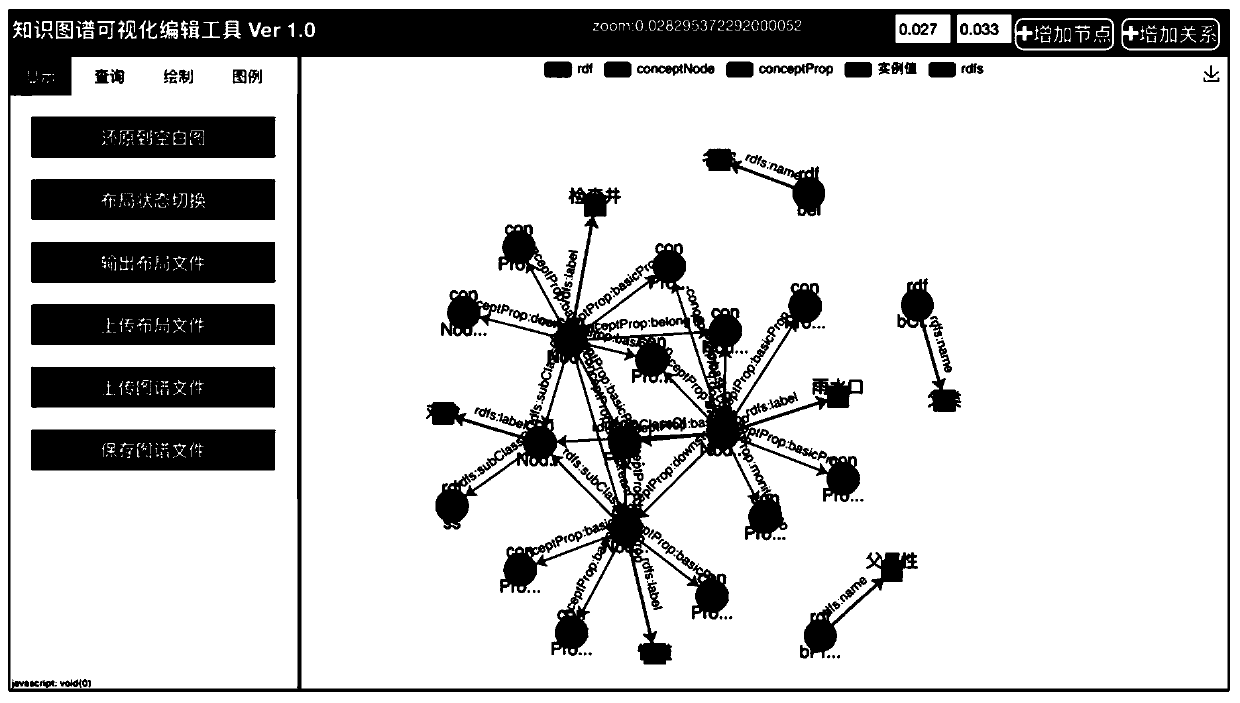

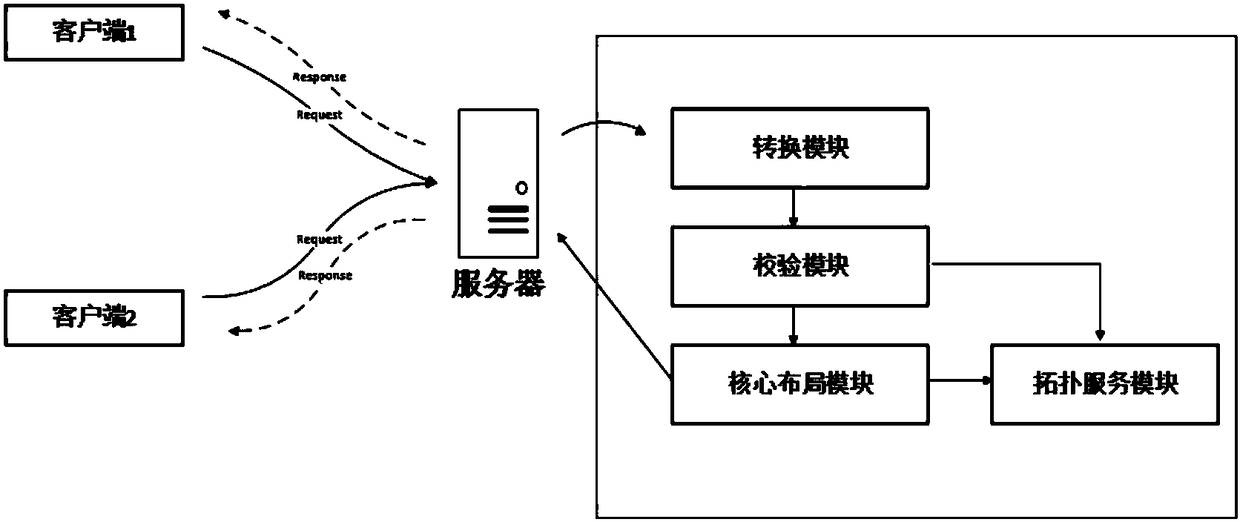

Knowledge graph visual editing and persistence implementation method and system architecture

PendingCN111339316AEasy to storePromote recoverySpecial data processing applicationsText database browsing/visualisationInteractive editingTheoretical computer science

Owner:HOHAI UNIV

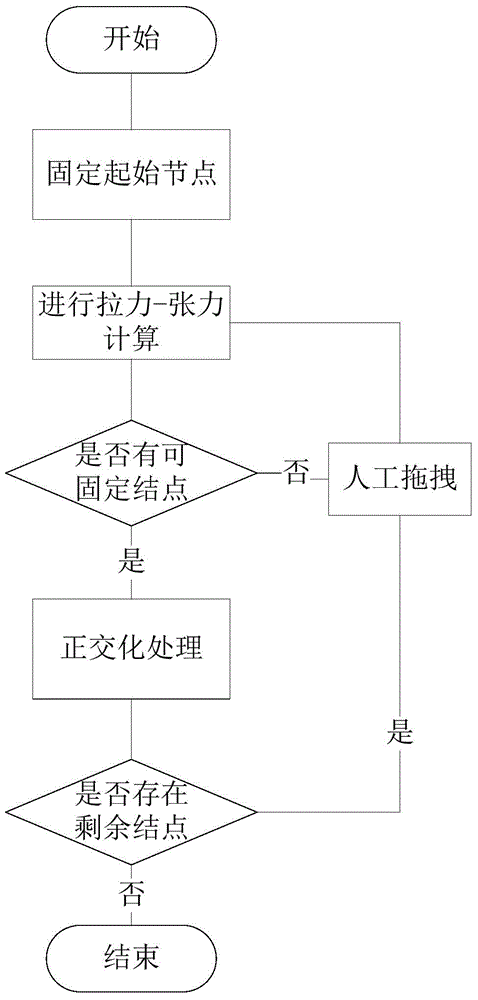

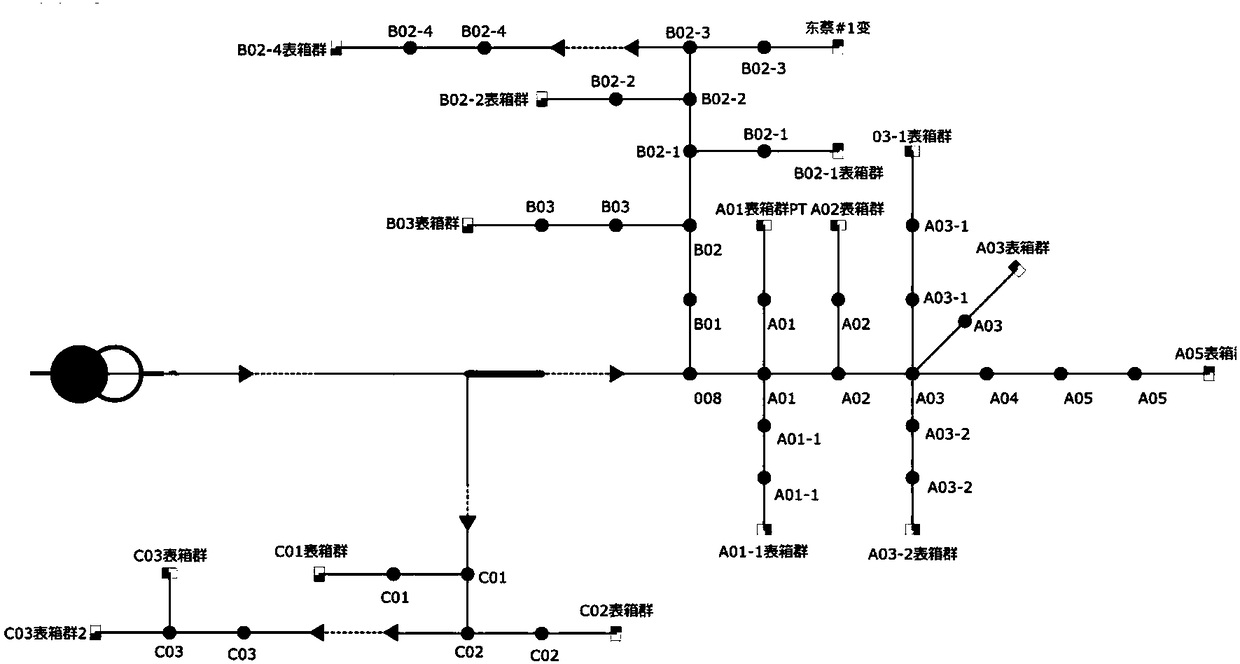

Layout optimization method of distribution network thematic maps

InactiveCN104951844AImprove usabilityImprove legibilityForecastingSystems intergating technologiesGraphicsParallel computing

The invention discloses a layout optimization method of distribution network thematic maps. The method includes the steps of optimizing the distribution network thematic maps of different types by means of force-directed layout, and performing optimization in a topological tree layout manner according to the need for local layout optimization. By the use of the method, the problems such as graphic overlapping, unreasonable layout and connecting line crossing occurring in manual drawing or using of the distribution network thematic maps are solved. At the premise of accurate and complete graphic representation, graphic layout is uniform, moderate in size and attractive and clear, and the availability and readability of the distribution network thematic maps is partly improved.

Owner:国网北京市电力公司顺义供电公司 +1

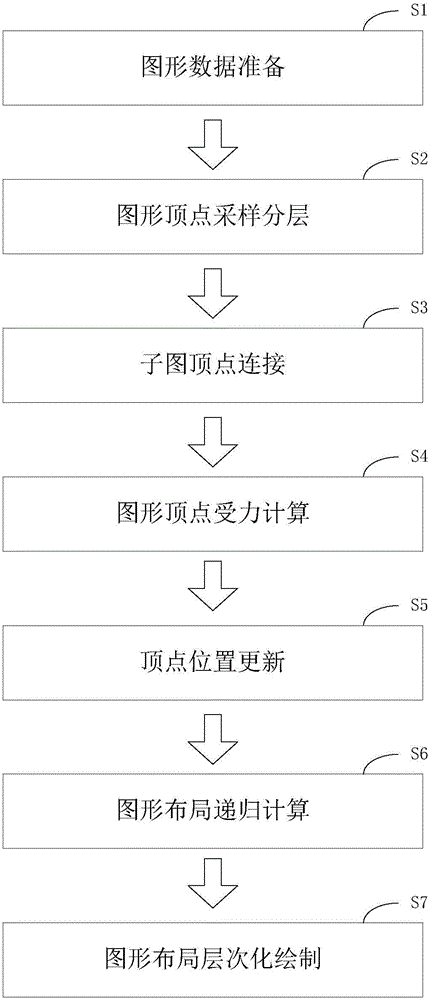

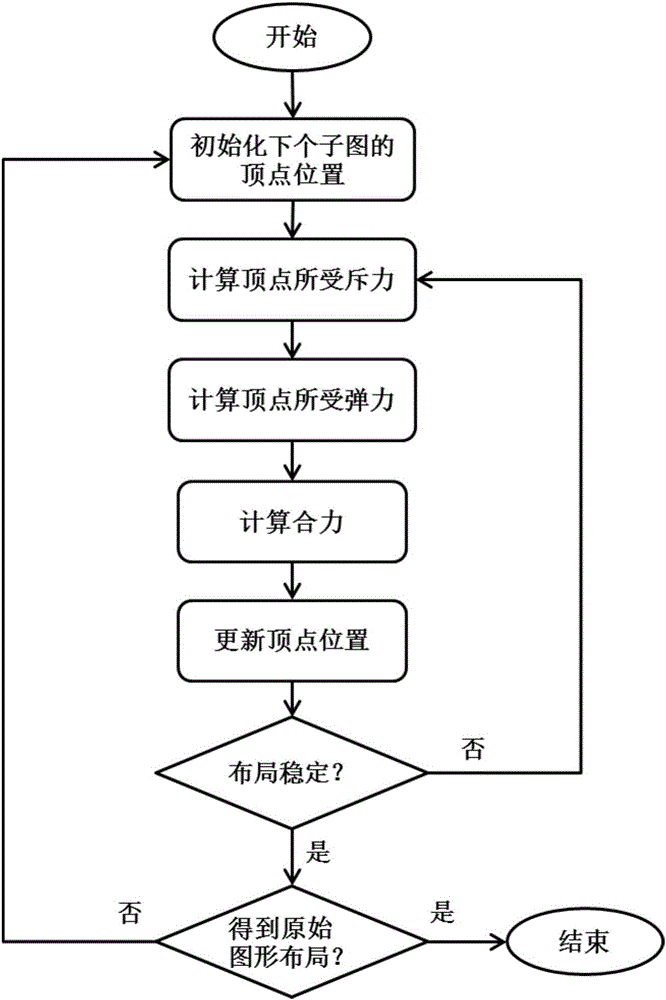

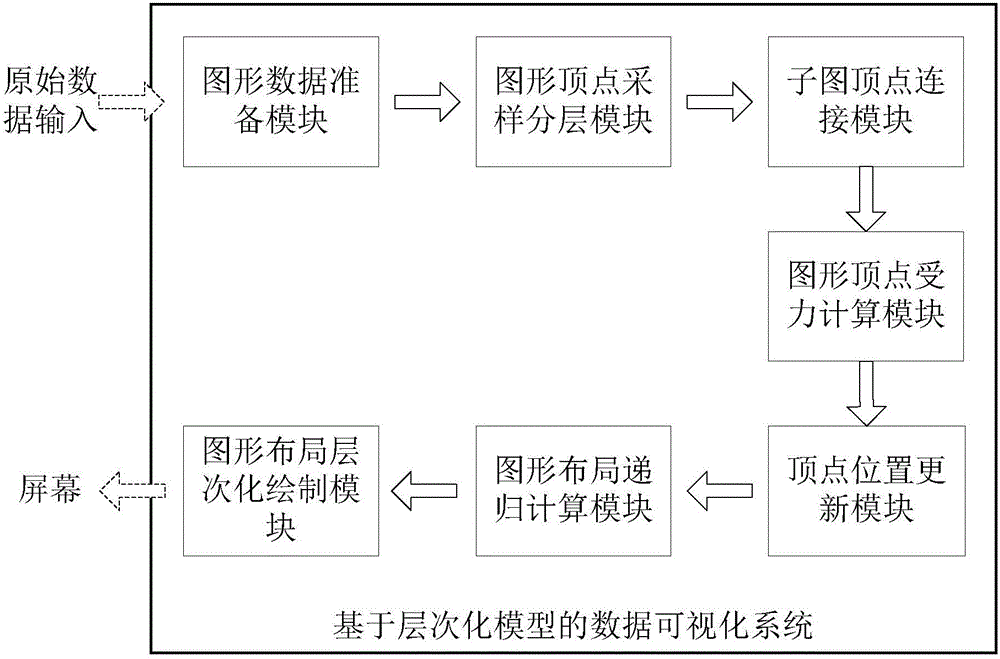

Data visualization method and data visualization system based on hierarchical model

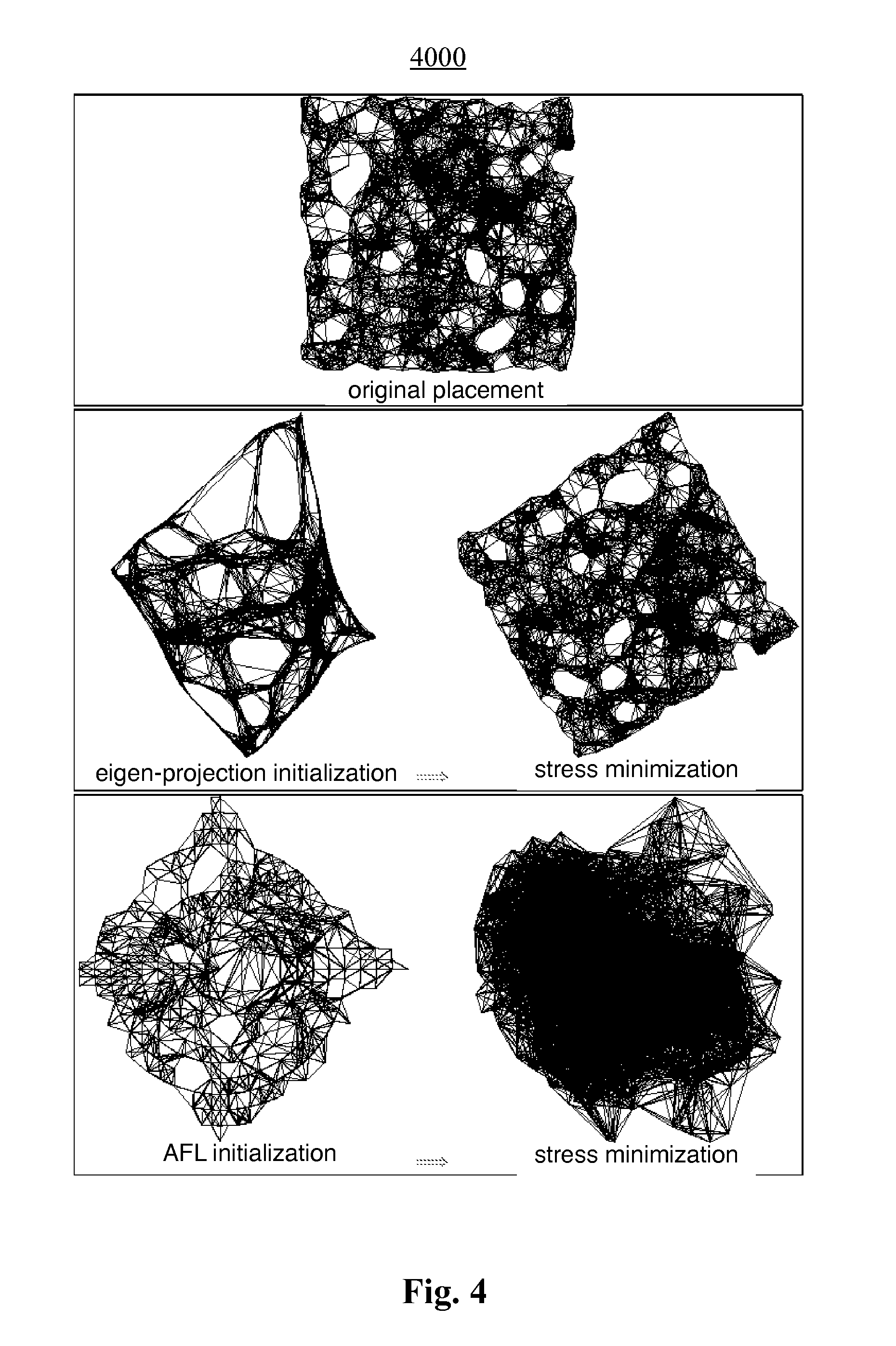

ActiveCN105912562AReduce the number of iterationsBeautiful layout effectVisual data miningStructured data browsingGraphicsData visualization

The invention discloses a data visualization method and a data visualization system based on a hierarchical model. The data visualization method comprises the following steps: graph data preparation, graph vertex sampling stratification, sub-graph vertex connection, graph vertex stress calculation, vertex position updating, graph layout recursive calculation, and graph layout hierarchical drawing. The data visualization system comprises a graph data preparation module, a graph vertex sampling stratification module, a sub-graph vertex connection module, a graph vertex stress calculation module, a vertex position updating module, a graph layout recursive calculation module, and a graph layout hierarchical drawing module. Algorithm convergence can be accelerated, the layout can be calculated correctly, and the effect stability is kept. In addition, graph layout of big data can be drawn scientifically, and convenient interactive operation is provided. Therefore, the data visualization method and the data visualization system have the advantage that beautiful layout can be calculated quickly and efficiently and users can be helped to mine the potential knowledge laws.

