Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Small cutting allowance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

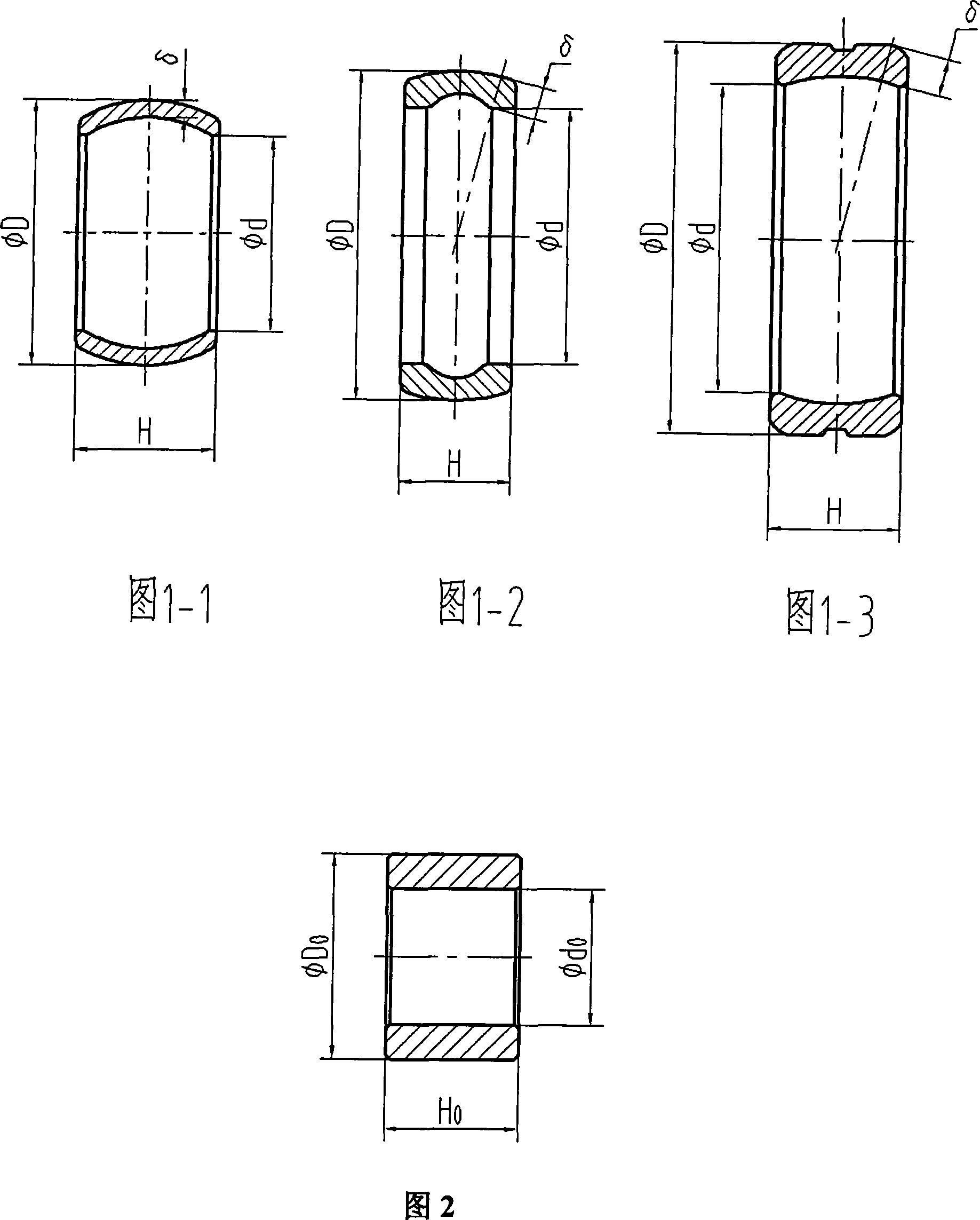

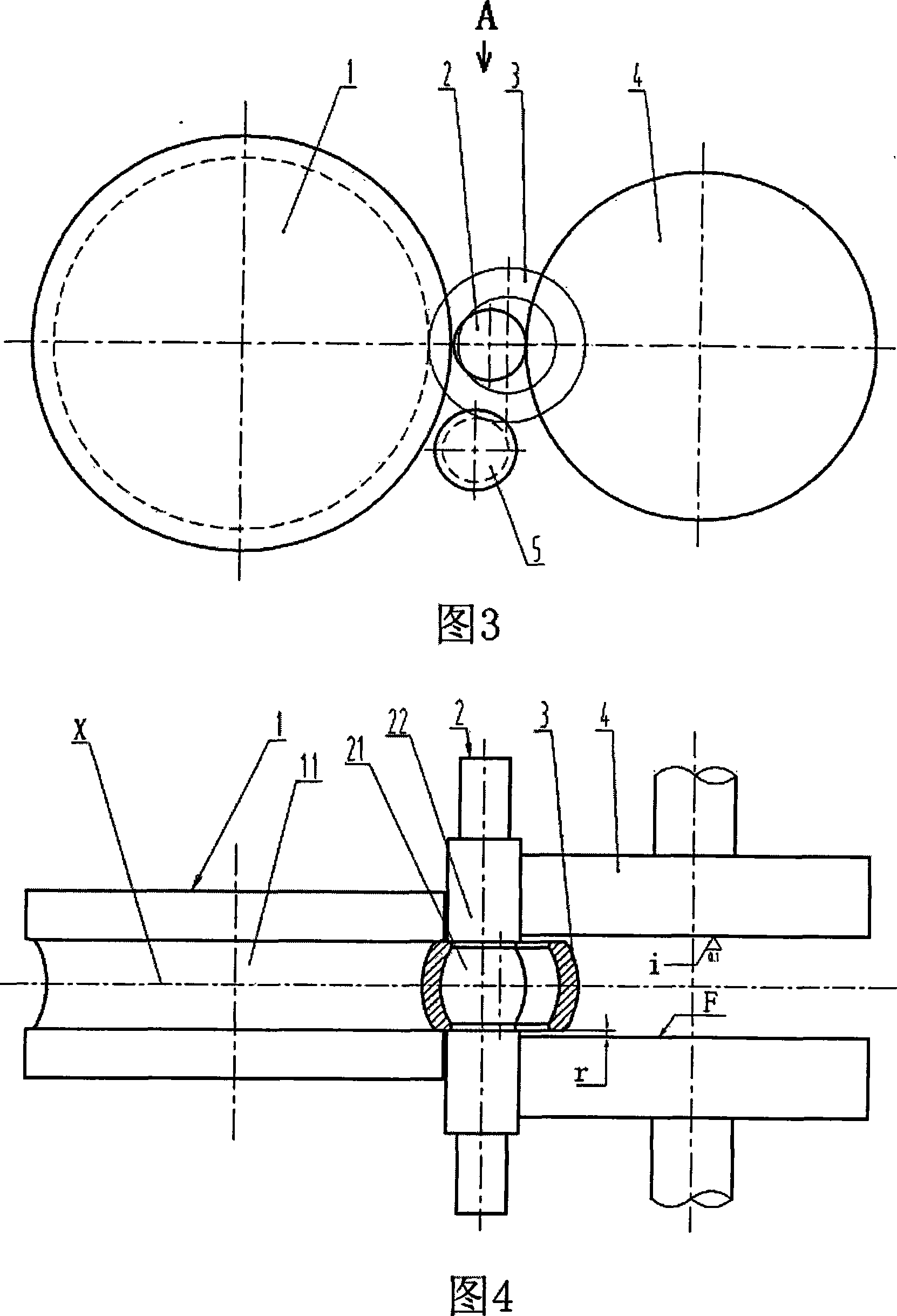

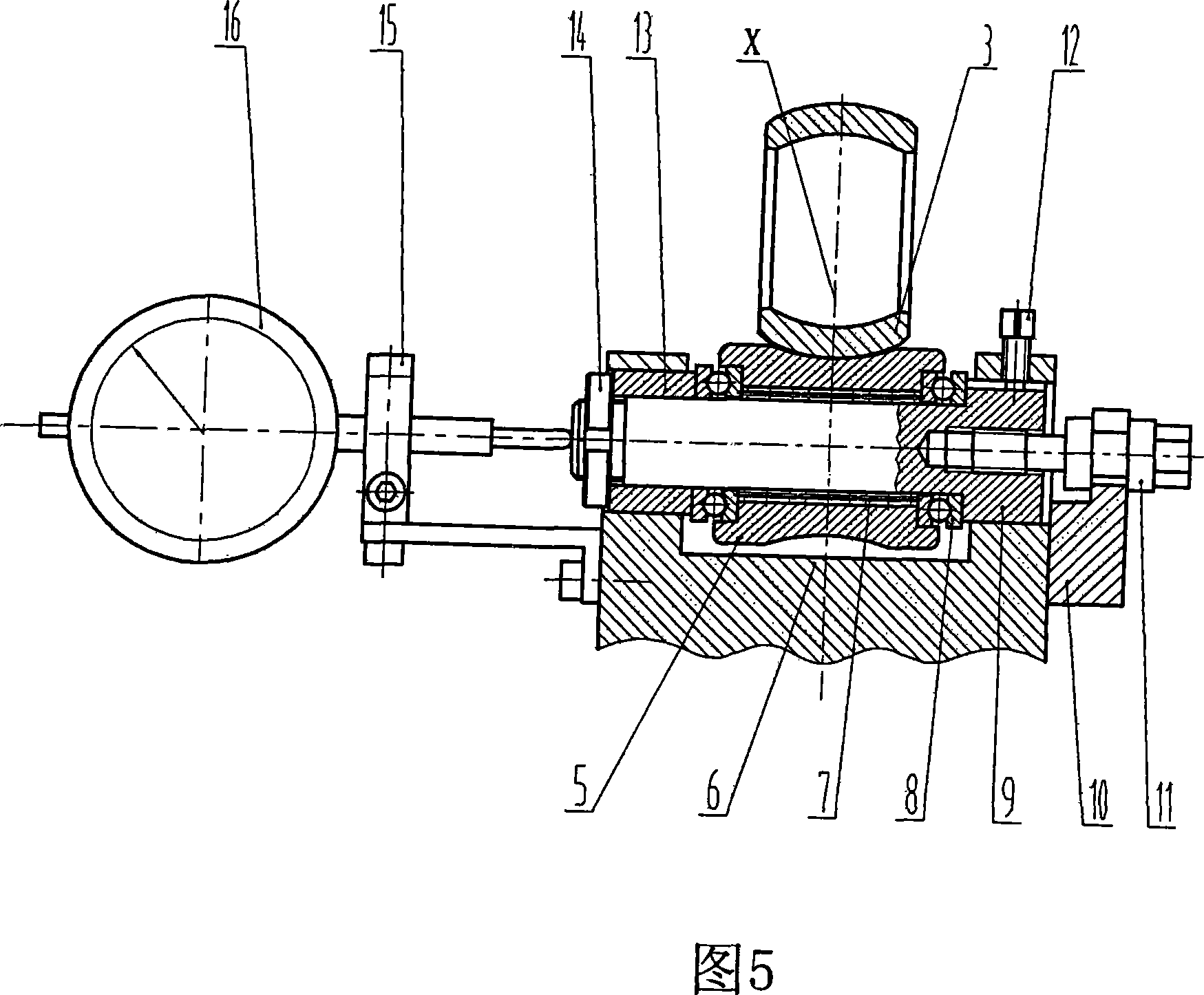

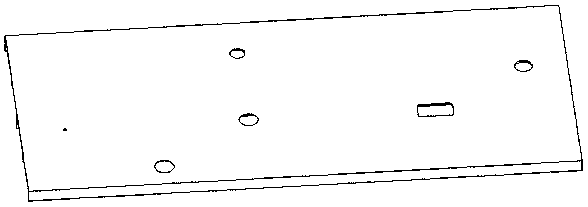

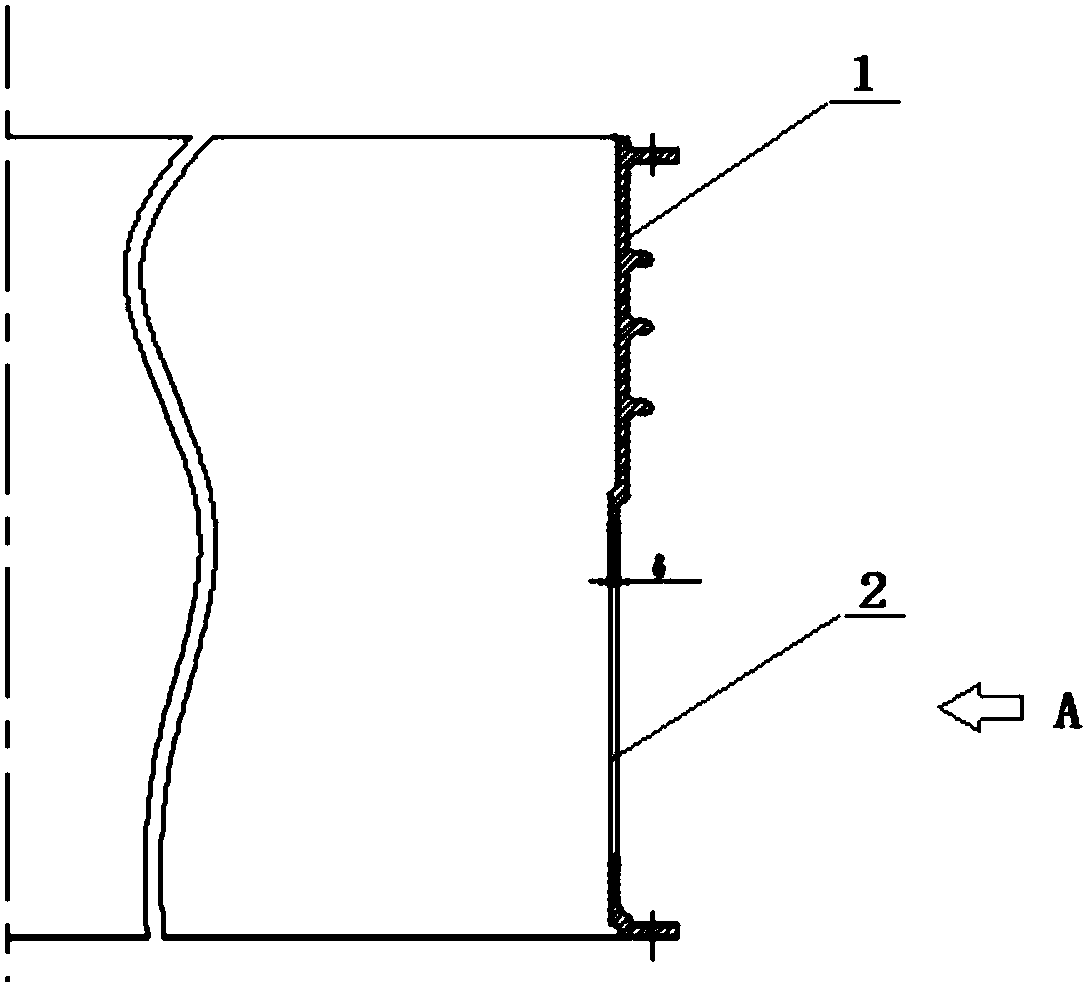

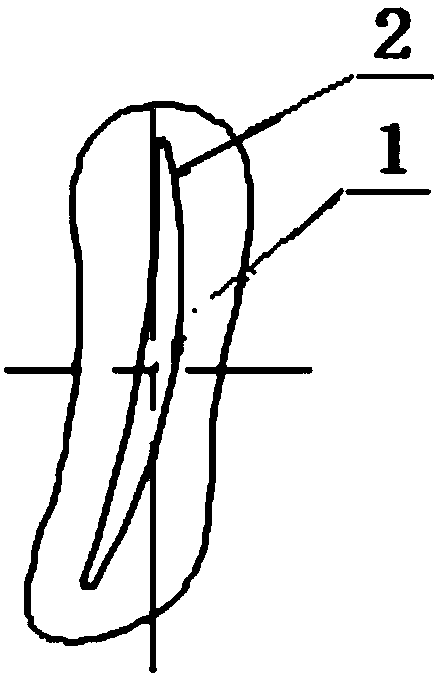

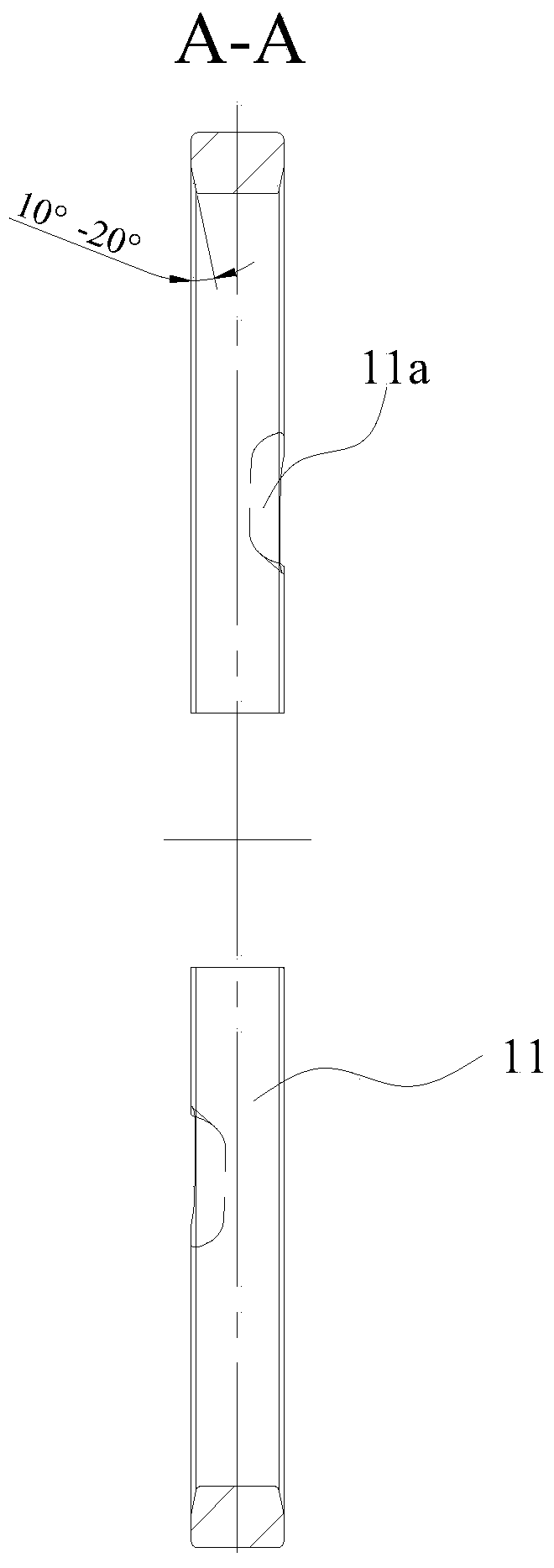

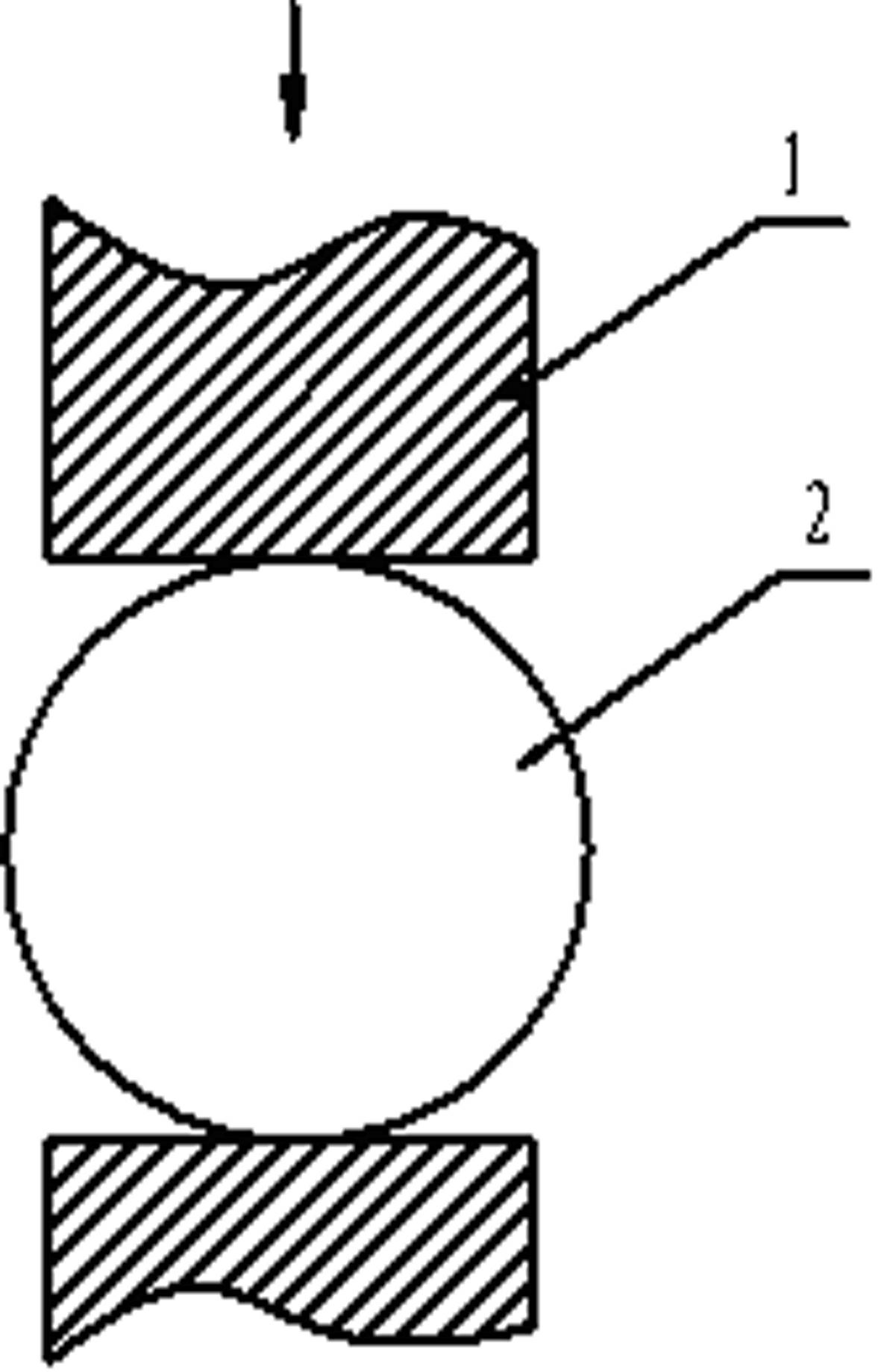

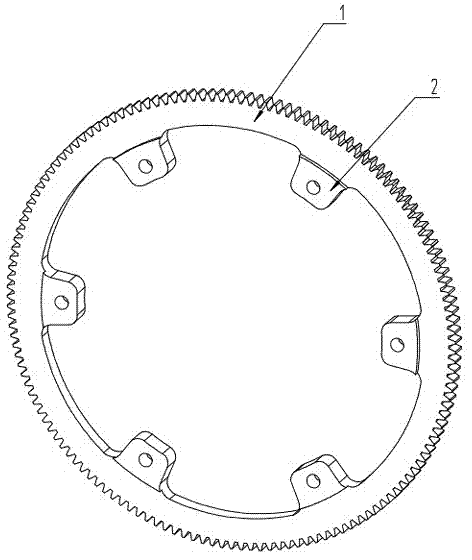

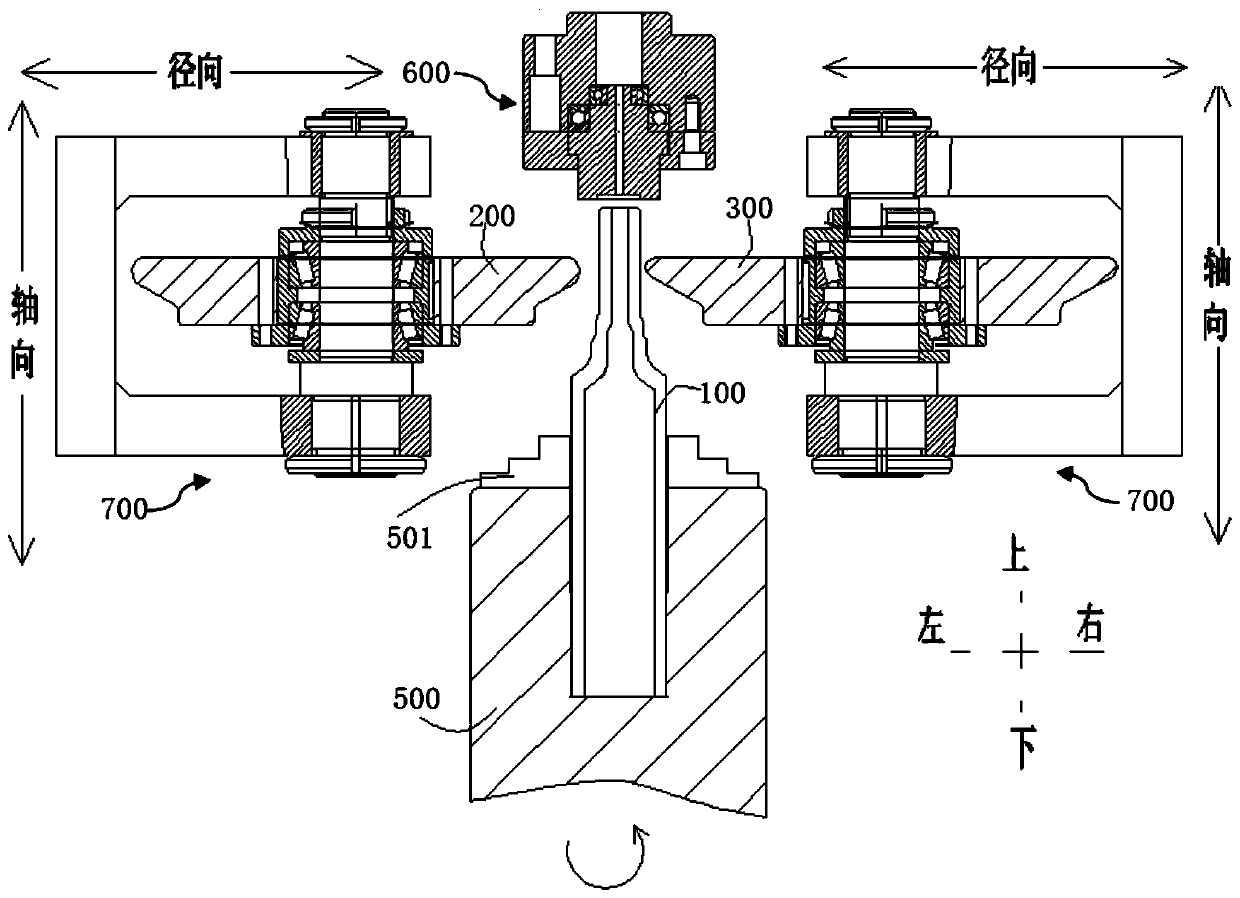

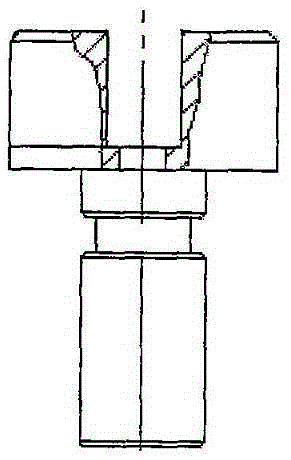

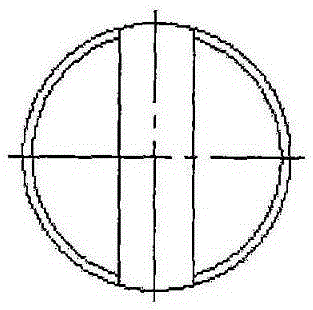

Processing method of enlarging cold-rolling of inside and outside spherical surface ferrule piece as well as device thereof

