A rough and fine drawing structure spline broach and its design method

A technology of spline broaching and design method, applied in broaching, broaching, mechanical equipment and other directions, can solve the problems of high processing cost, less processing quantity, roughness defect of gear tooth profile, etc. Not easy to collapse, the effect of small force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The spline broach of this embodiment and the related parameters of the spline to be processed are shown in Table 4. Combined with the exemplary content of the parameters shown in Table 4 in Tables 2 and 3, the method of the present invention is used to determine the relevant parameters of the broach.

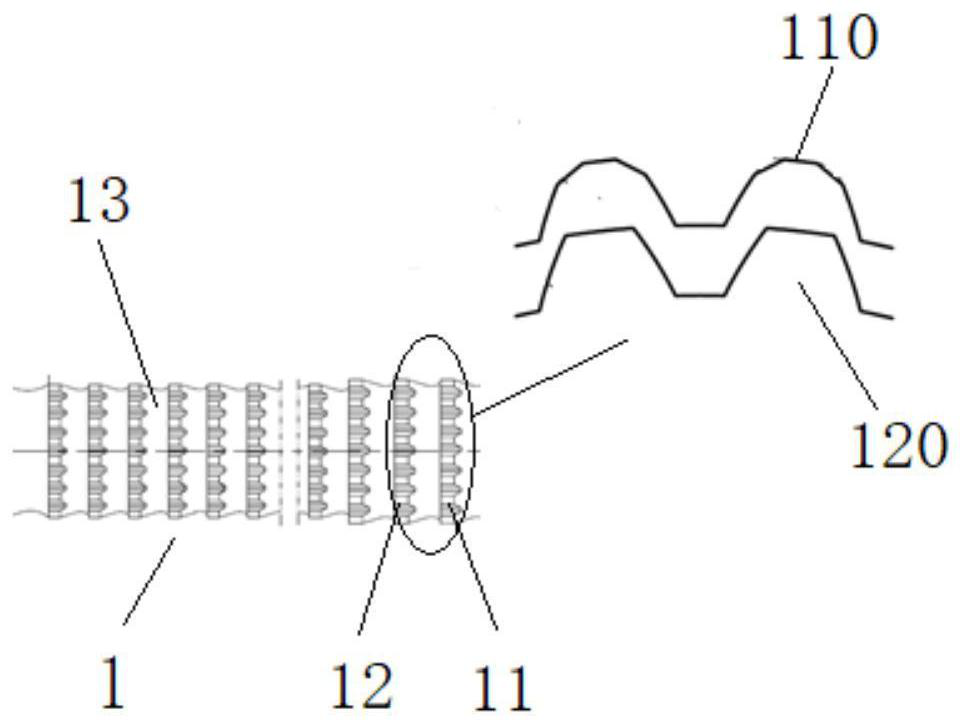

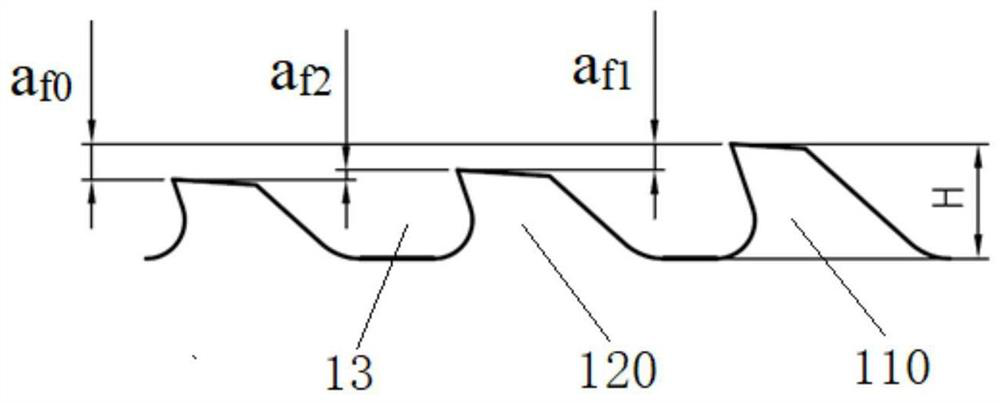

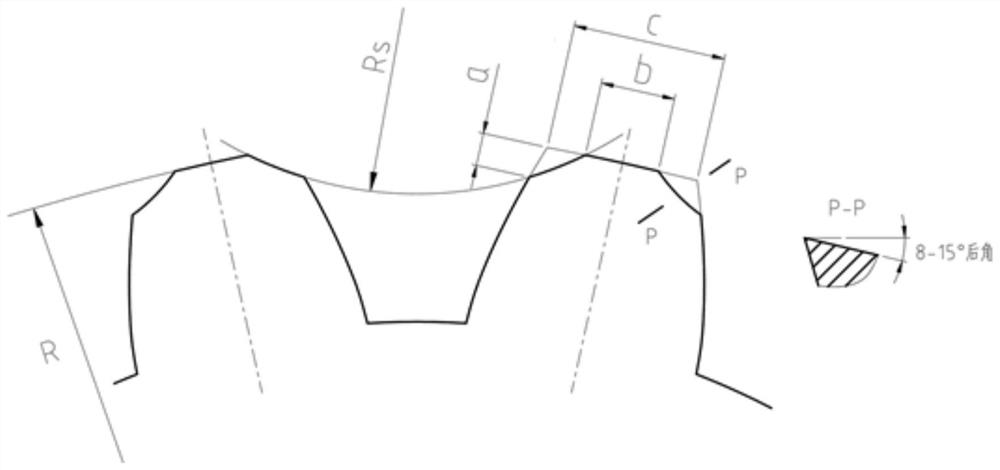

[0053] like Figure 1-4 As shown, the structures of the broaches of Models 1 and 2 of this embodiment are both composed of a rear shank portion, a spline alignment tooth portion, a spline cutting tooth portion, a round hole cutting portion and a front shank portion. The spline cutting tooth part 1 is composed of a cutter body 13 and a plurality of cutter tooth rings arranged on a plurality of concentric rings. The adjacent cutter tooth rings form a group of cutter tooth rings, and the chip direction is a rough broach in turn. The toothed ring 11 and a fine broaching toothed ring 12, wherein the coarse broaching toothed ring is composed of a plurality of annularly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com