Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Eliminate the effects of detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

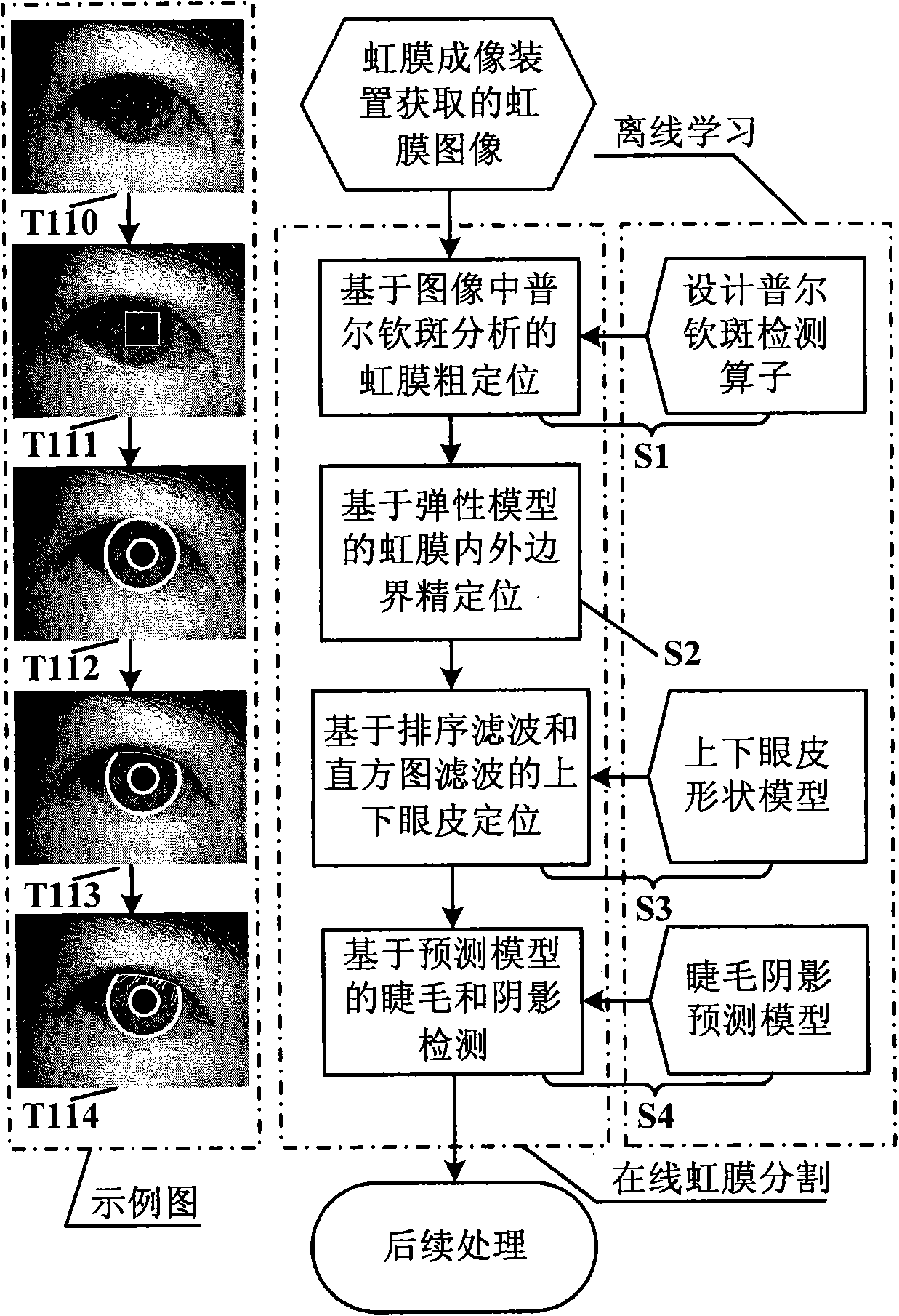

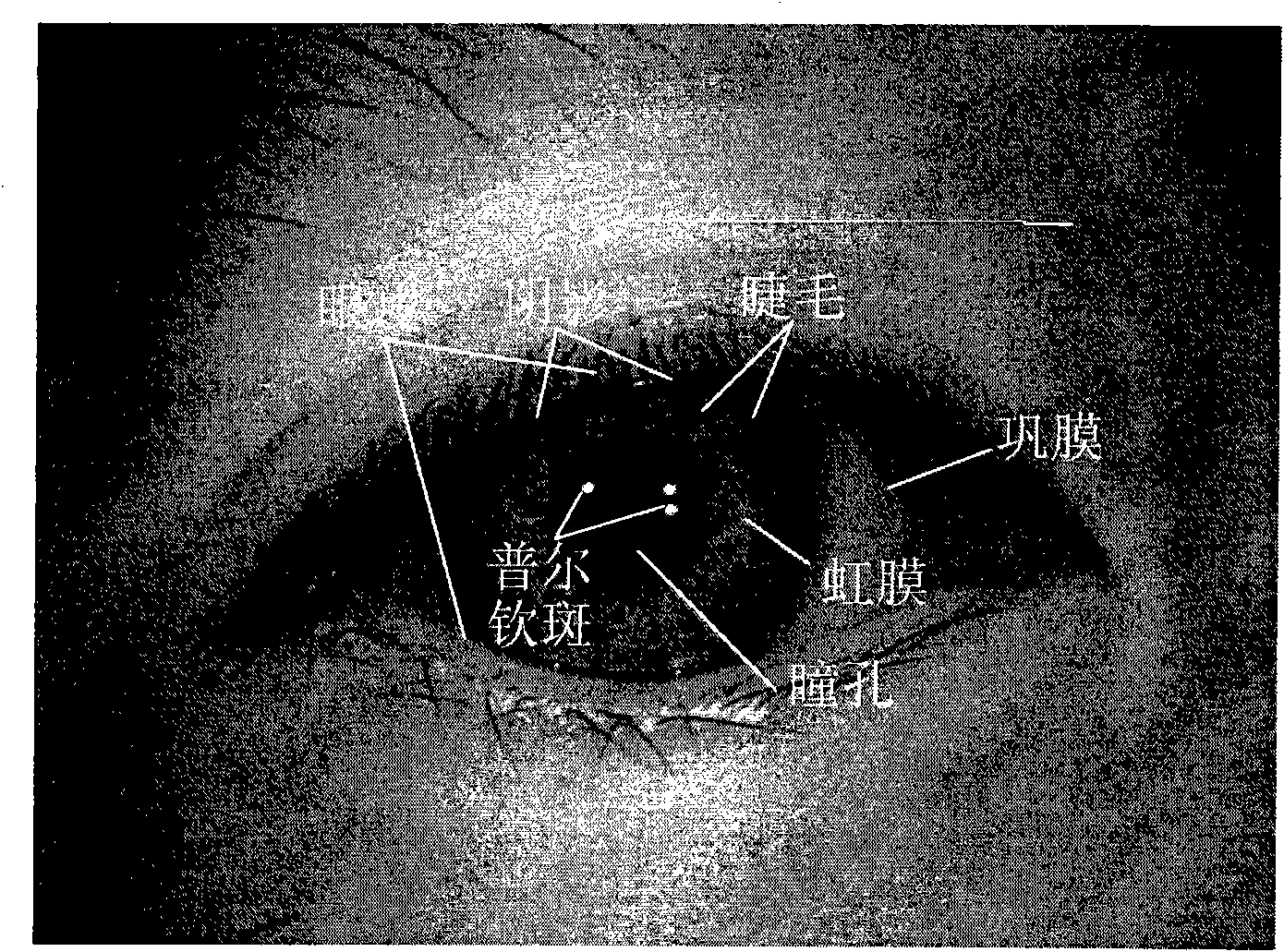

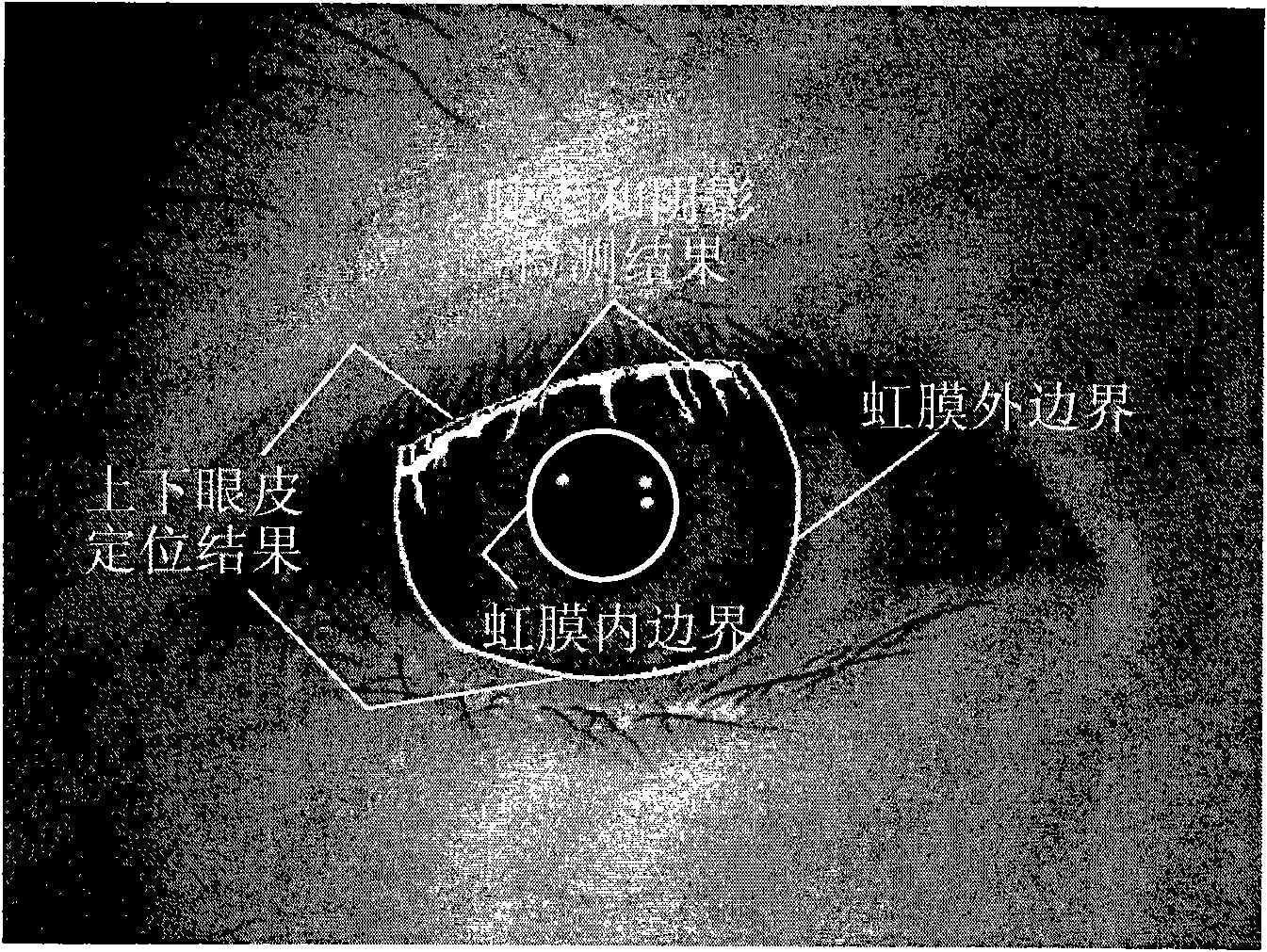

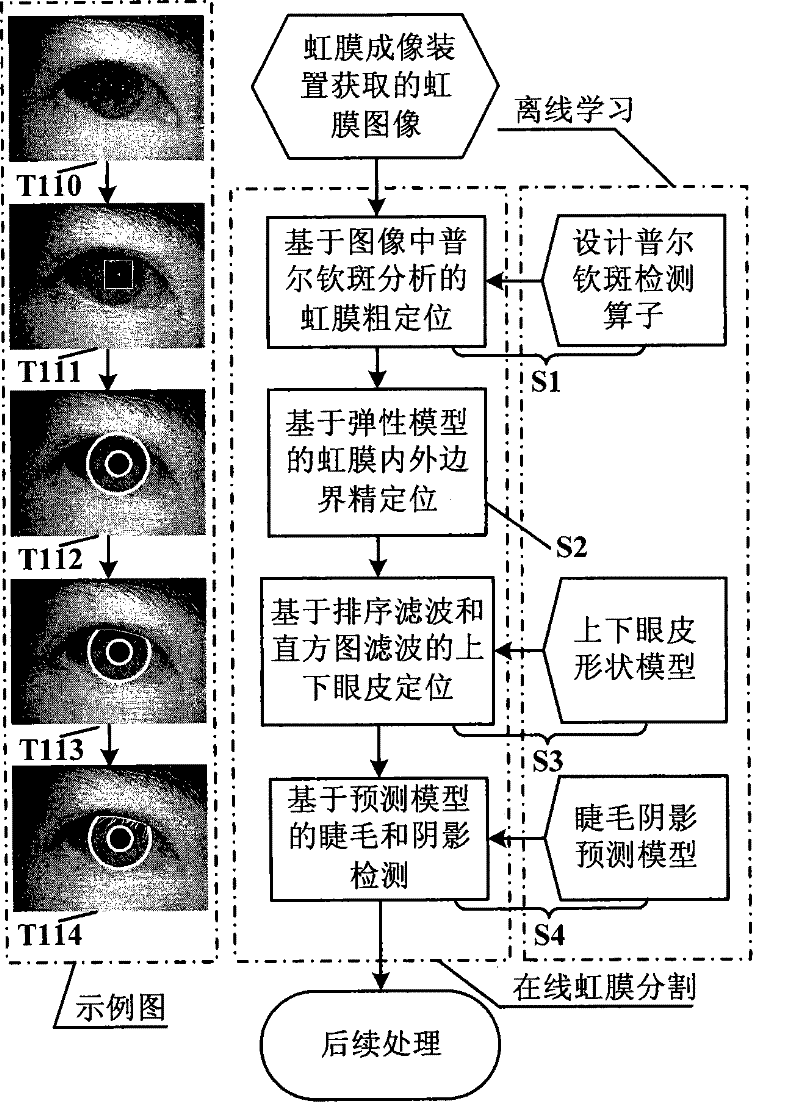

Effective image-region detection and segmentation method for iris recognition

ActiveCN101539991AAccurate upper and lower eyelid boundary parametersExact Boundary ParametersCharacter and pattern recognitionDigital data authenticationPurkinje imagesIdentity recognition

The invention discloses an effective image-region detection and segmentation method for iris recognition. The method comprises: S1, roughly positioning an iris on the basis of Purkinje image analysis in an iris image; S2, accurately positioning the inner and outer boundaries of the iris on the basis of an elastic force model; S3, positioning upper and lower eyelids of the iris on the basis of sorting filtering and histogram filtering; and S4, detecting lashes and shadow on the basis of a lash-shadow blocking-degree prediction model in the image. The method can rapidly and accurately obtain the boundaries of the iris, effectively solves the problems that the conventional iris segmentation algorithm is low in speed and precision, and provides rapid reliable positioning and segmenting results for subsequent iris feature analysis. The method can be widely used in a large number of application systems using iris recognition for identity recognition and security protection.

Owner:BEIJING IRISKING

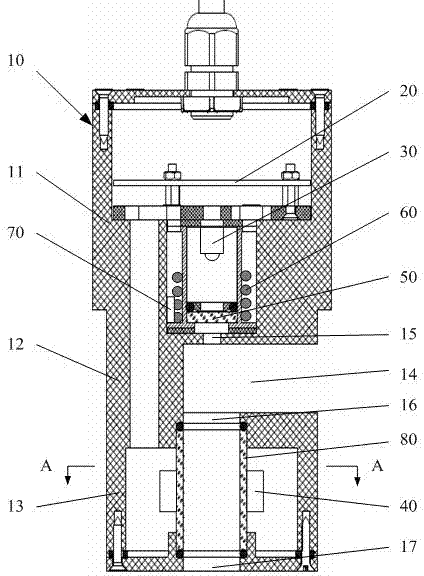

Turbidity sensor and water body turbidity on-line detection method

ActiveCN102928386AHigh Turbidity Detection AccuracyNot easy to splashScattering properties measurementsPollutantScattered light

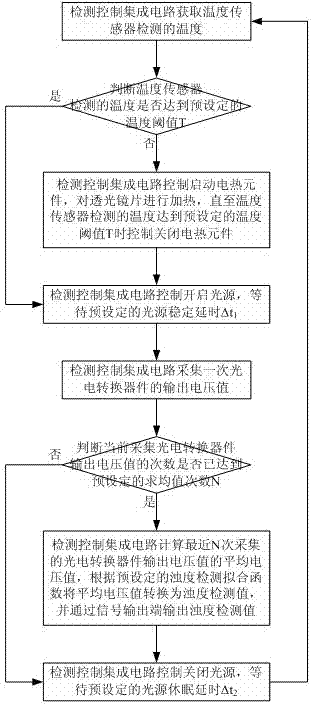

The invention discloses a turbidity sensor and a water body turbidity on-line detection method. The turbidity sensor is of a special structure; the phenomena that the turbidity detection accuracy is influenced by attaching pollutants in a water body on a transmitting lens is possibly avoided; the condensation water mist on the transmitting lens is prevented by virtue of heating so as to eliminate the influence of the mist of the transmitting lens on detection; scattered light of the water body is acquired by an annular photovoltaic conversion device in 360 degrees, so that the effective received quantity of the scattered light is increased to the maximum extent; and the signal of an operation amplifying device is not needed to be amplified to guarantee the stability and reliability of the turbidity sensor. By utilizing the water body turbidity on-line detection method of the turbidity sensor, output voltage values, acquired for many times of a photovoltaic conversion device, are used and a processing mode that the average value is taken is adopted; modes of heating and light control are combined during the detection process every time, so that the detection error caused by the mist of the transmitting lens and the unstable light sources is eliminated, and the turbidity detection accuracy is further guaranteed.

