Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384results about "Broaching tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithographic apparatus and method for determining Z position errors/variations and substrate table flatness

InactiveUS20060139595A1Easy to useComparable accuracyBroaching toolsPhotomechanical treatmentEngineeringPosition error

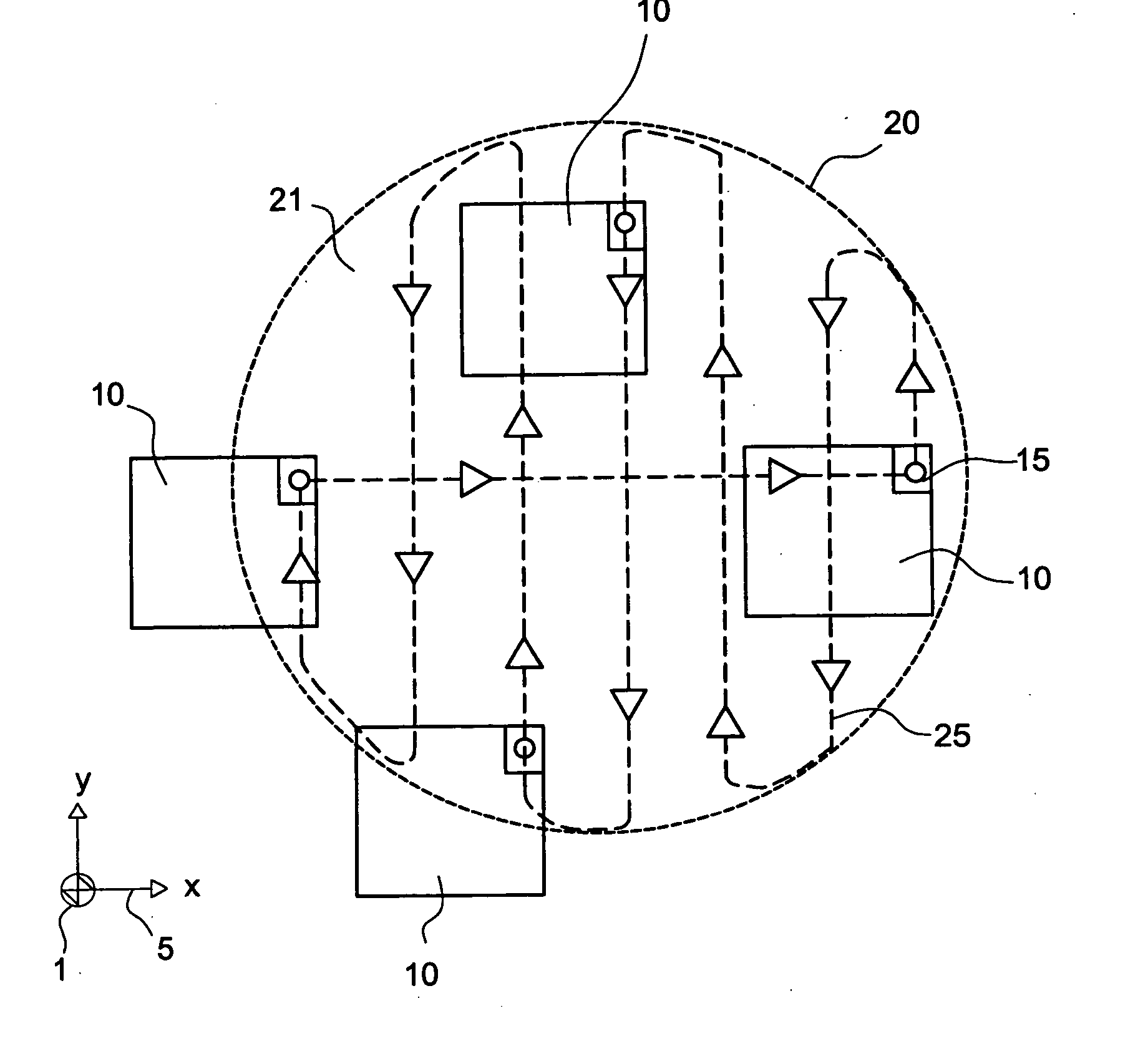

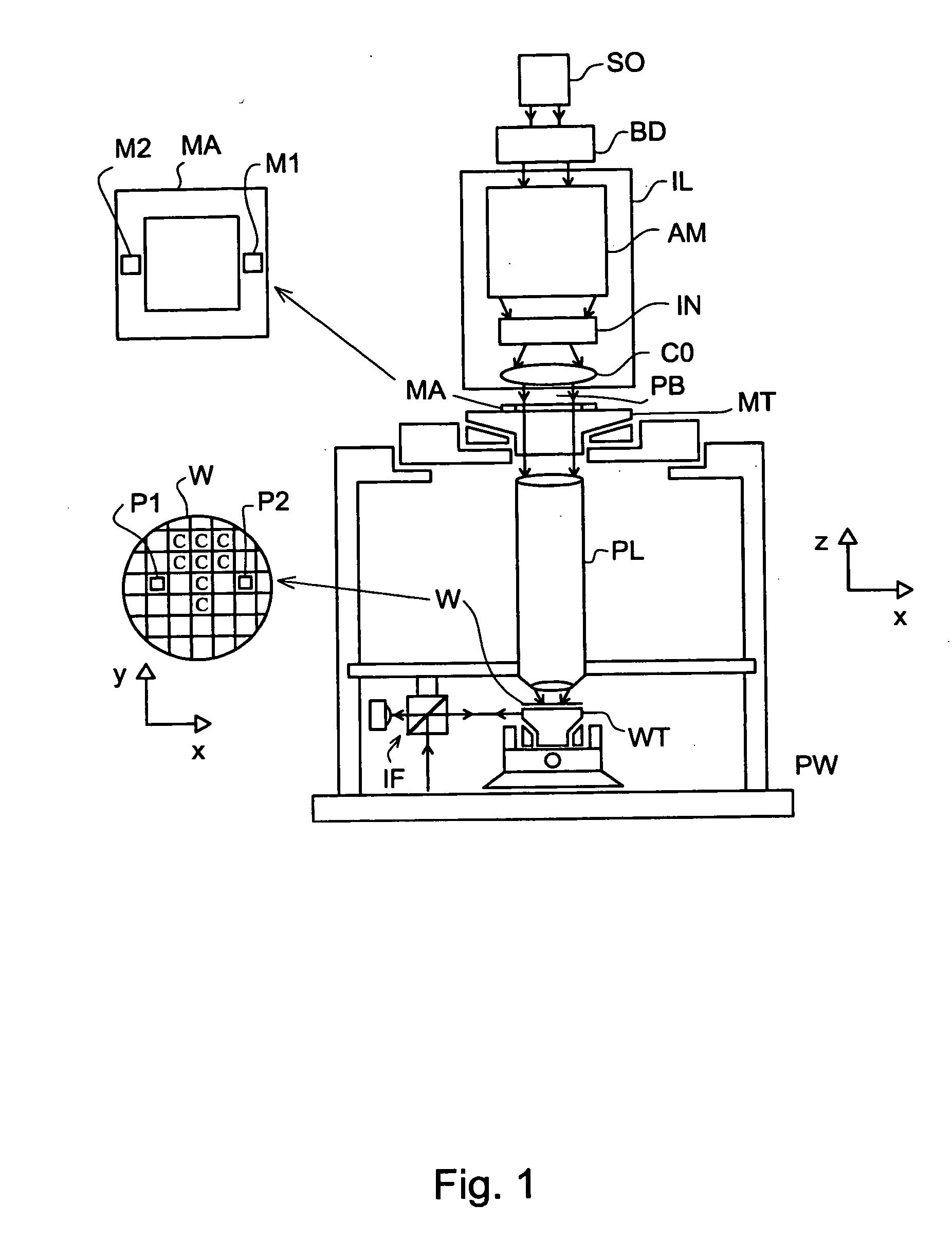

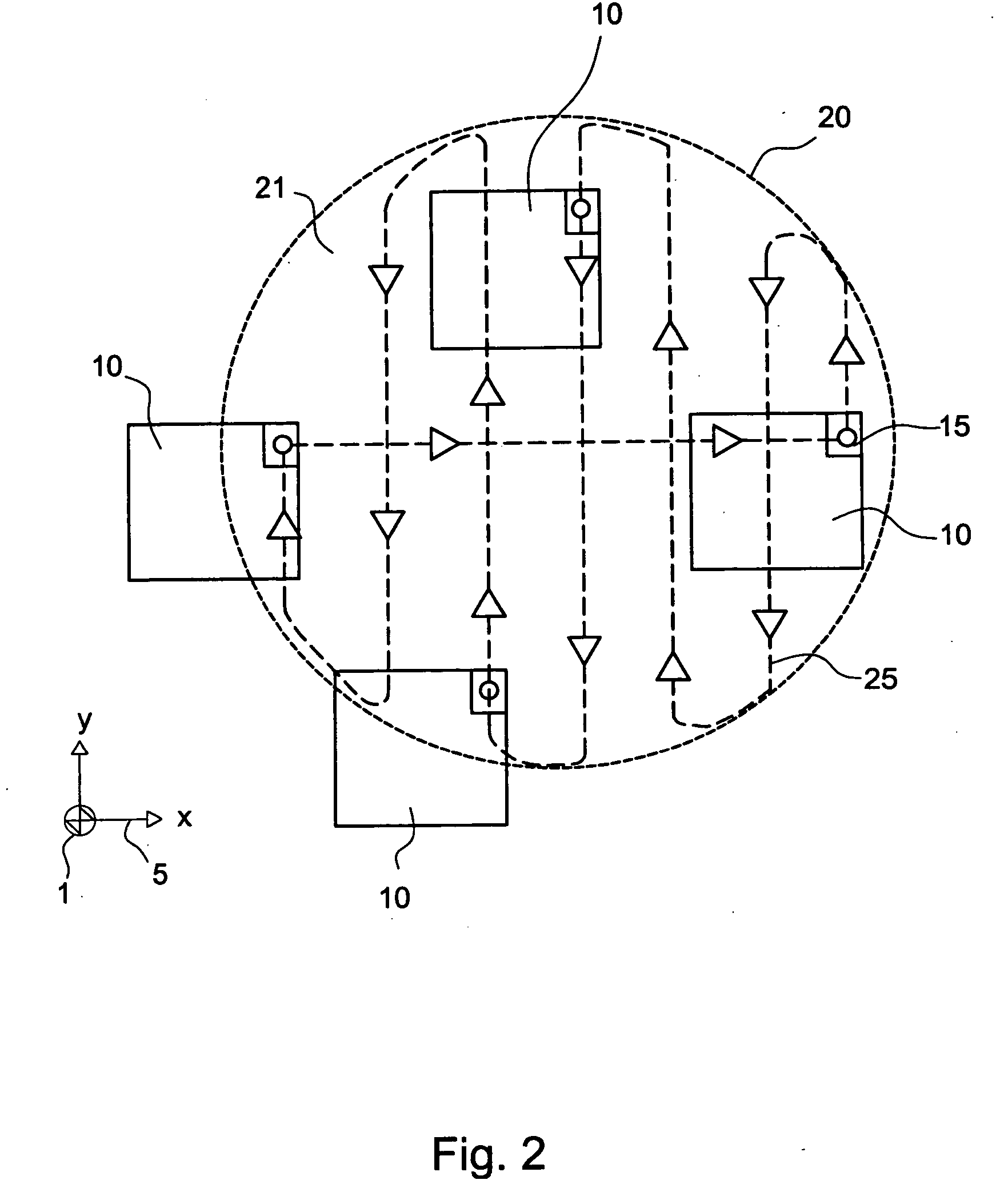

The invention pertains to a measurement system for measuring displacement of a moveable object relative to a base in at least a first direction of measurement, the moveable object having at least one reference part that is moveable in a plane of movement relative to the base, the actual movements of the reference part being within an area of said plane of movement that is bounded by a closed contour having a shape. The measurement system comprises a sensor head that operatively communicates with a planar element. The sensor head is mounted onto the base and the planar element being mounted onto the reference part of the moveable object or the other way around, wherein the planar element has a shape that is essentially identical to the shape of the closed contour.

Owner:ASML NETHERLANDS BV

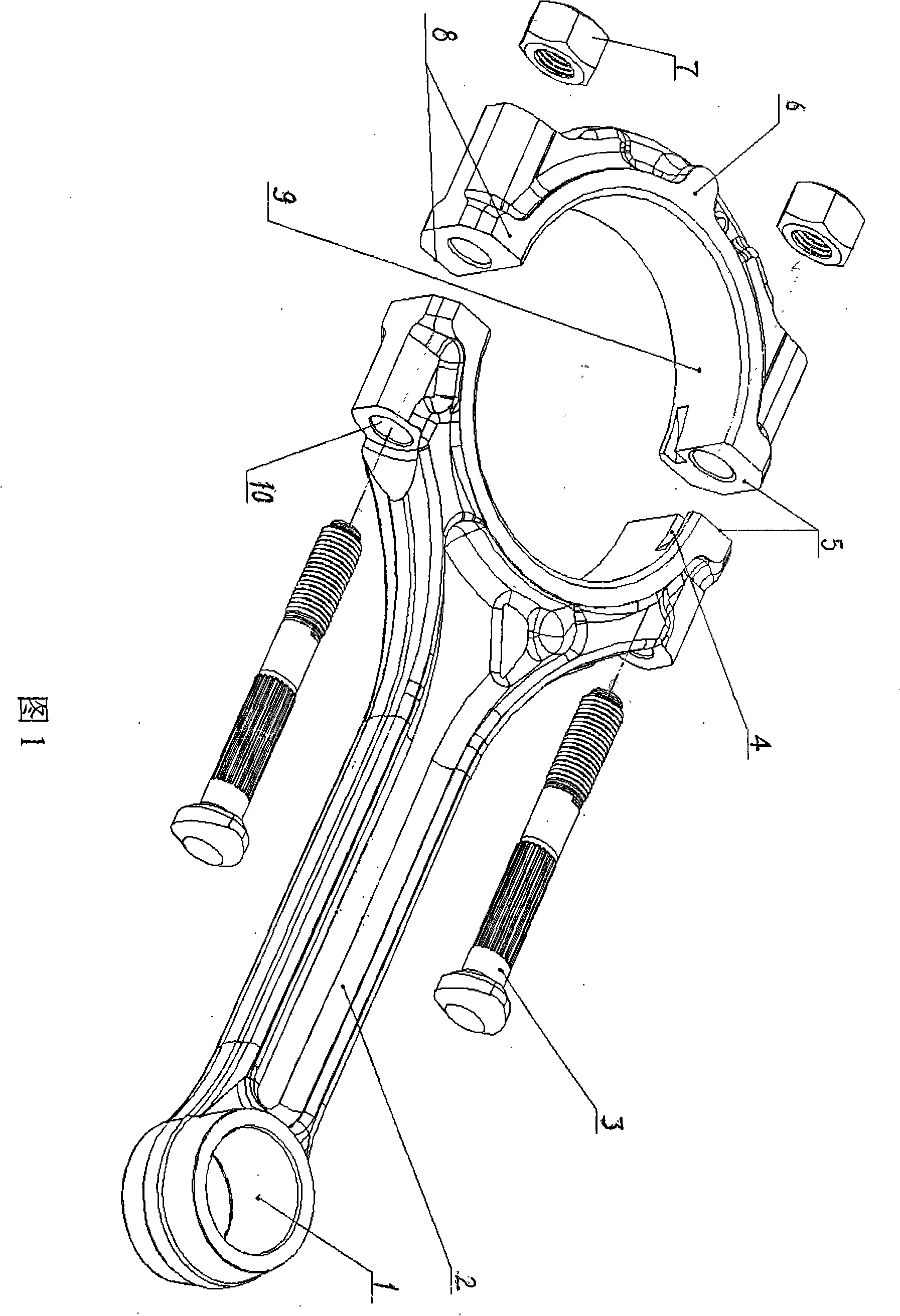

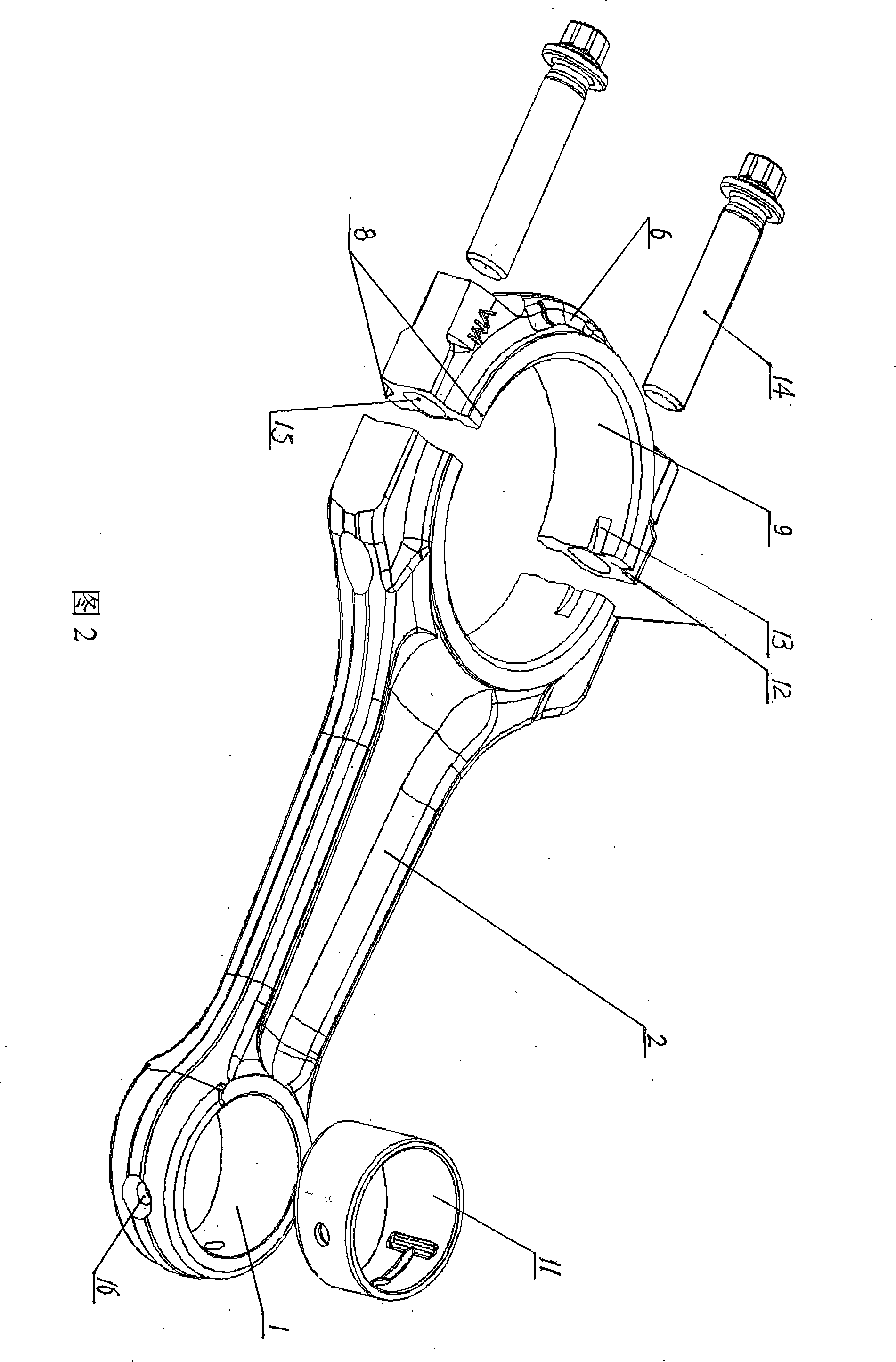

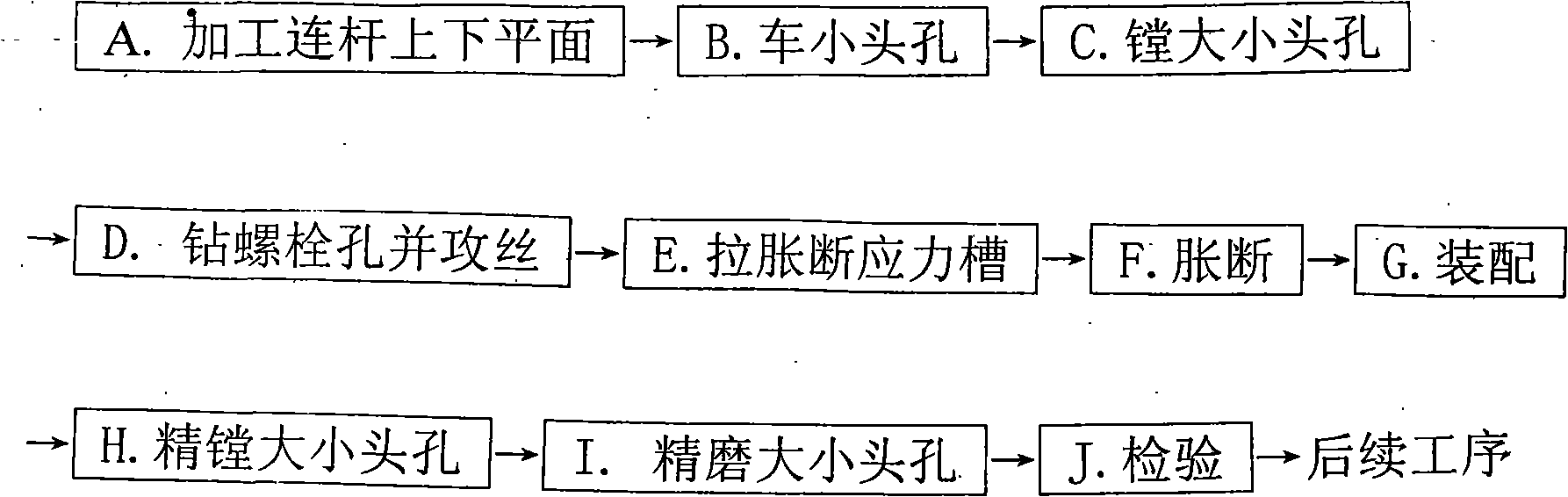

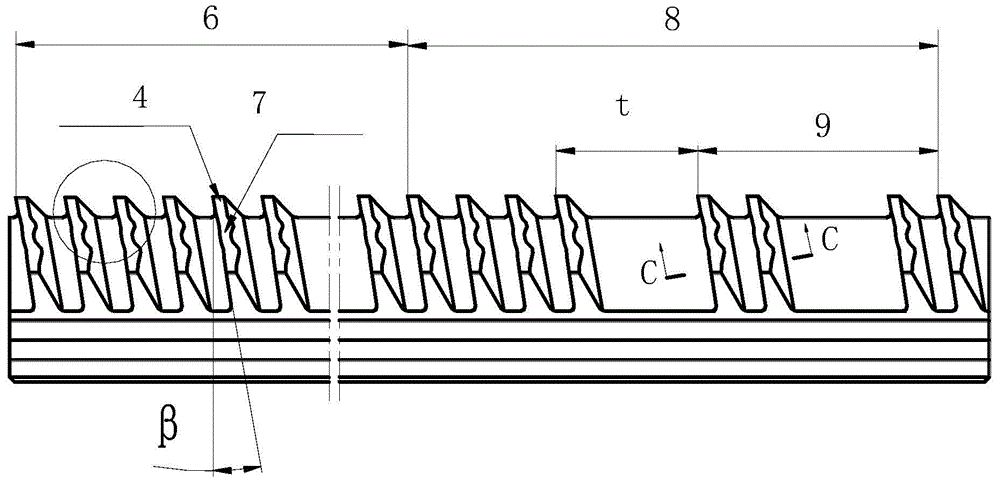

Method for processing fractured connecting rod for car engine

ActiveCN101352795AEasy to useReduce capital riskBroaching toolsPositioning apparatusDiesel engineAutomotive engine

The invention discloses an expansion-breaking processing method of a connection rod used for an automobile engine which is also applied to the processing of the connection rods of a diesel engine, a barge engine, etc. The method is mainly characterized by adopting a technical flow as follows: processing the upper plane and the lower plane of the connection rod; machining a small end hole; boring a small end hole and a big end hole; drilling a bolt hole and tapping; drawing an expansion-breaking stress slot; expansion-breaking; assembling; preciously boring the small end hole and the big end hole; preciously milling the small end hole and the big end hole, detecting, etc. Practical applications proves that the method reduces accumulated errors, thus effectively improving the use performance of a connection rod assembly; reducing working procedure and processing precision as well as improving efficiency; the method adopts a common device and a special clamp to finish the expansion-breaking processing, thus being applied to the multi-variety small-batch production of the connection rod and simultaneously reducing the investment risk.

