Hard broaching finish machining process for surface of internal keyway and device

A kind of hard broaching finishing and processing technology technology, applied in metal processing equipment, broaching machine, broaching and other directions, can solve the problems of fast and efficient finishing methods of inner keyway that have not been reported, achieve low cost, ensure stability, Guaranteed effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

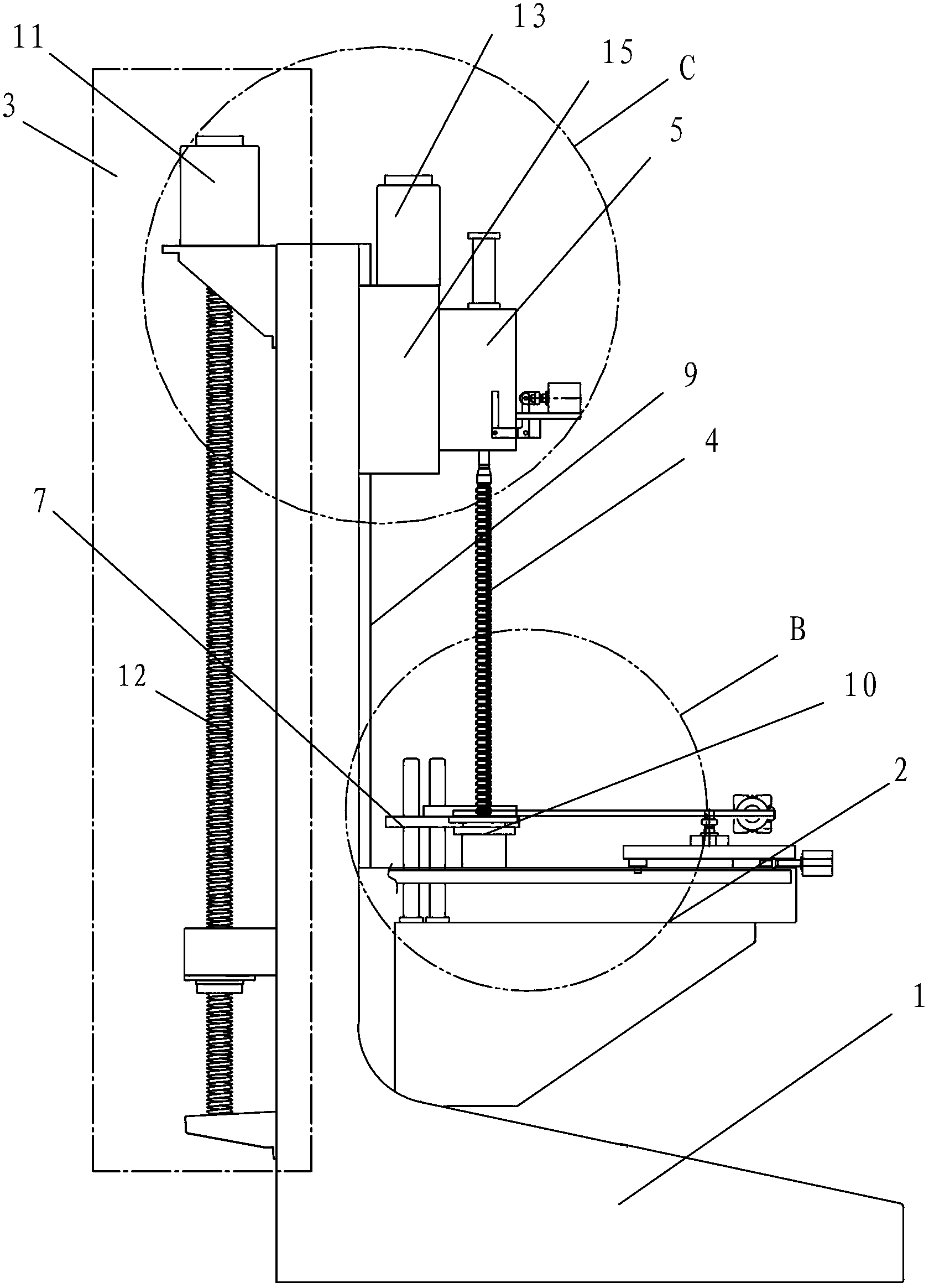

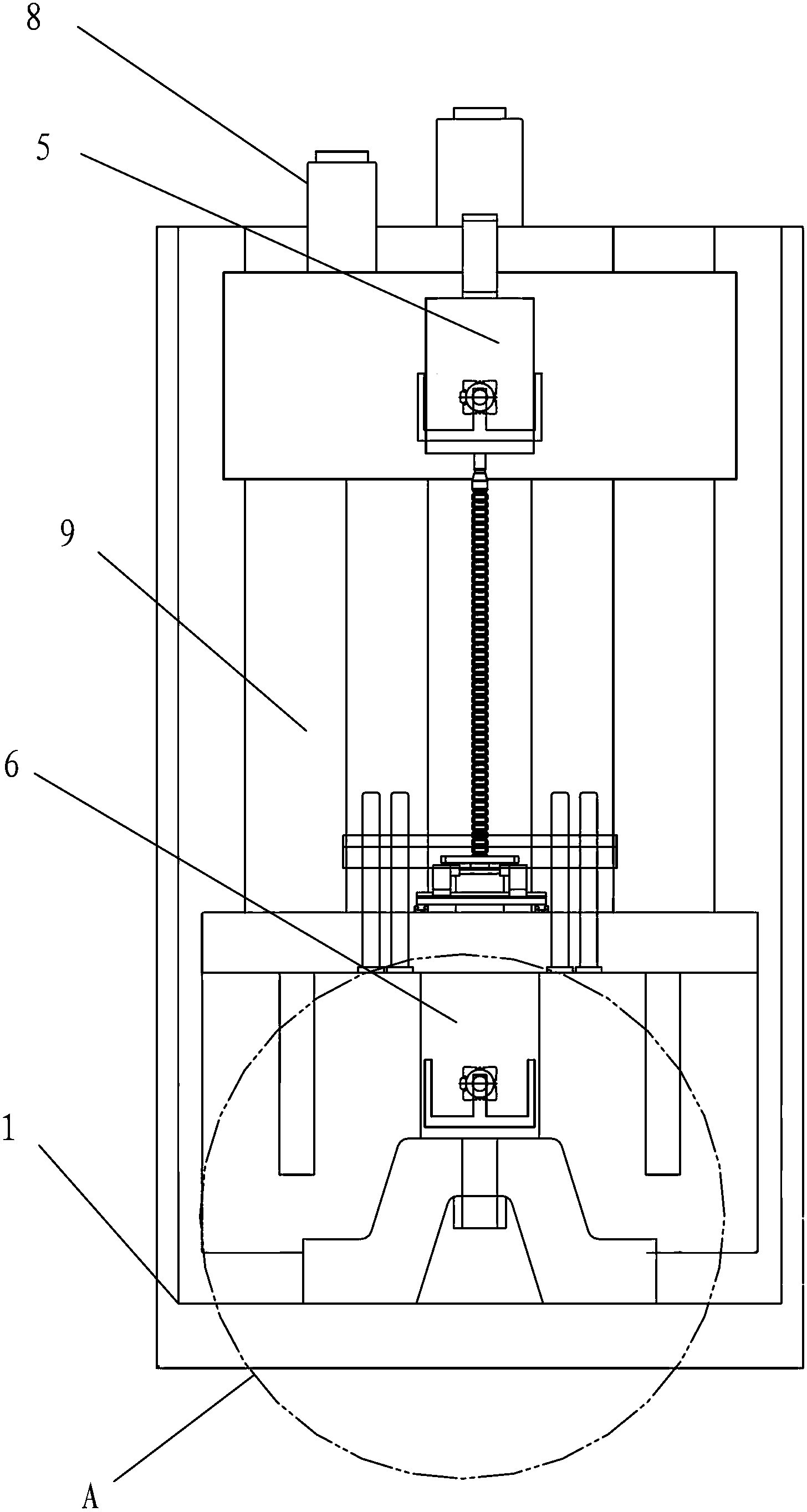

