Intelligent work piece correcting system and correcting method thereof

A workpiece, intelligent technology, applied in the intelligent workpiece correction system and the field of correction, can solve the problems of lack of suitable equipment, reduce work efficiency, worker health threats, etc., achieve high stability and reliability, improve production efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

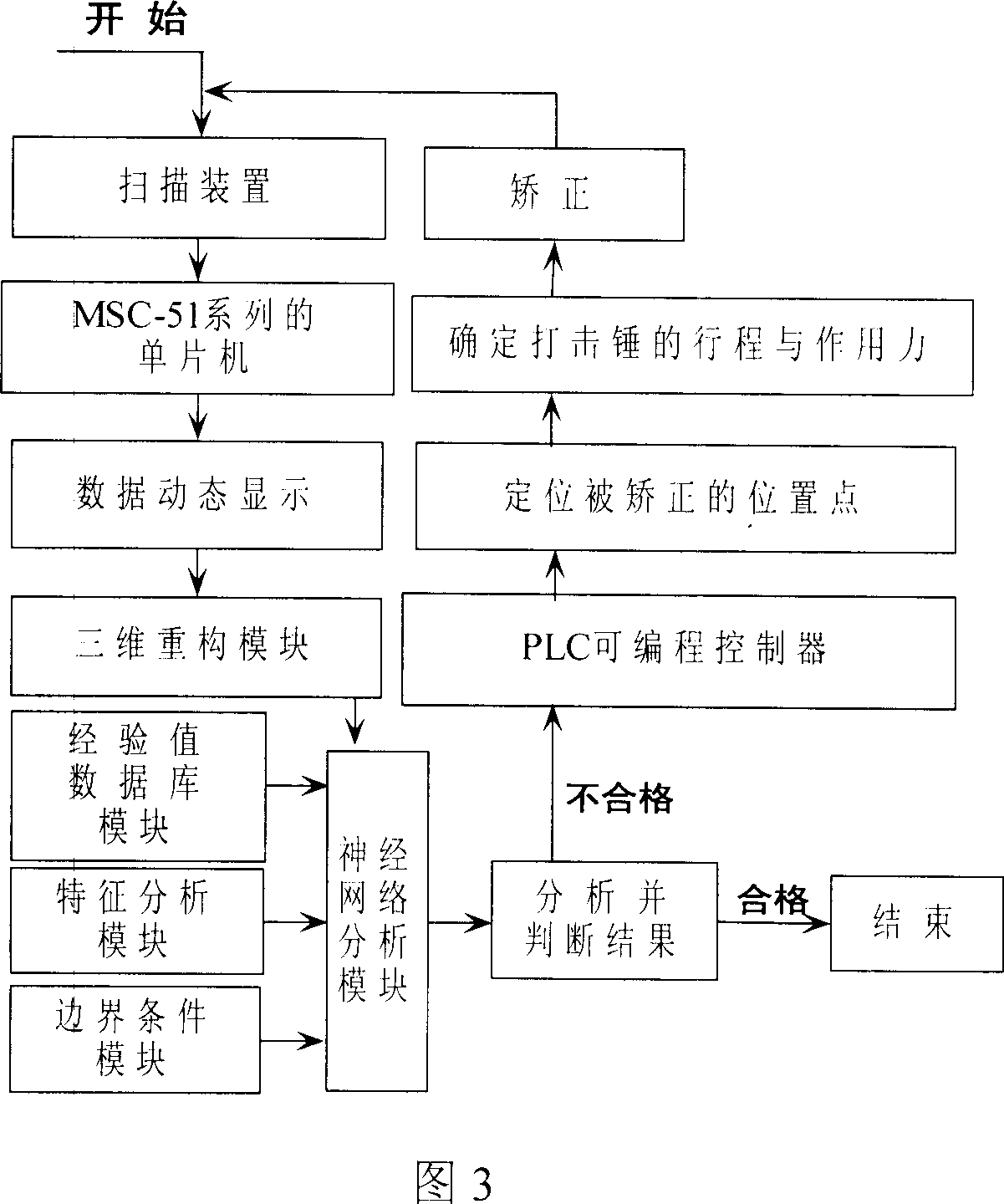

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