Owner:苏垦银河汽车部件盐城有限公司

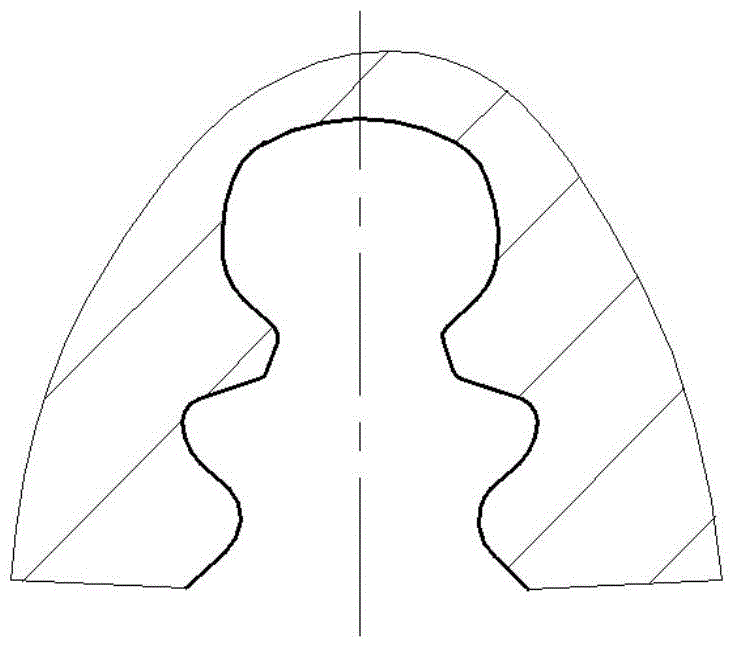

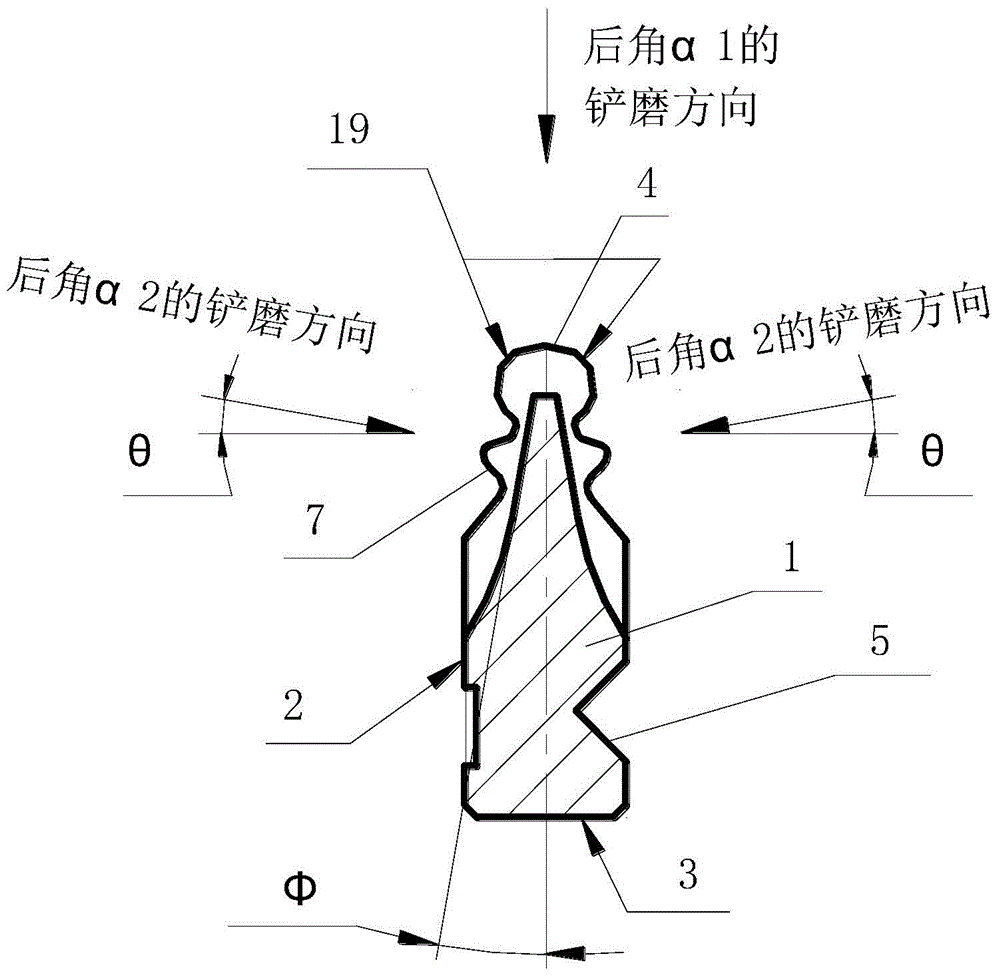

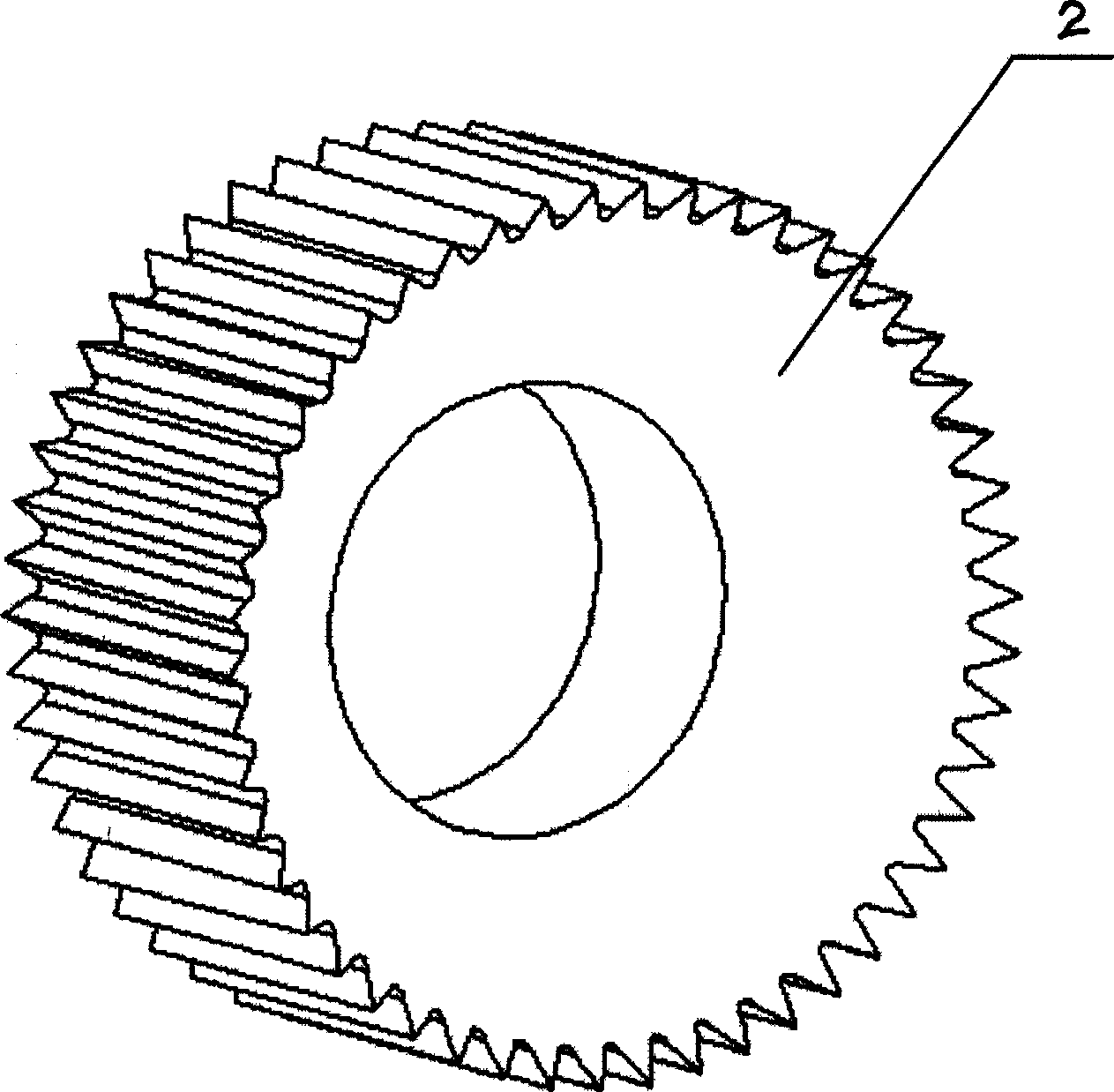

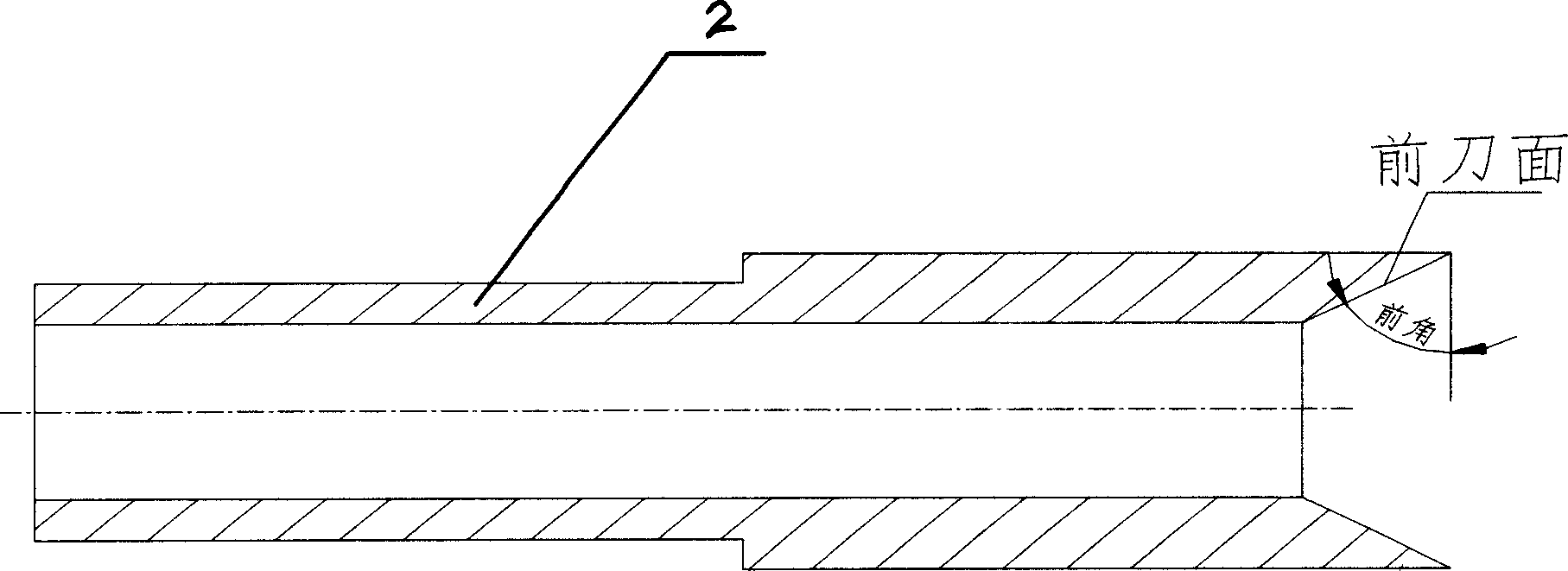

Broaching turbine disc tongue-and-groove full-profile tooth type finishing broach and grinding method thereof

The invention discloses a broaching turbine disc tongue-and-groove full-profile tooth type finishing broach. The broaching turbine disc tongue-and-groove full-profile tooth type finishing broach comprises a broach body and cutting teeth; one lateral side of the broach body is a lateral base side and the other lateral side is provided with a V-shaped groove which is used for compressing the broach; a center bisecting surface of the V-shaped groove is parallel to the broach body bottom side; the broach body bottom side is a bottom base side; the cutting teeth comprise top surface cutter teeth which are arranged on the top surface of the broach body and lateral side cutter teeth which are symmetrically arranged on bilateral sides of the broach body; the top surface cutter teeth and a rake face of the lateral side cutter teeth on the bilateral sides are in the same plane; a cutting tooth profile shape which is formed by the top surface cutter teeth and the lateral side cutter teeth on the bilateral sides is matched with a tongue-and-groove of a to-be-machined part to be used for broaching an engine turbine disc to be not allowed connecting a tongue-and-groove of the broach. The broaching turbine disc tongue-and-groove full-profile tooth type finishing broach achieves manufacturing and machining of the engine turbine disc and guarantees smooth product deliver.

Owner:AECC AVIATION POWER CO LTD

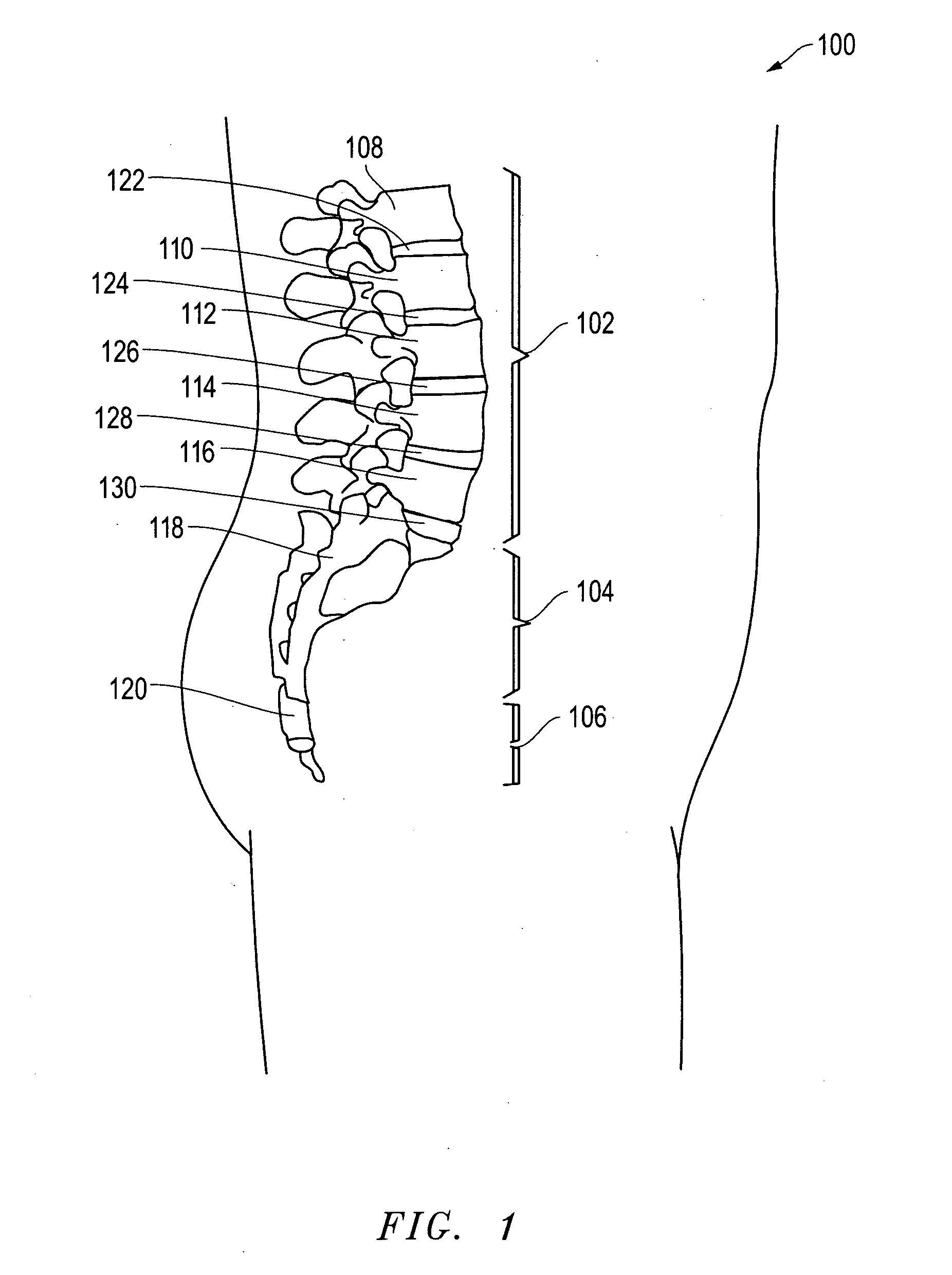

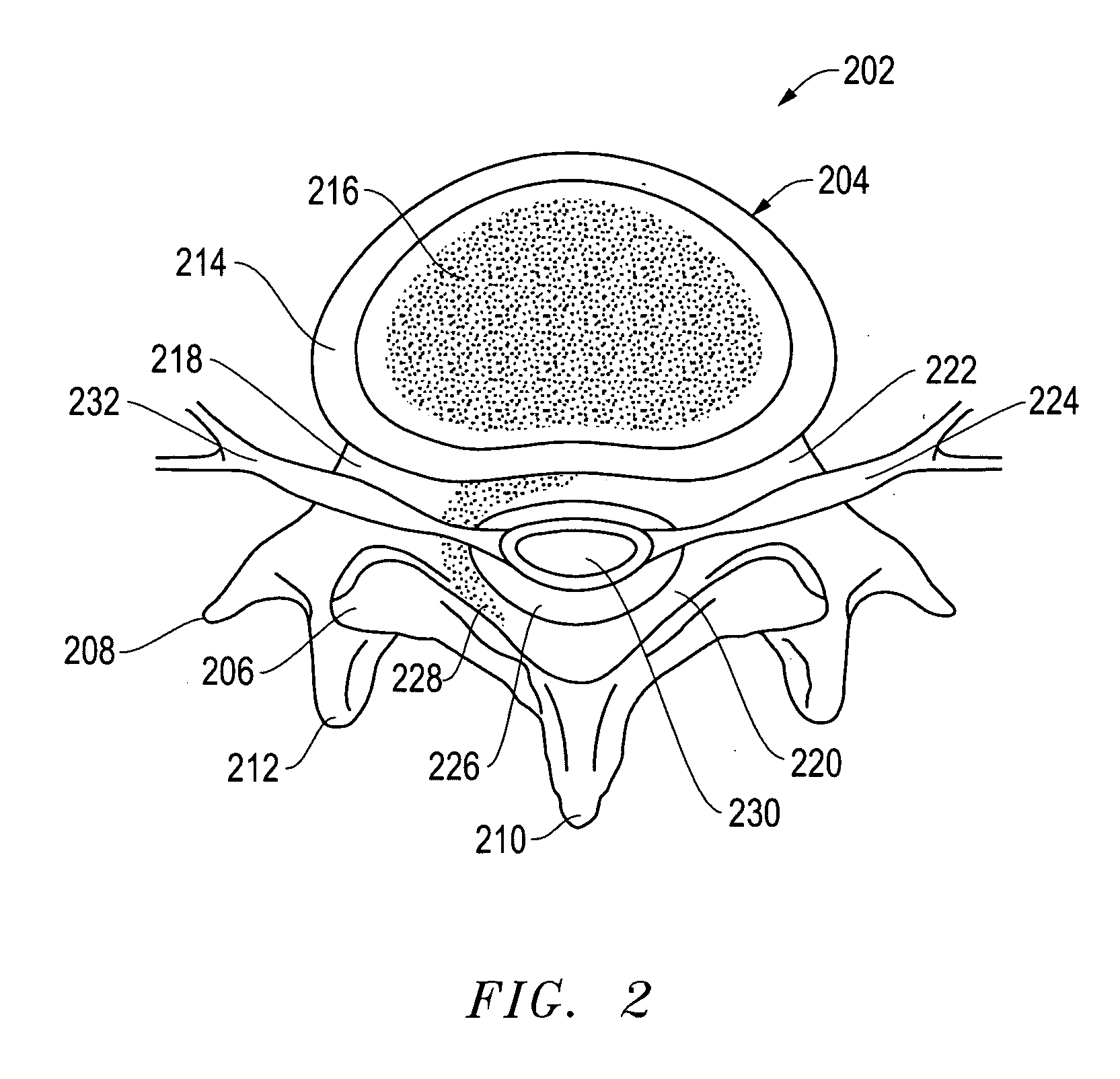

Tool for Finishing the Ends of Surgical Rods and Methods of Use

An apparatus for finishing an end of a rod including a shaping tool comprising a shaping assembly having a shaping housing and a shaping surface within the housing configured to engage an end of a rod and form a shaped rod end. The apparatus further including a finishing tool comprising a finishing assembly having a finishing surface for changing the contour of the shaped rod end to form a finished rod end.

Owner:WARSAW ORTHOPEDIC INC

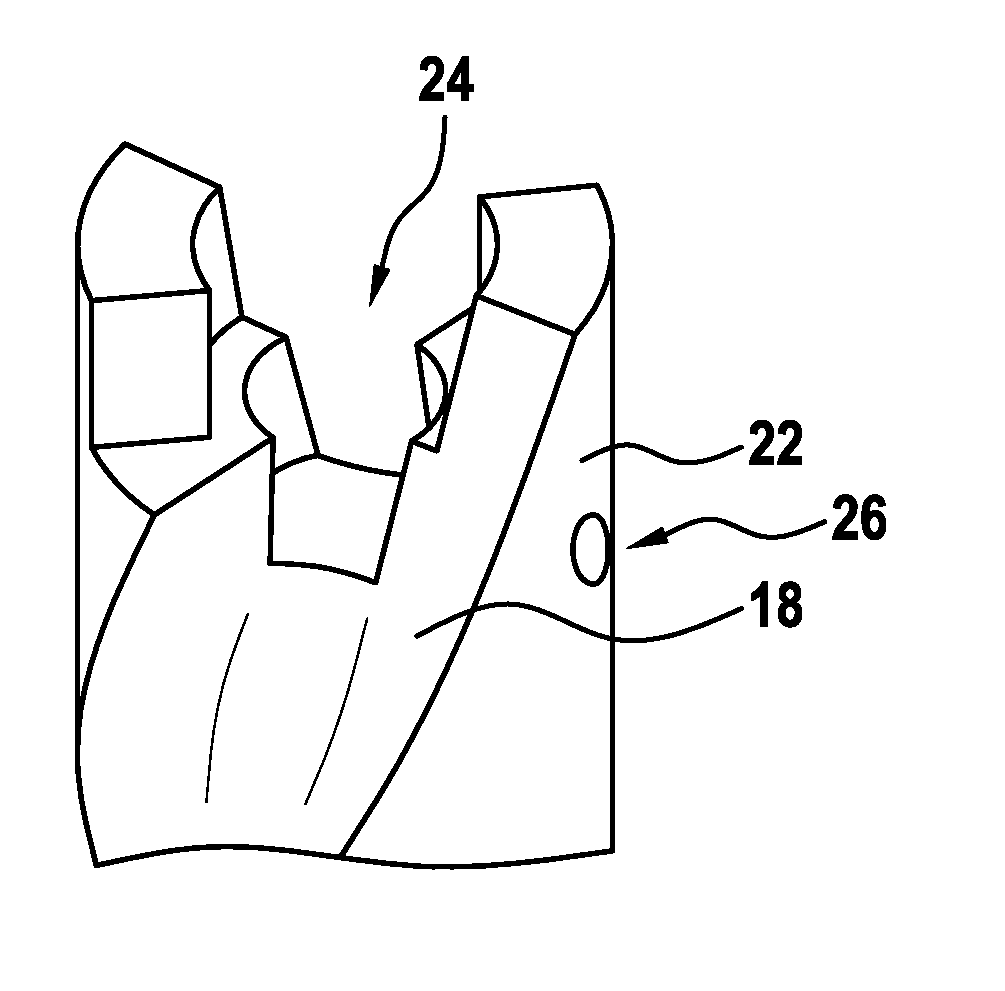

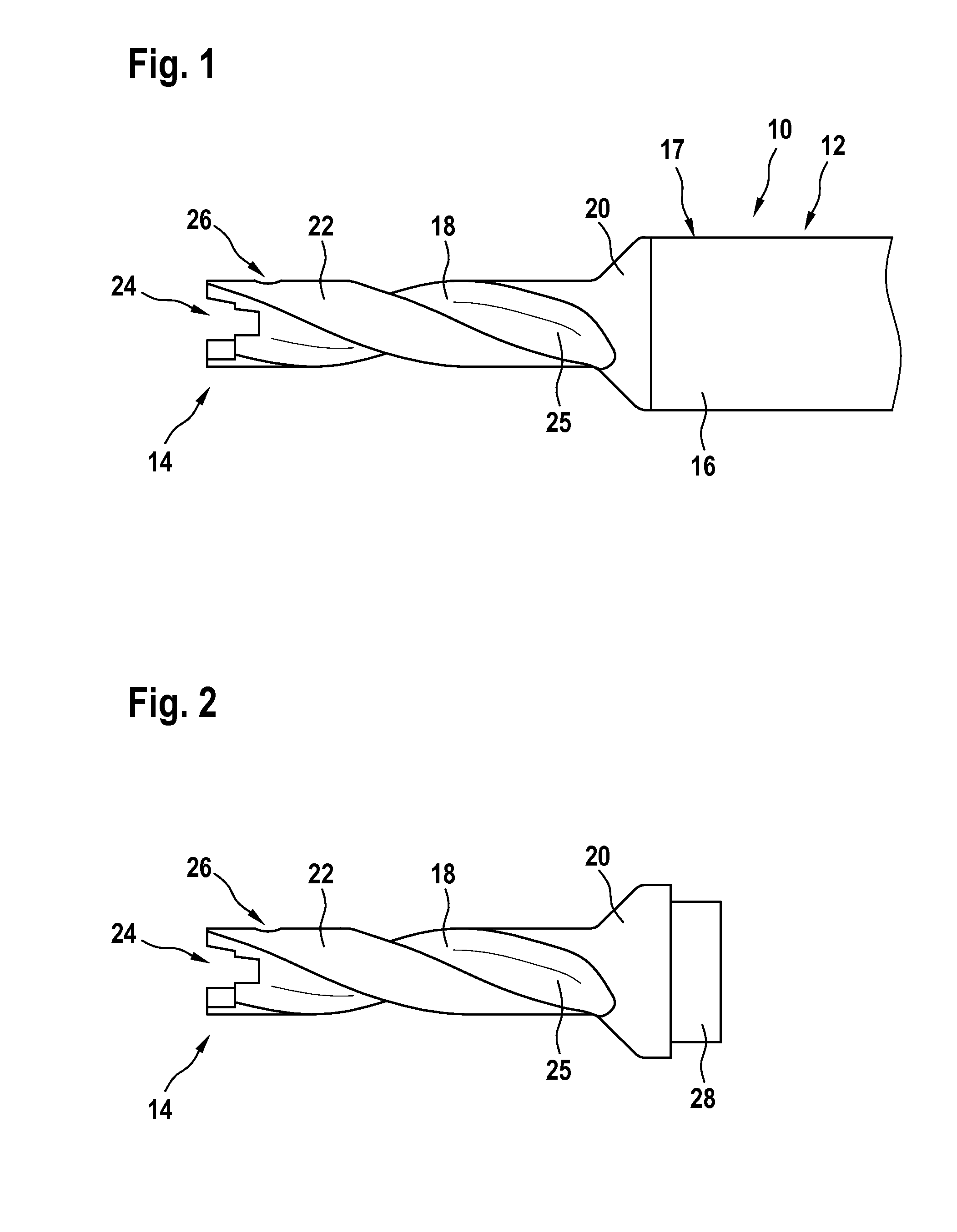

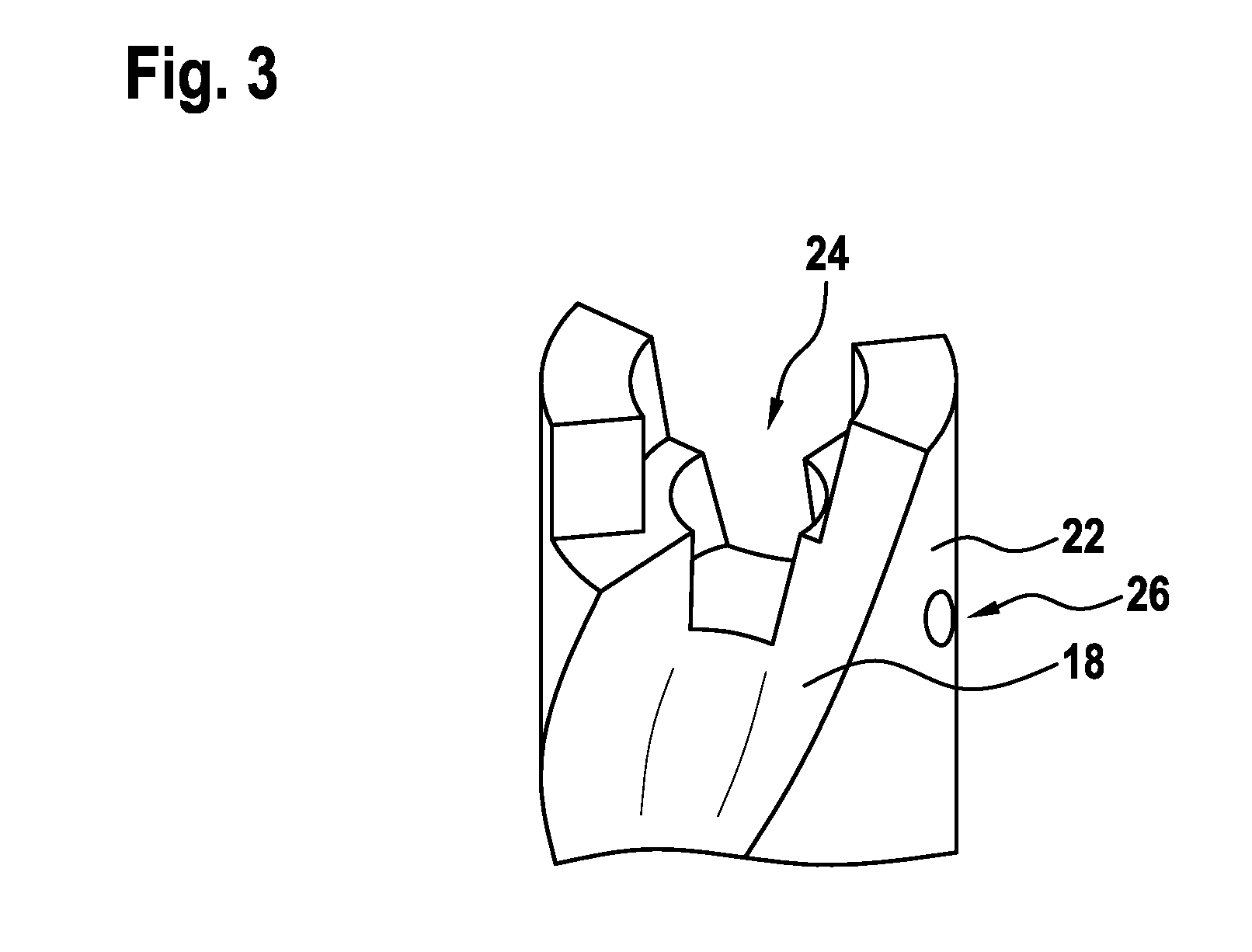

Hybrid cutting tool, chip transporting portion and process for producing a cutting tool

InactiveUS20140321931A1Complex structureSimple and cost-effective processThread cutting toolsTool workpiece connectionMilling cutterEngineering

Provision is made of a cutting tool, in particular a drill or a milling cutter, having a shank and a chip transporting portion, which receives a cutting insert, wherein the cutting tool is a hybrid composite body. Furthermore, a chip transporting portion for a cutting tool and also a process for producing a cutting tool are described.

Owner:KENNAMETAL INC

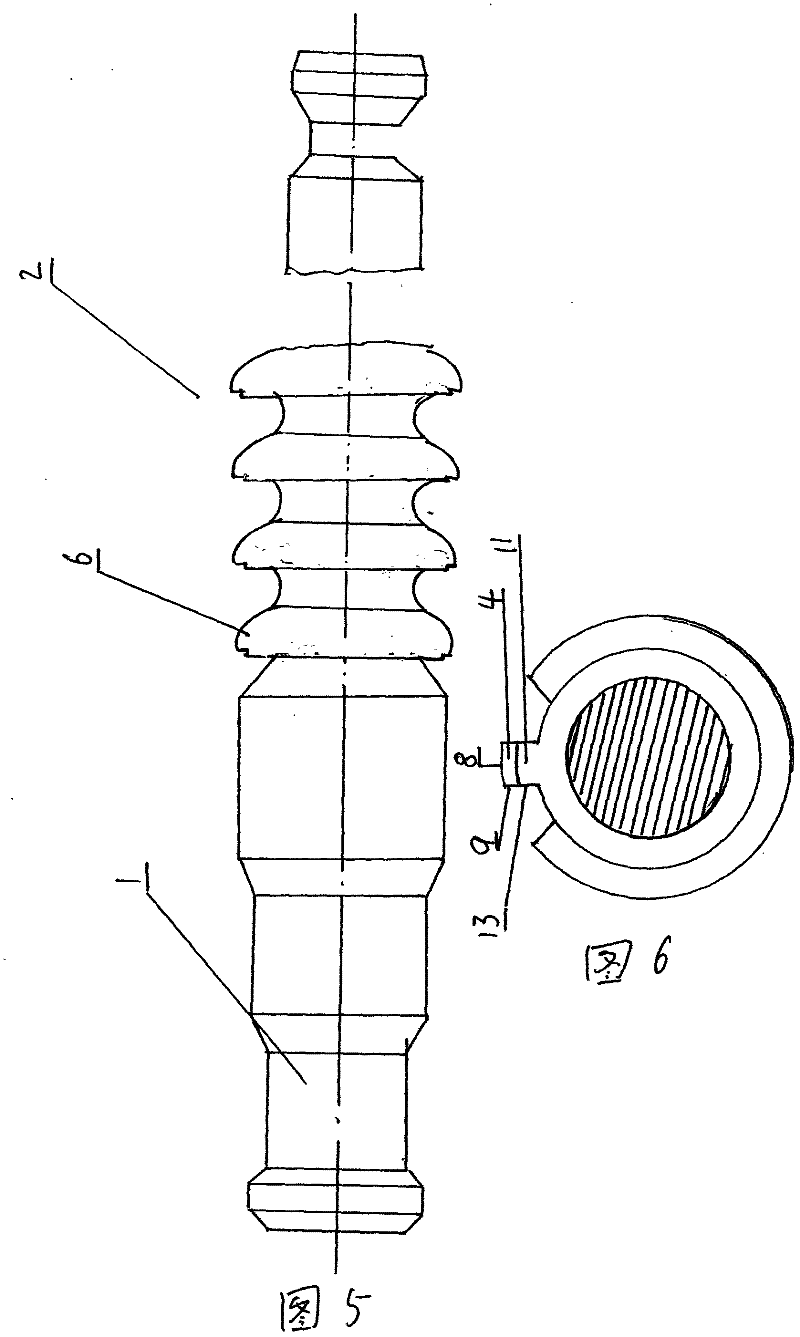

Special-shaped hole broach and machining process method thereof

InactiveCN104191036AGood technical effectAvoid stress deformationBroaching toolsNeck partsEngineering

