Universal elevator axis processing technique

A processing technology, general elevator technology, applied in the direction of shaft, shaft and bearing, mechanical equipment, etc., can solve the problems of uneven material structure, asymmetric structure, out of tolerance of small cone aperture, and achieve the improvement of internal structure uniformity, The effect of reducing internal stress accumulation and increasing the normalizing cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

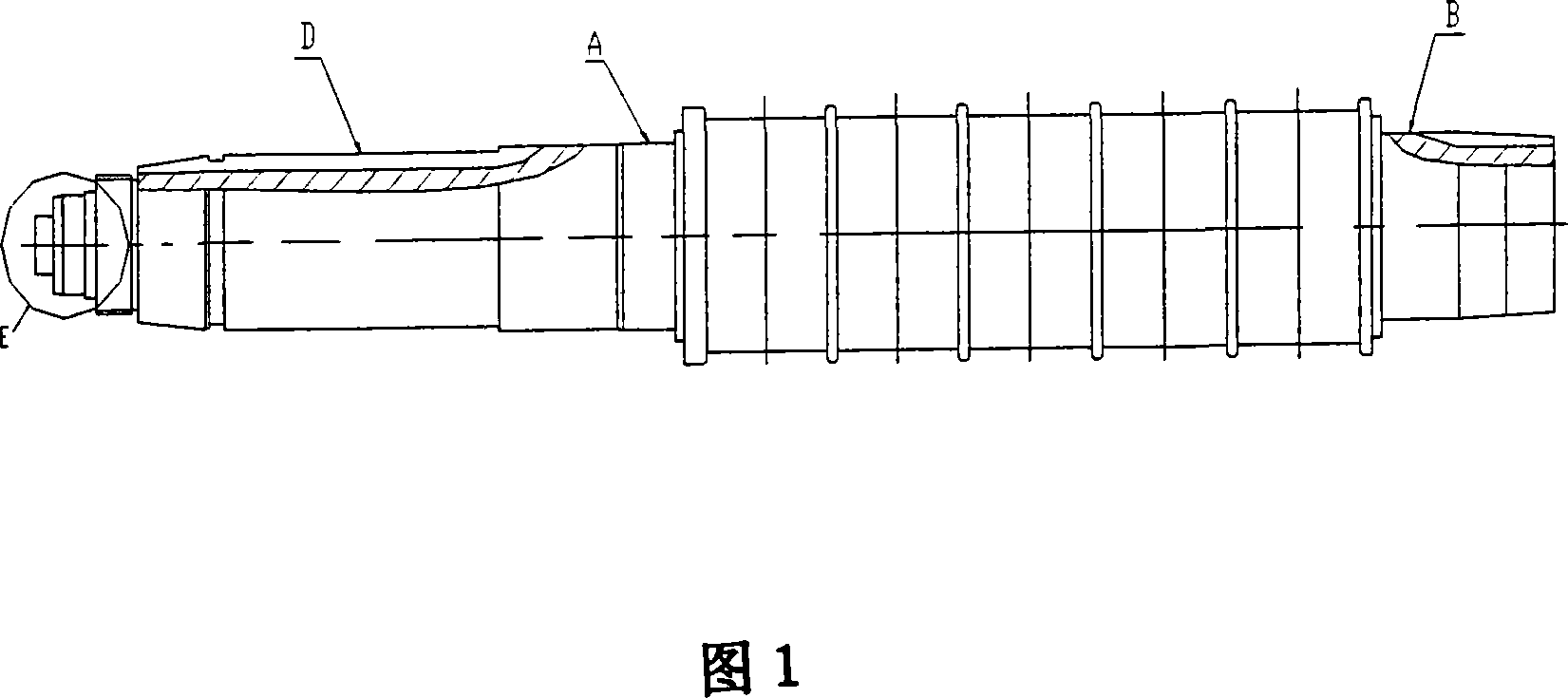

[0018] As shown in Figures 1 and 2, it is a schematic diagram of the elevator shaft structure. It is a general elevator shaft processing technology, which consists of 5 processes of rough turning, fine turning, milling, calibration, and fine grinding of the shaft diameter before normalizing. The process is as follows: :

[0019] The first step. Rough turning before normalizing: before normalizing, remove most of the machining allowance of the bar, so that the allowance at D of the bar is 30mm-50mm, and then normalize the bar. The normalizing temperature is 710°C;

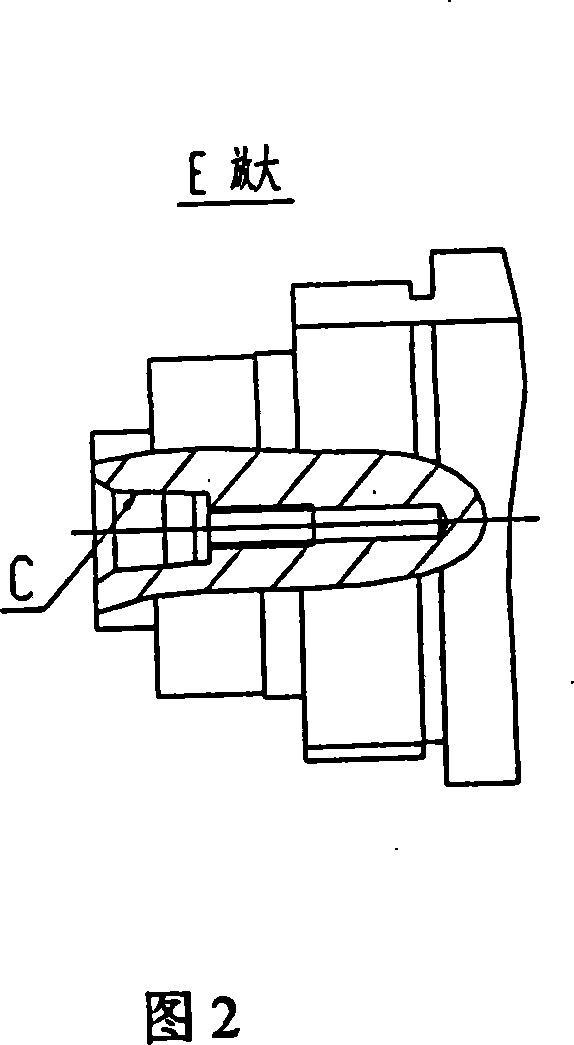

[0020] The machining datum of shaft parts is the center hole. According to the principle of datum first, the center hole is usually processed first, but generally there is a small taper hole C in the center hole of the elevator shaft, and the small taper hole is connected with the diameters A and B of the two shafts. The center line has strict runout requirements. Therefore, during rough machining, the end face and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com