Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Does not affect processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

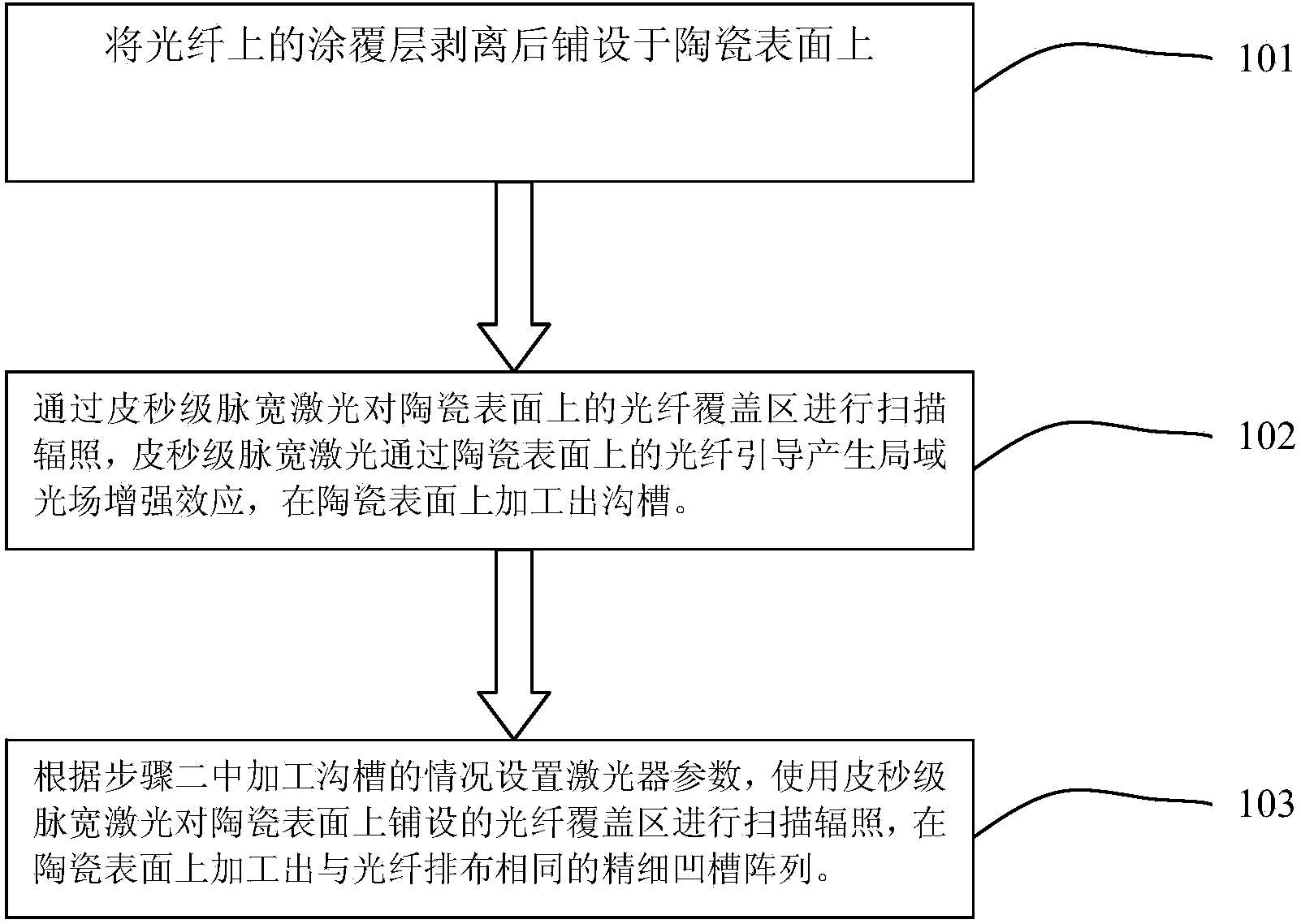

Laser machining method for fine scribing structure at ceramic surface

InactiveCN103862179AUniform wire diameterEasy to operateWelding/soldering/cutting articlesLaser beam welding apparatusHardnessOptical fiber cable

The invention discloses a laser machining method for a fine scribing structure at a ceramic surface. The method comprises the steps of peeling coatings on optical fibers and paving onto the ceramic surface; scanning and radiating an optical fiber covering area on the ceramic surface with a picosecond pulse width laser, using the picosecond pulse width laser to generate a local optical field enhancing effect by the guide of the optical fibers on the ceramic surface and machining grooves at the ceramic surface; setting laser parameters according to the groove machining conditions in the step II, scanning and radiating the optical fiber covering area paved on the ceramic surface by using the picosecond pulse width laser, and machining a fine groove array same as the optical fibers in arrangement on the ceramic surface. The picosecond pulse width laser beam is guided by adopting the optical fibers, the ceramic surface with high-melting point, high-hardness and high-brittleness physical properties is obtained, multiple fine scribing lines can be obtained at the same time, edges of the scribing lines have no cracks and heat affected zones and are smooth, the size diameters of the lines are uniform, and the minimal diameter limitation of the focus light beams on the scribing line diameter is broken through.