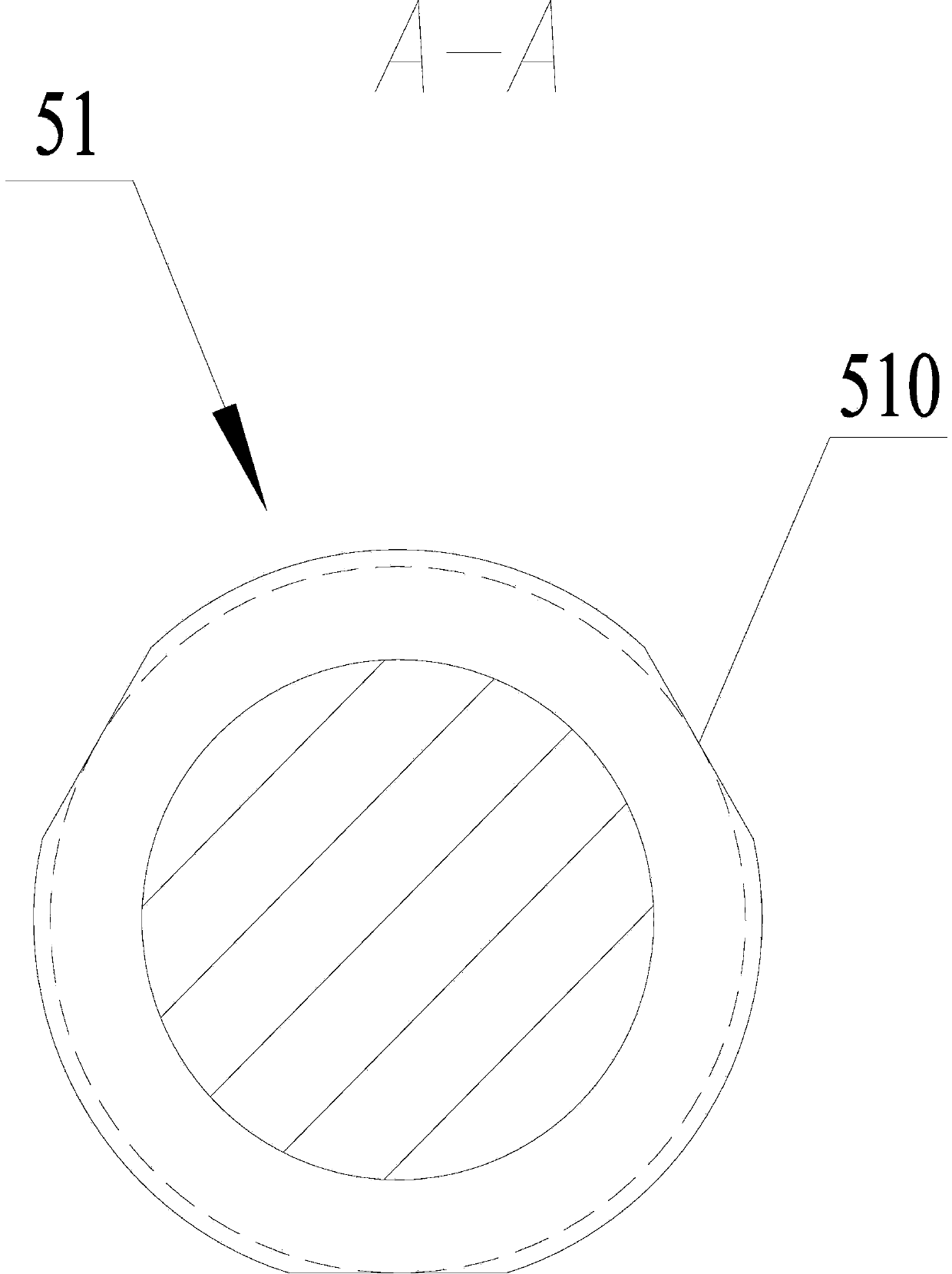

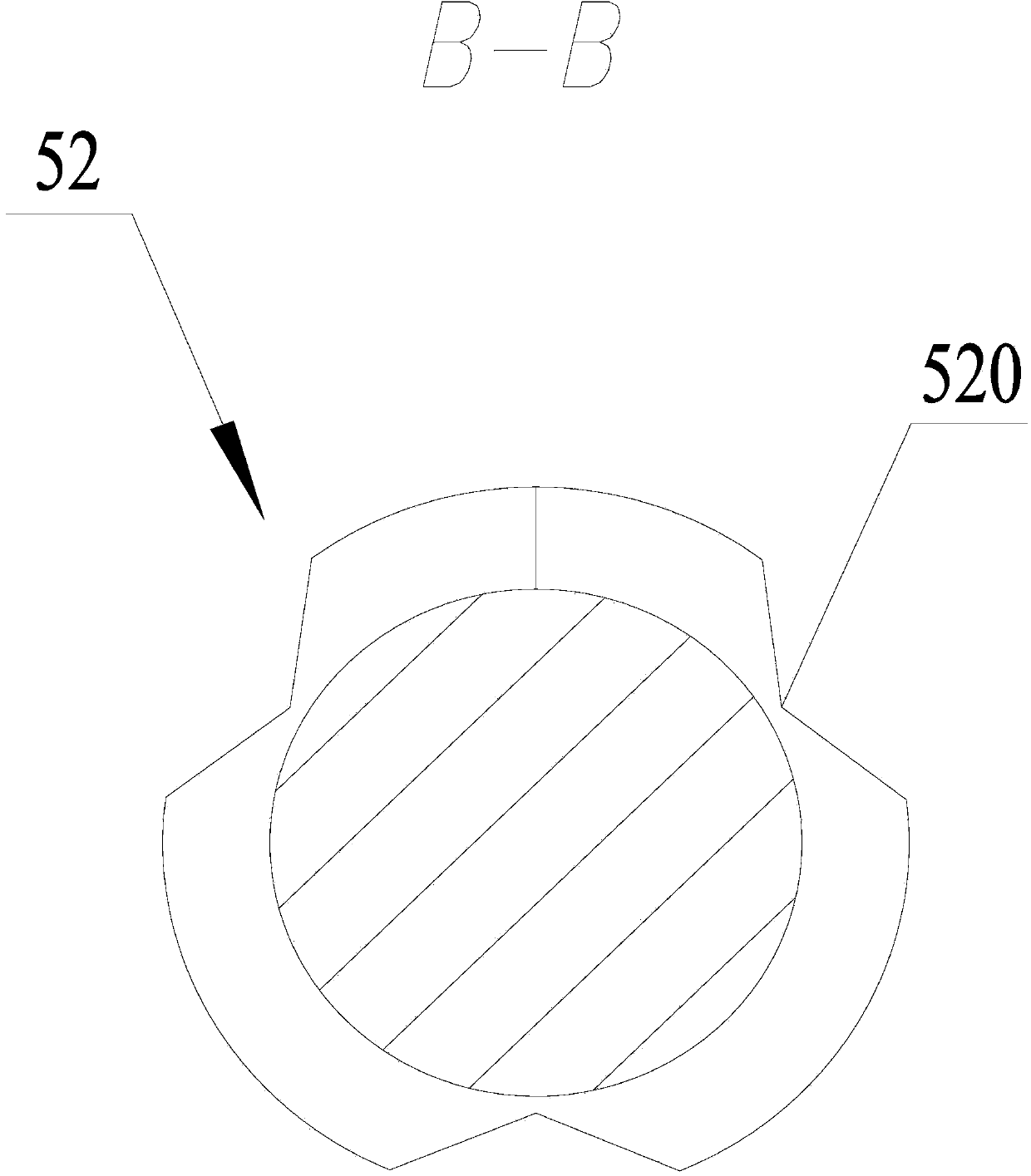

The invention relates to a broach and discloses a special-shaped hole broach which comprises a handle part, a neck part, a transition conical part, a front guide part, cutting parts and a tail part. The handle part, the neck part, the transition conical part, the front guide part, the cutting parts and the tail part are sequentially connected into a whole from the cutting-in end to the cutting-out end. A scrap containing groove is formed between every two adjacent cutting teeth. The total length from the front end of the handle part to the tail end of the tail part is not smaller than 1200 mm, and the outer diameters from the front guide part to the tail part in sequence are sequentially increased; the cutting parts comprise round hole teeth, circular arc teeth, cutting teeth, transition teeth and calibration teeth, wherein the round hole teeth, the circular arc teeth, the cutting teeth, the transition teeth and the calibration teeth are sequentially arranged from front to back and connected into a whole. The number of the teeth of the cutting parts is from 130 to 150. The invention further discloses a machining process method for the special-shaped hole broach. The broach is large in total length and high in slenderness ratio; the multiple cutting parts different in tooth shape are used for broaching a special-shaped hole, based on the high-precision ultra-slenderness machining and thermal treating process, a method for carrying out segmentation gradual grinding through a locating sleeve and a supporting point is adopted, it is ensured that jump of the solid broach is from 0.01 mm to 0.02 mm, stress deformation caused by cutter relieving and drooping can be effectively avoided, and therefore the stability of machining and forming is good.

Owner:金华市红太阳工具厂

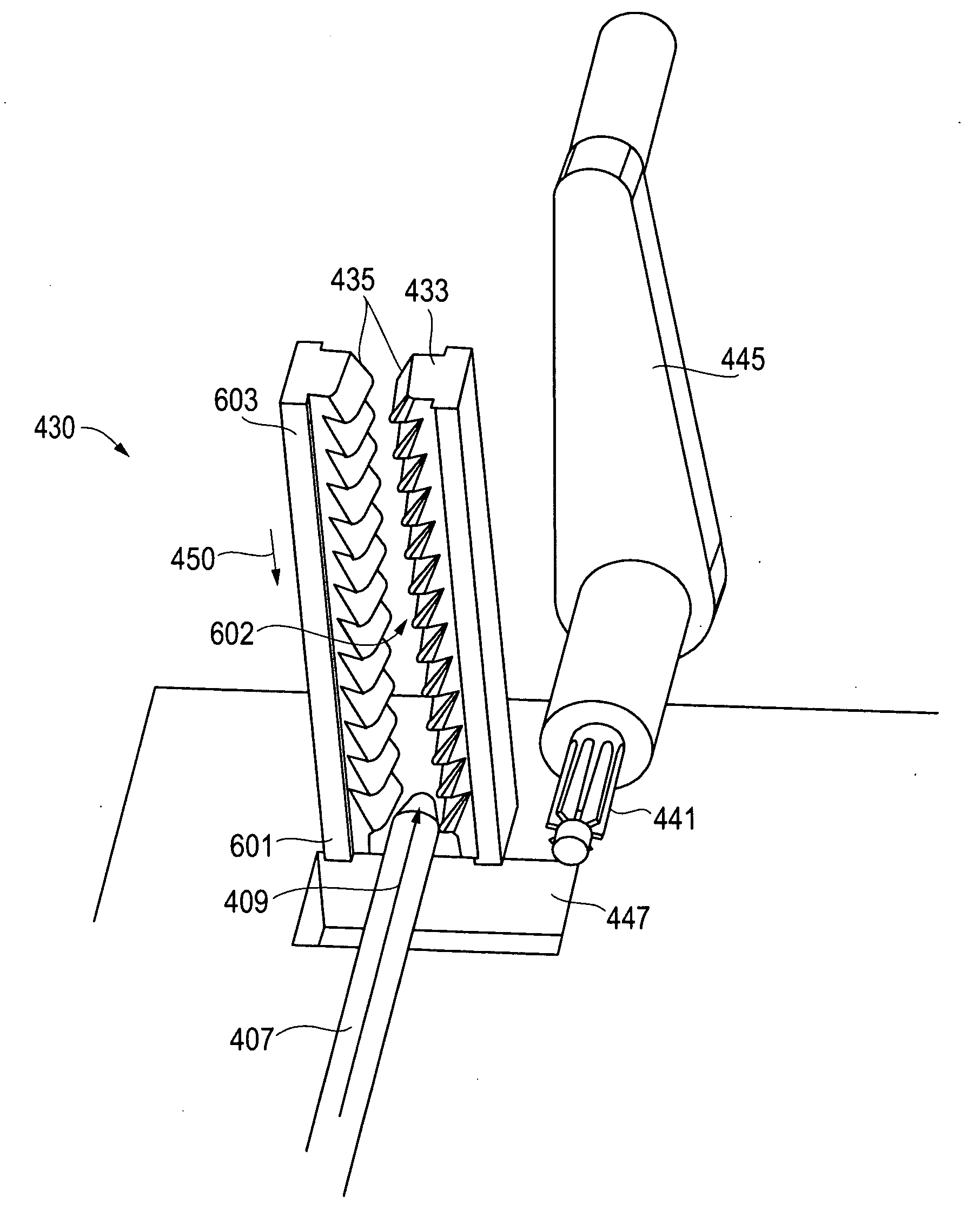

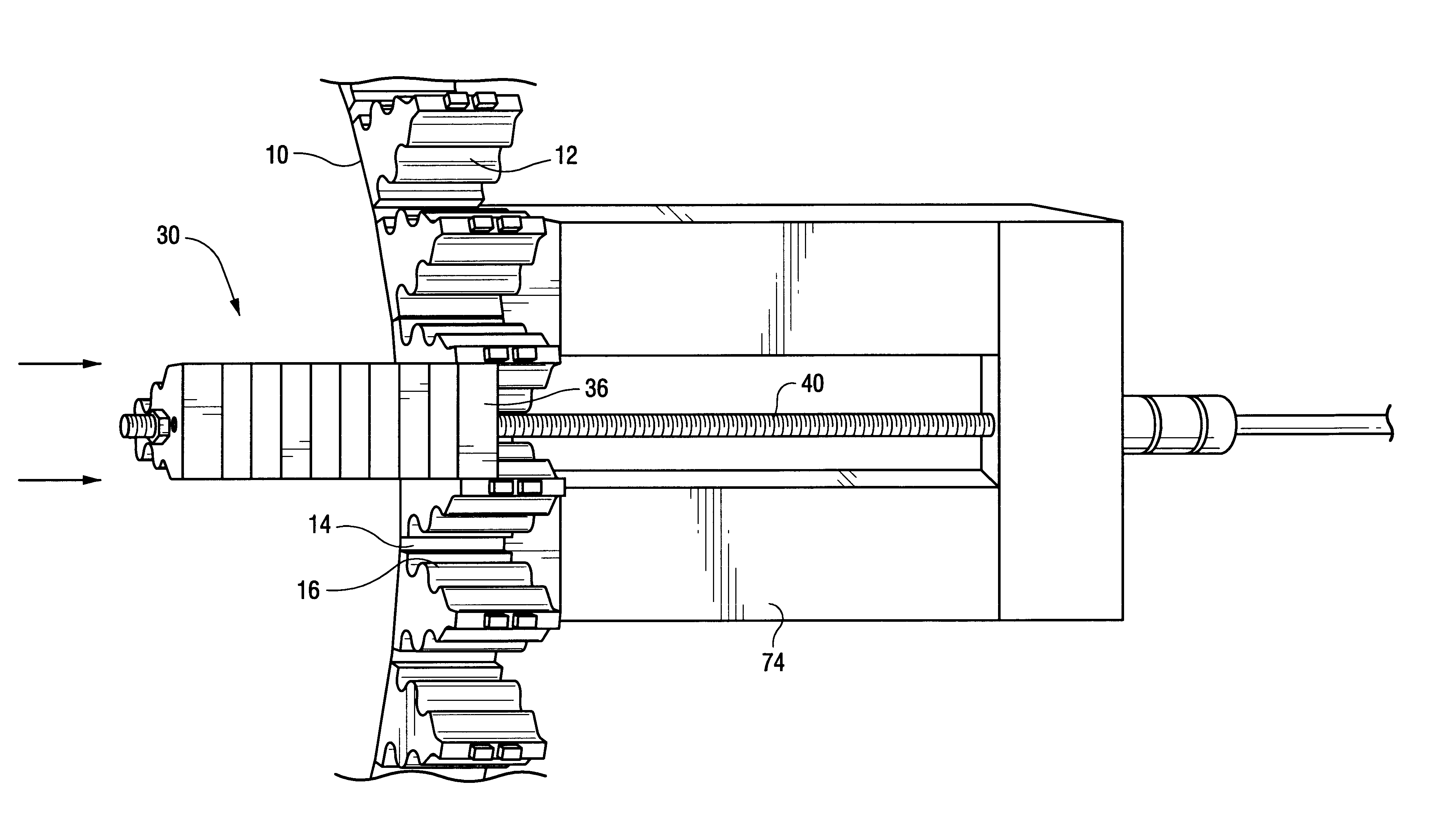

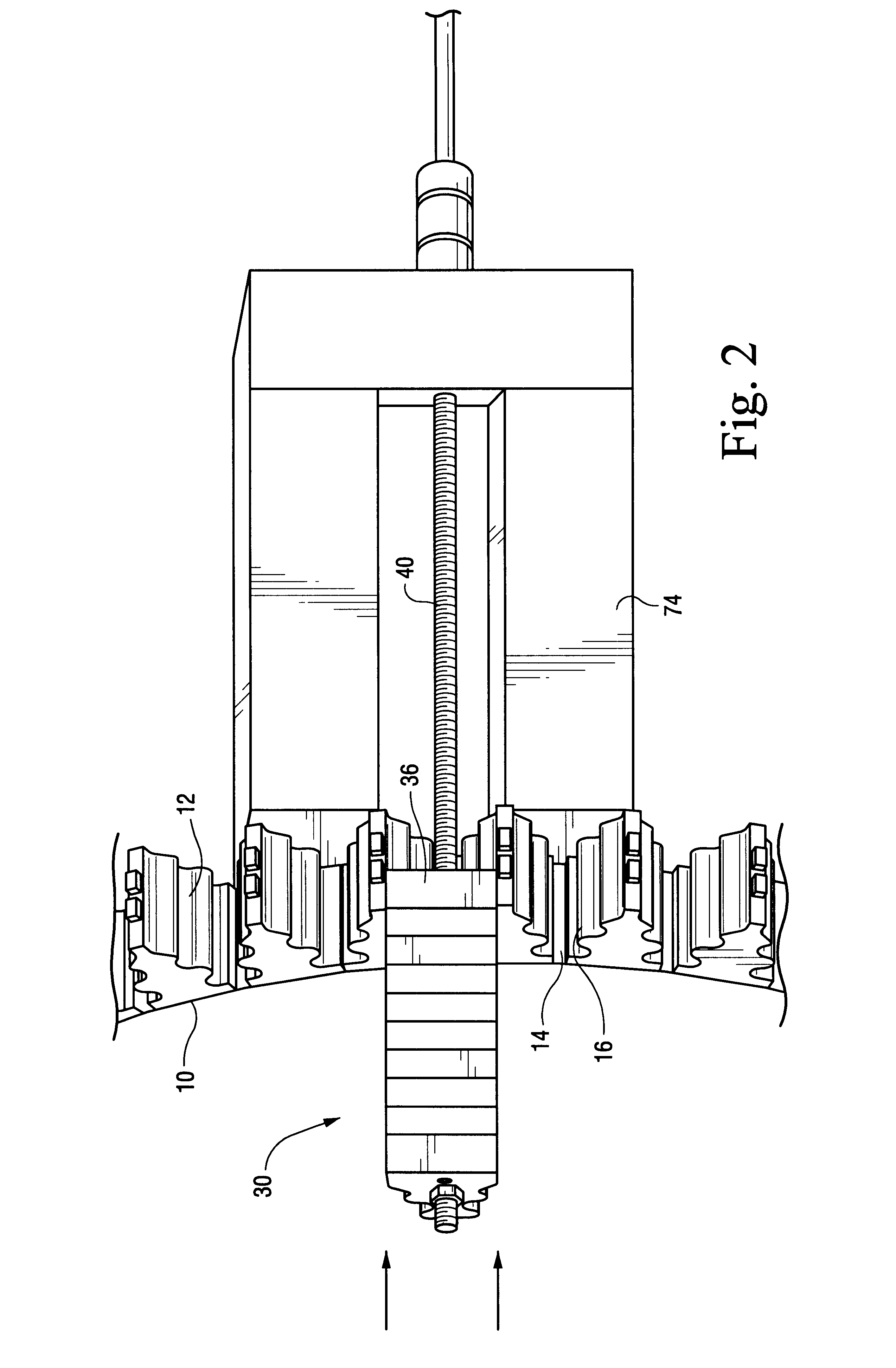

Multi-part dovetail repair broach assembly and methods of use

InactiveUS6676336B2Easy to importInexpensive to fabricateRectilinear broachBroaching toolsImpellerTurbine wheel

The broach assembly includes alternate spacers and cutters arranged in a sub-assembly having a lead at a leading end and a lag at a trailing end. The cutters have side margins in excess of the margins of the spacers for cutting material from the dovetail slots of the turbine wheel as the broach assembly passes through the slots. The bottom or apices of each spacer and cutter are tapered to form a continuously tapered surface along the bottom of the broach assembly. Upon passing the broach assembly through the slot, the assembly is progressively displaced in a radial outward direction to progressively cut the active dovetail slot surfaces. Shims may be disposed in the bottom of the slot to further displace the broach assembly radially outwardly in multiple passes.

Owner:GENERAL ELECTRIC CO

Efficient grinding method for tipping tooth tops of side-edge-free roughing broaches

ActiveCN103203666ADo not change envelope typeIncrease the number of times you can sharpenBroaching toolsEngineeringHeavy duty

The invention discloses an efficient grinding method for tipping tooth tops of side-edge-free roughing broaches. The efficient grinding method is characterized in that a magnetic workbench is deflected by a certain angle to grind triangular areas of tips of tipping teeth of a broach, follow-up teeth are ground according to shapes of the ground tipping teeth, the grinding allowance of the follow-up teeth is gradually reduced, the last three follow-up teeth of the broach are kept unground to guarantee the profile of the broach, accordingly, local envelope curves of the ground teeth of the broach are changed, and the tipping teeth of the side-edge-free roughing broach are efficiently ground. The efficient grinding method has the advantages that the profile of the original integral envelope curve of the broach is guaranteed, the grinding allowance is low, a blade of the broach is ground uniformly, the grinding time is greatly shortened, impact and vibration on the front-back teeth adjacent to the tipping teeth can be effectively reduced, the grinding efficiency is improved, grinding permissible times of the broach are increased, the service life of the broach is prolonged, the production cost is lowered, and the efficient grinding method is suitable for broaches with various structures and is particularly suitable for grinding side-edge-free roughing broaches for machining mortises of rotor discs of heavy-duty gas turbines.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