Owner:SOUTH CHINA UNIV OF TECH

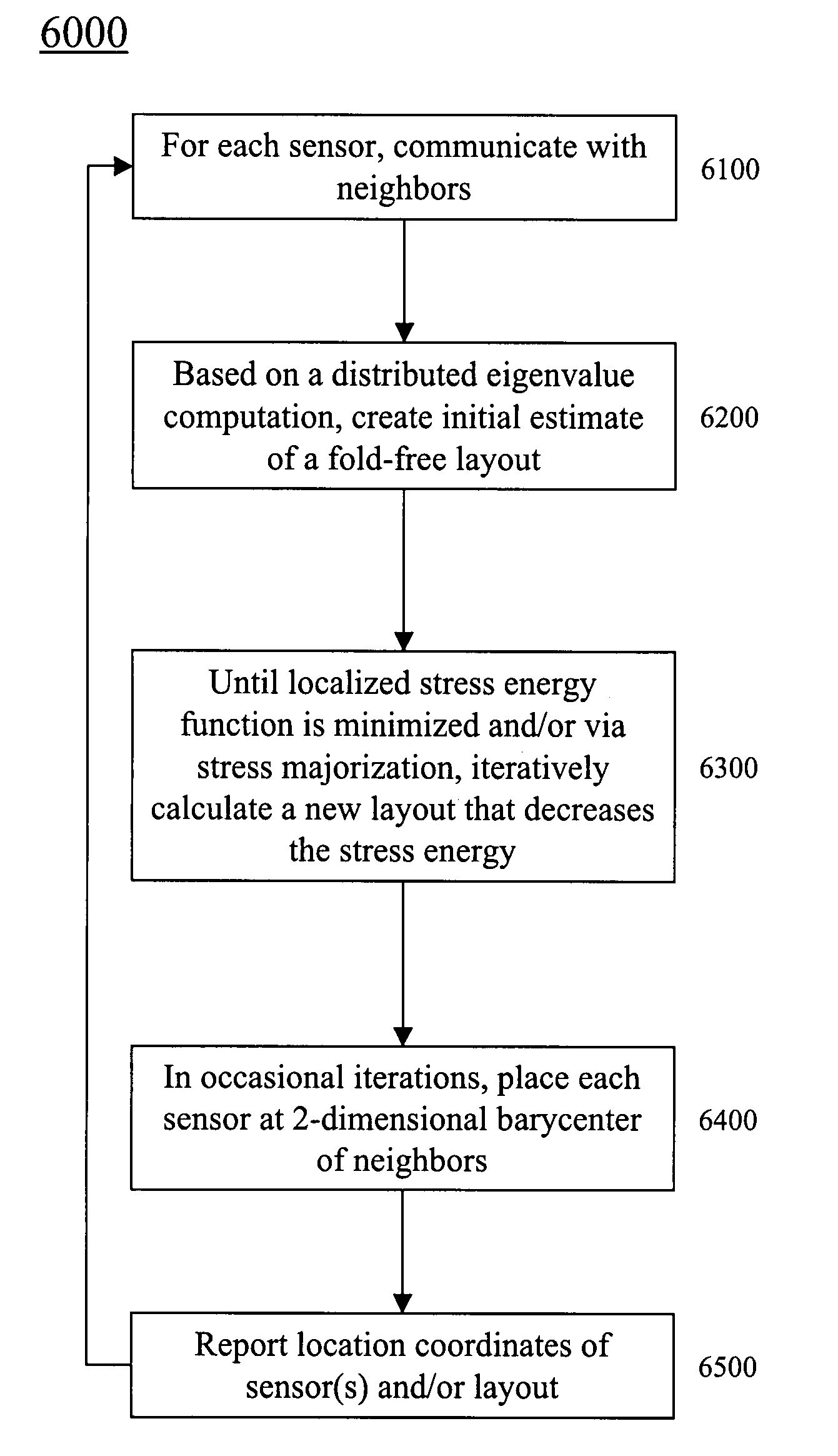

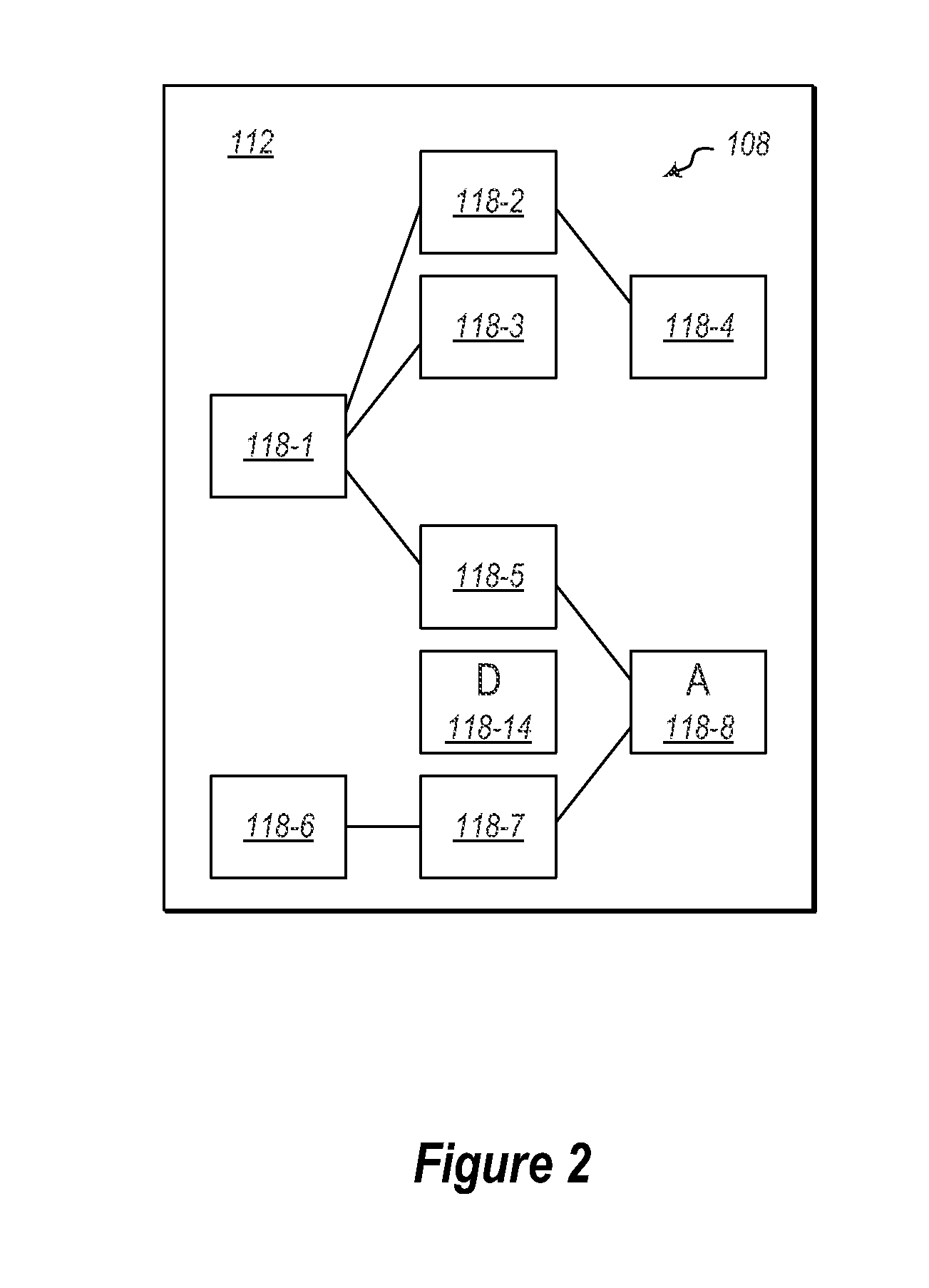

Distributed graph layout for sensor node networks

Certain exemplary embodiments comprise a method, comprising: in a sensor node network comprising a plurality of sensor nodes, each sensor node from the plurality of sensor nodes having location coordinates that are initially unknown, each sensor node from the plurality of sensor nodes having neighbors, each sensor node from the plurality of sensor nodes capable of determining distances only to that sensor node's neighbors: for each sensor node from the plurality of sensor nodes, communicating with that sensor node's neighbors; and based only on communications between neighbors, in a fully distributed manner, generating a sensor node network layout that indicates the location coordinates of each sensor node.