InactiveCN101176903AGood shape consistencyImprove mechanical propertiesMetal rollingHardnessMechanical property

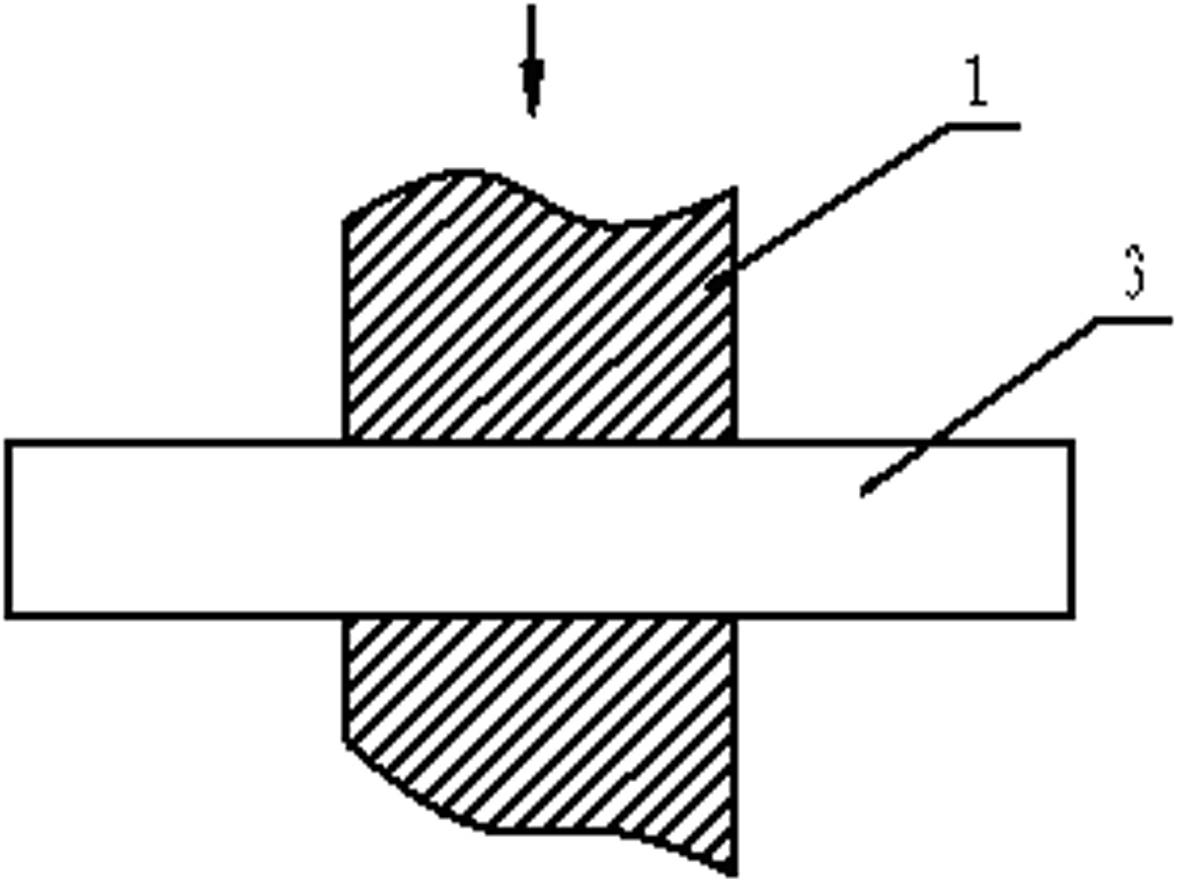

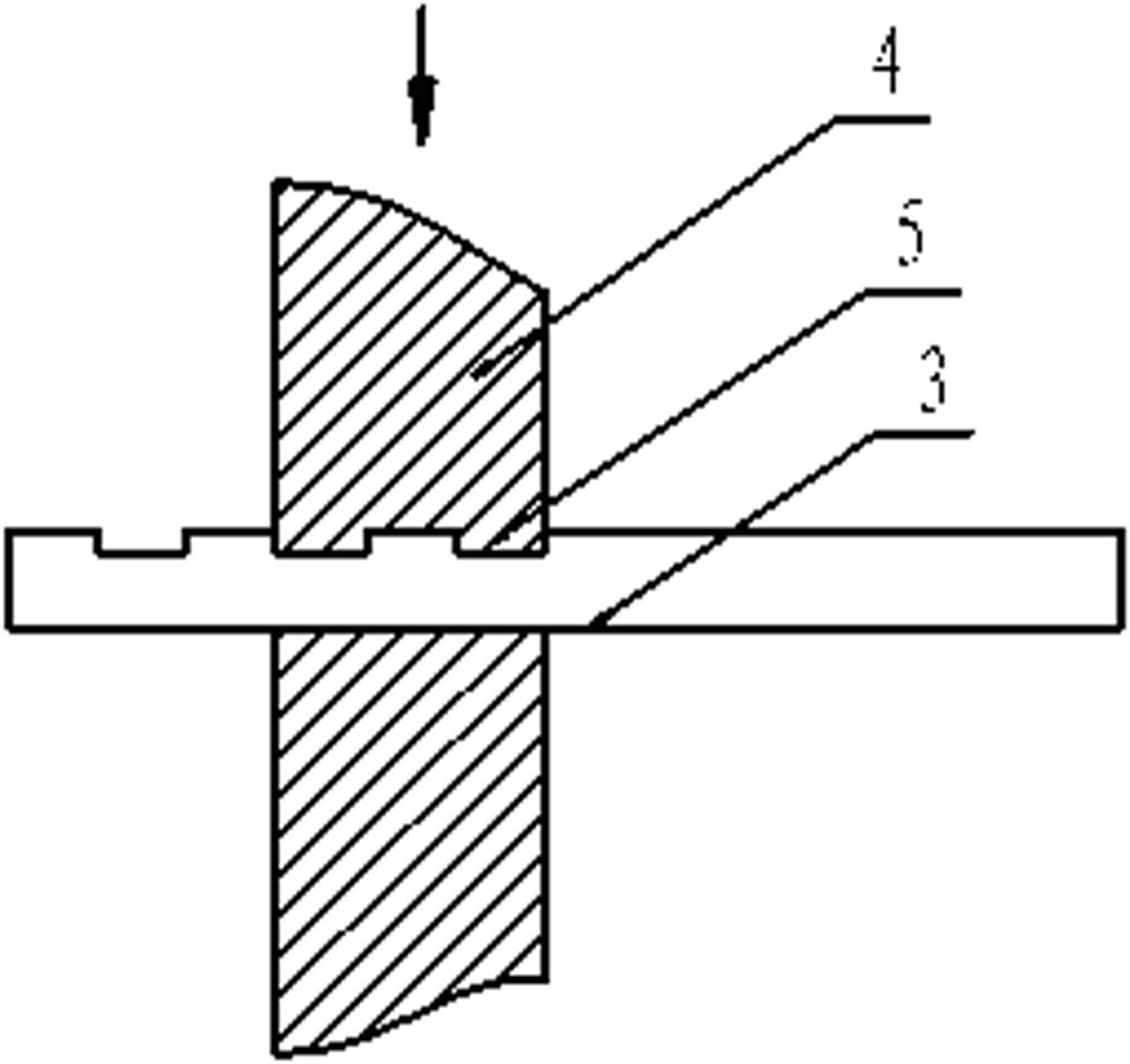

A method and device for cold rolling and expanding processing of inner and outer spherical metal rings, relating to the technical field of bearing parts processing; what is to be solved is the technical problem of processing inner and outer spherical metal rings of bearing parts; the inner and outer spherical The method for processing metal rings includes the following steps: 1) steel reforming, wherein metal bars are transformed into rings; 2) material is softened, and the rings are subjected to heat treatment to obtain lower hardness so as to facilitate cold rolling; 3) cold rolling blanks Preparation, the ring is processed into a certain precision cold rolling blank by cutting; 4) cold rolling forming, the cold rolling process is performed, the outer circular concave groove of the rolling wheel and the outer cylindrical convex shape of the mandrel in the mold part The grooved shaft enables the workpiece to be formed, and the thrust surfaces of the supporting roller and the support wheel are used to stabilize the workpiece position and limit the axial movement of the workpiece. The invention has the characteristics of improving the mechanical properties of the ring parts, high production efficiency, good shape consistency of workpieces, high processing precision and high material utilization rate.

Owner:刘岷

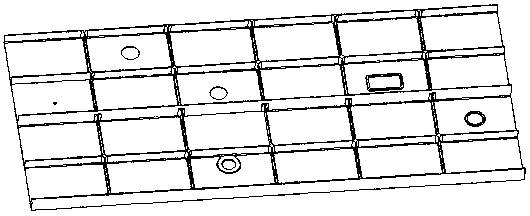

Milling method of high-precision suspended web

ActiveCN108746782ACut evenlyEven by forceWorkpiecesMilling equipment detailsWeb structureEngineering

The invention discloses a milling method of a high-precision suspended web. The milling method is used for efficient and stable milling of a large-size suspended web structure and comprises the stepsthat the glossy face of a part is subjected to rough milling, and the technical allowance is reserved; a frame face is subjected to rough milling, the technical allowance is reserved, and a pluralityof false bosses are reserved according to the structural characteristics, so that the structural rigidity of the part is improved; the frame face is pressed in an unstressed mode, a positioning datumface is corrected, and thus the situation that the machining error is caused by part deformation is prevented; a glossy face web is subjected to semi-fine milling, and the small allowance is reserved;and the glossy face web is subjected to finish machining in place in modes of a small-diameter tool in small cutting quantity and back-and-forth feed, and thus the situations that cutter back-off deformation is caused by the large cutting quantity, and the surface quality of a part becomes poor due to trajectory change and acceleration and deceleration of a machine tool are prevented. The millingstability of the large-size suspended web structure is effectively improved, the part machining efficiency and the surface quality integrity are improved, and reworking polishing of a bench worker isreduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

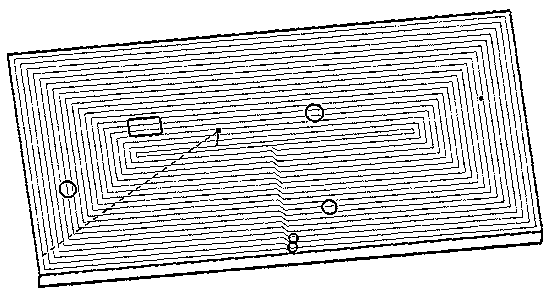

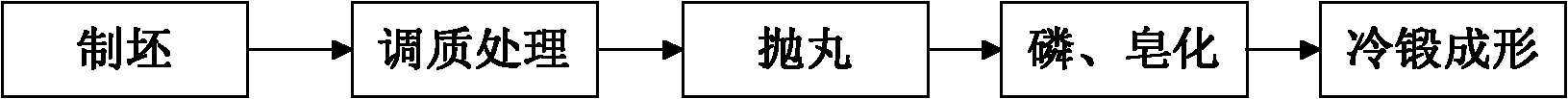

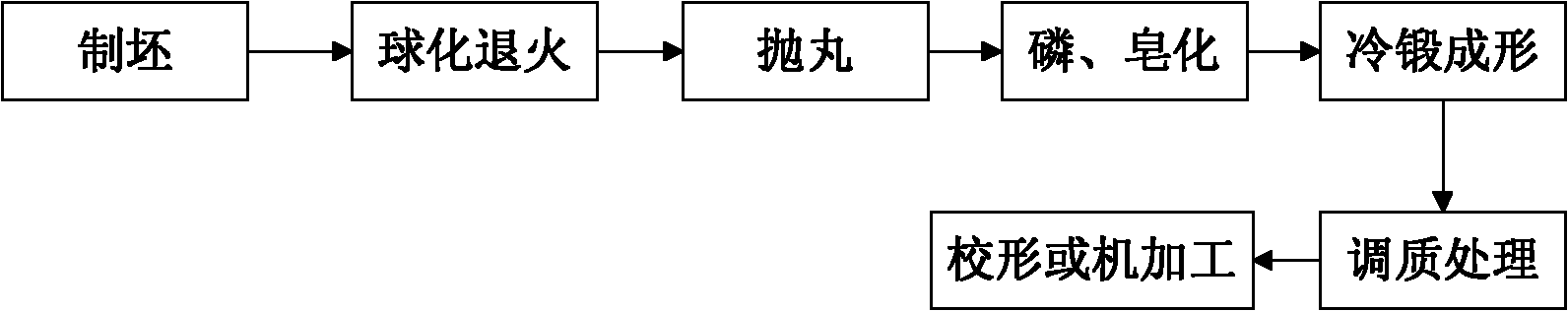

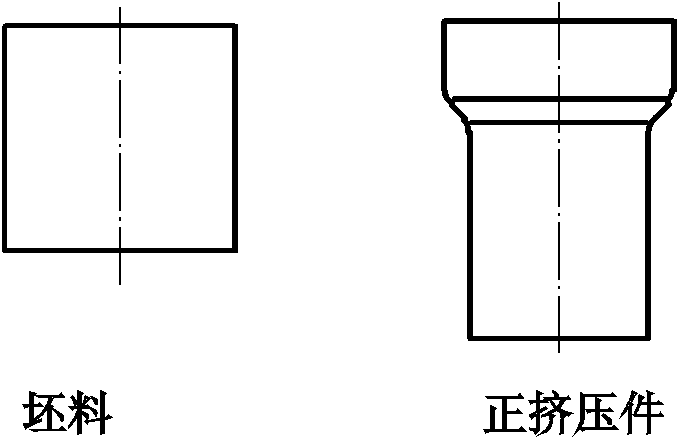

Cold forging processing method of hardened and tempered structural steel

InactiveCN102019335ASmall cutting allowanceSave raw materials and energyForging/hammering/pressing machinesQuenchingThermal treatment

The invention discloses a cold forging processing method of hardened and tempered structural steel, which belongs to the technical field of steel cold forging. The method comprises the following steps of: firstly, performing corresponding blank forming treatment on different blanks and performing quenching treatment and high-temperature tempering treatment so as to obtain a structural steel hardened and tempered blank; secondly, blowing steel shots out of a barrel-type shot blasting machine by using compressed air, continuously impacting the steel shots onto the hardened and tempered structural steel blank and phosphating and saponifying the structural steel blank; and lastly, deforming the structural steel blank by using a cold forging mold in a cold extruding or cold heading way so as to obtain a precision forming part. The classical cold forging process is changed completely, softening treatment is not performed before cold forging of a steel material, a mechanical part with high size accuracy and high comprehensive mechanical property is processed by material hardening and tempering treatment and cold forging deformation and reinforcement, and subsequent thermal treatment is not needed after cold forging forming.

Owner:SHANGHAI JIAO TONG UNIV +1

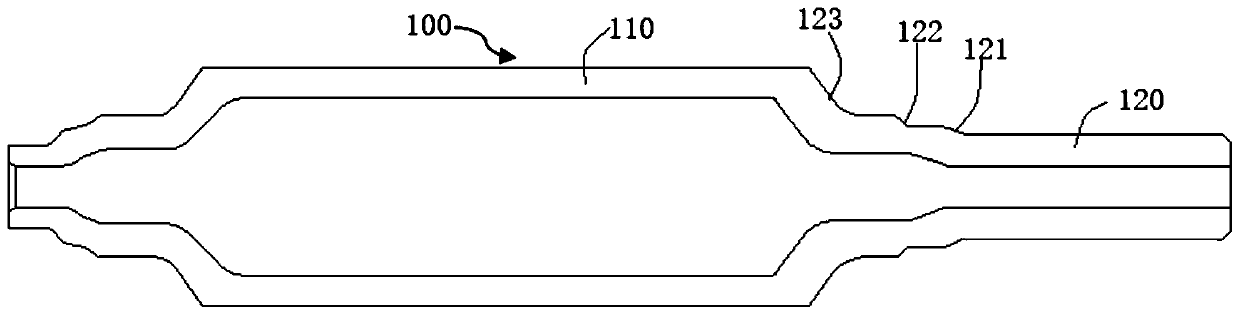

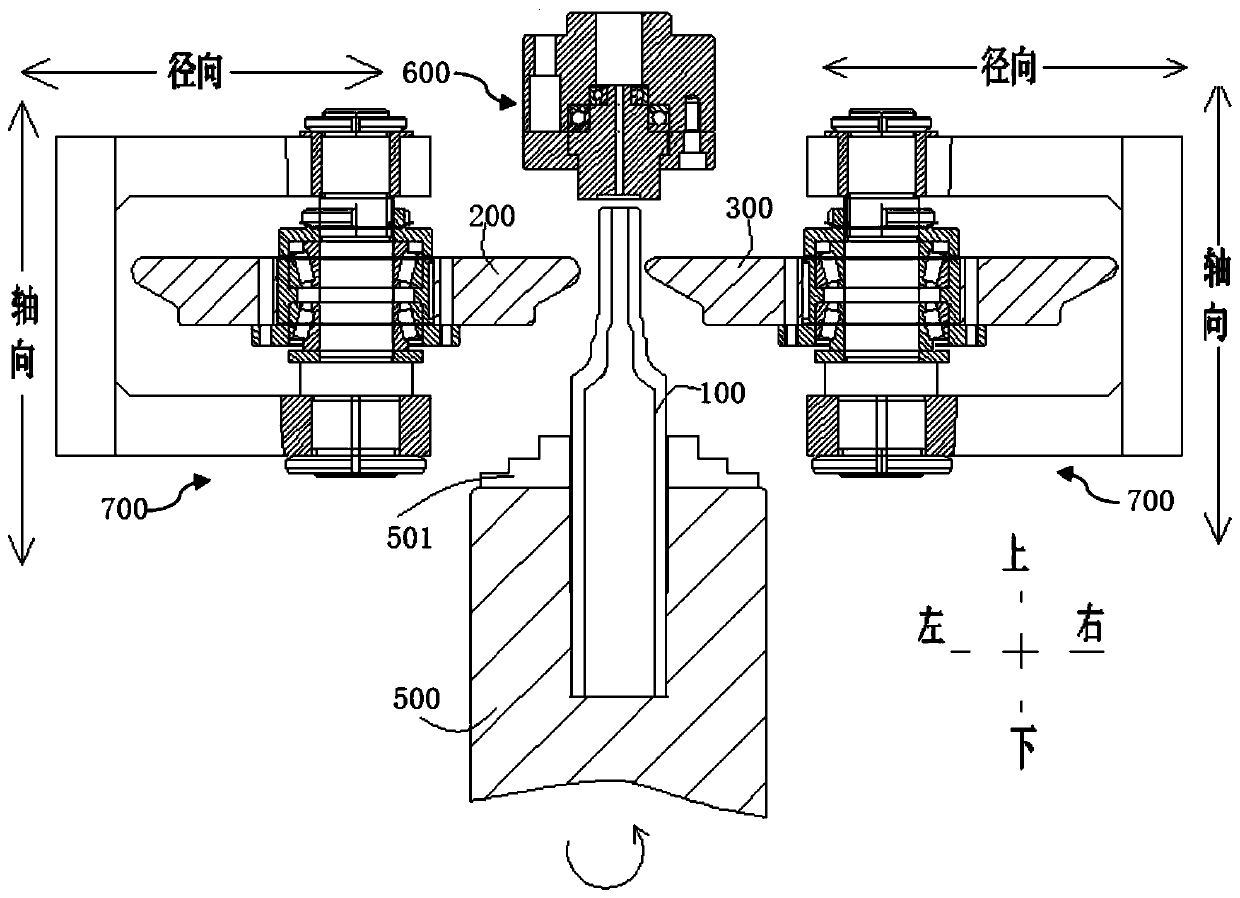

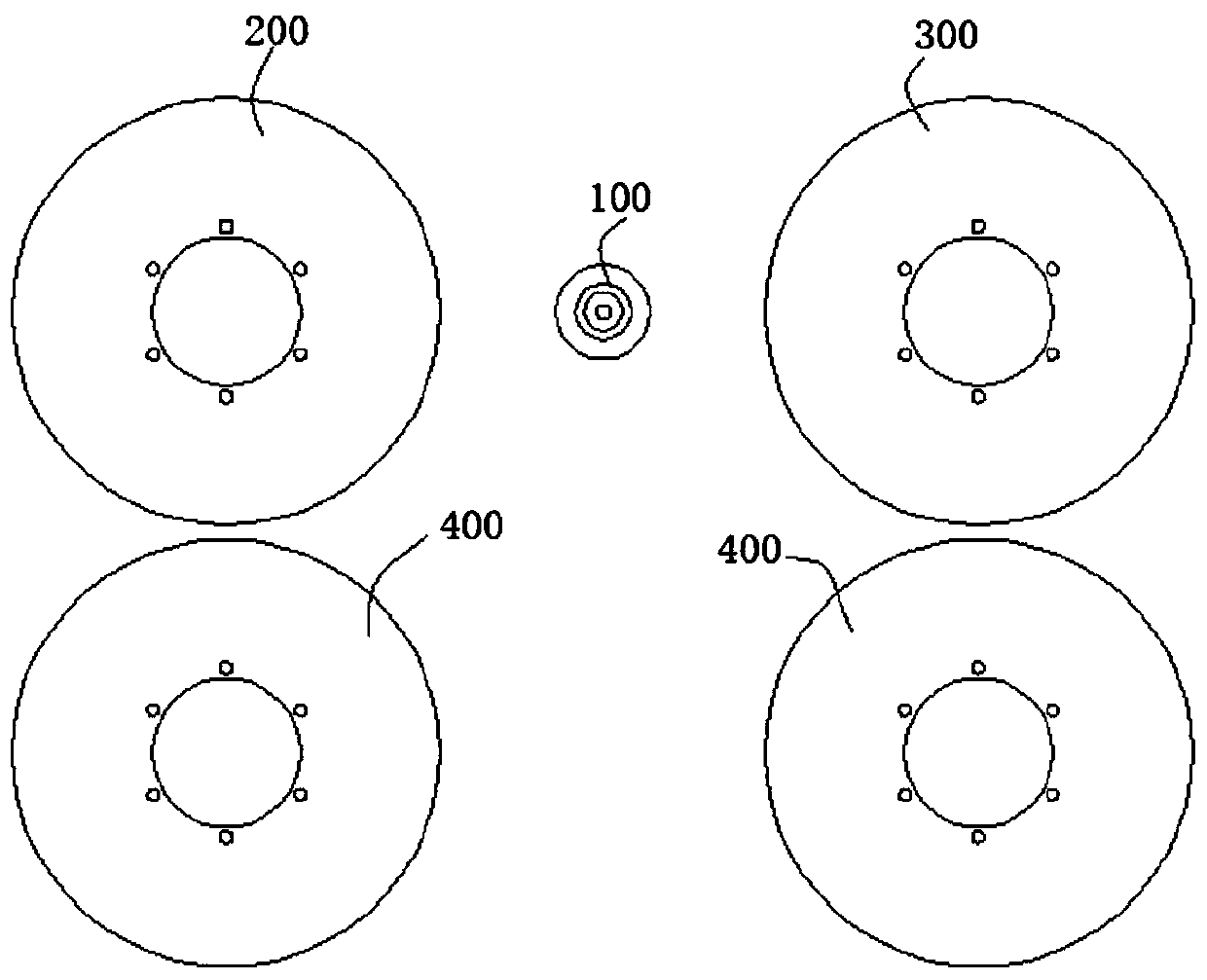

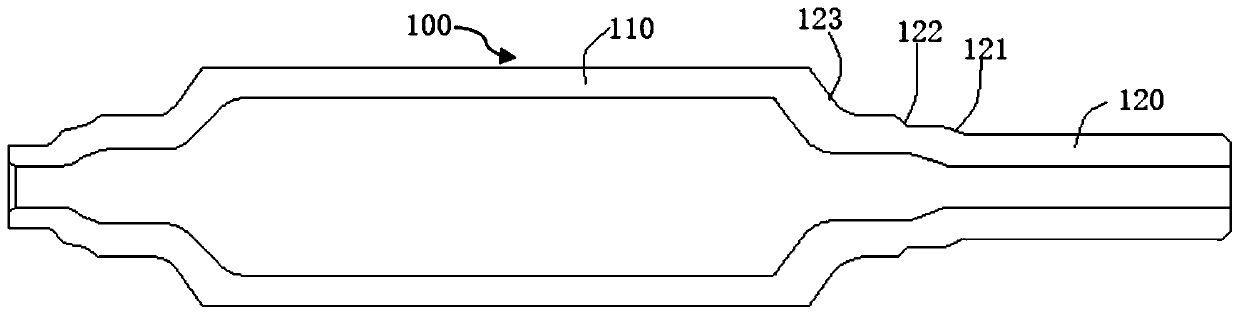

Coreless spinning machining method for large-scale multi-variable-diameter hollow shaft

The invention discloses a coreless spinning machining method for a large-scale multi-variable-diameter hollow shaft, and belongs to the field of spinning. The method comprises the following steps thatS1, a vertical spinning system is adopted, a blank is clamped in a lower die unit, the lower die unit drives a workpiece to rotate, rough spinning wheels and fine spinning wheels on the two sides ofthe workpiece simultaneously make contact with a workpiece to carry out dislocation spinning, and a point contact is used for carrying out curve reciprocating feeding spinning to form a rough spinningblank; S2, shifting the rough spinning wheels and the fine spinning wheels, enabling shaping rotary wheels on the two sides of the workpiece to be in contact with the workpiece for shaping and spinning, and carrying out wire contact shaping and finish on the shaping rotary wheels on the two sides only in the radial direction, so as to obtain a fine spinning blank; and S3, correspondingly carryingout spinning machining on the workpiece to be machined according to the above mode to obtain a rough blank. The method overcomes the problems that the hollow shaft is high in machining difficulty andpoor in forming quality in the prior art, the prepared product is high in precision, the subsequent machining allowance can be reduced to a great extent, the material utilization rate is high, and the production cost is reduced.