Owner:重庆远感科技有限公司

Formaldehyde detecting device and formaldehyde detecting method

ActiveCN109669008AEliminate the effects of detectionExtended service lifeMaterial analysisAir purifiersEnvironmental engineering

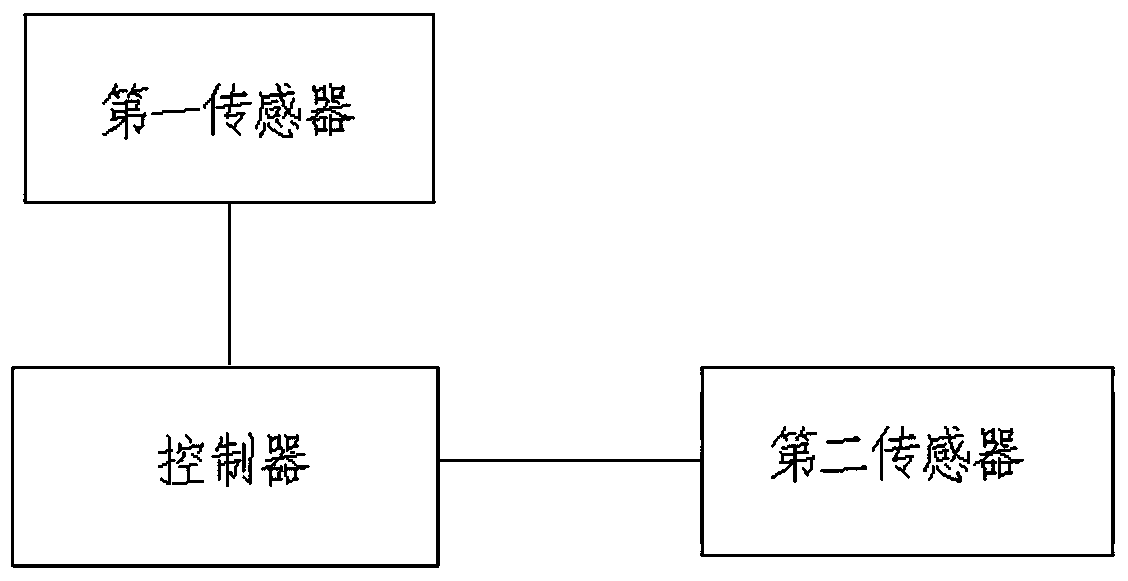

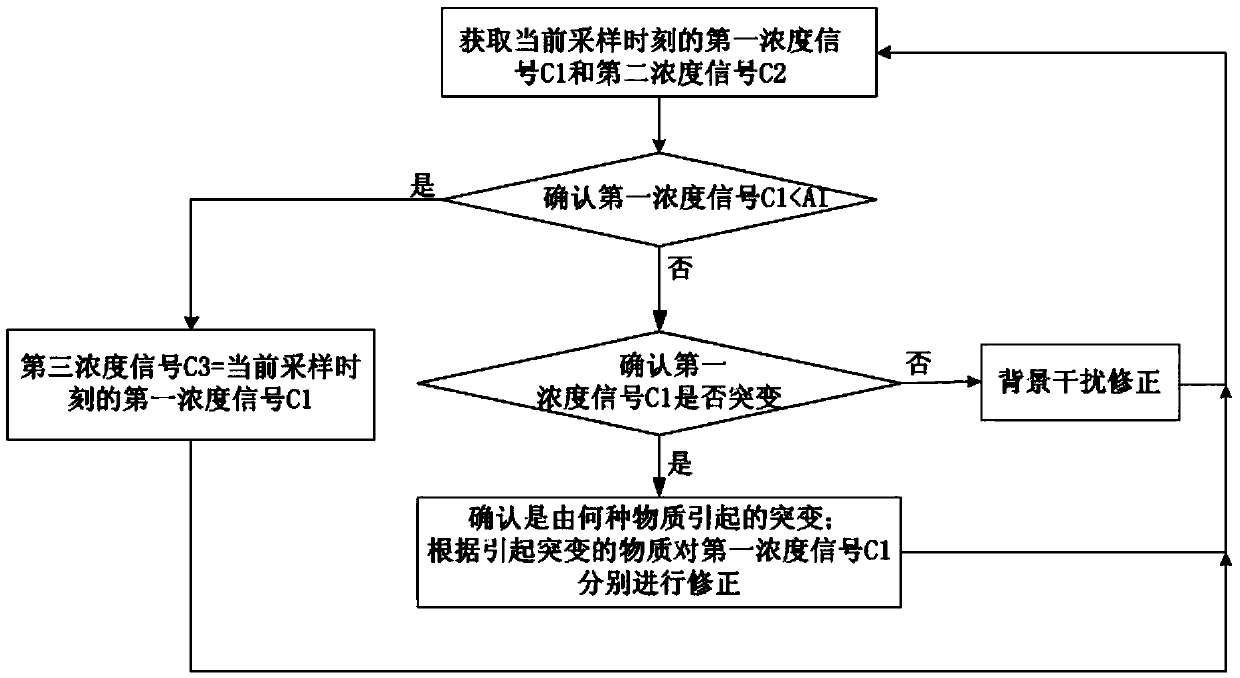

The invention relates to a formaldehyde detecting device and method. The device comprises a first sensor, a second sensor, a temperature and humidity sensor and a controller. The method comprises thesteps that a first concentration signal C1 output by the first sensor and a second concentration signal C2 output by the second sensor are subjected to temperature compensation and / or humidity compensation according to a detecting signal output by the temperature and humidity sensor, and a formaldehyde concentration value is obtained according to the compensated first concentration signal C1t, thecompensated second concentration signal C2t and a third concentration signal C3t output by an algorithm and stored in the controller. The formaldehyde detecting device disclosed by the invention canidentify the disturbance gas under different to-be-detected environments, overcomes the technical defect of inaccurate detection data caused by the disturbance gas, and can eliminate the influence ofthe temperature and the humidity on formaldehyde detection simultaneously, and a solution scheme with excellent anti-disturbance property and high precision is provided for large-scale application ofthe formaldehyde detecting device to the fields of air purifiers, heating ventilation air conditioners and the like.

Owner:WUHAN CUBIC OPTOELECTRONICS

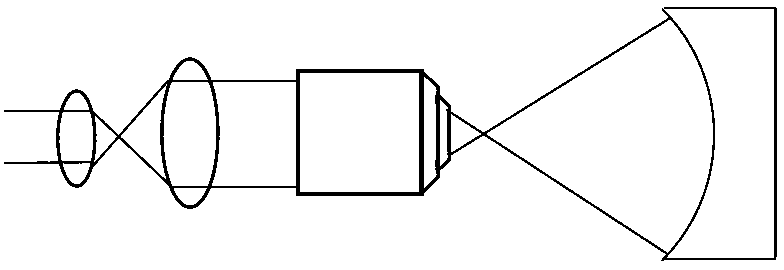

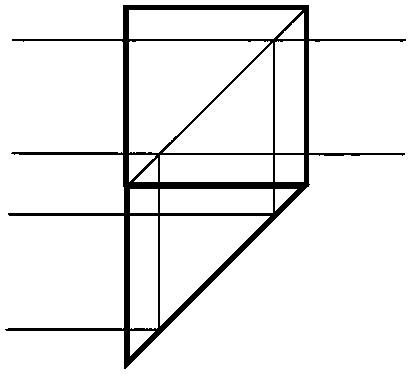

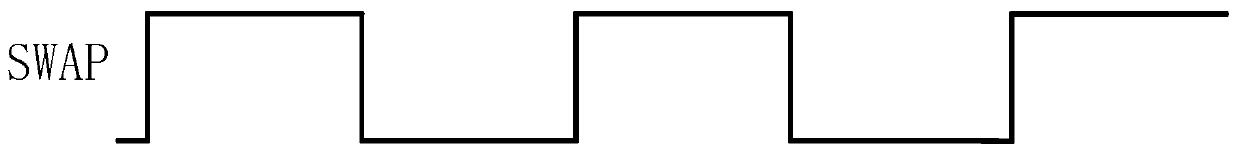

Octave type short coherence transient phase-shifting interferometer and measurement method used for detecting spherical topographic characteristics

ActiveCN103344176ARealize leak-free detectionIncrease contrastUsing optical meansBeam splitterMeasurement device

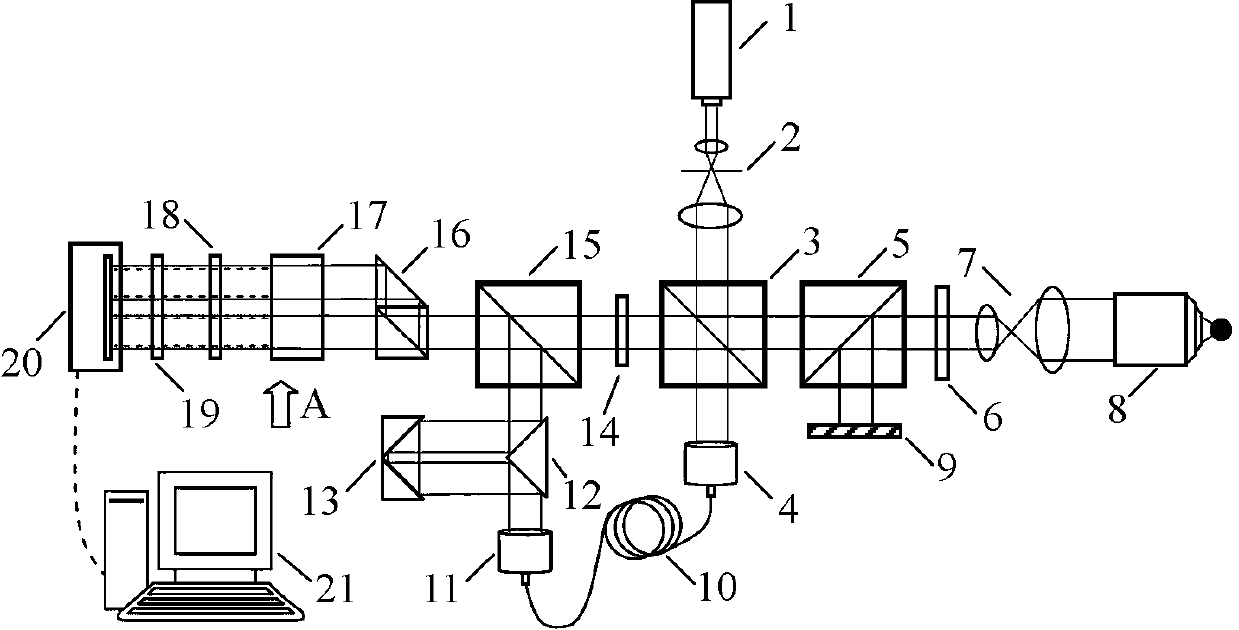

The invention discloses an octave type short coherence transient phase-shifting interferometer and a measurement method used for detecting spherical topographic characteristics and relates to the technical field of optical detection. The problems that a traditional time domain phase-shifting interference measurement device is narrow in detection range and low in measurement precision and is influenced by environmental factors are solved. The interferometer comprises a short coherence laser, a spatial filter, a beam splitter prism, an optical fiber coupling mirror, a polarization splitting prism, a lambda / 4 wave plate, a 4f beam-expanding system, a micro objective, a plane mirror, a single mode optical fiber, an optical fiber collimating lens, a corner cube mirror, a cube-corner prism, a lambda / 2 wave plate, a polarization splitting prism, a first parallel beam splitter, a second parallel beam splitter, a wave plate group, a polarizing film, an area array charge coupled device (CCD) and a computer. A positioning relationship among four interference images is obtained through four interference patterns of the area array CCD through the computer, so that the initial phase difference which corresponds to each pixel point in an interference field is solved, the optical path difference is further solved, and the spherical morphology is measured. The interferometer is suitable for detection of spherical topographic characteristics.

Owner:HARBIN INST OF TECH

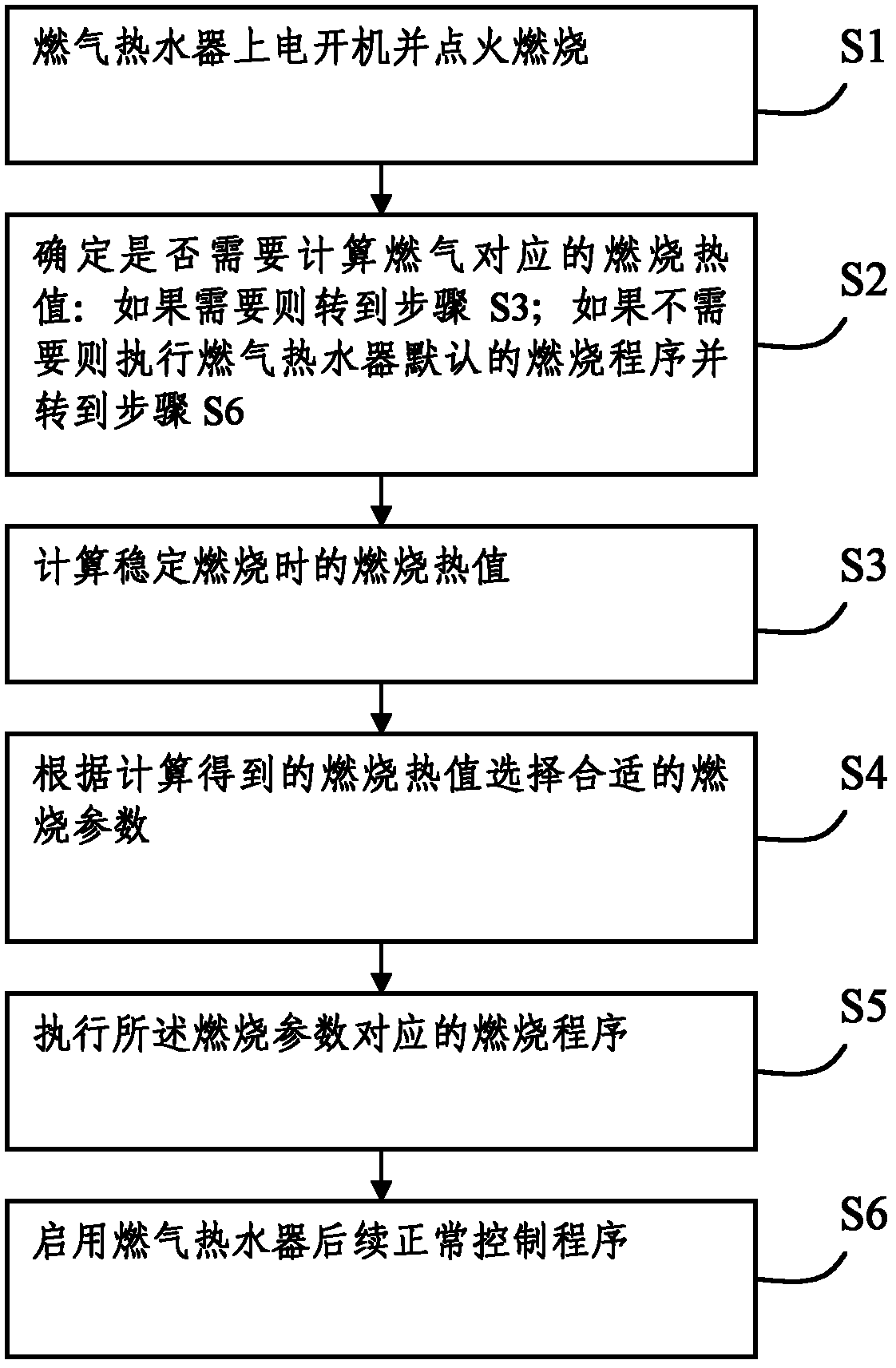

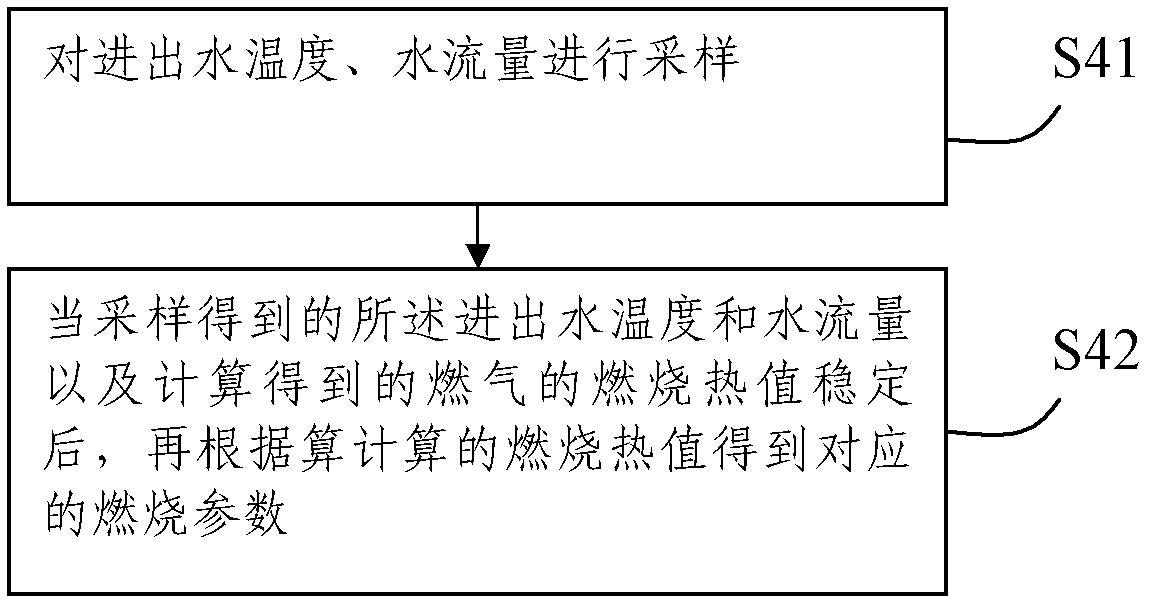

Fuel control method for fuel water heater

The invention discloses a fuel control method for a fuel water heater. The fuel control method includes the following steps: S1, powering on and starting up the fuel water heater and igniting for combustion; S2, determining whether calculation of a combustion heat value corresponding to fuel is needed or not, if yes, entering S3, and if not, executing a default combustion program of the fuel water heater and entering S6; S3, calculating a combustion heat value in stable combusting; S4, selecting a proper combustion parameter according to the combustion heat value; S5, executing the combustion program corresponding to the combustion parameter; S6, starting a subsequent normal control program of the fuel water heater. By the fuel control method, different kinds of gas sources of the fuel and difference, of the same kind of gas source, caused by areas or using time can be differentiated, and proper combustion parameters can be adopted correspondingly, so that the fuel can be combusted more fully.

Owner:HAIER GRP CORP +1

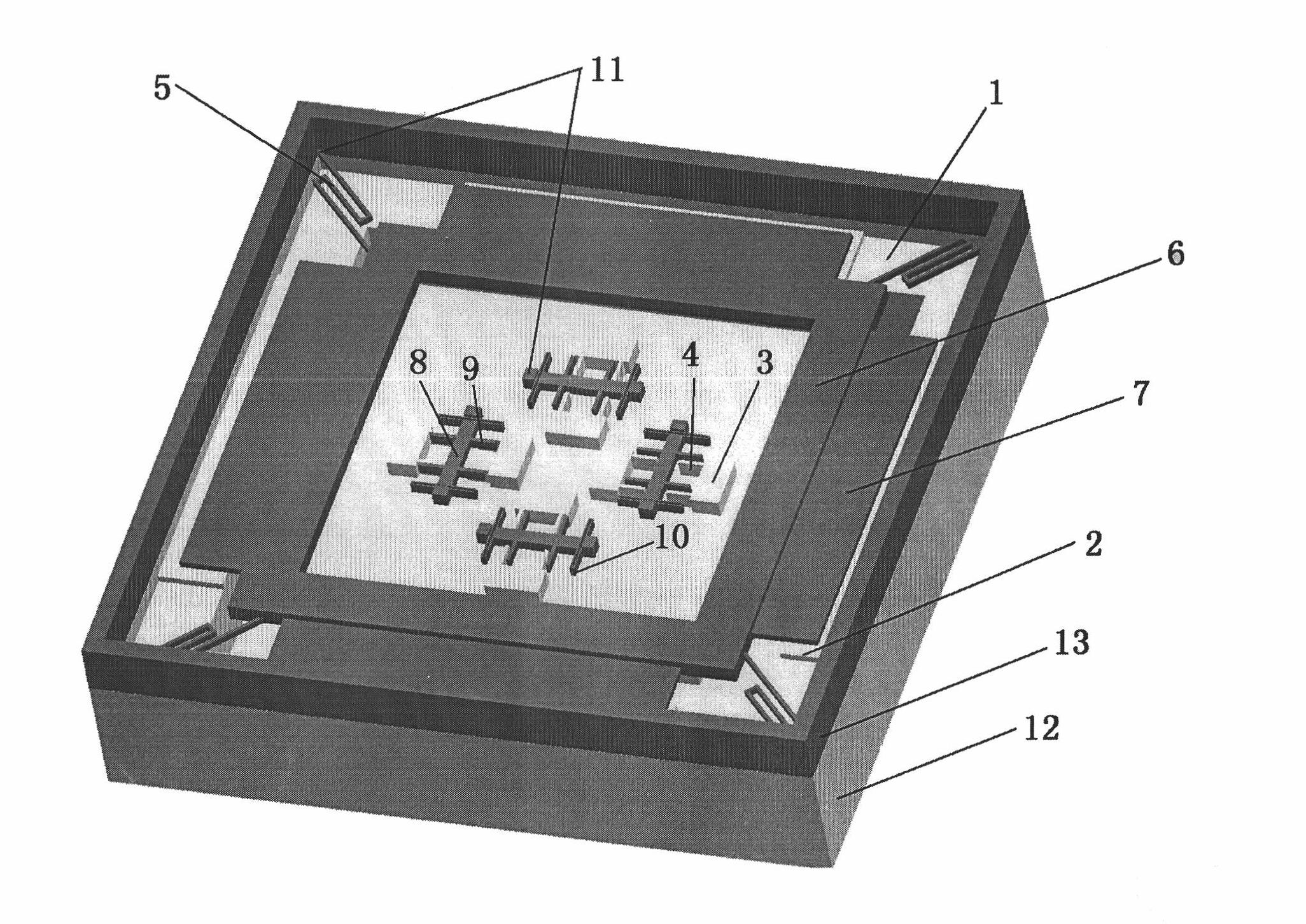

Three-axis capacitive micro accelerometer based on silicon on insulator (SOI) process and micropackage technology