Owner:AT&T INTPROP II L P

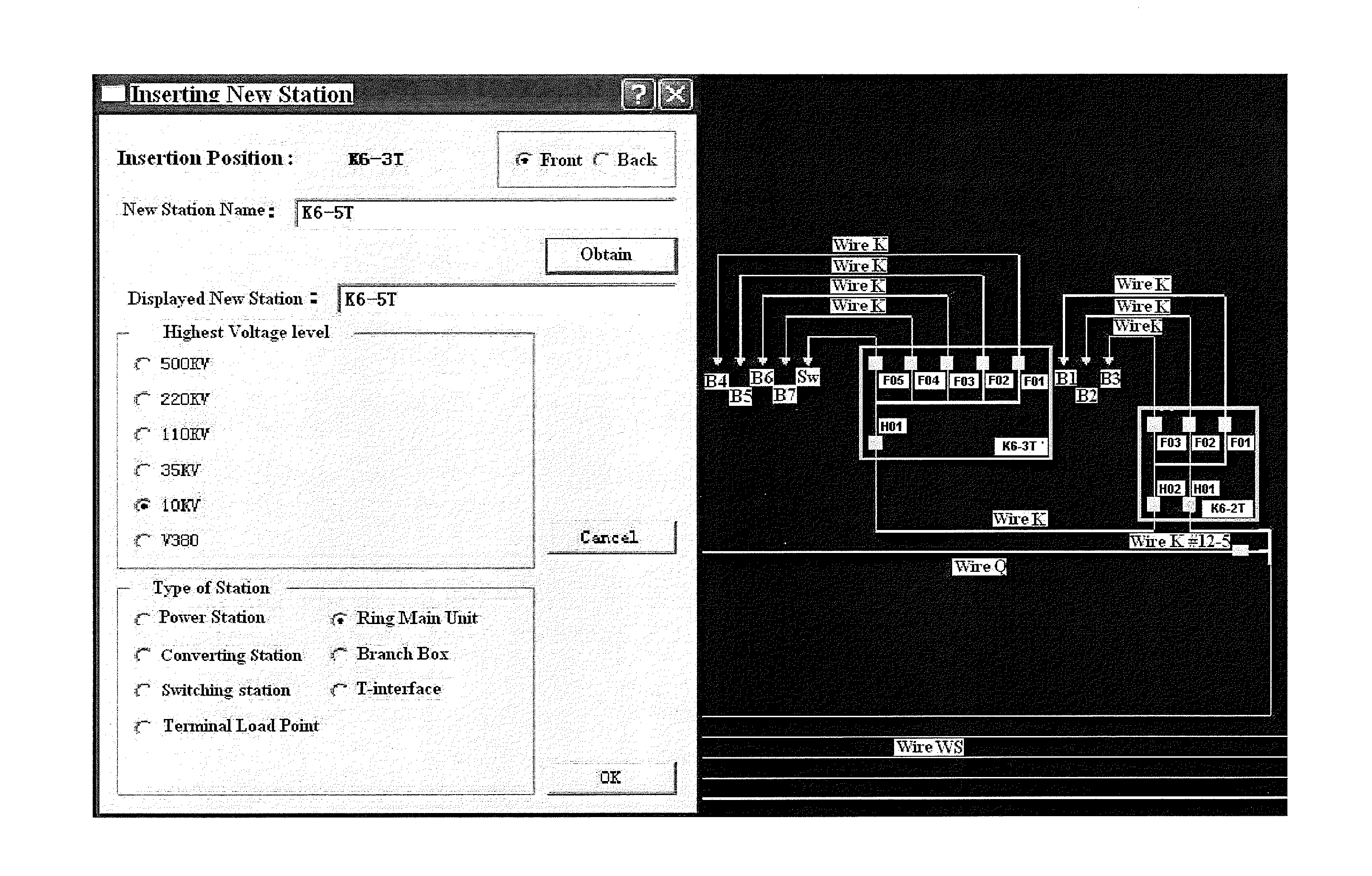

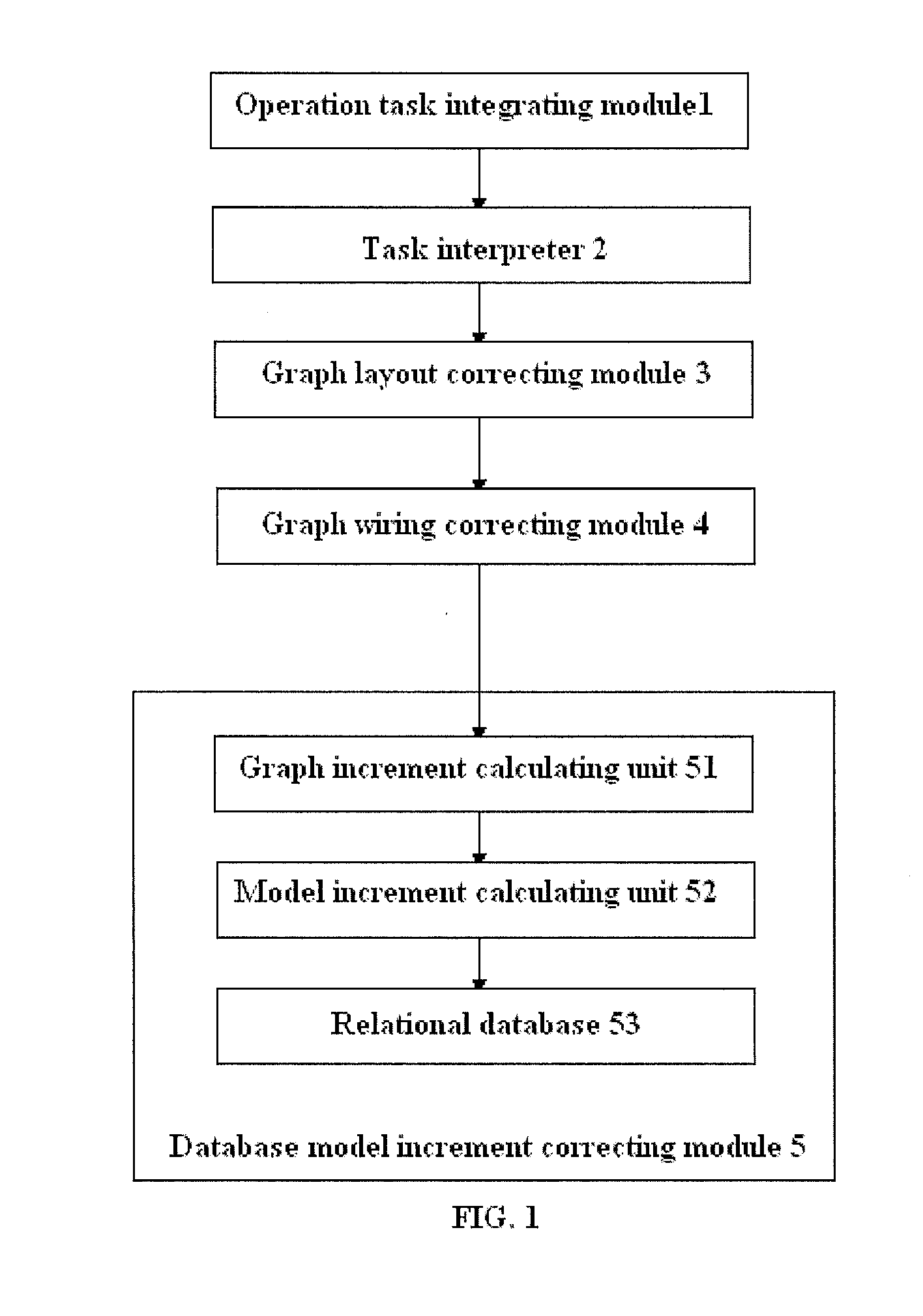

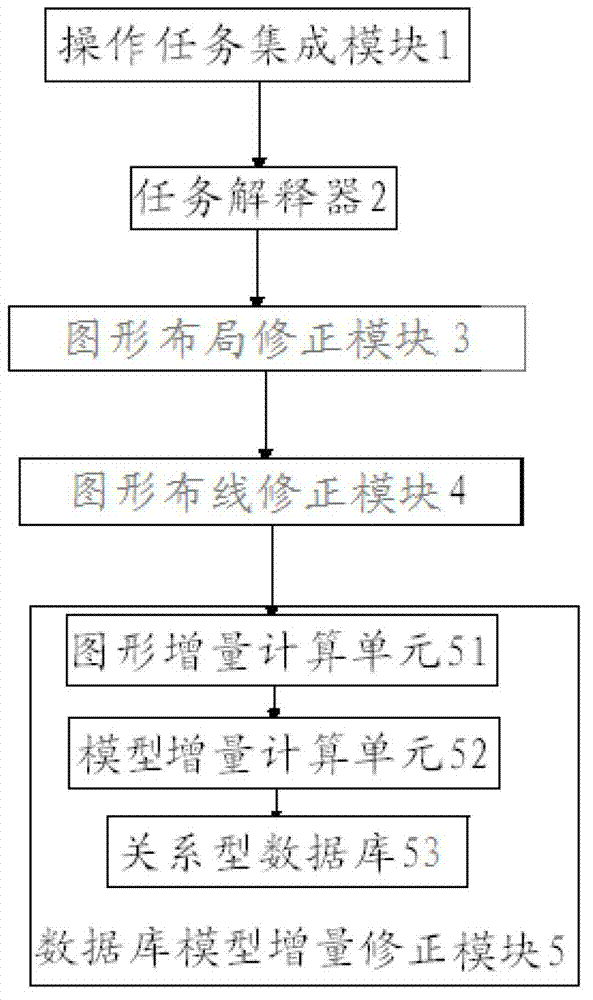

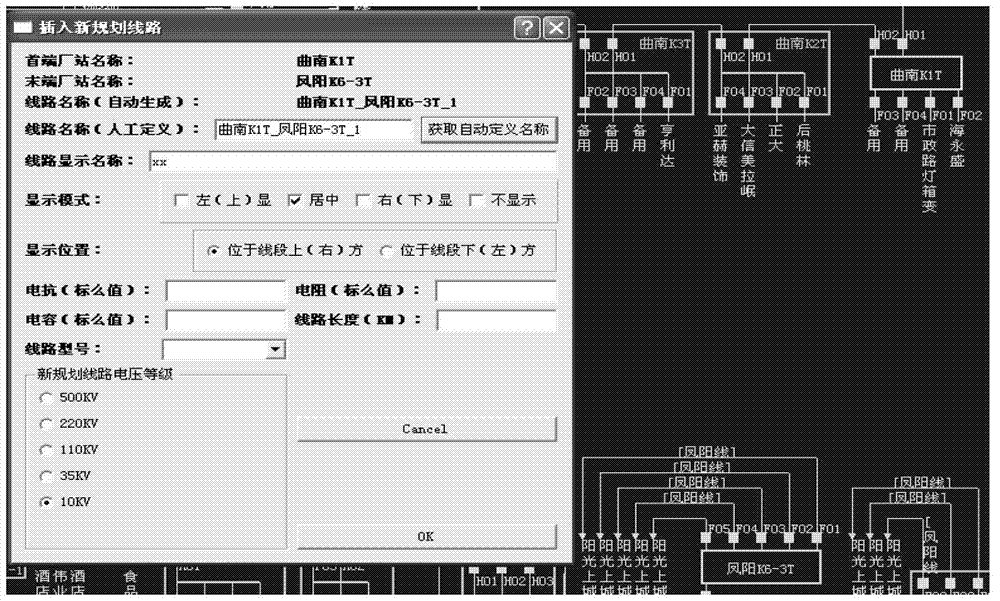

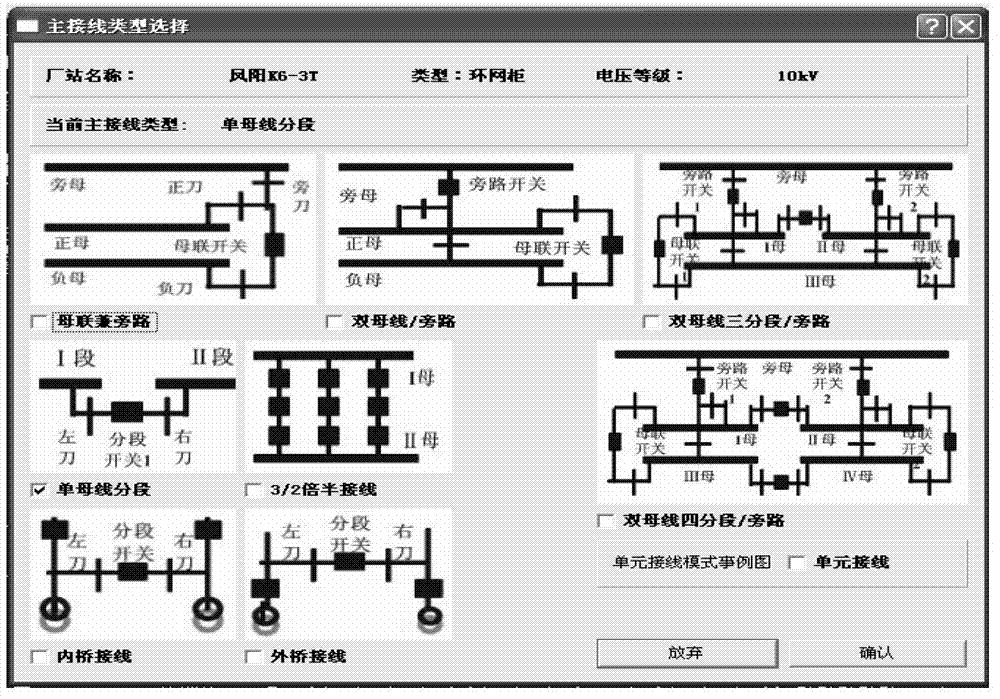

Modeling system and modeling method based on logical relation

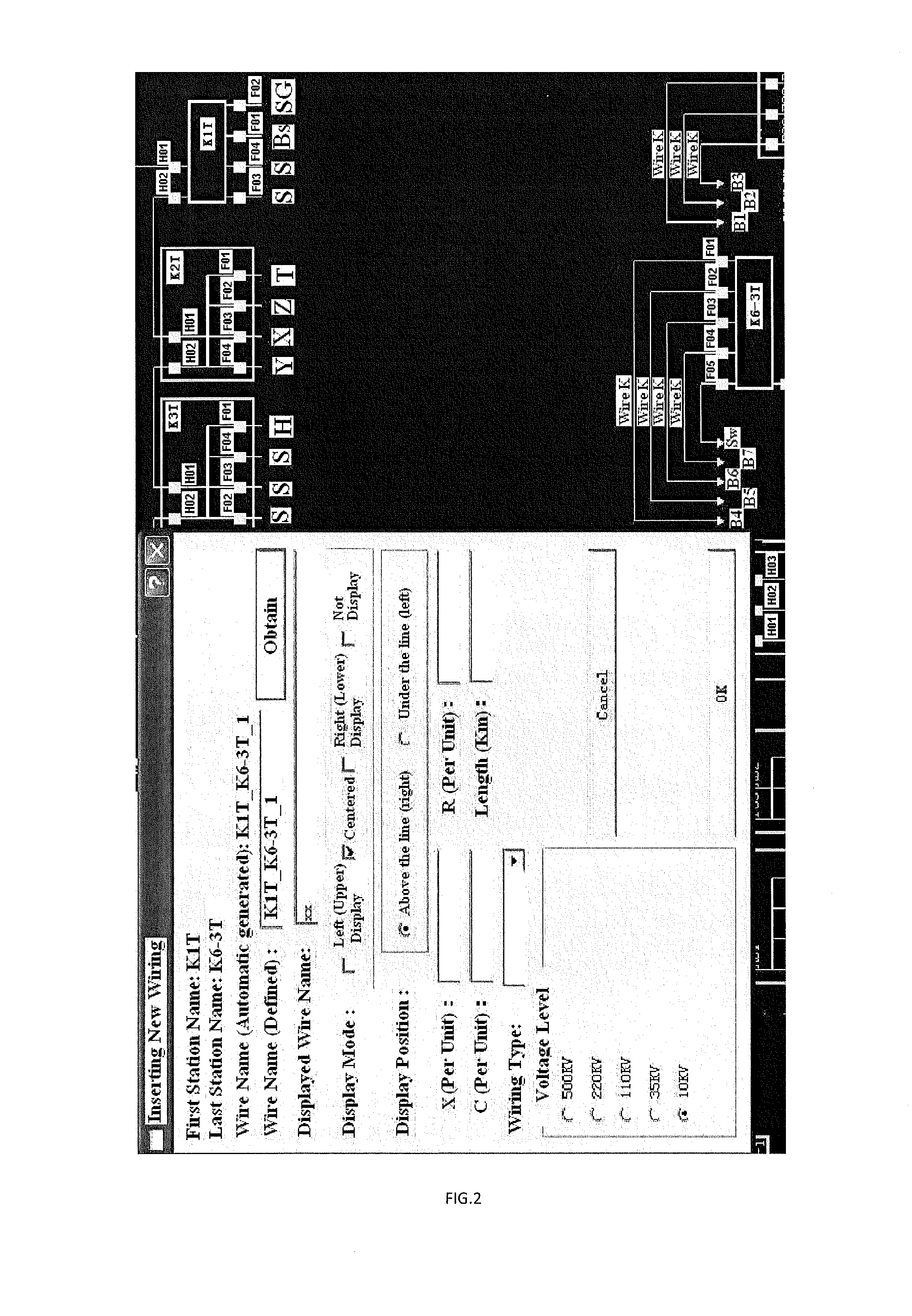

InactiveUS20140039865A1Easy to operateGuaranteed uptimeGeometric CADAnalogue computers for nuclear physicsGraphicsElectric power system

A modeling system and modeling method based on a logical relation, including an operation task integrating module, a task interpreter, a graph layout correcting module, a graph wiring correcting module and a database model increment correcting module, wherein the database model increment correcting module includes a graph increment calculating unit and a model increment calculating unit. The system, through description of the logical relation and based on support of the automatic wiring technology, realizes the graph-model integrated generation of a new grid model of the power system which is based on the description of the logical relation; the grid model is completely defined and modified on “one net”, which is different from the original way that the power system model is established on countless net graphs, thereby helping the grid operation manager to accurately and rapidly establish and modify the grid model of the full system.

Owner:STATE GRID SHANDONG ELECTRIC POWER

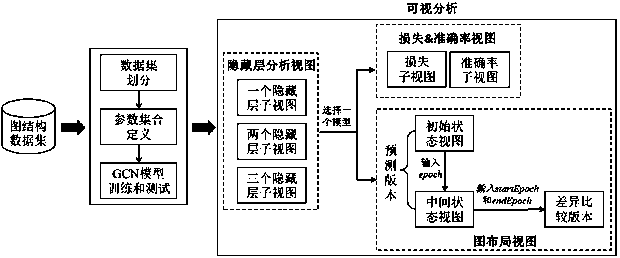

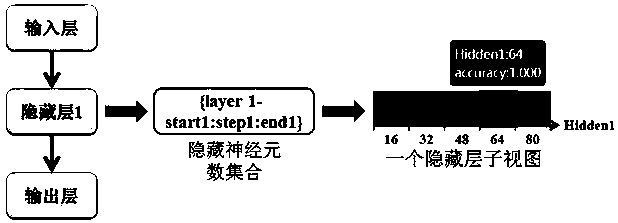

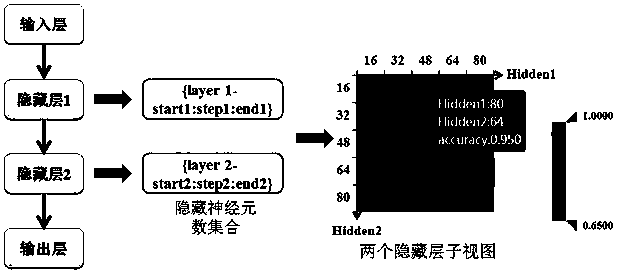

Visual analysis method for understanding graph convolutional neural network

ActiveCN110781933ACharacter and pattern recognitionNeural architecturesHidden layerGraph structured data

The invention discloses a visual analysis method for understanding a graph convolutional neural network. The method comprises the following steps of step 1, dividing an input graph structure data setinto a training set, a verification set and a test set; step 2, defining a parameter set, wherein the parameter set comprises a hidden layer number set and a hidden neuron number set; step 3, based onthe defined parameter set, training to obtain a series of graph convolutional neural network models; step 4, designing a hidden layer analysis view, and displaying the influence of hidden layer parameters on the classification accuracy; step 5, designing a loss and accuracy view, and displaying the change of the loss and classification accuracy in the iterative training process of the model; andstep 6, calculating the positions of the nodes in the graph by adopting a GraphTSNE visualization method, designing a graph layout view, and presenting the prediction condition of the nodes under different training step numbers and the difference of the prediction condition of the nodes between the two training step numbers.

Owner:HANGZHOU DIANZI UNIV

Modeling system and modeling method based on logical relationship

ActiveCN102819636ARealize automatic calculationRealize automatic calculation and addition and deletionGeometric CADSpecial data processing applicationsElectric power systemModel system

The invention discloses a modeling system based on a logical relationship, which comprises an operation task integrating module, a task interpreter, a graph layout correcting module, a graph wiring correcting module and a database model increment correcting module, wherein the database model increment correcting module comprises a graph increment calculating unit and a model increment calculatingunit. Furthermore, the invention discloses a modeling method using the modeling system. The system, through description of the logical relationship and based on support of the automatic wiring technology, realizes the pattern-model integrated generation of a new grid model of the power system which is based on the logical relationship description; the grid model is completely defined and modifiedon one net, which is different from the original way that the power system model is built on countless net patterns, thereby achieving and helping the grid operation manager to accurately and rapidlyestablish and modify the grid model of the full system; and the modeling system is clear and direct, reliable and accurate, and is easy.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO +2

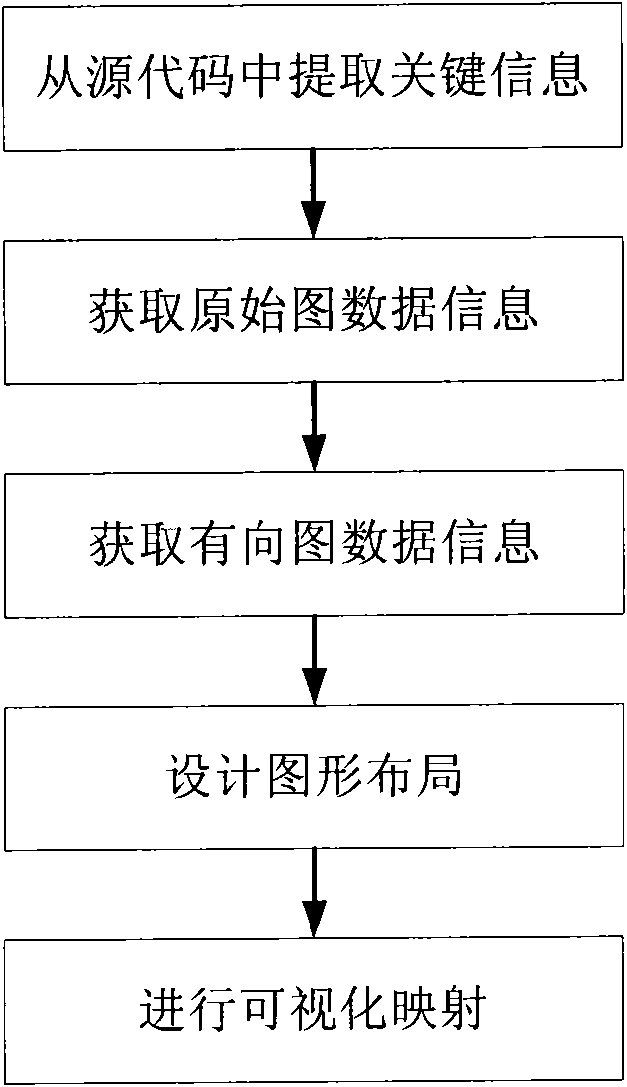

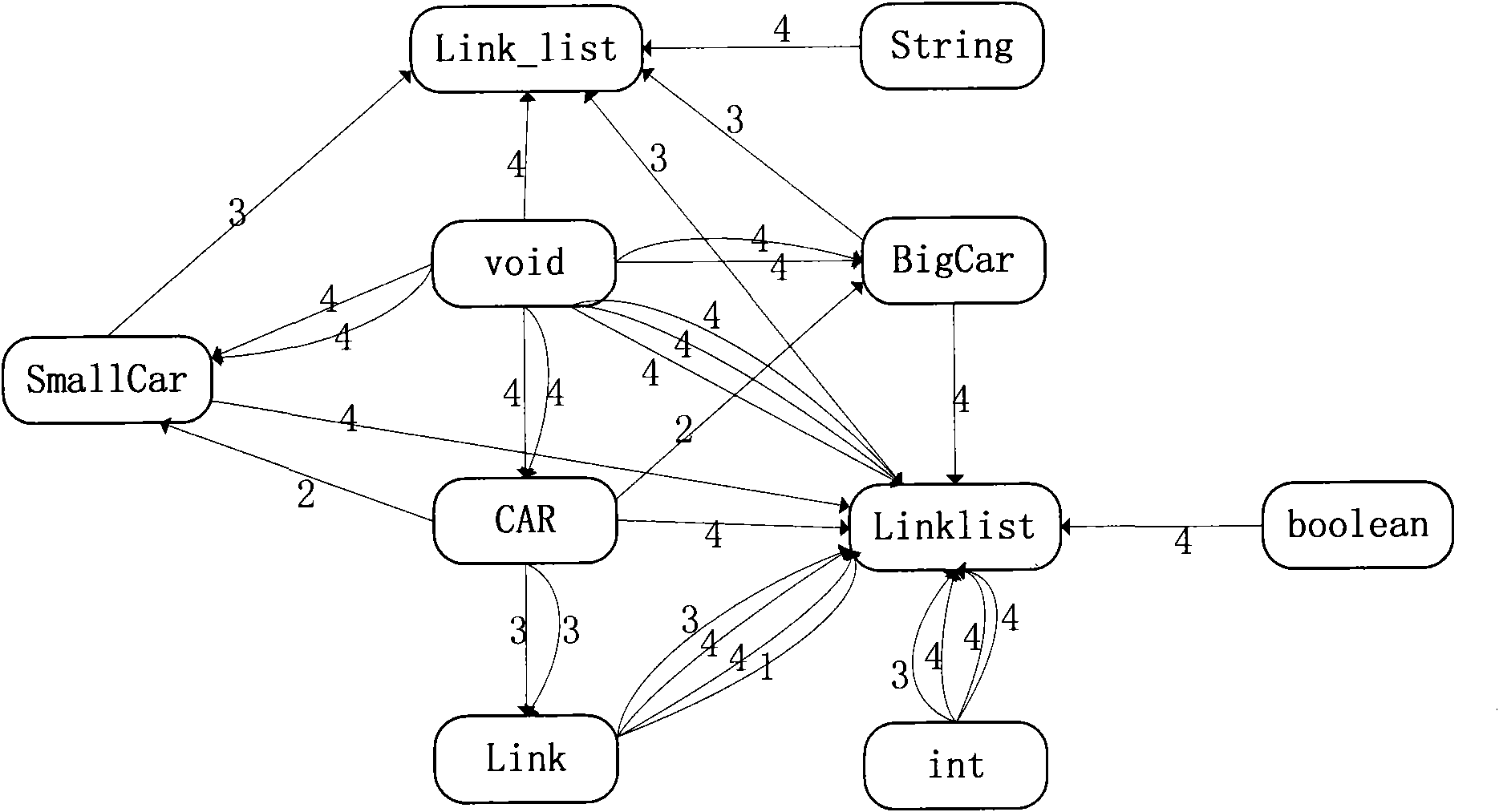

Software visualization method for object-oriented programming language source code

InactiveCN102385505AEasy to understandAccurate and intuitive internal structureSpecific program execution arrangementsDirected graphData information

The invention relates to a software visualization method for an object-oriented programming language source code, belonging to the technical field of software visualization. The method comprises the following steps of: (1) extracting key information from the source code; (2) acquiring data information of an original graph; (3) acquiring data information of a directed graph; (4) designing a graph layout; and (5) performing visualization mapping. With the adoption of the novel software visualization method for the object-oriented programming language source code provided by the invention, the defect of a class graph for the soft visualization is made up, and the internal structure of software and the status and the effect of types in the software can be accurately and intuitively reflected,so that a user can rapidly understand a software design level.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Systems and methods for switch stack emulation, monitoring, and control

Systems, methods, and machine-readable storage media to facilitate adaptive switch stack interaction are disclosed. Discovery may be performed via a network with respect to switches, each switch corresponding to a switch stack and including ports communicatively coupled to endpoint devices or access points. Switch data transmitted from the plurality of switches may be processed and used to develop models of the switches. Each model may include switch specifications, and a particular model may be used to emulate a particular switch. Emulation data may be created to facilitate a graphical representation formatted to represent the particular switch. The emulation data may be transmitted to an endpoint device to facilitate an emulation interface that may correspond to a graphical layout of the particular switch that allows access, via user-selectable interface elements, to a subset of the switch data that is mapped to the particular switch.