Owner:芜湖西诺普汽车零部件科技有限公司

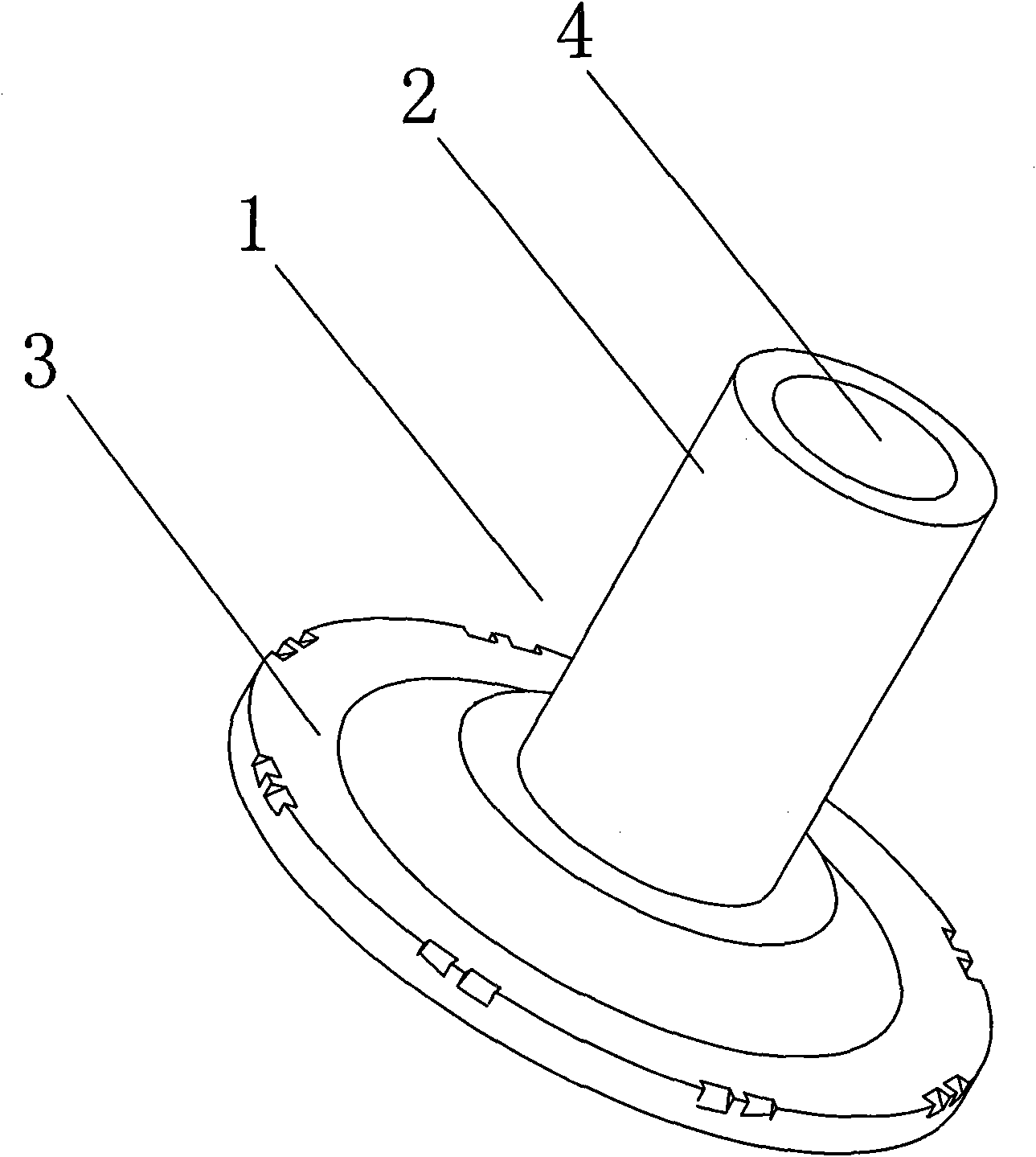

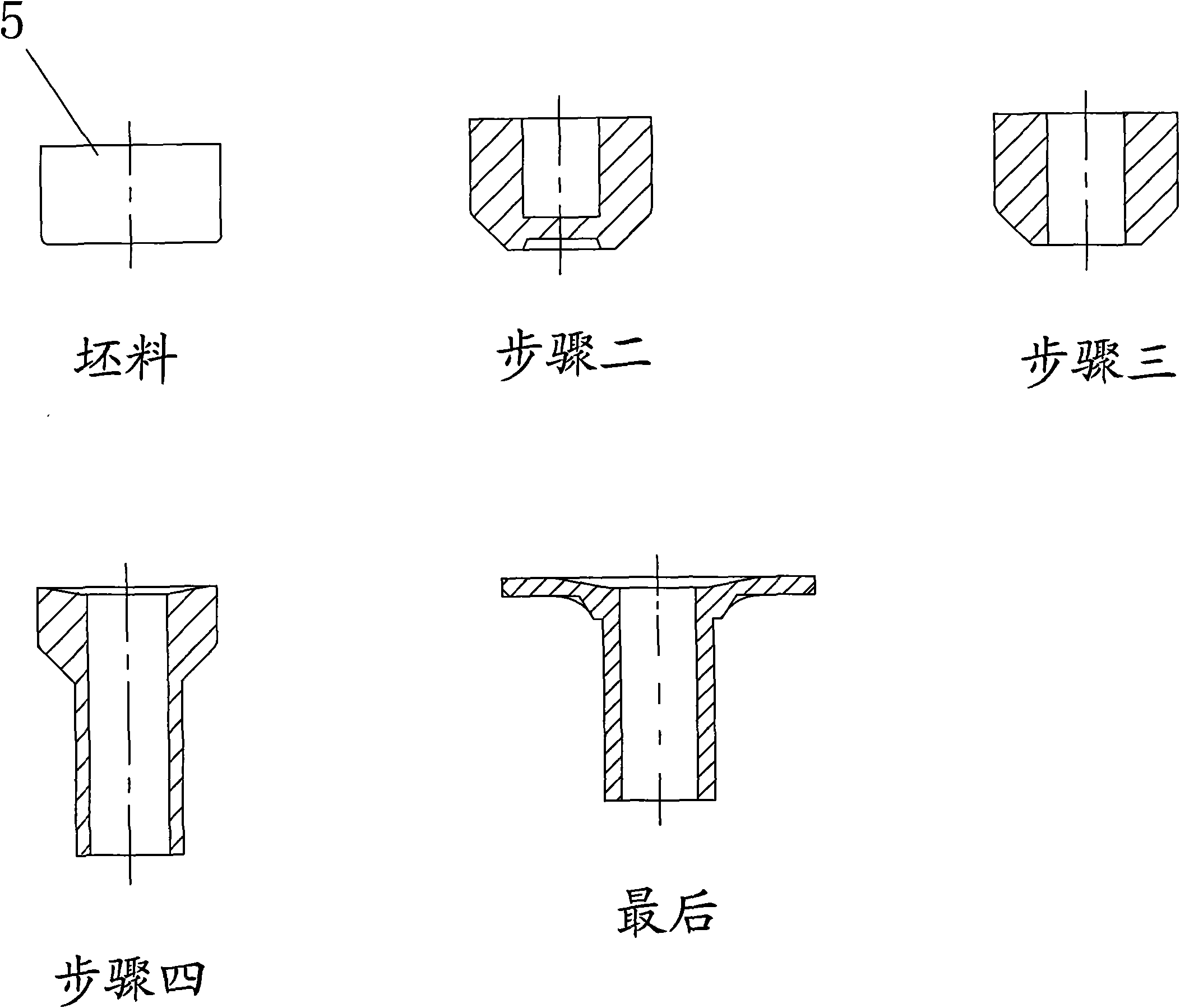

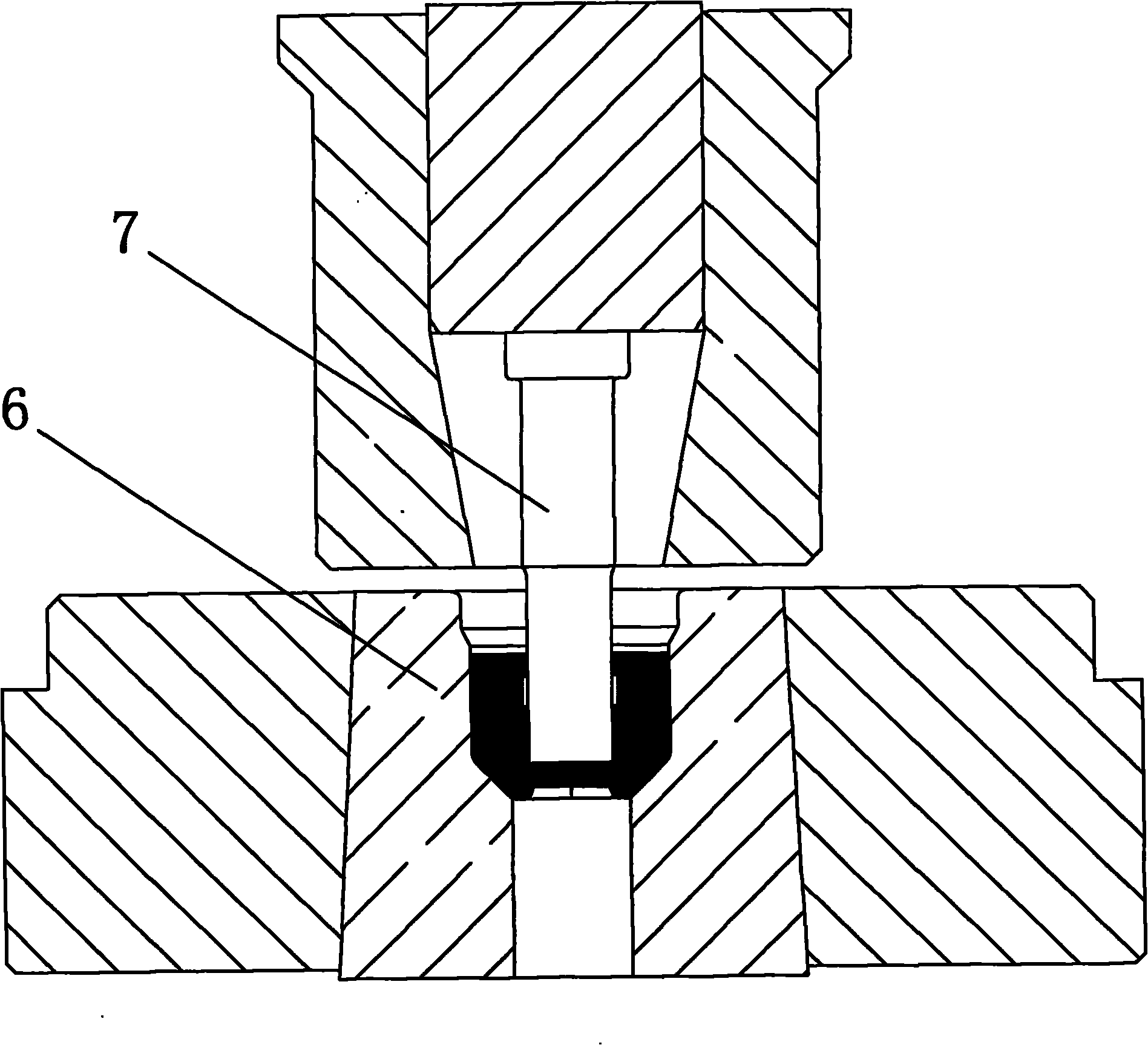

Cold heading extrusion forming processing method for shaft sleeve of clutch shaft of impeller type full-automatic washing machine

InactiveCN101966639AImprove mechanical propertiesSmall cutting allowanceMetal-working apparatusWashing machine with receptaclesEngineeringForm processing

The invention relates to a cold heading extrusion forming processing method for a shaft sleeve of a clutch shaft of an impeller type full-automatic washing machine. The shaft sleeve comprises a shaft sleeve tube and a base, wherein the base is arranged at the bottom end of the shaft sleeve tube, the shaft sleeve tube and the base are in an integrated shape, and an inner cavity of the shaft sleeve tube is communicated with the base. The cold heading extrusion forming processing method for the shaft sleeve overcomes defects of single cold heading or warm heading and then mechanical cutting in the traditional process, the shaft sleeve of the clutch shaft is manufactured through applying the advanced cold heading extrusion forming technique, the cutting allowance of mechanical processing can be reduced when the manufactured shaft sleeve of the clutch shaft is mechanically processed, in particular the process step of drilling middle holes is cancelled so that the cutting time of post processing is greatly reduced, the work efficiency is improved, the cost is lowered, raw materials are saved, the mechanical property of parts is synchronously enhanced through cold heading extrusion forming, and the service life of a product is prolonged.

Owner:佛山市顺德区君鸿实业有限公司

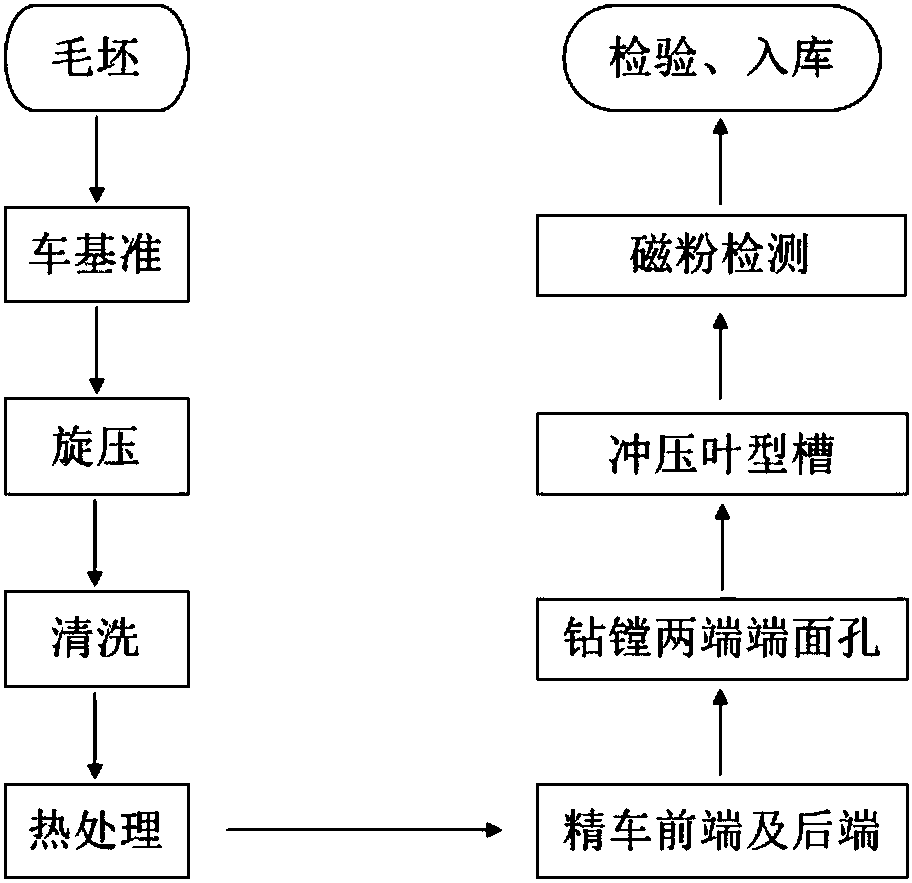

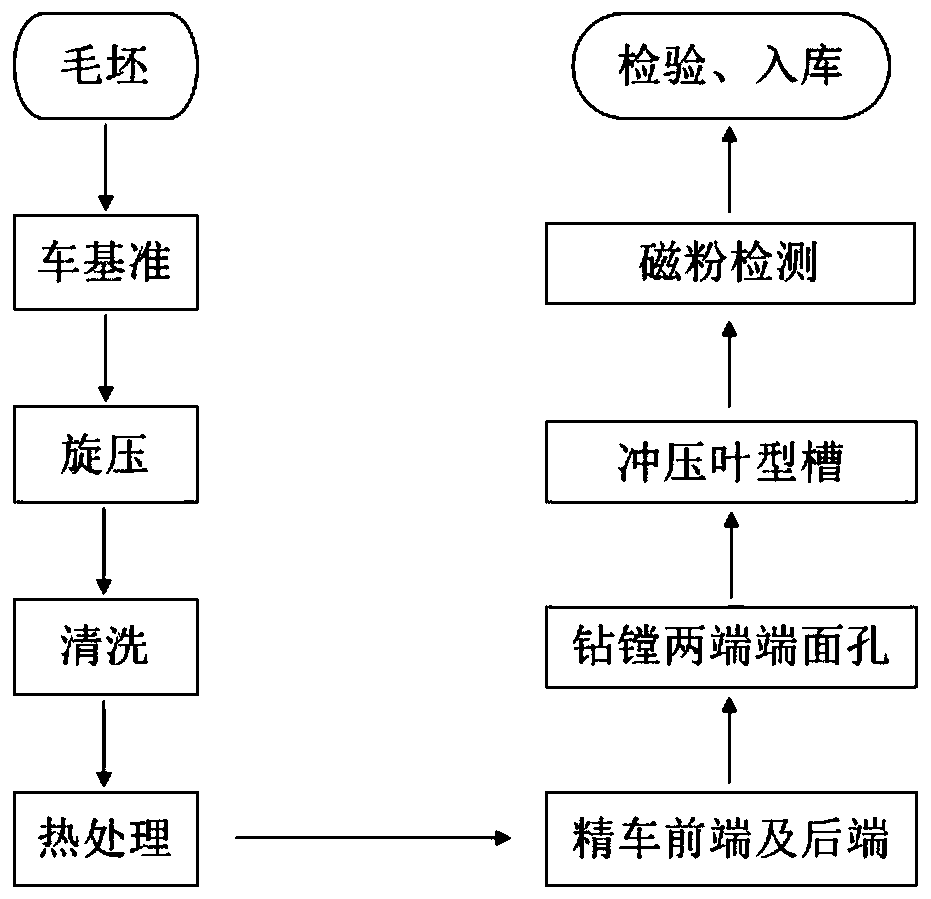

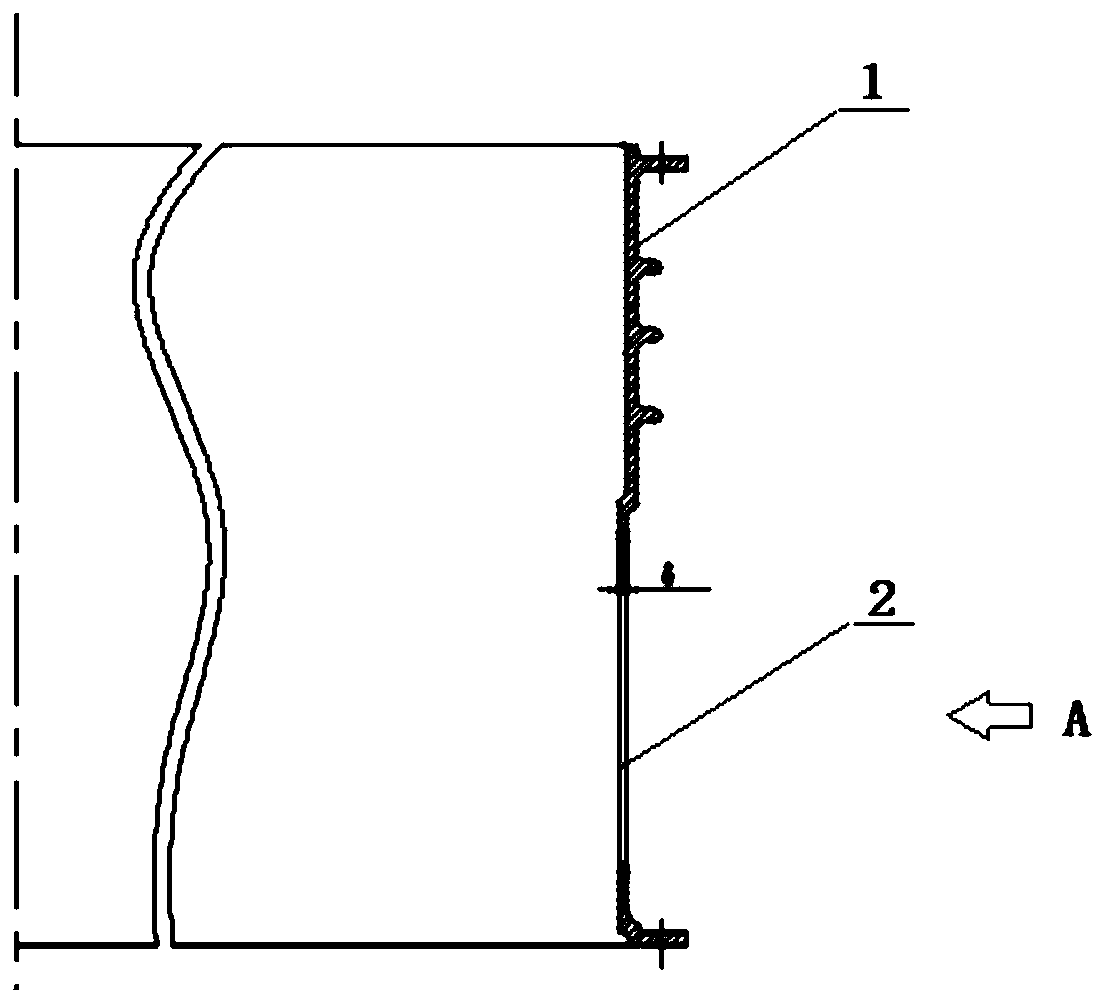

Machining method of low-pressure compressor casing

The invention relates to a machining method of a low-pressure compressor casing. The method comprises the following steps that 1, a blank is inspected; 2, a benchmark is turned; 3, spinning is carriedout, wherein the blank is subjected to drawing and spinning by using a powerful numerical control spinning machine, so that a workpiece is obtained, wherein the wall thickness delta and the roundnessof the workpiece are controlled to be within 0.1 mm, and a small amount of allowance is reserved at the two ends of the workpiece to be used for subsequent mechanical machining; 4, the workpiece is cleaned, wherein a lubricant on the surface of the workpiece is cleared; 5, heat treatment is carried out, wherein the spinning stress is eliminated through the heat treatment; 6, a finish turning is carried out on a front end of the workpiece and a rear end of the workpiece; 7, the end face holes at the two ends of the workpiece is drilled and bored; 8, stamping of blade-type grooves is carried out, wherein a numerical-control punching machine is used for equidistantly stamping the blade-shaped grooves on the workpiece in the radial direction and fine trimming is carried out, so that the position degree of the blade-shaped groove is ensured to be 0.2 mm, and the contour degree of the blade-shaped groove is 0.05 mm; 9, magnetic particle testing is carried out; and 10, checking and storing are carried out. According to the method, the requirements of case deformation control, surface quality control and cost control can be met.

