Front-view intelligent anti-glare device of vehicle and manufacturing method of anti-glare mirror thereof

A manufacturing method and anti-glare technology, which can be applied to optical observation devices, vehicle parts, optics, etc., can solve the problems of decreased sealing, low volume intrinsic resistivity, and decreased barrier properties of solvent-based electrolytes in ionic conductor layers of packages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (Example 1, a vehicle front-view intelligent anti-glare device)

[0077] Such as Image 6 Shown; A kind of vehicle forward-looking intelligent anti-glare device has control device 1 and anti-glare mirror 2 installed in the bracket 4; the output end of control device 1 is connected with the input end of anti-glare mirror 2;

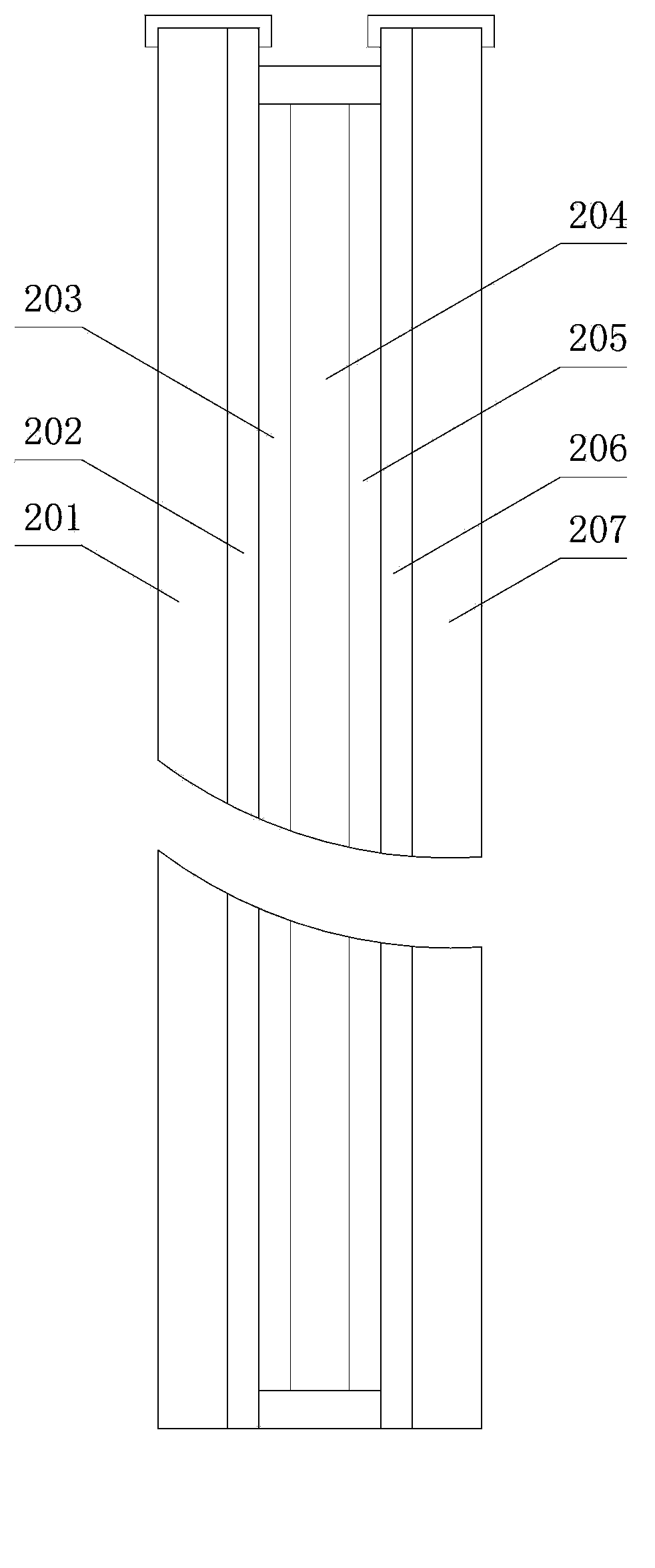

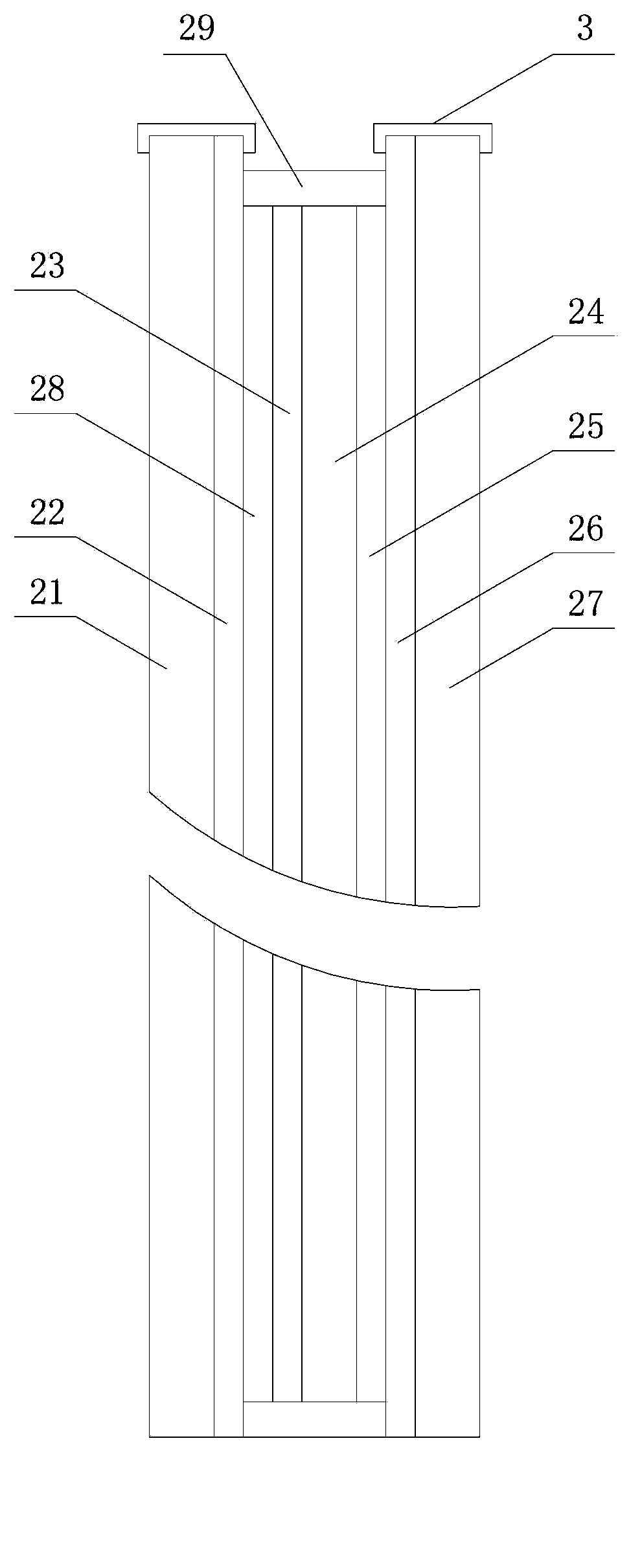

[0078] Such as figure 2 As shown, the anti-glare mirror 2 has a first substrate 21, a conductive layer 22, a monomer molecular coating 28, an electrochromic coating 23, an ion conductor layer 24, an ion storage layer 25, an ion conduction layer 26, and a first layer stacked in sequence. Two substrates 27; the first substrate 21 and the second substrate 27 are provided with a sealant layer 29 cured by ultraviolet rays or heat-cured, the first substrate 21 and the second substrate 27 are rigid transparent substrates; the ion conductor layer 24 is liquid type.

[0079] The electrochromic coating 23 of the anti-glare mirror 2 is a polymer electrochr...

Embodiment 2

[0088] (Example 2, a vehicle front-view intelligent anti-glare device)

[0089] Such as Figure 10 As shown, the intelligent electro-induced gradient anti-glare mirror 2 is fixed on the bracket, and the bracket is fixed on the front windshield through a vacuum suction cup. Adjust the height of the suction cup on the front windshield to ensure that the distance from the driver's eyes to the anti-glare mirror 2 is 200-400 mm, and the line formed by the bottom edge of the anti-glare mirror 2 and the driver's eyes falls about 30 meters in front of the road . This structure also ensures that the intelligent electro-gradient anti-glare device plays an anti-glare function.