InactiveCN102156201AReduce parasitic capacitanceReduce short channel effectAcceleration measurement using interia forcesPiezoelectric/electrostrictive devicesPhysicsImage resolution

The invention discloses a three-axis capacitive micro accelerometer, which comprises an SOI substrate, a mass block, a flexible beam, a tooth pivot, a fixed electrode and a movable electrode. The accelerometer has a structure of a central symmetry pattern, and the mass block passing through an XY plane in a Z-axis direction senses the accelerated speed in three orthogonal directions respectively.Due to the design of a beam in the shape like a Chinese character hui on the XY plane and the flexible beam in the Z-axis direction, the sensitivity and resolution of the accelerated speed in three orthogonal directions are improved. In addition, due to the application of the SOI process, the micro accelerometer has the advantages of low parasitic capacitance, low short channel effect, high speed, high integrated level, low power consumption, high temperature resistance, radiation resistance and the like. Finally, the novel method effectively solves the problem of package of microcomponents through the micropackage technology.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

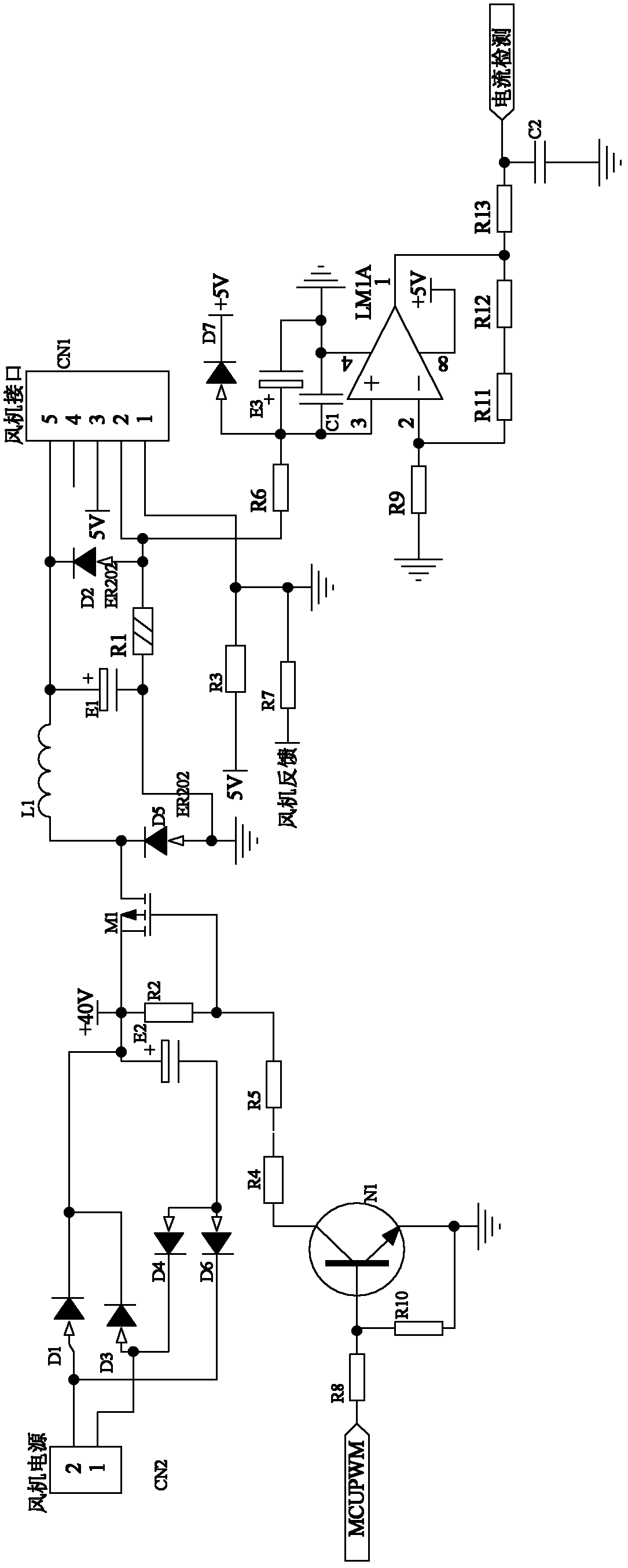

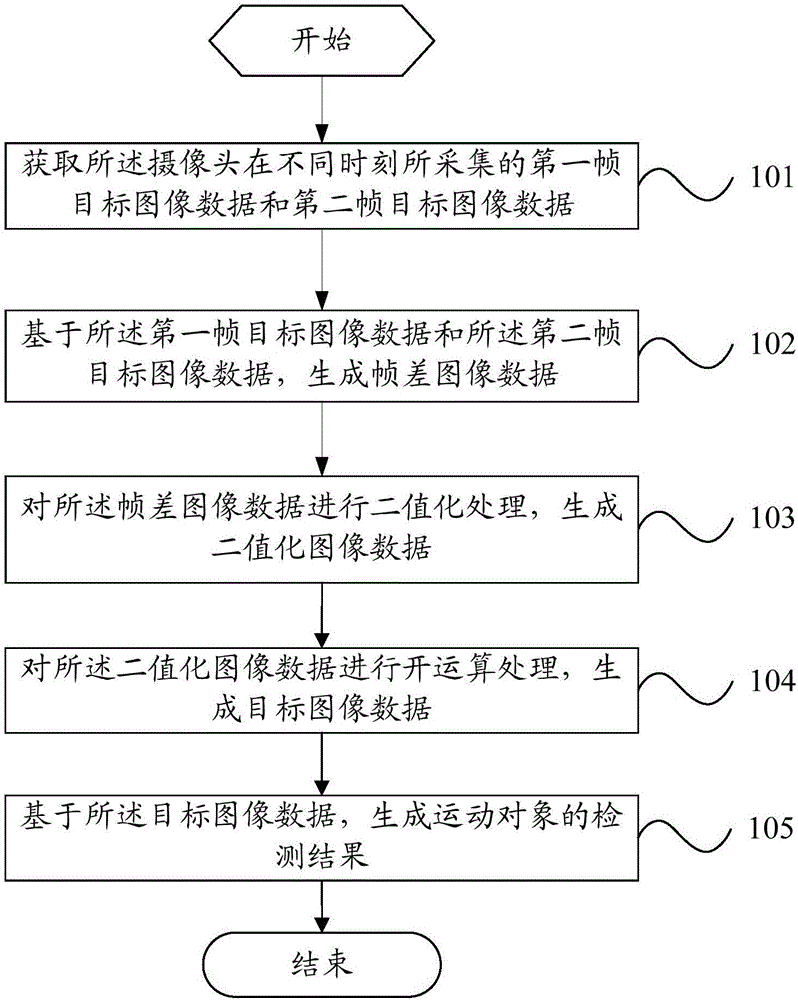

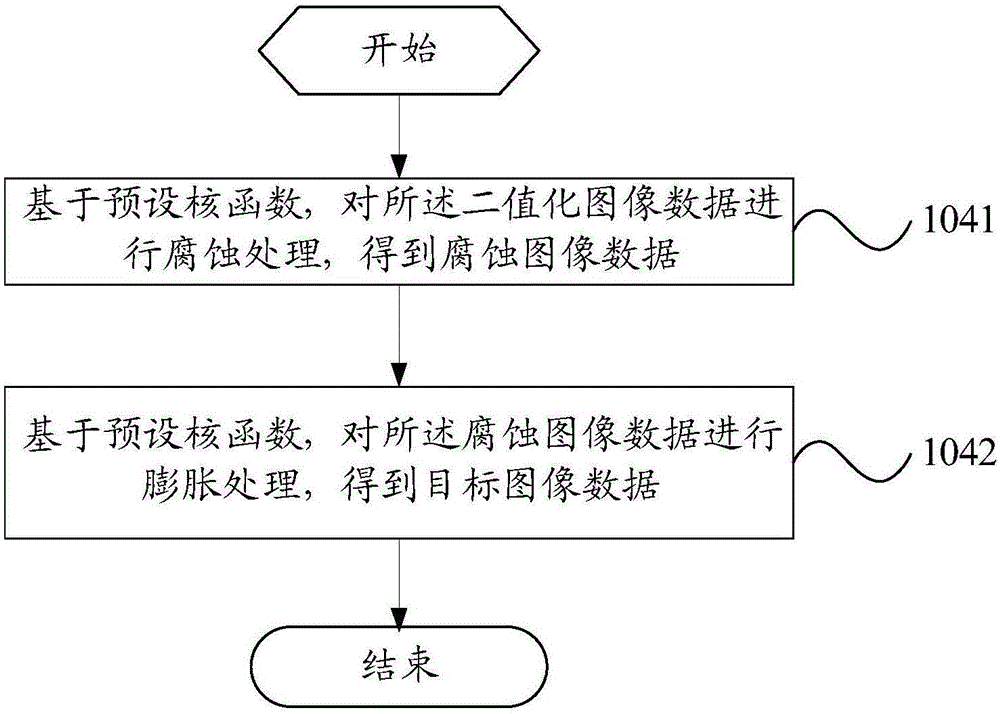

Movement object detection method and mobile terminal

InactiveCN106488133AThe test result is accurateEliminate the effects of detectionTelevision system detailsColor television detailsObject detectionObject based

The invention provides a movement object detection method and a mobile terminal, and relates to the communication technical field. The detection method comprises the steps of obtaining a first frame target image data and a second frame target image data collected by a camera at different moments; generating a frame difference image data based on the first frame target image data and the second frame target image data; performing binaryzation processing on the frame difference image data to generate a binaryzation image data; performing opening-algorithm processing on the binaryzation image data to generate a target image data; and generating a detection result of the movement object based on the target image data. By adoption of the scheme, the problem of misjudgement on movement caused by shaking when the mobile terminal is hand held in the prior art is solved.

Owner:VIVO MOBILE COMM CO LTD

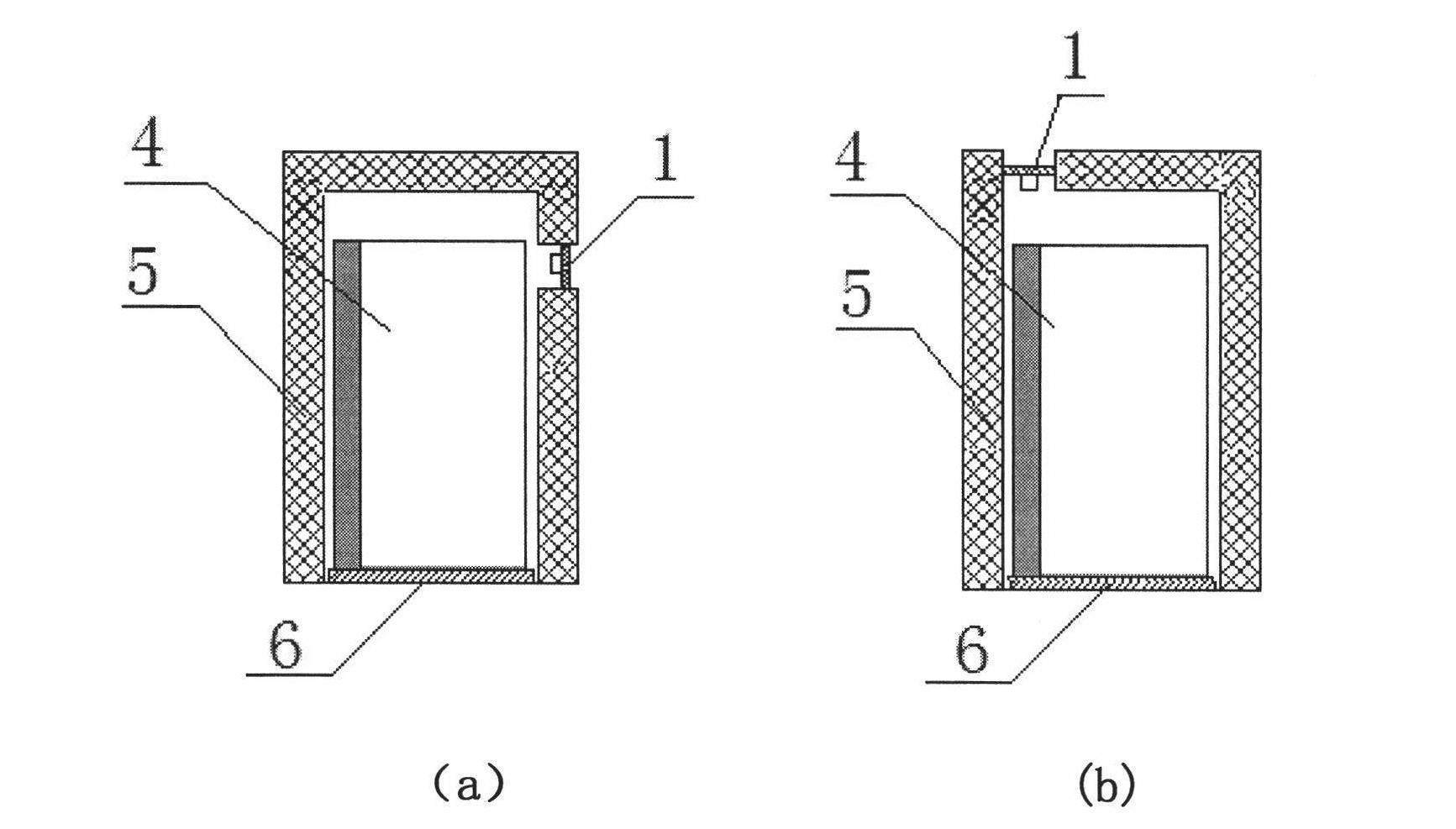

Front-view intelligent anti-glare device of vehicle and manufacturing method of anti-glare mirror thereof

ActiveCN103909868AControl detectionControl Auto SwitchNon-linear opticsOptical viewingEngineeringLight sensing

The invention relates to a front-view intelligent anti-glare device of a vehicle and a manufacturing method of an anti-glare mirror thereof. The front-view intelligent anti-glare device of the vehicle is provided with a control device installed in the support and the anti-glare mirror. The output end of the control device is connected with the input end of the anti-glare device. The control device is provided with an MCU microprocessor, a light sensor, a power supply module and a power supply output control module. The light sensor is provided with a casing and a light sensing mechanism arranged in the casing. The light sensing mechanism is provided with a glare sensor and an environment light sensor. The input end of the MCU microprocessor is respectively connected with the output end of the environment light sensor, the output end of the glare sensor and the output end of the power supply module, and the output end of the MCU microprocessor is connected with the input end of a power supply control module. The output end of the power supply control module is used for being connected with the input end of the anti-glare mirror through an electrode. A monomer molecular coating is added for the anti-glare mirror. The front-view intelligent anti-glare device senses the intensity through the light sensor, the MCU microprocessor receives, processes and sends signals to eliminate glare influence, and the running safety is ensured.

Owner:CHANGZHOU YAPU NEW MATERIALS CO LTD

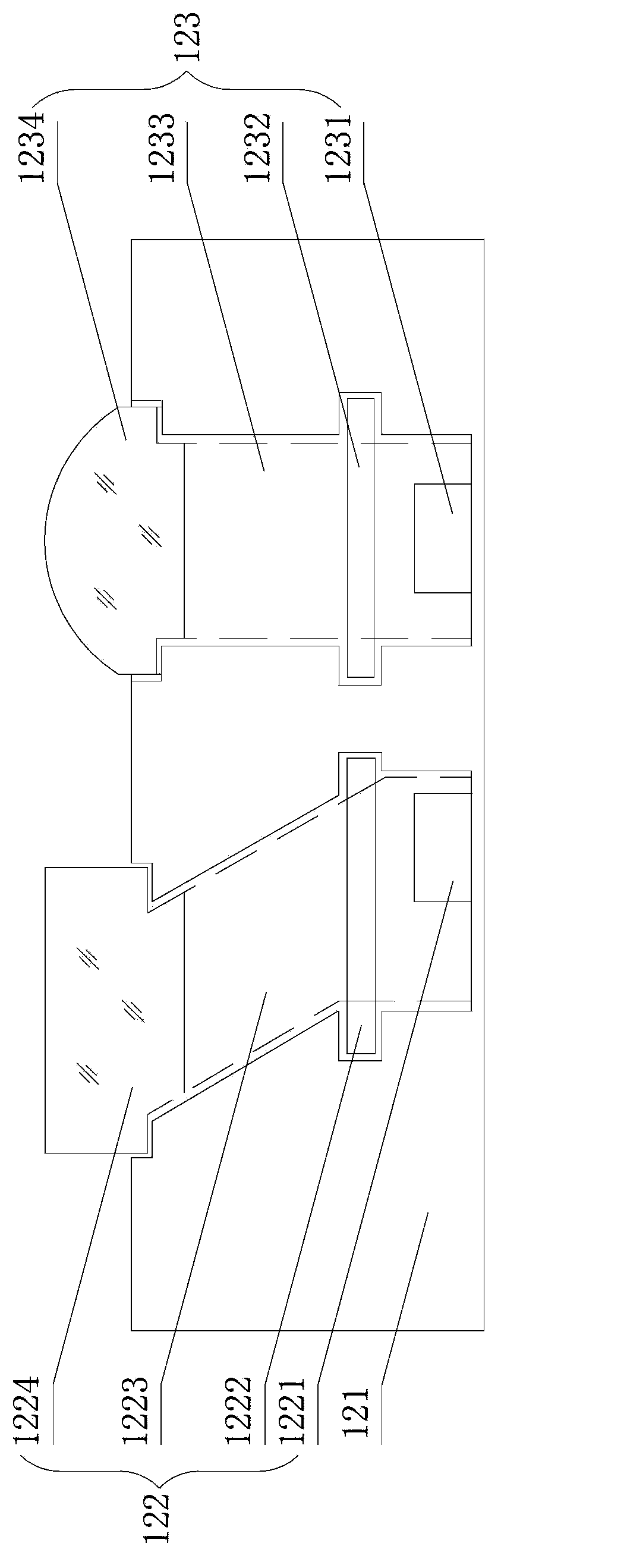

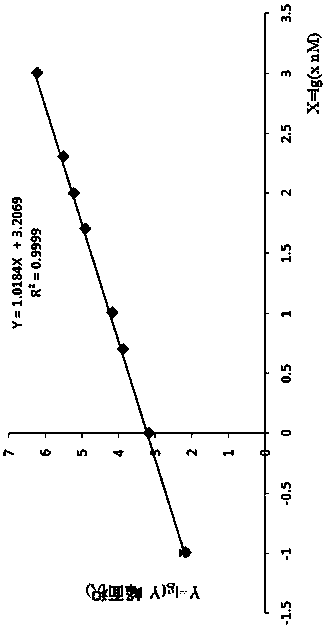

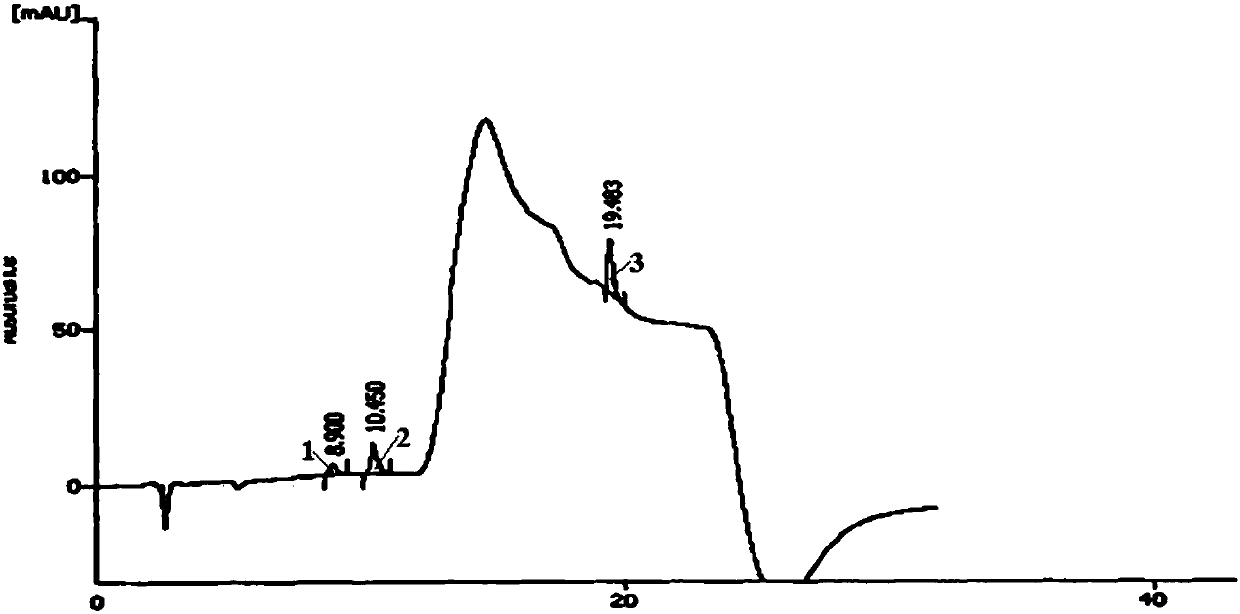

Method for detecting fish parvalbumin through liquid chromatography tandem mass spectrometry

ActiveCN108469495AEliminate the effects of detectionHigh purityComponent separationGas chromatography–mass spectrometryPeak area

The invention provides a method for detecting fish parvalbumin through liquid chromatography tandem mass spectrometry. The method comprises the following steps: step 1: choosing a characteristic peptide fragment; step 2: making a standard curve: taking the concentration value of a quantitative peptide fragment standard product as the x-coordinate and a quantitative daughter ion peak area as the y-coordinate to draw the standard curve, and obtaining an equation; step 3: processing and implementing enzymolysis on a to-be-detected fish meat sample to obtain a liquid supernatant, implementing HPLC-MRM-MS / MS detection on the liquid supernatant, obtaining the daughter ion peak area of the quantitative peptide fragment in the fish meat sample, resolving the concentration of the quantitative peptide fragment in the sample, and further obtaining the concentration of the parvalbumin in the sample. The invention aims at establishing a liquid chromatography tandem mass spectrometry method, and themethod has the advantages of accuracy, precision, sensitivity and the like.

