Analytical method for quantitatively measuring super-multi-target aroma components in tobacco

A technology for the quantitative determination of aroma components, applied in the direction of analysis materials, measuring devices, material separation, etc., can solve the problems of limited quantity of trace aroma components in tobacco leaves, incomplete disclosure of the material basis of tobacco leaves, loss of low boiling point substances, etc., and achieve low cost and environmental protection. The effect of being friendly and using less solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

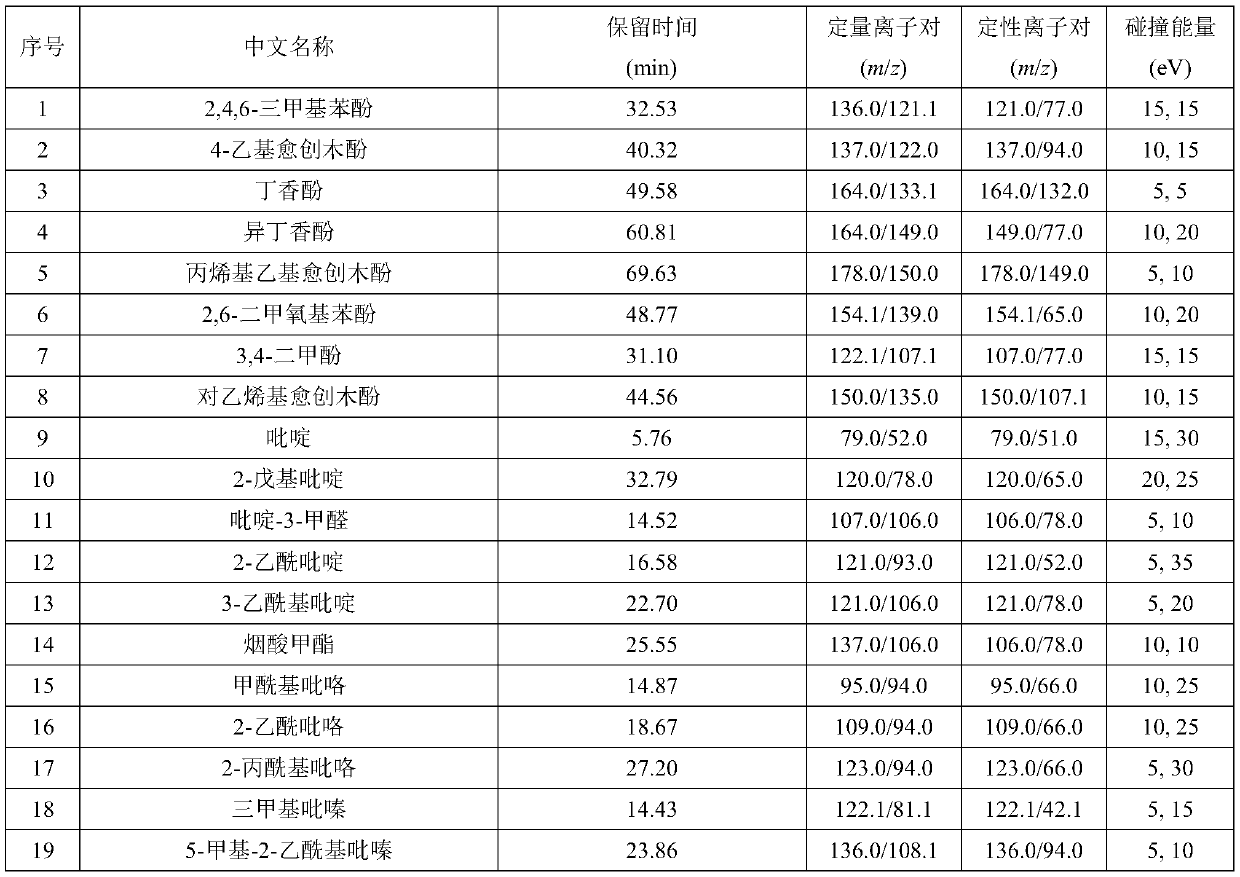

[0047] The matrix effect of 345 kinds of aroma components (361 chromatographic peaks in total) was investigated by the following formula: ME=B / A, wherein, A is the slope of the solvent standard working solution standard curve, and B is the slope of the matrix matching standard working solution standard curve . The concentrations of the standard working solutions were 0.01, 0.02, 0.05, 0.1, 0.2, 0.5 and 1 μg / mL, respectively.