Owner:重庆天骄航空动力有限公司

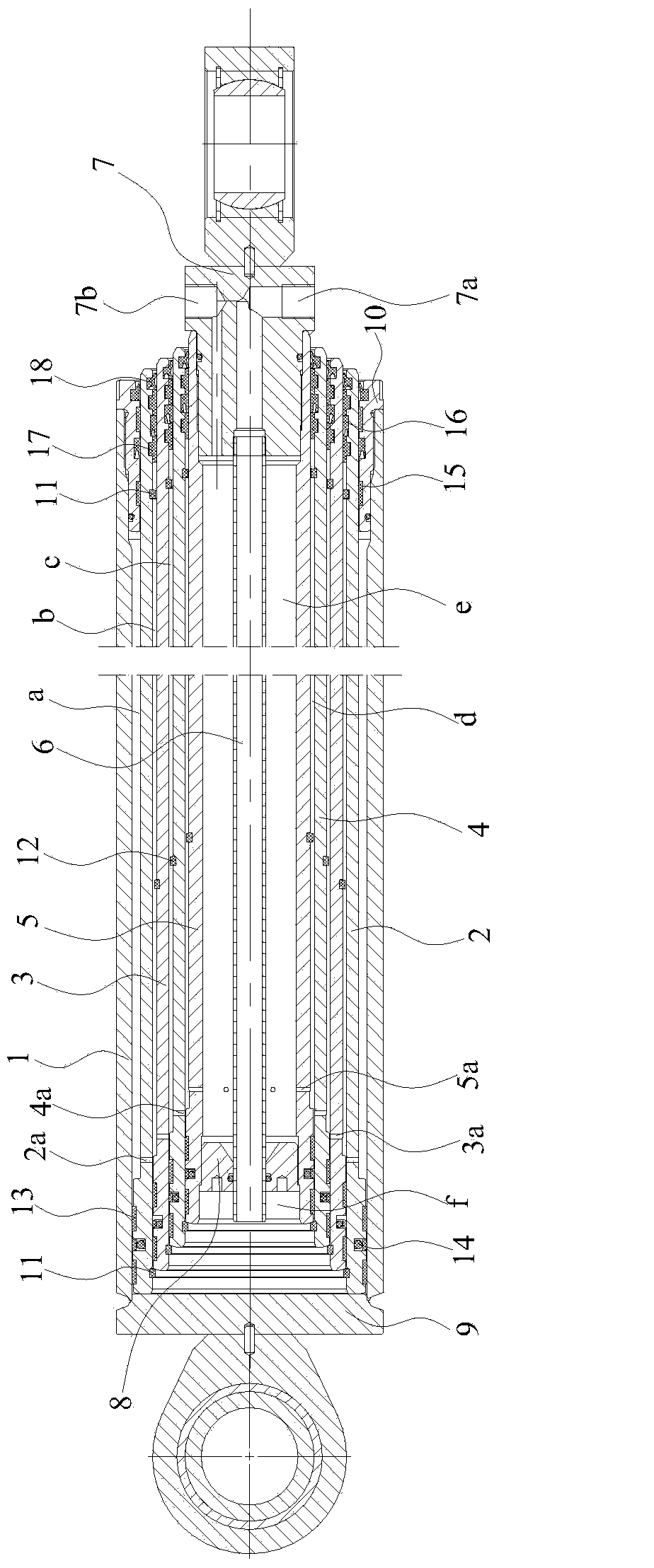

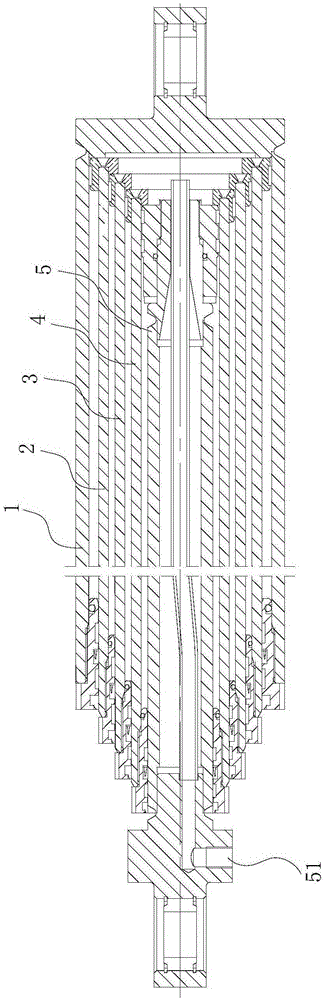

Double-purpose through hole type four-level oil cylinder

InactiveCN104196819ACompact structureHigh strengthFluid-pressure actuatorsEngineeringPulp and paper industry

A double-purpose through hole type four-level oil cylinder comprises an outer cylinder barrel, a cylinder bottom, a core tube assembly and through hole type middle cylinder barrels, wherein the core tube assembly is composed of an oil tube, an end cover and a piston, an extending oil opening and a retracting oil opening are formed in the end cover, and the extending oil opening is communicated with an inner cavity of the oil tube; chambers are formed between the outer cylinder barrel and the middle cylinder barrel adjacent to the outer cylinder barrel, between the adjacent middle cylinder barrels, and between the oil tube and the middle cylinder barrel adjacent to the oil tube, and an oil passing hole is formed in each middle cylinder barrel and communicated with the two corresponding adjacent chambers; the portion, close to the cylinder bottom end, of each middle cylinder barrel is provided with a piston structure, and gaps are formed between the piston structures and the piston and between the piston structures and the cylinder bottoms respectively and form a chamber together; limiting check rings used for holes are formed in the inner walls of the corresponding positions of the middle cylinder barrels, limiting check rings used for shafts are installed on the outer walls of the corresponding positions of the middle cylinder barrels, and the two end faces of the inner ring of each limiting check ring used for holes and the two end faces of the outer ring of each limiting check ring used for shafts are chamfered. The oil cylinder is low in machining cost and compact in structure, the extending strokes and the maximum strokes of cylinder barrels at all levels can be adjusted finely by adjusting the positions of the limiting check rings used for holes and the limiting check rings used for shafts.

Owner:BENGBU YELI MACHINERY

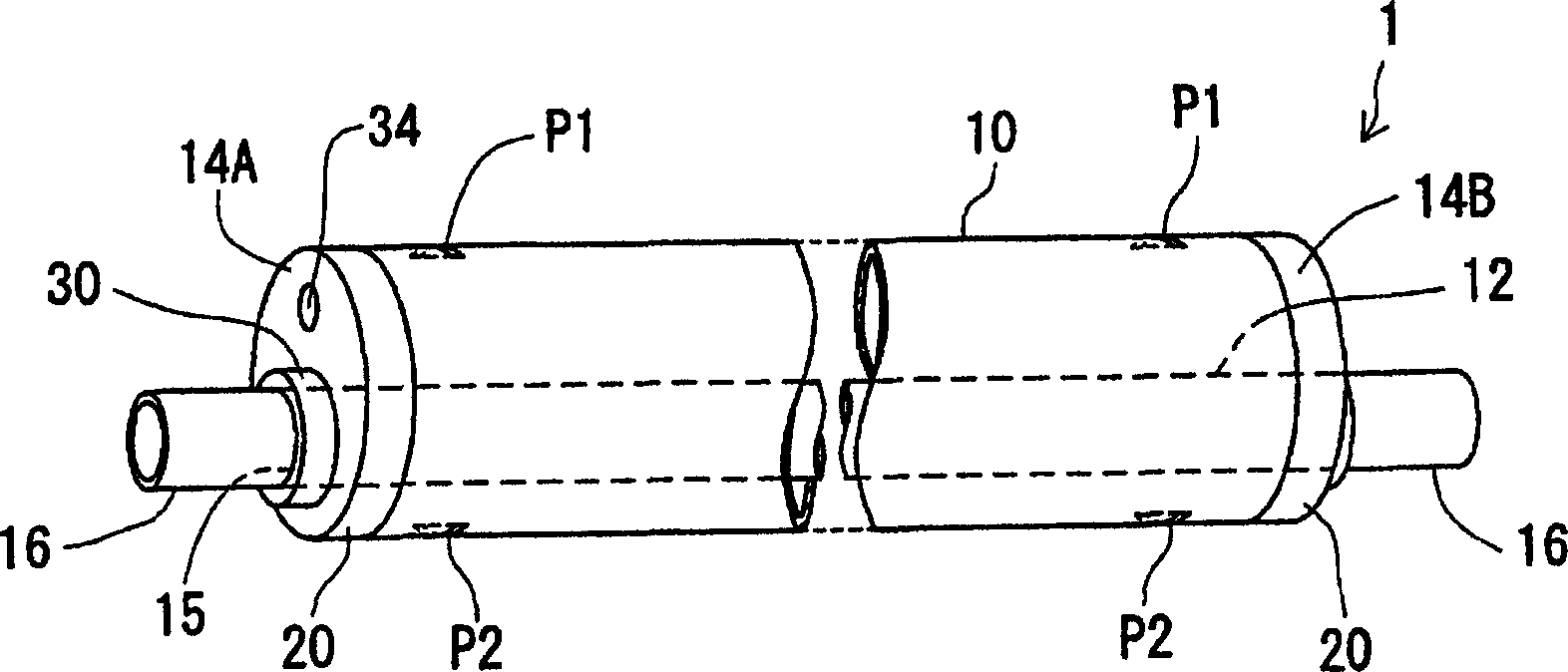

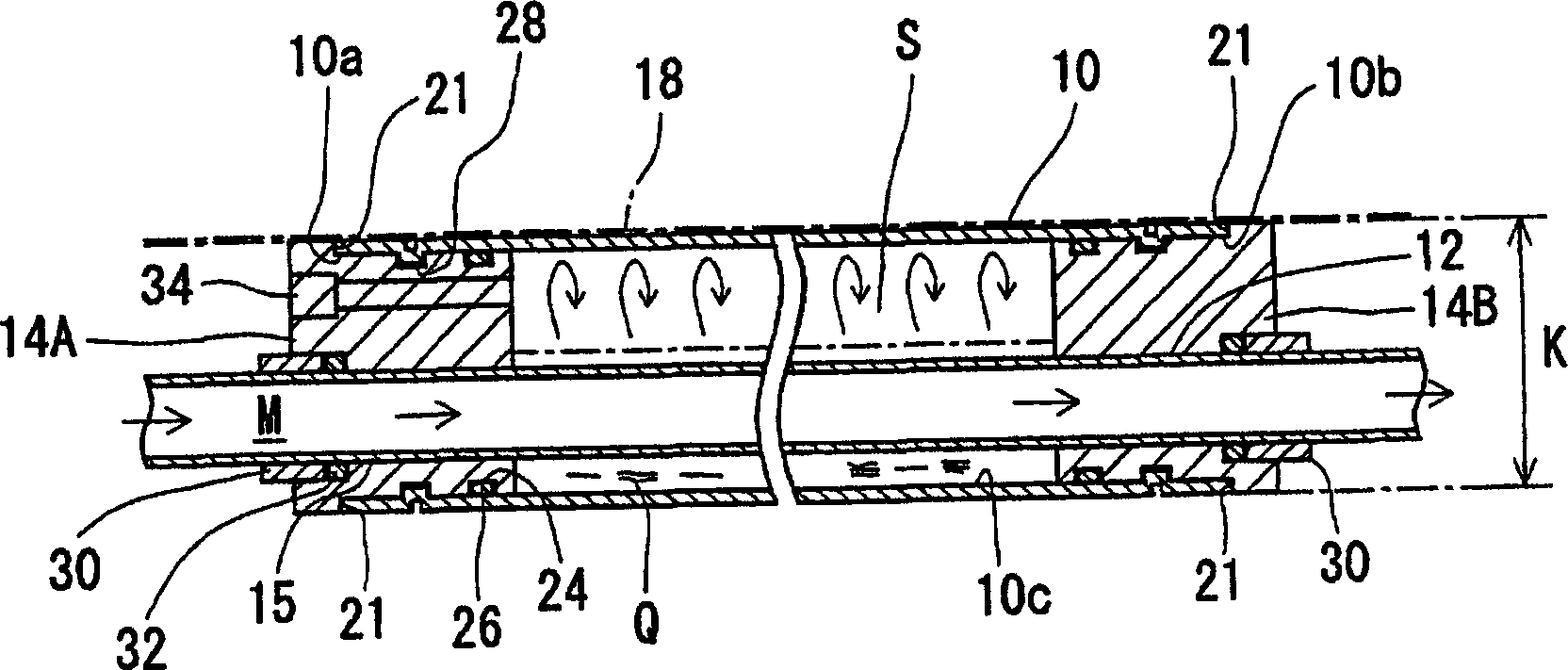

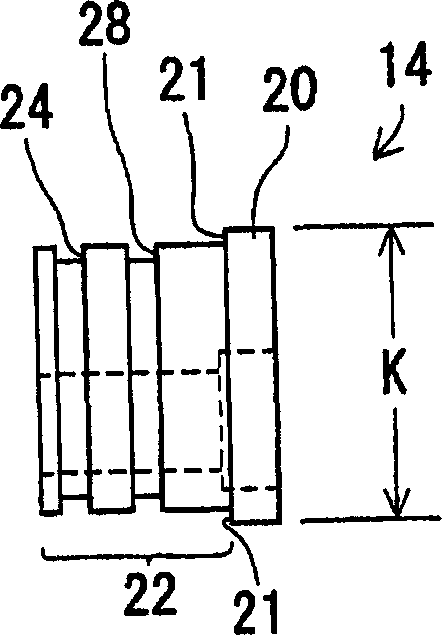

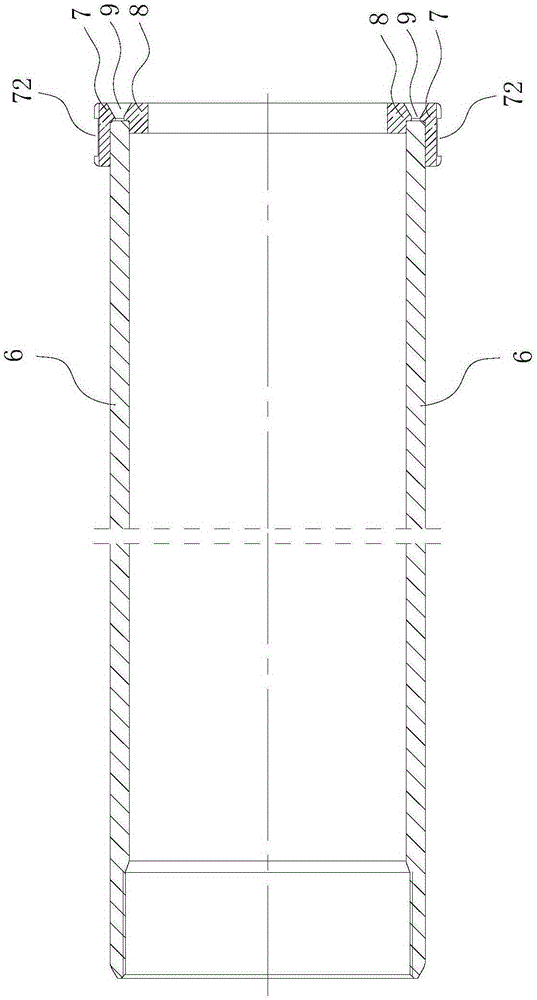

Thermosyphon and method of manufacturing the same

InactiveCN1833154AReduce heat transfer lossImprove heat transfer efficiencyIndirect heat exchangersSustainable buildingsDouble tubeHeat transfer efficiency

A thermosyphon formed in a simple structure, enabling an increase in heat transfer efficiency for transferring heat from the thermosyphon to the outside, and manufacturable at low cost and a method of manufacturing the thermosyphon. The double tube type thermosyphon is formed in a single and constant outside diameter size of cylindrical shape having an outer tube (10) and plug bodies (14). The outer tube (10) and the plug bodies (14) are formed in the constant outside diameter (K) size so as to come into contact simultaneously with one plane put on the upper outer surface thereof. Thus, for example, when the syphon is installed under a floor, the syphon is continuously fitted to an upper heat transfer plate in the longitudinal direction to reduce heat transfer loss and increase the heat transfer efficiency. Also, the yielding of material can be increased by reducing cut-out portions.