Owner:OCEAN UNIV OF CHINA

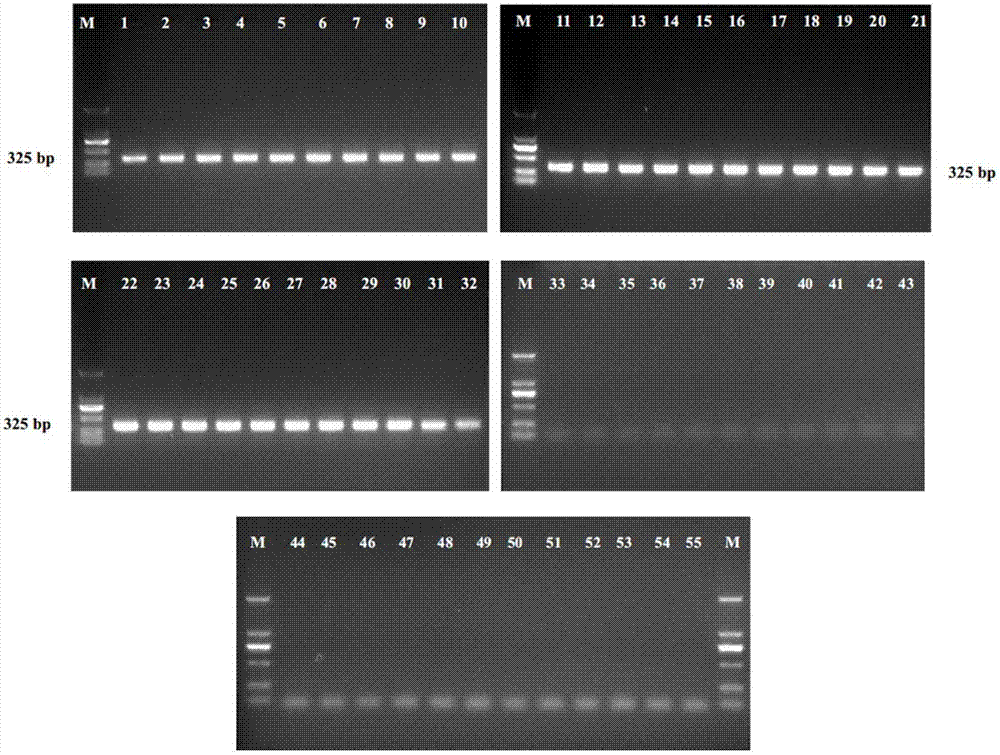

Highly specific gene fragment of Cronobacter spp. and its application

ActiveCN102816761AGood specificityHigh specificityMicrobiological testing/measurementAgainst vector-borne diseasesPolymerase chain reactionBase sequence

The invention relates to a Cronobacter spp. 16S rDNA gene based sequence, and also provides a method for specific detection of Cronobacter spp. by combining magnetic beads and a nested PCR (polymerase chain reaction) technology. The advantage of the invention lies in that: a specific probe and primers of the Cronobacter spp. 16S rDNA gene sequence are utilized, and magnetic beads are combined to conduct rapid and specific capture and enrichment of a Cronobacter spp. target gene in a sample, finally amplification detection is performed through the nested PCR technology, and the detection sensitivity is improved.

Owner:WUXI ZODOLABS BIOTECH

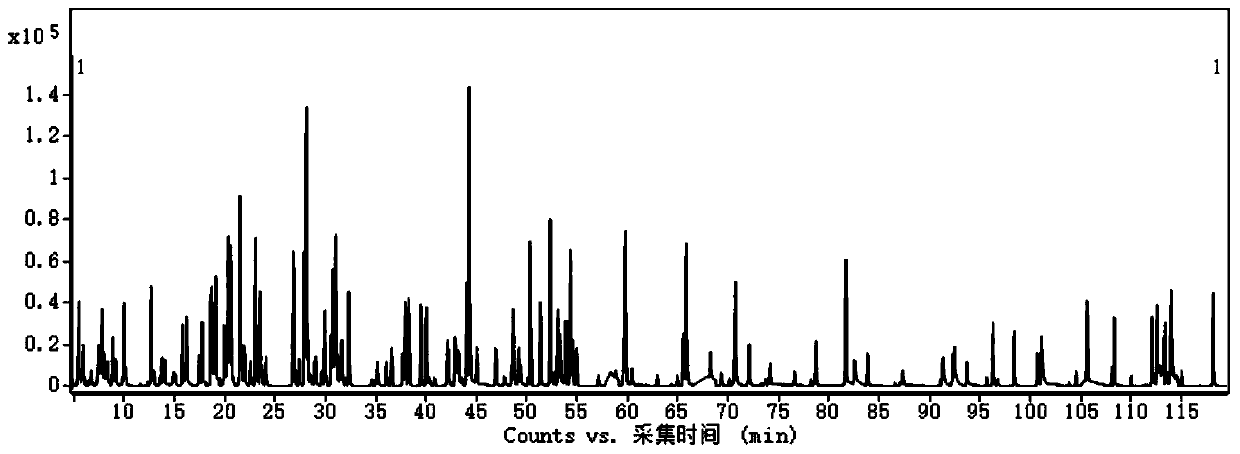

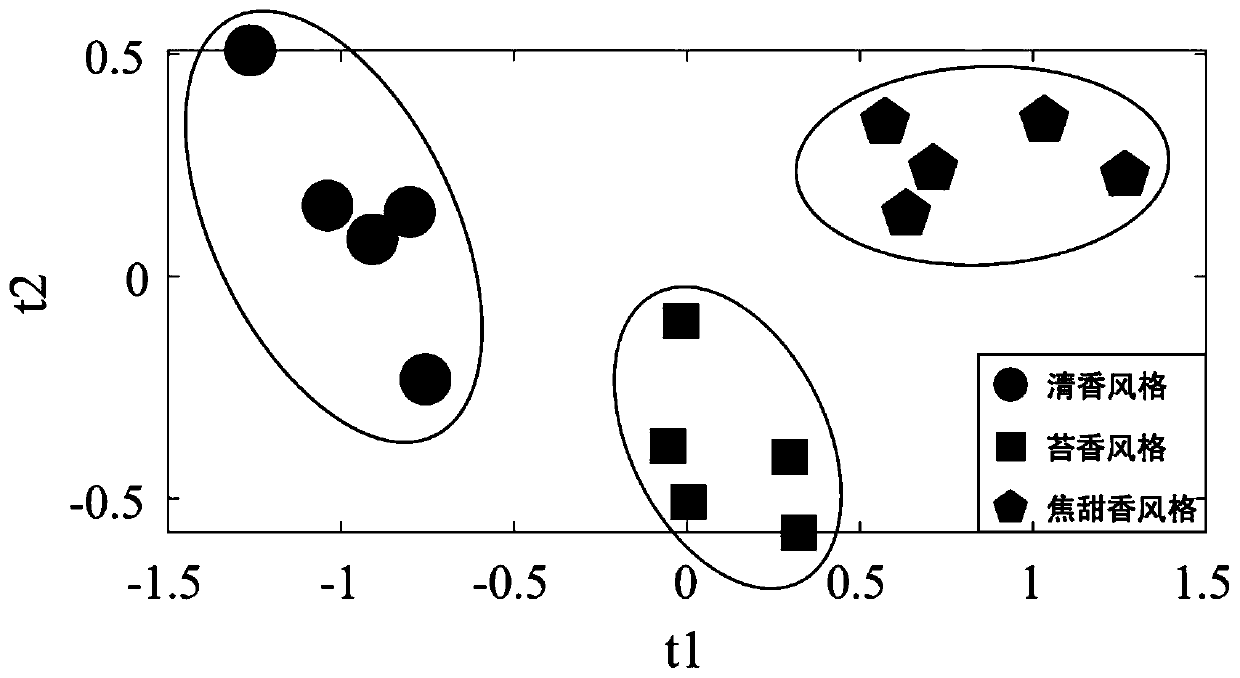

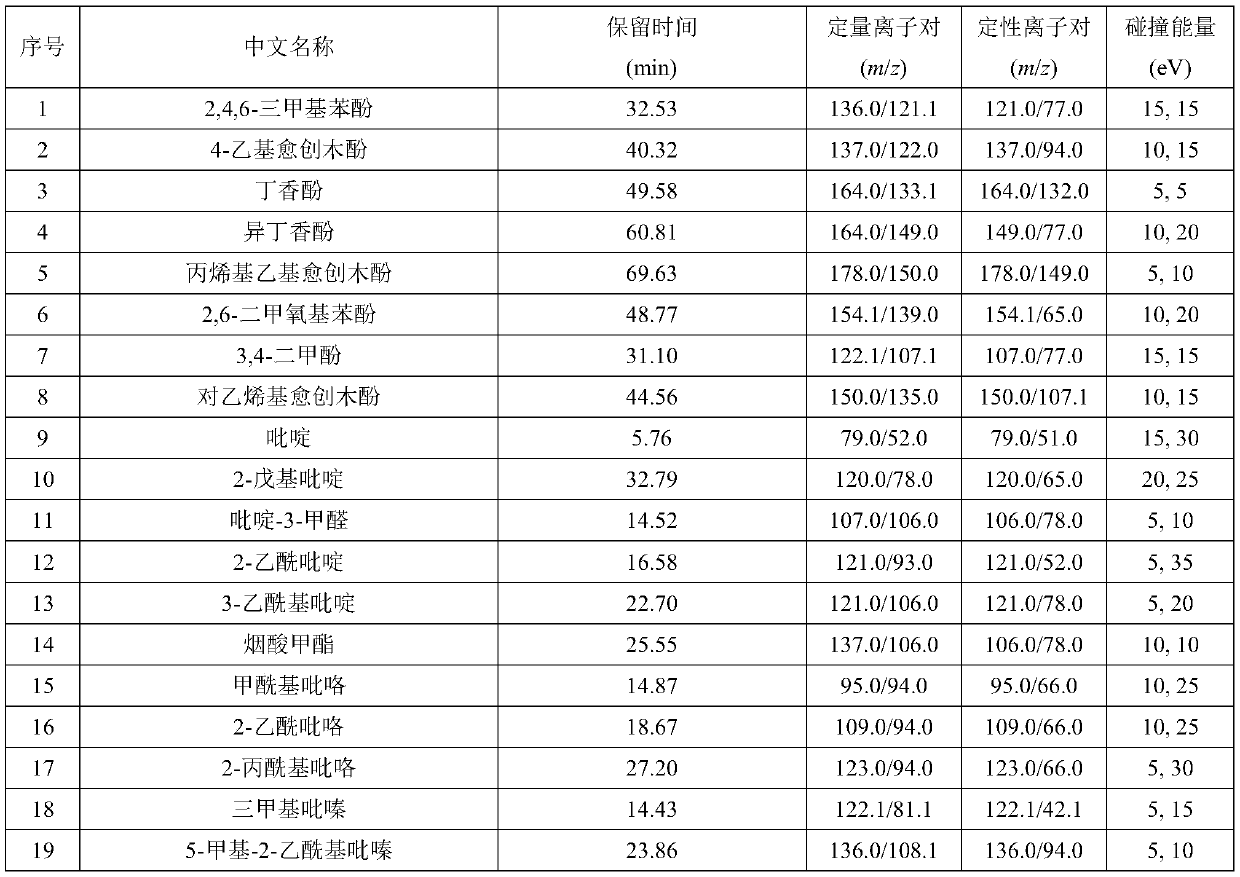

Analytical method for quantitatively measuring super-multi-target aroma components in tobacco

The invention, which belongs to the technical field of tobacco component detection, relates to an analytical method for quantitatively measuring super-multi-target aroma components in tobacco. The method comprises the following steps that: a tobacco sample is immersed in an acidic buffer solution and extraction is performed by an organic solvent; a multi-walled carbon nanotube is used as a reversesolid phase-dispersed adsorbent and vortexing and centrifugation are performed to purify the sample; and then simultaneous detection of 345 kinds of aroma component in tobacco is realized by combining gas chromatography-tandem mass spectrometry. The method has advantages of simple and rapid operation, high flux, low cost, low solvent dosage, good environmental friendly effect, wide range of analytical compounds, high accuracy, high precision, high sensitivity and high repeatability and can satisfy the demand of rapid detection and analysis of aroma component in tobacco.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for determining water-soluble protein content of soybean by near-infrared spectroscopy

PendingCN110018134AAvoid measurement errorsThe measured value is accurateSamplingMaterial analysis by optical meansWater solublePre treatment

The invention provides a method for determining water-soluble protein content of soybean by near-infrared spectroscopy, and relates to the technical field of near-infrared spectroscopy detection. Themethod provided by the invention comprises the following steps of removing seed coat of the soybean to be determined, and scanning the peeled soybean with a near-infrared spectrometer to obtain an original spectrum; and bringing the original spectrum into a soybean water-soluble protein content prediction model to obtain the water-soluble protein content of the soybean, wherein the soybean water-soluble protein content prediction model is constructed by performing seed coat removal, degreasing and chemical determination on the soybean, pre-treating the original spectrum by various methods, comparing the measured value with the predicted value, and evaluating the quantitative analysis model obtained by a PLS regression method, thereby improving the accuracy of the prediction model of the water-soluble protein content of the soybean. The method provided by the invention solves the measurement error caused by color difference of the seed coats, and removes the effect of the fat particleson the water-soluble protein by first degreasing the peeled soybean when constructing a prediction model of the water-soluble protein content of the soybean to further obtain a more accurate prediction model.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI +1

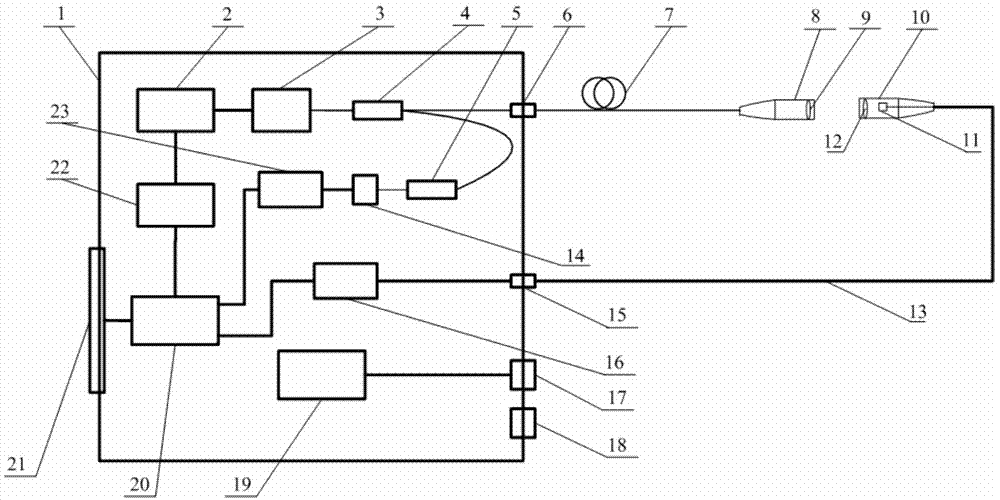

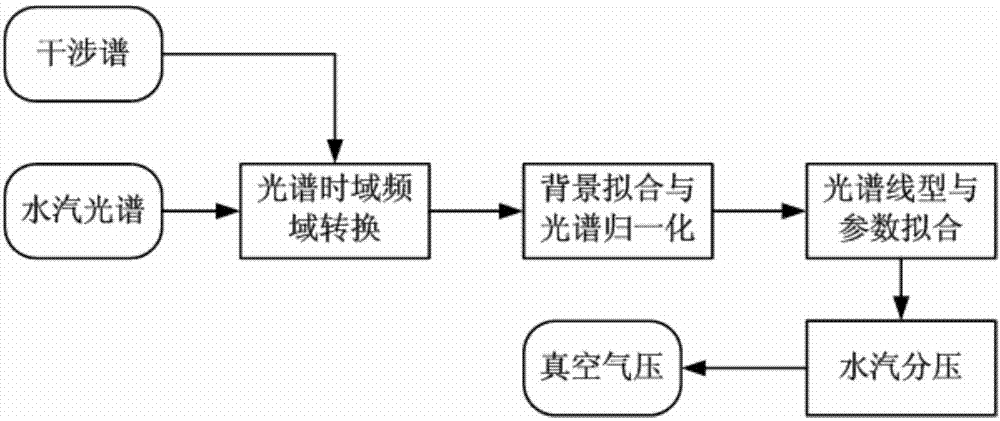

Vacuum degree detection method and system based on infrared laser spectrum

ActiveCN104848985AQuick checkAchieve separationMeasurement of fluid loss/gain rateVacuum gaugesSteam pressureDoppler broadening

The invention discloses a vacuum degree detection method and system based on an infrared laser spectrum. By use of the high-resolution absorption line broadening characteristic of adsorption steam released by the headspace of a sealing container, through double-optical-path detection, by use of synchronization interference fringe signals, the time domain of a detection spectrum is converted to a frequency domain, the absolute value of spectral line broadening is obtained, and absolute measurement of a gas pressure intensity is realized; light intensity information is obtained by use of a background fitting algorithm, and the influence of the change of the transmittance of the container on detection is eliminated through normalization processing; rapid fitting is performed on a steam absorption line by use of a composite linear model, and Doppler-broadening and pressure broadening of the spectral line broadening are separated from each other; and through synchronous measurement of steam pressure dividing, the precision of vacuum air pressure measurement is improved. The method and system provided by the invention can be applied to vacuum degree detection of a vacuum sealing container in foodstuff and medical industries and realize rapid leak detection.

Owner:黄山市开发投资集团有限公司

C-reactive protein magnetic particle detection kit and use method thereof

PendingCN107656043AHigh sensitivityImprove featuresChemiluminescene/bioluminescenceBiological testingReagent stripWorking fluid

The invention discloses a C-reactive protein detection kit and a use method thereof. The kit comprises a reagent strip composed of a plurality of hole sites arranged side by side, and reagents in thereagent strip contain a CRP magnetic bead working solution and a CRP acridinium ester-labeled working solution; and the kit further comprises a calibrating substance, a pre-excitation solution, an excitation solution and a magnetic bead cleaning solution, and a magnetic rod sleeve is arranged in one of the hole sites on the reagent strip. The C-reactive protein detection kit and the use method thereof are based on a chemiluminescence immunoassay technique, and has the advantages of improvement of the sensitivity, the specificity and the precision of C-reactive protein detection, realization ofadaptation of detection to many sample types, and maximal elimination of the influences of sample differences on the detection.