Owner:CHCA

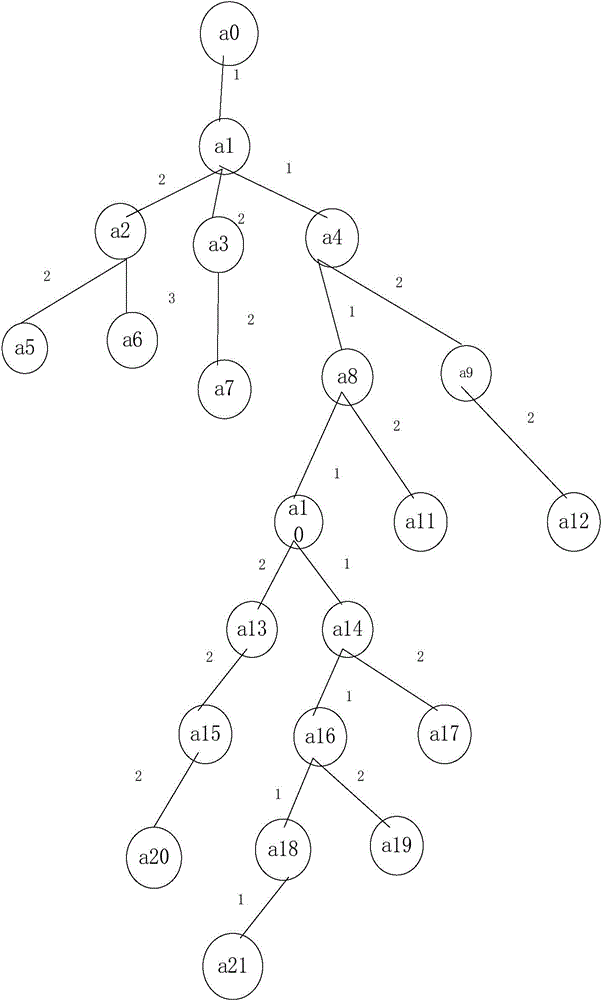

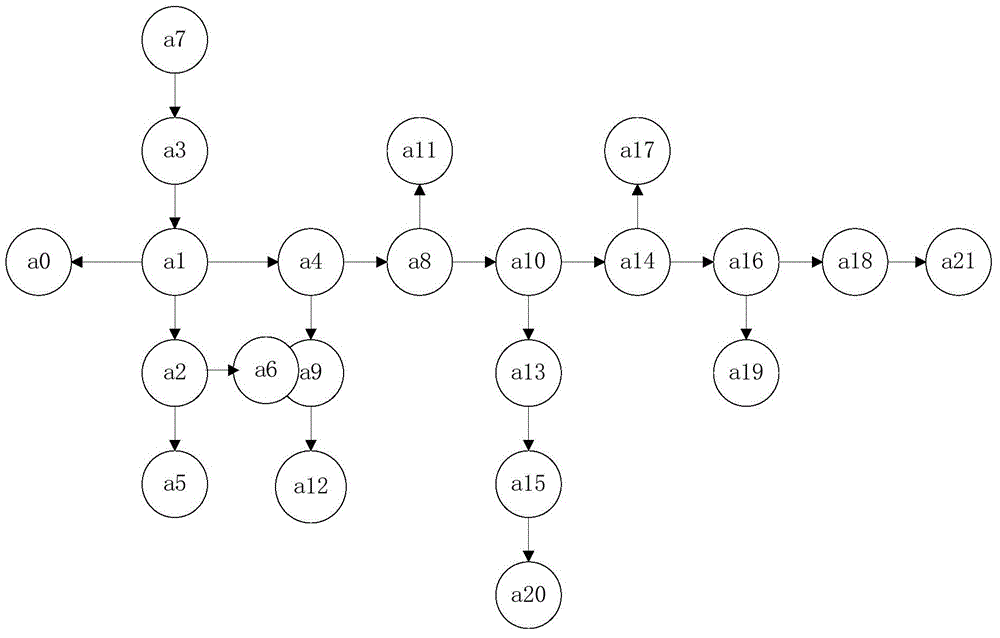

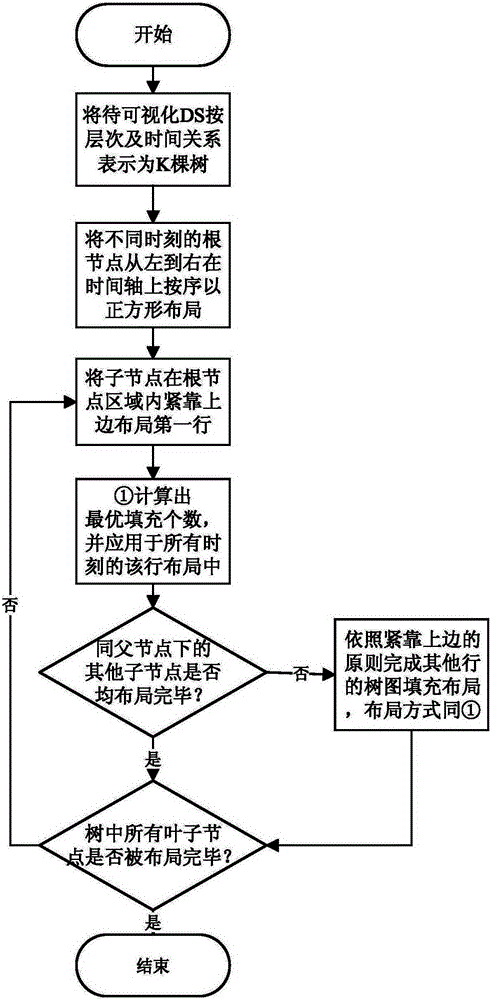

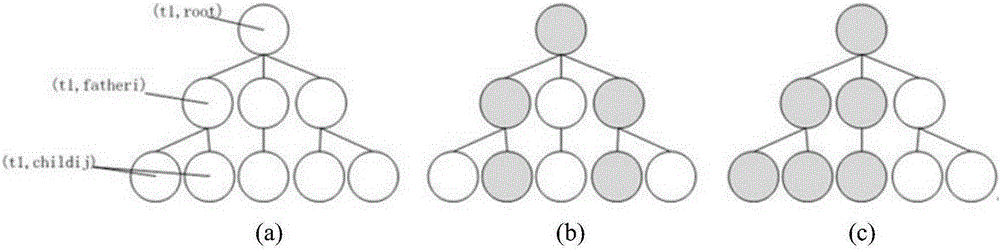

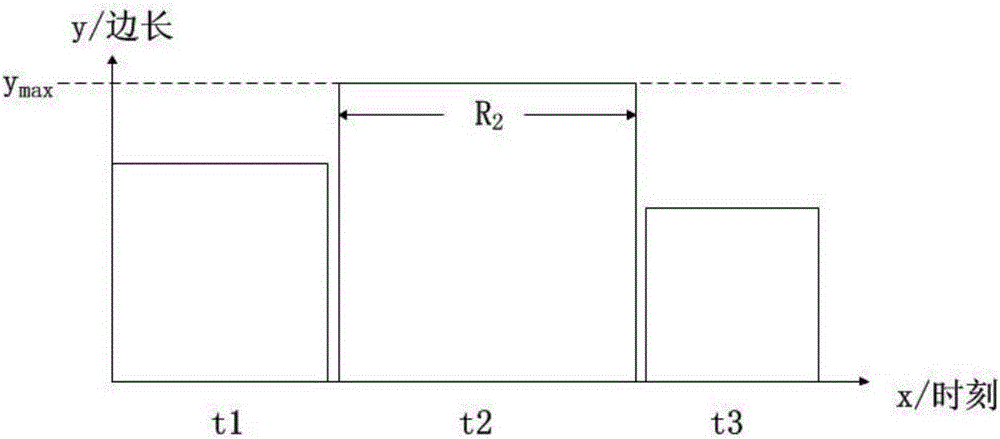

Time-varying tree graph layout method and application for time-varying and hierarchical data

ActiveCN105354335ACapable of displaying time attributesPrecise and fast findSpecial data processing applicationsRelationship - FatherData set

The invention discloses a time-varying tree graph layout method for time-varying and hierarchical data. The time-varying tree graph layout method comprises the steps of representing a data set DS into K trees based on a hierarchy and time relation; performing arrangement and layout on root nodes (tk, root) of trees or sub trees in different moments on a timer shaft in sequence; performing layout for the first line in a corresponding region of child nodes of (tk, root) by adopting a line layout mode; repeating to execute the layout until all the child nodes under a father node are subjected to layout; and finally finishing the time-varying tree graph layout for the to-be-displayed overall data set DS. The time-varying tree graph layout method provided by the invention is applied to the display and analysis of time-varying and hierarchical pesticide residues data; the original layout region in each moment is set to be square; the tree graph filling layout is finished by adopting a line layout mode; and the generated tree graph can display both of the hierarchical characteristic and time attribute of the pesticide residues data, so that the time-varying tree graph layout method is quite good in the visualization effect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Method and apparatus for displaying graphical representations of graph layouts

The invention includes a method and apparatus for displaying a graphical representation of a graph including nodes and edges. A layout of the graph is determined. The layout of the graph is determined by determining respective positions of each of the nodes and edges within the layout. The position of each node is determined using a first model and, optionally, a second force model, wherein the first force model comprises a substantially linear repulsive force in a first region, a substantially exponential repulsive force in a second region, and an attractive force in a third region. In one embodiment, the position of each edge may be determined using the first force model. A graphical representation of the layout is generated. The graphical representation of the layout is displayed to one or more users.

Owner:PIECE FUTURE PTE LTD

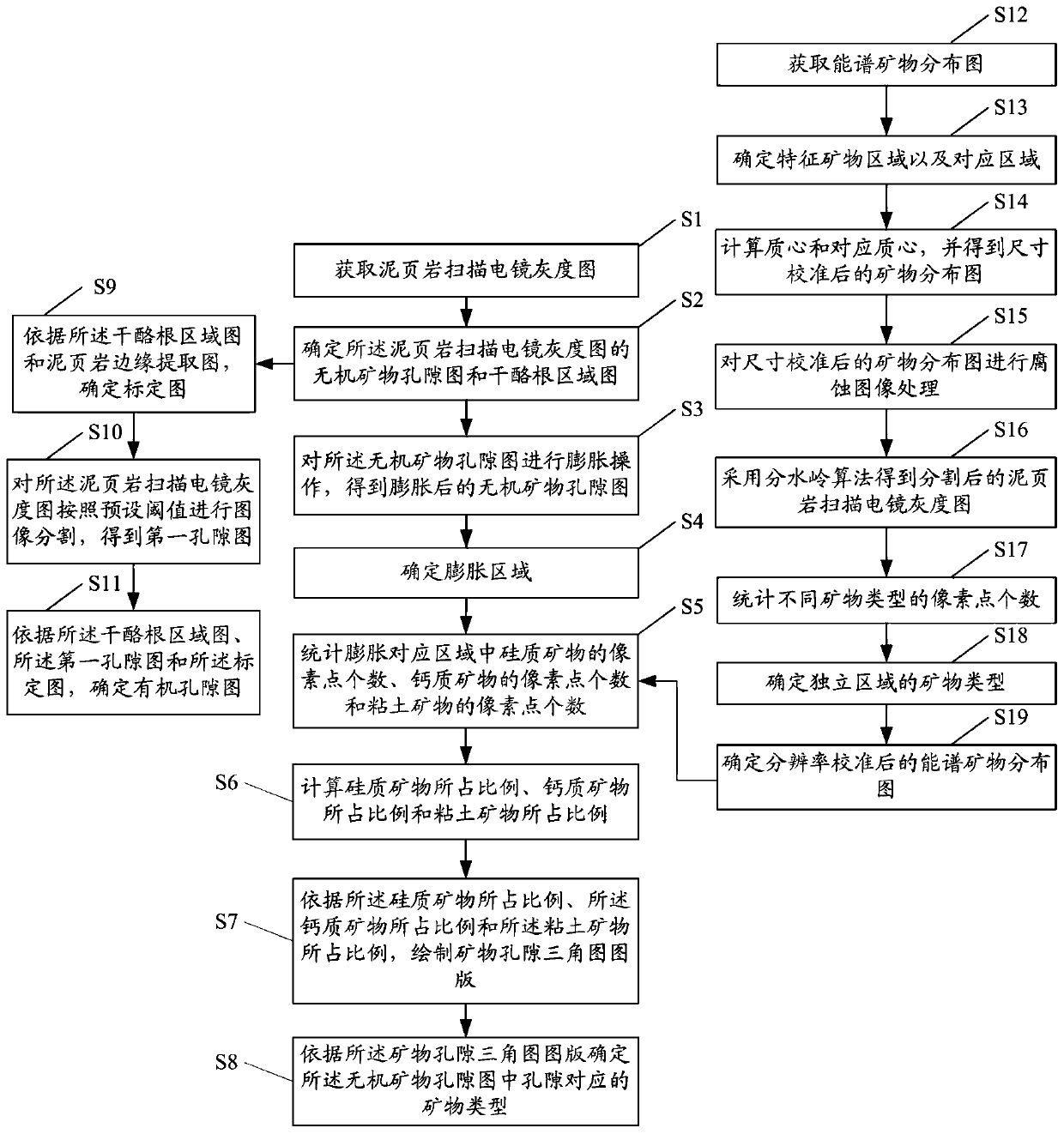

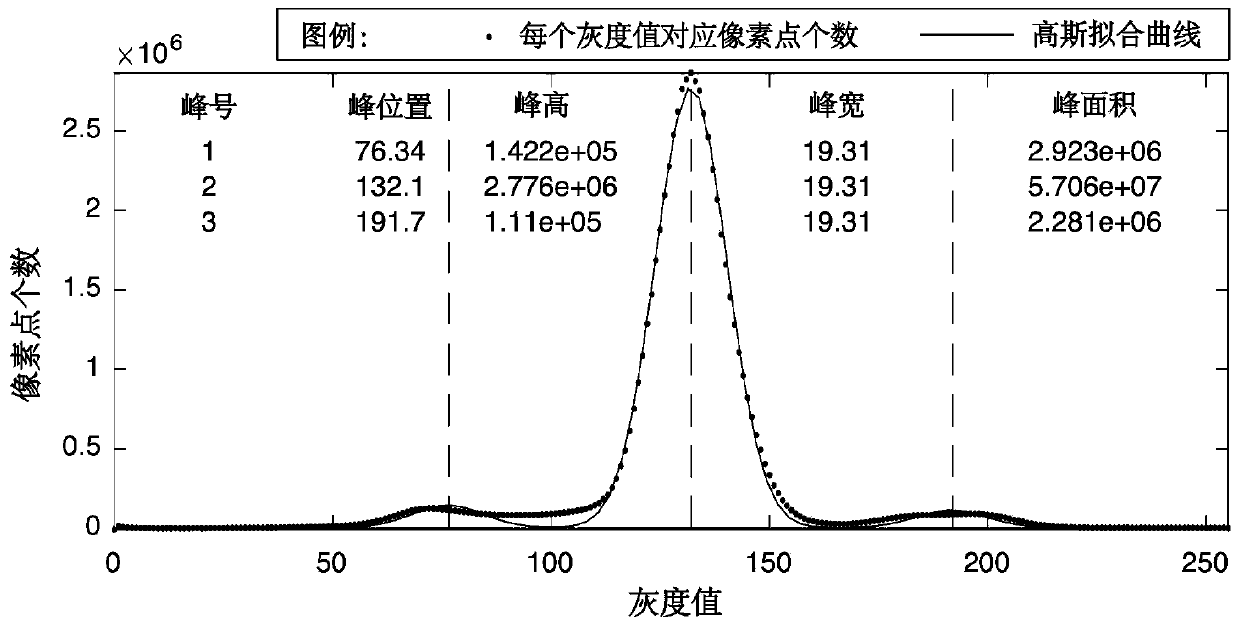

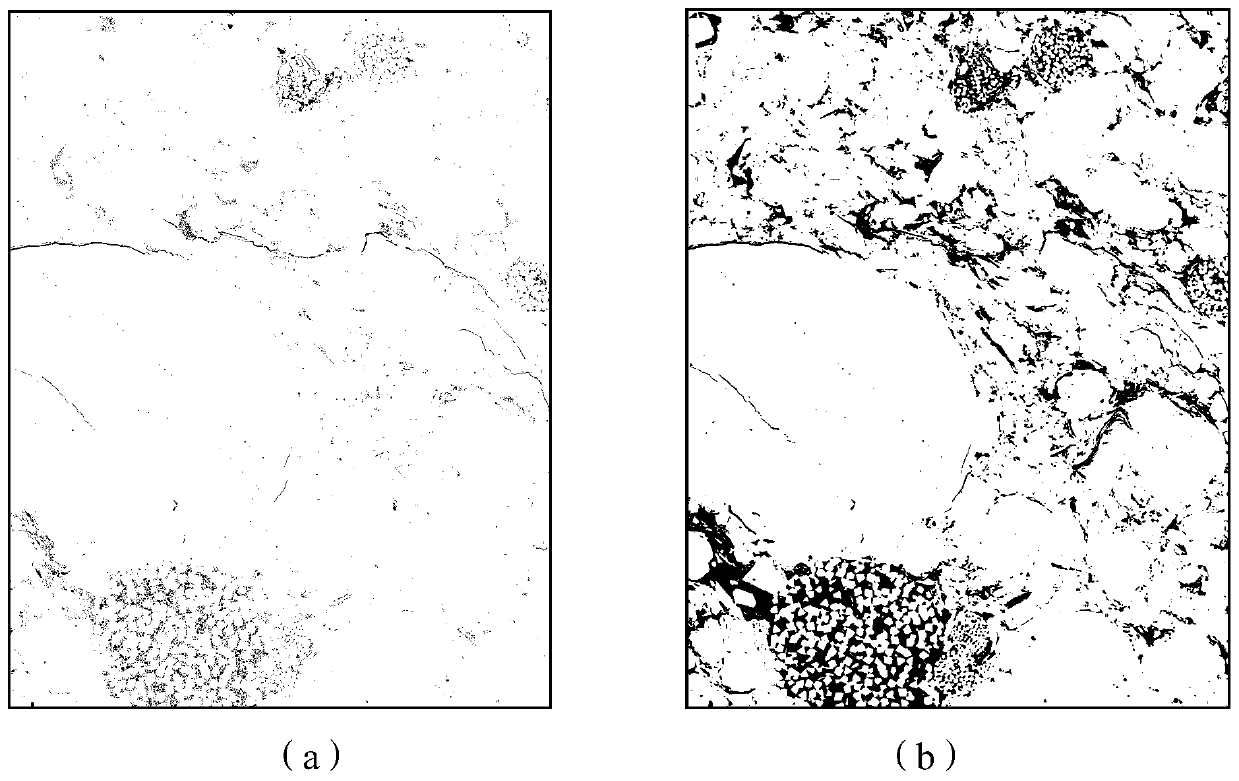

Method and system for automatically identifying different mineral pores of shale

ActiveCN110146533AImprove recognition accuracyImage enhancementImage analysisCalcium in biologyKerogen

The invention discloses a method and system for automatically identifying different mineral pores of shale. The method comprises the following steps that: the inorganic mineral pore image and a kerogen area image of a shale scanning electron microscope grayscale image are determined; expansion operation is performed on the inorganic mineral pore image, so that an expanded inorganic mineral pore image is obtained; the inorganic mineral pore image is compared with the expanded inorganic mineral pore image, a region which exists in the expanded inorganic mineral pore image while dose not exist inthe inorganic mineral pore image is determined as an expanded region; the quantities of the pixel points of siliceous minerals, calcium minerals and clay minerals are put into statistics; the proportion of the siliceous minerals, the proportion of the calcium minerals, the proportion of the clay minerals are calculated according to the quantities of the pixel points of the minerals; a mineral pore triangular graph layout is drawn according to the proportions of the minerals; and mineral types corresponding to pores in the inorganic mineral pore image are determined according to the mineral pore triangular graph layout. The method disclosed by the invention not only can improve the precision of mineral pore identification, but also can be used for quantitatively identifying minerals controlling pores.

