Tubular workpiece fluid abrasive finishing device and finishing method thereof

A technology of finishing and fluid abrasives, applied in the direction of grinding drive device, grinding workpiece support, metal processing equipment, etc., can solve problems such as fixture sealing problem, eliminate processing error, shorten processing time, and achieve obvious processing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

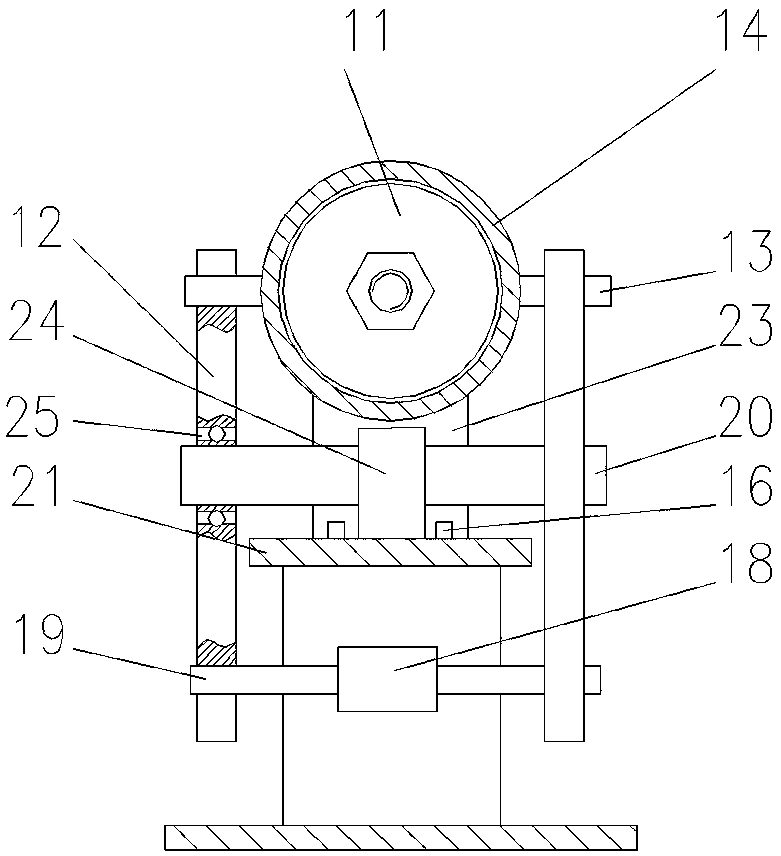

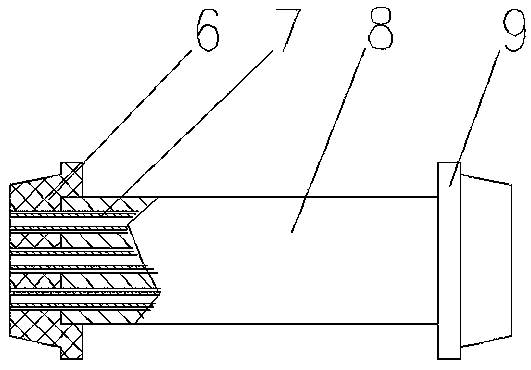

[0036] like Figure 1 to Figure 4 A fluid abrasive finishing device for tubular workpieces is shown, which includes a frame 21, a hydraulic cylinder, a pusher cylinder and a tubular workpiece fixture 8, and the hydraulic cylinder includes a left hydraulic cylinder 1, a right hydraulic cylinder 15 and a lower hydraulic cylinder 17. The pushing cylinder includes a left pushing cylinder 2 and a right pushing cylinder 14, wherein:

[0037] The right side of the upper surface of the frame 21 is provided with a guide rail 16, the left support frame 22 is arranged on the top of the left side of the frame 21, the right support frame 23 is arranged on the top of the guide rail 16, and the right support frame 23 reciprocates horizontally along the guide rail 16 sports;

[0038] The left push cylinder 2 is fixedly installed on the left support frame 22 along the horizontal direction, the left hydraulic cylinder 1 is arranged on the left side of the left push cylinder 2, and the piston rod...

Embodiment 2

[0056] The finishing method of a fluid abrasive finishing device for tubular workpieces provided in the second embodiment is the same as that described in the first embodiment, and will not be repeated here.

[0057] The fluid abrasive finishing device for tubular workpieces provided in the second embodiment is different in that the tubular workpiece clamp 8 between the two rubber pads is replaced with a non-straight circular tube clamp on the basis of the first embodiment. For example, curved pipe workpiece fixtures can also achieve the effect of finishing the inner wall of the pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com