Owner:SUZHOU SYM BIO LIFESCI CO LTD

Metal pipeline defect detection technology based on variable-frequency alternating-current potential fall method

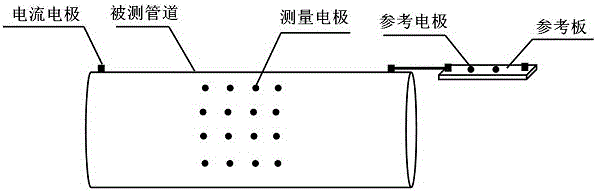

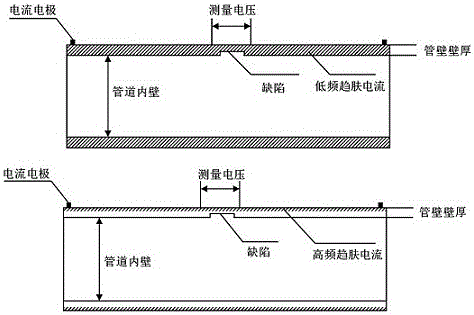

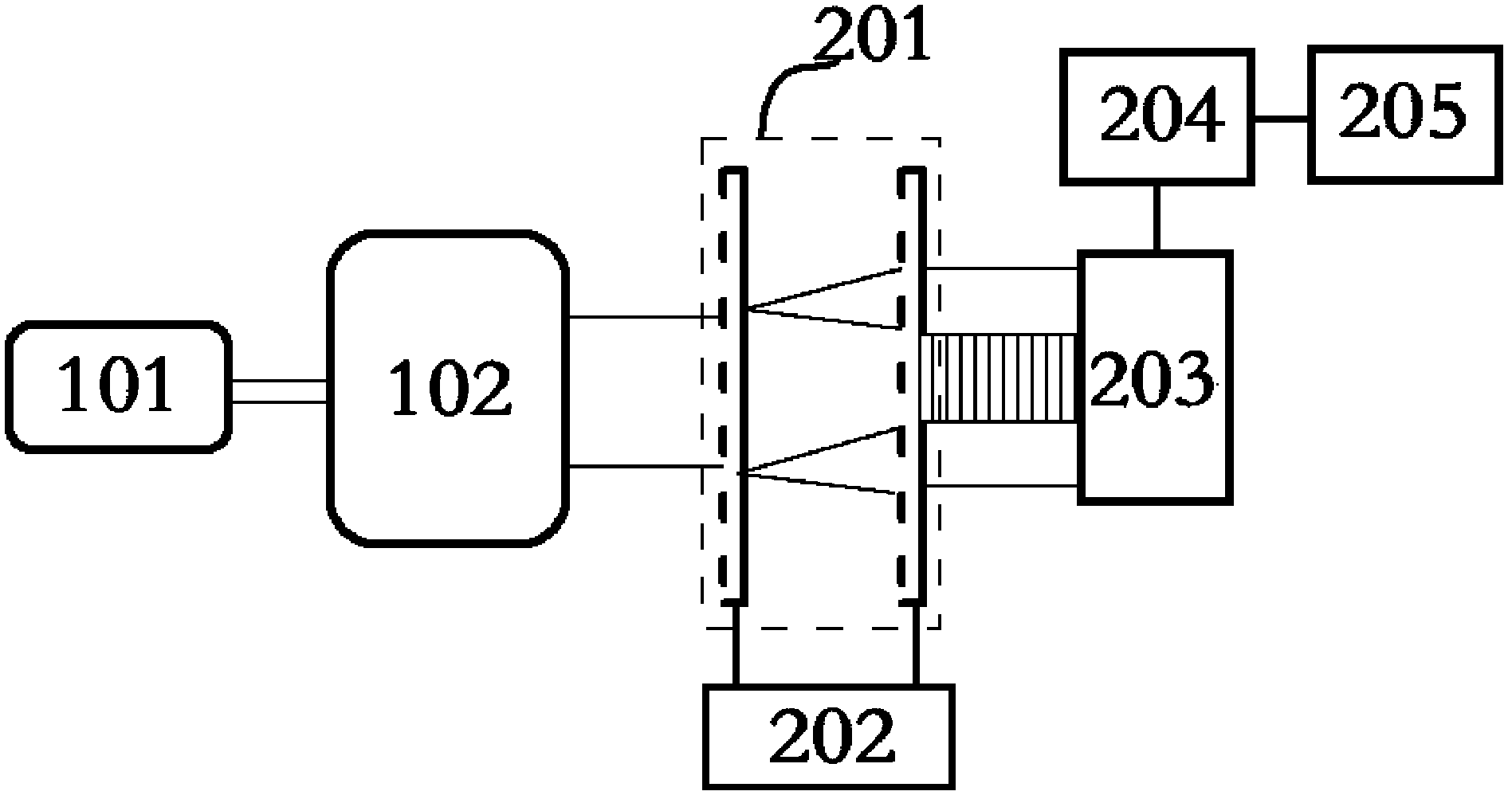

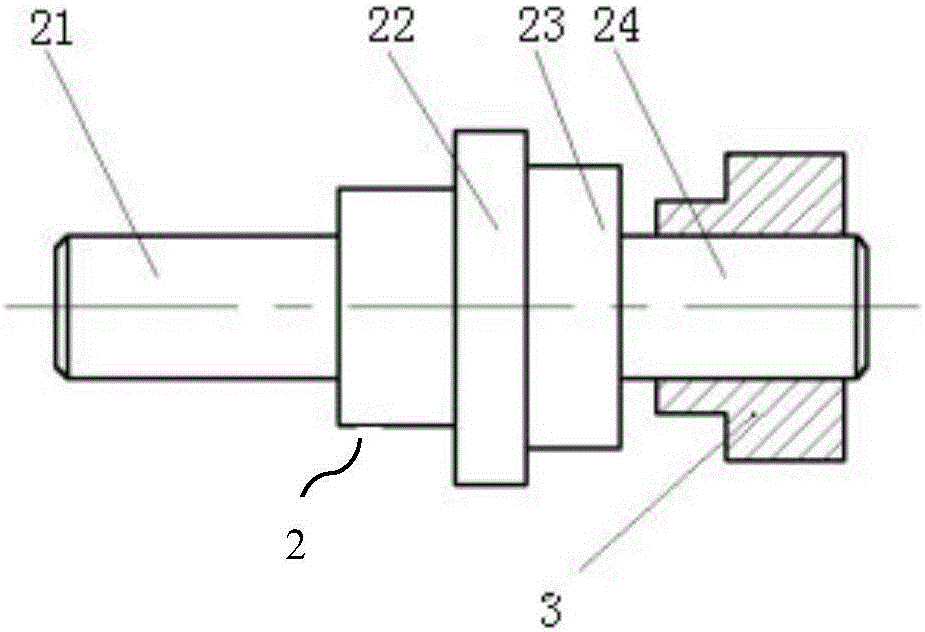

InactiveCN106501318AImprove reliabilityEliminate measurement errorsMaterial analysis by electric/magnetic meansPhysicsNondestructive testing

The invention discloses metal pipeline defect detection technology based on a variable-frequency alternating-current potential fall method and belongs to the technical field of nondestructive detection. Excitation current electrodes (1) are mounted at two ends of a to-be-detected area of a detected metal pipeline (3), measuring electrodes (2) are mounted in the to-be-detected area, and alternating-current excitation currents different in frequency are applied to the detected pipeline (3) through the excitation current electrodes (1); due to existence of skin effect, when the excitation currents are high in frequency, a skin current (4) only exists in a shallow layer close to the outer wall of the metal pipeline and will exist in the whole wall of the metal pipeline along with frequency lowering; existence of a defect (5) may influence distribution of the skin current (4), and influences amplitude of voltage among the measuring electrodes (2) in other words, and depth information of the detect can be acquired through differential deviation of the voltage. By the technology, measuring of original voltage, reference voltage and original wall thickness is not needed, and influence on measuring caused by system drift and errors in measuring the original wall thickness can be effectively overcome.

Owner:SICHUAN UNIV

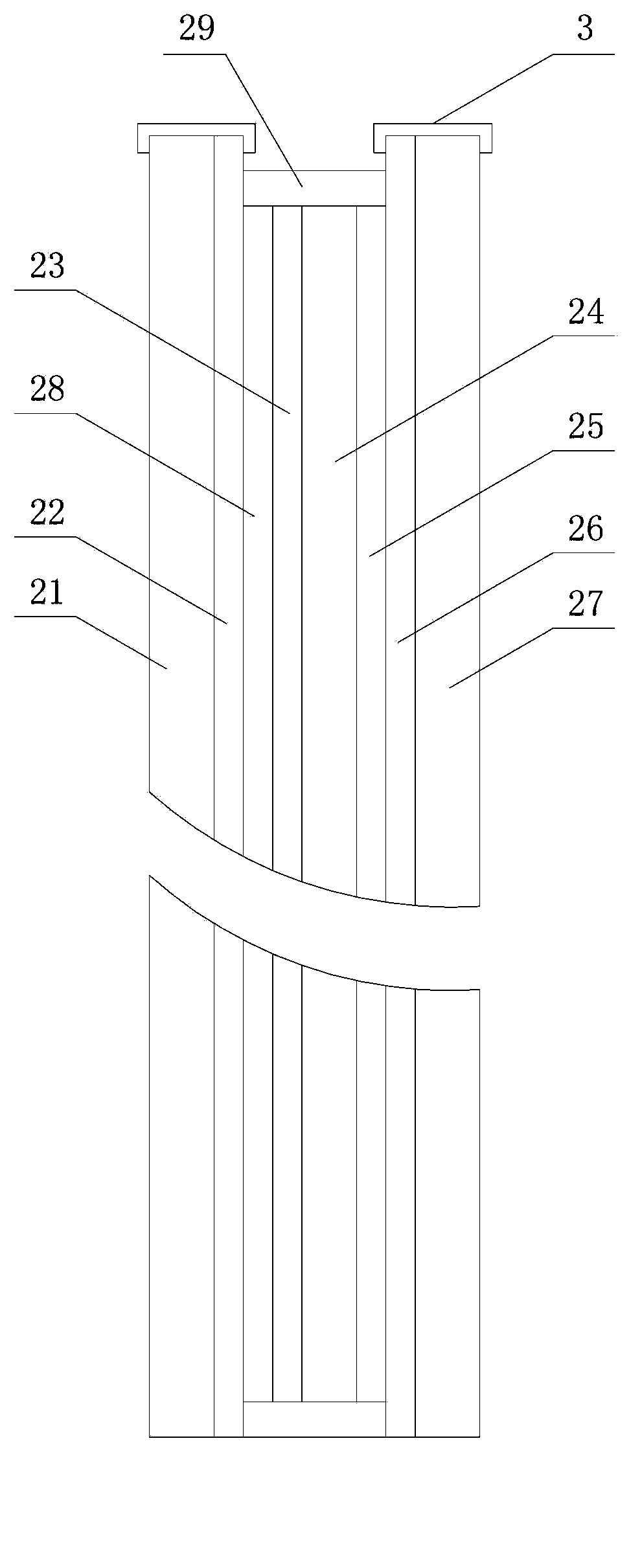

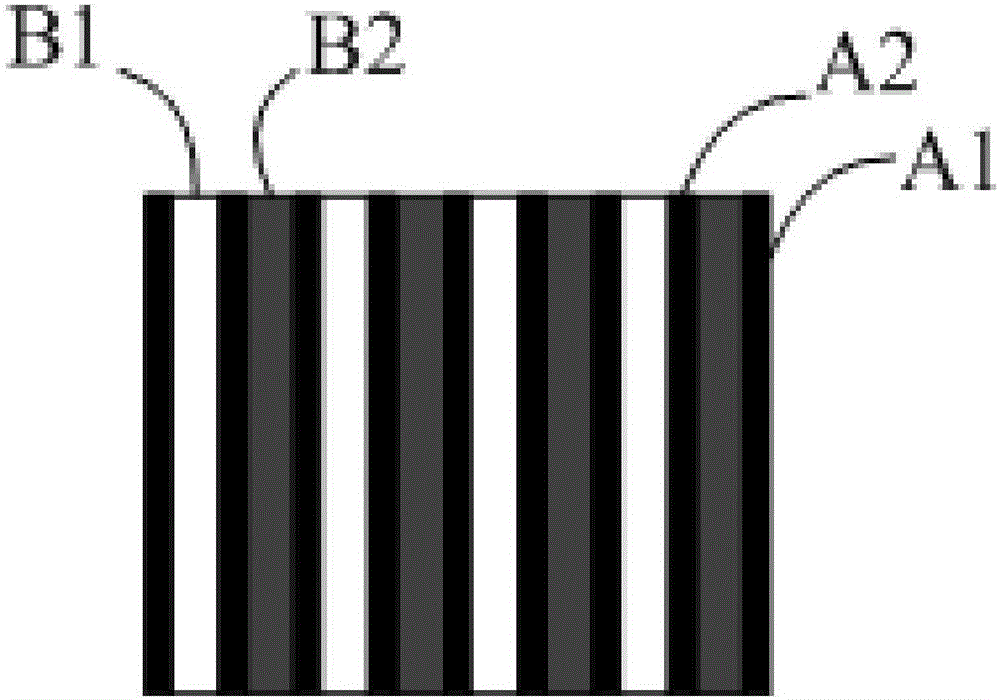

Wavefront aberration detection device and method for beam expansion and collimation system

ActiveCN102252765AEliminate the effects of detectionImprove detection accuracyOptical measurementsPhase gratingLight beam

The invention provides a wavefront aberration detection device and a wavefront aberration detection method for a beam expansion and collimation system. The detection device comprises a shearing unit, an adjustment unit, a photoelectric detection unit, a storage unit and a signal processing unit; the shearing unit and the photoelectric detection unit are arranged on an optical path of an outgoing beam of the beam expansion and collimation system sequentially; the shearing unit is positioned between the beam expansion and collimation system and the photoelectric detection unit; the shearing unit comprises a one-dimensional phase grating A and a one-dimensional phase grating B and is used for shearing incident optical waves; the width of a non-light-transmitting part between two adjacent light-transmitting parts of the two one-dimensional phase gratings is p / 6; the width of the light-transmitting parts is p / 3, and p is the cycle of the one-dimensional phase grating; and the p is set to be more than or equal to 16 beta, and beta is the pixel size of the photoelectric detection unit. The device can eliminate the influence of + / -3 grade or + / 3 multiple grade of diffraction light and the energy of the formed interference beam waves is mainly concentrated in + / -1 grade of diffraction beam waves and the influence of other multiple grade of diffraction beam waves on the wavefront aberration is eliminated, so that the detection accuracy is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

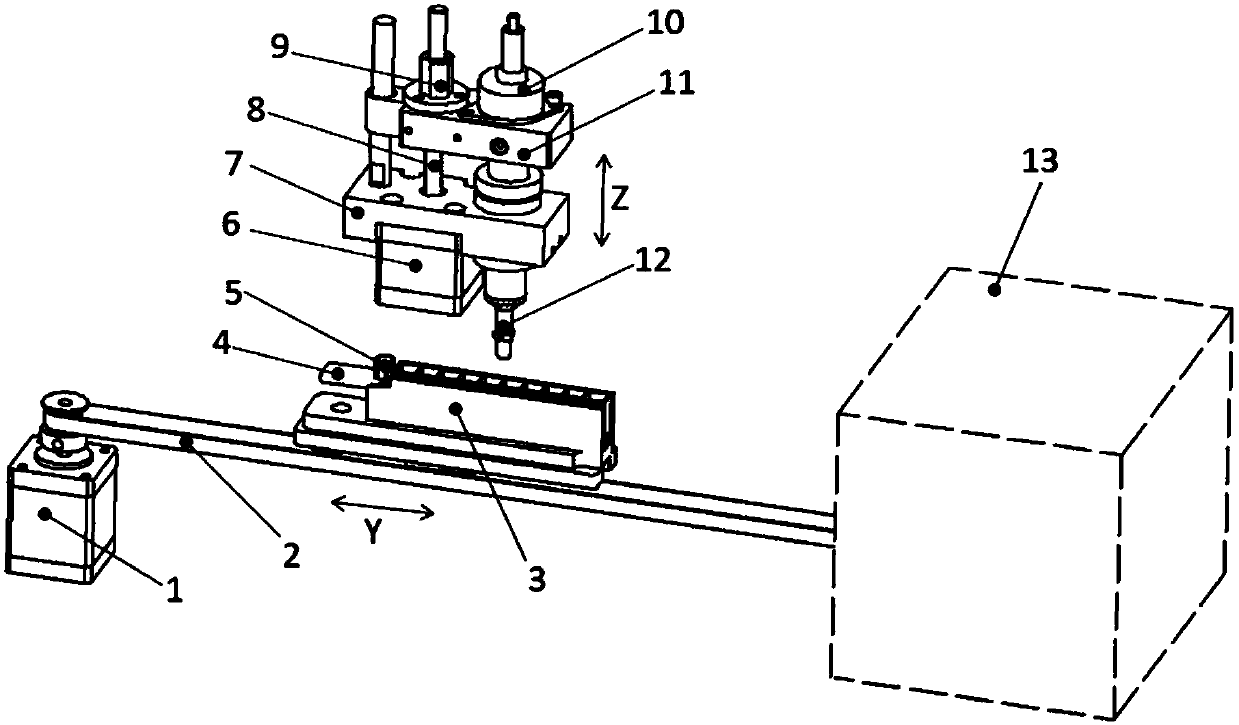

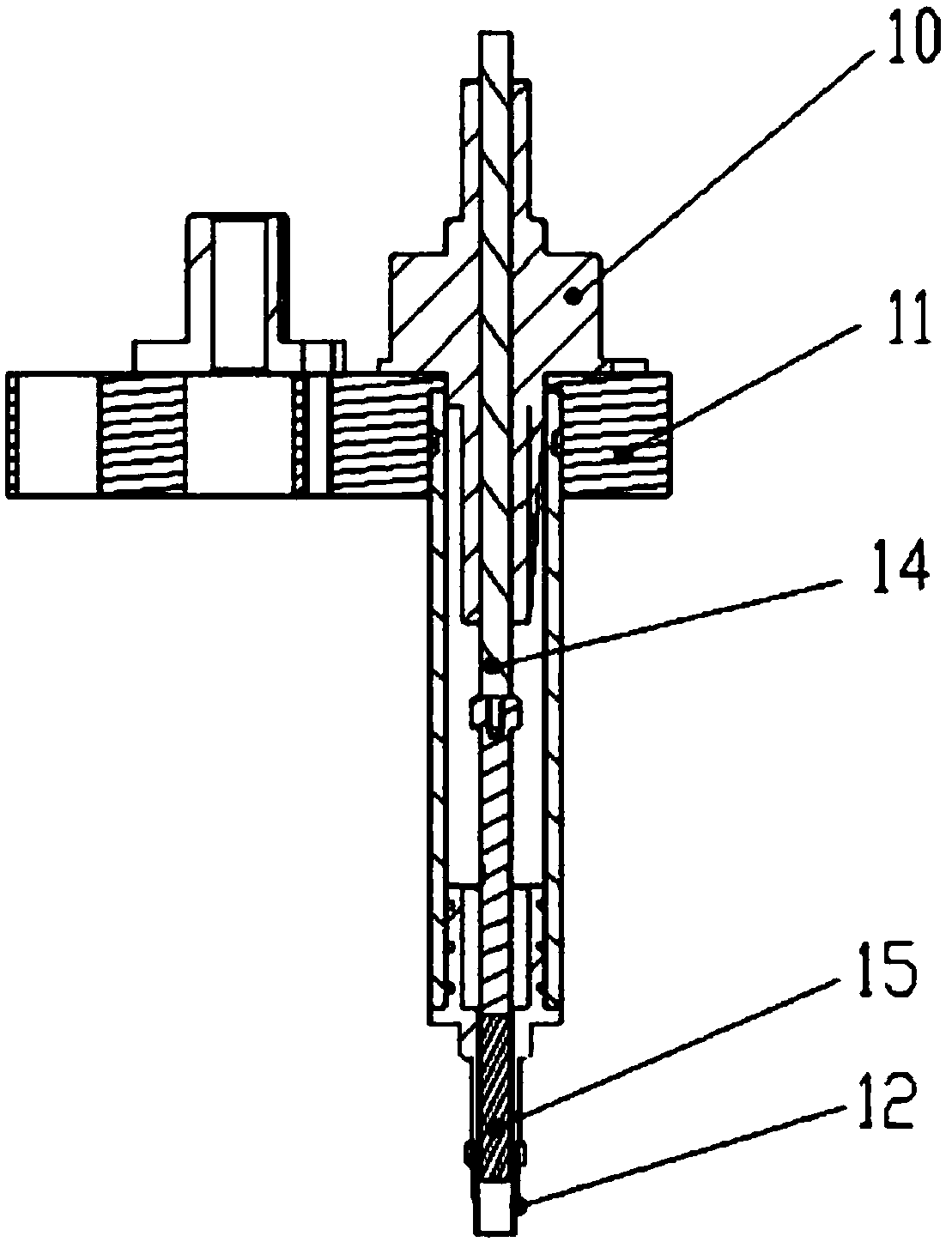

Centering measurement apparatus for measuring center distance of two intersecting holes in intersecting hole system

ActiveCN105841587AEliminate machining errorsEliminate the effects of detectionMechanical clearance measurementsEngineeringCam

The invention discloses a centering measurement apparatus for measuring the center distance of two intersecting holes in an intersecting hole system. The centering measurement apparatus comprises a two-hole positioning and centering device including an elastic centering expanding sleeve, a centering pull bar, a centering pressure bar, an eccentric wheel compacting mechanism and a positioning pin, a variable-pitch cam mechanism including a handle, a servo-actuated eccentric cam, a bearing positioning circular section and a cooperative column, and an auxiliary centering mechanism, wherein the two-hole positioning and centering device is inserted in a first hole system of a part to be measured, the eccentric wheel compacting mechanism is rotated to move the centering pull bar and centering pressure bar and open the elastic centering expanding sleeve to center the first hole system, and the variable-pitch cam mechanism and the auxiliary centering mechanism are inserted in two sides of a second hole system of the part to be measured. The handle is rotated to drive the cam to rotate, so that the rim of the cam is tangent to the excircle of the elastic centering expanding sleeve, and angle scales corresponding to different center distances of the first hole system and the second hole system are radially marked on the end face of the servo-actuated eccentric cam. The actual center distance of the intersecting holes of the part to be measured can be rapidly obtained by observing the angle graduation lines, and rapid and accurate measurement is realized.