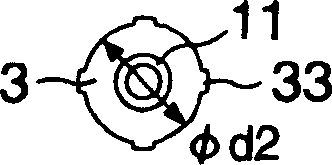

Internal broach

Owner:FORST TECH

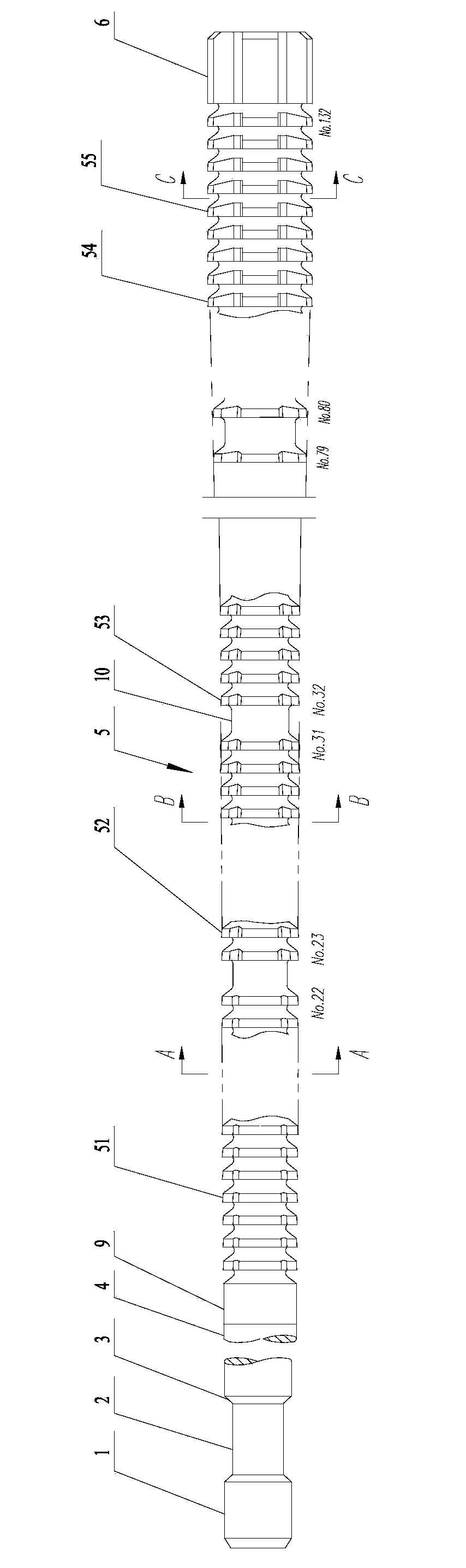

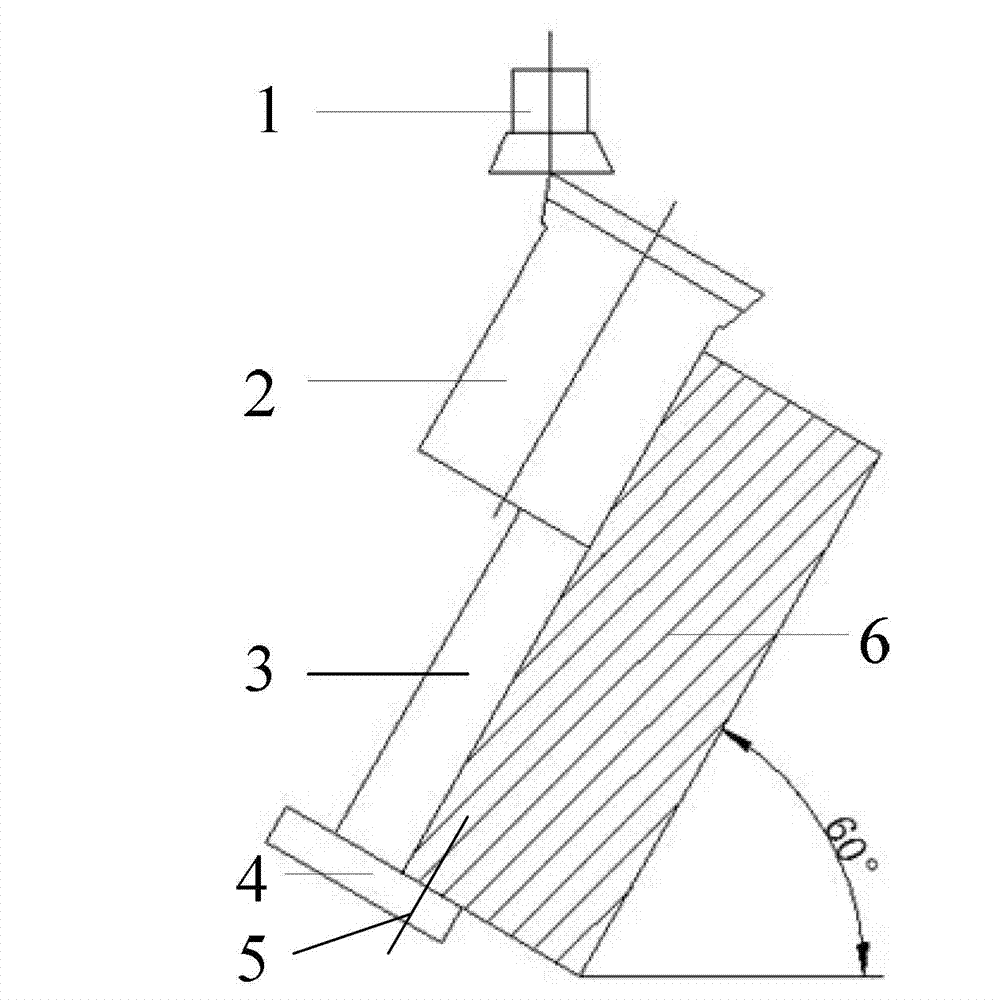

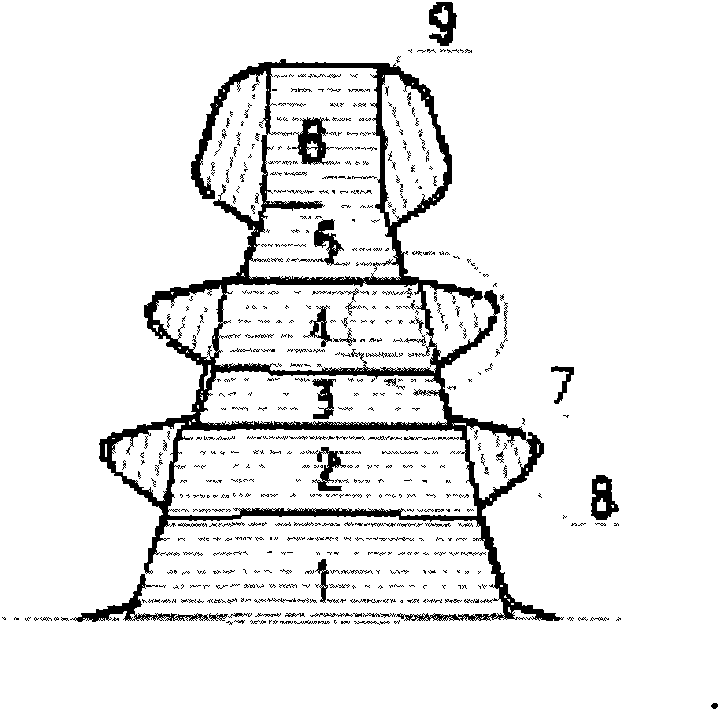

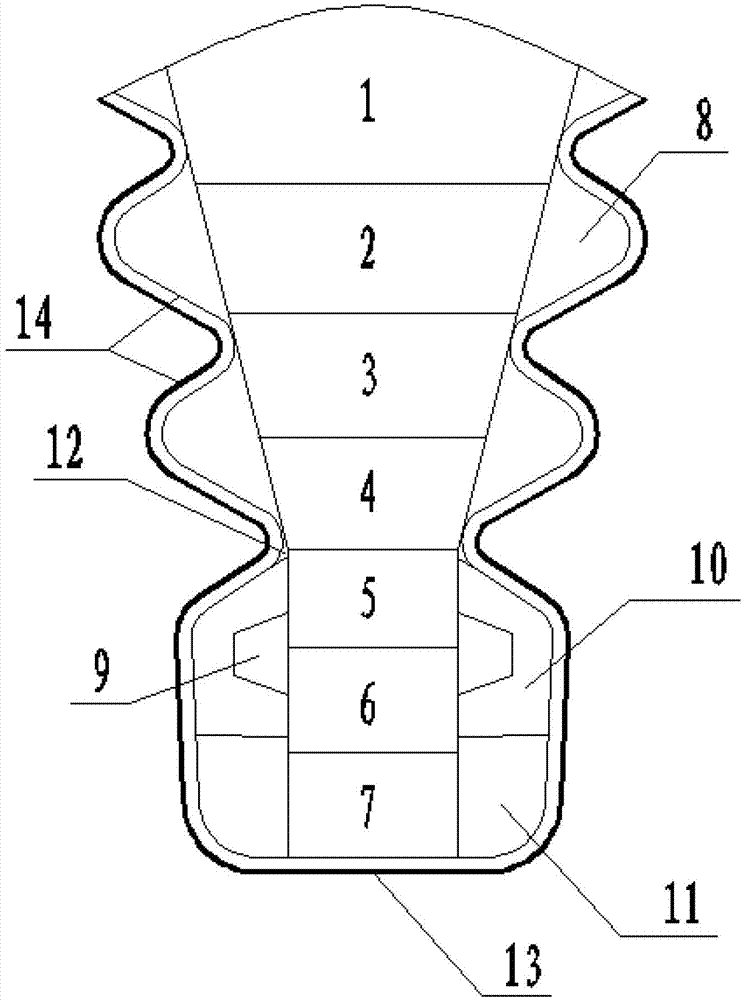

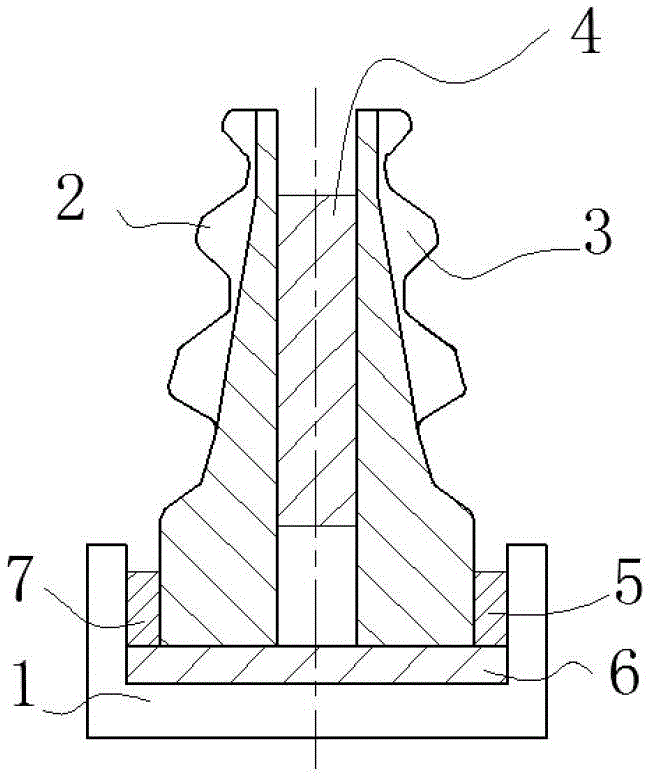

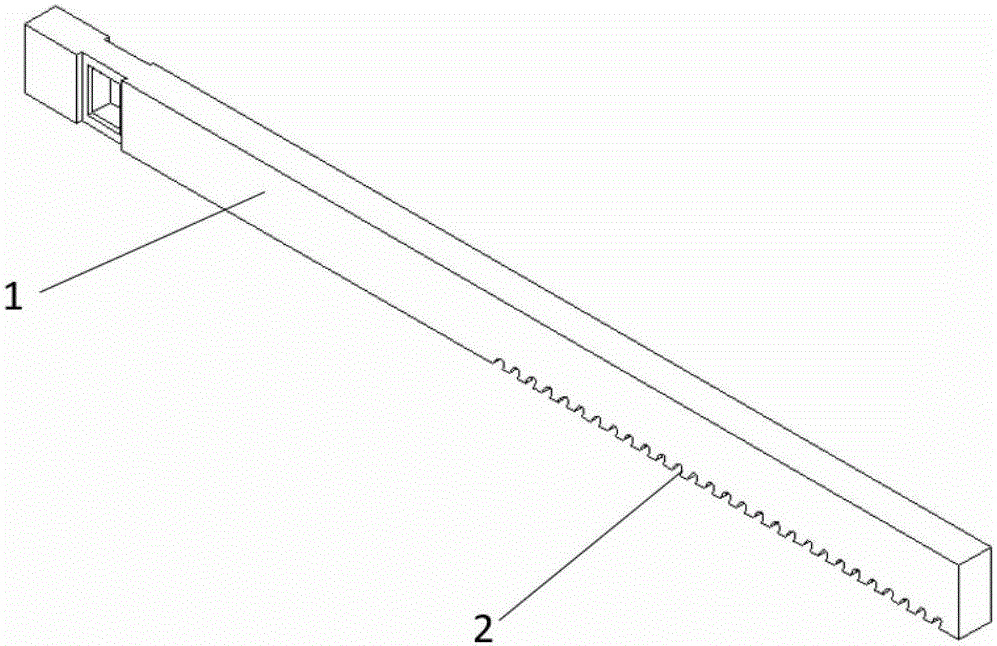

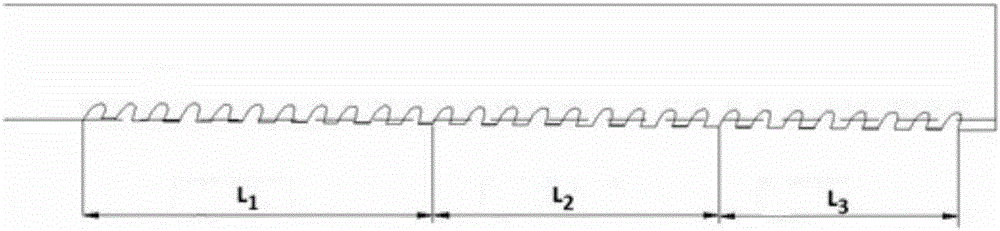

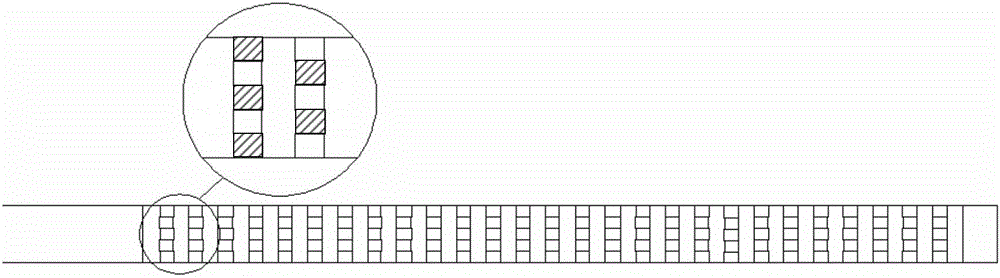

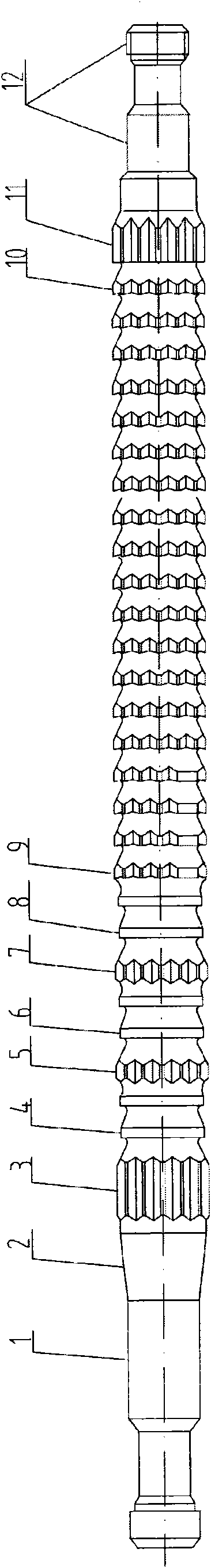

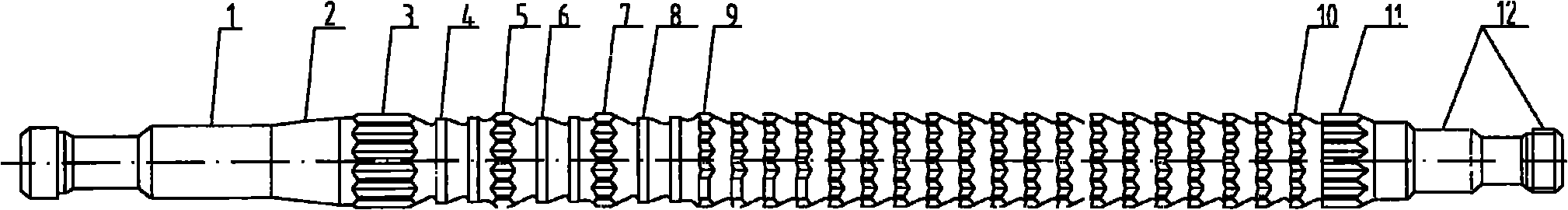

Turbine disk fir-shaped mortise broaching tool

InactiveCN101774045AShorten the lengthIncreased durabilityBroaching toolsPositioning apparatusEngineeringTurbine

The invention relates to a turbine disk fir-shaped mortise broaching tool, which is characterized in that a milled chamfer angle of 0.2x45 DEG is arranged on a sharp corner at two sides of the bladewidth of the turbine disk fir-shaped mortise broaching tool, parts 1 to 6 are slotted roughly, a seventh part is roughly broached with a mortise thread shape, an eighth part is precisely broached with a mortise thread-form sectional surface, and the top surface of a ninth part is precisely broached; the parts 1 to 6 adopt six slotting cutters, the seventh part adopts one rough-broaching thread-form cutter, the eighth part adopts one precise-broaching thread-form cutter, and the ninth part adopts one top-surface broach which is also named cap knife. The turbine disk fir-shaped mortise broaching tool has the advantages that the design structure of the broach is changed, the service life of the slotting broach is improved, and the manufacturing precision and the product complete qualification rate of the thread-form precise broach are broken through. The debugging period is successfully shortened, the trial broaching at one time is completely qualified, the production efficiency is improved by 30 percent, and the service life of the broach is prolonged. Compared with the combination-type broach and the powder metallurgy broach, the broaching tool with the above structure has simpler manufacturing process, good interchangeability, safe application and low cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

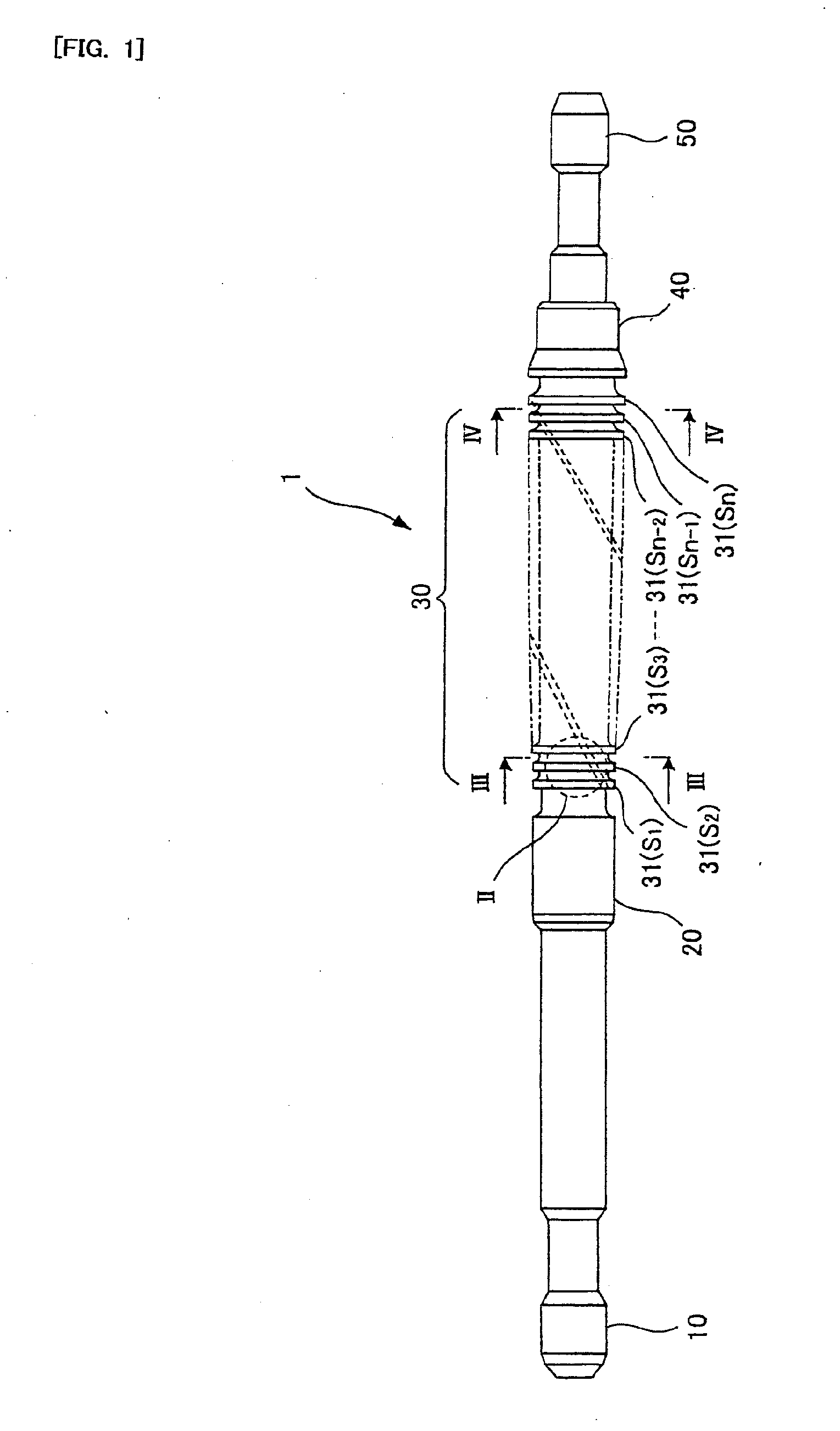

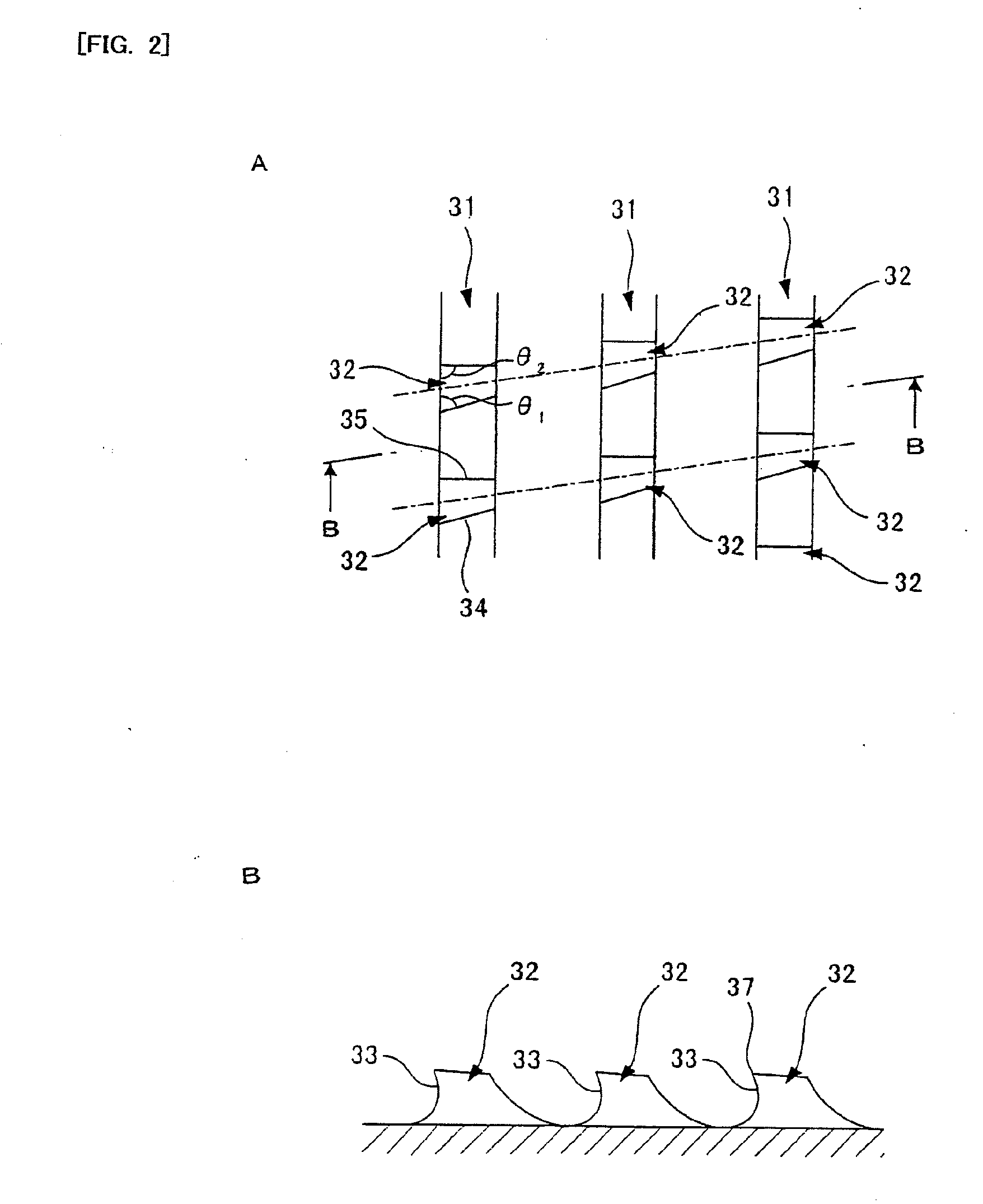

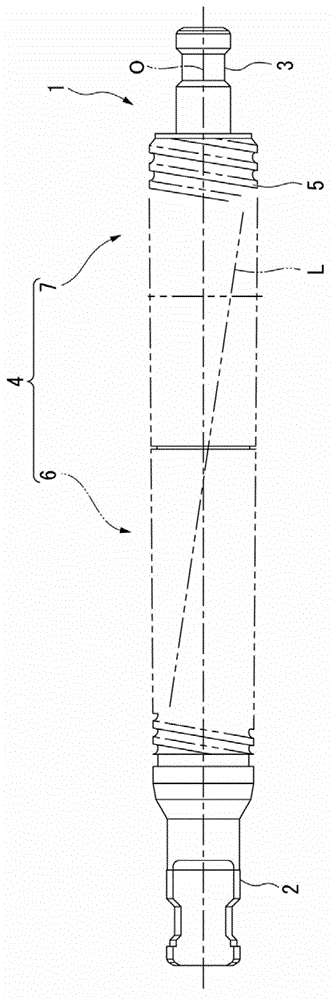

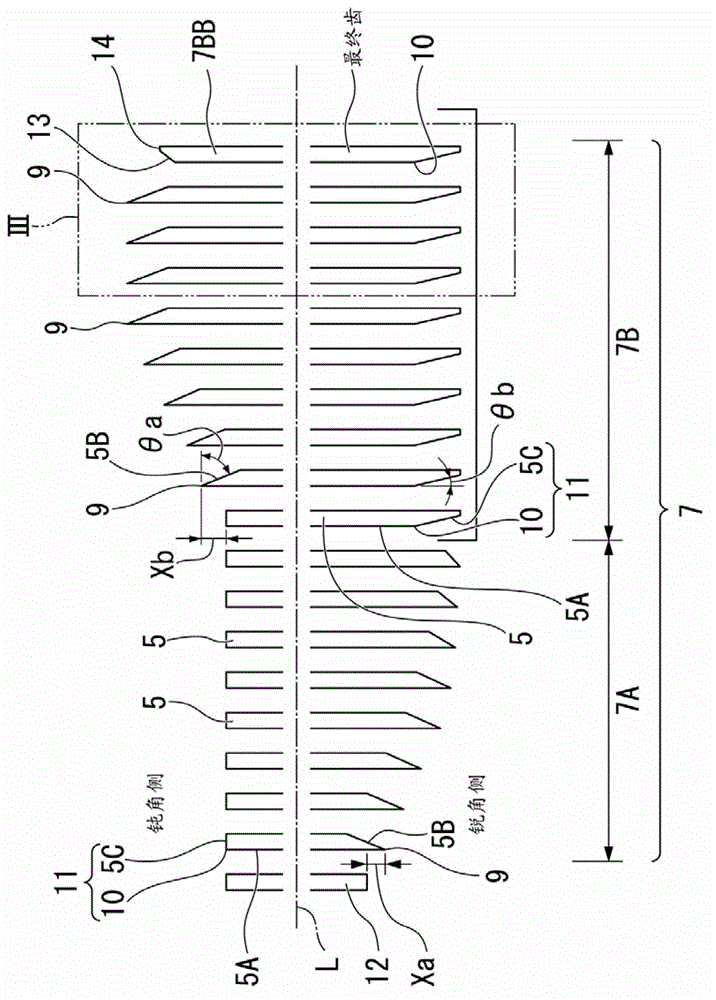

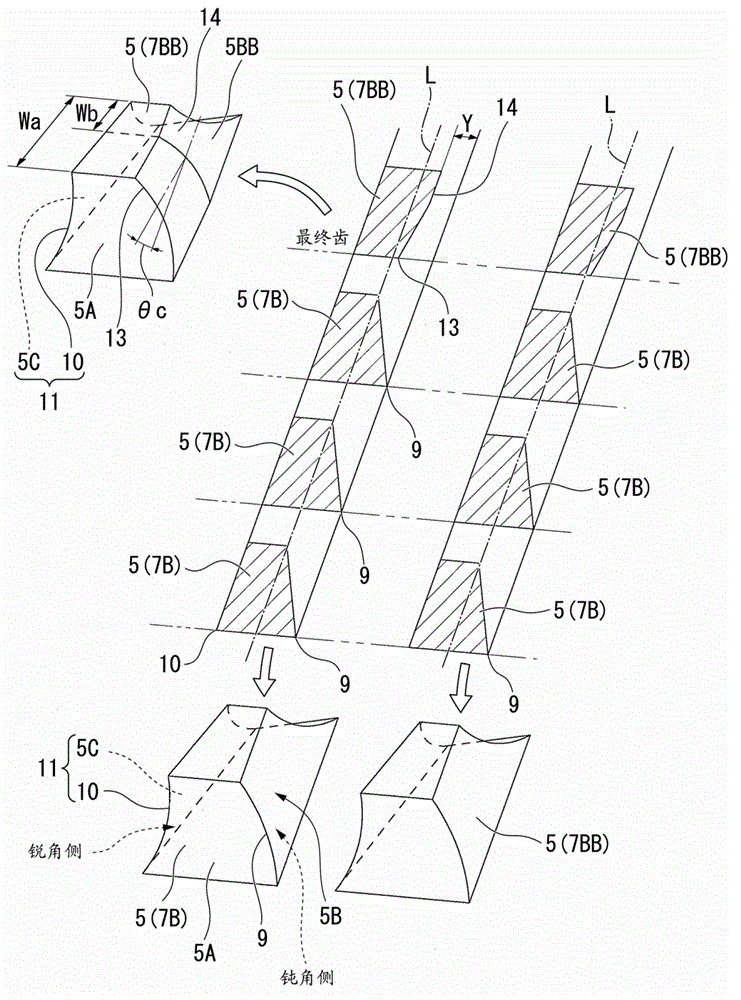

Helical broach for roughing

InactiveUS20110020078A1Reduce the balanceReduce the differenceRectilinear broachBroaching toolsAcute angleEngineering

A helical broach 1 for roughing includes a cutting tooth part 30 in which n spline teeth 31 are arranged side by side in an axial direction. The spline teeth 31 each include cutting teeth 32 which are arranged at a predetermined helix angle. The cutting teeth 32 each have an acute angle portion and an obtuse angle portion on both sides thereof in a circumferential direction. The cutting teeth disposed on the first to n−1th spline teeth 31 (S1 to Sn−1) in the circumferential direction are each formed in such a way that its height on the acute angle portion side differs from that on the obtuse angle portion side. The cutting teeth (Sn) of the nth spline tooth (Sn) are each formed in such a way that its height stays constant in the circumferential direction.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

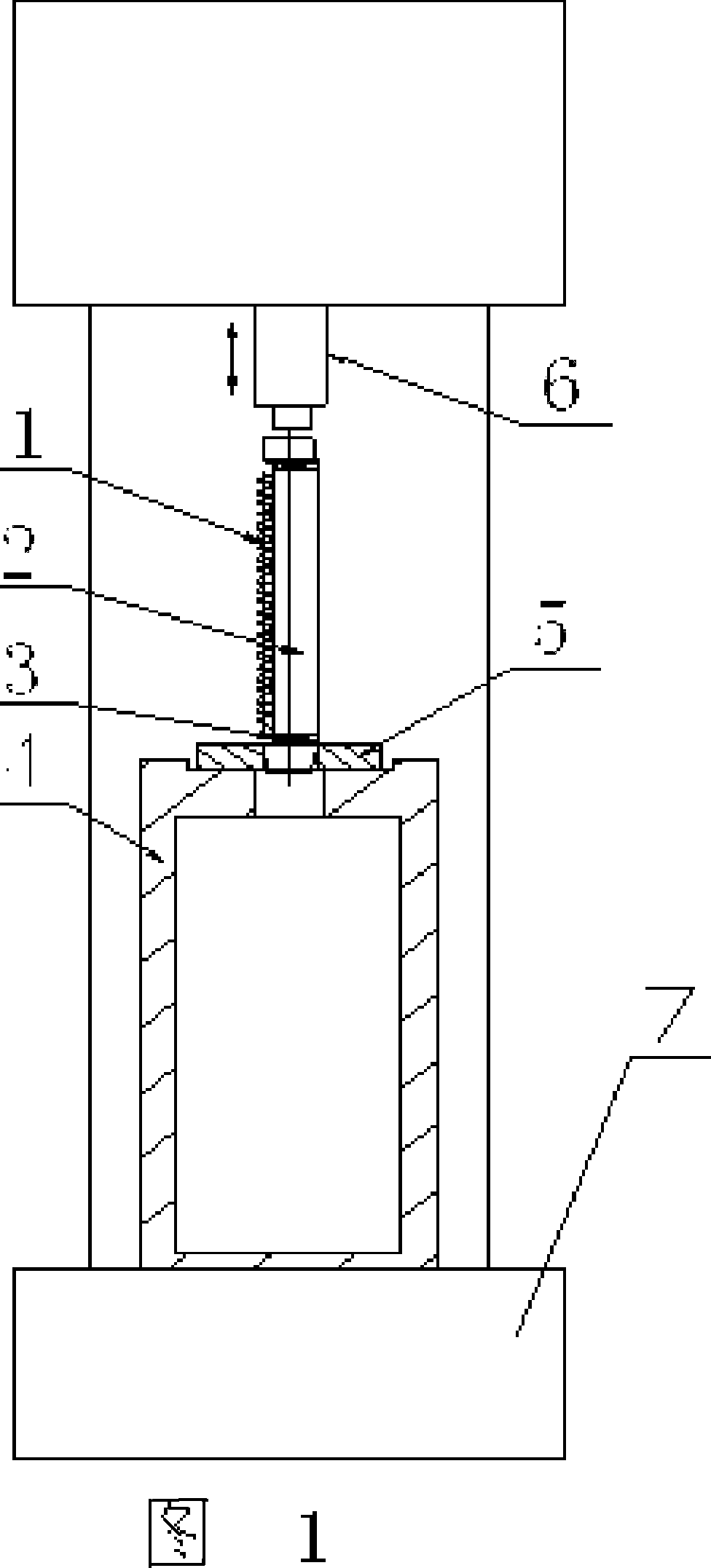

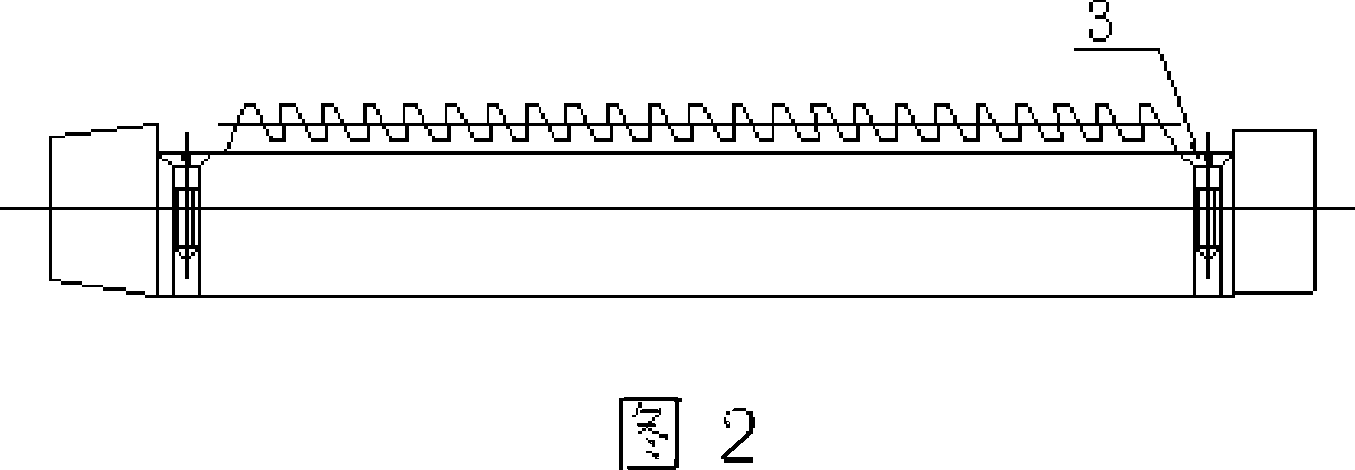

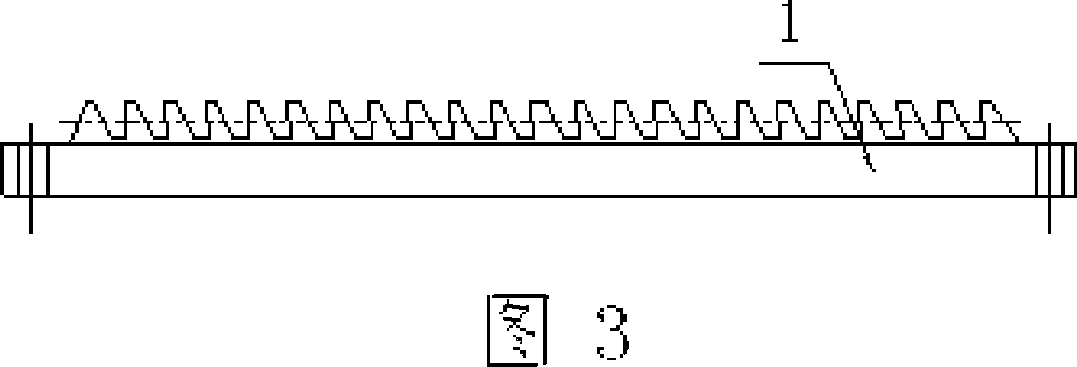

Method for processing gear inner hole key slot and special device

InactiveCN1943940ASimple and fast operationIncrease productivityBroaching toolsBroaching machinesGear wheelMachining

The present invention discloses method and device for machining key slot in gear inner hole. The method includes fixing one support on the press bench, setting the workpiece on the support, inserting the conical guide part of the combined tool into the inner hole of the workpiece, pressing the combined tool to pass through the inner hole with pressure mandrel, cutting the key slot with the pushing broach in the combined tool, and loosening the mandrel to unload the workpiece and the combined tool to complete the machining. The device specially for machining key slot in gear inner hole includes a pressure mandrel on a press, a support on the bench of the press, and a combined tool. The combined tool consists of a pushing broach, a broach pouch and a locking screw for connection. The present invention is used in cutting single key slot in inner hole of gear of non-ferrous metal and plastic.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