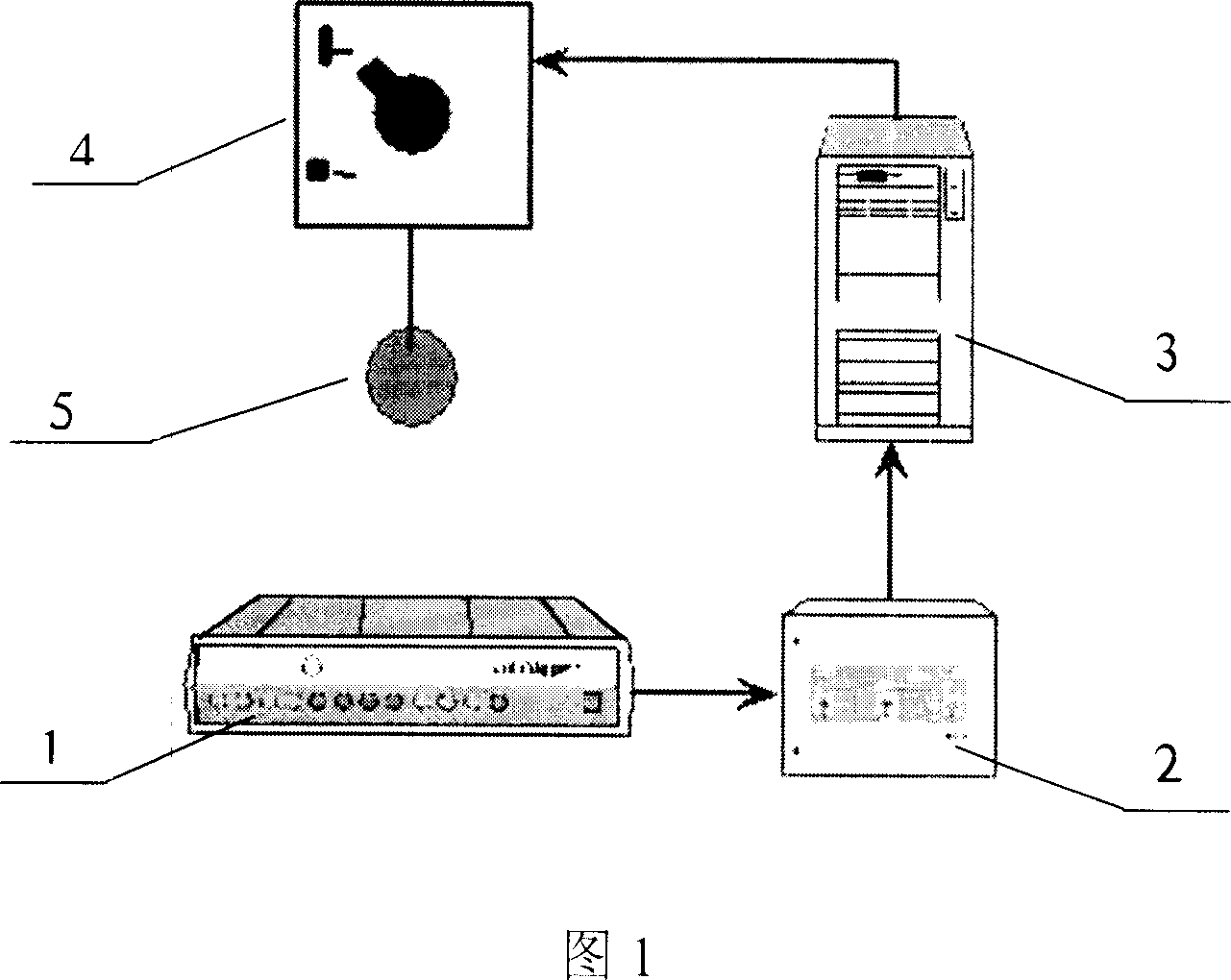

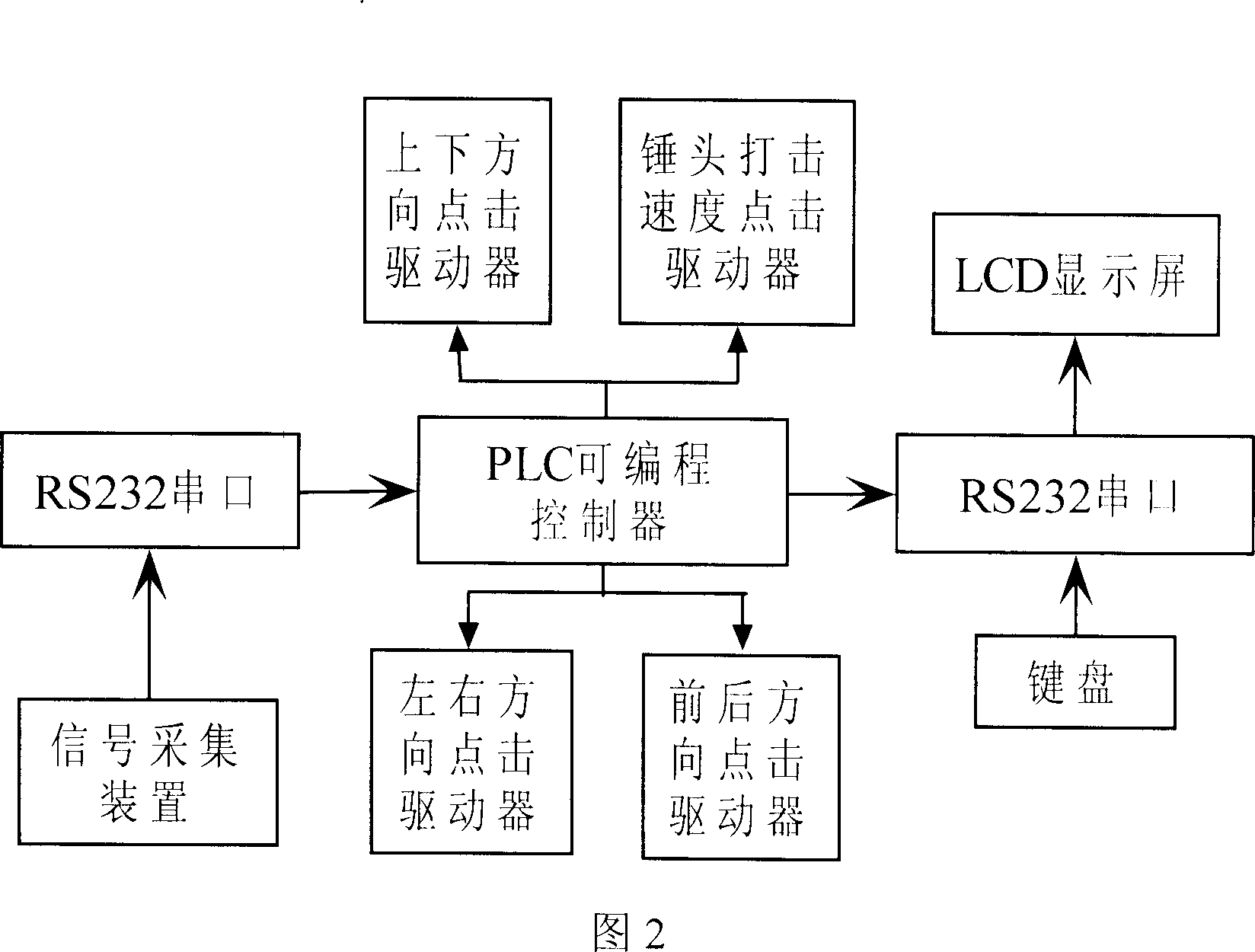

[0026] The intelligent workpiece correction system as shown in Figure 1 is characterized in that: it includes a workbench 1, a PC 3, a controller 4, and a hammer 5, and one end of the workbench 1 is provided with a signal acquisition device 2, and the signal acquisition device 2 includes interconnected scanning devices and MSC-51 series single-chip microcomputers, PC 3 is connected with the MSC-51 series single-chip microcomputers of the signal acquisition device 2, and controller 4 includes interconnected actuators and PLC programmable controllers, The PLC programmable controller of the controller 4 is connected with the PC 3 , and the actuator of the controller 4 is connected with the hammer 5 .

[0027] Wherein the MSC-51 series single-chip microcomputer of the signal acquisition device 2 is connected with the PC 3 through the RS232 serial port.

[0028] The PC 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com