Owner:CHONGQING JIANSHE IND GRP

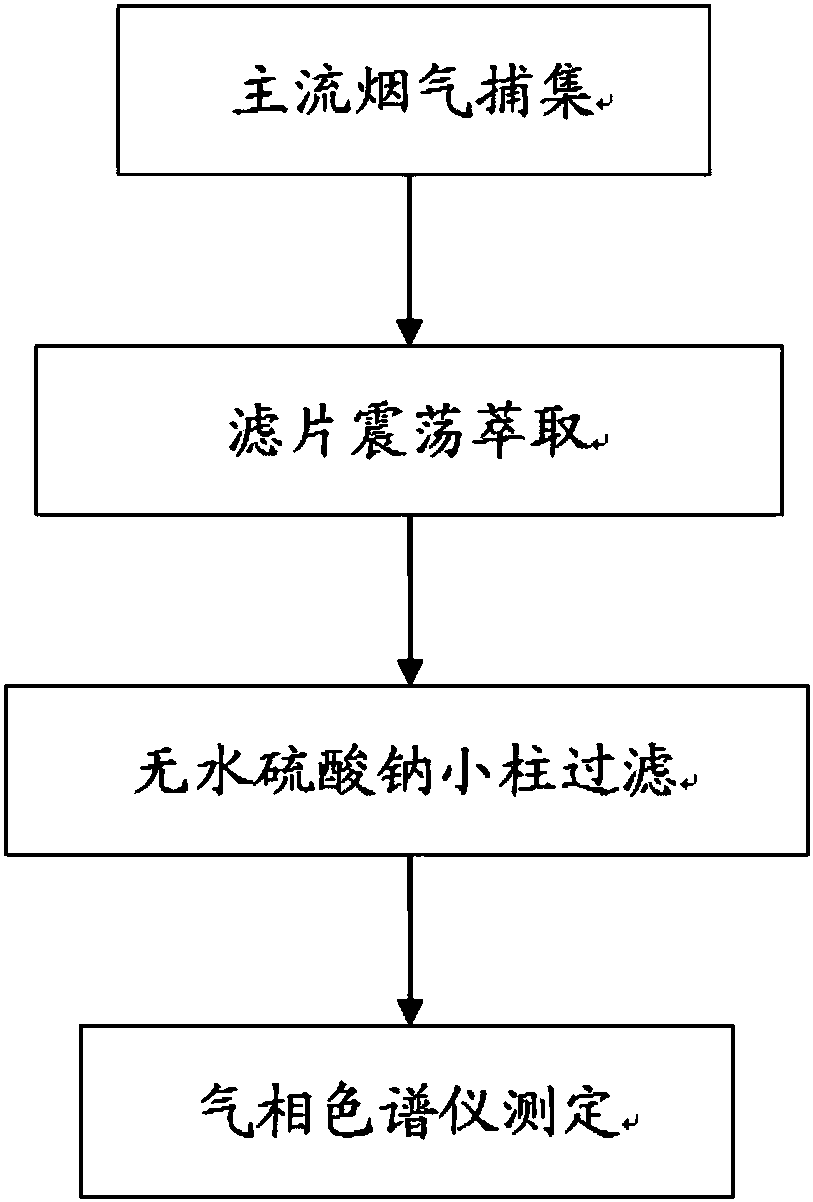

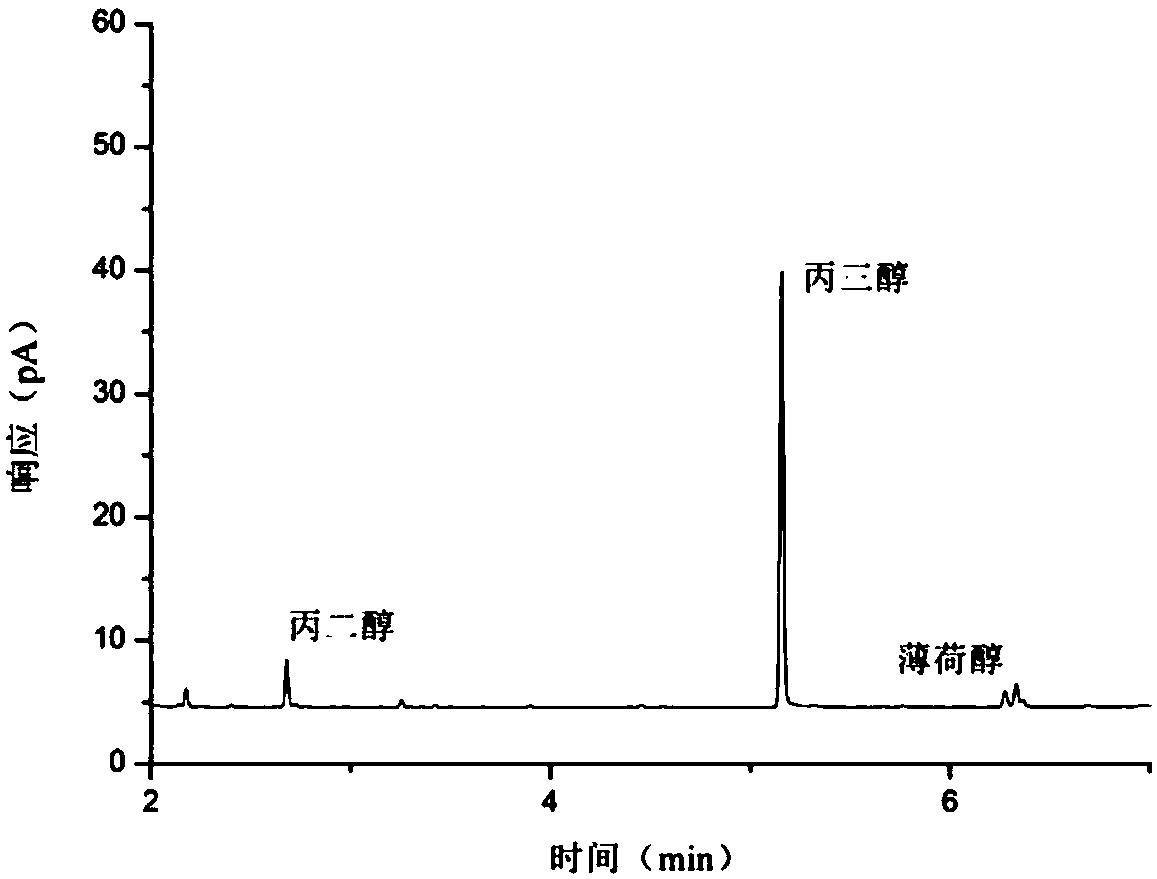

Detection method of alcohols and other compounds in mainstream smoke of heat-not-burn cigarettes

ActiveCN108303477AImprove efficiency and accuracyImprove detection efficiencyComponent separationPHENOL LIQUIDChemistry

The invention provides a detection method of alcohol compounds (1,2-propylene glycol, glycerol and menthol), phenols and free nicotine in mainstream smoke of heat-not-burn cigarettes. The detection method comprises the following steps: (1) preparing a test sample solution, including capturing the alcohol compounds in the mainstream smoke of the heat-not-burn cigarettes by using a filter; (2) preparing a standard solution; (3) measuring the content of the alcohol compounds in the mainstream smoke of the heat-not-burn cigarettes with gas chromatography under the conditions that a chromatographiccolumn and a CP-1301 silica gel column capillary column are included. The content of the main alcohol compounds (1,2-propylene glycol, glycerol and menthol), phenols and free nicotine in the mainstream smoke of the heat-not-burn cigarettes can be detected accurately, efficiently and environmentally friendly with the method.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

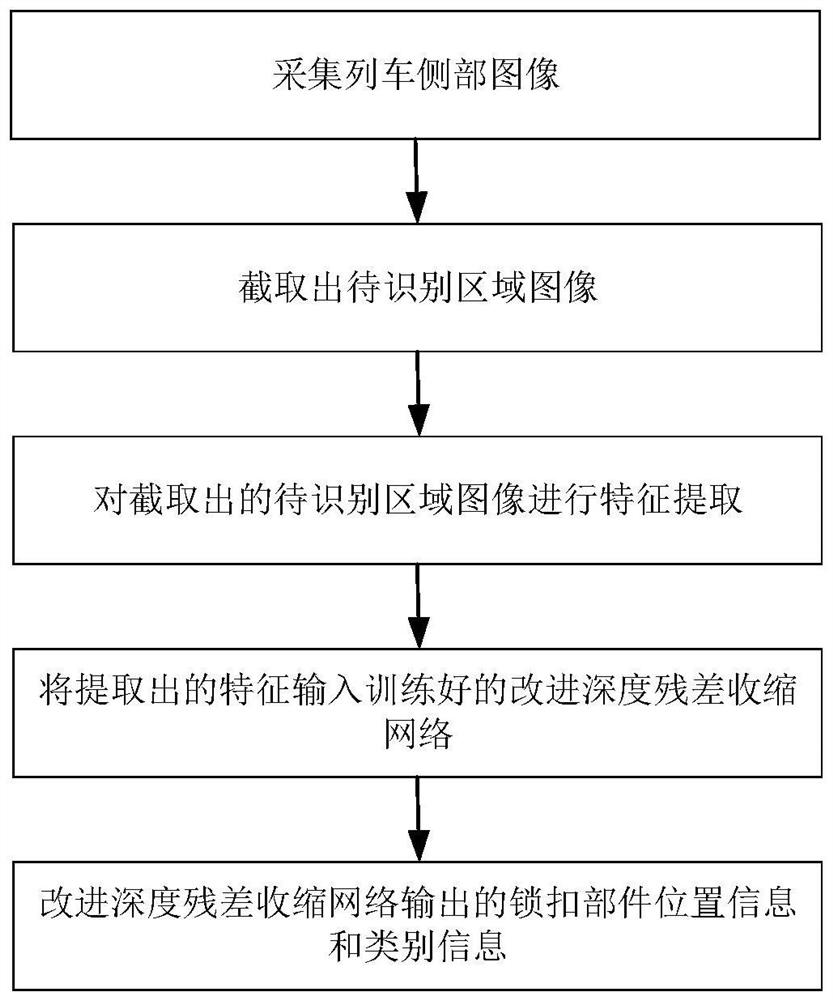

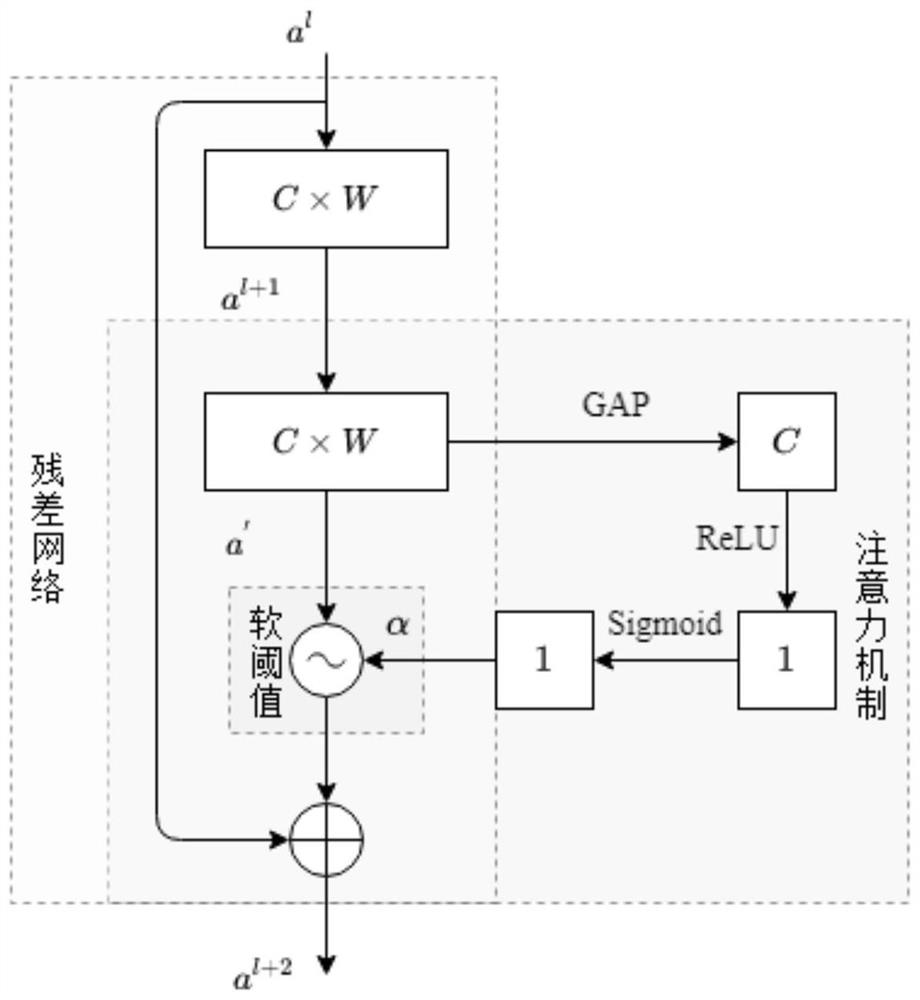

Lock catch loss fault detection method, system and device

ActiveCN112508013AReduce manual inspection costsImprove stabilityCharacter and pattern recognitionNeural architecturesFeature extractionSimulation

The invention discloses a lock catch loss fault detection method, system and device, and belongs to the technical field of train lock catch loss fault detection. According to the invention, the problems of low detection accuracy and low detection efficiency when the lock catch loss fault is detected in a manual image checking mode are solved. The method is specifically realized through the following steps: collecting a complete image of the side part of a train, and intercepting a to-be-identified lock catch part image from the collected complete image of the side part of the train; carrying out feature extraction on the intercepted to-be-identified lock catch part image; inputting the extracted features into the trained improved deep residual shrinkage network, and outputting position information and category information of the lock catch component through the trained improved deep residual shrinkage network. The method can be applied to train lock catch loss fault detection.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Effective image-region detection and segmentation method for iris recognition

ActiveCN101539991BHigh precisionHigh speedCharacter and pattern recognitionDigital data authenticationPurkinje imagesIdentity recognition

Owner:BEIJING IRISKING

Outer diameter measuring device

InactiveCN107543474AAccurately determine eligibilityEliminate the effects of detectionMechanical diameter measurementsMeasurement deviceEngineering

The invention discloses a device for measuring outer diameter, which comprises a base, and is characterized in that a stopper is provided at one end of the base, a raised rib is provided in the middle of the base, and on the base between the stopper and the rib A socket is provided, and two horizontal positioning columns are fixed on the side wall of the block. The rib plate is provided with a horizontal through hole, and a horizontal notch connected with the through hole is provided on one side of the through hole. , the ribs above and below the notch form a pair of splints, a dial gauge is installed in the through hole, the probe of the dial gauge is located on one side of the positioning column, and the two horizontal positioning columns and the probe of the dial gauge are on the circumference The upper and lower ribs are connected by bolts. The invention can eliminate the influence of personnel factors on the detection, and accurately determine whether the product to be tested is qualified.