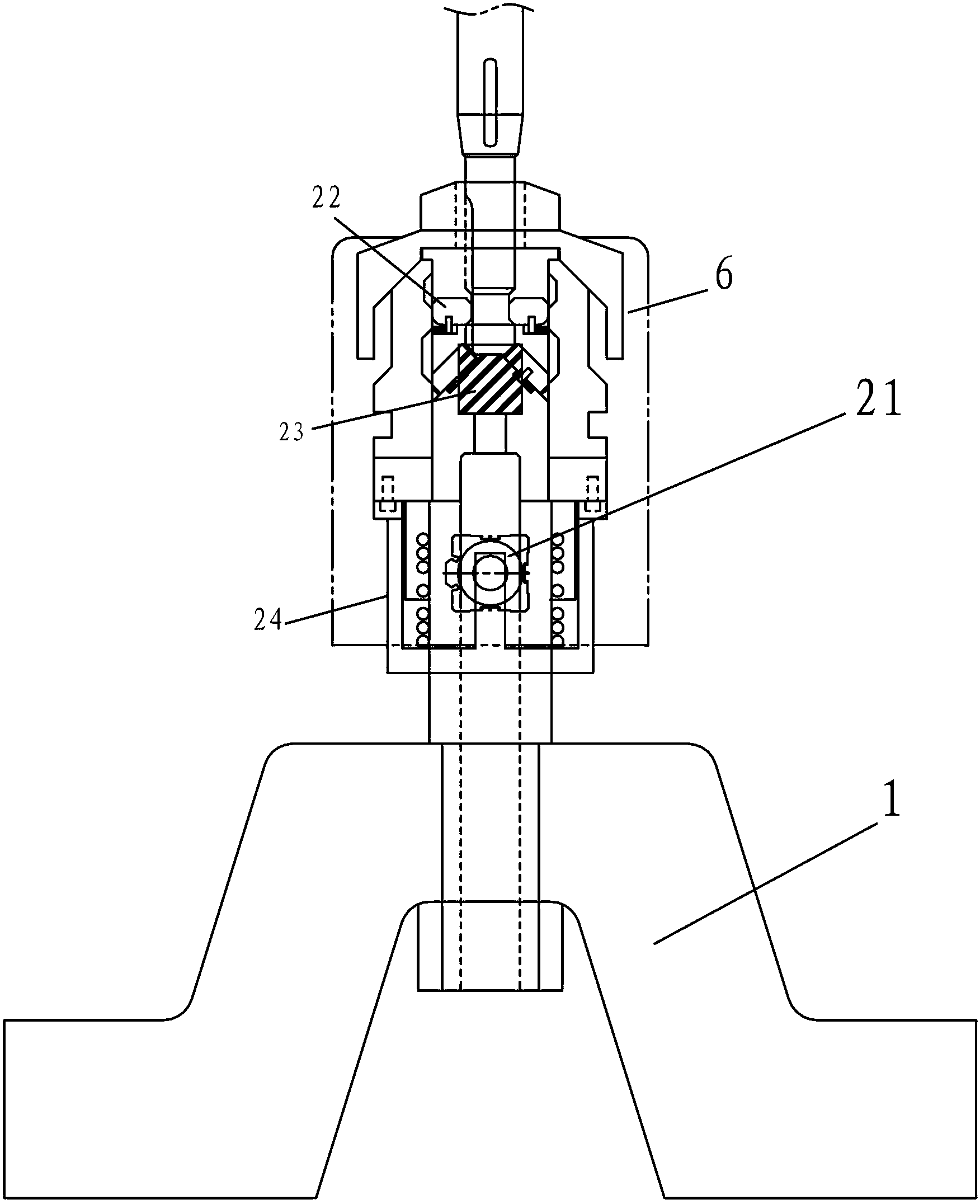

[0027] Referring to the accompanying drawings, the present invention is a hard broaching and finishing equipment for internal keyway surface, which includes a bed 1, a workbench 2, a workbench driving device 3, a tool 4, an upper tool holder 5, a lower tool holder 6, and a guiding and positioning device 7 , tool driving device 8, the workbench 2 is installed on the guide track 9 on the bed 1, driven by the workbench drive device 3 to move along the guide track 9; above and below the workbench 2 On the bed 1 of the bed, an upper tool seat 5 and a lower tool seat 6 are respectively arranged, and the upper tool seat 5 and the lower tool seat 6 are coaxially installed; the two ends of the tool 4 are respectively fixed on the upper tool seat 5 , in the lower tool seat 6; the bed 1 is also provided with a tool driving device 8 that drives the upper tool seat 5 to move axially and linearly; A fixture 10 for processing workpieces and a guiding and positioning device 7 for axially fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com