Owner:NORTHEAST GASOLINEEUM UNIV +1

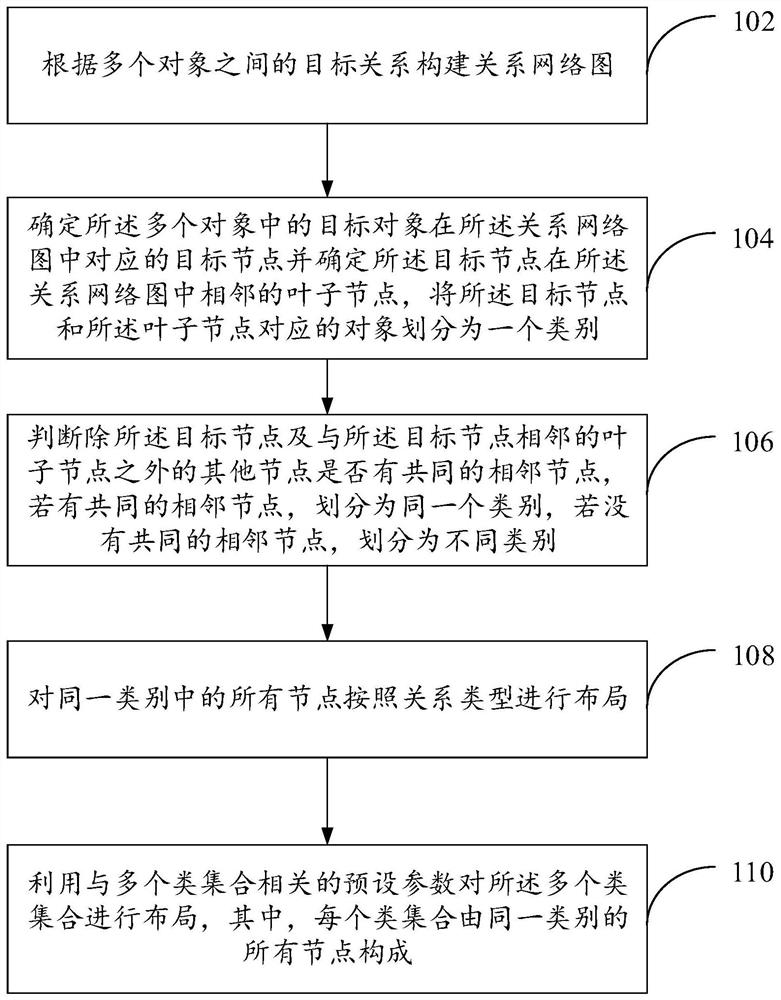

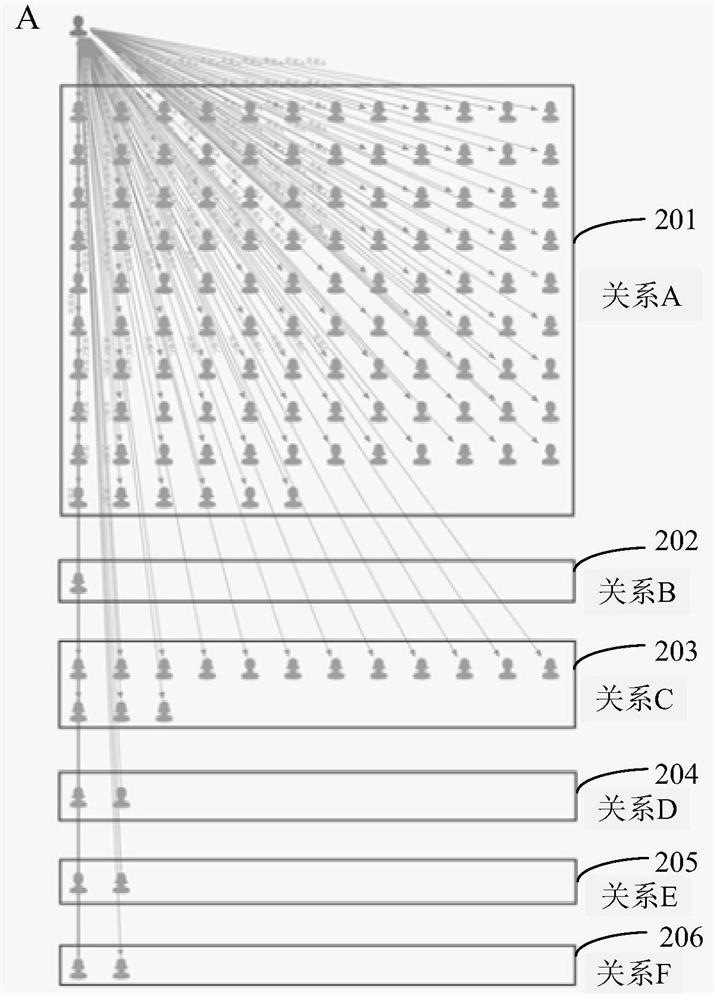

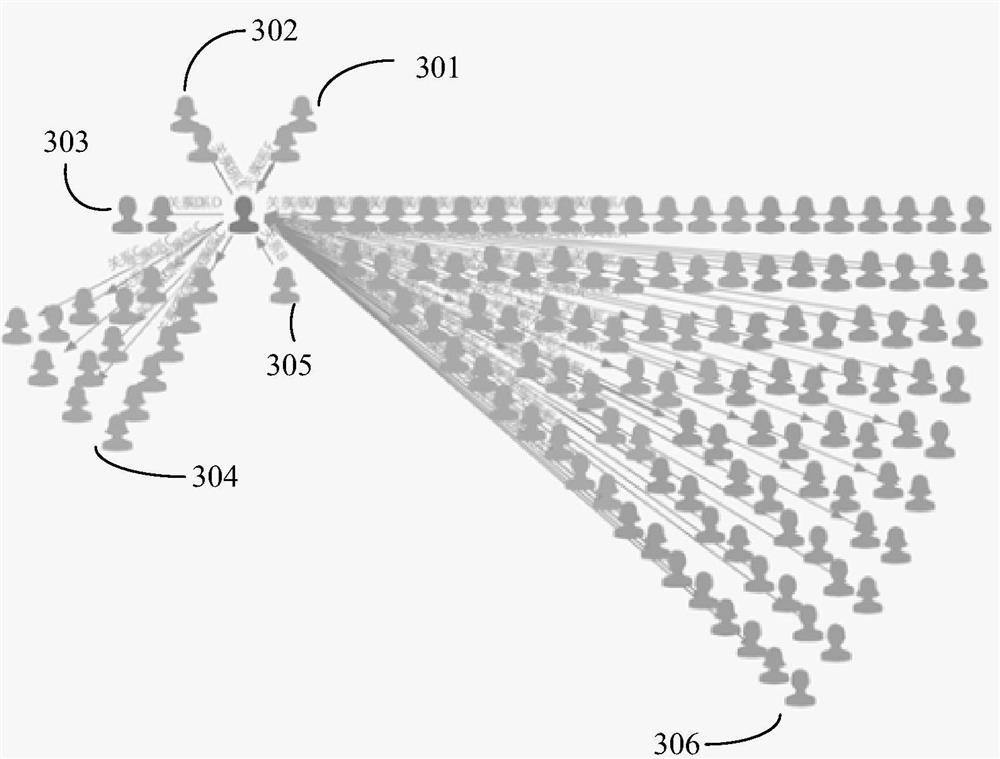

Relational network graph layout method and device

PendingCN112100289AImprove processing efficiencySave processing resourcesRelational databasesSpecial data processing applicationsTheoretical computer scienceGoal node

The invention provides a relational network diagram layout method and device. The relational network graph layout method comprises the following steps: constructing a relational network graph according to a target relationship among a plurality of objects; determining a target node corresponding to a target object in the plurality of objects in the relational network graph, determining an adjacentleaf node of the target node in the relational network graph, and classifying the target node and the object corresponding to the leaf node into one category; determining whether other nodes except the target node and the leaf node adjacent to the target node have a common adjacent node or not, if so, classifying the nodes into the same category, and if not, classifying the nodes into different categories; laying all the nodes in the same category according to the relationship type; and laying a plurality of category sets by utilizing preset parameters related to the plurality of category sets. According to the method, the objects with the same relationship are gathered, so that the relationship reaches an ordered state from an disordered state, the processing efficiency is improved, andthe processing resources are saved.

Owner:杭州橙鹰数据技术有限公司

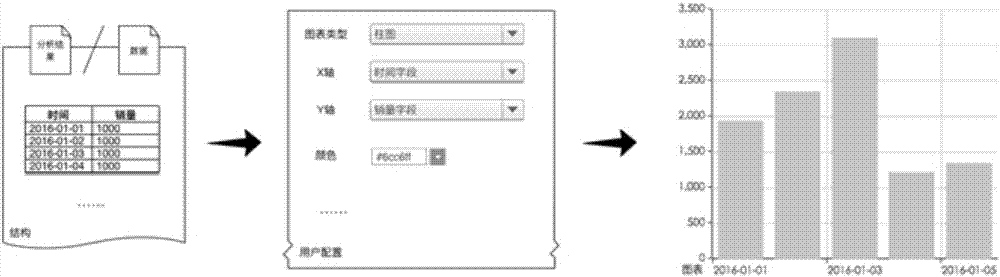

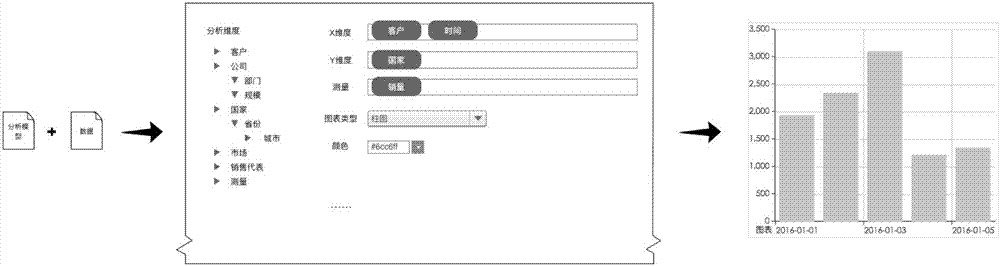

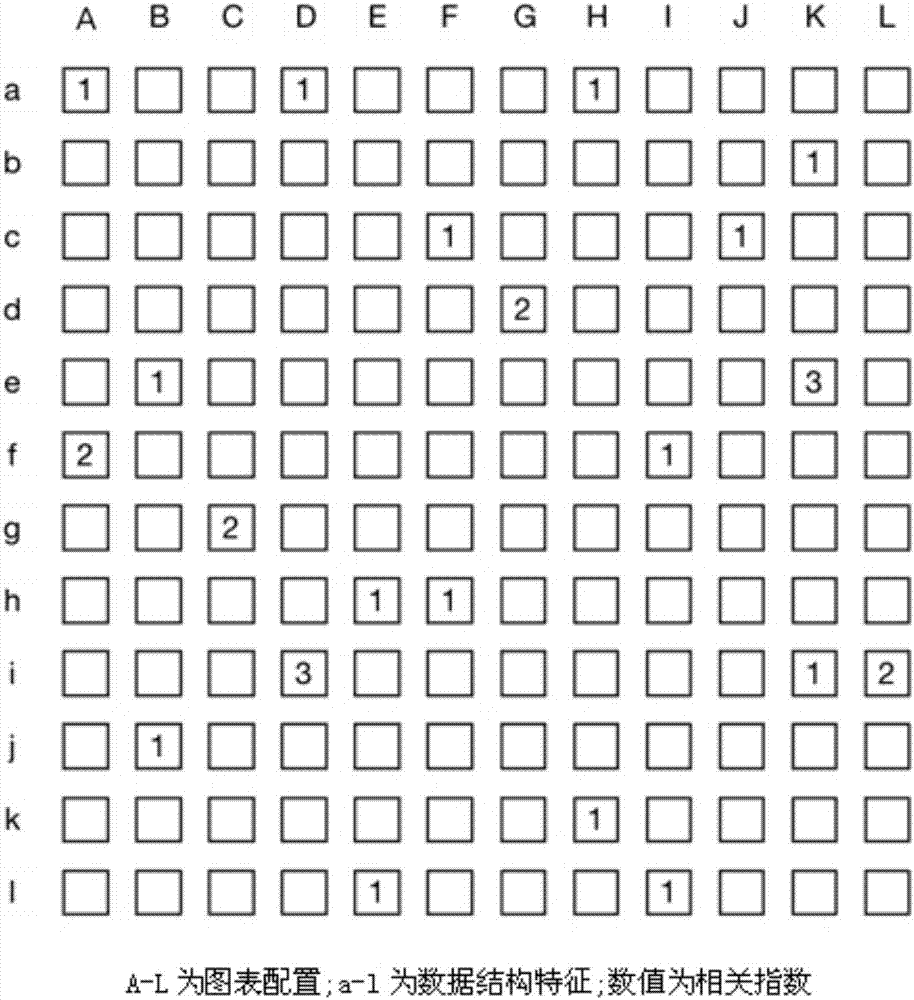

Method and system for automated visualized presentation based on data structure identification

InactiveCN107169119AEasy to useReduce the difficulty of operationVisual data miningStructured data browsingUsabilityData mining

The invention discloses a method for automated visualized presentation based on data structure identification. The method comprises the following steps: receiving data input, through data structure description rules, generating data structure description information of input data; according to the data structure description information, extracting structure characteristic vector information of the data; identifying the extracted data structure characteristic vector information, hereby obtaining graph configuration matched with a characteristic vector; according to graph configuration information, generating multi-graph layout and obtaining a visual graph. On the other hand, the invention also provides a presentation system for realizing the method, users do not need to select a visual representation of the data according to experience, and the system begins with data structure of an analysis result. Through recognition and matching types of each dimension, contents and other information in the data structure, rational configuration is automatically performed on graphs, layout is automatically planned, and a problem of usability in a conventional analysis result visualized presentation method.

Owner:九次方大数据信息集团有限公司

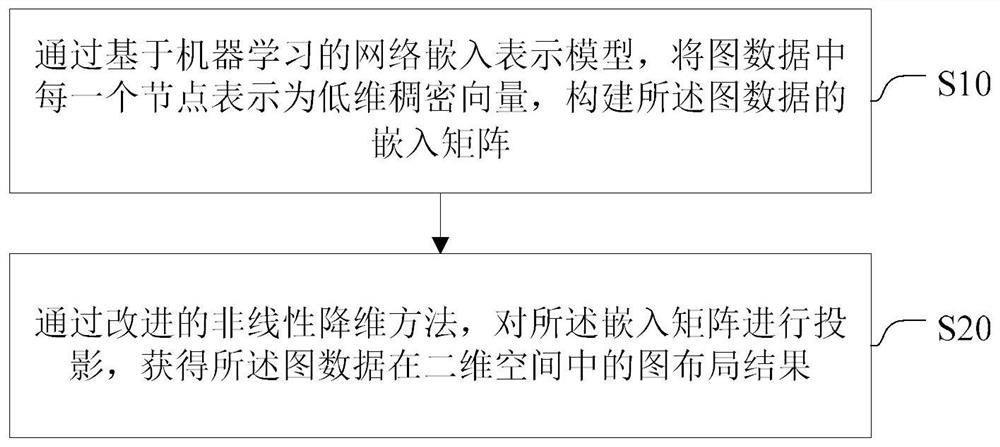

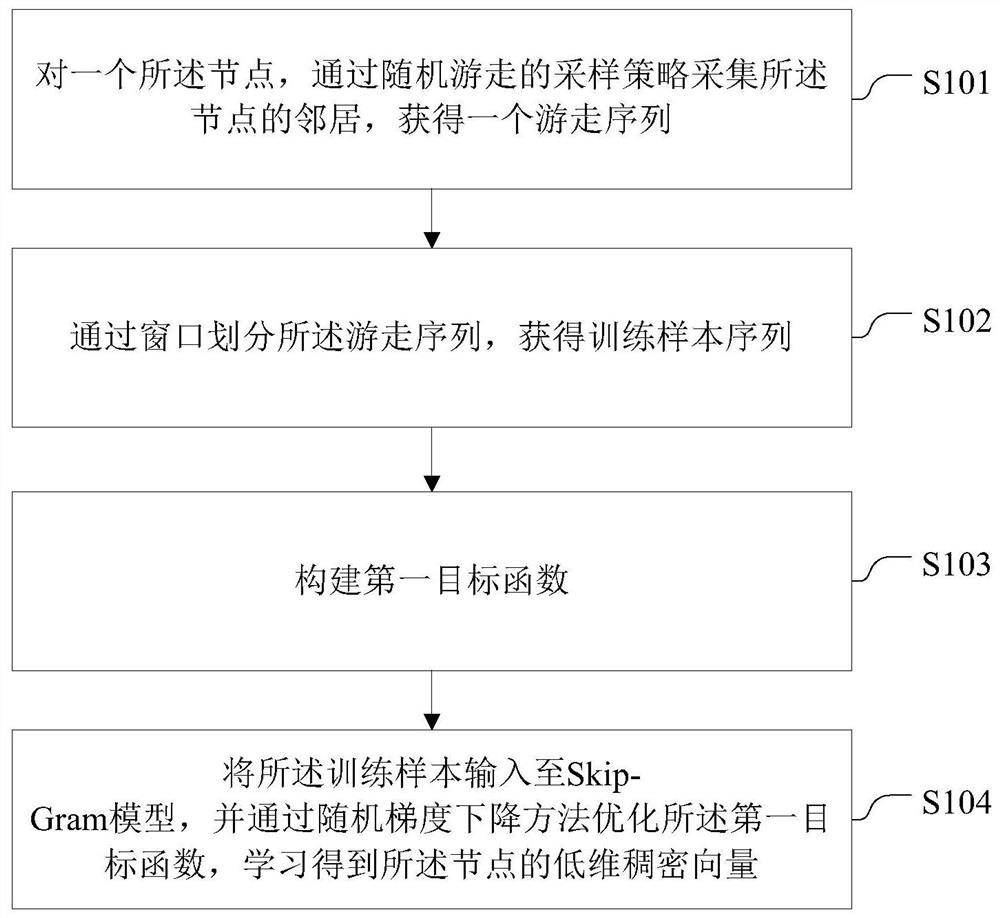

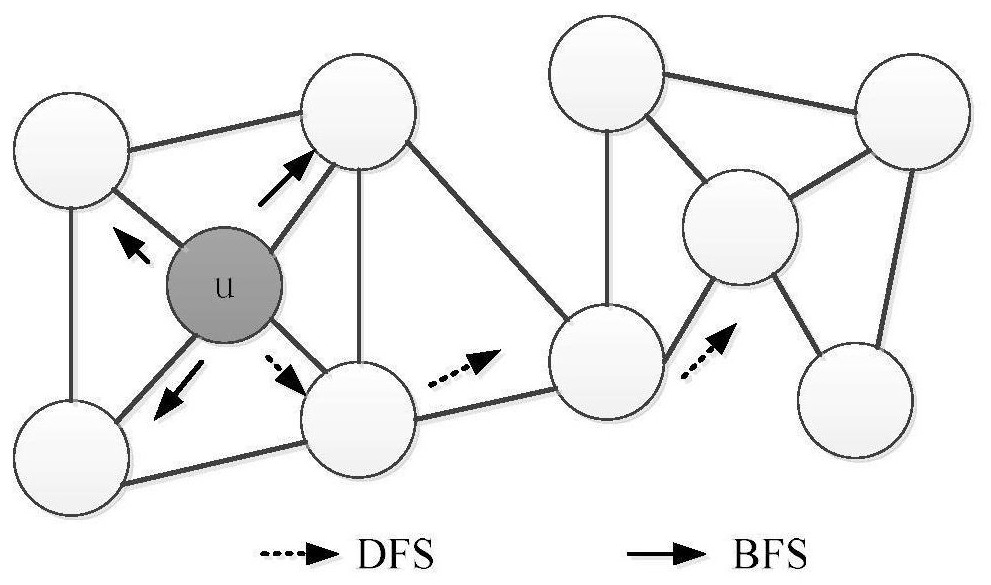

Graph layout method and device for large-scale network

ActiveCN112417633AKeep localMaintain propertiesGeometric CADCharacter and pattern recognitionAlgorithmTheoretical computer science