Owner:内江市帆航制钉有限责任公司

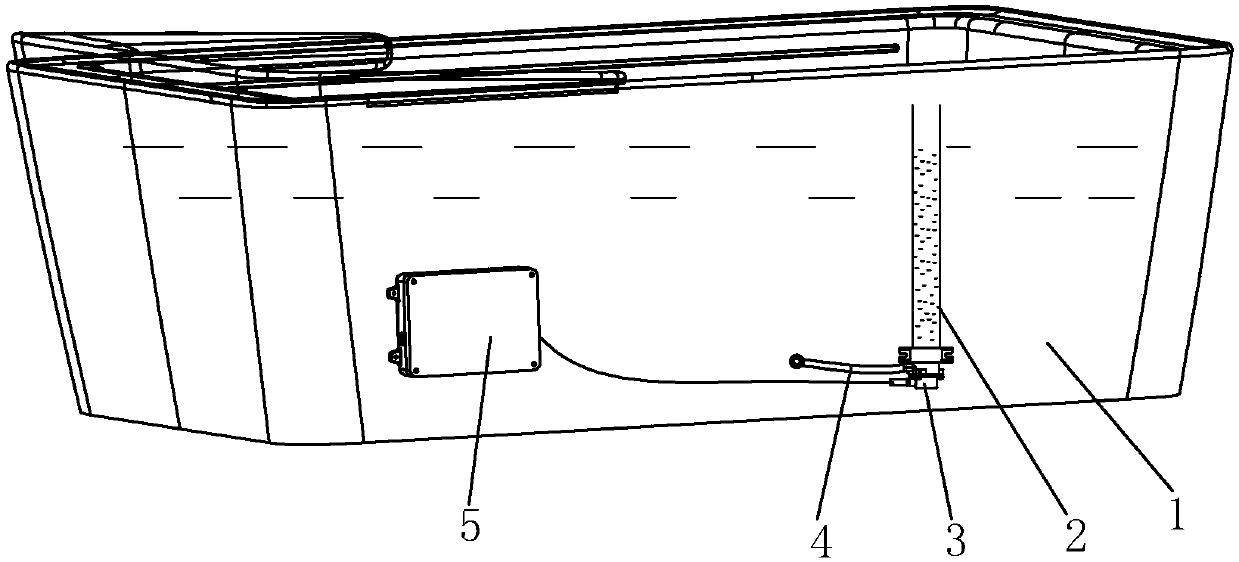

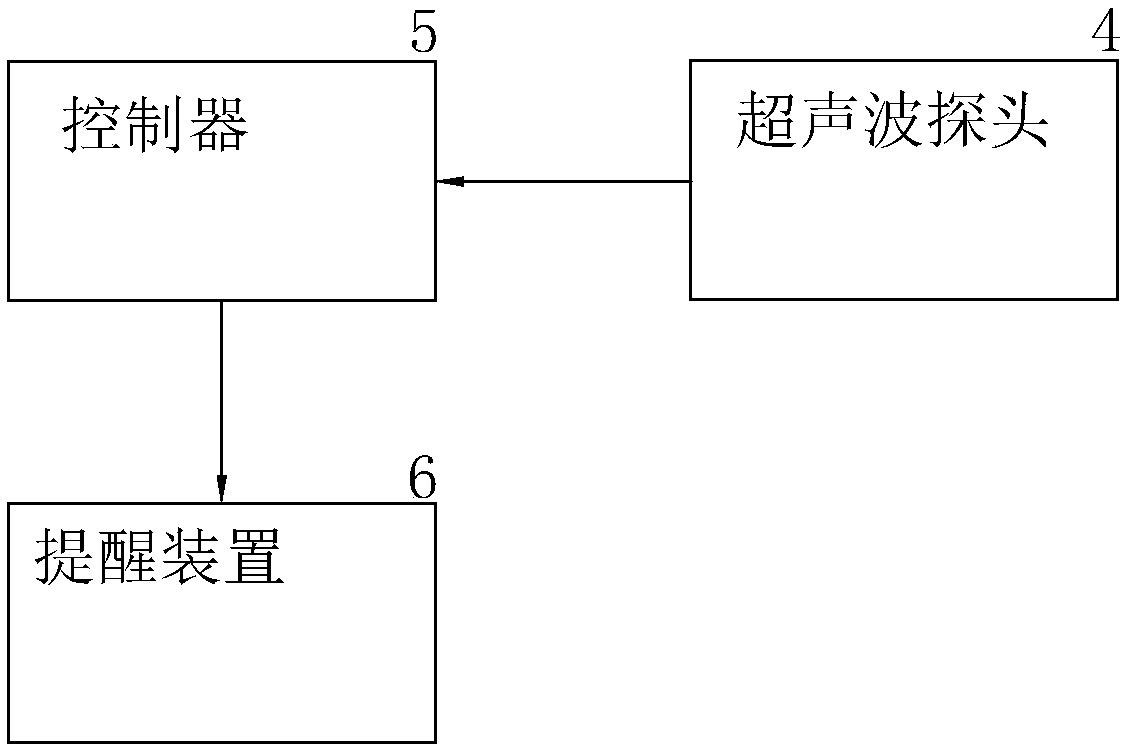

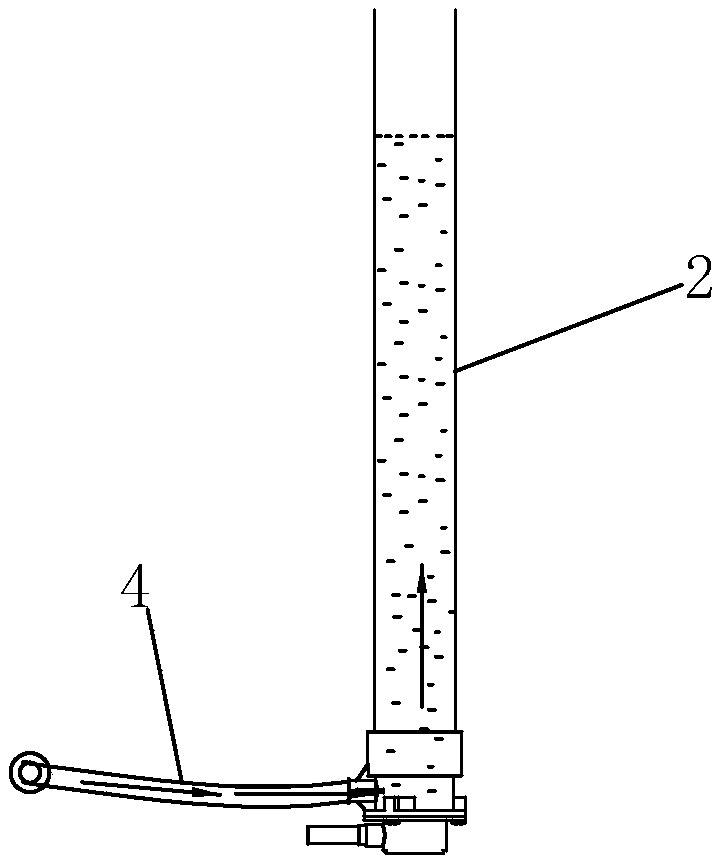

Intelligent bathing device and method for implementing reminding of long bathing time

PendingCN107687881AAvoid dizziness or even faintingPrevent and protect healthMachines/enginesAlarmsEngineeringEmergency medicine

The invention discloses an intelligent bathing device and a method for implementing reminding of long bathing time. The bathing device comprises a bathing device body, a water level detecting device,a controller and a reminding device. The water level detecting device is used for acquiring water level data of the bathing device body; the controller is used for processing water level data, starting timing when a water level data change is larger than a first set value and outputting a control command when timing time is larger than or equal to a second set valve; the reminding device is used for sending reminding signals; an output of the water level detecting device is connected to an input of the controller, and an output of the controller is connected to the reminding device. The intelligent bathing device and the method for implementing reminding of long bathing time have advantages that the water level data of the bathing device body can be acquired in real time, timing is startedwhen the water level data change is larger than the first set value, and the reminding signal is outputted when the timing time is larger than or equal to the second set valve, so that a user can bereminded of long bathing time and protected from feeling dizzy and even passing out due to excessively long bathing time, and prevention and protection of user health can be realized.

Owner:JOMOO KITCHEN & BATHROOM

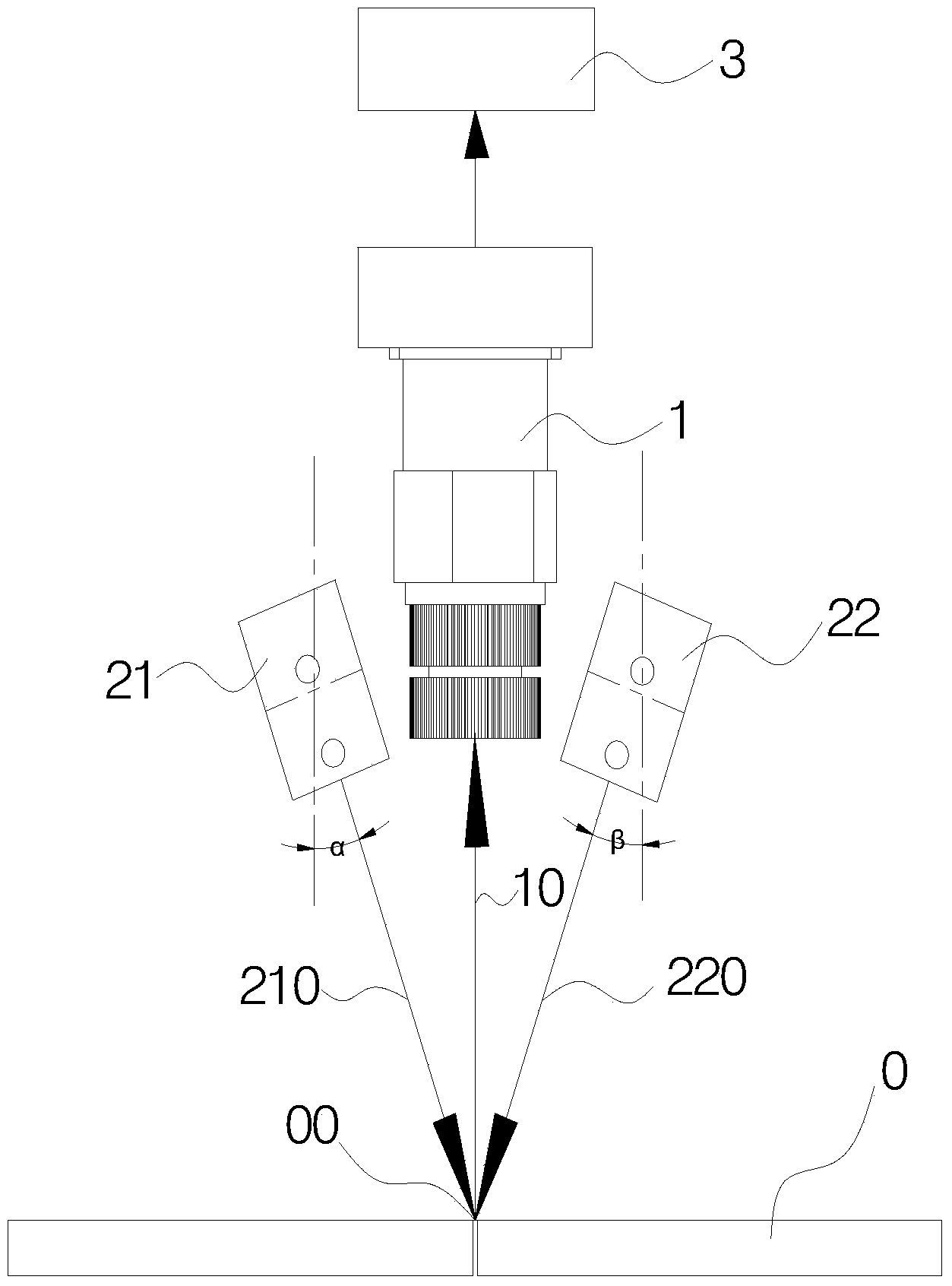

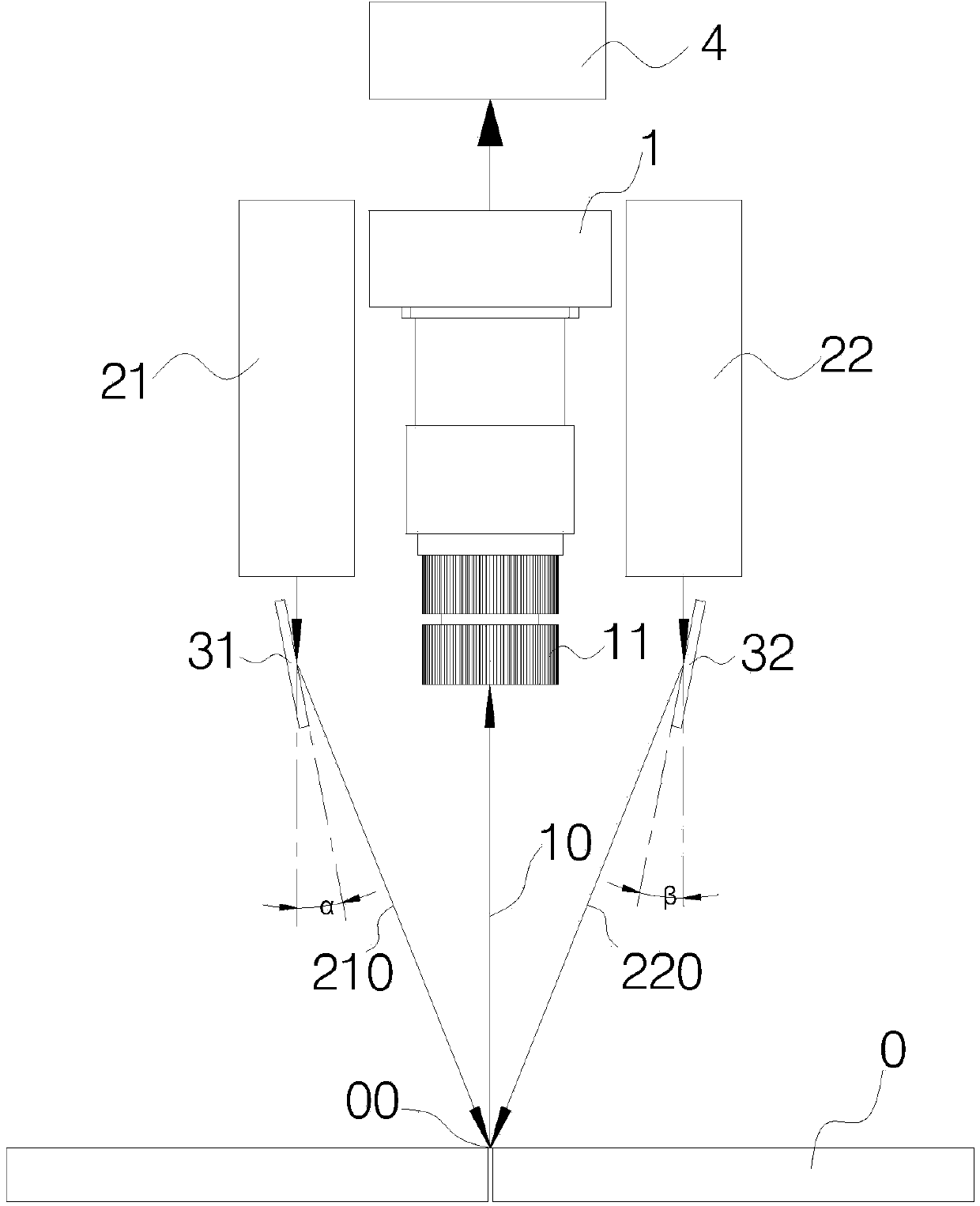

Plain butt weld detection system based on dual-path converged adjustable light path

InactiveCN103728306AAdjust the incident angleAdjust the angle of the light source to change the angle of incidenceMaterial analysis by optical meansLight irradiationHigh definition

The invention relates to a plain butt weld detection system based on a dual-path converged adjustable light path. The plain butt weld detection system comprises an imaging device and an image controller, wherein the image controller is connected with the imaging device; two light source generation devices are symmetrically arranged on both sides of the imaging device, can rotate at a certain angle with a vertical direction; light rays emitted from the light source generation devices pass through a detected plate to enter the imaging device, the imaging device transmits an image to the image controller, and the image controller processes the received image to obtain a high-definition weld detection image. The detection system disclosed by the invention realizes the detection illumination of a plain butt weld by utilizing the dual-path converged light path, thereby enhancing the illumination intensity and eliminating the influence of a shadow generated through a single-path light irradiation weld on the detection of a weld position; the light path is changed by adjusting the angles of the light sources and the adjustment of the optimal incident angle of the light path before convergence can be realized, so that the weld illumination of different positions can be realized and an clearly imaged weld image is obtained.

Owner:TANGSHAN YINGLAI SCI & TECH

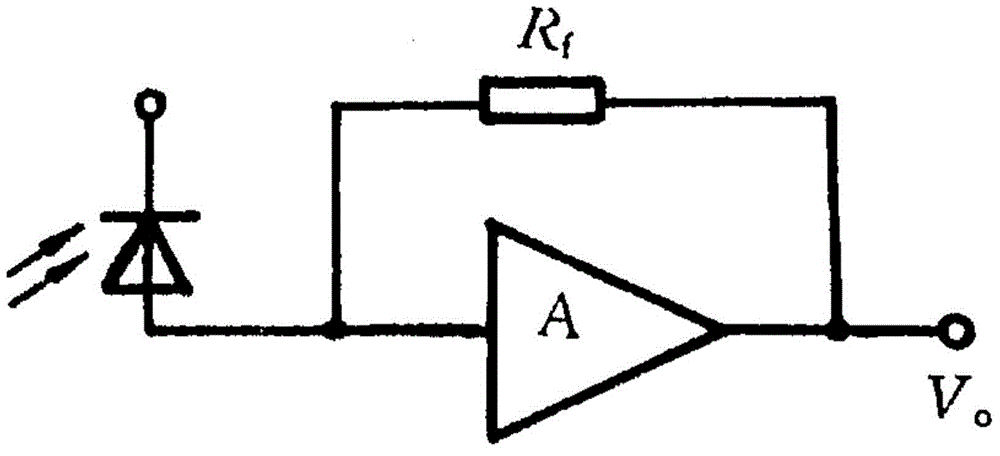

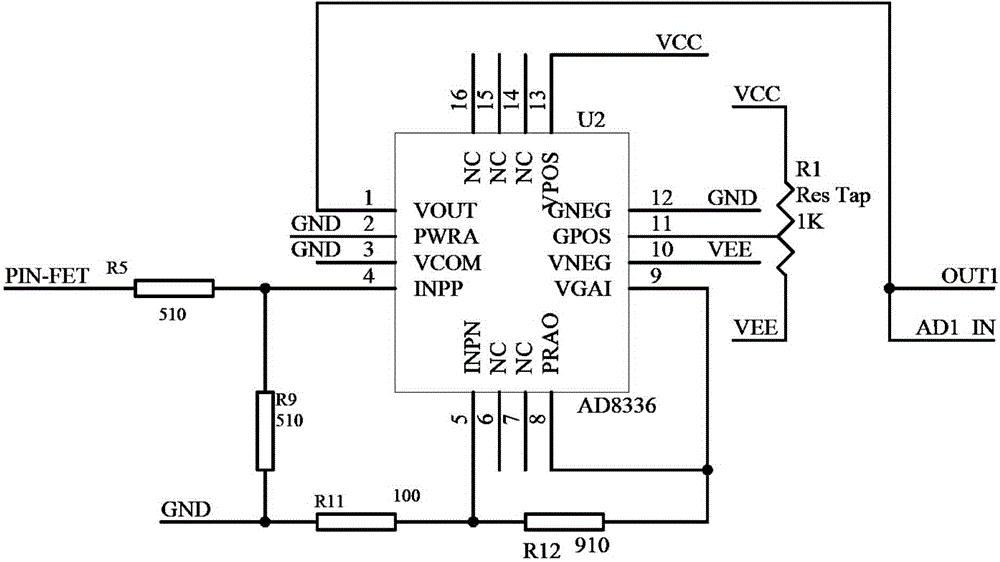

Self-adaptation gain equalization type distributed optical fiber sensing optical signal receiving method and device

ActiveCN104596558AEliminate the effects of detectionGuaranteed SensitivityConverting sensor output opticallyAudio power amplifierEngineering

The invention discloses a self-adaptation gain equalization type distributed optical fiber sensing optical signal receiving method and device. The self-adaptation gain equalization type distributed optical fiber sensing optical signal receiving method and device can automatically adapt to various kinds of optical fibers and various kinds of lasers, and have the disturbance distinguishing function, the influence caused by sensing information on system parameter control is eliminated, the inherent offset output by a pre-amplifier can be eliminated, slow drifting of the pre-amplifier can be compensated for, the automatic gain equalization function of a distributed optical fiber sensing system is fulfilled, the spatial dynamic range of the system is enlarged, uniformity of flexibility within the spatial range is guaranteed, and the self-adaptation gain equalization type distributed optical fiber sensing optical signal receiving method and device have high adaptability and stability.