Owner:武原力

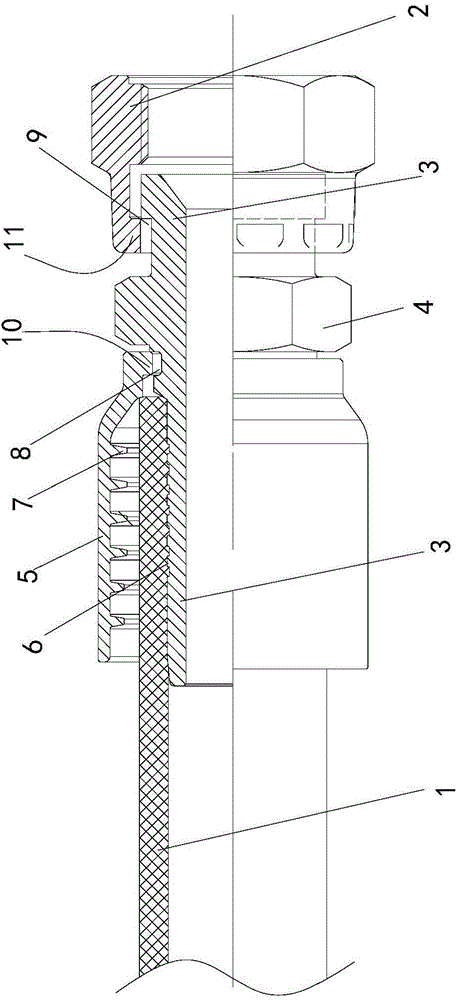

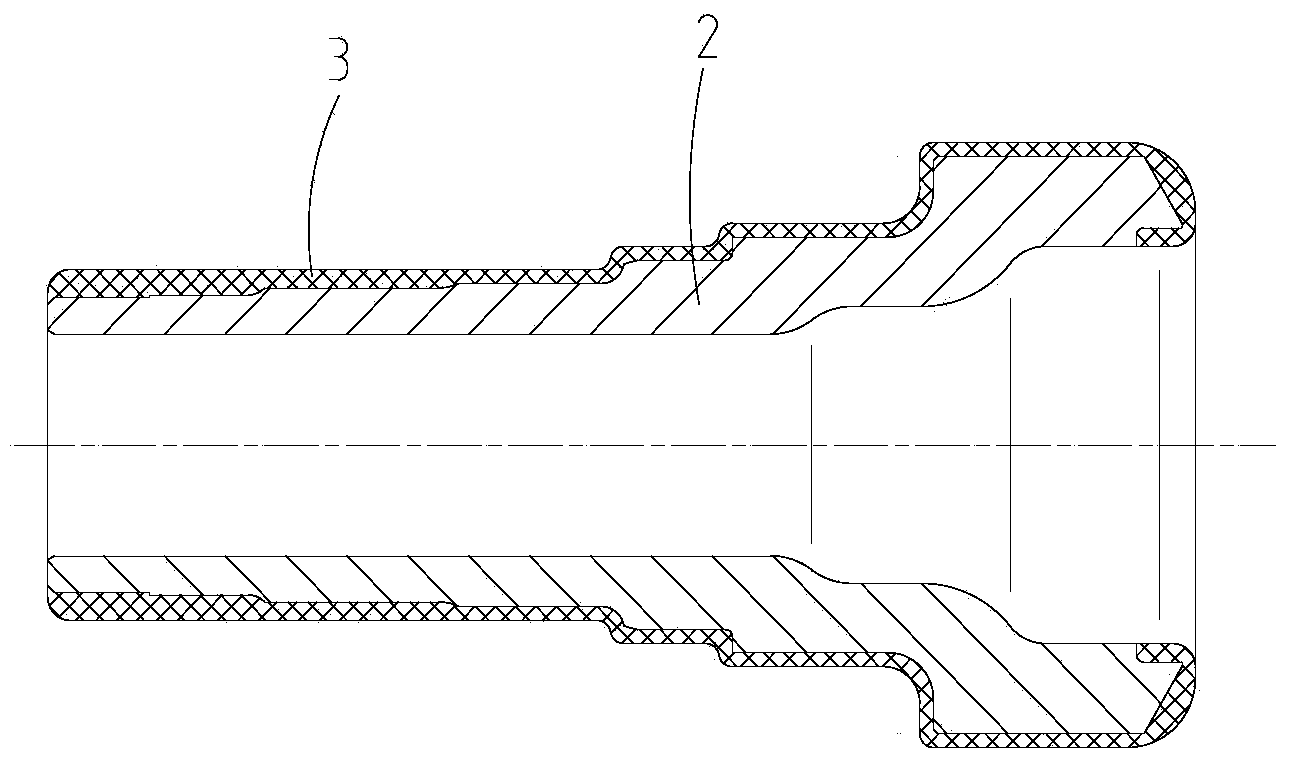

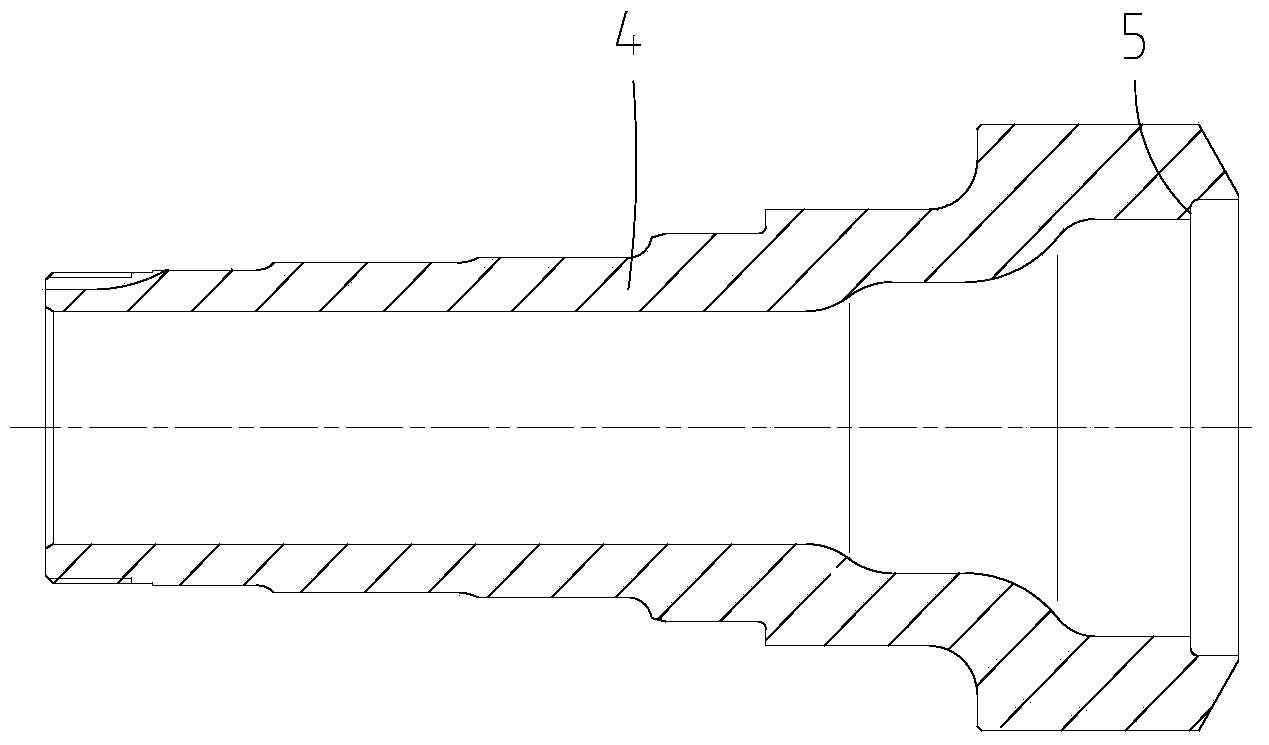

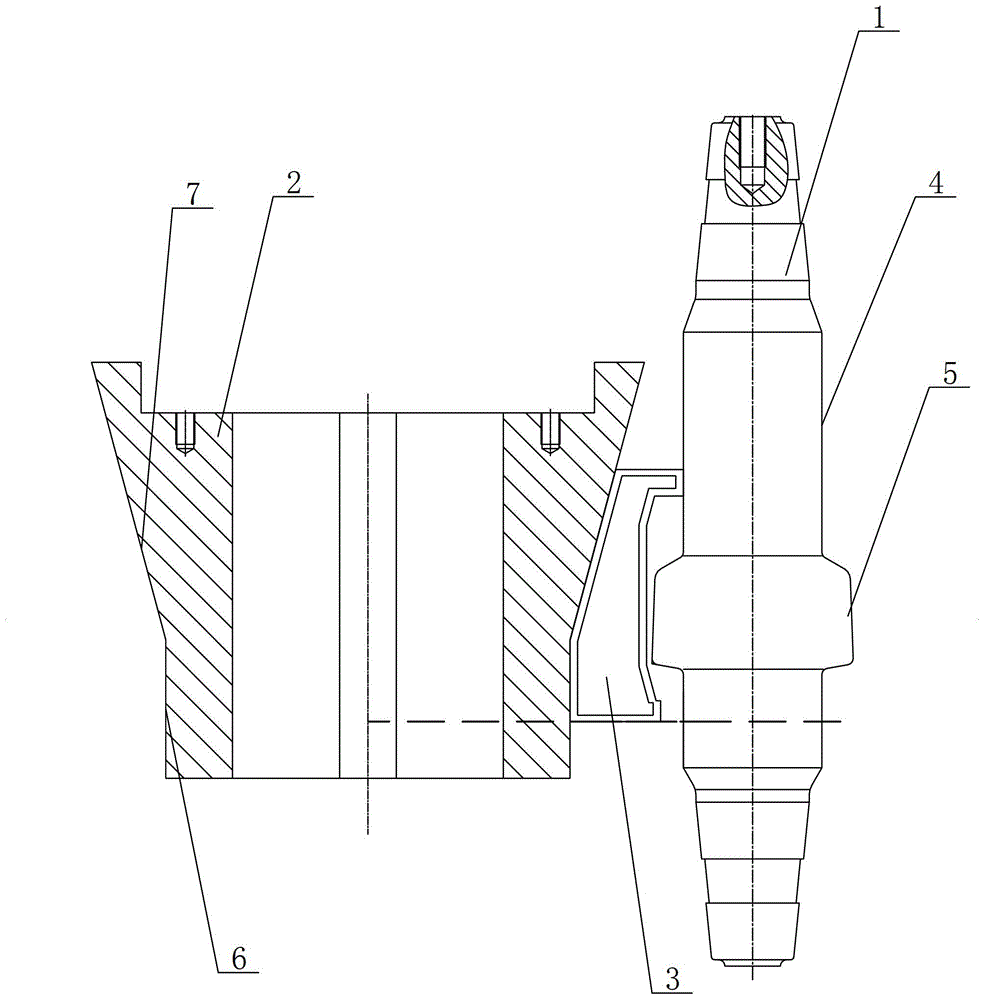

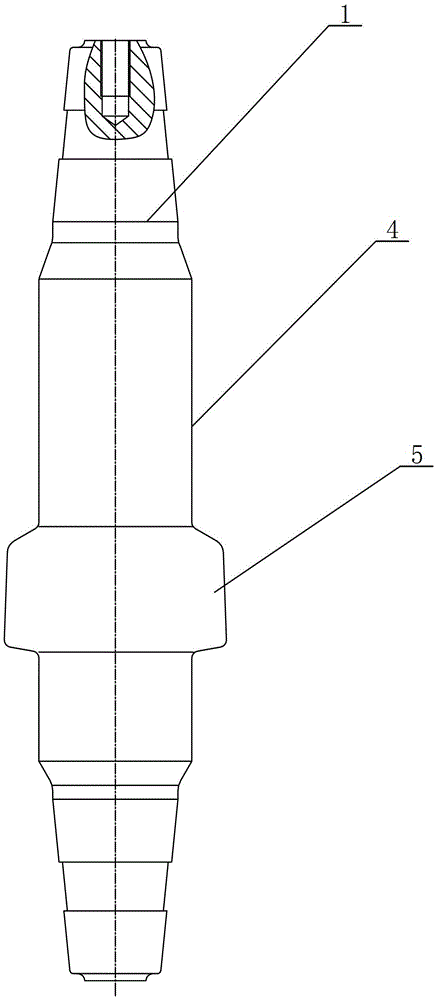

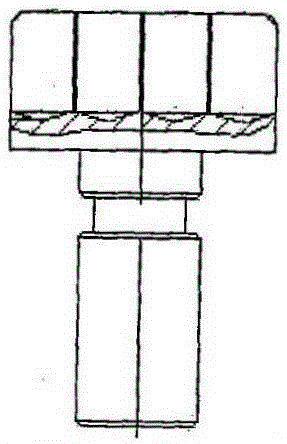

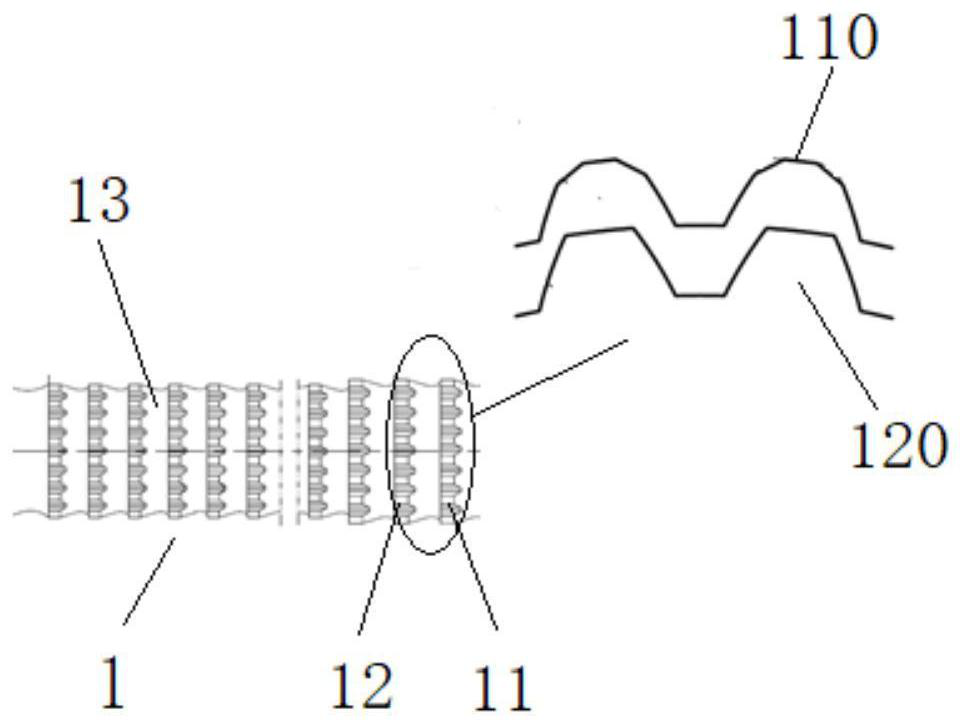

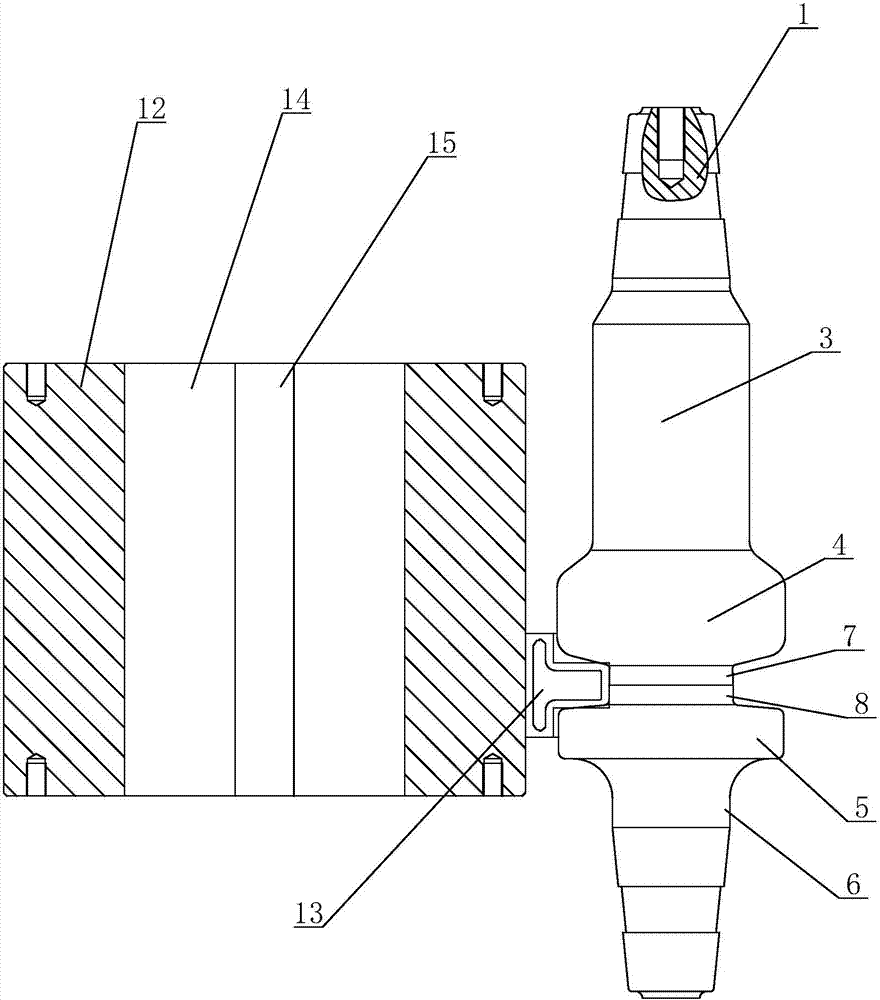

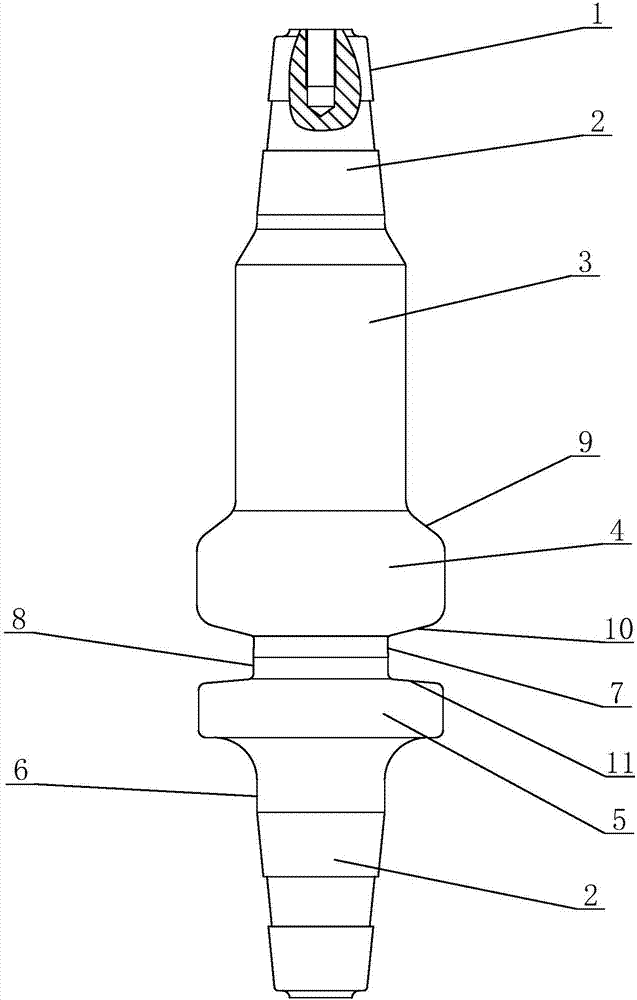

Engine oil inlet pipe joint and machining method thereof

InactiveCN104564455ASmall cutting allowanceImprove sealingMachines/enginesLiquid fuel feedersMachining processPetroleum engineering

The invention discloses an engine oil inlet pipe joint and a machining method thereof. The engine oil inlet pipe joint comprises a bamboo joint type connecting pipe (3), a bushing (5), a fastening nut (4) and an external nut (2), wherein the bamboo joint type connecting pipe (3) is connected with a rubber pipe (1); the fastening nut (4) and the bamboo joint type connecting pipe (3) are integrally formed; the external nut (2) sleeves one end of the bamboo joint type connecting pipe (3); the bushing (5) sleeves the outer side of the other end of the bamboo joint type connecting pipe (3); the rubber pipe (1) is positioned between the outer wall of the bamboo joint type connecting pipe (3) and the inner wall of the bushing (5); the outer wall of the bamboo joint type connecting pipe (3) is provided with a plurality of annular bumps (6) which are embedded into the inner wall of the rubber pipe (1); the inner wall of the bushing (5) is provided with a plurality of clamping teeth (7) which are embedded into the outer wall of the rubber pipe (1). The engine oil inlet pipe joint which is low in production cost and reliable in rubber pipe connection and the engine oil inlet pipe joint machining method which is simple in machining processes and firm and reliable in rubber pipe connection are provided.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

Method for machining hub shaft tube

The invention discloses a method for machining a hub shaft tube. The machining method comprises the following steps: firstly, extruding a hollow steel tube to form a hub shaft tube blank; secondly, machining the hub shaft tube blank to obtain the hub shaft tube. By adopting the machining method, the metal chipping allowance of the outer surface of the hub shaft tube can be reduced remarkably, and the material utilization ratio is effectively increased. Meanwhile, an all-fiber texture of the hub shaft tube which is distributed in the axial direction can be well kept, the metallographic structure of the hub shaft tube is stabilized, and the service life is prolonged.

Owner:湖南中联重科车桥有限公司 +1

Thermal treatment method of metal tube and said thermal treatment apparatus

InactiveCN1455005ANo increase in electricity costsSmall cutting allowanceIncreasing energy efficiencyFurnace typesOperation modeDepth of penetration

The present invention provides a heat-treatment technique. It is characterized by that when said invention adopts a continuous mobile inductive heating and cooling operation mode to treat the external surface of workpieces of roll, etc., at the same time it can inhibit the outer diameter deformation due to heat treatment. At the same time of making heat treatment of external surface of said workpiece of roll, etc. the inner surface of said workpiece can be cooled, and the depth of penetration of the induced current in the induction heating process can be limited in a certain range to reduce deformation of its outer diameter.

Owner:DAI ICHI HIGH FREQUENCY

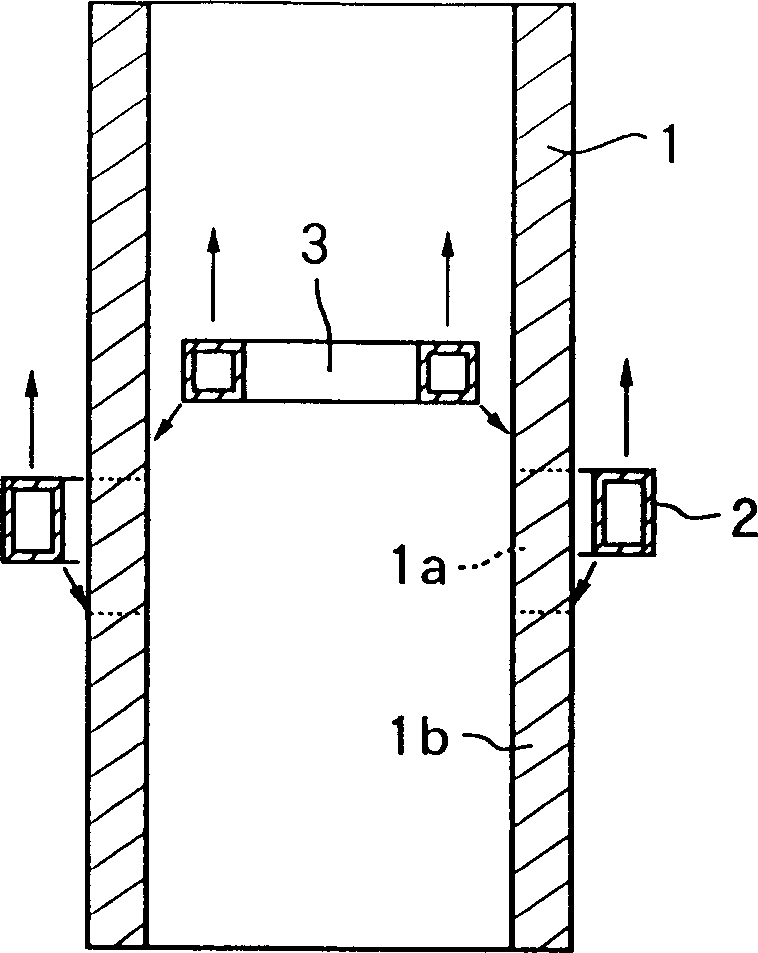

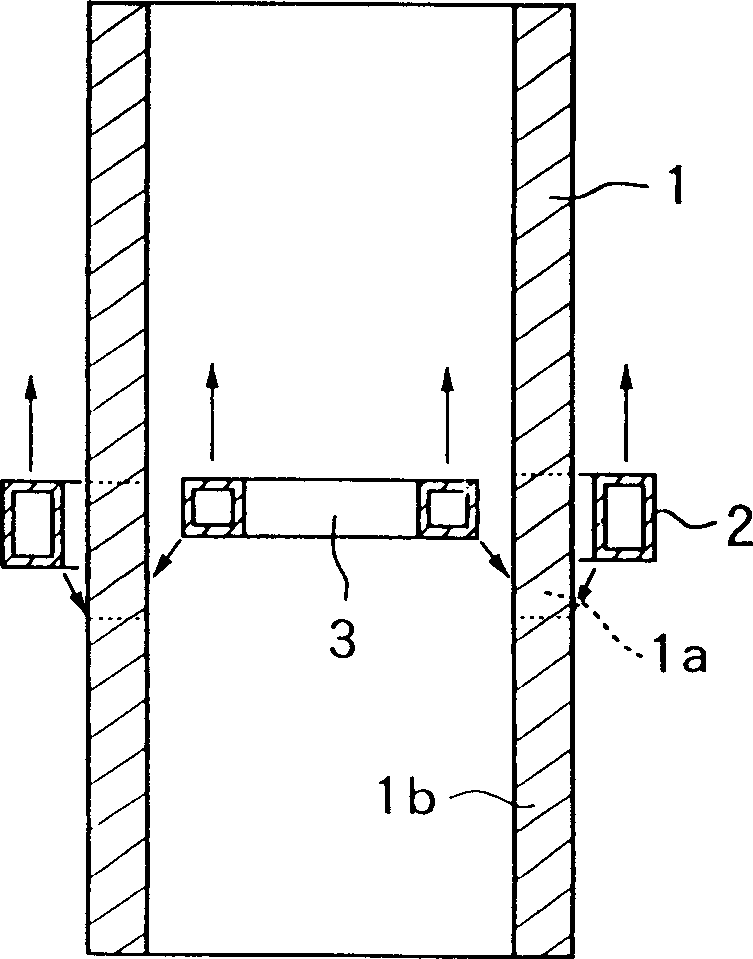

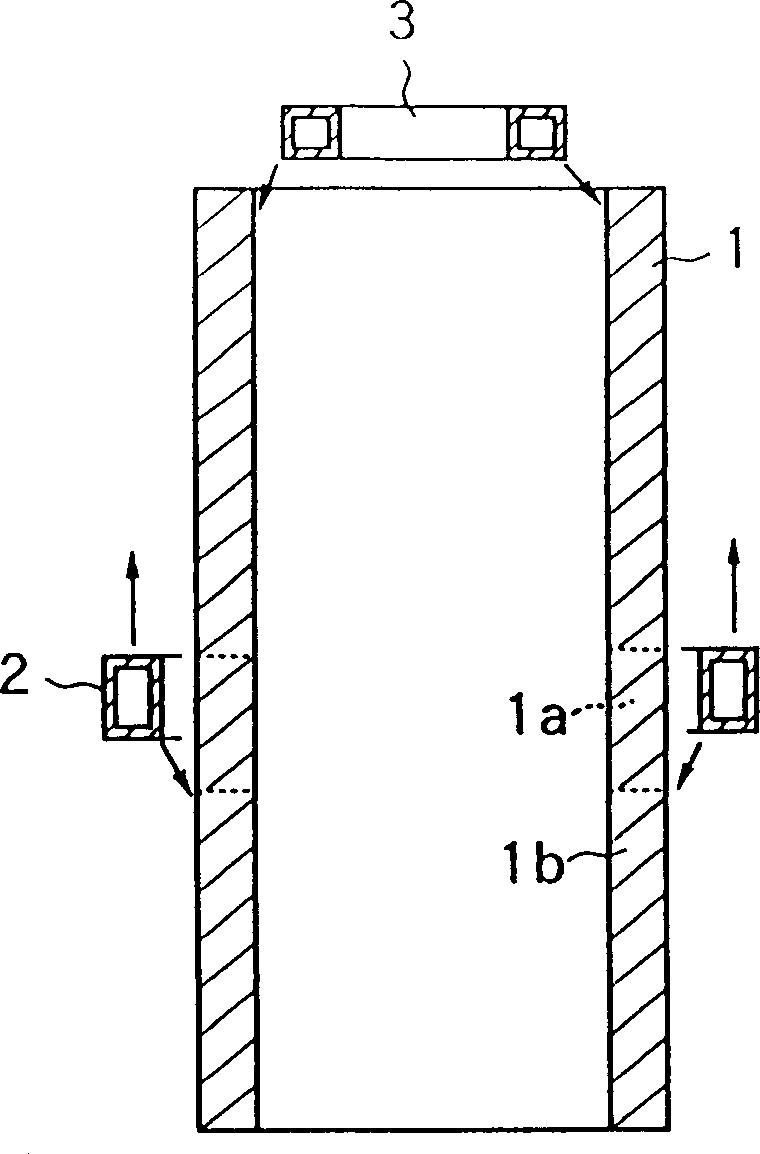

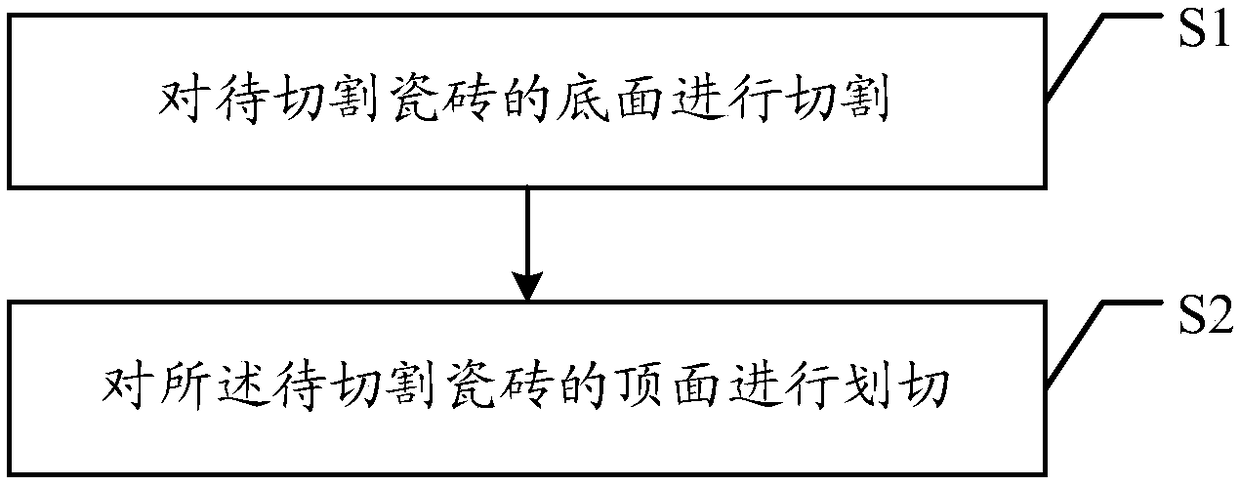

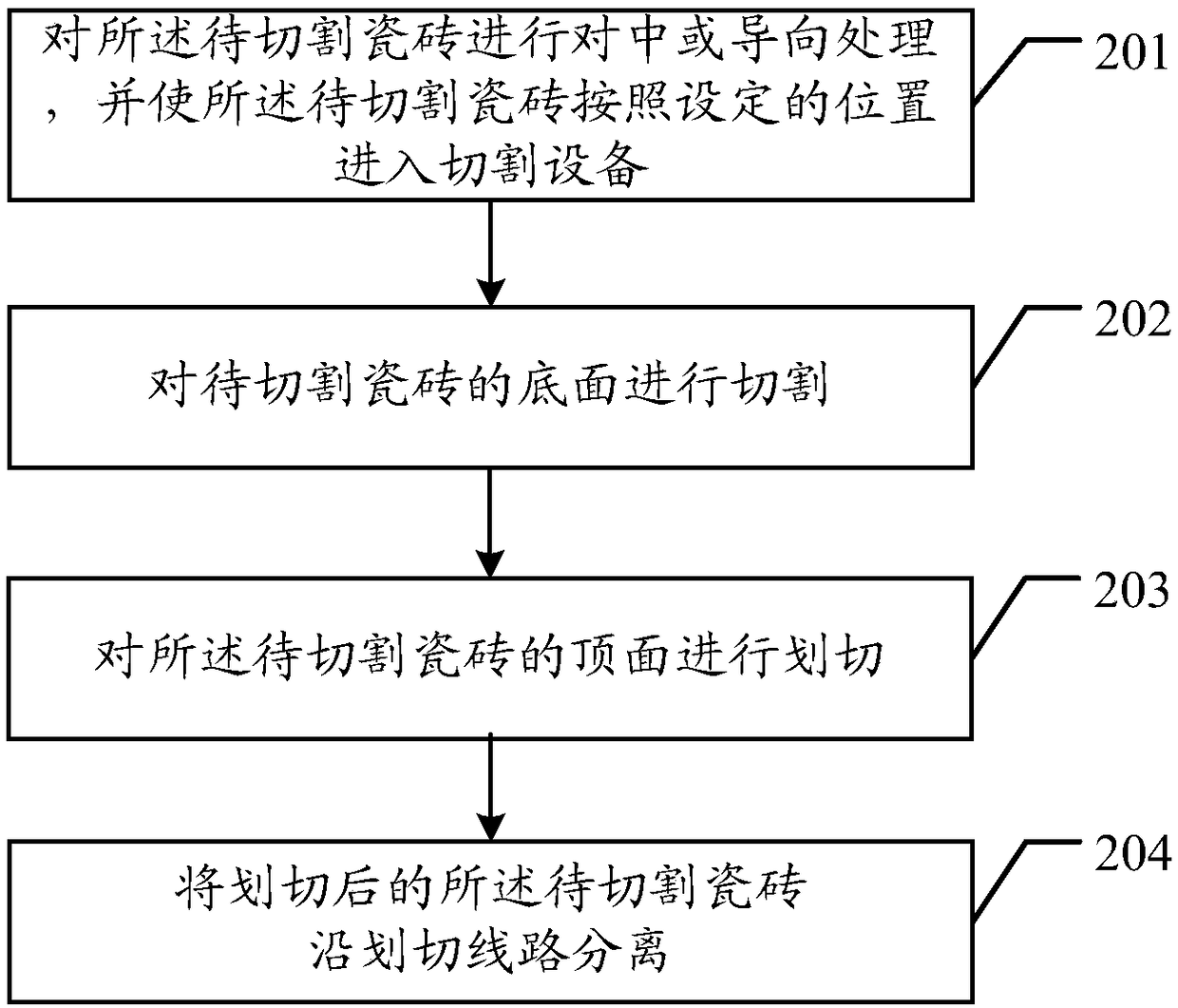

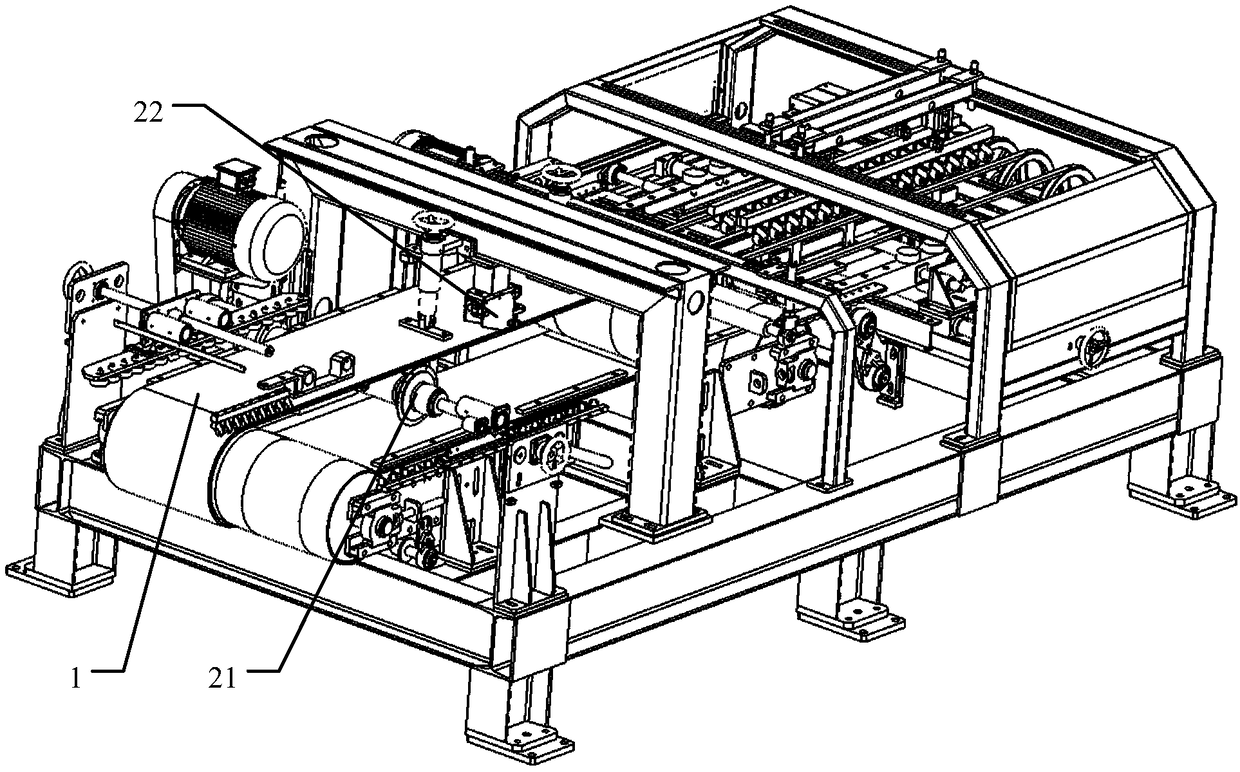

Ceramic tile cutting process and device

PendingCN109333831ASmall cutting allowanceReduce lossStone-like material working toolsMetallurgyScratch marks

The invention discloses a ceramic tile cutting process and device. By the adoption of a ceramic tile cutting method for cutting the bottom and scratching the face, one knife cuts the bottom face of ato-be-cut ceramic tile to a certain depth, another knife scratches marks on the top face of the to-be-cut ceramic tile, the back face of the to-be-cut ceramic tile is cut off along the cutting line through a breaking device, and the probability of breaking like edge breakage and bottom falling in the cutting process of the to-be-cut ceramic tile is effectively reduced. The ceramic tile cutting device comprises a ceramic tile cutting device body which comprises a conveying mechanism and a cutting mechanism; the cutting mechanism comprises a bottom cutting module and a face scratching module; the bottom cutting module is arranged below the conveying mechanism and used for cutting the bottom face of the to-be-cut ceramic tile; and the face scratching module is arranged above the conveying mechanism and used for scratching the top face of the to-be-cut ceramic tile.