The invention discloses a graph layout method for a large-scale network, and the method comprises the steps of enabling each node in graph data to be expressed as a low-dimensional dense vector through a network embedding expression model based on machine learning, and constructing an embedding matrix of the graph data; and projecting the embedded matrix through an improved nonlinear dimension reduction algorithm to obtain a graph layout result of graph data in a two-dimensional space. The invention further discloses a graph layout device for the large-scale network. According to the invention, the calculation efficiency is higher, the required storage space is smaller, the local and global structure characteristics of the graph data can be maintained, meanwhile, the nodes with higher degree values in the graph data can be relatively dispersed from the neighbor nodes under the condition of maintaining local structure information, and the possible congestion or overlapping phenomenon can be effectively relieved.

Owner:NAT UNIV OF DEFENSE TECH

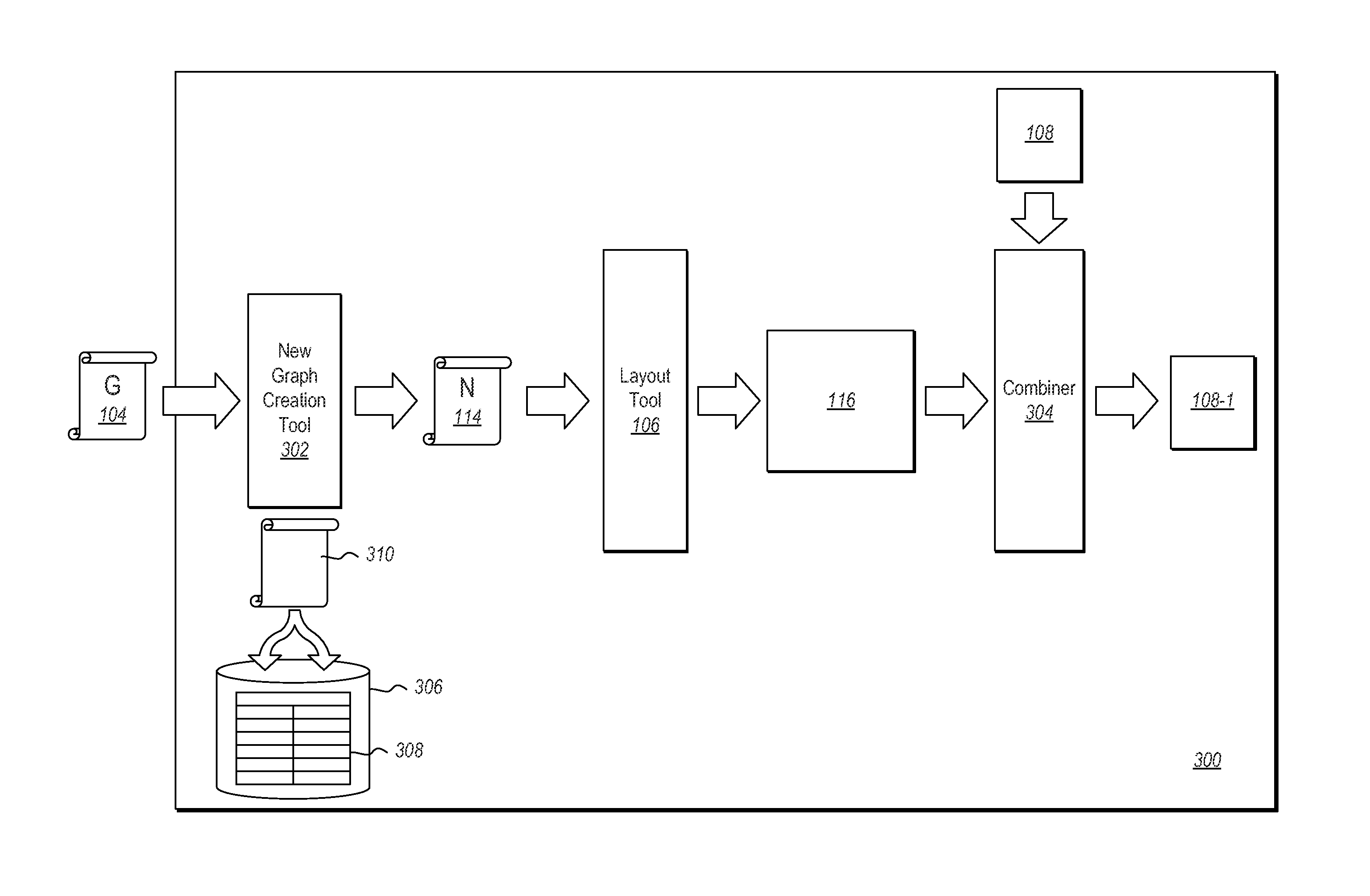

Incremental Automatic Layout of Graph Diagram for Disjoint Graphs

Adding a new disjoint graph diagram to an existing graph diagram. A set of one or more new nodes from a graph to be added to a first graph diagram are identified. An automatic graph diagram layout of the set of one or more new nodes is performed creating a second graph diagram. The first graph diagram is aligned along a first axis with the second graph diagram Nodes in the first graph diagram that are at least partially between a first point and a second point of boundaries of the second graph diagram are identified. A boundary is created around the nodes in the first graph diagram that are between the first and second points. The second graph diagram is moved along a second axis toward the boundary to create a combined graph diagram.

Owner:MICROSOFT TECH LICENSING LLC

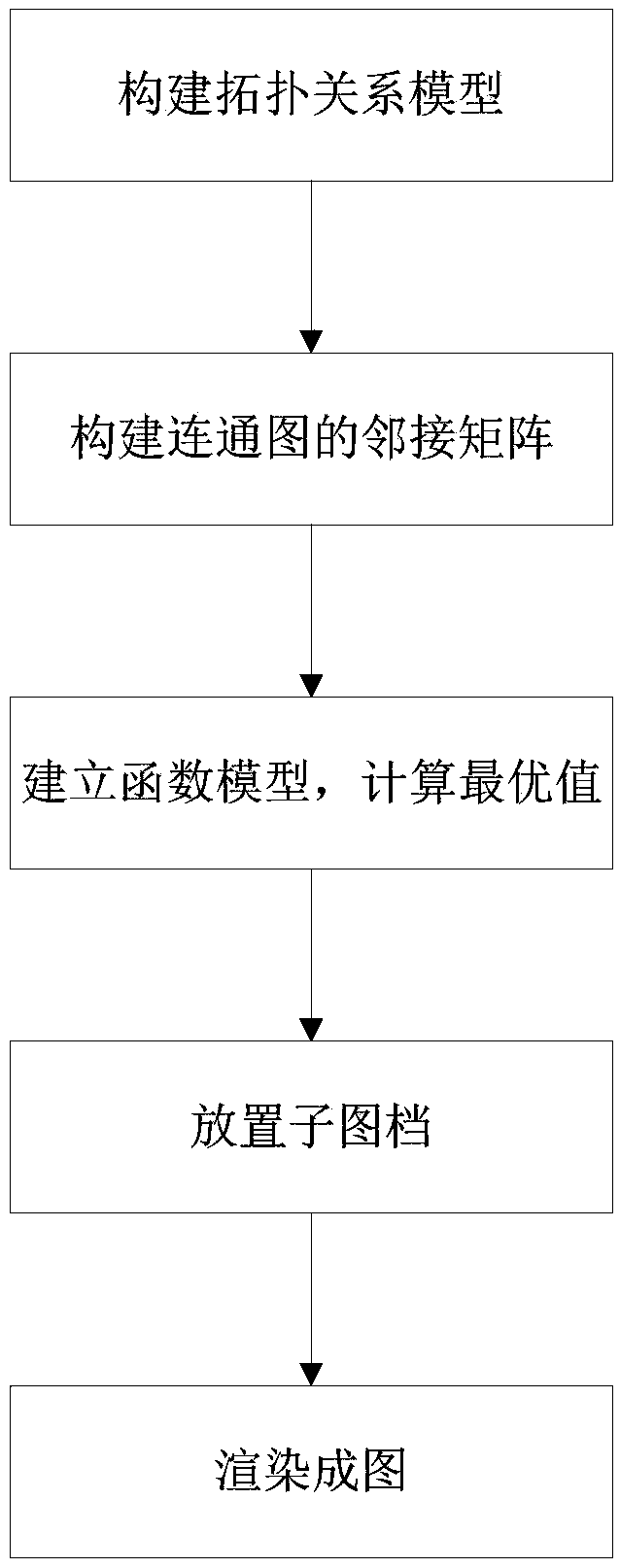

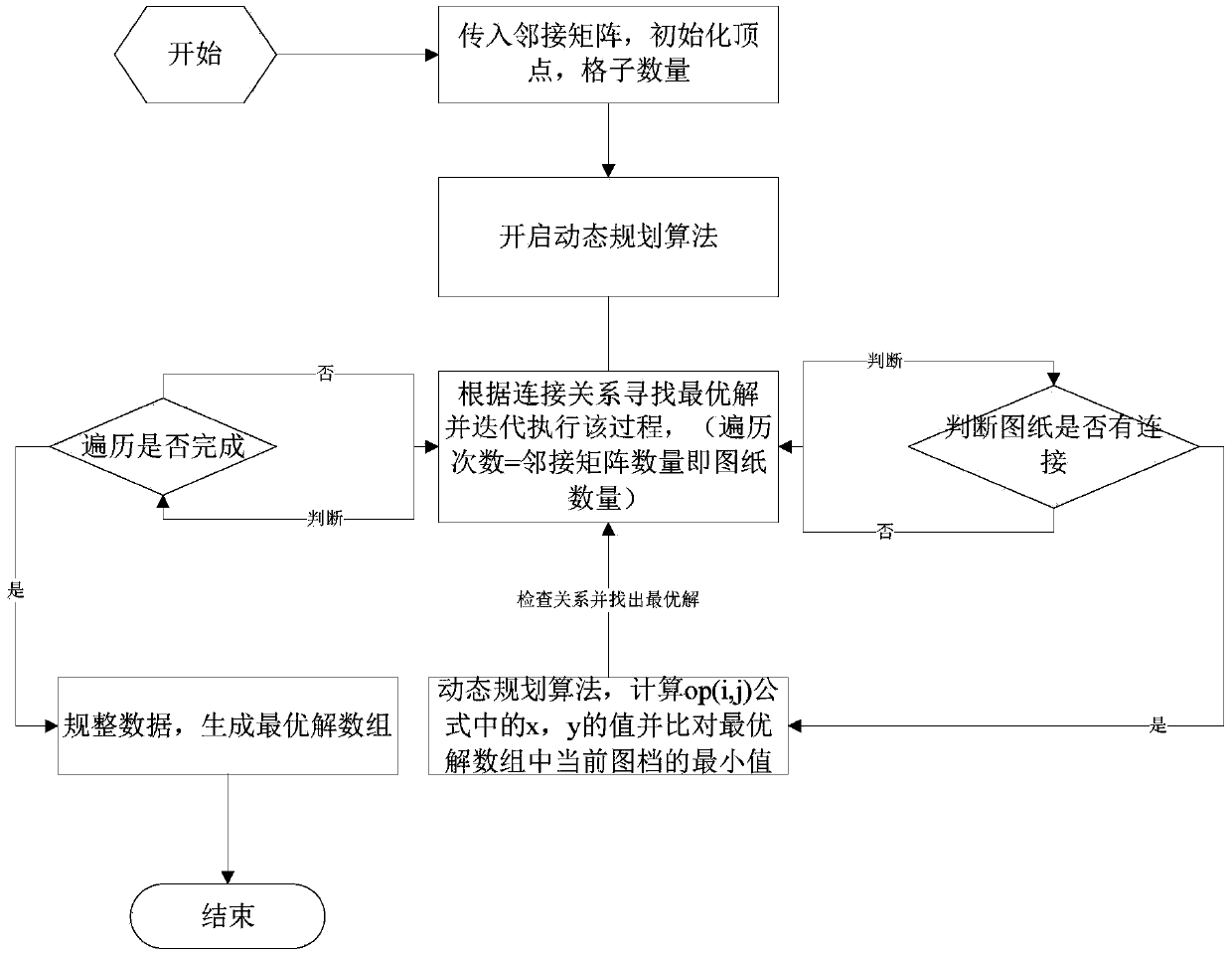

Dynamic programming algorithm-based grid theme graph layout method

ActiveCN105373661AQuick mapPerfect pictureSpecial data processing applicationsRelational modelElectric power system

The invention discloses a dynamic programming algorithm-based grid theme graph layout method. The dynamic programming algorithm-based grid theme graph layout method is characterized by comprising the following steps: (1) building a single-line graph-based ring network topological relation model according to spatial data of a power system; (2) building a connected graph formed by N vertexes and an N*N adjacent matrix according to the built topological relation model and the number N of sub-graph files; (3) building a function model, and calculating an optimal value according to a dynamic programming algorithm until the sub-graph files are completely traversed; (4) distributing the sub-graph files; and (5) rendering the sub-graph files into a graph. A layout method which is best for a power grid is extended and expanded on the basis of the dynamic programming algorithm; the graph can be quickly and perfectly formed; and the problem of the rendering efficiency of a grid system under a large amount of data is solved.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +2

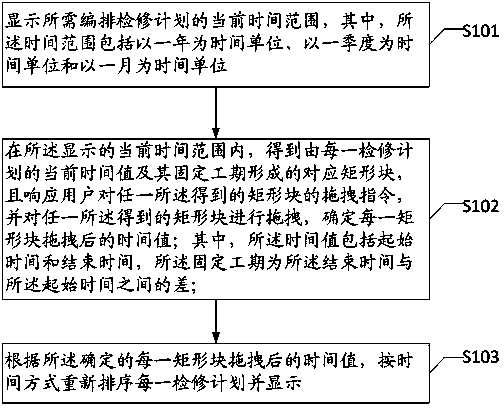

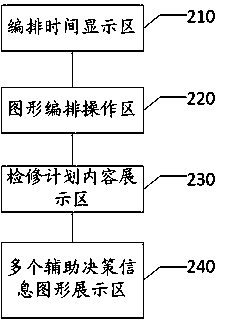

Power grid maintenance schedule graph layout method and system

InactiveCN104240033AReduce labor intensityImprove work efficiencyResourcesInformation technology support systemGraphicsTime range

The invention provides a power grid maintenance schedule graph layout method. The method includes the steps that the current time ranges of maintenance schedules are displayed, wherein the units of the time ranges are a year, a quarter and a month; within the current time ranges, corresponding rectangular blocks formed by the current time value of each maintenance schedule and the fixed construction period of each maintenance schedule are obtained, a response to a dragging command sent by a user to any rectangular block is made, any rectangular block is dragged, and the time value acquired after each rectangular block is dragged is determined, wherein each time value comprises start time and stop time, and each fixed construction period is the difference between the end time and the start time; according to the time value acquired after each rectangular block is dragged, the maintenance schedules are rearranged in a time mode and displayed. By the implementation of the method, the maintenance schedules can be reasonably arranged, the risks of arrangement errors of the maintenance schedules are reduced, the labor intensity of schedule arrangement staff can be relieved, work efficiency is improved, and time and labor can be saved.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Curved surface workpiece surface array microstructure graph layout method

ActiveCN104741791AEliminate layoutEliminate machining errorsLaser beam welding apparatusGraphicsIsoetes triquetra

The invention provides a curved surface workpiece surface array microstructure graph layout method. The method includes the following steps that the boundary dimension of the surface of a free curved surface workpiece is measured through a reverse engineering method, and a reconstructed curved surface is obtained; the reconstructed curved surface is divided into a plurality of curved surface equilateral triangles distributed in a seamless mode; the vertex coordinates Pi of all the nonredundant curved surface equilateral triangles are recorded, and the tangent planes Ki and the outer-normal vectors Vi of the positions of the reconstructed curved surface where the Pi is located are worked out; in all the tangent planes Ki or the planes parallel to the tangent planes Ki, the Pi points corresponding to the tangent planes Ki serve as the geometric center points, design graphs Gi of a unit microstructure are correspondingly distributed, and the requirement that the inclined angles between the same corresponding feature edge line of the design graphs of all the tangent planes and the projection lines of space benchmark vectors in the Ki are fixed values respectively is met. According to the curved surface workpiece surface array microstructure graph layout method, the calculation scale is stable, convergence is maintained, layout efficiency is high, and the layout and machining error of the surface array microstructure graphs can be completely eliminated.