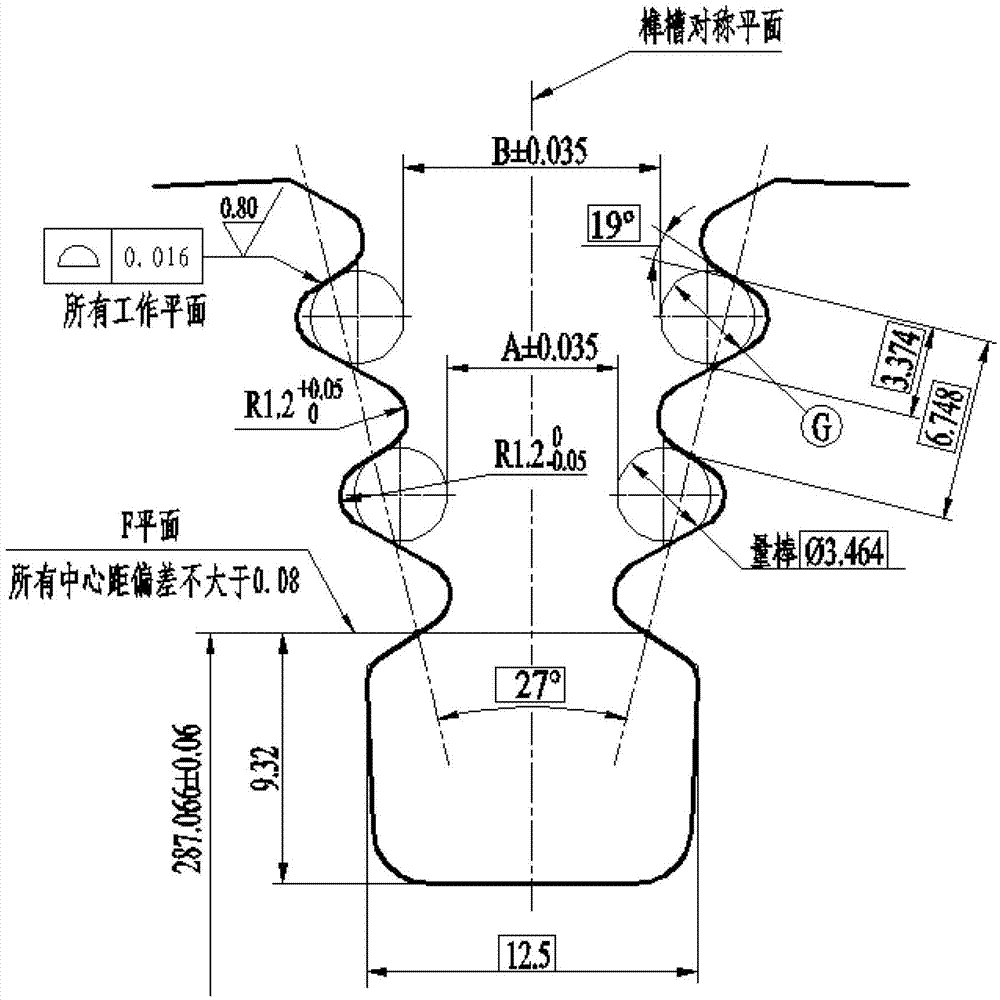

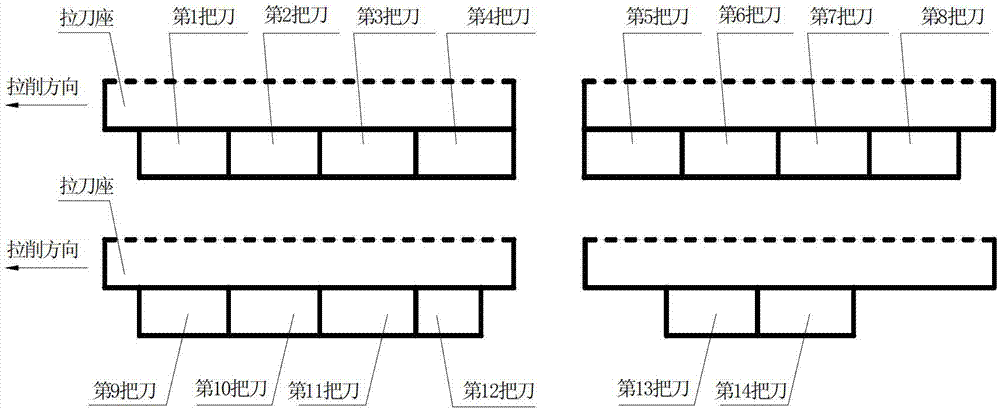

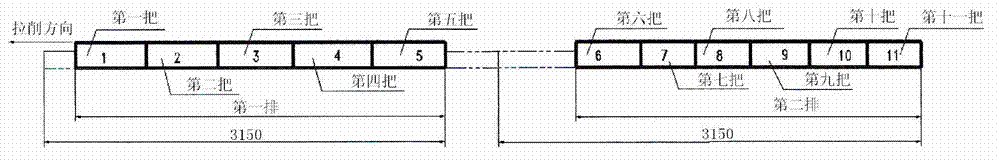

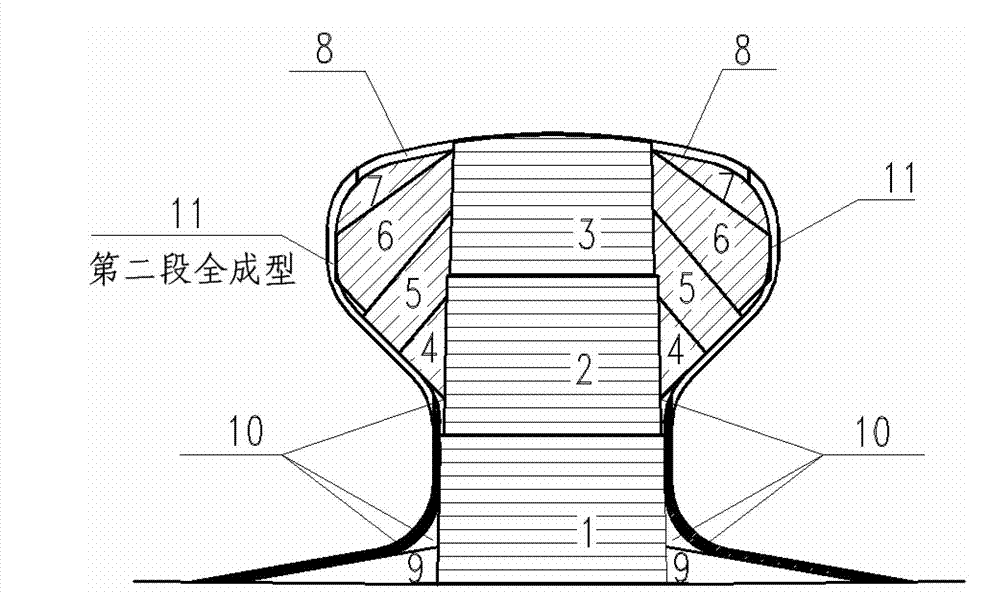

High-accuracy mortise broaching processing method for turbine disk made of powder high-temperature alloy material

InactiveCN102962513AControl and reduce broaching distortionMeet processing needsBroaching toolsBroaching machinesHardnessSuperalloy

The invention discloses a high-accuracy mortise broaching processing method for a turbine disk made of a powder high-temperature alloy material. Broaching tools made of an imported powder high-speed steel material ASP2060 are adopted; the hardness HRC of the broaching tools is 66-68; 14 fourteen broaching tools in a complete set are adopted; first to seventh broaching tools are necking tools; an eighth broaching tool is a roughing tooth type tool; ninth to eleventh broaching tools are roughing tooth bottom cut tools; a twelfth broaching tool is a roughing tooth top circular arc tool; a thirteenth broaching tool is a finish broaching tank bottom circular arc tool; a fourteenth broaching tool is a finish broaching tooth type tool; the broaching tools are made of an ASP2060 powder high-temperature alloy material; the front angles of the broaching tools are 15 degrees; the back angles of the broaching tools are 3 degrees; the rise per teeth of the rough necking tools are 0.045-0.06 millimeters; the rise per tooth of the roughing tooth type tool is 0.02-0.035 millimeters; the rise per tooth of the finish broaching tank bottom circular arc tool is 0.02 millimeters; the rise per tooth of the finish broaching tooth type toolfourteenth broaching tool is 0-0.03 millimeters; gradual cutting and complete molding are adopted in a broaching way; the rough broaching speed is 1 meter per minute; and the finish broaching speed is 1-1.5 meters per minute. The high-accuracy mortise broaching processing method has the advantages that: broaching deformation of parts is controlled and reduced effectively, the processing requirements of a high-accuracy powder metallurgy disk are met, and the requirement of a high-accuracy mortise on size accuracy on a high-accuracy mortise is met effectively.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

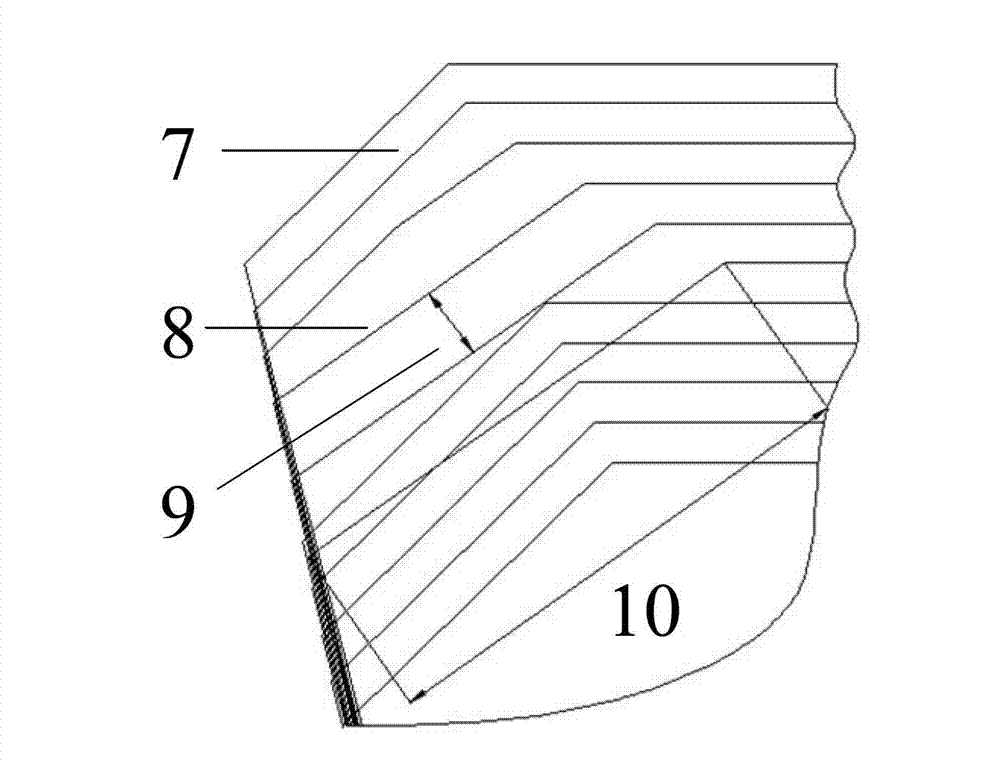

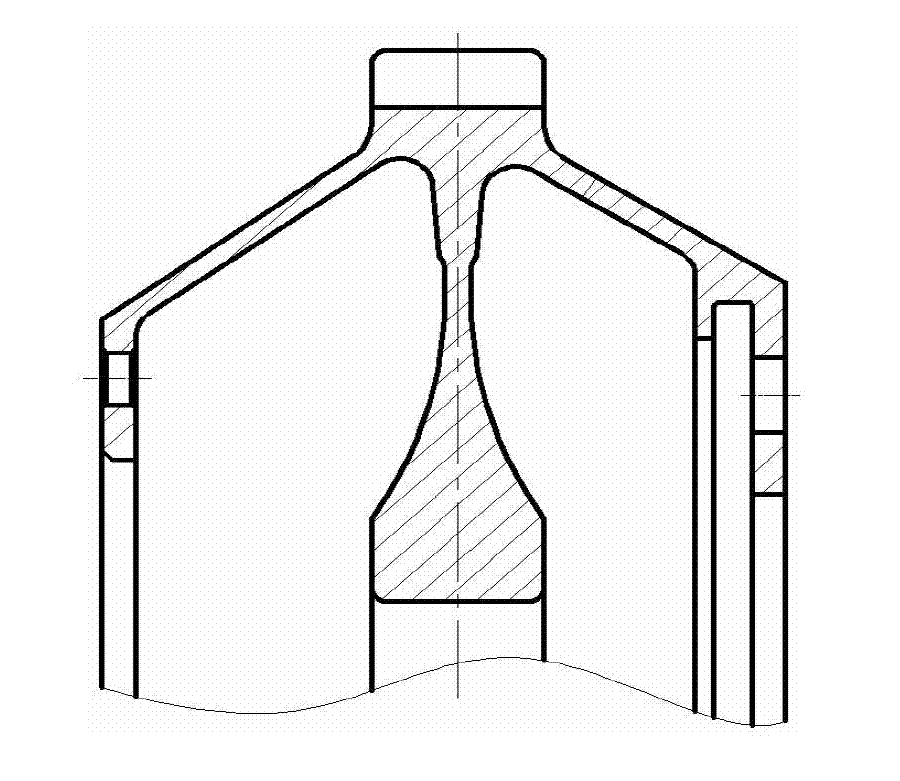

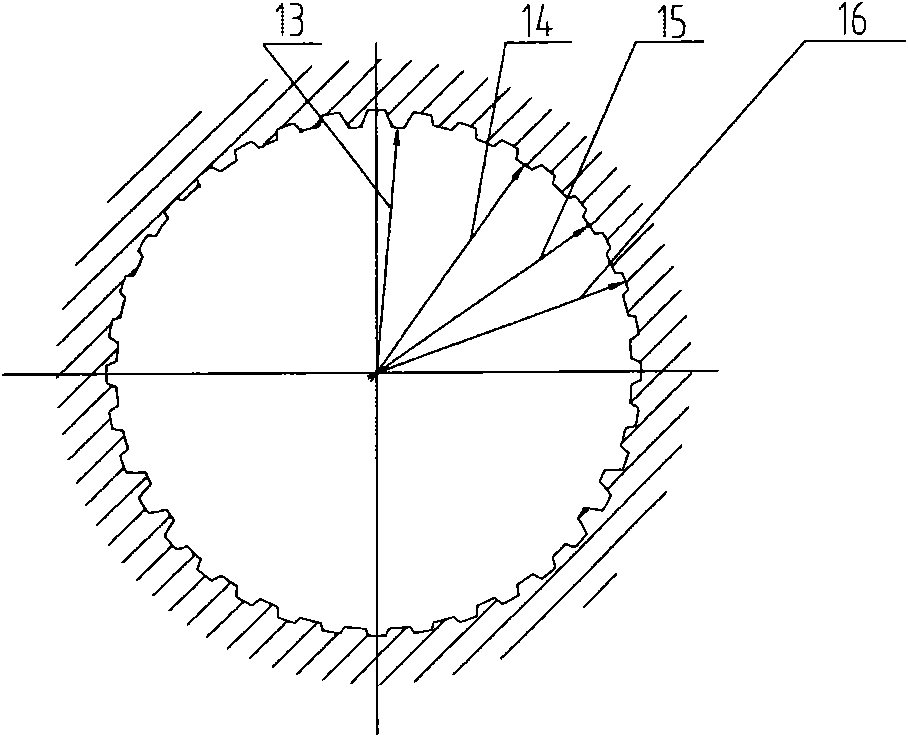

Broaching method and special tool for high-accuracy small-sized mortises

InactiveCN103071853AGuaranteed lifeGuaranteed durabilityBroaching toolsBroaching machinesAir compressorTurbine

The invention discloses a broaching method and a special tool for high-accuracy small-sized mortises. A special broaching tool is used for machining a to-be-machined workpiece. The structure of the special broaching tool meets the requirement that straight chamfers or / and round chamfers capable of participating in broaching are arranged on tooth crests of the broaching tool. The broaching method for the high-accuracy small-sized mortise meets the requirements that a broaching machining allowance elimination mode comprises the step of machining the workpiece by using main blades on the tooth crests of the broaching tools or / and the chamfer parts of the broaching tools, and the chamfer parts of the broaching tool are the straight chamfers or / and the round chamfers on the two sides of blades on the tooth crests; and totally 11 broaching tools are formed into a complete set, and are sequentially used for machining all the contour shapes of the mortises. The method and the special tool are mainly applied to the broaching machining of mortises of core parts of aero-engines and gas turbines such as turbine disks and air compressor disks, can be popularized and used for like parts, and have broad application prospect in a series of new-generation aero-engines and gas turbines, and a technical bottleneck in the broaching of specially-structured high-accuracy small-sized mortises is solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Adjustable finishing broach of wheel disc and tenon slot combination surface

InactiveCN102717149AMaintain and improve geometric accuracyEliminate size deviationBroaching toolsTongue and grooveGas turbines

The invention discloses an adjustable finishing broach of wheel disc and tenon slot combination surface. The adjustable finishing broach comprises a mounting section, a cutting section and an adjusting section, wherein the cutting section consists of two halves of separate contour line blade elements and fixed on the mounting section through the adjusting section, and the adjusting section is a replaceable element to adjust the position of the contour line of the cutting section. According to the invention, the dimensional deviation of reground cutting edge can be removed; the geometric accuracy of precisely processed contour line is kept; the tool cost is reduced, and the service life of the tool is prolonged; and the adjustable finishing broach is suitable for broaching machining of the wheel disc and the tenon slot of a heavy gas turbine rotor.

Owner:SHANGHAI JIAO TONG UNIV

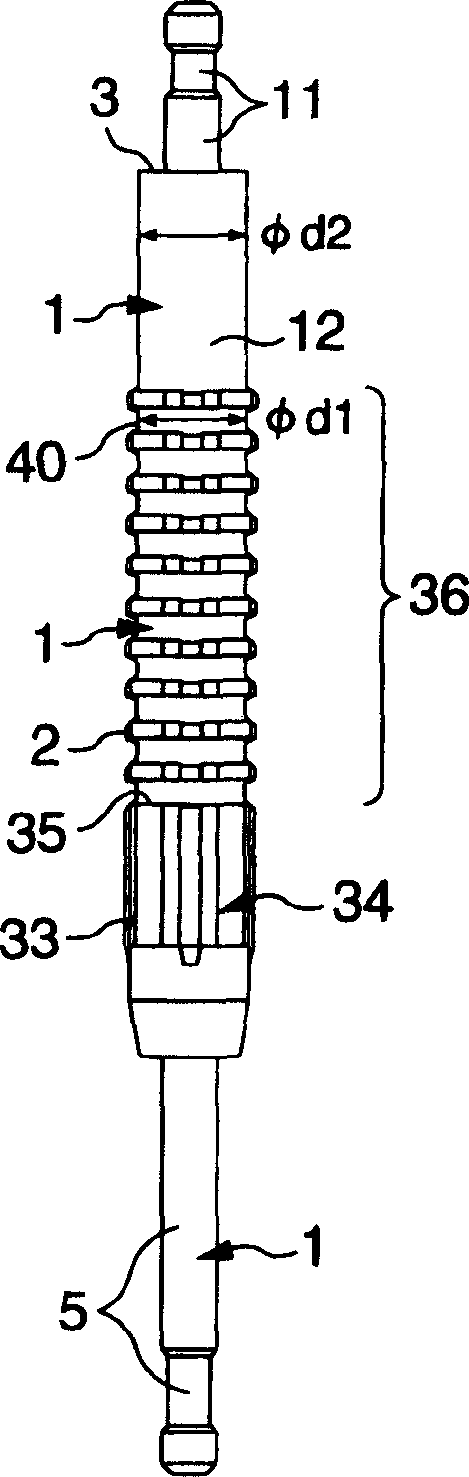

Internal broach

InactiveUS6918716B2Reduce capacityAvoid pinchingRectilinear broachBroaching toolsEngineeringMechanical engineering

An internal broach for internally broaching profiles, defined by a bottom and flanks, of female serrations of a work piece, comprises a toothed portion with several rows of broach cutting teeth disposed successively counter to a direction of broaching, successive broach cutting teeth being allocated to each other for broaching a profile. The broach cutting teeth have bottom cutting blades and first and second sides. The first sides are guide flanks, the edges of which are guide edges without cutting ability. The second sides are flank-cutting-blade relief surfaces, the edges of which are designed as flank blades with cutting ability.

Owner:FORST TECH

Cemented carbide broach and broaching machine

InactiveCN1550278AEasy to cutWon't breakRectilinear broachBroaching toolsEngineeringCemented carbide

A broach has a main body of a cemented carbide material. On this main body, a front grip portion, a cylindrical portion following the front grip portion and provided with a plurality of guide parts in its outer periphery, a broach cutting edge portion following an end of the cylindrical portion and having a number of cutting edges, and a cylindrical extension following the broach cutting edge portion and having a maximum outer periphery dimension to such an extent that the extension does not interfere with a work are integrally provided. On an end surface of the cylindrical extension, a load receiving shoulder is formed, which leads to a rear grip portion including a small-diameter part and is orthogonal to or inclined with respect to a broach axis. The load receiving shoulder has a sufficient area to bear a cutting load. A broaching machine grips the rear grip portion with its load receiving surface abutting against the load receiving shoulder of the cemented carbide broach. The broach, even when having a small diameter, does not suffer from an insufficient tensile strength of the front grip portion.

Owner:NACHI-FUJIKOSHI

Cutting tool with cutting insert having multiple cutting edges, and cutting insert therefor

A cutting tool includes a cutting insert. The insert includes a top side including a plurality of cutting edges, the cutting edges being arranged one after another in a longitudinally direction of the insert and extending substantially perpendicularly to a longitudinal, vertical axial plane of the insert. The insert includes a side wall extending downwardly relative to a plane of the top side of the insert, the side wall including a side supporting surface. The cutting tool includes a toolholder. The toolholder includes a side abutment surface against which the side supporting surface of the insert is adapted to be supported. A clamp is provided for clamping the side supporting surface of the insert against the side abutment surface of the toolholder.

Owner:SECO TOOLS AB

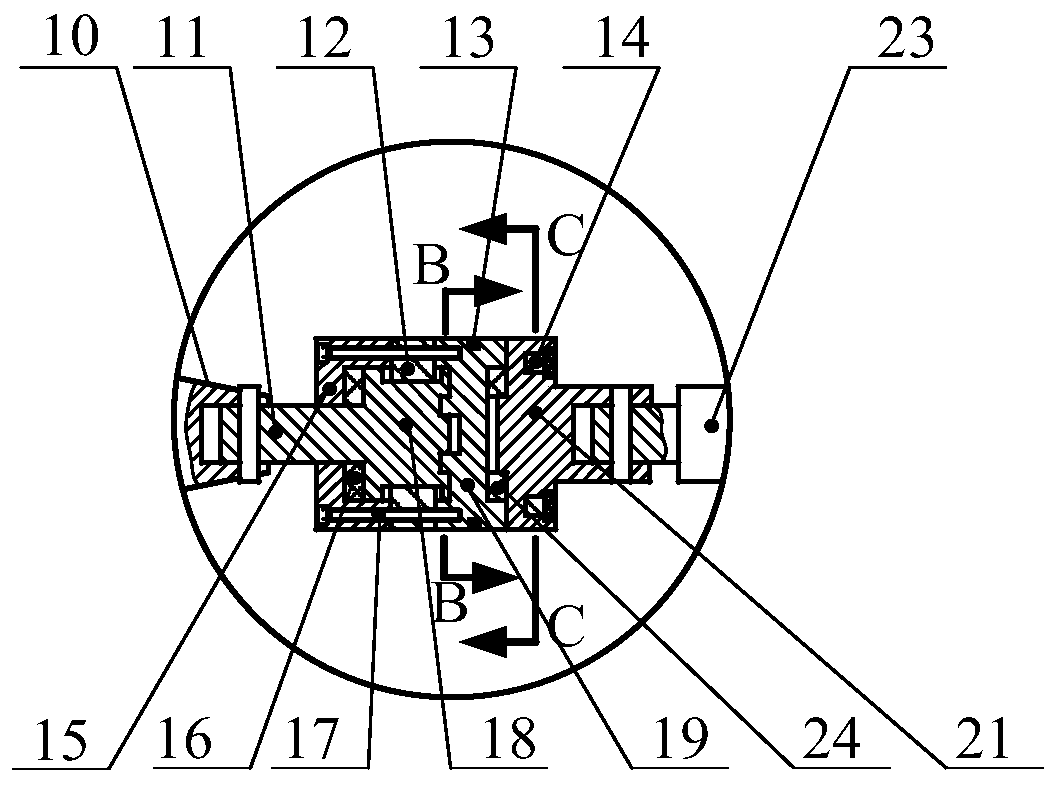

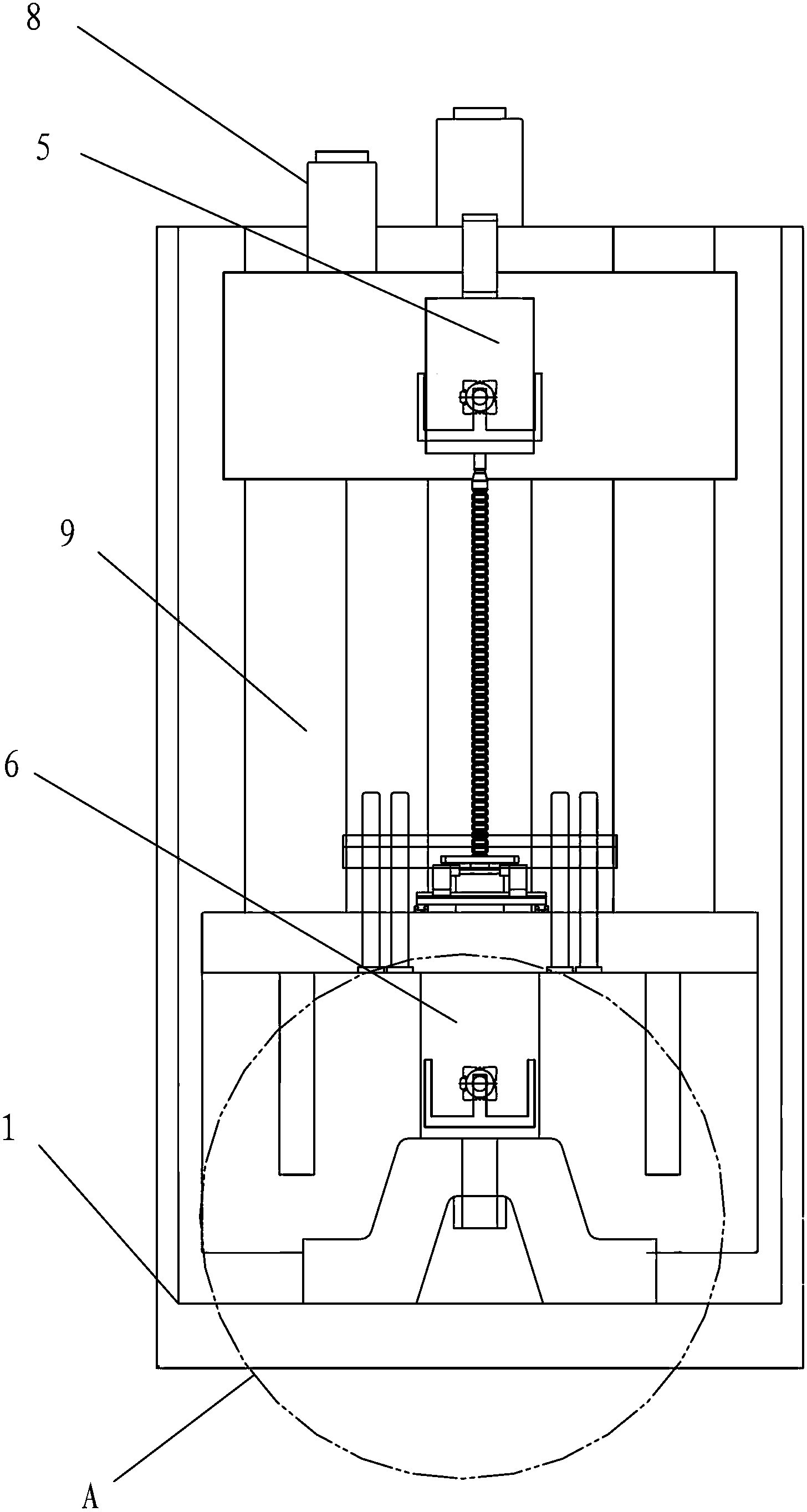

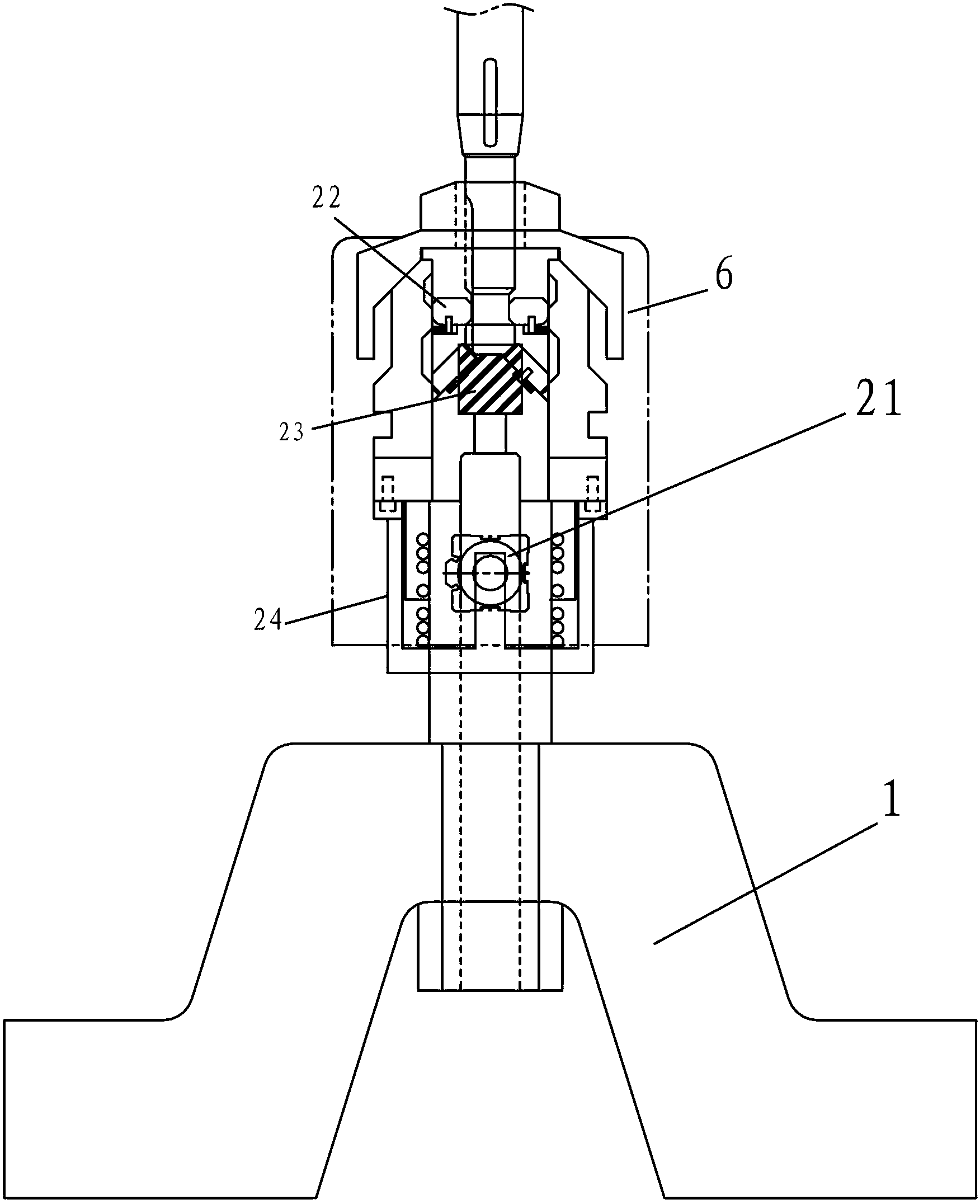

Ultrasonic broaching tool, high-efficiency precise ultrasonic broaching device and broaching process thereof

ActiveCN109967789AExtended service lifeImprove broaching efficiencyBroaching accessoriesBroaching toolsGratingUltrasonic sensor

The invention discloses an ultrasonic broaching tool, a high-efficiency precise ultrasonic broaching device and a broaching process thereof. An existing broaching tool and an existing broaching machine are not provided with integrated information acquisition devices and are short in service life. The ultrasonic broaching tool comprises an ultrasonic transducer, a detection assembly and a broachingtool body. The detection assembly comprises a detection substrate, a laser transceiving belt, an image sensor, an axial pressure sensor, a first radial pressure sensor and a second radial pressure sensor. The high-efficiency precise ultrasonic broaching device comprises a broaching machine body, an optical grating and the ultrasonic broaching tool. The broaching machine body comprises a broachingmachine drive assembly, a broaching machine body, a broaching machine guide rail and a fast positioning and clamping device. A broaching tool three-directional vibration value, a broaching tool axialtensile force, a broaching tool displacement value, and a workpiece dimension based on an image are measured. Real-time detection data is provided for a working condition feedback loop and a stop control loop of a control system. The service life of the broaching tool can be effectively prolonged.