Owner:SOUTHEAST UNIV

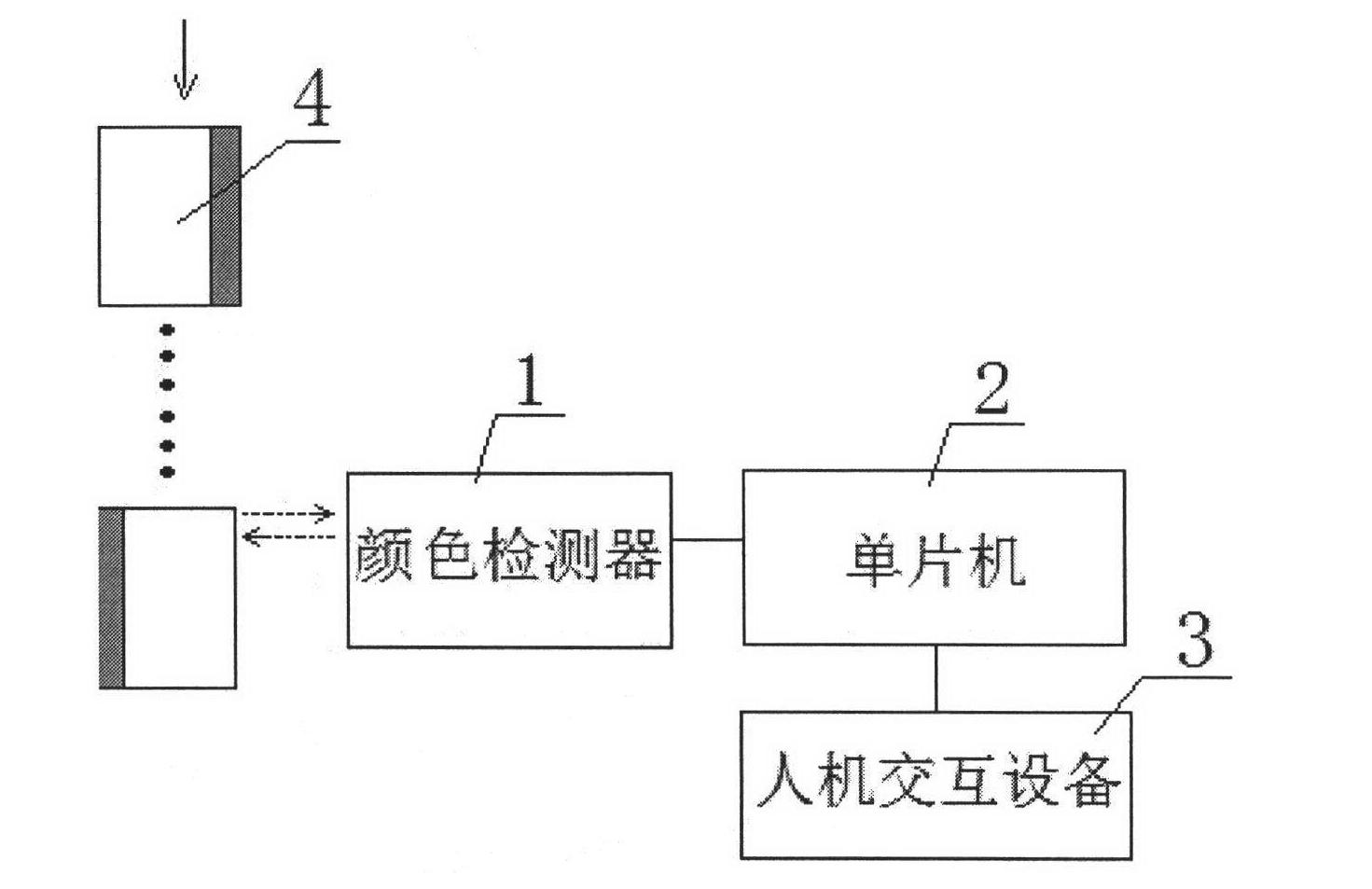

Device and method for automatically detecting surface of common mahjong tile

InactiveCN102614657AThe test result is accurateReduce manufacturing costIndoor gamesSensing by electromagnetic radiationComputer graphics (images)Interaction device

The invention relates to a device and a method for automatically detecting a surface of a common mahjong tile. The device is characterized by consisting of a color detector, a singlechip and a man-machine interaction device, wherein the color detector comprises a light source and a color sensor, and the man-machine interaction device comprises a button and an indication lamp; the singlechip is connected with the color sensor, the button and the indication lamp; and the color detector is arranged in the outer wall of a mahjong tile conveying channel. The method comprises the following steps of: (1) collecting surface color information of two tiles through the singlechip in advance and storing the surface color information; and (2) when a mahjong tile machine works, analyzing and comparing the collected surface color information with pre-stored color information by the singlechip to judge the surface of the mahjong tile. Compared with the prior art, the device for automatically detecting the surface of the common mahjong tile, disclosed by the invention, has the advantages of having an exact surface detection result, configuring no dust removing mechanism, and eliminating the influence of factors, such as temperature, on detection; in addition, the mahjong tile can utilize the common mahjong tile so as to reduce the production cost.

Owner:LIAOCHENG YULIN IND DESIGN CO LTD

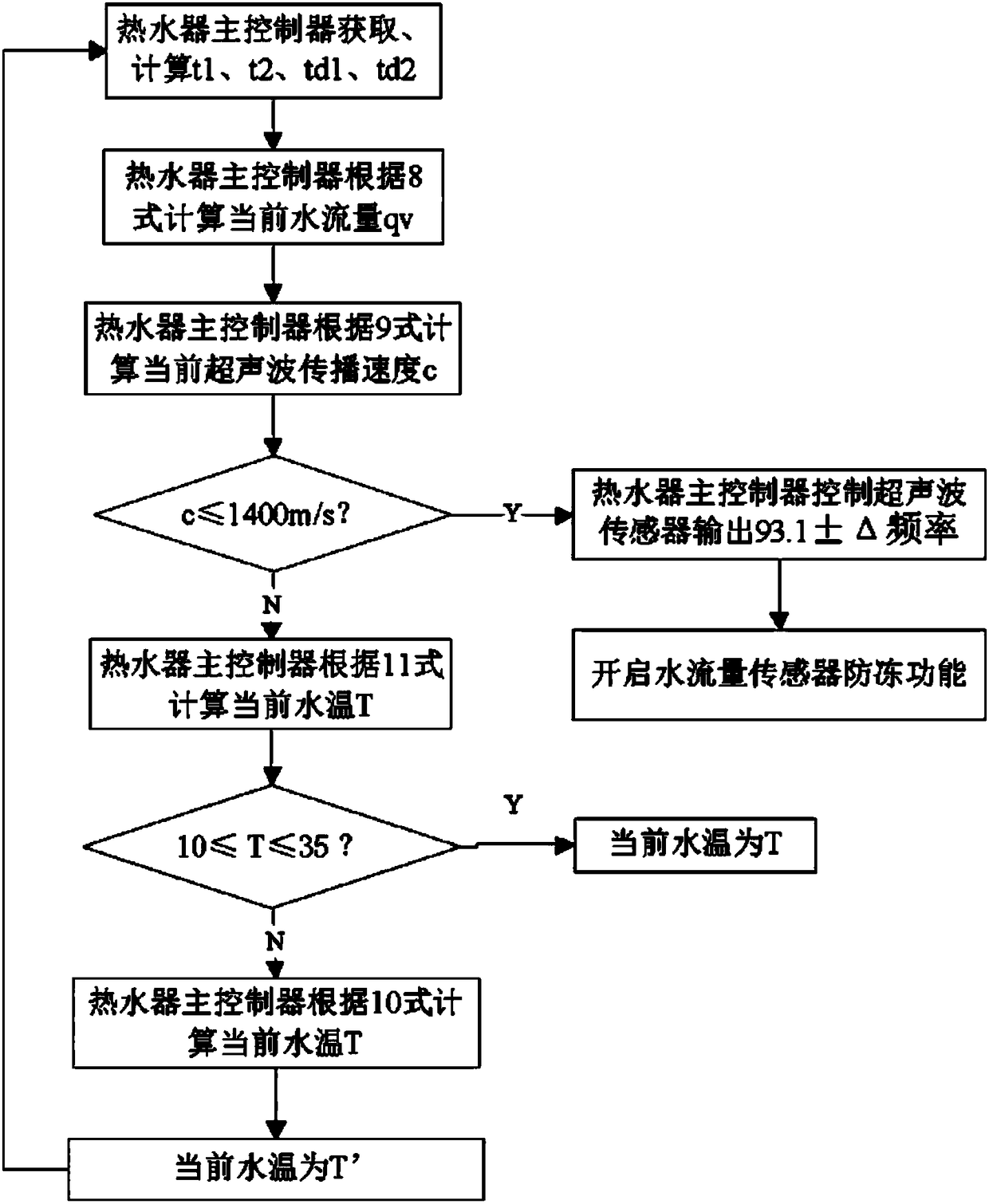

Method for detecting water flow rate and water temperature and water flow rate sensor

PendingCN108414039AEliminate the effects of detectionTo achieve the purpose of detecting water temperatureVolume/mass flow measurementWater flowHydrology

The invention discloses a method for detecting the water flow rate and water temperature. By arranging two ultrasonic receiving and transmission devices, according to the time difference and transmission distance of signals received by the ultrasonic receiving and transmission devices and the diameter of a pipe body, the water flow rate of a water flow rate sensor is precisely calculated in real time, and the influence of water temperature change on detection of the water flow rate is completely removed. In addition, according to the time difference, the transmission distance and the diameterof the pipe body, the ultrasonic transmission speed at the current water temperature can be calculated, then the current water temperature is inversely deduced according to the ultrasonic transmissionspeed, and the aim of detecting the water temperature without a temperature sensor is achieved. According to the water flow rate sensor, a pair of ultrasonic receiving and transmission devices are arranged at the same side of the pipe body, the distance between the ultrasonic receiving and transmission devices is stably controlled, the situation is avoided that other non-mechanical water flow rate sensors are greatly influenced by factors such as corner installation and included angle precision of the sensors, and the detection precision is higher.

Owner:GUANGDONG MACRO GAS APPLIANCE

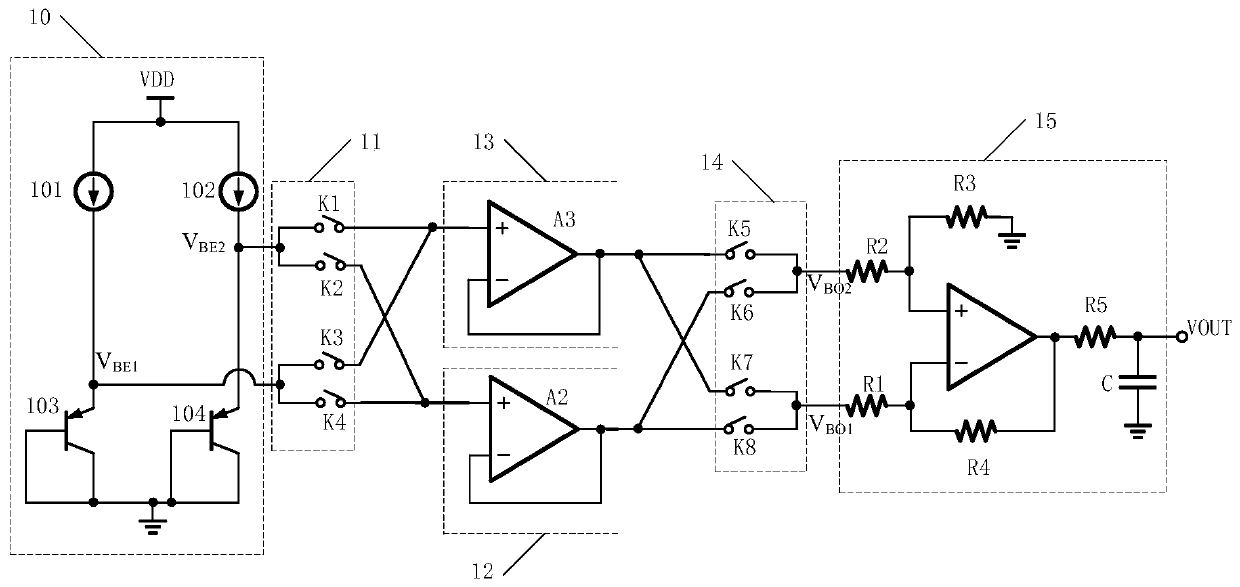

Chip temperature detection circuit and audio power amplifier

InactiveCN110068394AEliminate the effects of detectionEliminate the effects ofElectronic circuit testingCurrent/voltage measurementProcess deviationsPower flow

The invention provides a chip temperature detection circuit and an audio power amplifier. The chip temperature detection circuit comprises a temperature sampling unit, a first control unit, a first buffer unit, a second buffer unit, a second control unit and a comparison and amplification unit. Through the temperature sampling unit, the buffer units and the comparison and amplification unit, temperature sampling voltage can be obtained so that the temperatures of chips can be obtained according to the temperature sampling voltage, thereby eliminating the influences, on current detection of loudspeakers, of temperature changes; and through the first and second control units which are alternately operated under a first state and a second state, the influences, on the temperature sampling voltage, of offset voltage generated by process deviations of the buffer units are eliminated, so that the correctness of chip temperature detection results is improved.

Owner:SHANGHAI AWINIC TECH CO LTD

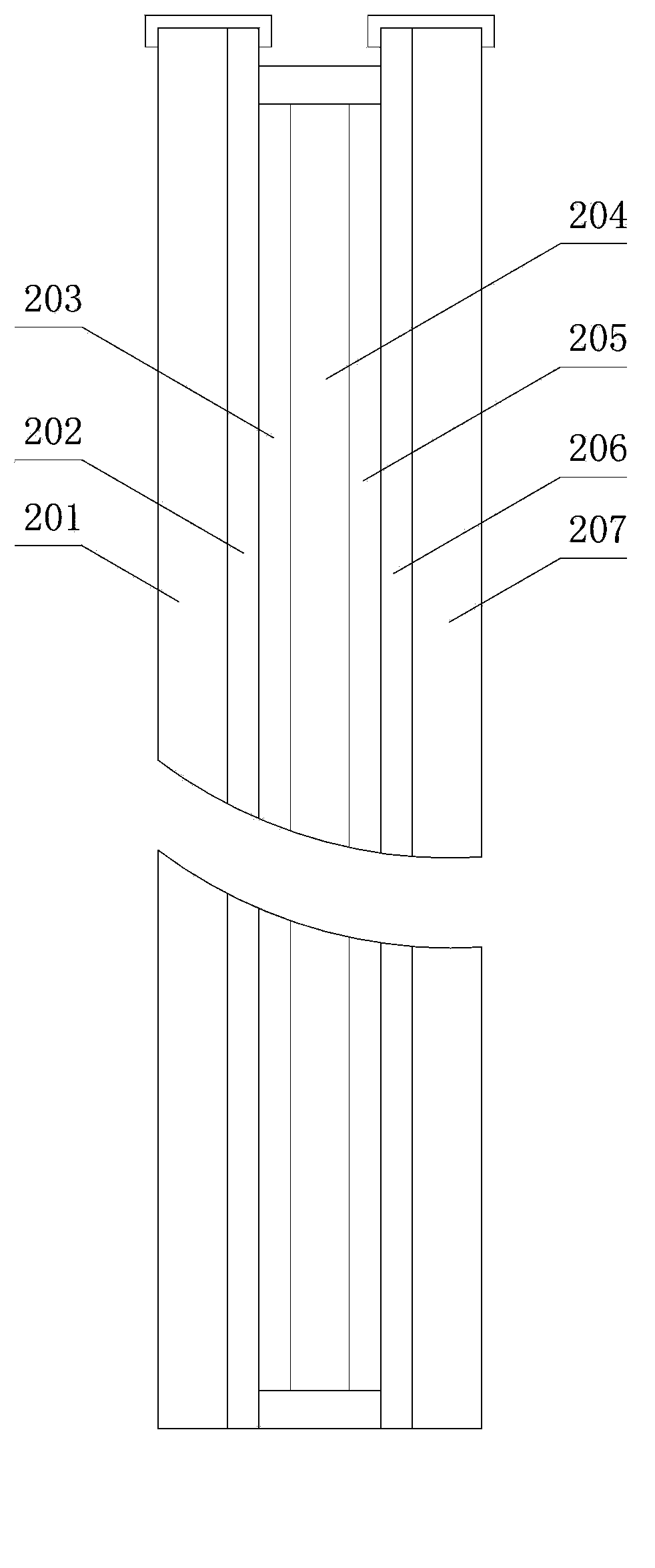

Pressure measuring device and method of fiber difference interference

InactiveCN106404269AEliminate the effects of detectionImprove detection accuracyVolume/mass flow by differential pressureConverting sensor output opticallyFiberDifferential pressure

The invention provides a pressure measuring device and method of fiber difference interference. The device comprises a fiber laser unit, a fiber coupling unit, a reflection difference unit, a fiber beam expanding and collimating unit, a photoelectric detection unit, a storage unit and a signal processing unit; and the reflection difference unit includes a reflection phase grating of a special structural design, and used to cut reflected light waves. The reflection phase grating includes two non-light-transmission parts and two reflection light parts in one period; the two reflection light parts include a direct reflection part (without phase delay) and a pai-phase delayed reflectin part; and the duty ratio of the reflection phase grating is 1 / 2, namely, the proportion of the size of the non-light-transmission parts to that of the reflection light parts is 1 / 2. The device of the invention can be used to realize pressure measurement of high temperature and high corrosion, and has advantages including being resistant to electromagnetic interference and radiation. In addition, a differential pressure type flowmeter is combined to realize high-temperature medium flow measurement.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

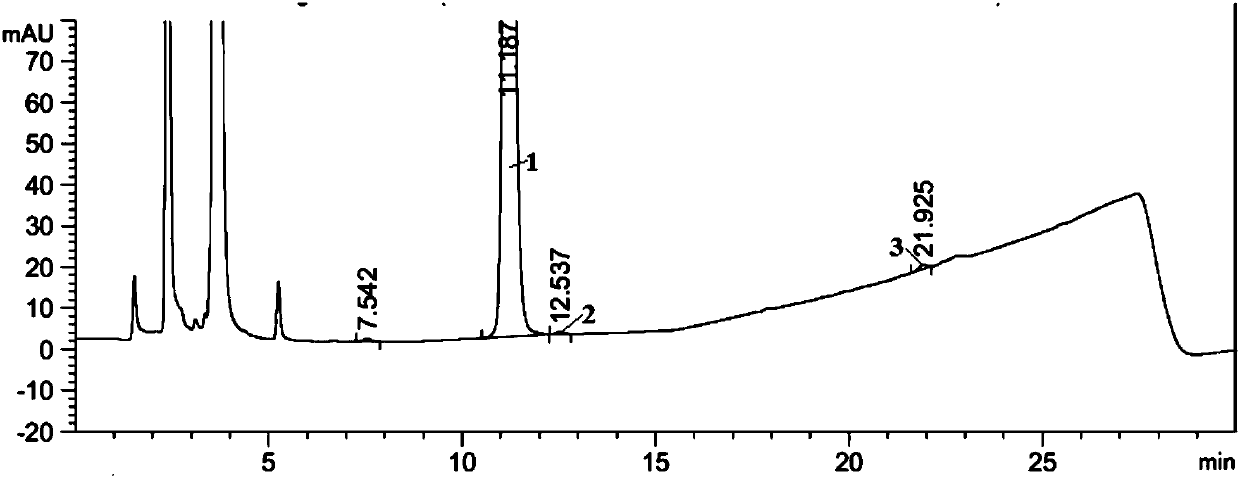

Method for testing amorolfine hydrochloride and interferent of amorolfine hydrochloride

ActiveCN107764909AEasy to separateGood peak shapeComponent separationTest sampleAmorolfine hydrochloride

The invention provides a method for testing amorolfine hydrochloride and interferent of amorolfine hydrochloride. The method comprises the following steps: 1) preparing a test sample solution; 2) preparing a control solution; 3) performing detection. According to the method for testing the amorolfine hydrochloride and the interferent of the amorolfine hydrochloride, pretreatment with optimized conditions and an HPLC (High Performance Liquid Chromatography) detection method are implemented, target components can be effectively separated from the interferent, the contents of the amorolfine hydrochloride and the interferent of the amorolfine hydrochloride are accurately tested, control on amorolfine hydrochloride and interferent of the amorolfine hydrochloride in amorolfine hydrochloride cream products is achieved, and the quality of an amorolfine hydrochloride product is ensured.

Owner:上海正大通用药业股份有限公司

Unbeveledend butt weld detection system based on reflecting two-way converging adjustable light path

InactiveCN103743743AAchieve changeEliminate the effects of detectionMaterial analysis by optical meansHigh definitionLight source

The invention relates to an unbeveledend butt weld detection system based on a reflecting two-way converging adjustable light path. The detection system comprises an imaging device and an image controller connected with the imaging device, wherein two light source generators are symmetrically and fixedly arranged at two sides of the imaging device, reflectors are arranged right below the light exits of the light source generators, the reflectors can rotate around the vertical direction so as to form certain angle, the light ray emitted from the light source generator is firstly reflected by the reflector, then passes through a plate to be detected and enters the imaging device, an image formed by the imaging device is transmitted to the image controller by the imaging device, and the image controller processes the received image so as to obtain a high definition weld inspection image. According to the detection system, the butt weld is illuminated by the reflecting two-way converging light path, therefore, the illumination intensity is enhanced, furthermore, and the influence of the shadow generated by irradiating the weld joint by one-way light on welding position detection is eliminated; the reflectors change the light path, thus decreasing the size of the system, and being beneficial to imaging in later period.

Owner:TANGSHAN YINGLAI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com