Owner:WENZHOU UNIVERSITY

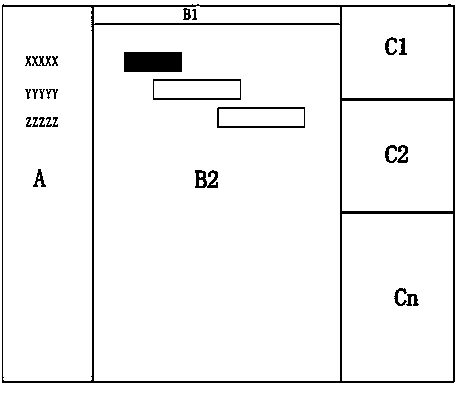

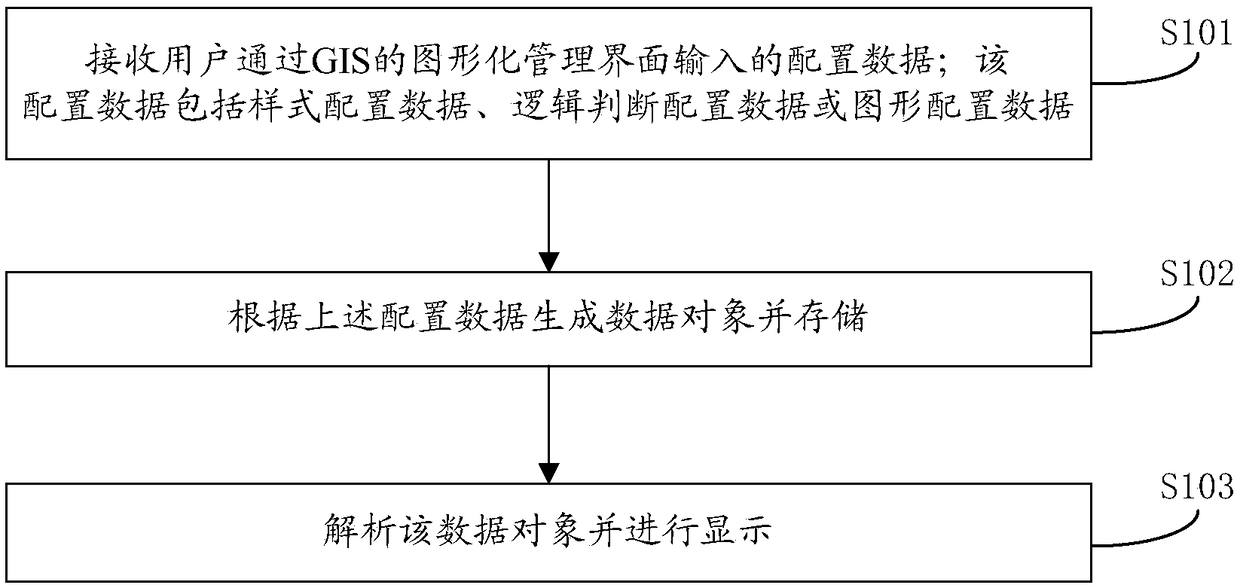

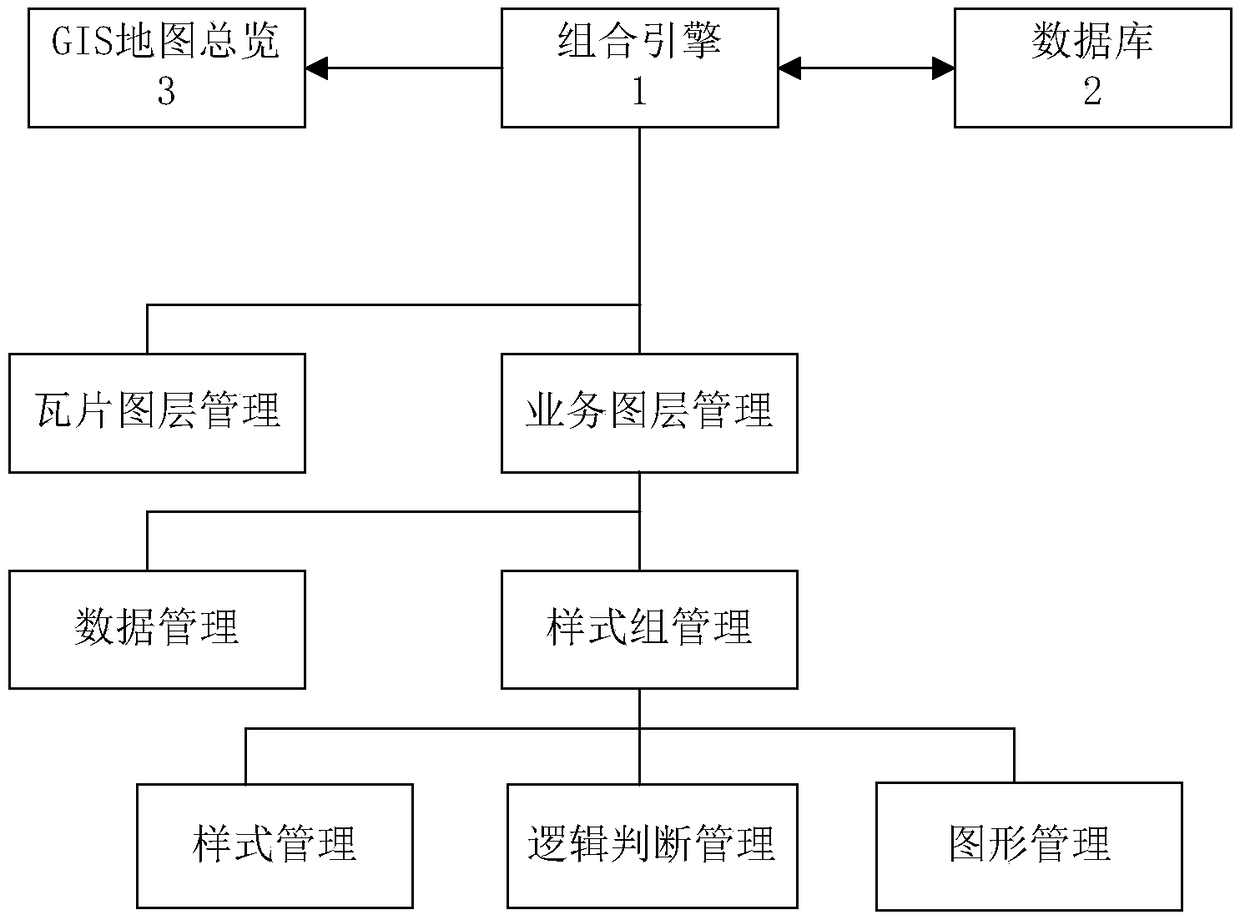

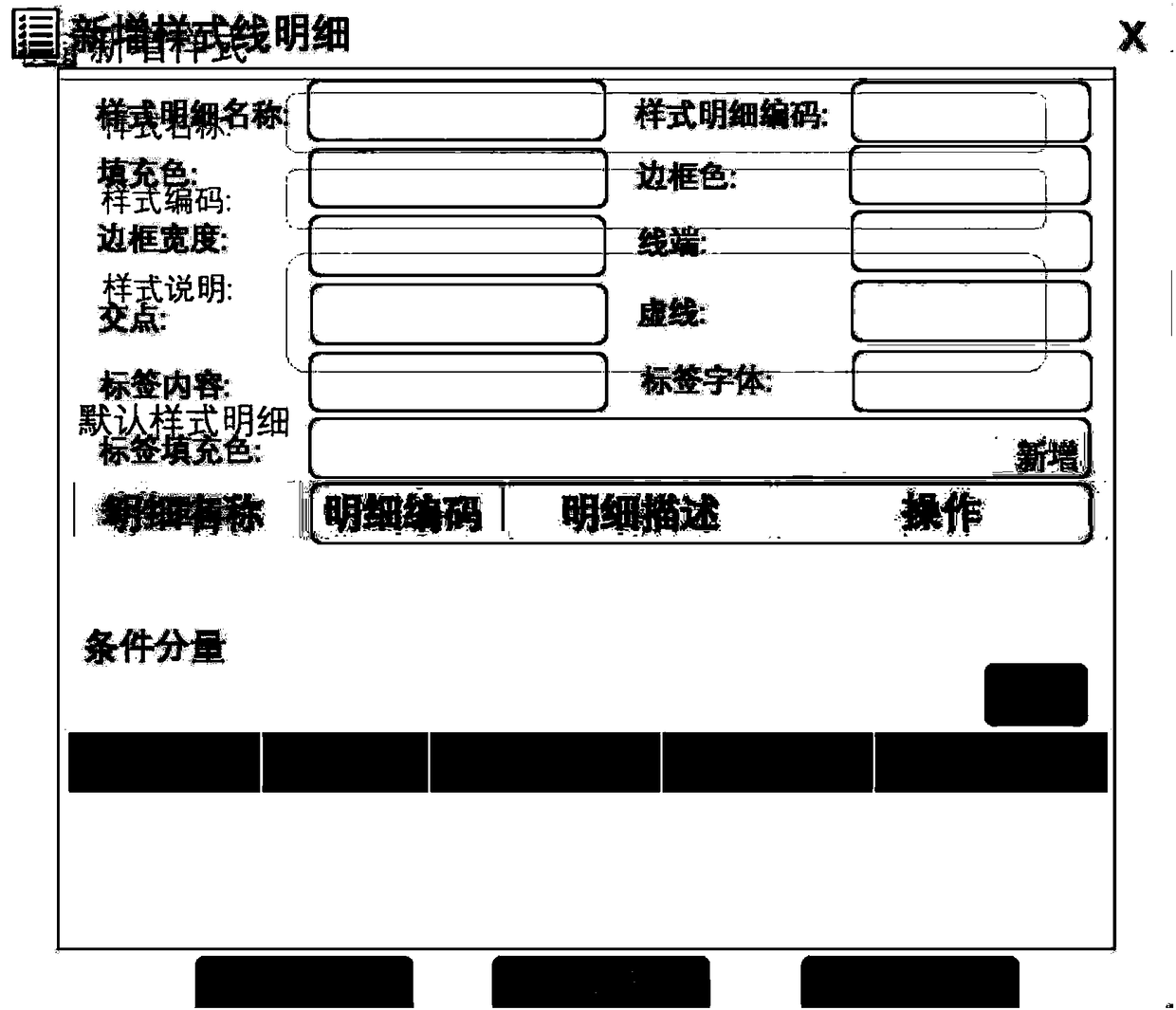

GIS display method, device and system

InactiveCN108153572AEasy to modifyEasy to operateProgram loading/initiatingGeographical information databasesGraphicsGraph Layout

The invention provides a GIS display method, device and system, and relates to the technical field of geographic information. The GIS display method includes the steps of receiving layout data input through a GIS graphical management interface by a user, wherein the layout data includes style layout data or logical judgment layout data or graph layout data; according to the layout data, generatingand saving a data object; parsing and displaying the data object. The GIS display method, device and system aim at that the user does not need to manually carry out code modification or file configuration, so that modification is more convenient, and operation is easier; moreover, by means of the GIS display method, graphic customization and three-dimensional GIS display can be further conducted,so that the visuality of the system is greatly improved.

Owner:BEIJING E TECHSTAR

Laser etching preparation method for surface array microstructure on basis of curved surface workpiece appearance

ActiveCN104741794AEliminate layoutEliminate machining errorsLaser beam welding apparatusLaser etchingSpatial Orientations

The invention provides a laser etching preparation method for a surface array microstructure on the basis of a curved surface workpiece appearance. The method includes the steps that the free curved surface workpiece appearance to be processed is measured by the adoption of a reverse engineering method in a modeling mode, and design graph layout of the surface array microstructure is conducted on the basis of a reconstructed curved surface model; then, laser etching processing path planning is conducted on a design graph, the spatial orientation of a laser processing head relative to a free curved surface workpiece is adjusted according to a tangent plane where a processing path is located, a geometric center point and a corresponding outer-normal vector, laser beams are reflected to the free curved surface workpiece in the normal direction, and laser etching processing is conducted on geometric lines one by one. According to the method, it can be effectively guaranteed that the focus of the laser beams is located on the surface of the free curved surface workpiece all the time in the processing procedure or a certain defocusing distance exists between the focus of the laser beams and the surface of the free curved surface workpiece, a brand new accurate focusing laser processing method is provided, layout and processing errors of the surface array microstructure graph are completely eliminated, and accuracy and stability of laser etching processing technical quality are ensured.

Owner:WENZHOU UNIVERSITY

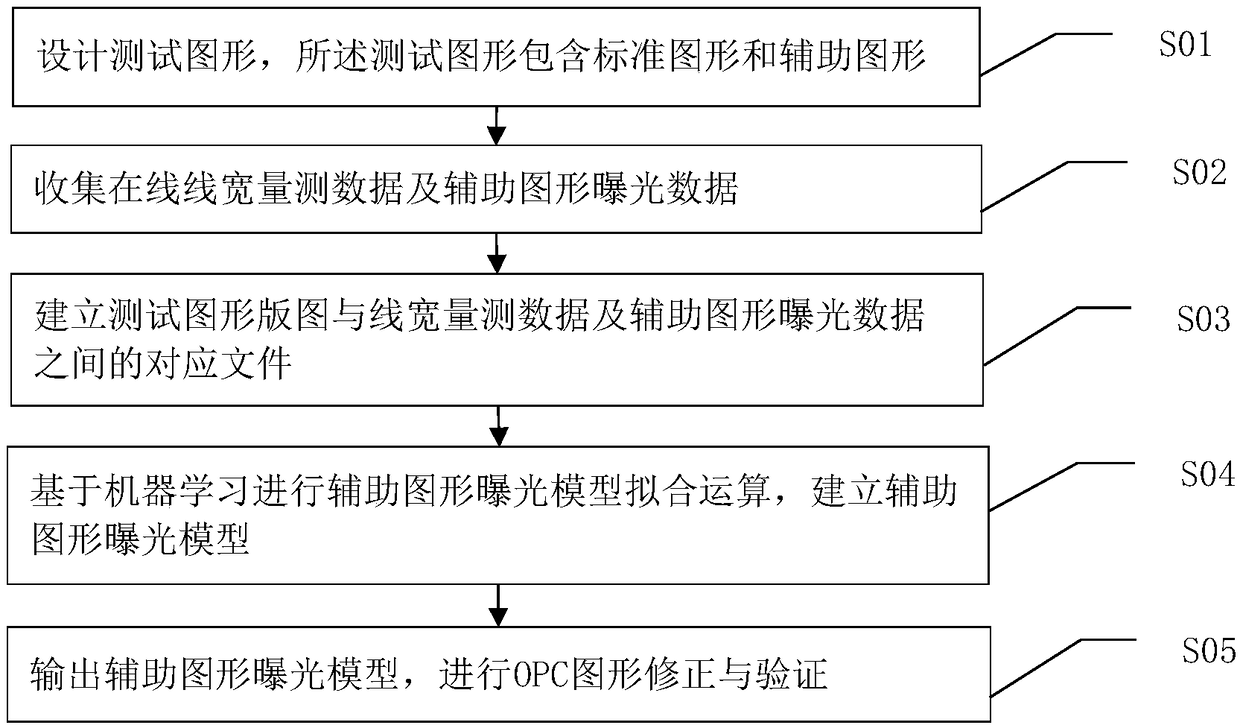

Method for establishing auxiliary graph exposure model

The invention discloses a method for establishing an auxiliary graph exposure model. The method comprises the following steps: S01, designing a test graph, including standard graphs and auxiliary graphs; S02, collecting online line width measurement data and auxiliary graph exposure data; S03, establishing a testing graph layout and a corresponding file between the line width measurement data andthe auxiliary graph exposure data; S04, performing auxiliary graph exposure model fitting operation based on machine learning to establish an auxiliary graph exposure model; and S05, outputting the auxiliary graph exposure model, and performing OPC graph correction and verification. By adopting the method, an auxiliary graph exposure model with higher accuracy can be obtained.

