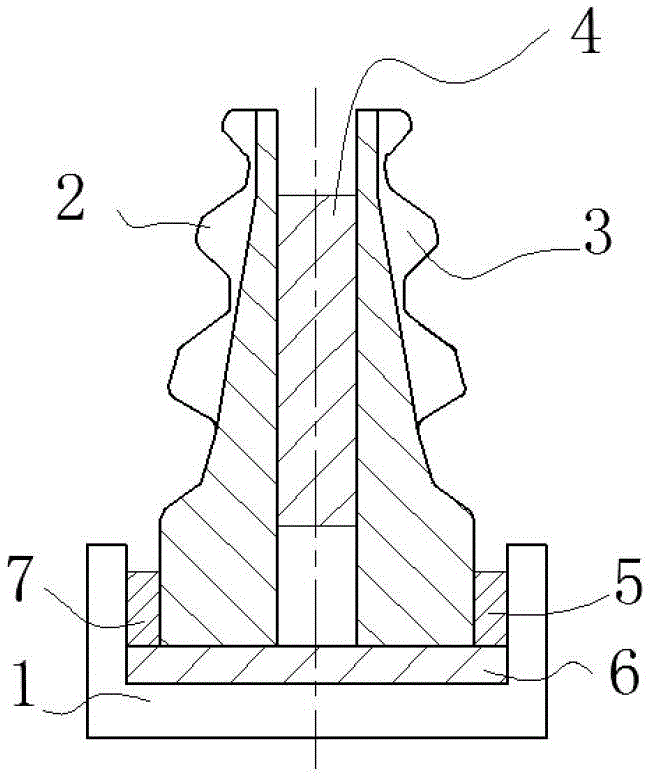

Adjustable finishing broach of wheel disc and tenon slot combination surface

A combined and fine broaching technology, which is applied in the direction of broaching tools, broaching machines, metal processing equipment, etc., can solve the problems of not having the function of adjusting side profile lines and reducing the geometric accuracy of side profile lines, so as to reduce the first-time manufacturing accuracy Requirements, overcoming the non-adjustable height, maintaining and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

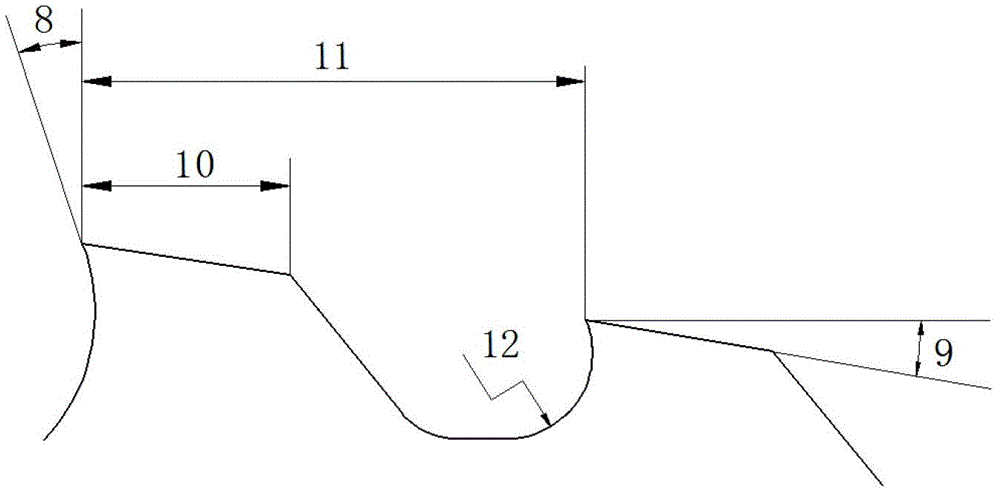

[0029] This embodiment selects the rake angle 8 of 20° to ensure the surface roughness during fine broaching; selects the relief angle 9 of 3° to reduce the flank wear of the tool flank due to the springback deformation of the material, and Reserve a certain allowance for regrinding; the tooth thickness 10 of the cutting part is selected as 8 mm, and the tooth spacing 11 is 31 mm to ensure that the cutting edge has sufficient strength; the radius of the chip flute 12 is selected as R2.5 mm to It is used for thin-layer cutting chips during fine drawing.

Embodiment 2

[0031] The rake angle 8 is 15°, the rear angle 9 is 5°, the tooth thickness 10 is 6 mm, the tooth spacing 11 is 20 mm, and the radius 12 of the chip flute is R5 mm.

Embodiment 3

[0033] The rake angle 8 is 25°, the rear angle 9 is 2°, the tooth thickness 10 is 9 mm, the tooth spacing 11 is 32 mm, and the chip flute radius 12 is R3.5 mm.

[0034] When the present invention is working, the profile combined and separated adjustable structure is used to maintain the geometric accuracy of the side profile line after regrinding of the tool, so as to meet the strict requirements of the tenon and groove processing of the heavy-duty gas turbine rotor disk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com