Owner:HANGZHOU DIANZI UNIV

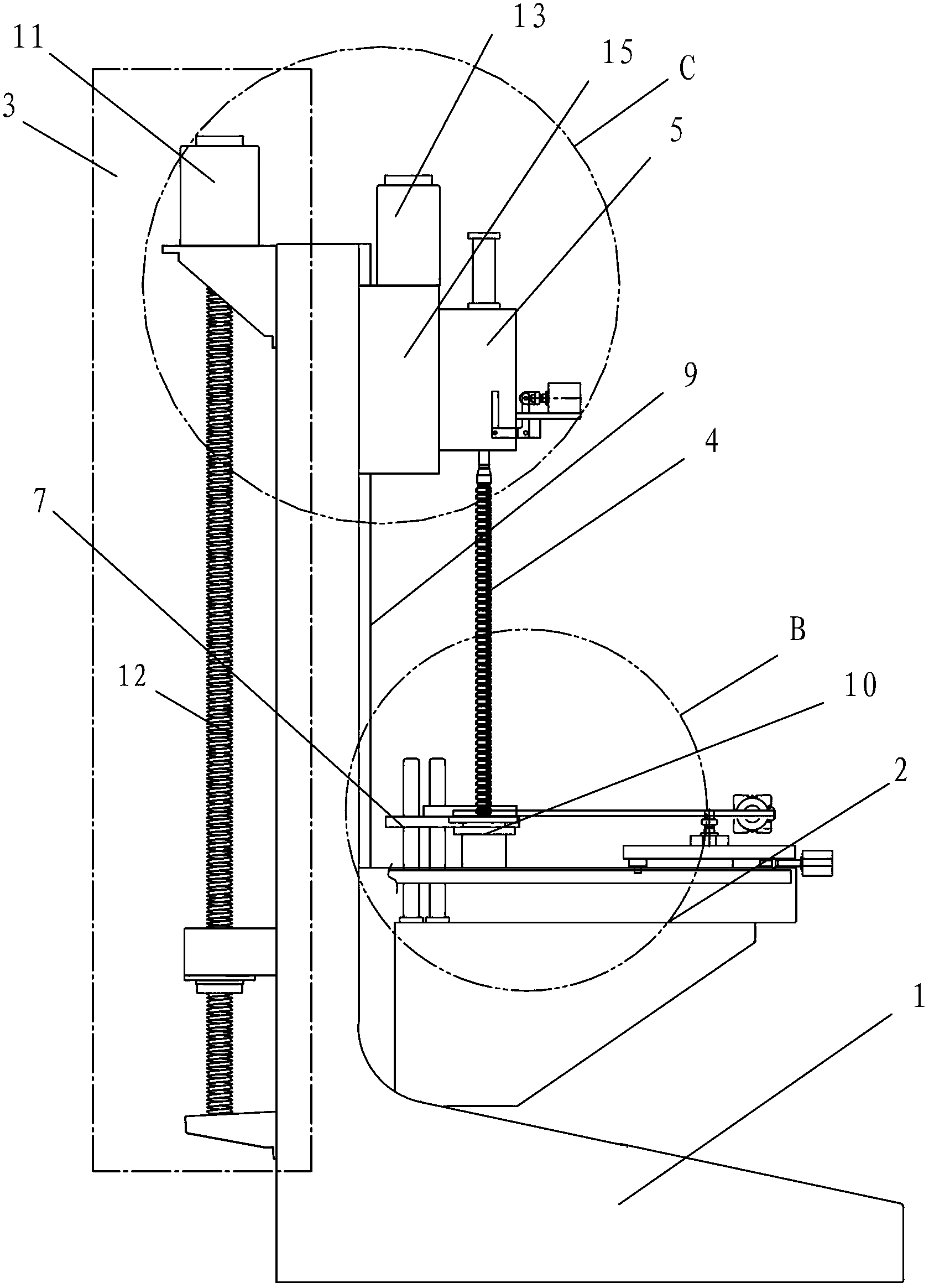

Hard broaching finish machining process for surface of internal keyway and device

InactiveCN102699419AGuaranteed stabilityOvercoming the challenges of broachingBroaching toolsBroaching machinesMachining processMachine tool

The invention relates to a hard broaching finish machining process for a surface of an internal keyway. The internal keyway of a part is sleeved at one end of a cutter which is same with the internal keyway in shape to fix both ends of the cutter so that the part moves along the cutter axially at a speed of 4-10m / s. During movement, deviation of the center of the internal keyway in the part and the axis of the cutter is maintained smaller than or equal to 0.01mm. The cutter is of a sectionally differential stepped structure. The blade hardness is greater than or equal to HRC67. The invention further provides a hard broaching finish machining device for the surface of the internal keyway. Both ends of the cutter are respectively fixed on an upper tool apron and a lower tool apron which are located above and below a work table and installed coaxially. A work table drive device drives the work table to move along a guide rail on a machine tool body to realize high speed machining of an internal spline of a workpiece to be machined. The hard broaching finish machining process for the surface of the internal keyway and the device provided by the invention are simple in process method and reasonable in structure of the device, and has high machining precision and efficiency for internal keyways, and low cost and energy consumption, and industrialized production can be realized in a large scale.

Owner:尹时中

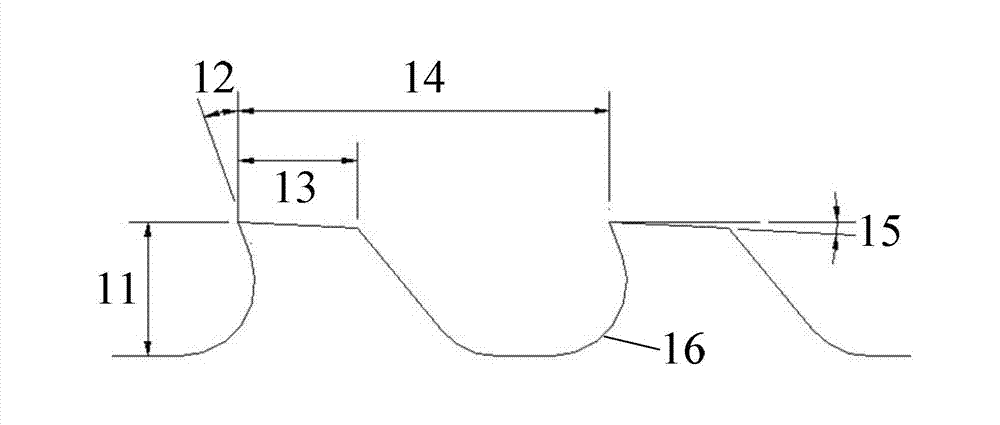

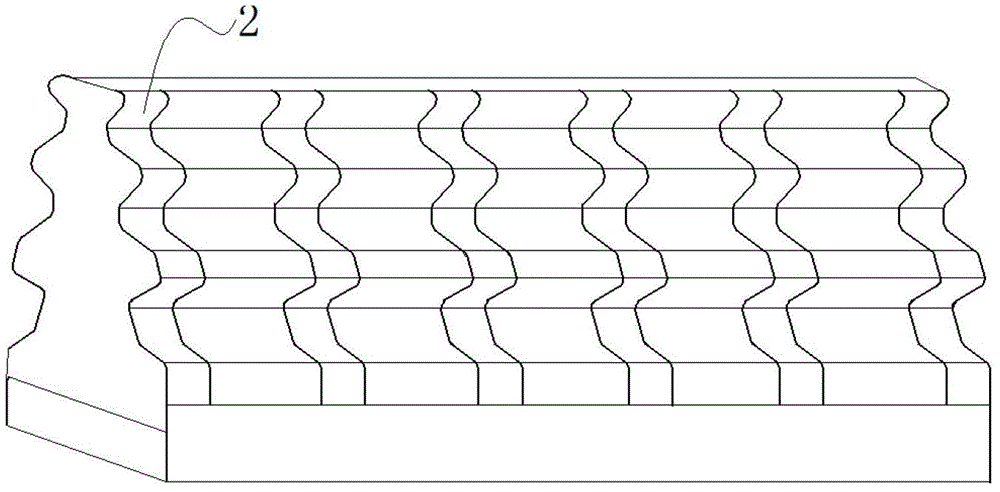

Wheel groove finish broach tooth profile numerical control grinding process

ActiveCN103252687AImprove broaching qualityAvoid chip jammingBroaching toolsGrinding/polishing safety devicesNumerical controlEngineering

Owner:EST TOOLS

Broaching tool imitating shape of mantis mouthparts palate and preparation method of broaching tool imitating shape of mantis mouthparts palate

ActiveCN105904022AExcellent machinabilityImprove cutting performanceBroaching toolsArthropod mouthpartsEngineering

The invention discloses a broaching tool imitating the shape of a mantis mouthparts palate and a preparation method of the broaching tool imitating the shape of the mantis mouthparts palate. An existing broaching tool is large in workload, and abrasion of the tool is serious. Grooves are formed in the top faces of tool teeth of the broaching tool; the rise per tooth of a tool tooth part of a tool head is in arithmetic progression distribution; in the direction from a tooth crest to a tooth groove, the gradient change of the area of the cross section of the tool teeth of the tool head and the gradient change of the area of the cross section of the mantis palate are consistent; and the compactness and the hardness of the surfaces of the tool teeth of the tool head are both larger than those of the interior. The preparation method of the broaching tool includes the steps that a mantis palate three-dimensional curved surface model is constructed, the area gradient of the mantis palate is acquired, the area gradient of the tool teeth of the tool head in the direction from the tooth crest to the tooth groove is determined, and the outline of the tool teeth is designed according to the area gradient of the toot teeth; the multiple grooves are machined in the top face of each tool tooth; on the same longitudinal cross section of the tool head, the positions of the grooves in each tool tooth correspond to the top faces of the portions, not provided with grooves, of the tool teeth; and heat treatment of the tool head is performed. The cutting performance of the broaching tool is optimized, the cutting load is reduced, and the service life of the broaching tool is prolonged.

Owner:HANGZHOU DIANZI UNIV

Broaching apparatus and method for producing a gear member with tapered gear teeth

Owner:GM GLOBAL TECH OPERATIONS LLC

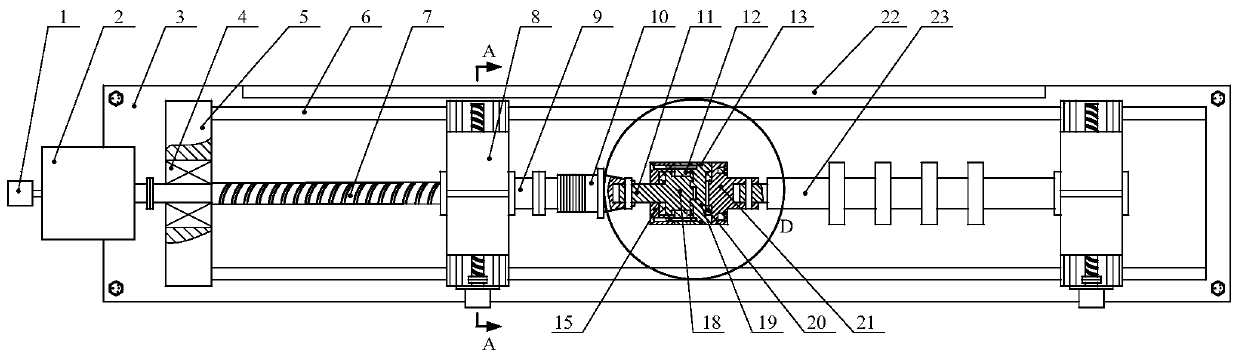

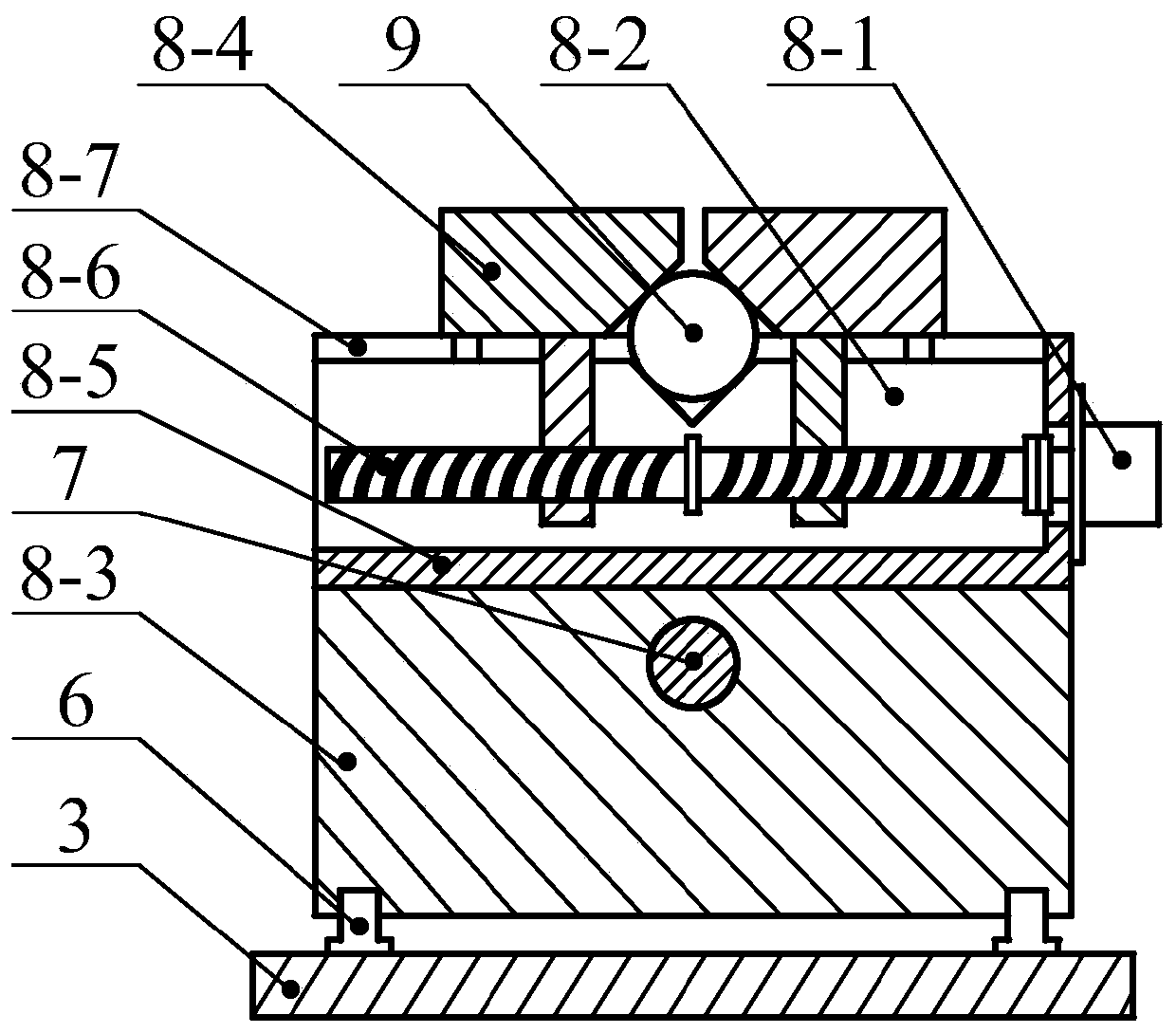

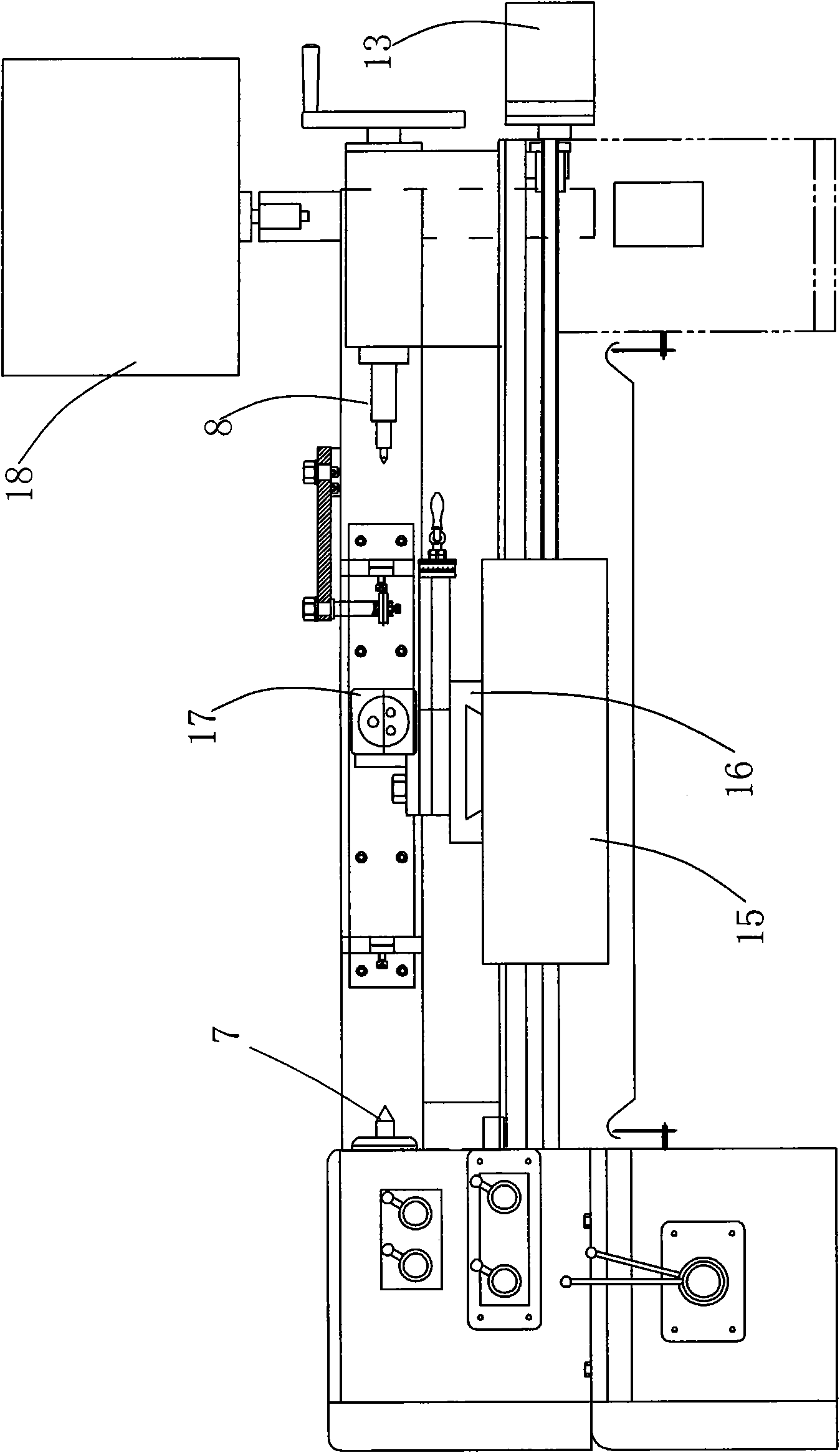

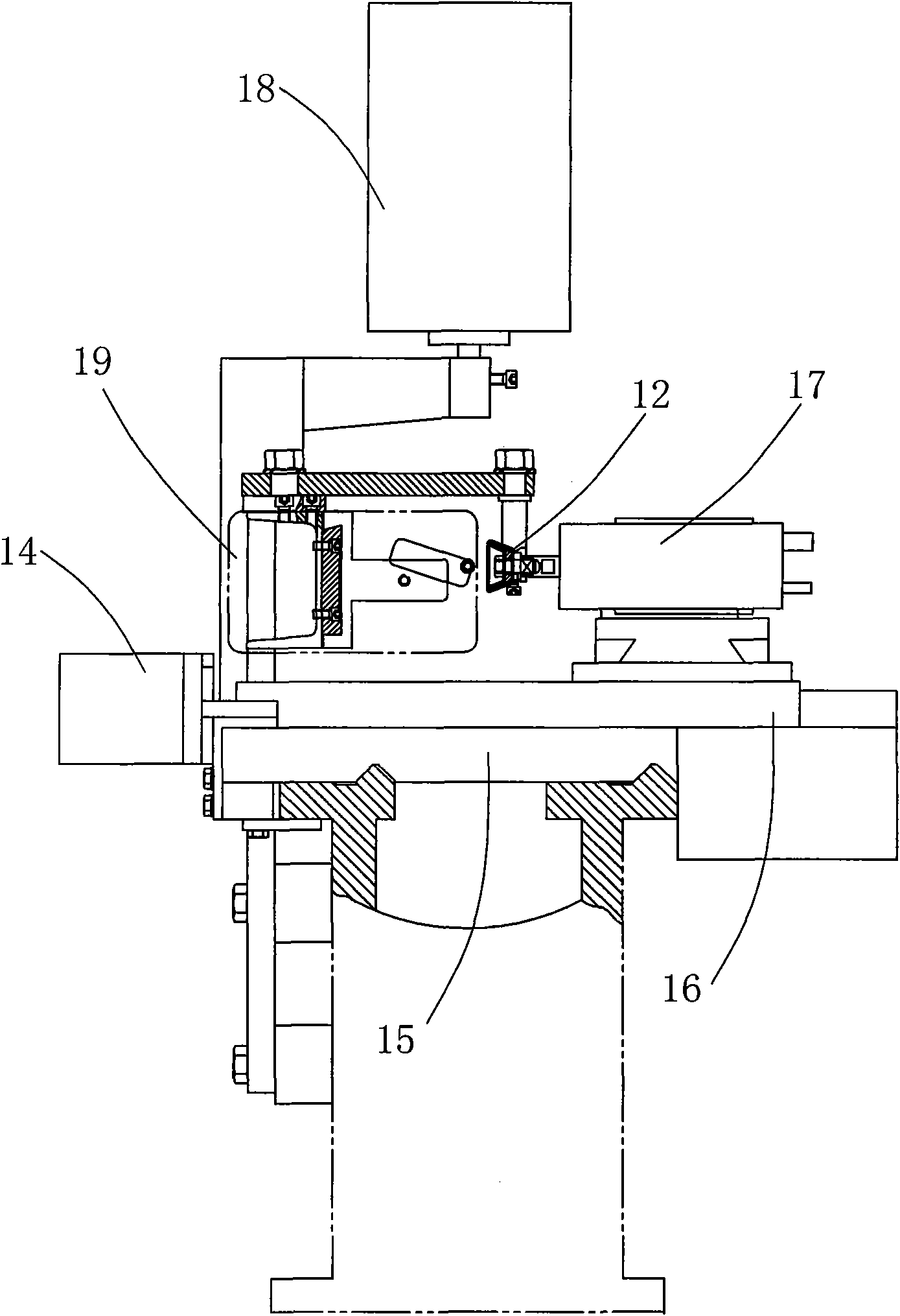

Special circular broach numerical control cutter-sharpening machine tool

ActiveCN101670536AGuarantee the stability of sharpening qualityExtended service lifeBroaching toolsHigh-speed grindingEngineering

The invention discloses a special circular broach numerical control cutter-sharpening machine tool which takes a numerical control lathe as a substrate; two ends of a broach is rotatably erected on the lathe; the body of one side of the lathe is distributed with a plurality of broach supporting frames along the axial direction of the broach so as to form strengthening support to the broach; the body of the other side of the lathe is provided with a big carriage which can move along the axial direction of the broach, and a middle carriage which can move along the radial direction of the broach,wherein the middle carriage can be movably arranged on the big carriage; moreover, a variable frequency high-speed grinding head and a grinding wheel which is driven by the variable frequency high-speed grinding head are arranged on the middle carriage; the axial movement of the big carriage is driven by a number 1 stepping motor; the radial movement of the middle carriage is driven by a number 2stepping motor; and the number 1 stepping motor and the number 2 stepping motor are controlled by a numerical control system on the lathe in a combining way. The special circular broach numerical control cutter-sharpening machine tool not only can avoid the broach from bending when in cutter sharpening, but also can be controlled by the numerical control system to dress the radial feed size of the grinding wheel, effectively ensures the consistency of the broach pitch and shape, and can prolong the service life of an internal spline and the circular broach.

Owner:六安永达机械股份有限公司

Composite broach

InactiveCN102229008AHeat dissipationPlay the role of crack resistanceBroaching toolsAnnular cutterEngineering

The invention provides a composite broach, which has the advantages of high heat radiating efficiency, small resistance, long service life, and high cracking-resistant strength of a cutting blade and is easy for positioning during broaching. The composite broach comprises a broach head and is characterized in that a plurality of annular cutter blocks are configured on the broach head, and a cutting face or a chamfering face is formed on the broach head; a composite cutting face is convexly arranged at the inner side of the cutting face and provided with a composite cutting blade or a composite lateral cutting blade and a reinforcing platform; and a notched blade is arranged on the cutting blade or the lateral cutting blade, a groove extends to the cutting face or a rear cutting face or a lateral cutting face in an opening manner or is distributed on the cutting face or the rear cutting face or the lateral cutting face or the composite cutting face or a composite lateral cutting face side or a composite rear cutting face in a gradually enlarged shape.

Owner:王树彬

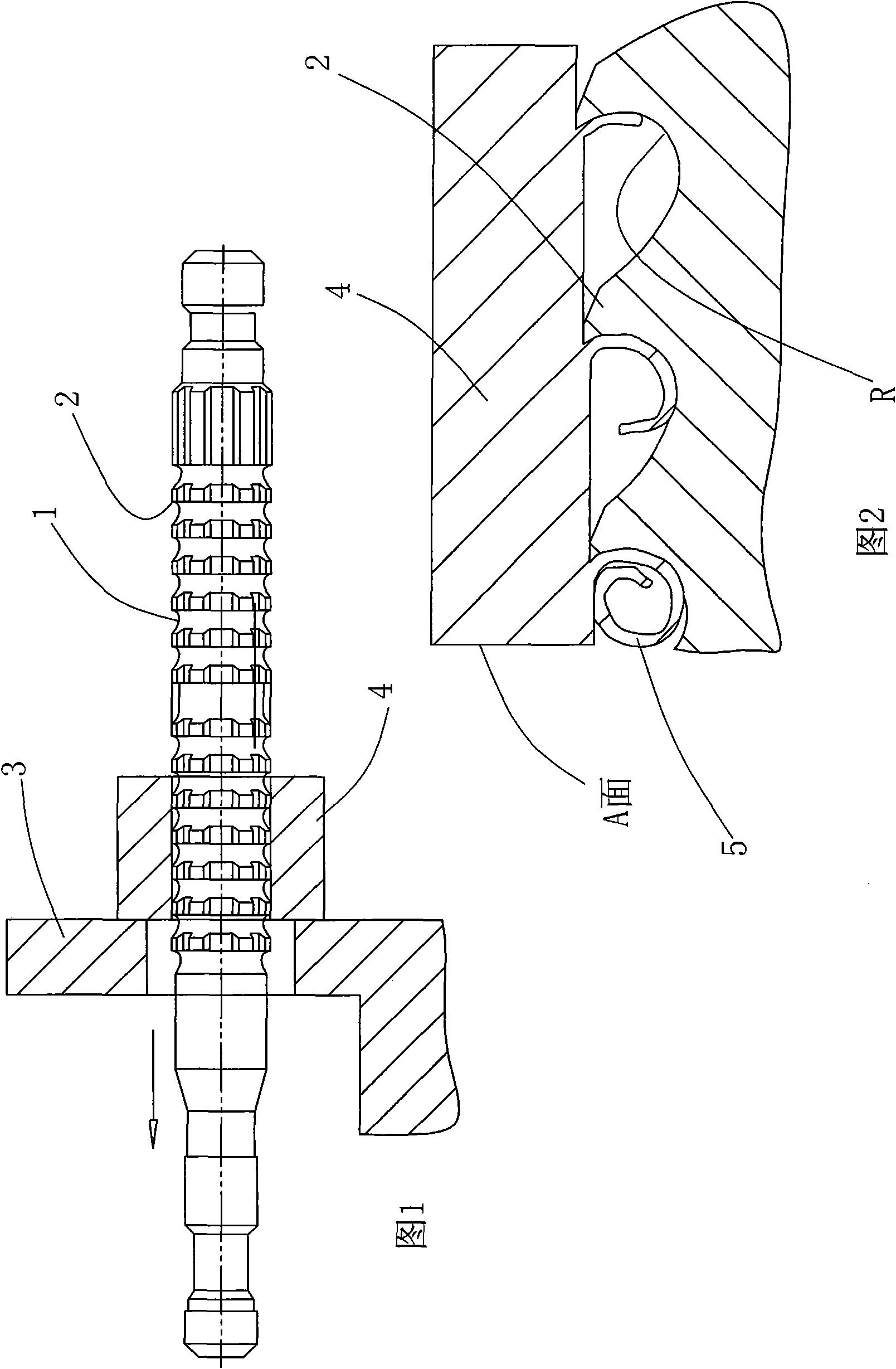

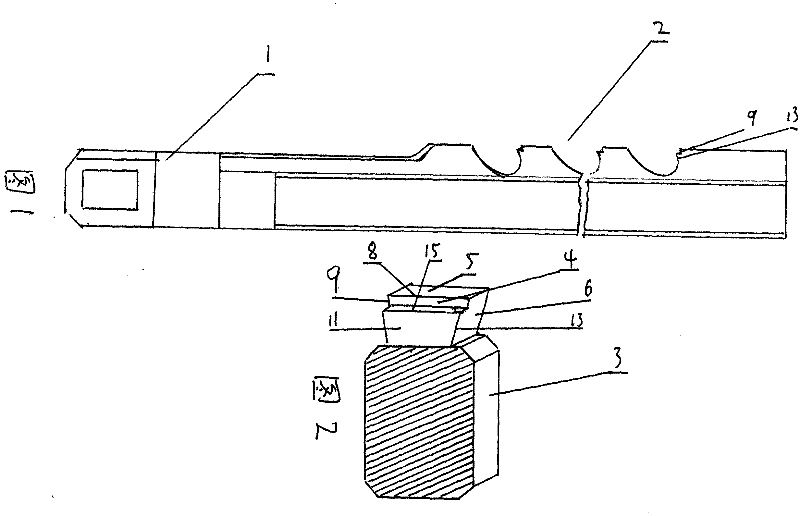

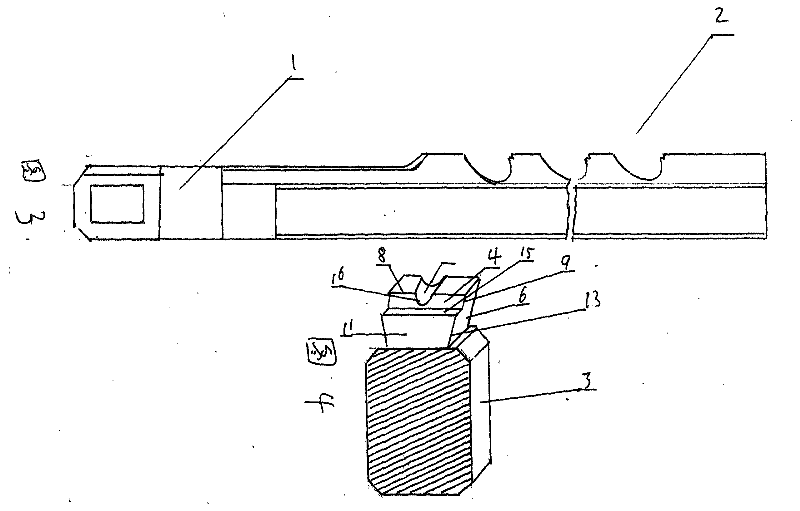

Producing device and its producing method for capillary tissue micro groove of heat pipe inner wall

InactiveCN1586777AReduce weightCapillary is reliableBroaching toolsBroaching machinesEngineeringHeat pipe

The device for making the micro capillary grooves in the inner wall of heat pipe mainly consists of positioning rod, cutter and pull rod. The positioning rod is mounted on one side surface of the pull rod, and the cutter is mounted on the other side surface of the pull rod. The present invention also relates to the method of making the micro capillary grooves in the inner wall of heat pipe with the said device. The making process features that the pull rod is drawn axially to drive the cutter to broach in the inner wall of the heat pipe base and the inner wall surface of the heat pipe base cracks to form capillary micro grooves. The improved capillary structure makes the heat pipe possess excellent heat transferring performance and lowers the production cost of heat pipe.