Owner:上海微阱电子科技有限公司

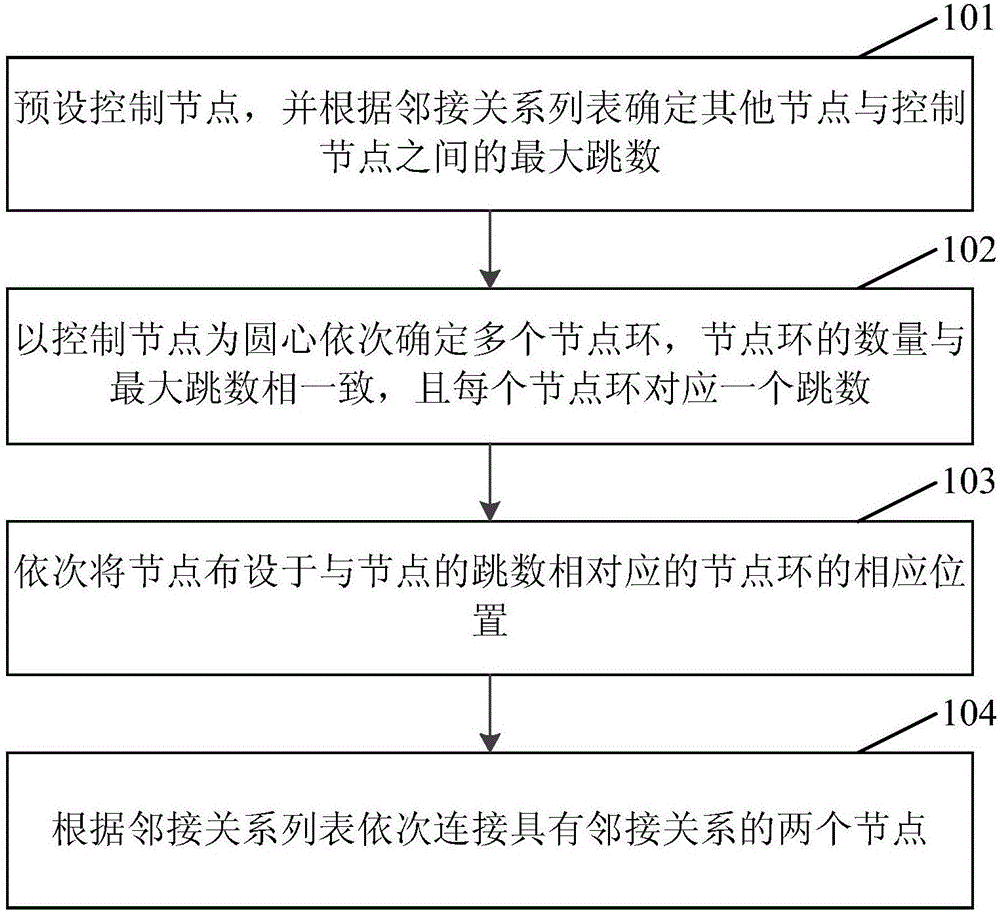

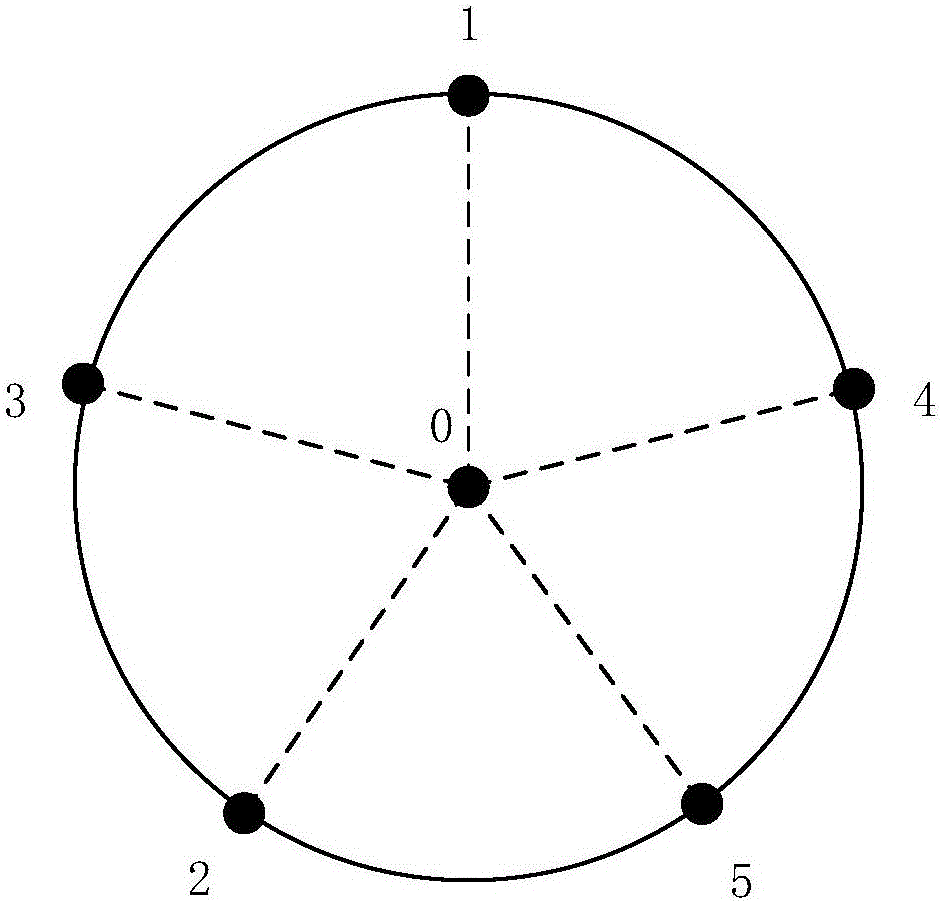

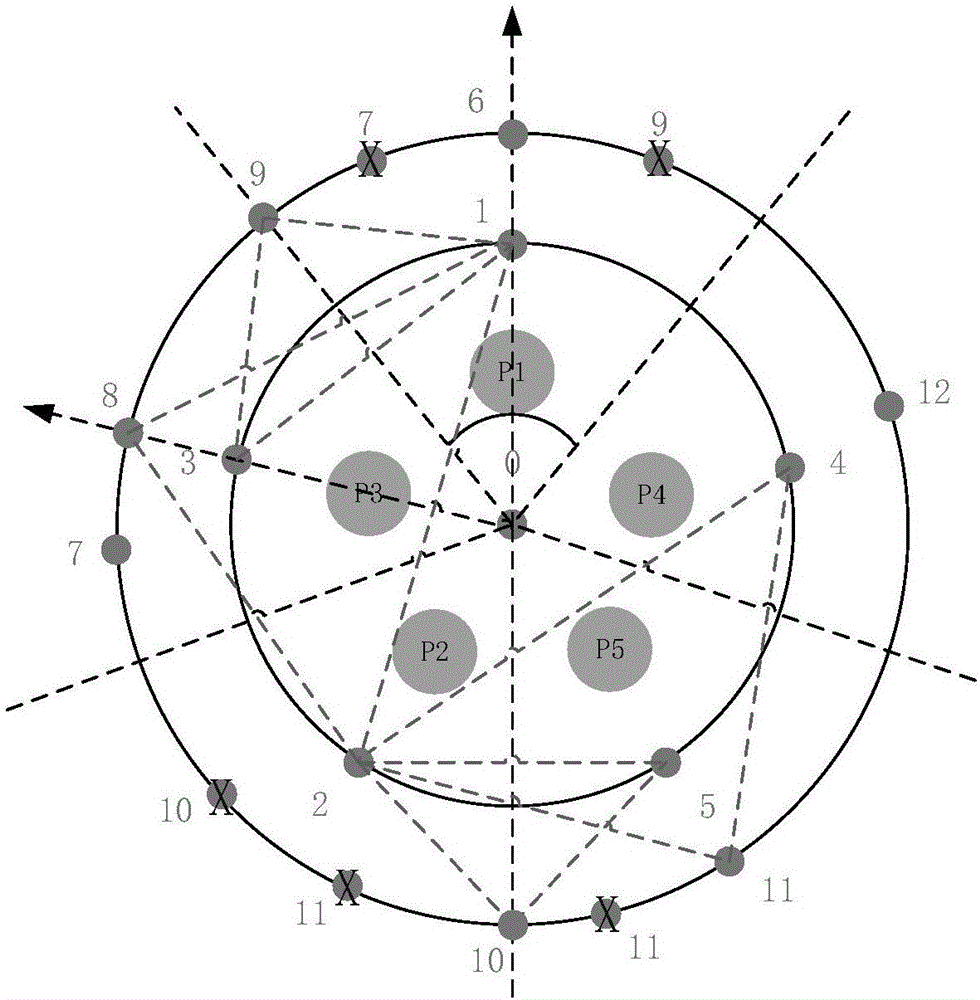

Graph layout method and device

InactiveCN106202559AImprove optimization efficiencyReasonable layoutOther databases browsing/visualisationSpecial data processing applicationsParallel computingControl mode

The invention discloses a graph layout method and device. The method includes the steps that a control node is preset, the maximum hop between other nodes and the control mode is determined according to an adjacency relationship list, and adjacency relationships between the nodes are saved in the adjacency relationship list; multiple node rings are sequentially determined with the control mode as the circle center, wherein the number of the node rings is consistent with the maximum hop, and each node ring corresponds to one hop; the nodes are sequentially distributed at corresponding positions of the node rings corresponding to the hops of the nodes; every two nodes with the adjacency relationship are sequentially connected according to the adjacency relationship list. By means of the method, node layout can accord with an energy model as much as possible, energy of a system can be primarily reduced, and accordingly optimization efficiency of a force-directed algorithm can be improved.

Owner:国网山西省电力公司超高压变电分公司 +3

Distributed graph layout for sensor node networks

InactiveUS7966143B1Position fixationTesting/calibration of speed/acceleration/shock measurement devicesGraphicsSensor node

Certain exemplary embodiments comprise a method, comprising: in a sensor node network comprising a plurality of sensor nodes, each sensor node from the plurality of sensor nodes having location coordinates that are initially unknown, each sensor node from the plurality of sensor nodes having neighbors, each sensor node from the plurality of sensor nodes capable of determining distances only to that sensor node's neighbors: for each sensor node from the plurality of sensor nodes, communicating with that sensor node's neighbors; and based only on communications between neighbors, in a fully distributed manner, generating a sensor node network layout that indicates the location coordinates of each sensor node.

Owner:AT & T INTPROP II LP

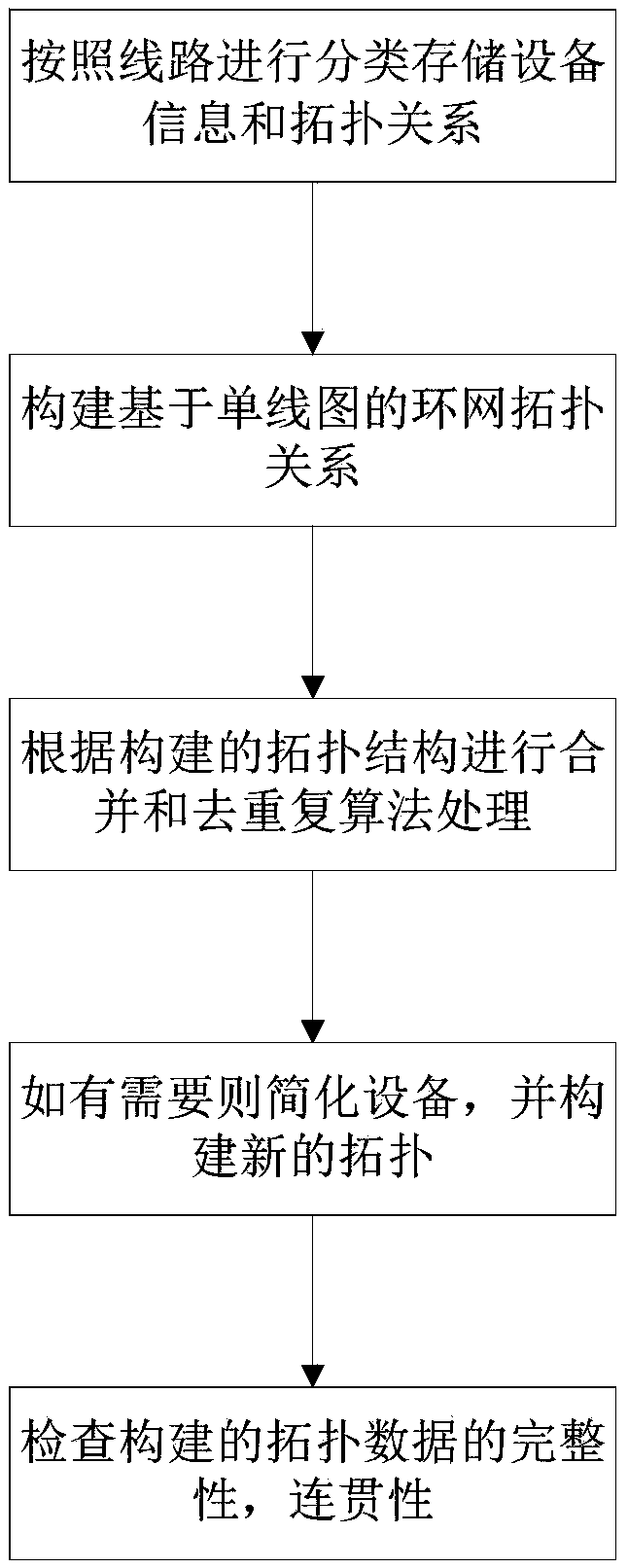

Graph layout and topology service-based low-voltage transformer area automatic generation technology

ActiveCN108427823ASolve efficiency problemsSolve the workloadGeometric CADSpecial data processing applicationsGraphicsTransformer

The invention discloses a graph layout and topology service-based low-voltage transformer area automatic generation technology, which can effectively solve the problem of numerous and complex equipment in a low-voltage transformer area, perform efficient simulation and correspondence on various relationships among the equipment in the low-voltage transformer area, finish efficient self-check of asingle topology relationship or a whole topology network created by simulation, simplify management work of the transformer area and ensure data consistency, security and correctness. According to theautomatic generation technology, mainly complex professional elements in a power business are stripped; large-scale and disordered equipment is managed at a graphic level; the complete topology relationship network can effectively ensure the accuracy of graph formation and simulate a power transmission relationship; a low-voltage transformer area graph is automatically generated by performing position calculation through an automatic graph formation algorithm according to a connection sequence of topology; and meanwhile, collision and spacing between graphs are calculated, so that quickness and beauty of graph formation can be ensured.

Owner:JIANGSU ELECTRIC POWER CO +2

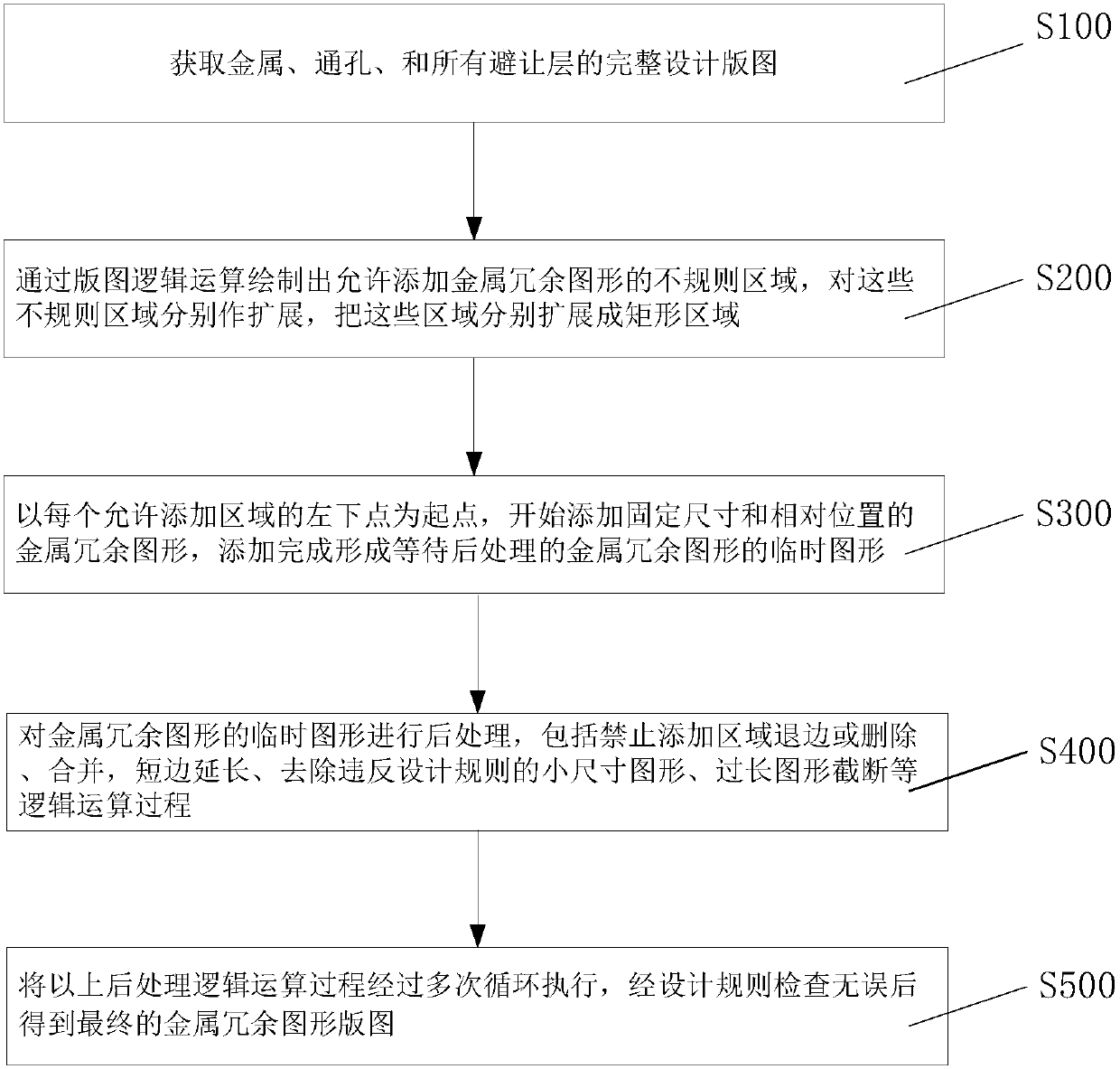

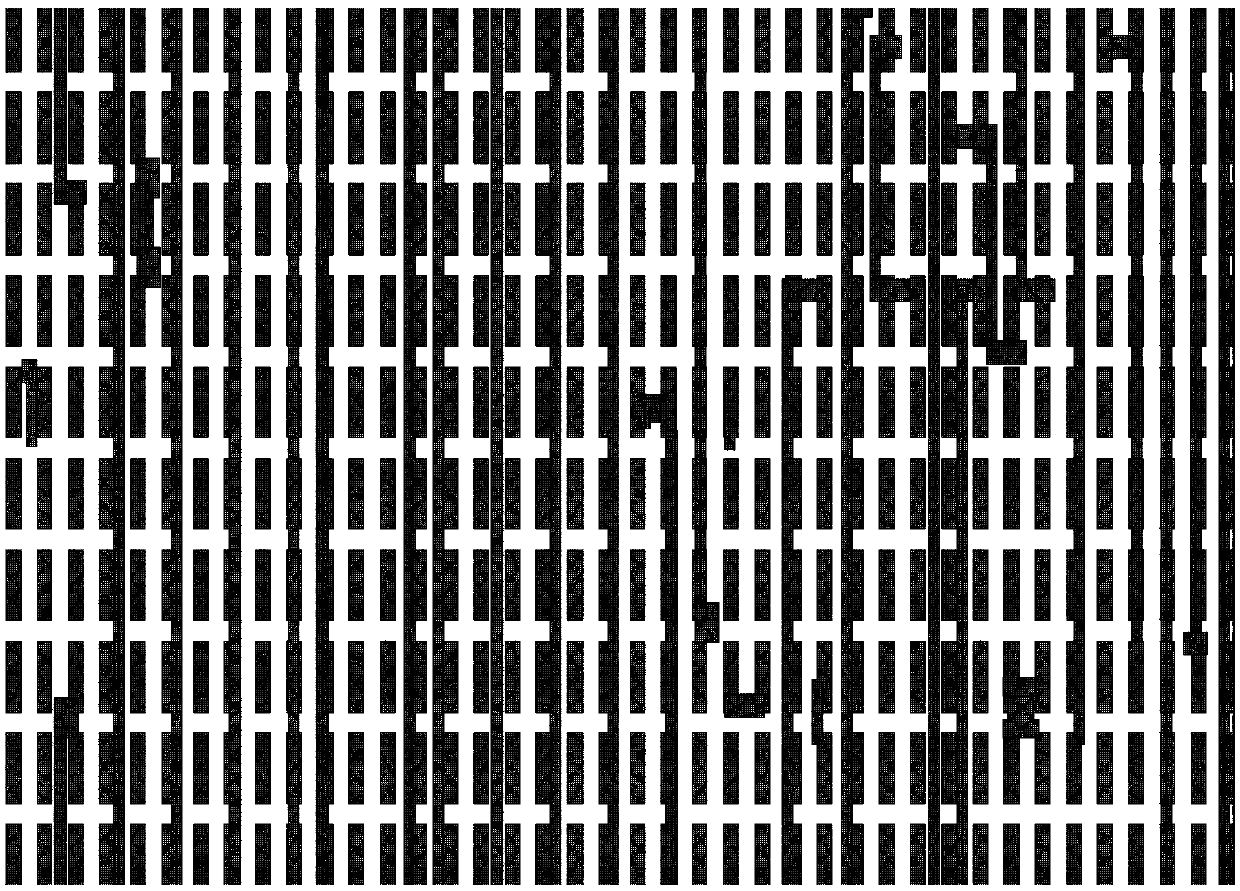

Metal redundant graph drawing method for improving CMP morphology

InactiveCN107657115ASafe without compromising designDoes not affect the designCAD circuit designSpecial data processing applicationsGraphicsLogical operations

The invention provides a metal redundant graph drawing method for improving CMP morphology. The method comprises the steps that a complete design layout of metal, through holes and all clearance layers is acquired; irregular regions allowing addition of metal redundant graphs are drawn through layout logic operation, and the irregular regions are expanded respectively to be rectangular regions; the metal redundant graphs with fixed sizes and relative positions are added with a lower left point of each region allowing addition being a starting point, and temporary graphs, waiting for post-processing, of the metal redundant graphs are formed; the temporary graphs of the metal redundant graphs are post-processed, including forbidding of addition or deletion or merging of region receding edges, extension of short edges, removal of small-sized graphs violating design rules, truncation of overlong graphs and other logic operation processes; and the post-processing logic operation processes are executed cyclically, and a final metal redundant graph layout is obtained after no error is found through checking according to the design rules. Through the method, the problems of poor surface uniformity and bad flatness caused by insufficient metal density can be better solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com