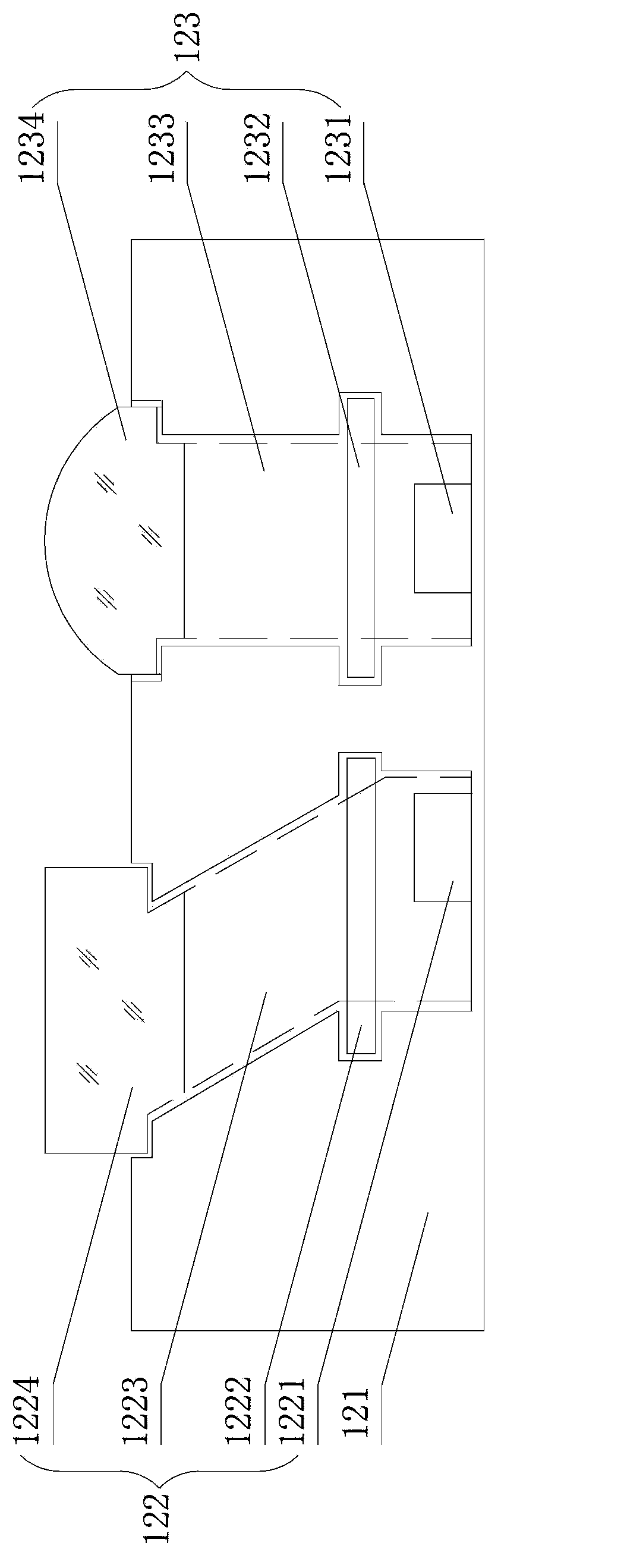

[0090] The working principle of the present invention is: when meeting cars at night and encountering glare, the glare sensor 122 and the ambient light sensor 123 generate photocurrent after receiving light, and the MCU microprocessor 11 in the control device simulates the voltage produced by the photocurrent. ...

Embodiment 3

[0100] (Example 3, a method for manufacturing an anti-glare mirror of a forward-looking intelligent anti-glare device for a vehicle)

[0101] The anti-glare mirror 2 has a first substrate 21, a conductive layer 22, an electrochromic coating 23, an ion conductor layer 24, an ion storage layer 25, an ion conduction layer 26 and a second substrate 27 stacked in sequence; it is characterized in that: the conduction layer There is also a monomer molecular coating 28 between the 22 and the electrochromic coating 23; the manufacture method of the anti-glare mirror 2 comprises the following steps:

[0102] a. Make the first substrate 21 and the second substrate 22: put the ITO conductive glass with a square resistance of 12 ohm / □ and a light transmittance of 90% on a special-shaped glass cutting machine and cut them into shapes. The sizes are 26.5*7.5cm and 27*7.2 cm, then, use DI deionization and water-based cleaning agent to clean it on the ultrasonic machine several times; finally,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com