Owner:SOUTH CHINA UNIV OF TECH

Helical broach

ActiveCN103068509ASmooth movementGood precisionRectilinear broachBroaching toolsGroove widthEngineering

This helical broach forms a twisted groove at the inner periphery of a machined hole of a work by means of a plurality of cutting blades. The plurality of cutting blades have: a plurality of groove depth-expanding blades that are arrayed towards the tip of a broach body; and a plurality of groove width-expanding blades that are arrayed towards the base of the broach body. The plurality of groove width-expanding blades have a cutting blade and a guiding blade. The groove width-expanding blade positioned furthest towards the base of the broach body is formed with a guiding blade instead of a cutting blade at the edge of intersection of a scooping surface and the lateral surface that faces one of the wall surfaces from among both groove wall surfaces of the twisted groove of the work.

Owner:MITSUBISHI MATERIALS CORP

Involute spline broach and broaching method thereof

The invention discloses an involute spline broach which comprises a handle, a transition cone, guiding keys, a cutting tooth, a corrected tooth, and a supporting part. The involute spline broach is characterized in that the cutting tooth comprises a small inner diameter cutting tooth, a middle inner diameter cutting tooth, a large inner diameter cutting tooth and a tooth-shaped cutting tooth, and the tooth-shape cutting tooth has the functions of cutting and guiding allocation. The guiding key on the right side of the transition cone and the guiding key on the left side of the supporting part are provided with lengthened guiding teeth. The lengthened guiding keys on the left side of the broach is rightward provided with the small inner diameter cutting tooth, the guiding key, the middle inner diameter cutting tooth, the guiding key, the large inner diameter cutting tooth, the tooth-shape cutting tooth, the corrected tooth, the guiding key, and the supporting part successively. According to the invention, three involute spline broaches with different inner diameters can be manufactured at one step, the axiality requirement of three different diameters of a workpiece to be machined and the consistency of spline tooth chamferings can be effectively ensured.