Owner:佛山市爱陶机电设备有限公司

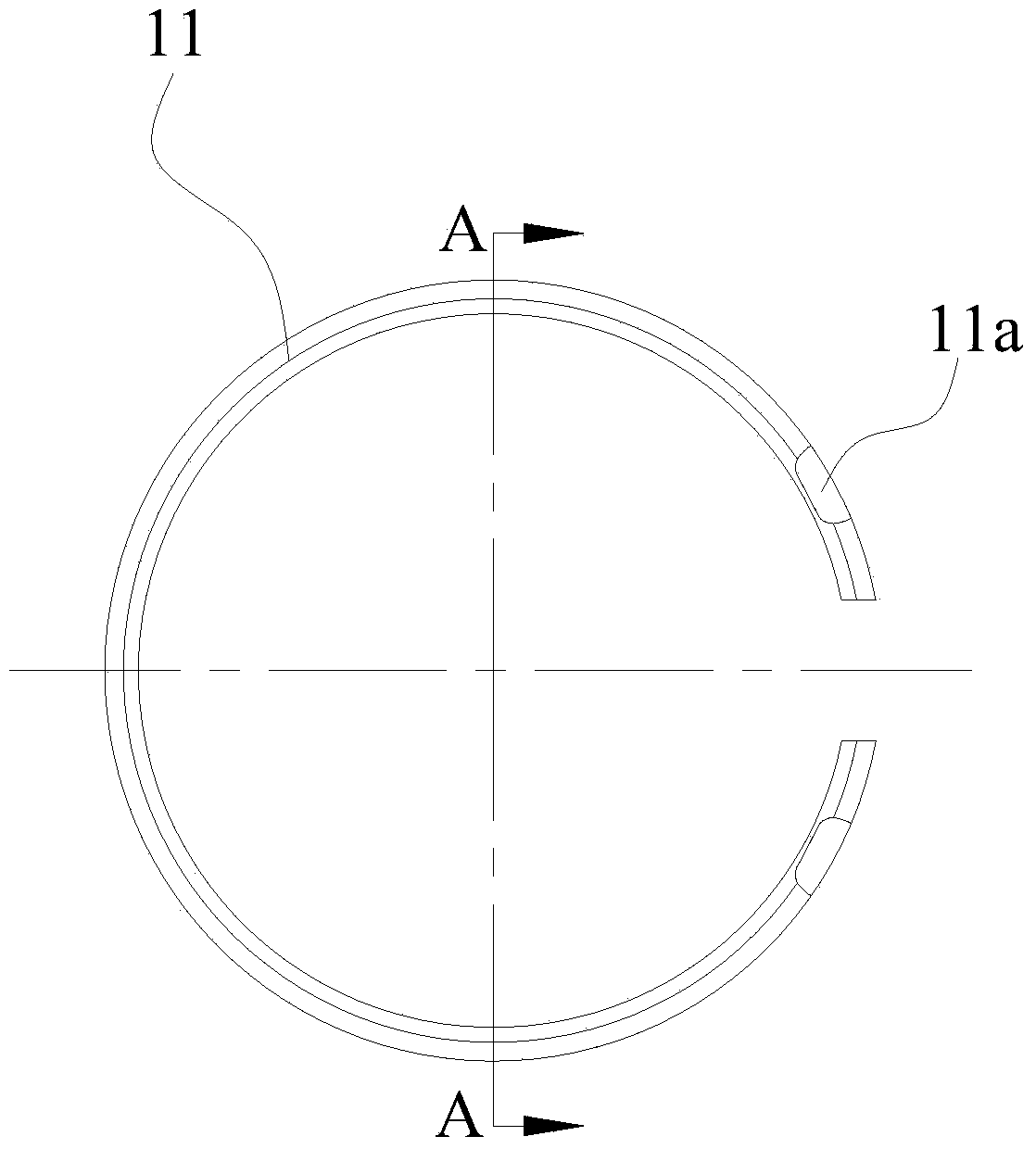

Single-acting welded type four-stage oil cylinder

InactiveCN105179370ACompact structureSmall cutting allowanceCylindersFluid-pressure actuatorsPulp and paper industryPipe support

The invention discloses a single-acting welded type four-stage oil cylinder which comprises an outer cylinder barrel, a primary cylinder barrel, a secondary cylinder barrel, a third-stage cylinder barrel and a piston rod assembly sequentially arranged in a sleeving manner from external to internal, wherein each of the primary cylinder barrel, the secondary cylinder barrel and the third-stage cylinder barrel is formed by welding a steel pipe, a piston and an internal limiting ring; the internal part of the end face of each steel pipe supports the corresponding internal limiting ring; the external part of the end face of each steel pipe is sleeved with the corresponding piston; the piston, the internal limiting ring and the end face of the steel pipe are assembled and welded to form a welding groove; an oil groove is formed in each piston in the axial direction, and a support circular groove is machined in the piston transversely. The single-acting welded type four-stage oil cylinder is more compact, adopts the welded type structure, is an integrity formed by welding the internal limiting rings, the pistons and the steel pipes, is small in chipping allowance, low in cost, simple in processing technology and high in efficiency; the pistons are machined after welding, so that the size of the support circular groove and the coaxiality of the support circular groove and the steel pipes are ensured, and the operational stationarity of the oil cylinder is ensured; the oil grooves are additionally formed in the pistons, so that the oil mass is increased, and the overall working efficiency of the oil cylinder is improved.

Owner:BENGBU YELI MACHINERY

A slider forging die structure

ActiveCN103447442BSmall cutting allowanceSave materialForging/hammering/pressing machinesEngineeringFlange

The invention discloses a slider forging mold structure, which is used for the production and manufacture of sliders in a rubber tire forming mold, which includes a core roller and a main mold, and a forging is arranged between the core roller and the main mold, wherein the core roller The middle part is a cylindrical section with a cylindrical structure, and the cylindrical section is provided with a shoulder, the upper end of the shoulder is inclined downward, and the lower end is inclined upward, and the side of the shoulder is from top to bottom Inclined to the outside, the main mold includes a vertical section, and the upper end of the vertical section extends obliquely outwards with a bent section. The slider forging mold structure above is processed by the mold to produce a slider forging closer to the product shape. The subsequent processing has a small cutting allowance, saves materials, and reduces processing costs. quality and performance.

Owner:WUXI LONGDI PRECISED FORGINGS

Manufacturing method for water cooled walls

InactiveCN102513793AImprove performanceAvoid Casting DefectsMetal-working apparatusChemical industryIngot

The invention relates to the technical field of water cooled walls for coal gasifiers and ironmaking blast furnaces in the metal and chemical industries, and particularly discloses a manufacturing method for water cooled walls, which includes the following six steps: casting a cast ingot, forging copper plate blank, forging a groove, processing a cooling channel, bending and forming and obtaining a finished product. The master operation is to utilize a forging press to forge and press the pure copper cast ingot into a copper plate with a groove, to drill holes and process the cooling channel, to utilize an arc-shaped forging and pressing mould for bending and forming and to obtain a finished product after finishing treatment by machining. The manufacturing method for water cooled walls avoids casting defects of casting water cooled walls, also greatly reduces chipping allowance for processing water cooled walls with a copper plate directly, and enables the performance of water cooled waters to be greatly improved and manufacturing cost to be greatly lowered.

Owner:YANTAI WANLONG VACUUM METALLURGY

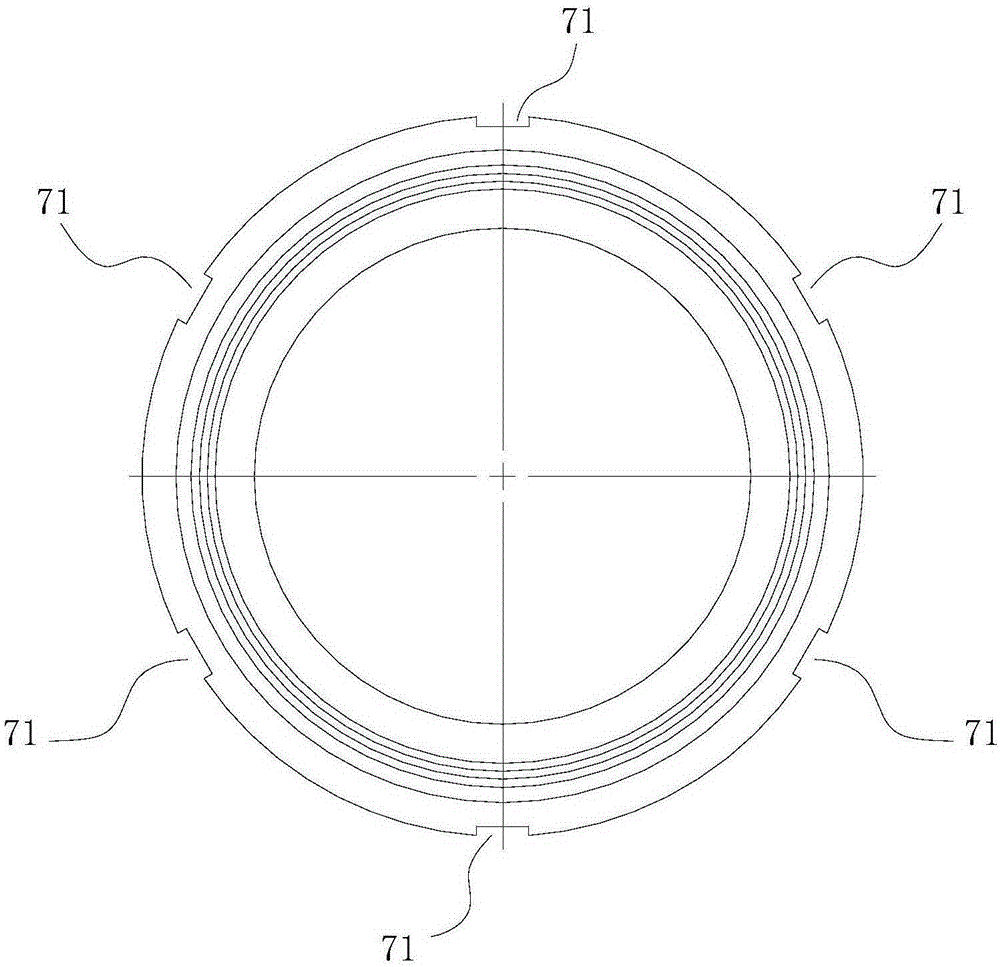

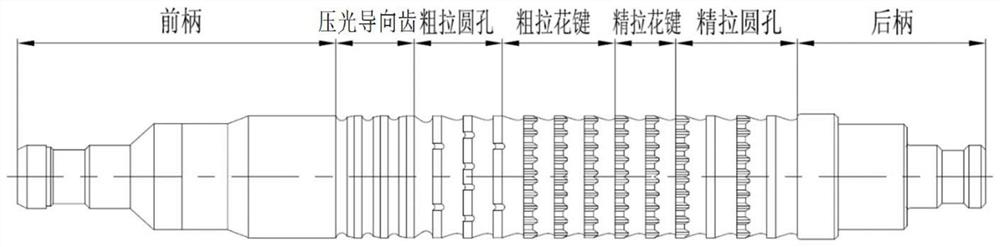

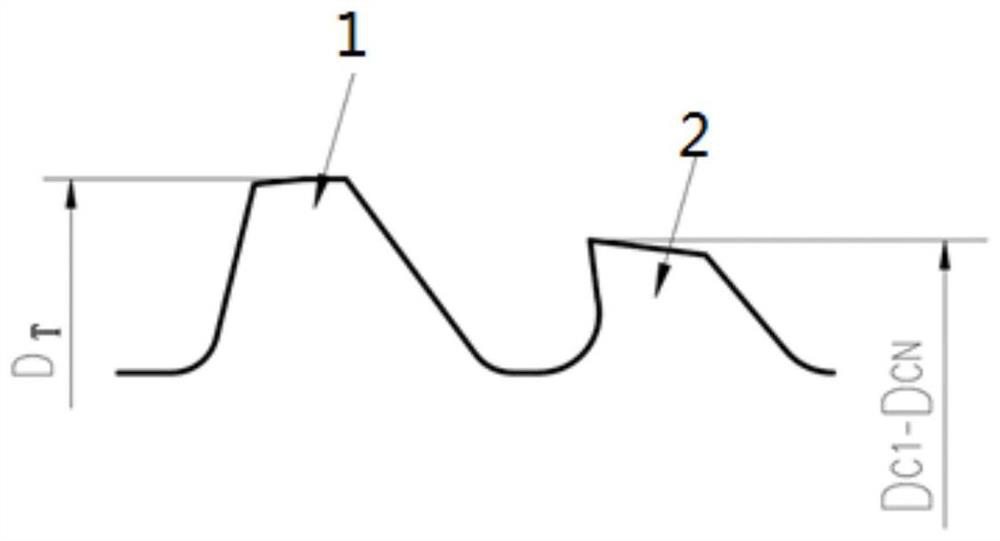

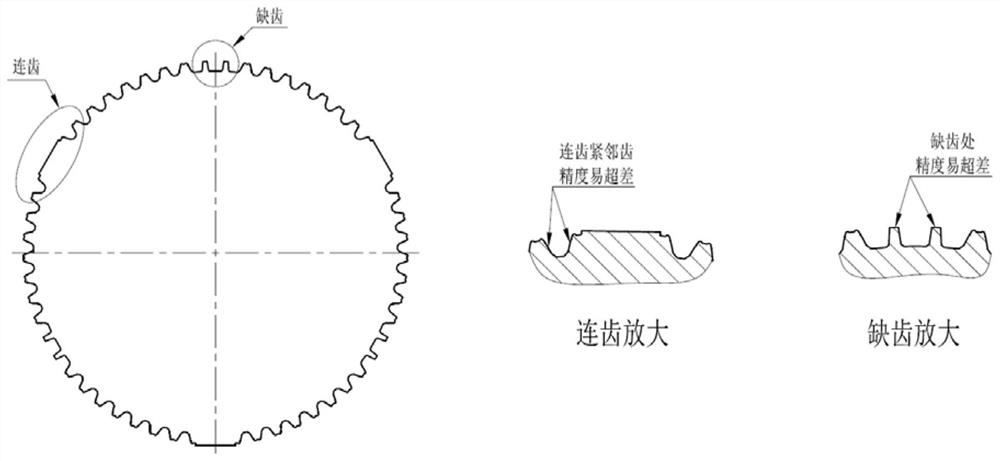

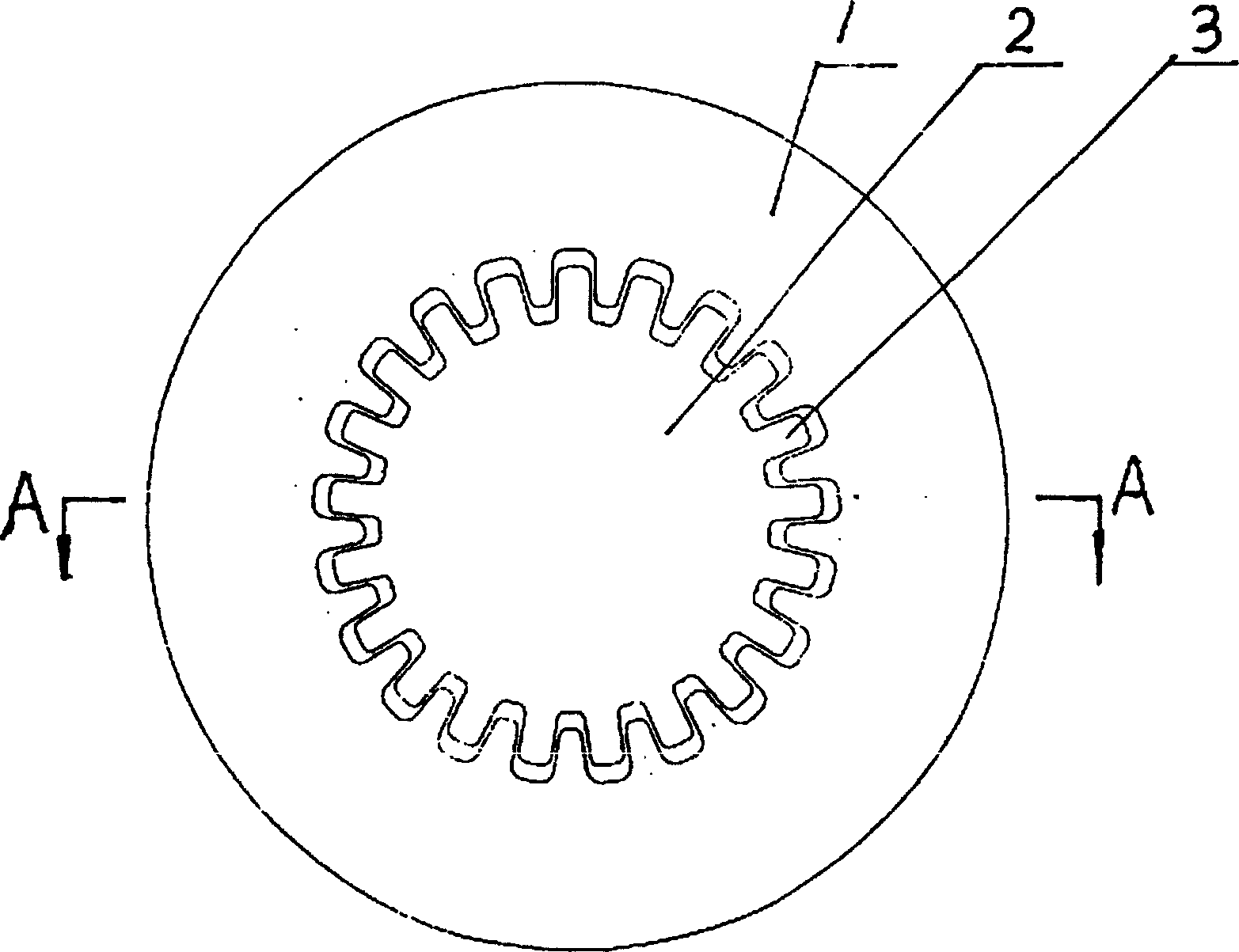

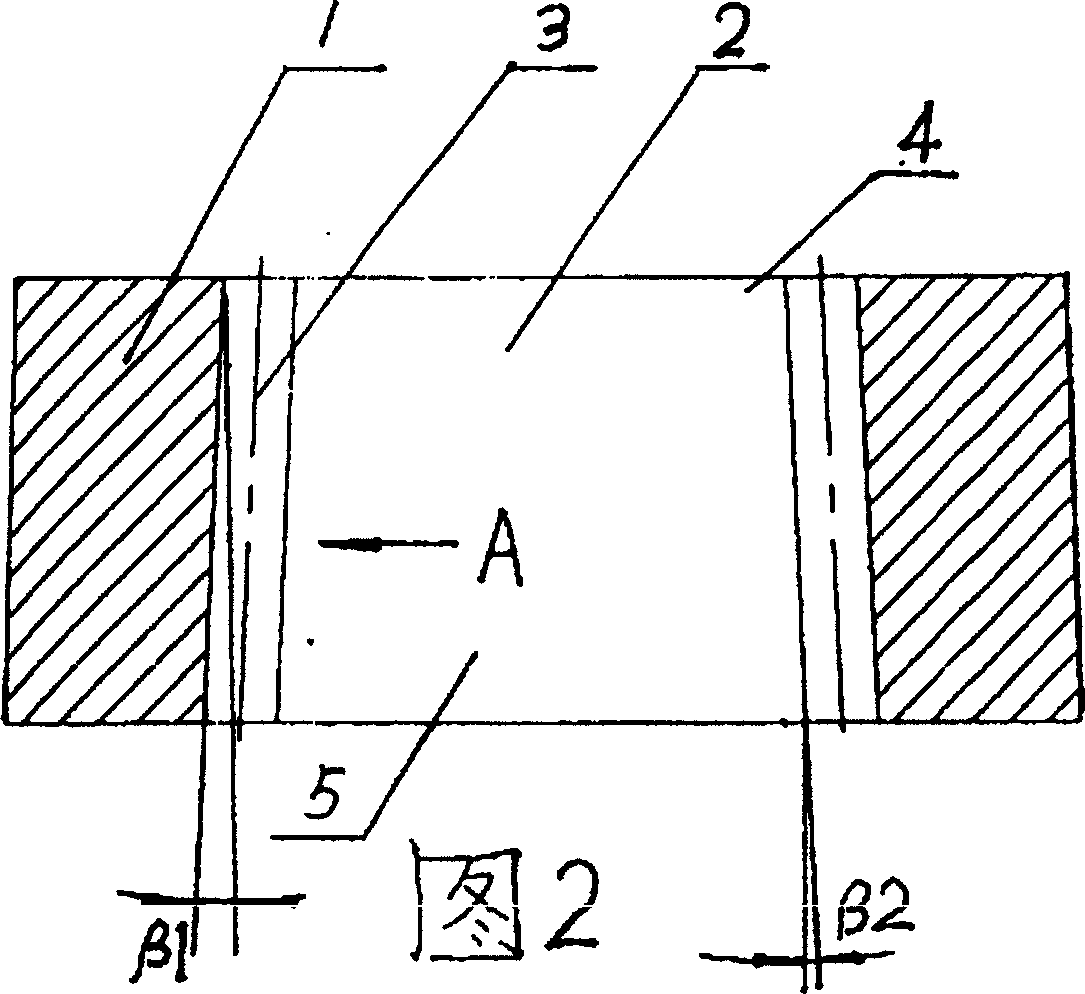

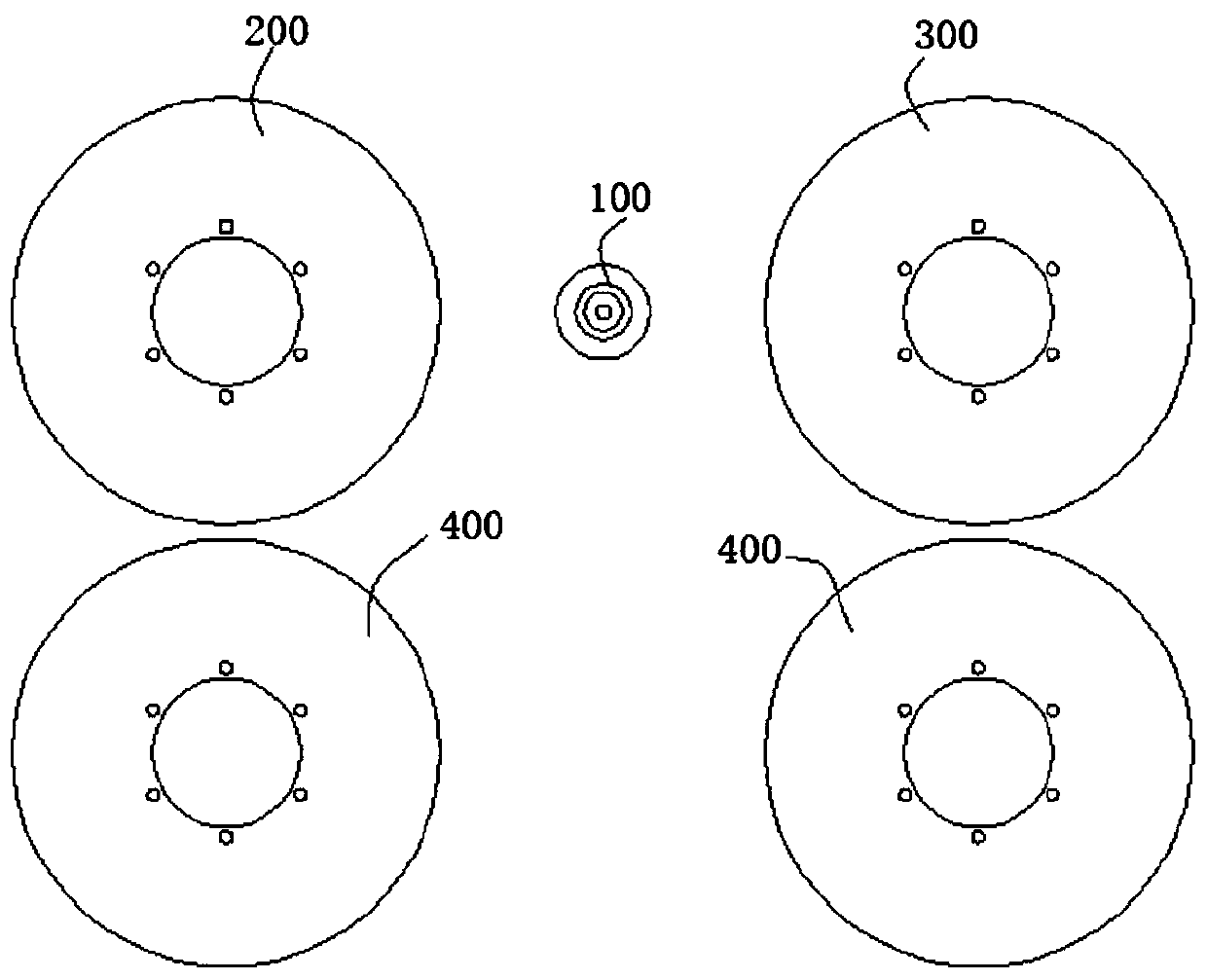

High-precision involute spline broach and design method thereof

InactiveCN112222524AReduced broaching forceEliminate or reduce distortionBroaching toolsBroachingTooth part

The invention discloses a high-precision involute spline broach and a design method thereof. The high-precision involute spline broach comprises a calendaring guide tooth part, wherein the calendaringguide tooth part comprises a plurality of calendaring guide tooth rings that are concentrically arranged, the calendaring guide tooth rings are used for guiding a workpiece, and each calendaring guide tooth ring comprises a plurality of calendaring guide teeth that are annularly distributed; the outer diameter of a first tooth of the calendaring guide tooth is DY1, and DY1 is equal to D0l-delta;the outer diameter of the last calendaring guide tooth is DYN, wherein DYN=DYN+phi / 2, the tooth number NY of the calendaring guide tooth, and NY is equal to [(DYN-DY1) / fy]; D0l is the lower differenceof the hole before drawing of the workpiece, D0[mu] is the upper difference of the hole before drawing of the workpiece, delta is a guide gap, phi is a roundness error of the hole before drawing of the workpiece, fy is the tooth rise amount of the press polish guide teeth, and [] represents the nearby rounding of the result. According to a synchronizer thin-wall part machined by the structure, the procedure percent of pass is greatly increased, the machining quality of a workpiece is guaranteed, and meanwhile, due to separation of a rough broaching procedure and a fine broaching procedure, rough cutting teeth do not participate in final tooth profile forming, so that the cutting allowance of fine broaching teeth is small, and the service life of a broach is prolonged.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