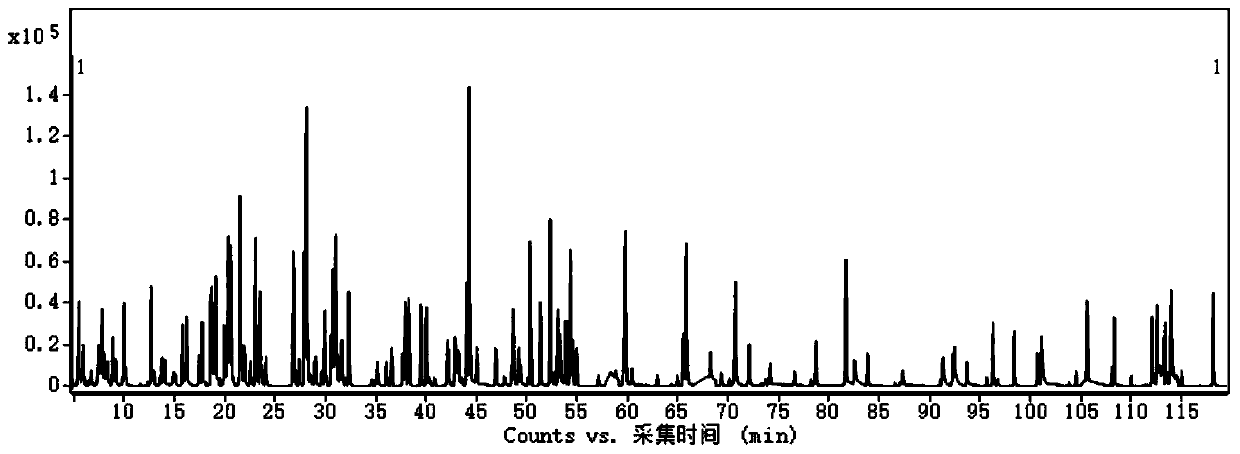

[0048] GC-MS / MS analysis conditions are as follows:

[0049] Gas chromatography conditions: Chromatographic column: elastic quartz capillary column, stationary phase is 50% phenyl-methylpolysiloxane, size 60m×0.25mm×0.25μm, pre-column connected in series at the inlet port (5m×0.25mm) ; Inlet temperature: 280°C; Injection volume: 0.8μL; Injection method: splitless injection, splitless time 1min; Carrier gas: Helium, constant flow mode, flow rate 1.5mL / min; The temperature is 75°C, kept for 5 minutes, then raised to 150°C at 1°C / min, kept for 1min, then ...

example 2

[0055] Weigh 2g of tobacco powder sample into a 50mL stoppered centrifuge tube, add 10mL of phosphate buffer to adjust the pH to 3, vortex to completely infiltrate the sample, let it stand for 20min; add 10mL of acetonitrile and 80μL of 30.0mg / L d 8 -Acetophenone internal standard working solution, vortex at 2500r / min for 2min, then put it into the refrigerator at -18℃ for 10min; take it out, add 4g of anhydrous magnesium sulfate, 1g of sodium chloride and shake vigorously quickly, then refrigerate at 2500r / min Vortex 2min at 8000r / min, centrifuge at 8000r / min for 3min; take 1mL of supernatant in a 2mL centrifuge tube, add 150mg of anhydrous magnesium sulfate and 10mg of multi-walled carbon nanotubes, vortex at 2500r / min for 2min, and centrifuge at 8000r / min 3min; the supernatant was filtered through a 0.22μm organic phase filter and analyzed by GC-MS / MS;

[0056] GC-MS / MS analysis conditions are as follows:

[0057] Gas chromatography conditions: Chromatographic column: elas...

example 3

[0072] Weigh 2g of tobacco powder sample into a 50mL stoppered centrifuge tube, add the standard solution to make the addition level of the target substance 0.5μg / g, add 10mL of phosphate buffer to adjust the pH value to 3, vortex to completely infiltrate the sample, and statically Set aside for 20min; add 10mL acetonitrile and 80μL 30.0mg / L d 8 -Acetophenone internal standard working solution, vortex at 2500r / min for 2min, then put it into the refrigerator at -18℃ for 10min; take it out, add 4g of anhydrous magnesium sulfate, 1g of sodium chloride and shake vigorously quickly, then refrigerate at 2500r / min Vortex 2min at 8000r / min, centrifuge at 8000r / min for 3min; take 1mL of supernatant in a 2mL centrifuge tube, add 150mg of anhydrous magnesium sulfate and 10mg of multi-walled carbon nanotubes, vortex at 2500r / min for 2min, and centrifuge at 8000r / min 3min; the supernatant was filtered through a 0.22 μm organic phase filter and then analyzed by GC-MS / MS; the conditions for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com