Ultrasonic broaching tool, high-efficiency precise ultrasonic broaching device and broaching process thereof

A technology of ultrasonic and ultrasonic transducers, which is applied in broaching devices, accessories of broaching devices, broaching tools, etc., can solve the problems of complex shapes and many processing procedures, and achieve the effect of improving service life and broaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

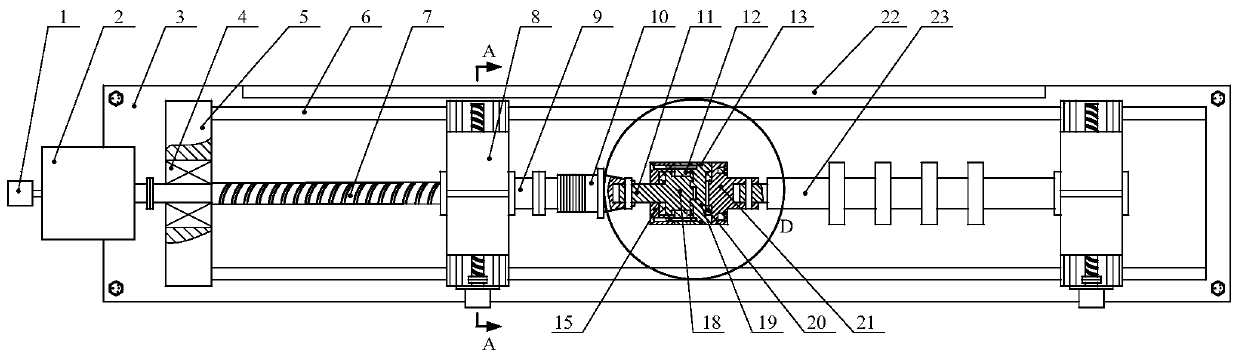

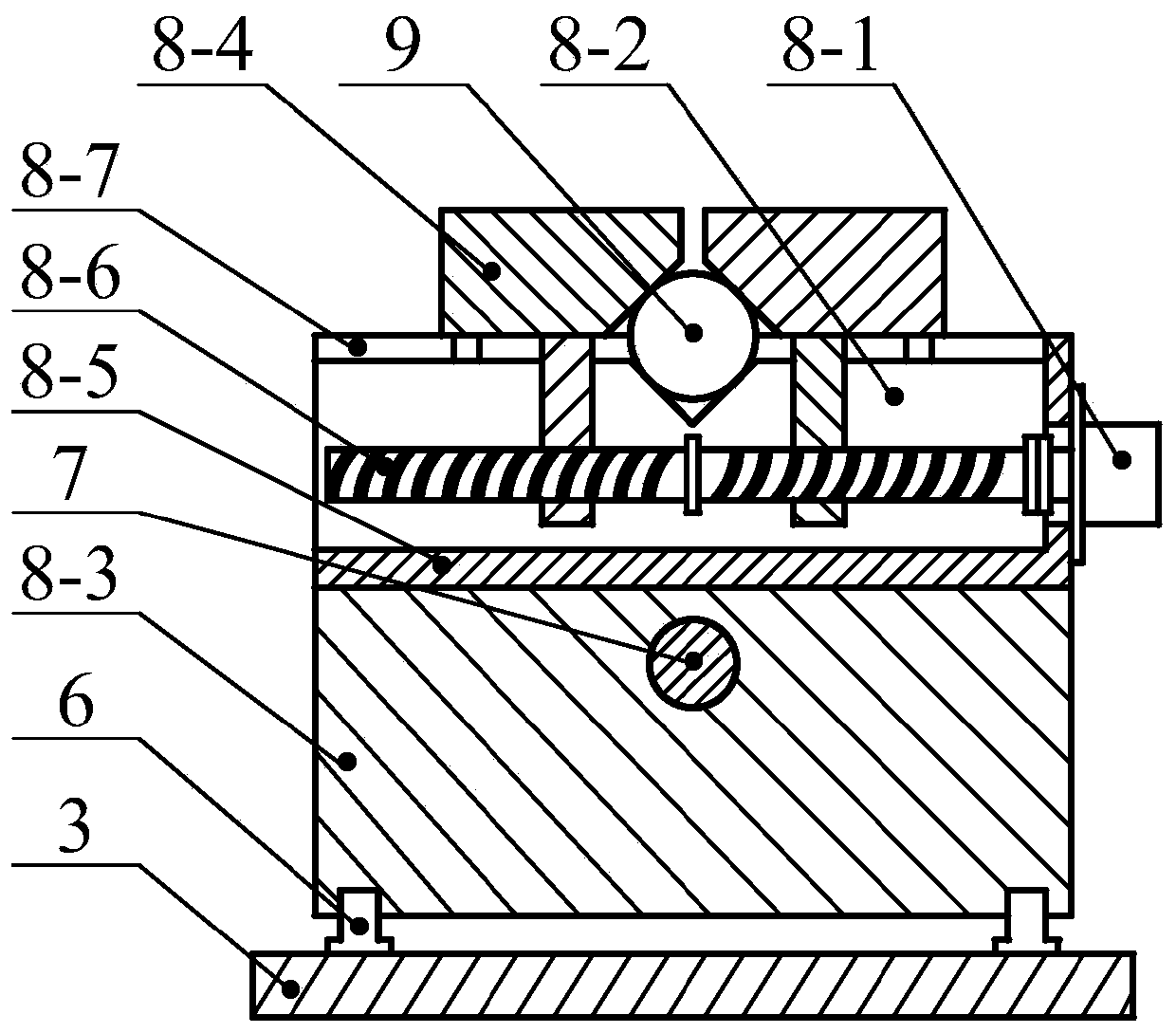

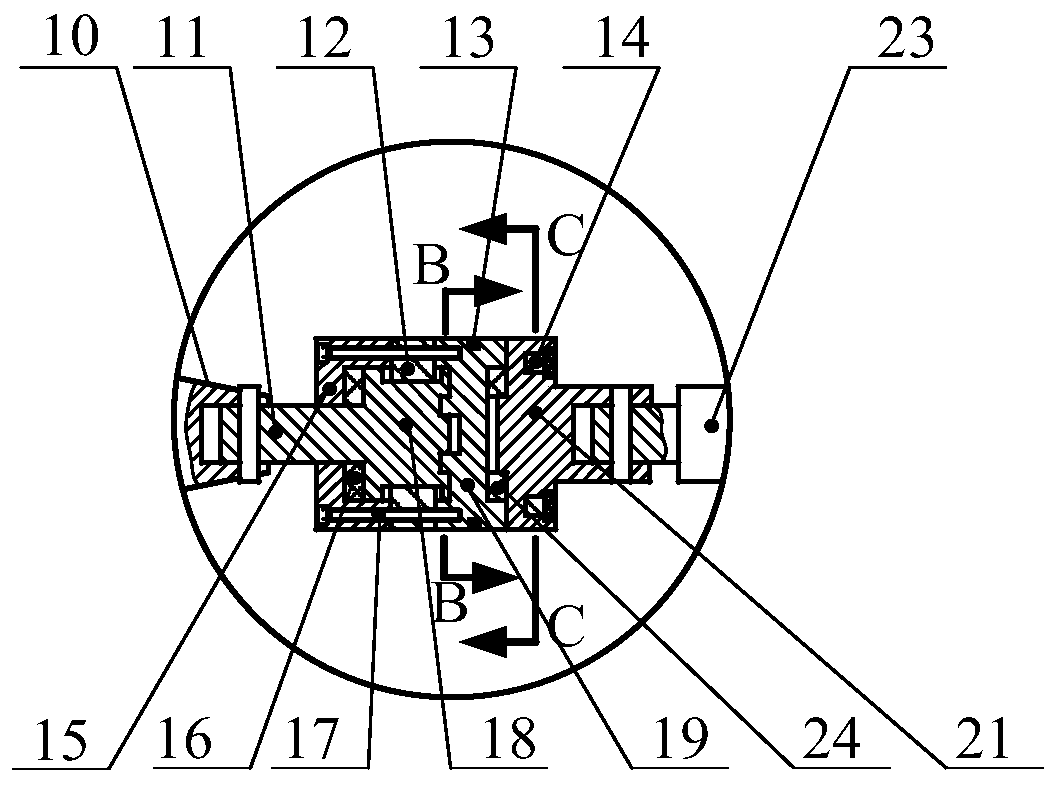

[0044] like figure 1 As shown, the high-efficiency precision ultrasonic broaching device includes a broaching machine body, a grating 22, an ultrasonic broach and a controller. The broaching machine body includes a photoelectric encoder 1, a broaching machine driving motor 2, a bed 3, a bearing 4, a bearing seat 5, a broaching machine guide rail 6, a broaching machine screw 7 and a quick positioning clamping device 8. Two broaching bed guide rails 6 are all fixed on the bed 3. The grating 22 is fixed on one side of the bed 3 . The arrangement direction of the slits on the grating 22 is parallel to the longitudinal direction of the broaching machine guide rail 6 . The bearing block 5 is fixed on one end of the bed 3 . One end of the broaching machine screw 7 and the bearing seat 5 form a rotating pair through the bearing 4 . The broaching machine drive motor 2 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com