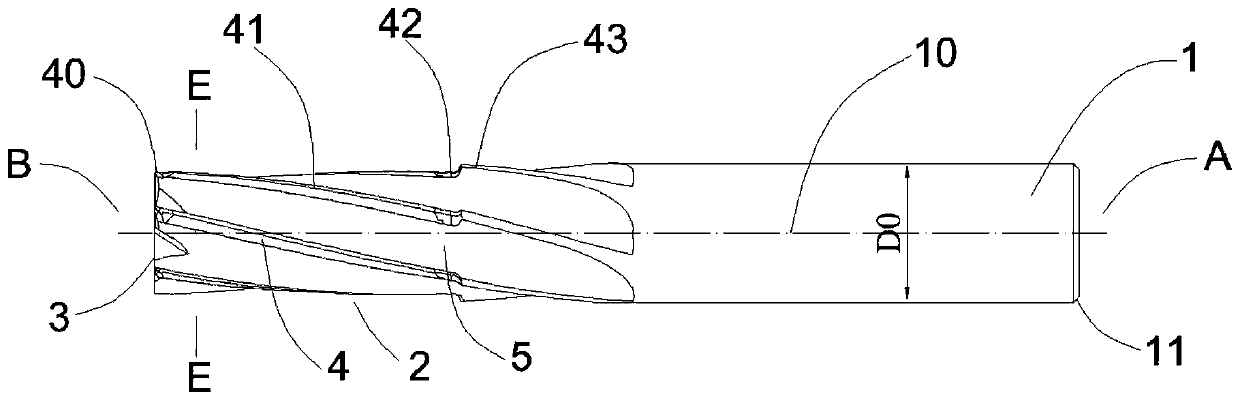

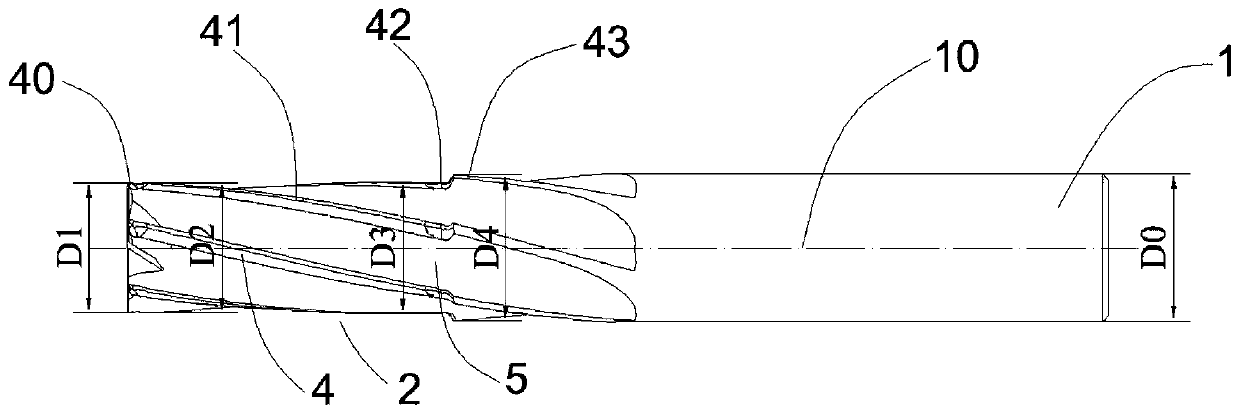

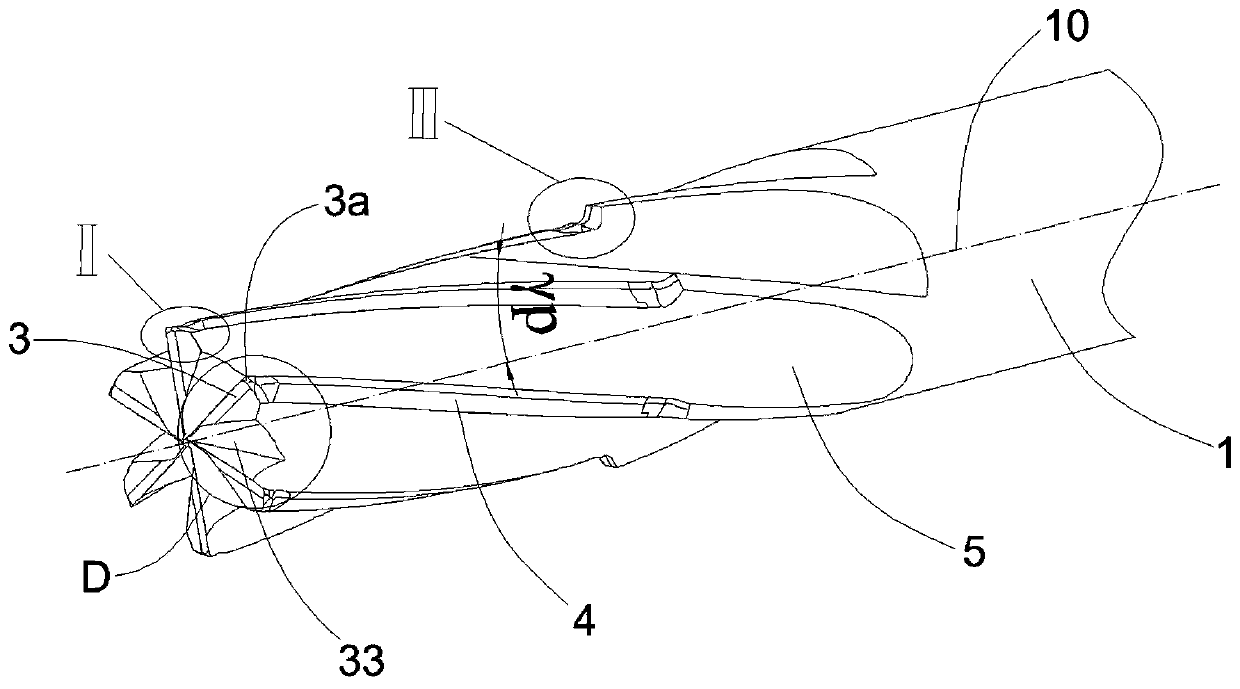

Multi-step forming reamer

The invention discloses a multi-step forming reamer. The multi-step forming reamer comprises a shank (1) and a reamer body (2), wherein the reamer body (2) comprises a plurality of end cutting edges (3), peripheral cutting edges (4) connected between the end cutting edges (3) and the shank (1), and chip removal grooves (5) correspondingly formed between the peripheral cutting edges (4); each of the peripheral cutting edges (4) is of a right hand spiral structure and is provided with at least two steps; rake angles of the steps are positive rake angles; and the closer the steps are to the shank(1), the larger the diameters and rake angles of the steps are. In the multi-step forming reamer, the step with the largest diameter adopts a large rake angle, and the rake angle of the step with thesmallest diameter can be ensured to be the positive rake angle so as to enhance the sharpness of the cutting edges, reduce the cutting resistance, and significantly improve the surface quality and roughness of inner walls of holes.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Manufacturing method of elevator gear blank

InactiveCN103692174AOrganizational structure is stableIncrease productivityManufacturing cost reductionGear wheel

The invention discloses a manufacturing method of elevator gear blank. An outer ring and lugs of a gear can be respectively processed, a processing method of the outer ring comprises the steps of round steel blanking, forging, chambering and groove face-down welding, a processing method of the lugs comprises the steps of round steel blanking, die forging forming and groove face-down welding, the outer ring and the lugs can be welded into a whole, and then normalizing can be carried out. The outer ring and the lugs select No.20-No.35 steels with good welding performance, and the design drawing requirement can be achieved by an inner hole of the outer ring and the lugs by utilizing die forging without metalworking; non-deformation welding is ensured by adopting a tool clamp; the welding stress is removed by adopting a normalizing technology, and the design rigidity is achieved. The gear which is manufactured by adopting the manufacturing method has the characteristics that the forming is simple and convenient, the material rigidity is increased, the energy and the consumption are reduced, the labor intensity of a worker is reduced, the production efficiency is increased, and the manufacturing cost is reduced.

Owner:SHAOYANG XIANGBAO AUTO PARTS

Method for making rotary pipe

InactiveCN1451630AIncrease productivityThe preparation method is scientific and reasonableGlass forming apparatusGlass productionPolymer scienceSludge

A process for preparing the rotary tube used to prepare glass tube includes proportionally mixing raw materials to become sludge, vacuumizing, pressure moulding for shaping, and firing. Its advantages are high quality, resistance to heat shock and corrosion, density, strength and size precision, big diameter and long service life.

Owner:ZIBO GT INDAL CERAMICS

Gear precision plastic forming process and its forming mould

The invention belongs to a gear precision plastic forming process and a forming die thereof. The forming die has a gear-shaped cavity with a profile of a gear part. The gear-shaped cavity has a feed section with an inclined top and root, a sizing section similar to the gear part, and a discharge section with an inclined top and root. The forming process is to put the heated blanks into different gear plastic precision molds one by one, carry out warm extrusion to form gear blanks, and process the teeth of the gear blanks by shaping, cold shaping or shaving. The forming process and the forming die thereof have small forming force, good forming quality, high production efficiency and low cost.

Owner:ZHONGBEI UNIV

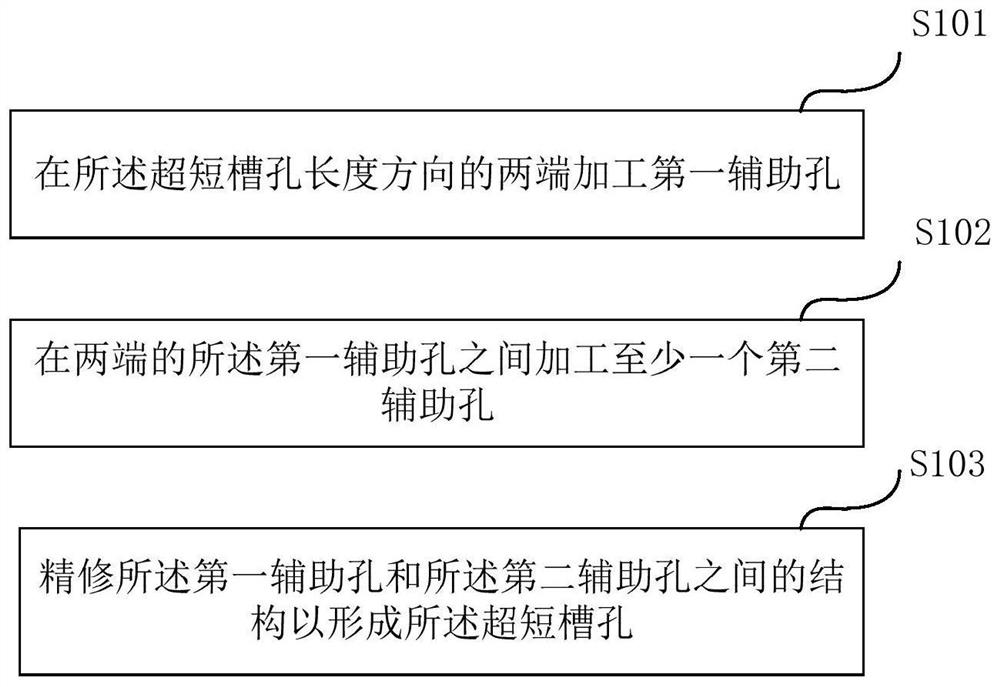

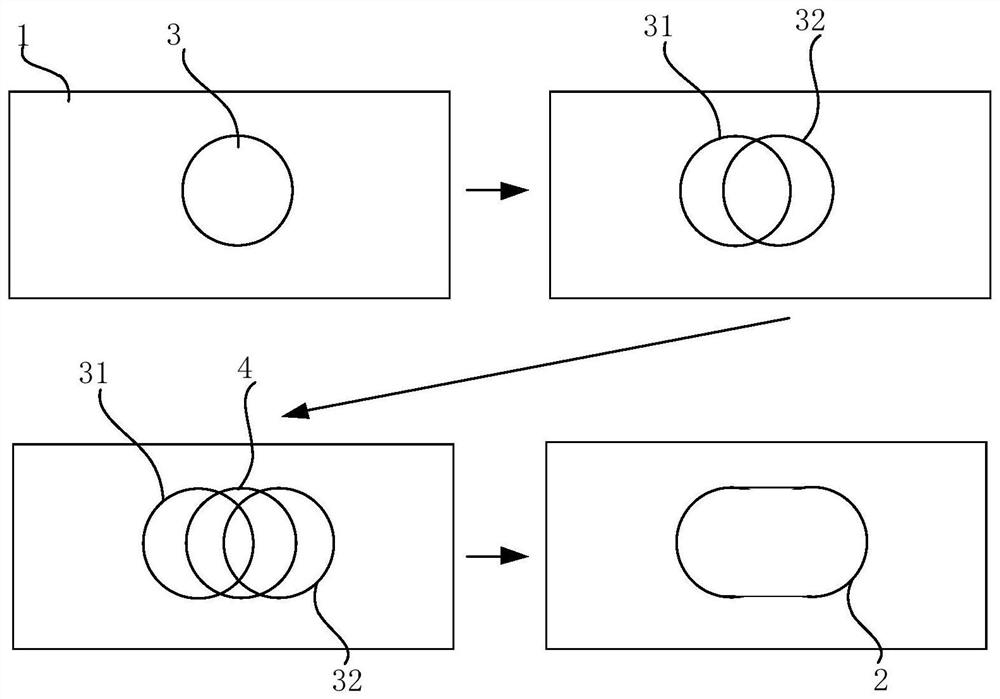

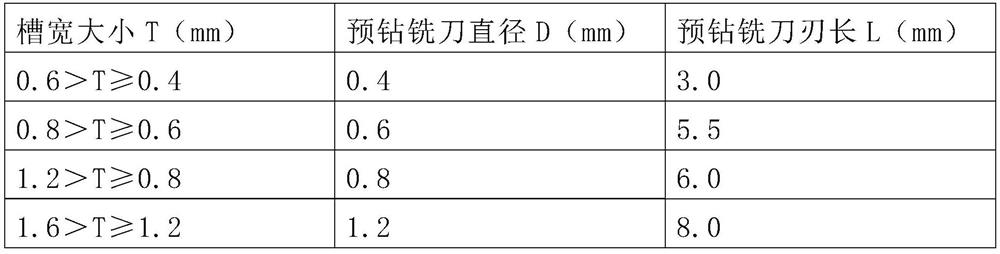

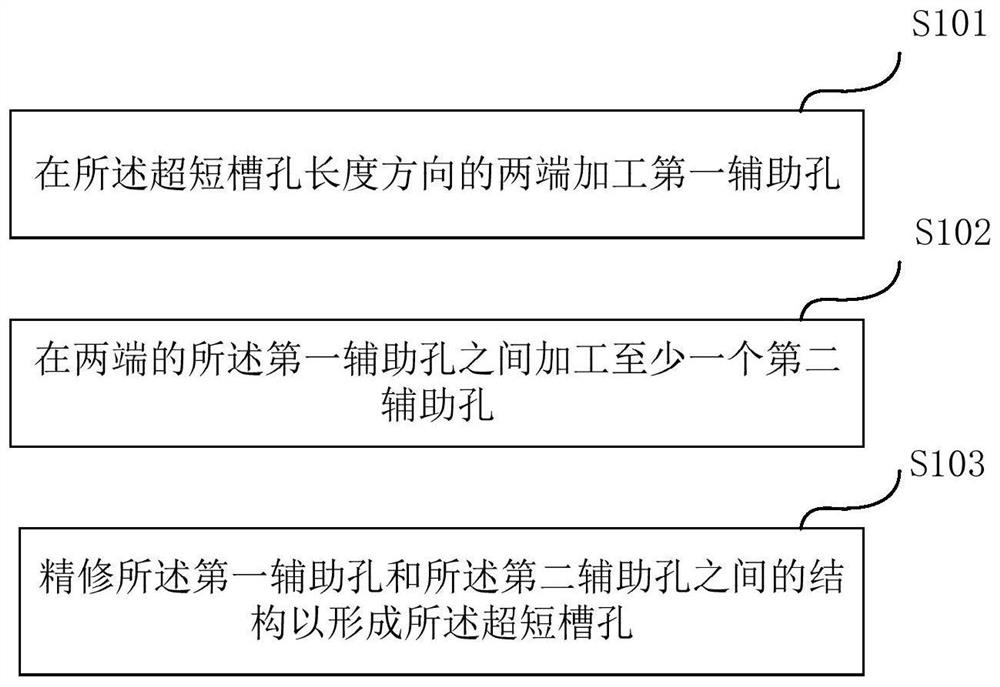

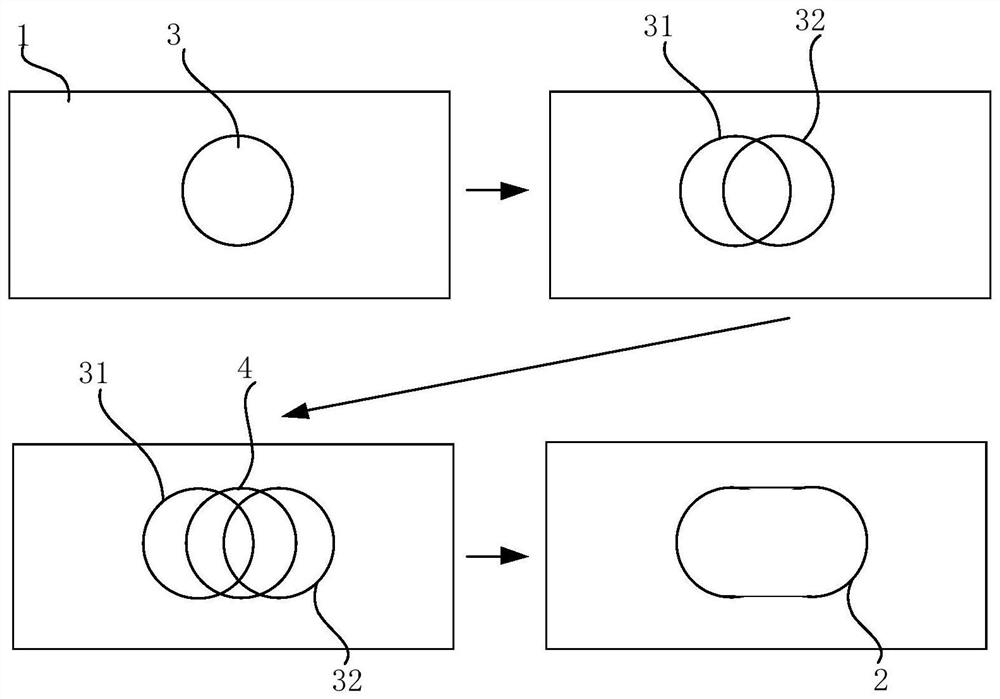

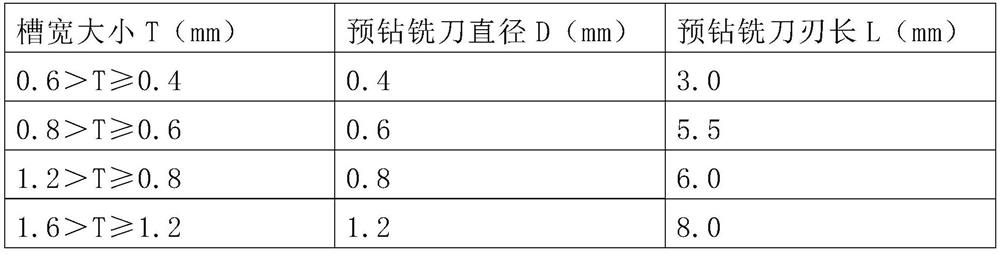

Circuit board ultra-short slot machining method

ActiveCN113043374AGuaranteed machining accuracySmall cutting allowanceMetal working apparatusEngineeringMechanical engineering

The embodiment of the invention provides a circuit board ultra-short slot machining method, and belongs to the technical field of circuit board manufacturing. The method comprises the following steps of: machining first auxiliary holes at two ends of an ultra-short slot in the length direction, machining at least one second auxiliary hole between the first auxiliary holes at the two ends, and finely trimming the structure between the first auxiliary holes and the second auxiliary holes to form the ultra-short slot. The first auxiliary holes and the second auxiliary holes are drilled in advance before the ultra-short slot is machined, so that a pre-drilled groove with the shape close to that of the ultra-short slot is drilled in a to-be-slotted position of a circuit board, and most materials in the ultra-short slot are removed. According to the circuit board ultra-short slot machining method, the ultra-short slot is obtained through further fine trimming on the basis of the pre-drilled groove, due to the fact that most materials are removed in advance, the cutting allowance of a groove cutter is small at the moment, the borne transverse unbalanced force is correspondingly reduced, deflection is not prone to being generated, and therefore the machining precision of the circuit board ultra-short slot is guaranteed.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

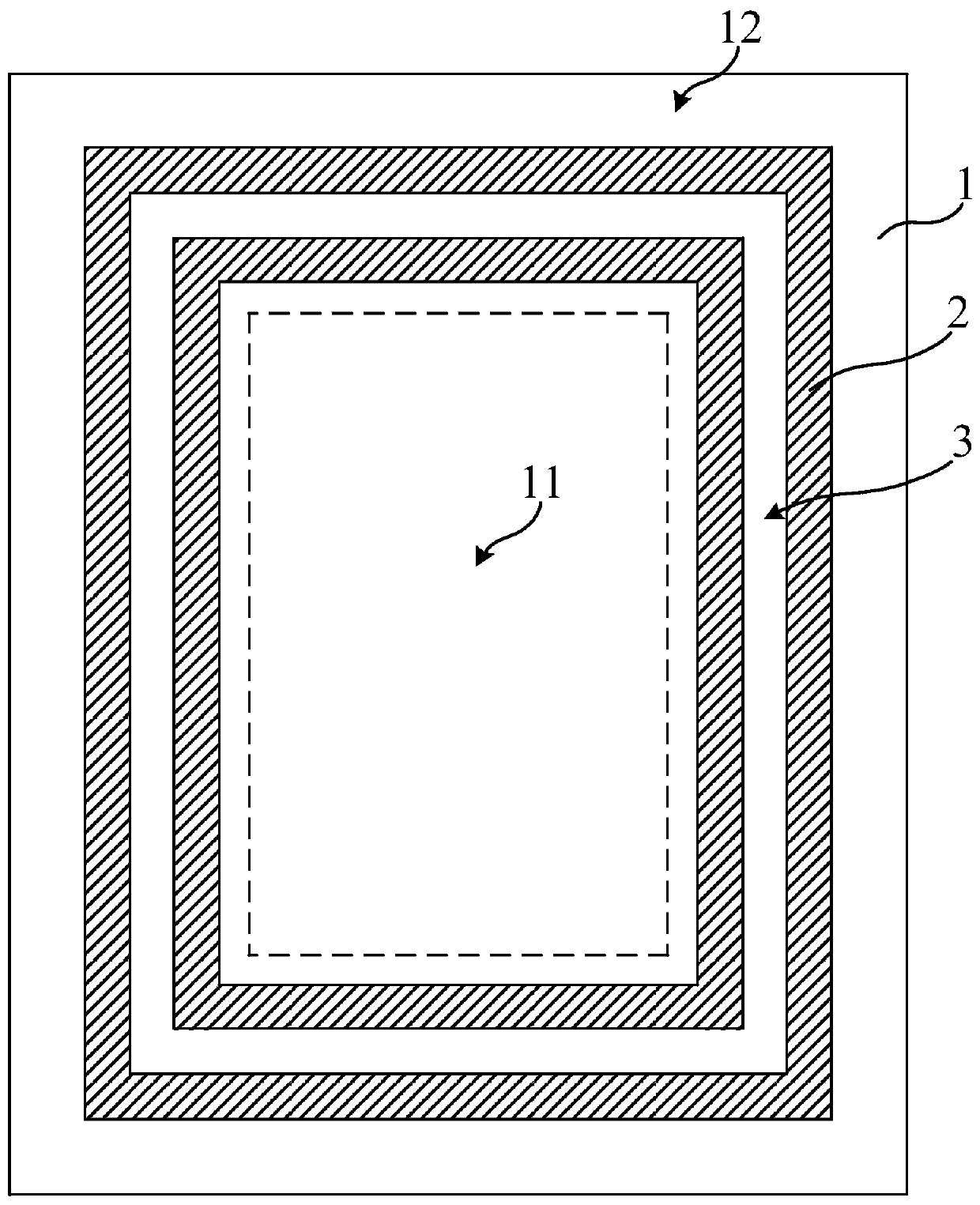

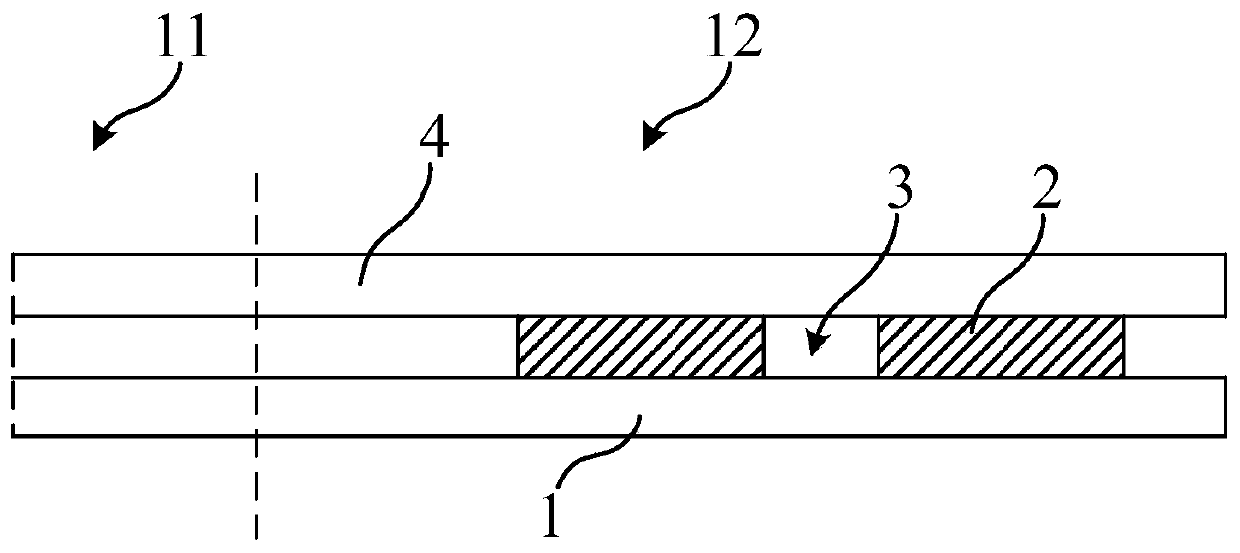

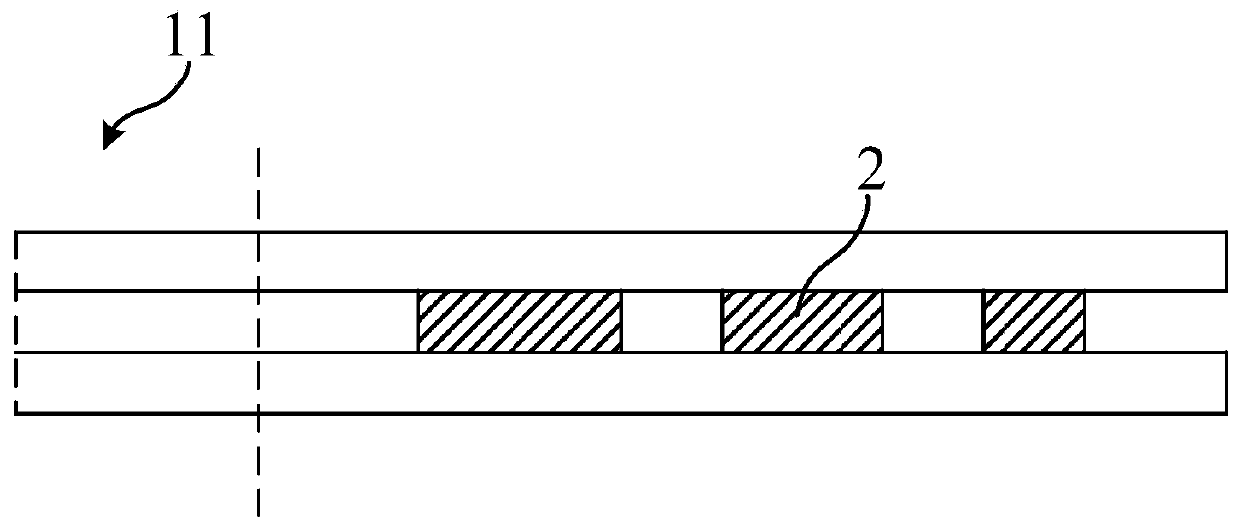

Display panel and preparation method thereof, and display device

ActiveCN110797474ASmall width designConducive to narrow bezel designSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to the technical field of display panels and discloses a display panel and a preparation method thereof, and a display device. The display panel comprises a substrate and at least two glass packaging bodies, wherein the substrate defines a display area and a non-display area surrounding the display area, the at least two glass packaging bodies are arranged in the non-displayarea of the substrate, the at least two glass packaging bodies are sequentially arranged at intervals in the direction away from the display area, and a gap exists between every two adjacent glass packaging bodies. The display panel is advantaged in that narrow frame design of the display panel can be facilitated.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