Owner:江苏建民工具有限公司

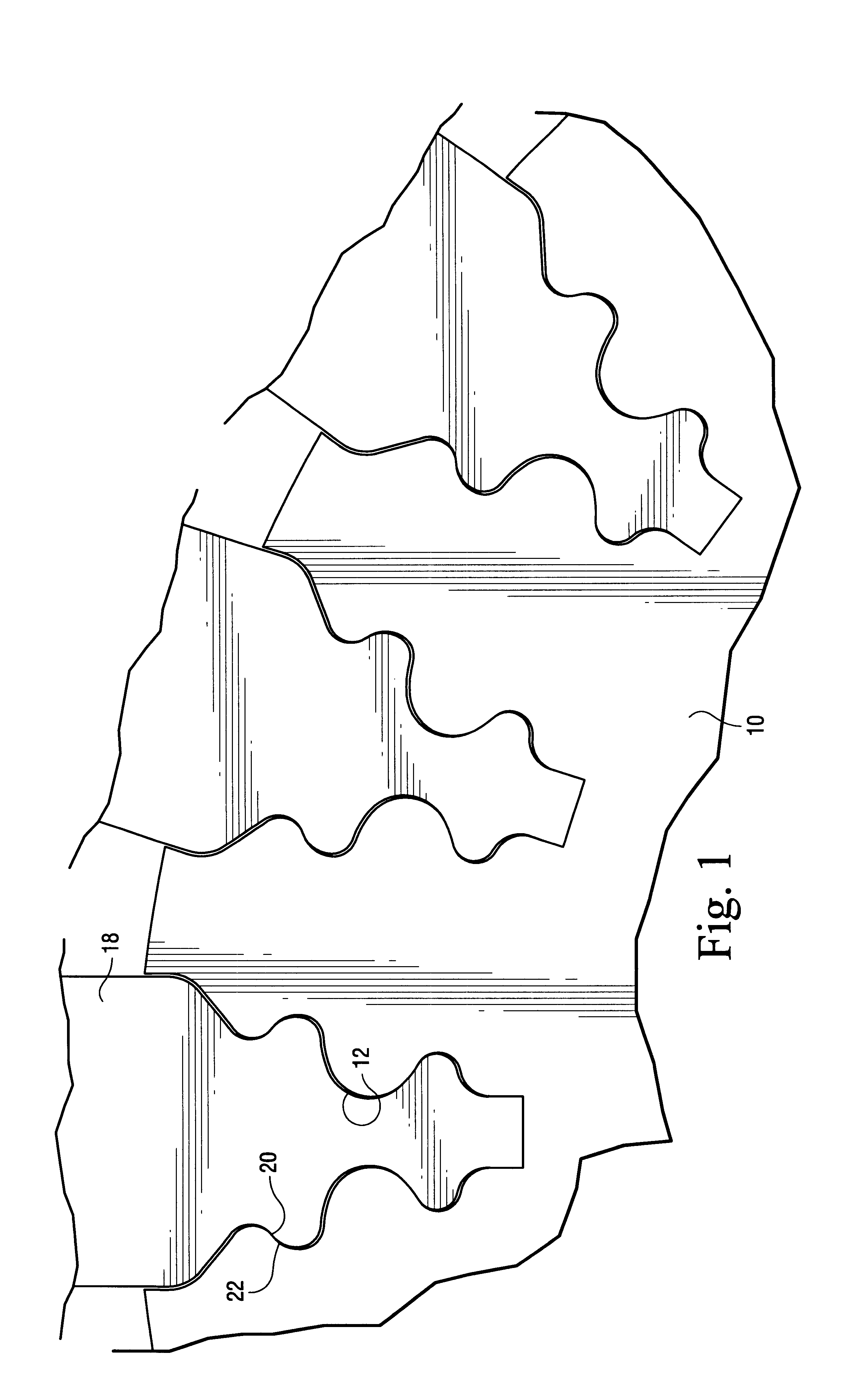

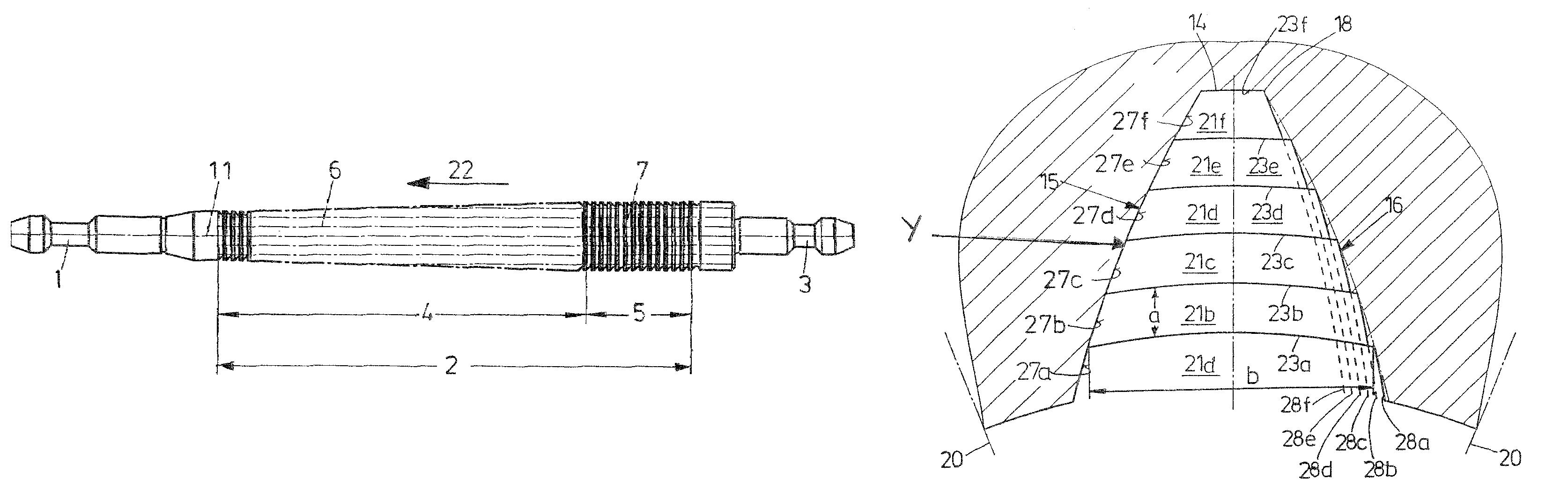

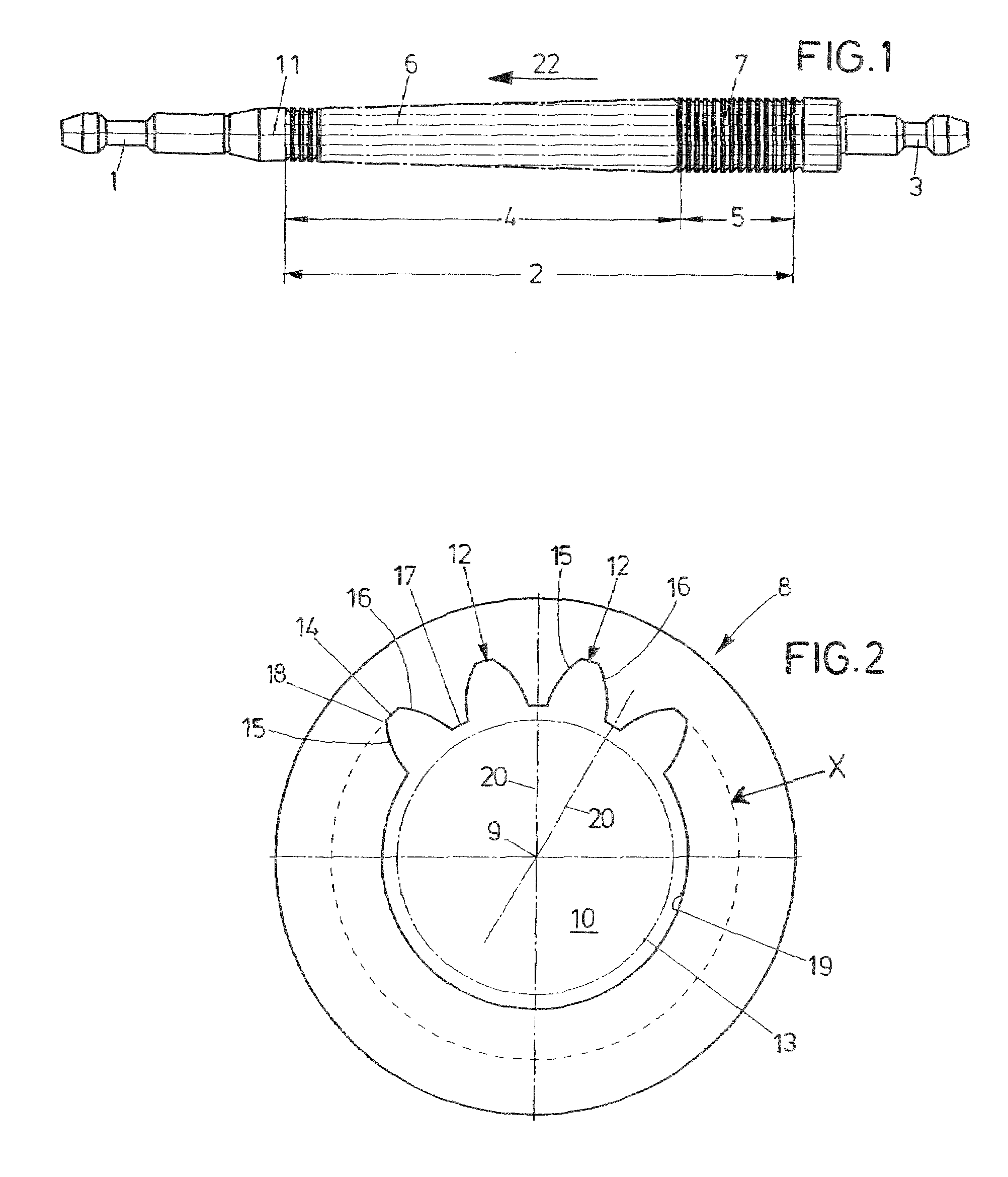

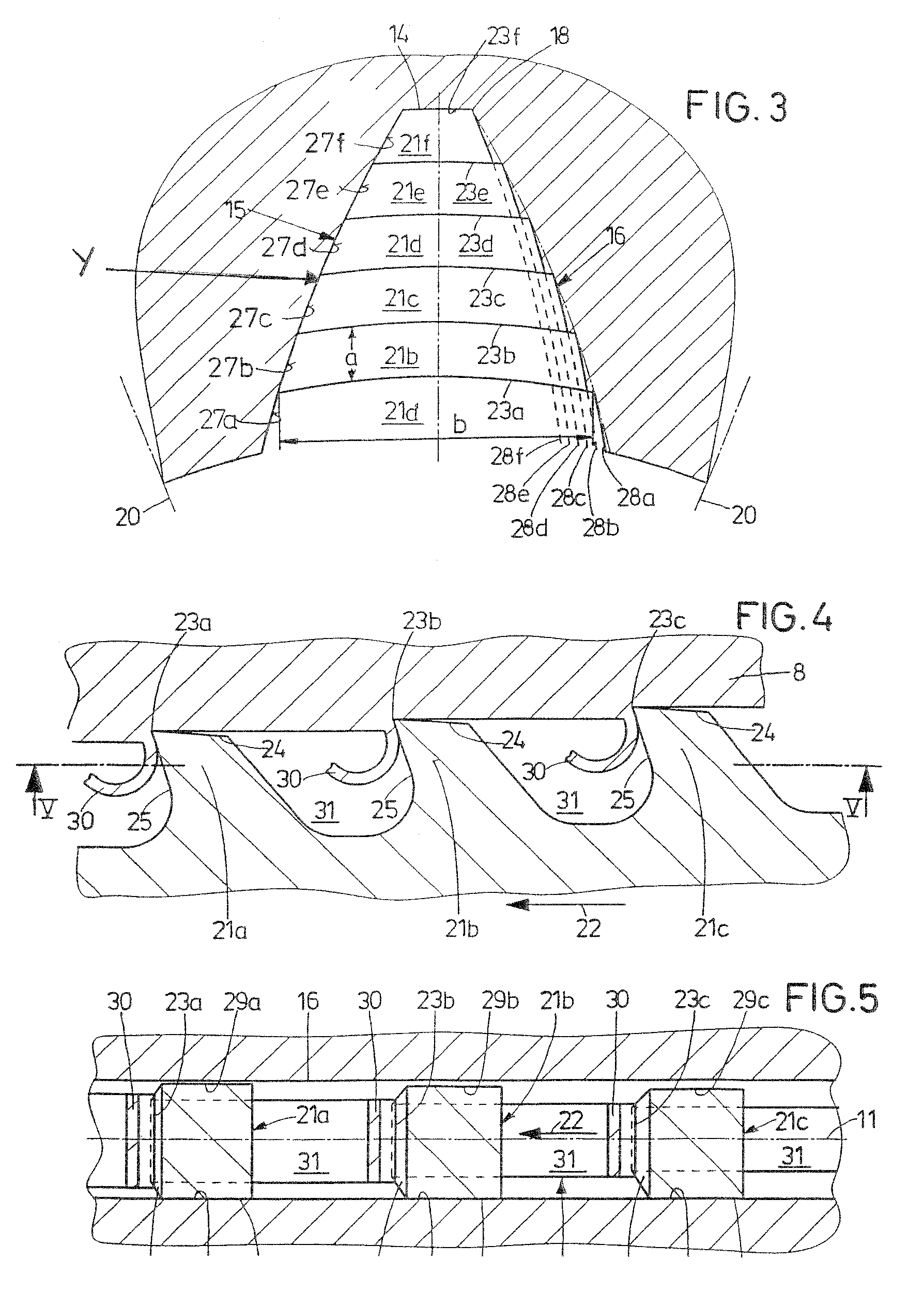

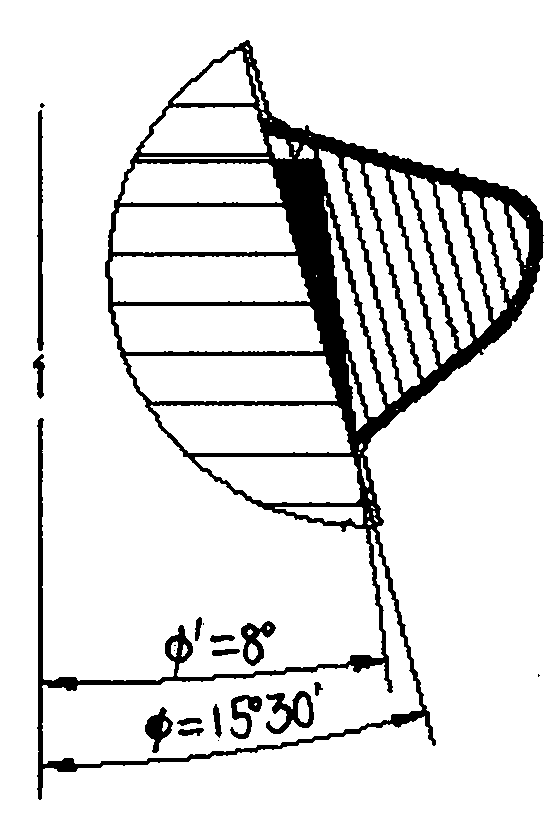

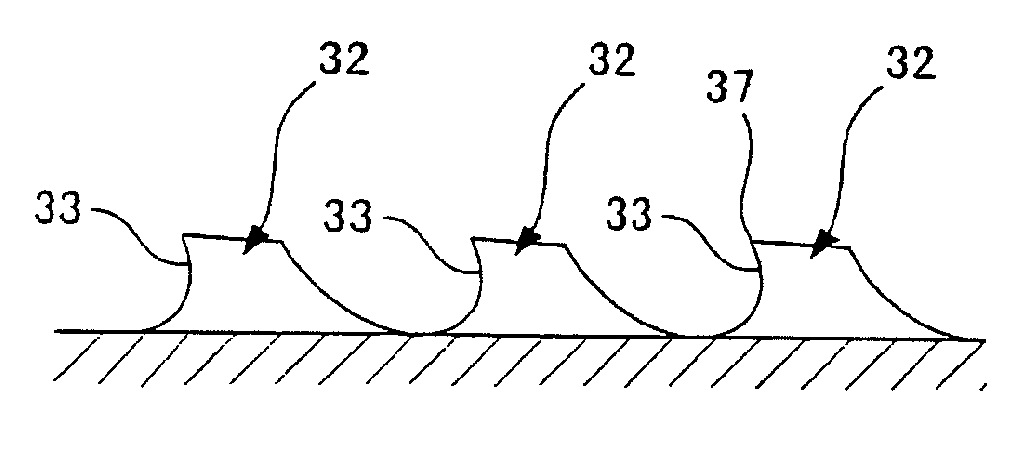

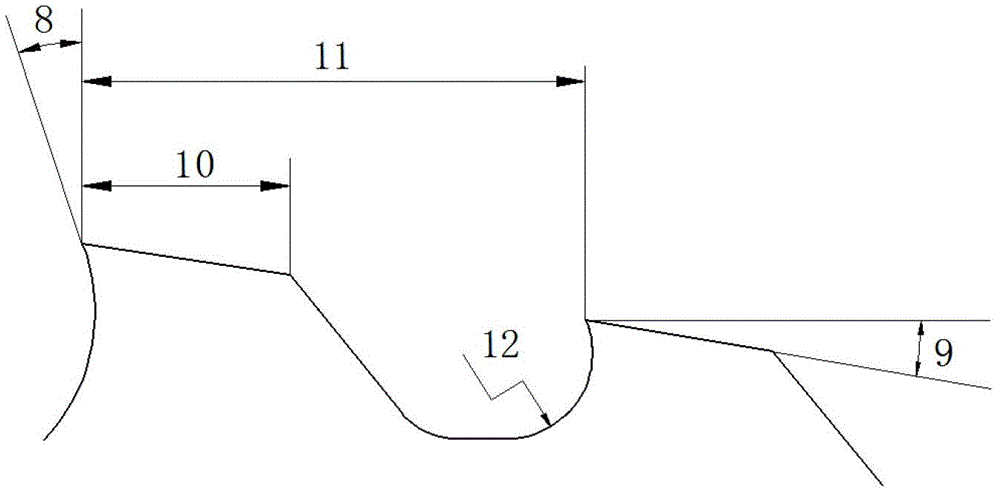

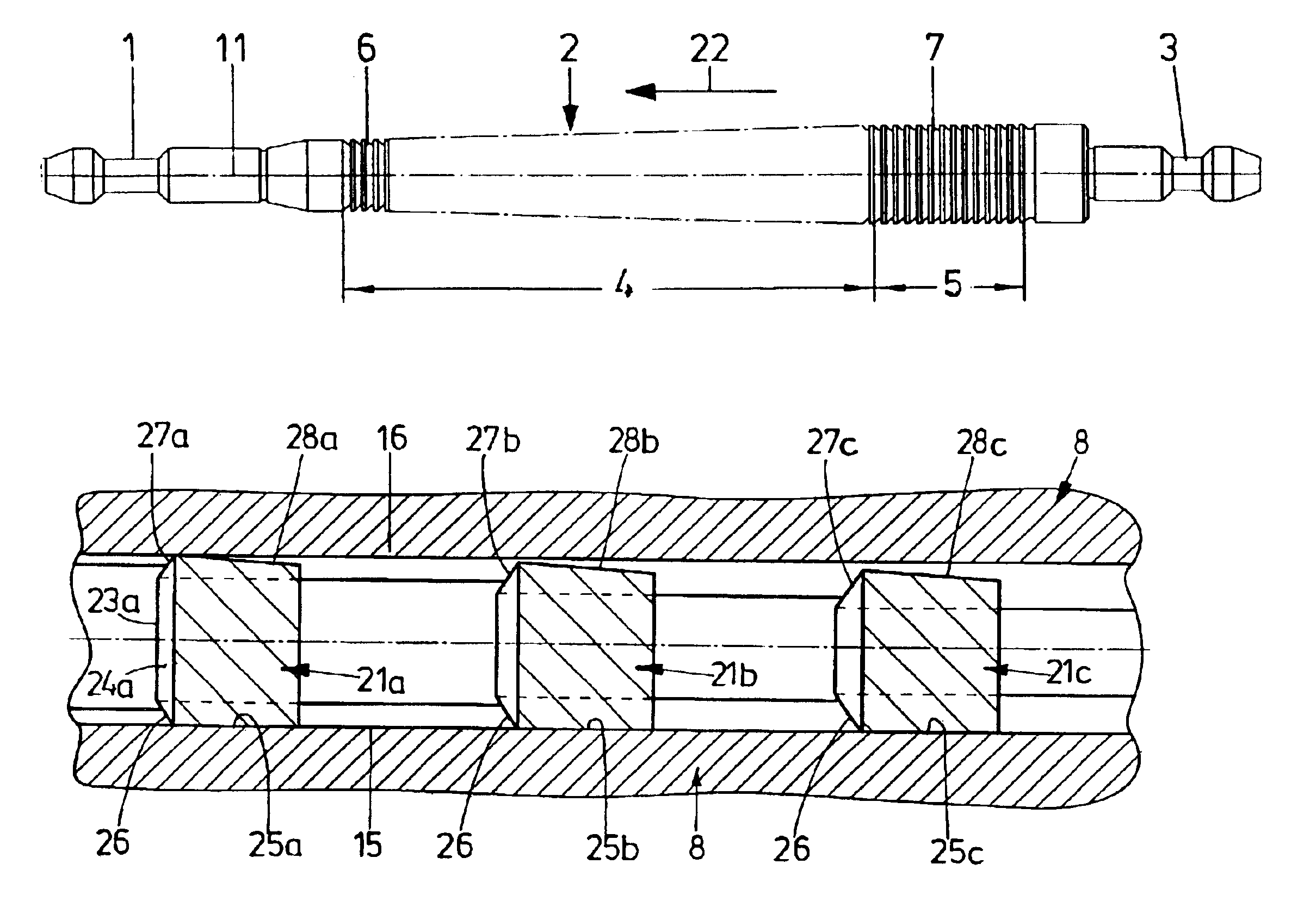

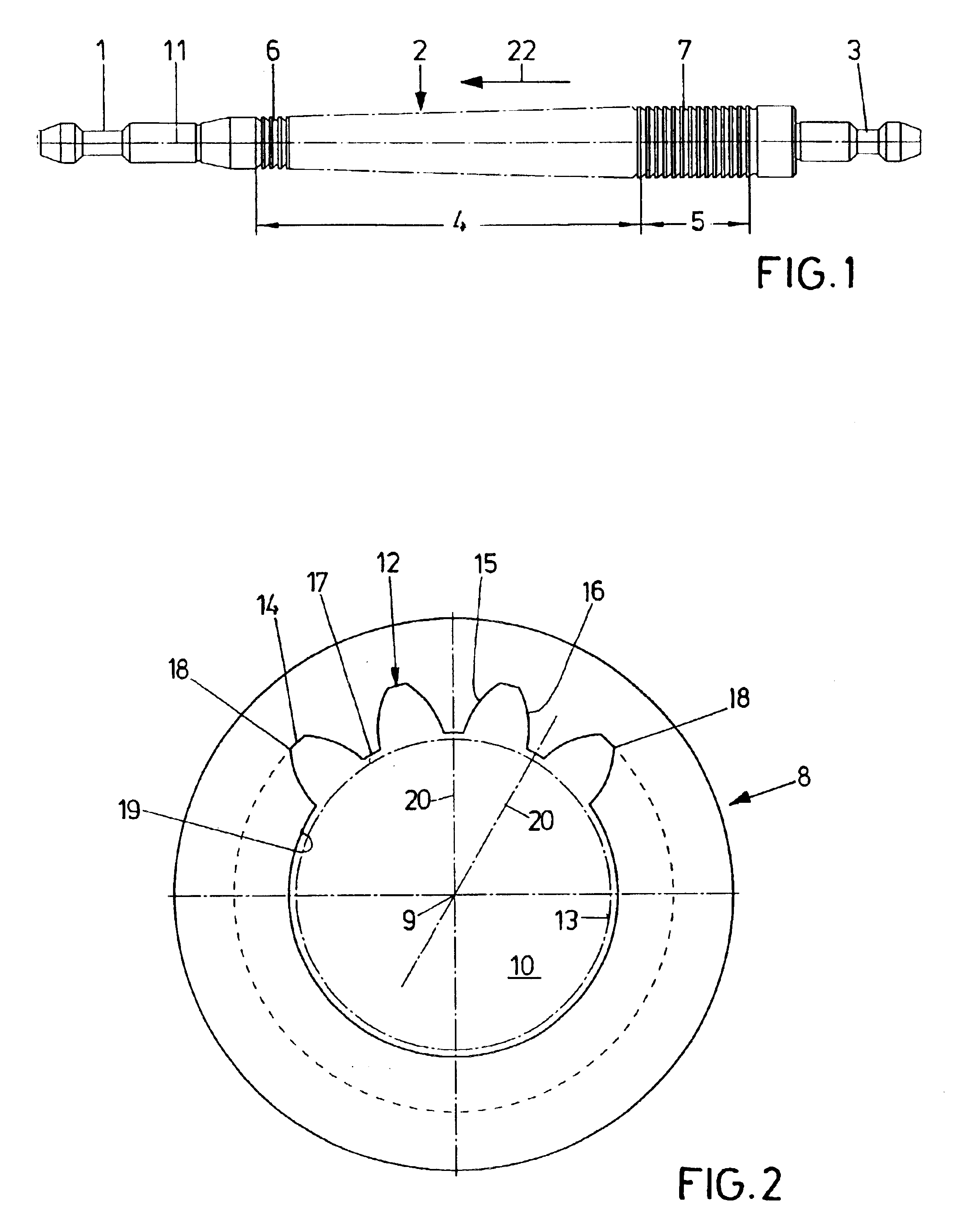

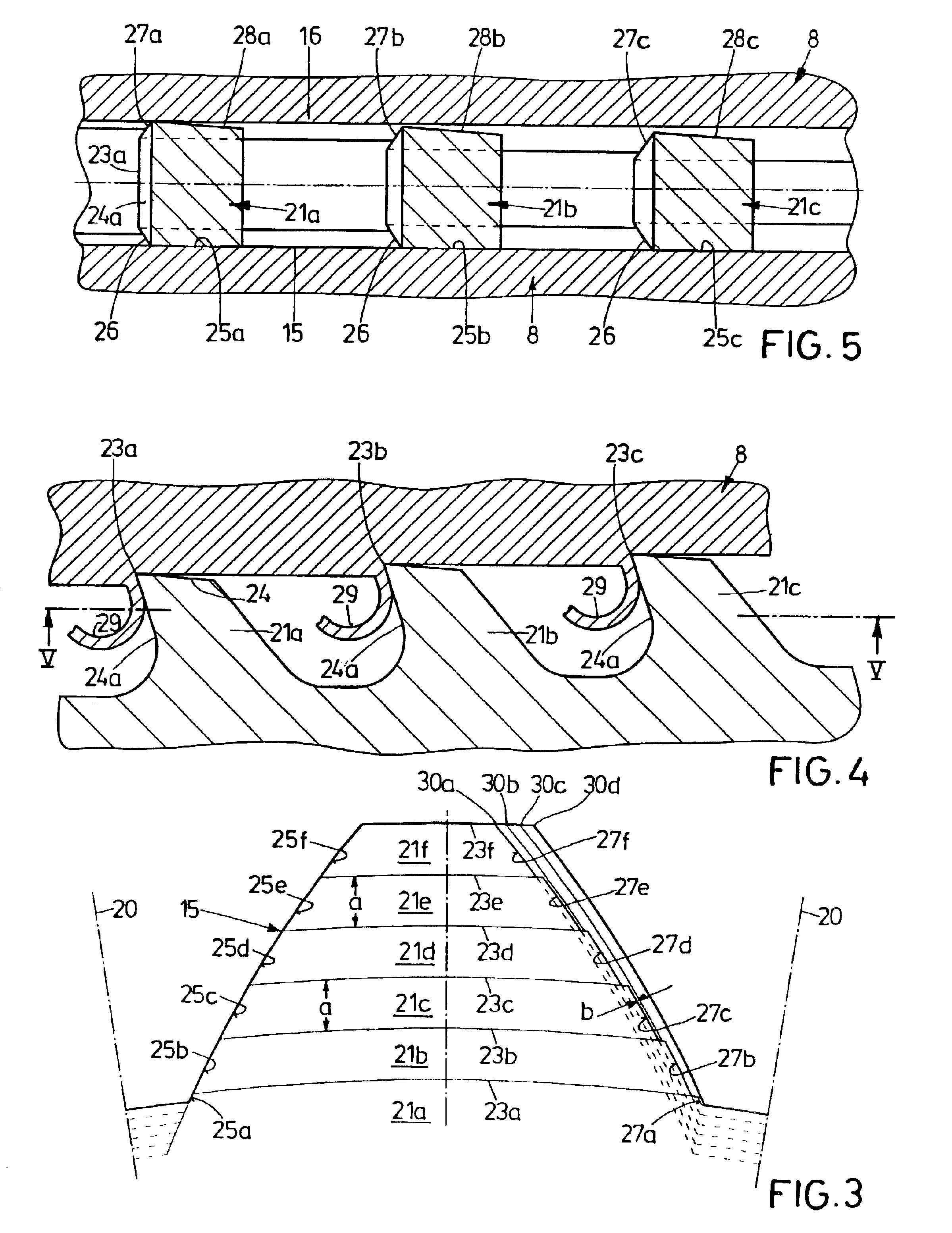

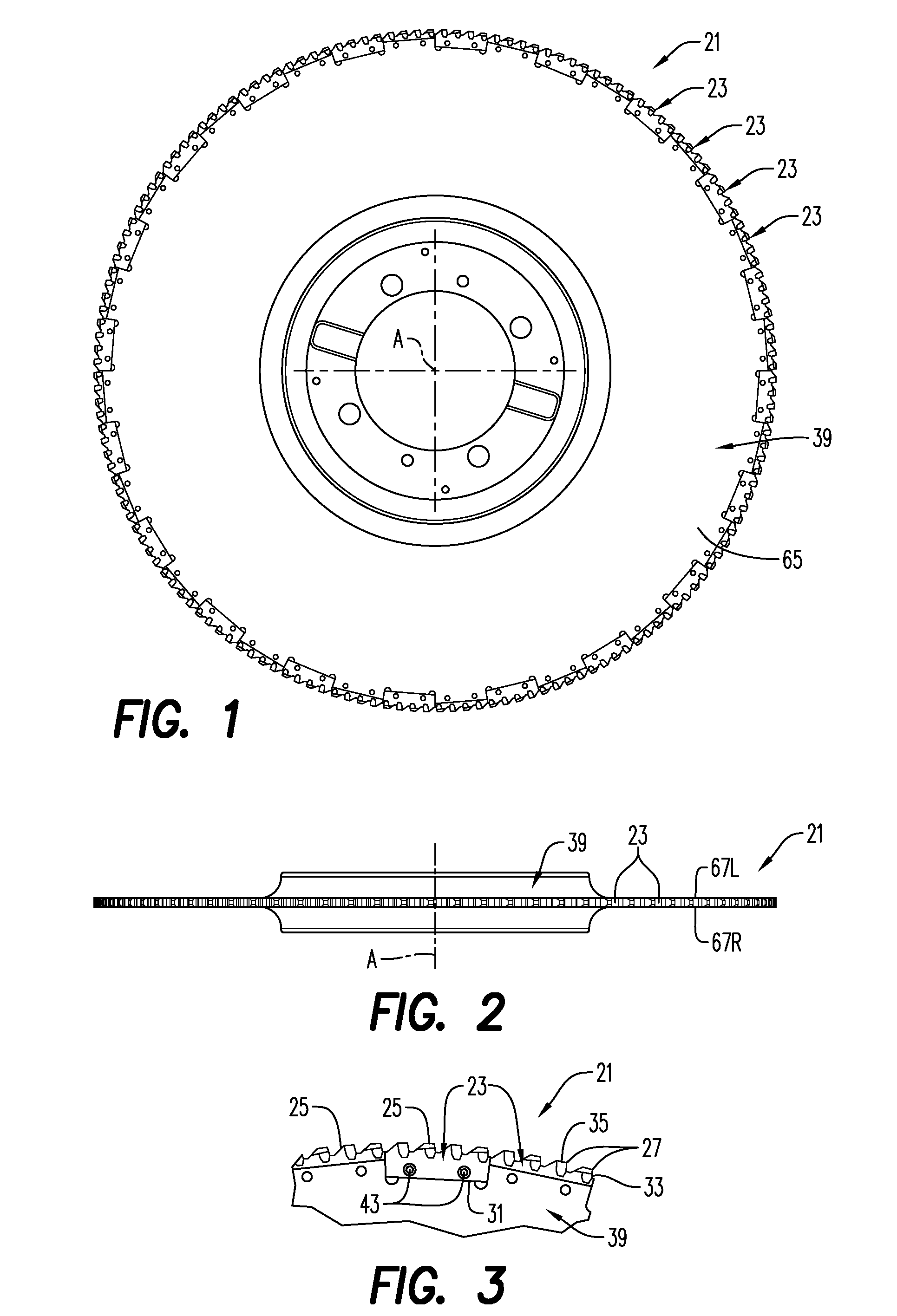

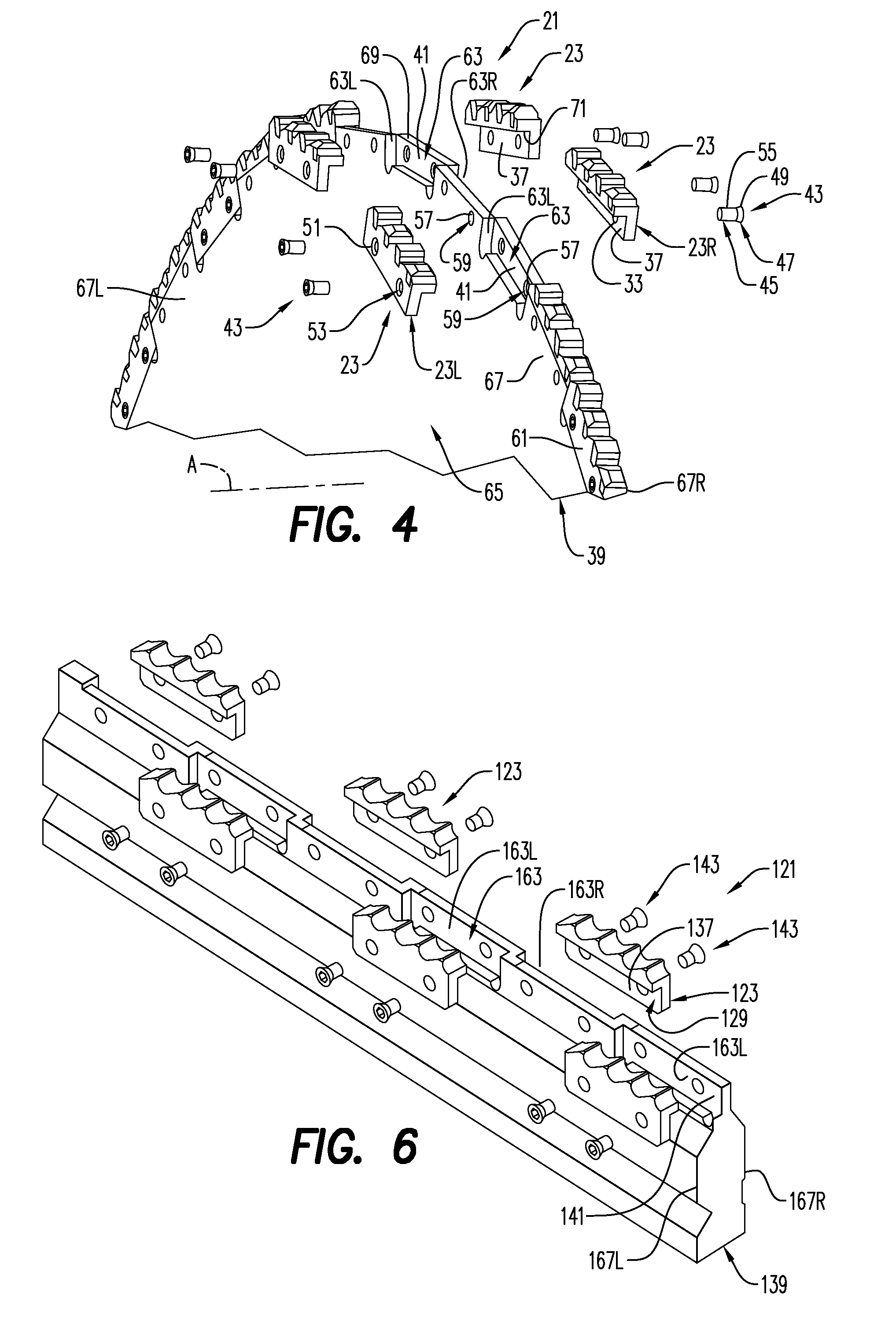

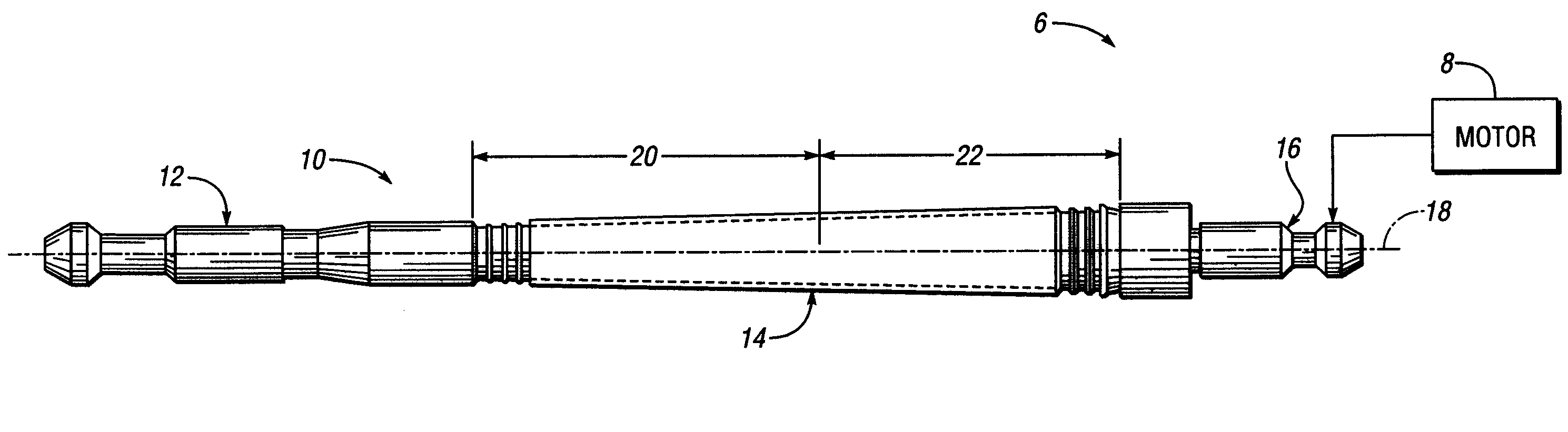

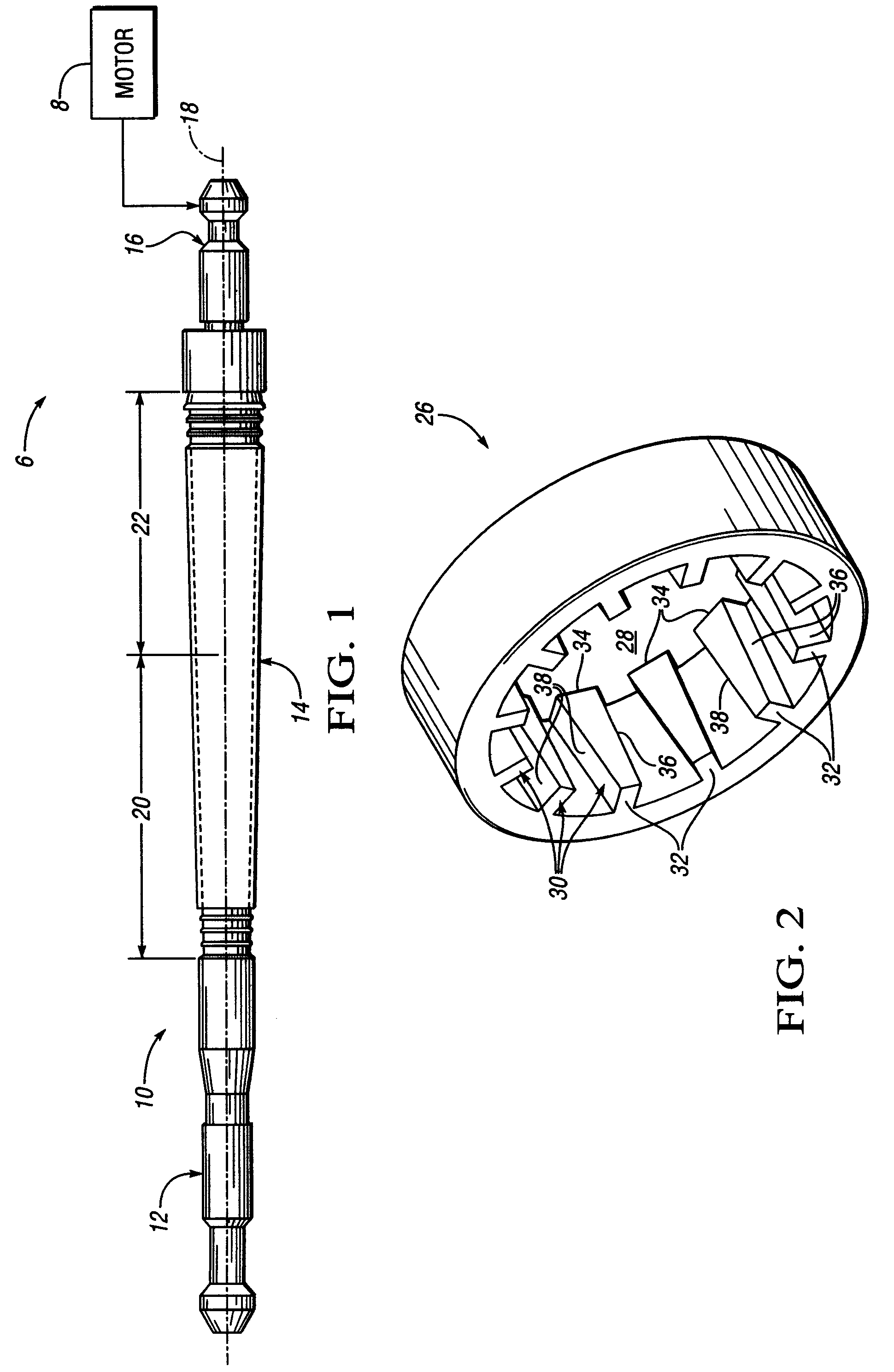

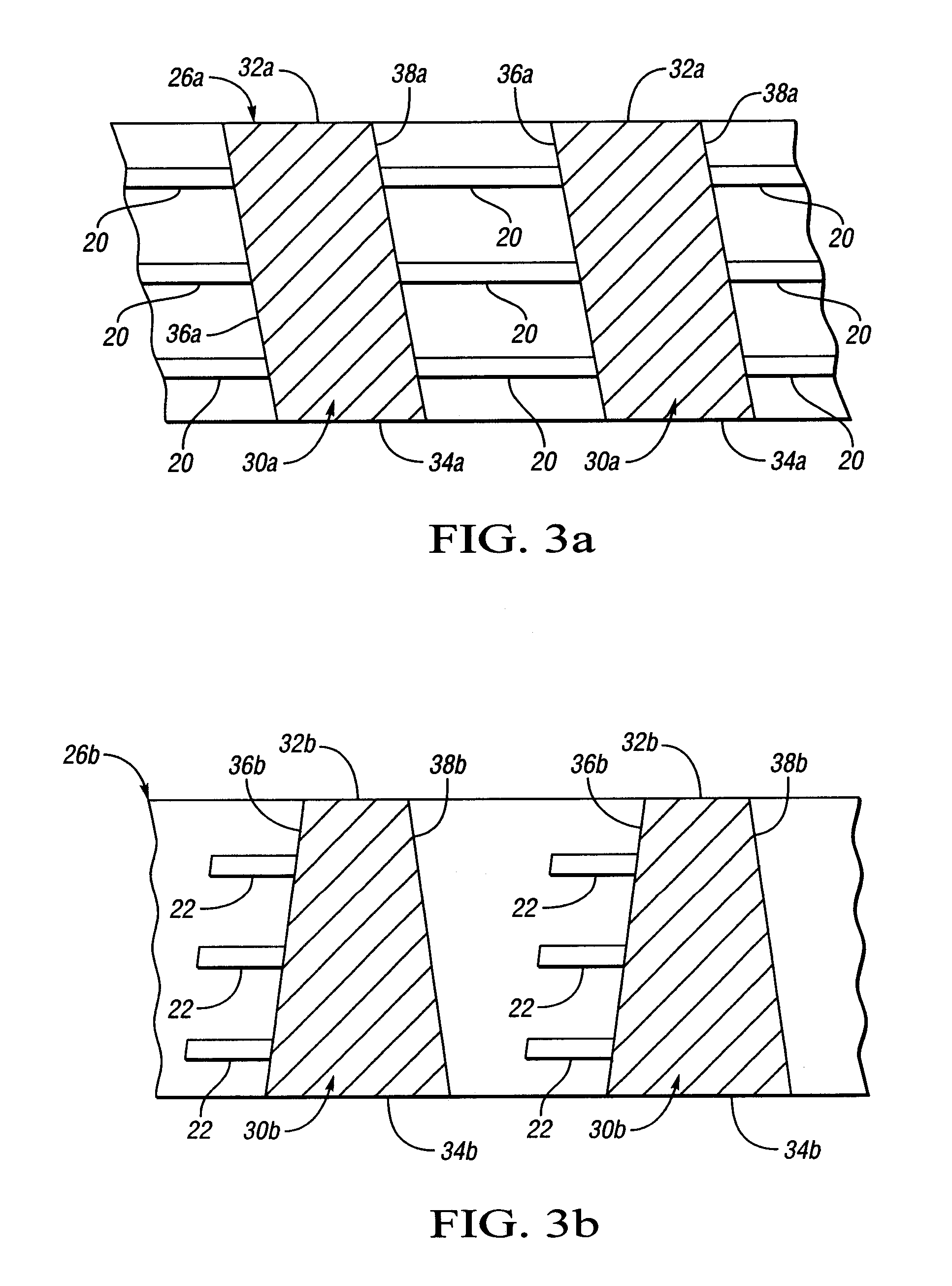

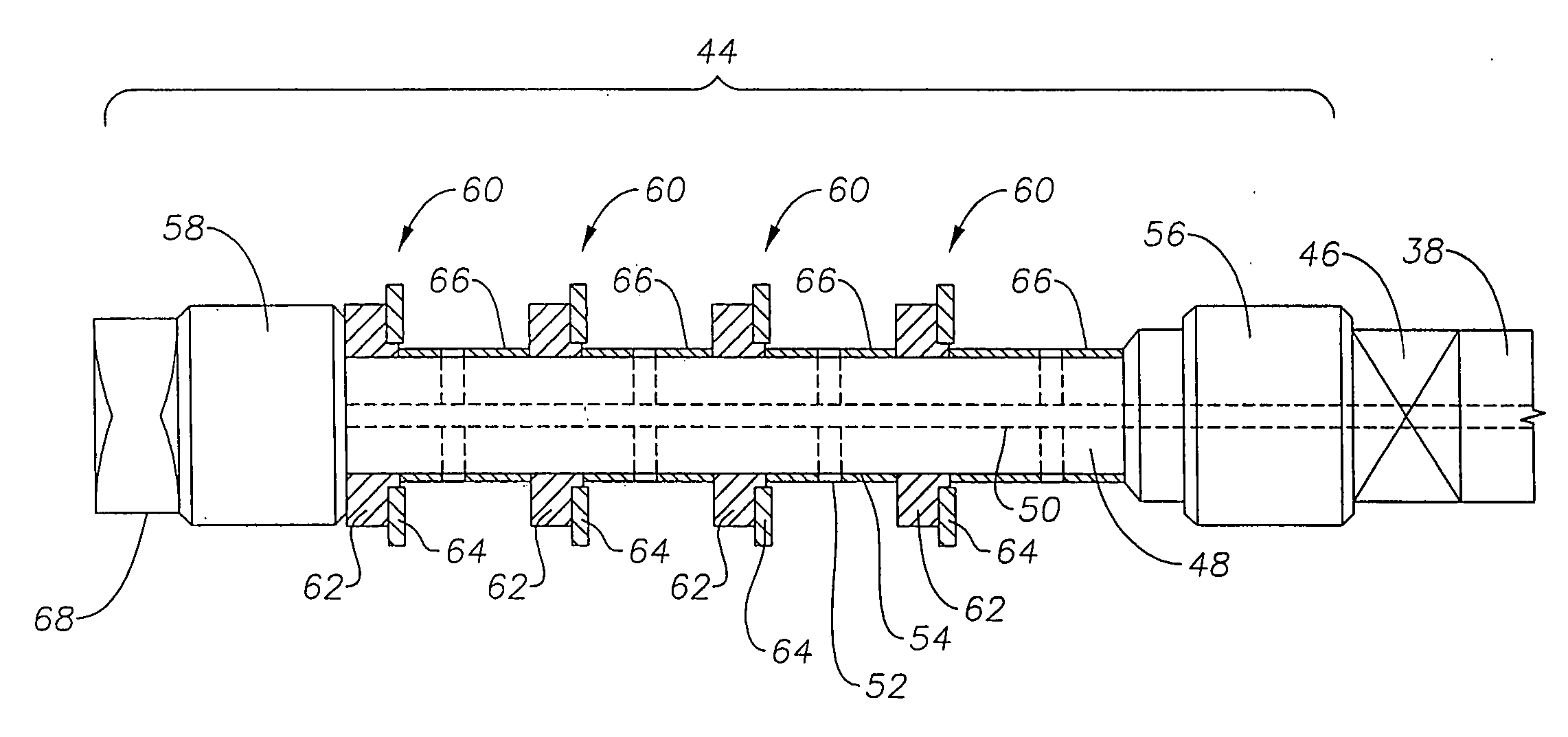

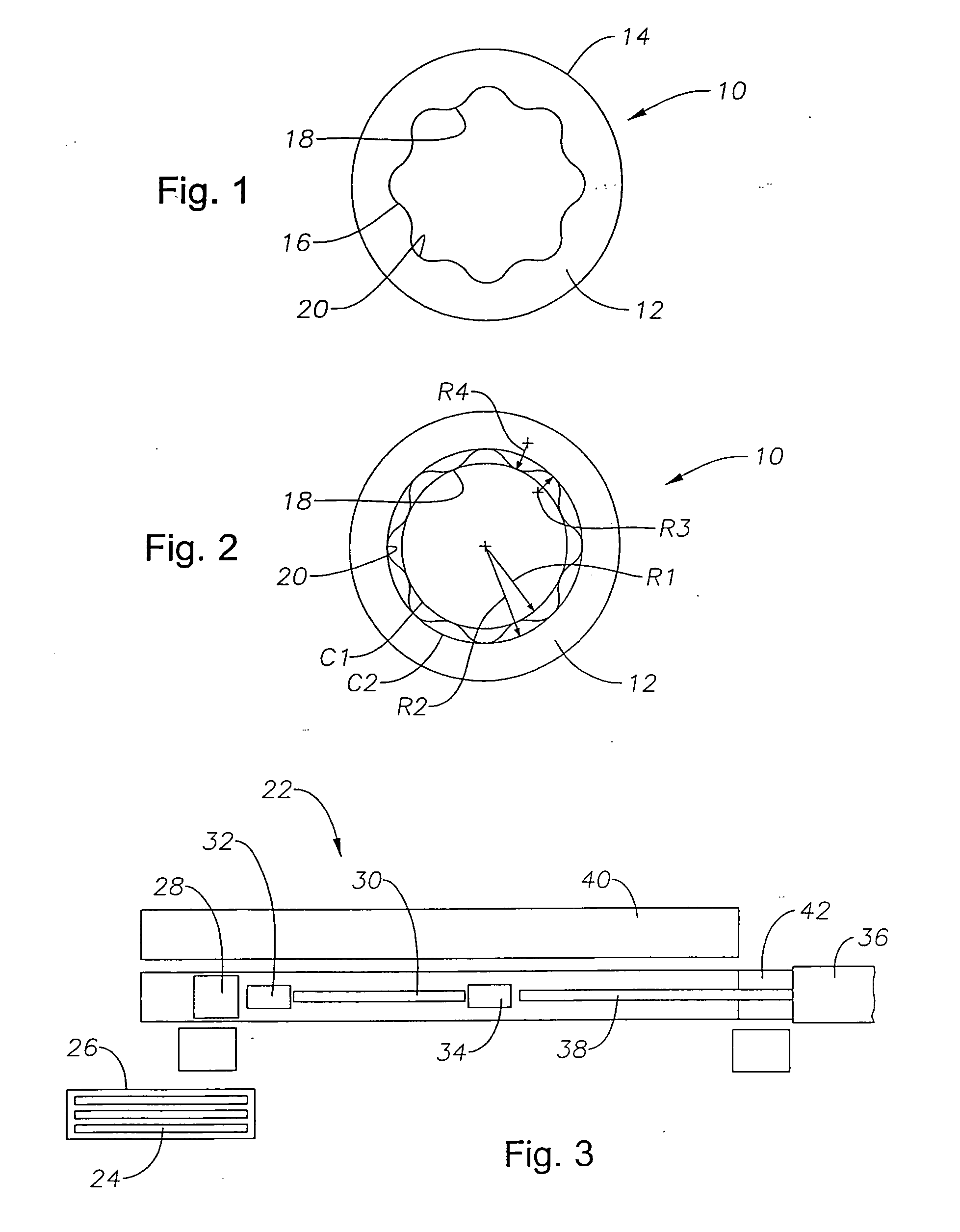

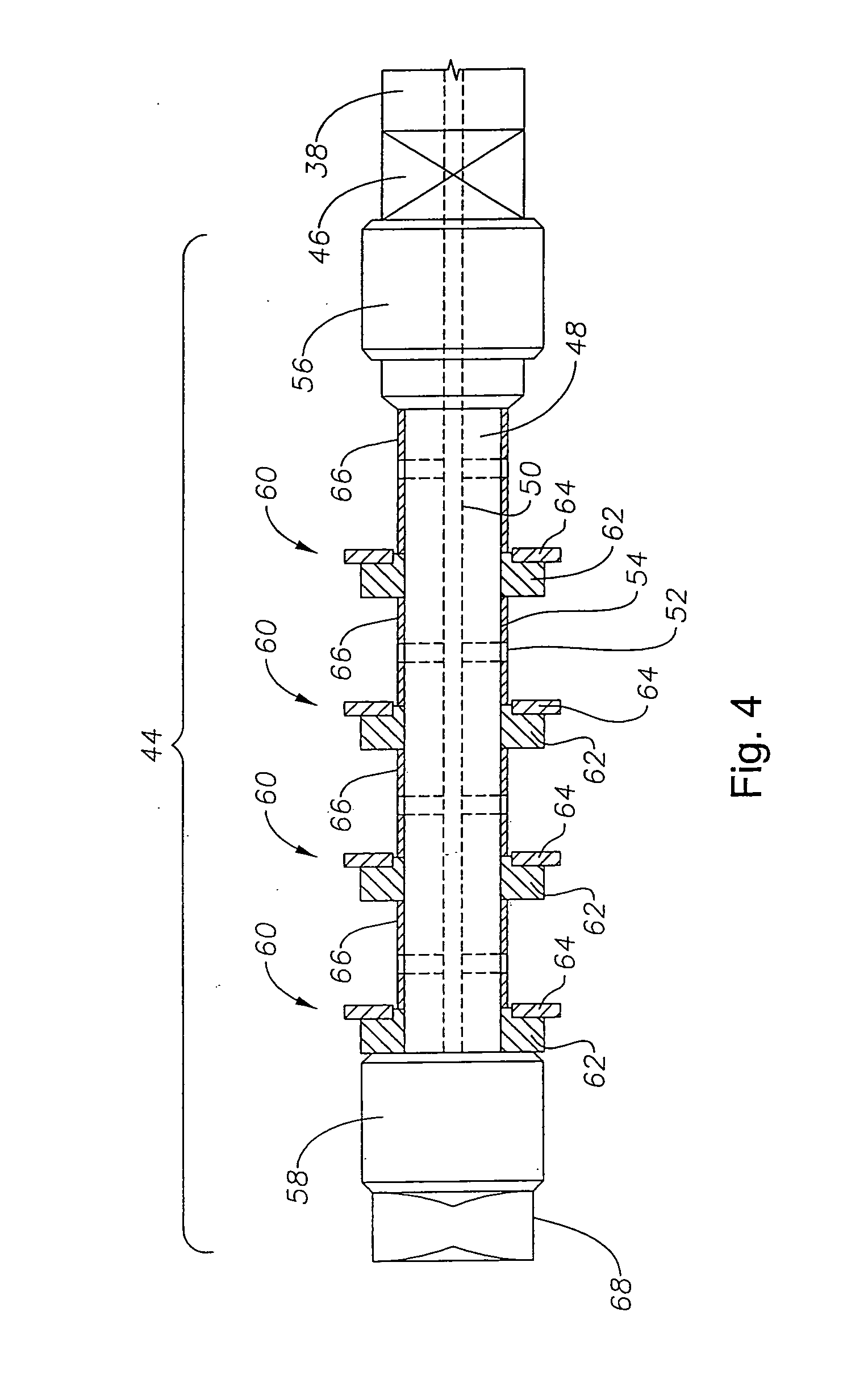

Centrifugally-cast tube and related method and apparatus for making same

InactiveUS20060056934A1High dimensional accuracyImprove roughness accuracyBroaching accessoriesRectilinear broachMetal dustingEnhanced heat transfer

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:DEMAREST JOEL +1

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The table also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com