A coreless spinning processing method of a large-scale multiple-diameter variable hollow shaft

The invention discloses a coreless spinning processing method for a large-scale multiple-diameter variable hollow shaft, which belongs to the field of spinning. The present invention includes the following steps: S1. Using a vertical spinning system, the blank is clamped in the lower mold unit, and the lower mold unit drives the workpiece to rotate, and the rough spinning wheel and the fine spinning wheel on both sides of the workpiece contact the workpiece at the same time for staggered spinning , and perform curve back-and-forth feeding spinning with point contact to form a rough spinning blank; S2, shift the rough spinning wheel and fine spinning wheel, and the shaping spinning wheels on both sides of the workpiece contact the workpiece for shaping and spinning, and the shaping on both sides The rotary wheel only carries out line contact shaping and fine spinning along the radial direction, so as to obtain the fine spinning blank; S3, according to the above method, carry out spinning processing on the workpiece to be processed respectively, and obtain the rough blank. The invention overcomes the problems of high processing difficulty and poor molding quality of the hollow shaft in the prior art, and the prepared product has high precision, can greatly reduce subsequent processing allowance, has high material utilization rate, and reduces production cost.

Owner:芜湖西诺普汽车零部件科技有限公司

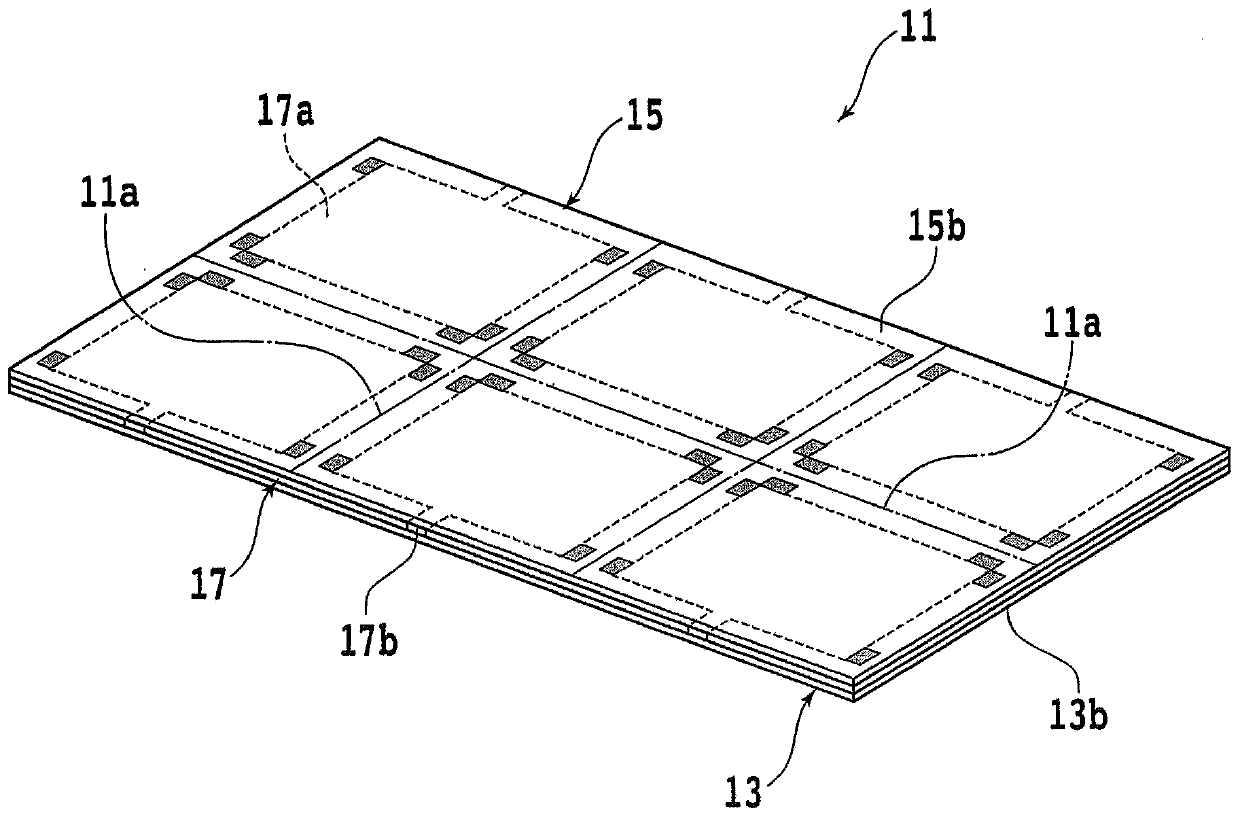

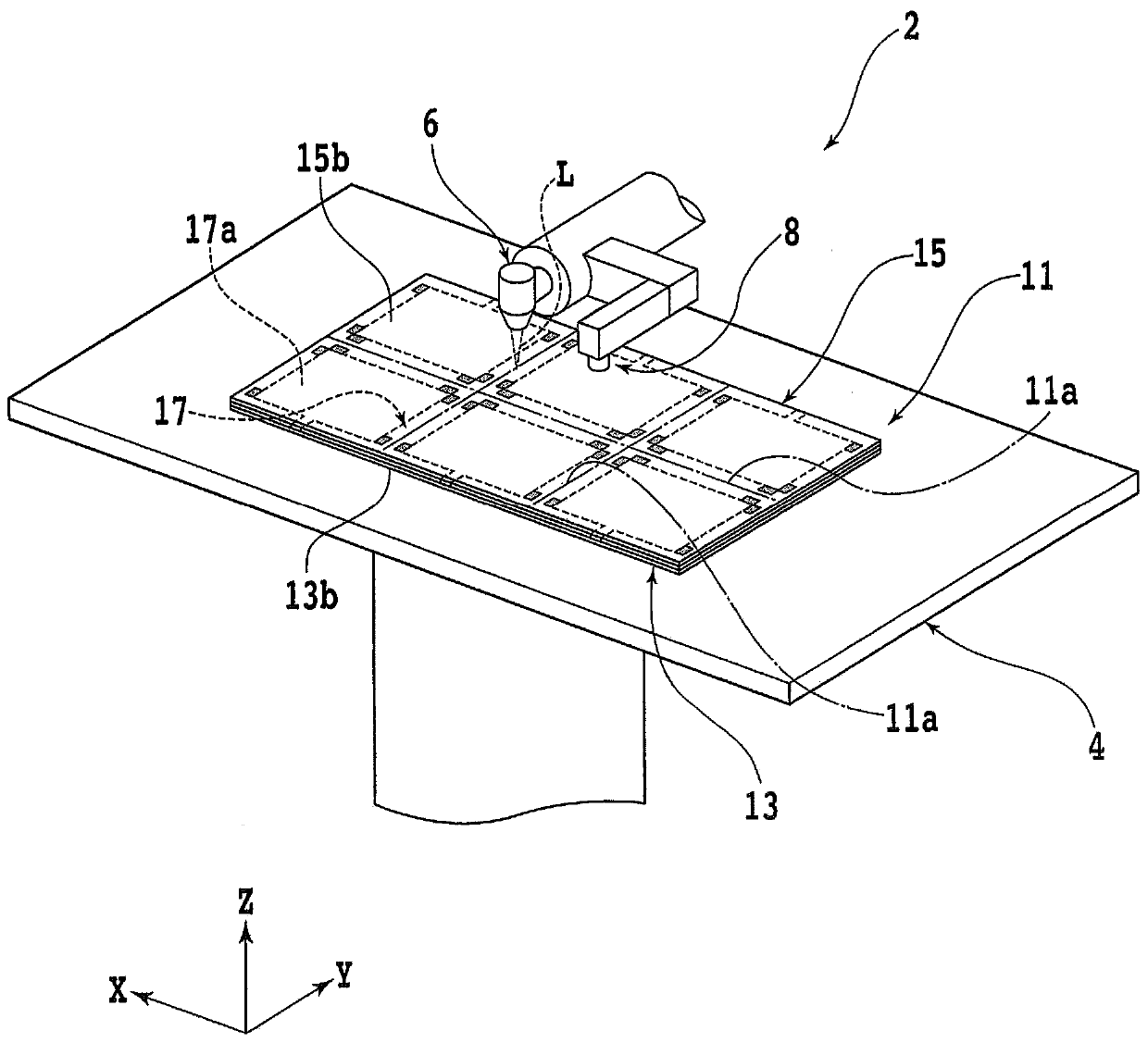

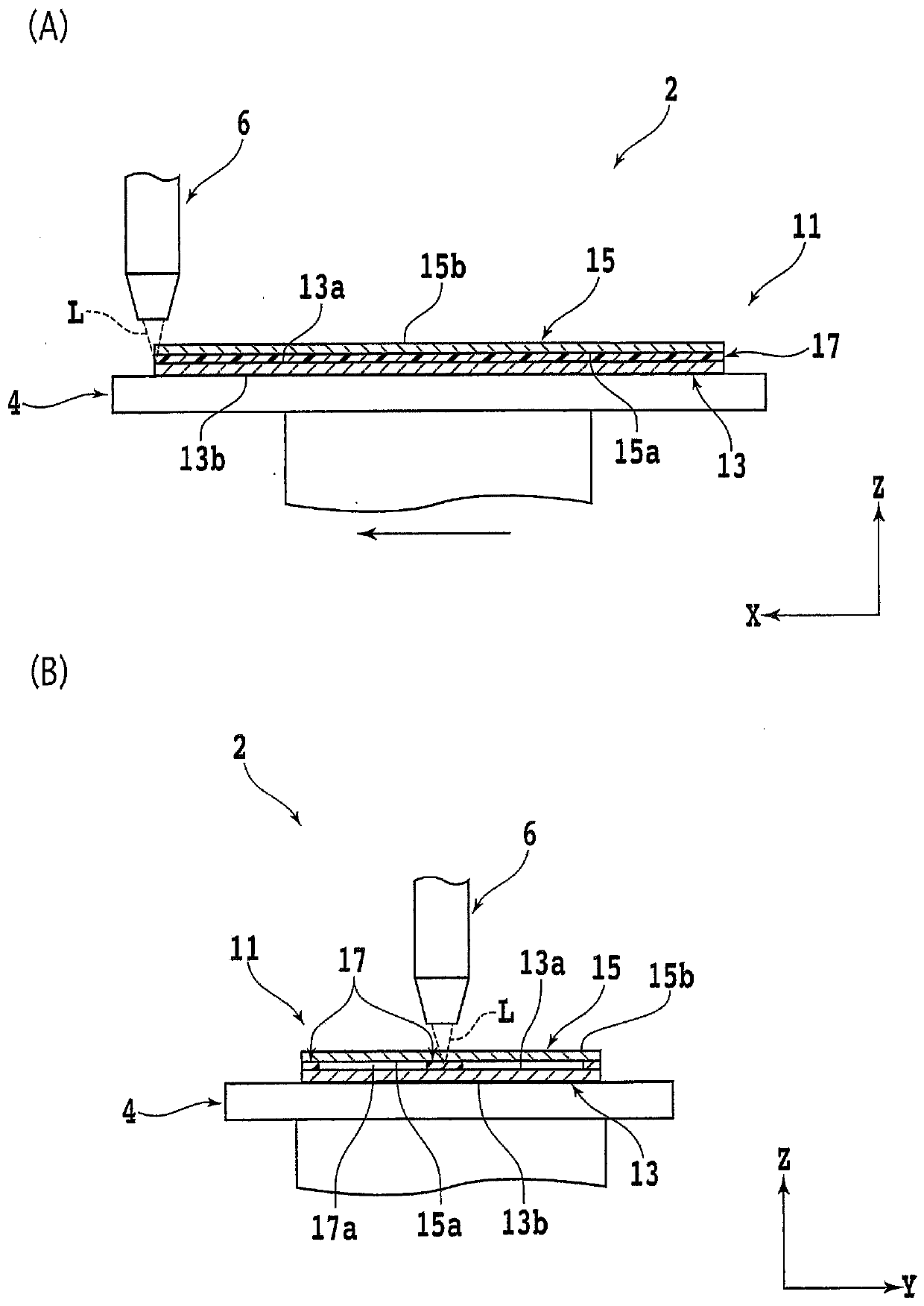

Method for manufacturing liquid crystal panel

Provided is a method for manufacturing a liquid crystal panel to reduce the amount of cutting when the liquid crystal panel is cut out from a bonded substrate. A method for manufacturing a liquid crystal panel comprises processing a bonded substrate to produce a plurality of liquid crystal panels, the bonded substrate comprising: a sealing tape dividing a plurality of liquid crystal chambers, andtwo glass substrates attached to each other through the sealing tape. The method for manufacturing the liquid crystal panel includes a laser processing step of positioning the condensed region of a laser beam passing through the wavelength of the glass substrates inside the bonded substrate and between two adjacent liquid crystal chambers while irradiating the laser beam along the sealing strip, and forming a shield tunnel including pores and a modified portion surrounding the pores in the bonded substrate; and a dividing step of along the shield tunnel formed on the bonded substrate, dividingthe bonded substrate into a plurality of liquid crystal panels.

Owner:DISCO CORP

Mechanical part machining method

InactiveCN106736253ASmall cutting allowanceDiamond flower is cheapMachine partsMechanical components

The invention discloses a mechanical part machining method. A machining method of a groove in a mechanical part comprises the following steps: a plurality of holes are firstly drilled by a drilling machine; most cutting quantities are taken away; and then, a milling tool is used for once milling to reach a needed size. The aperture of the drilled holes is slightly smaller than the width of the groove; and the depth of the holes is slightly smaller than the depth of the groove. In the new process, a plurality of holes are firstly drilled by the drilling machine, and most cutting quantities are taken away, so that the cutting allowance is largely reduced, and the milling tool can once mill to reach the needed size. Two procedures of drilling and milling including clamping need about 7-8 minutes. From the aspect of wear of the tool, after the new process is adopted to machine more than 800 products, the milling tool is not narrowed, and the only change is that the back angle of the milling tool is blunt, so that the milling tool can be continuously used only through grinding the back angle by operators. Drilling bits for drilling are lower in cost; and the drilling operation is simpler. The new process is unanimously praised by the operators.

Owner:黑龙江万向鹏程科技发展有限公司

A rough and fine drawing structure spline broach and its design method

ActiveCN111633283BIncrease the number of single processingIncrease the frequency of sharpeningBroaching toolsGear teeth manufacturing toolsEngineeringBroaching

The invention discloses a rough and fine drawing structure spline broach and a design method thereof. The disclosed broach includes a spline cutting tooth, and the spline cutting tooth includes a plurality of concentrically arranged knife tooth rings along the cutting direction, two adjacent knife tooth rings form a group of knife tooth rings, and each group of knife tooth rings consists of a The rough broaching tooth ring and a finishing broaching tooth ring are composed of a rough broaching tooth top with concave fillets on both sides; The amount of lift is the same, and the tooth lift of each group of cutter rings is the same, and the tooth lift of the fine-drawn teeth of the same group of cutter rings is smaller than that of the rough-drawn teeth. The disclosed method is the design method of the broach of the present invention. This broach has a certain resistance to edge chipping. When chipping occurs, because the rough-drawing tooth does not participate in the formation of the final tooth profile, it will not affect the processing quality of the gear tooth surface; Small and durable.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

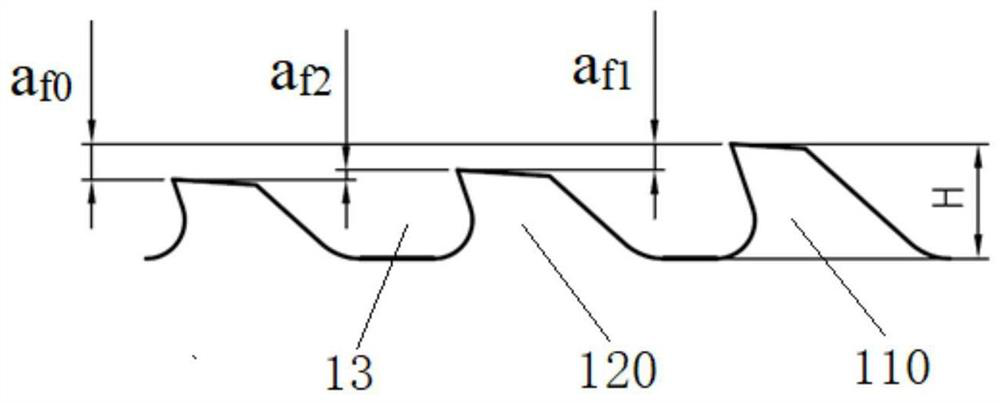

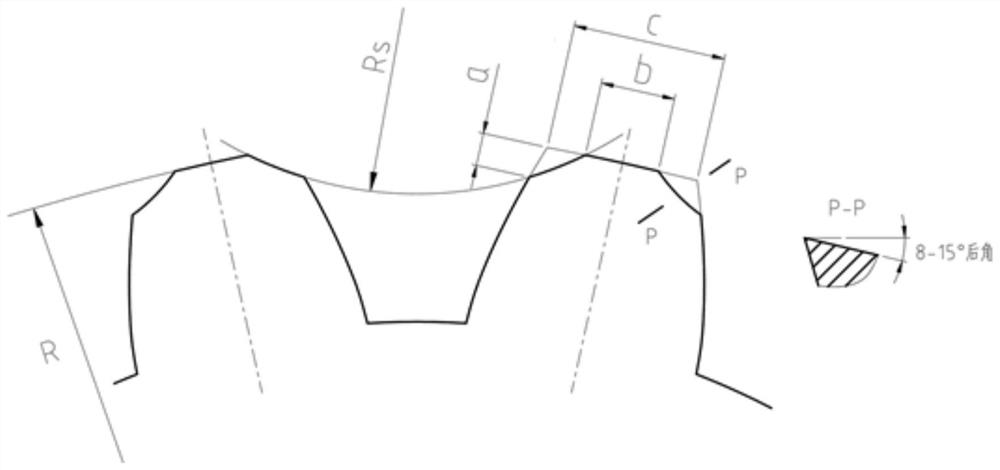

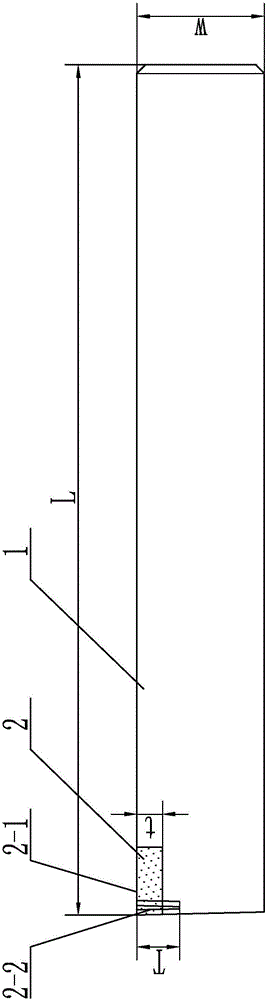

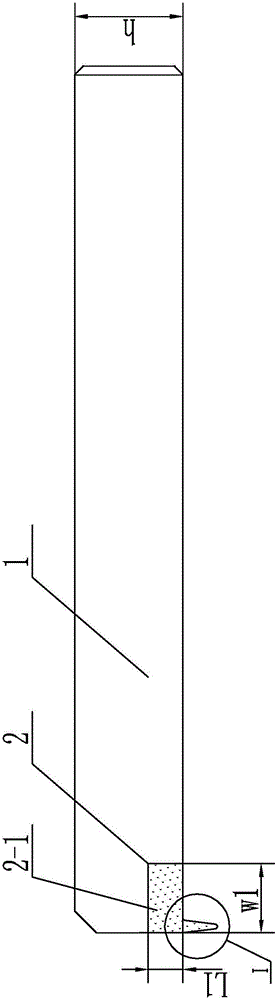

A processing tool and processing method for inner hole tooth groove of steam seal ring

The invention relates to a cutter and method for machining inner hole tooth grooves of vapor sealing rings. The problems that in the prior art, when the inner hole tooth grooves of the vapor sealing rings are machined, a center lathe is selected for conducting machining, grooving is carried out with a 1 mm grooving cutter, then vapor sealing teeth are machined through a vapor sealing tooth groove molding lathe cutter, namely a 15-degree R0.6 vapor sealing tooth lathe cutter, three-face full contact is adopted in the design, the resisting power is large, a cutter head is prone to being broken, cutter stabbing is generated, the cutter is damaged, tooth inversing on the vapor sealing rings is prone to being caused, and the machining cutter and machined workpieces are prone to being lost are solved. The cutter comprises a cutter handle and a cutter head part, the cutter handle is in a cuboid shape, the cutter head part comprises a compressing block and a cutting edge part, the compressing block is in a cuboid shape, a rectangular notch is formed in one end of the cutter handle, the cutting edge part is fixedly installed in the rectangular notch of the cutter handle through the compressing block, and the cutter edge part is located on one side of the cutter handle. The cutter and method are used for machining the inner hole tooth grooves of the vapor sealing rings.

Owner:HARBIN TURBINE +1

A processing method for a casing of a low-pressure compressor

The invention relates to a machining method of a low-pressure compressor casing. The method comprises the following steps that 1, a blank is inspected; 2, a benchmark is turned; 3, spinning is carriedout, wherein the blank is subjected to drawing and spinning by using a powerful numerical control spinning machine, so that a workpiece is obtained, wherein the wall thickness delta and the roundnessof the workpiece are controlled to be within 0.1 mm, and a small amount of allowance is reserved at the two ends of the workpiece to be used for subsequent mechanical machining; 4, the workpiece is cleaned, wherein a lubricant on the surface of the workpiece is cleared; 5, heat treatment is carried out, wherein the spinning stress is eliminated through the heat treatment; 6, a finish turning is carried out on a front end of the workpiece and a rear end of the workpiece; 7, the end face holes at the two ends of the workpiece is drilled and bored; 8, stamping of blade-type grooves is carried out, wherein a numerical-control punching machine is used for equidistantly stamping the blade-shaped grooves on the workpiece in the radial direction and fine trimming is carried out, so that the position degree of the blade-shaped groove is ensured to be 0.2 mm, and the contour degree of the blade-shaped groove is 0.05 mm; 9, magnetic particle testing is carried out; and 10, checking and storing are carried out. According to the method, the requirements of case deformation control, surface quality control and cost control can be met.

Owner:重庆天骄航空动力有限公司

A method for processing ultra-short slot holes in circuit boards

ActiveCN113043374BGuaranteed machining accuracySmall cutting allowanceMetal working apparatusEngineeringProcessing accuracy

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Mold for machining large-scale mechanical hub gasket

InactiveCN107486529ASmall cutting allowanceSave materialForging/hammering/pressing machinesEngineeringForge

The invention discloses a mold for machining a large-scale mechanical hub gasket. The mold comprises a core roller and a main mold, wherein mounting sections are correspondingly arranged at the two ends of the core roller; a first cylindrical section, a first convex shoulder part, a second convex shoulder part and a second cylindrical section are sequentially arranged between the two mounting sections; the first convex shoulder part and the second convex shoulder part are arranged at intervals, and an inclined cone section and a third cylindrical section are sequentially arranged between the first convex shoulder part and the second convex shoulder part; the inclined cone section is inclined inwards; the main mold is arranged on one side of the core roller; and the main mold is of a cylindrical structure in whole, and a central hole is formed in the main mold. The mold for machining the large-scale mechanical hub gasket can be used for machining a forge piece which is closer to a product in shape, the cutting allowance of subsequent machining is small, materials are saved, and the machining cost is low; and meanwhile, a certain rolling space for machining of the forge piece is reserved by the mold, so that the quality and the performance of the product are ensured.

Owner:许斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com