Owner:BEIJING UNIV OF TECH

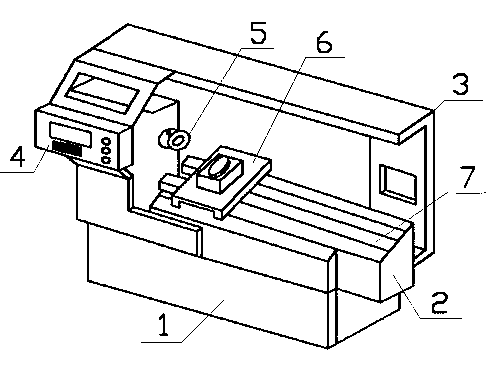

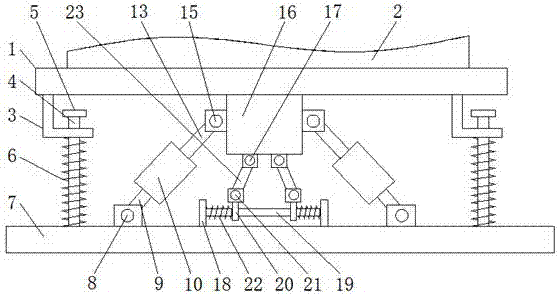

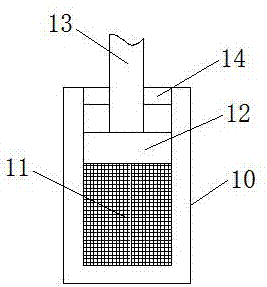

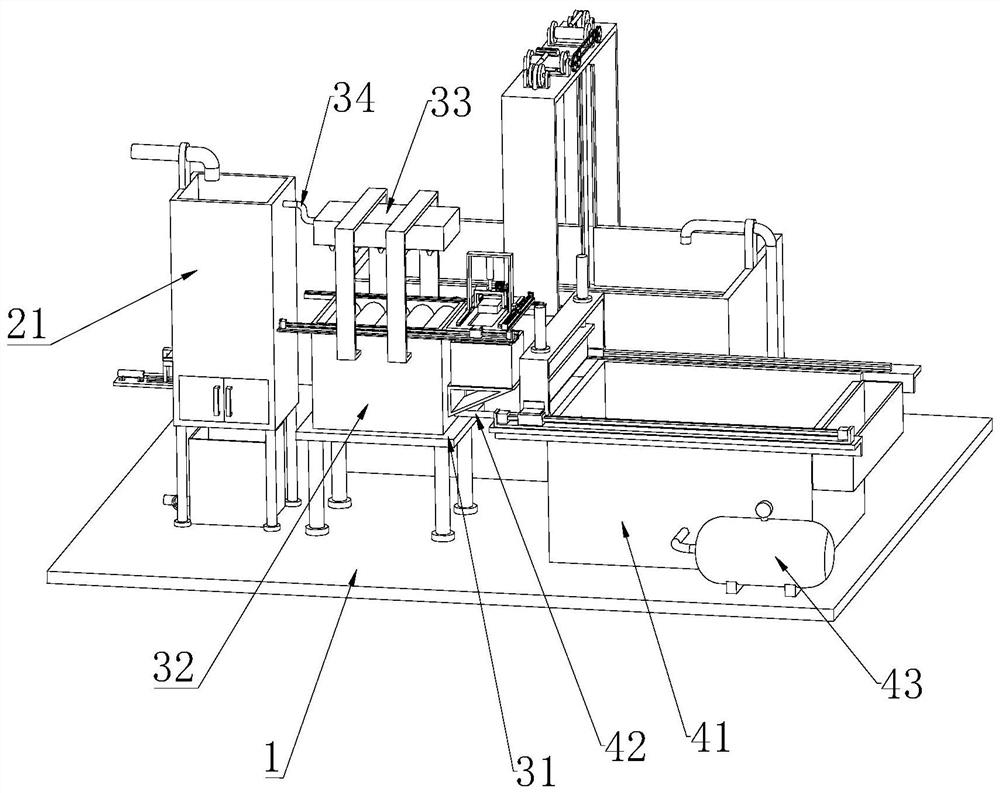

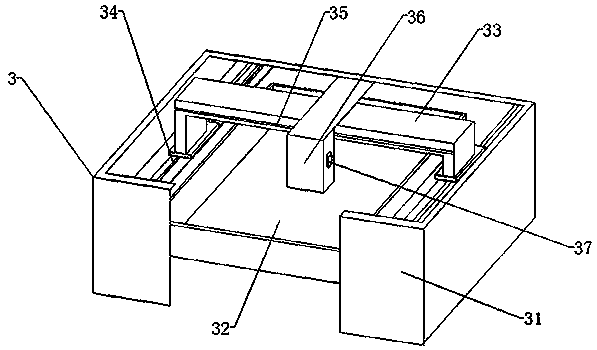

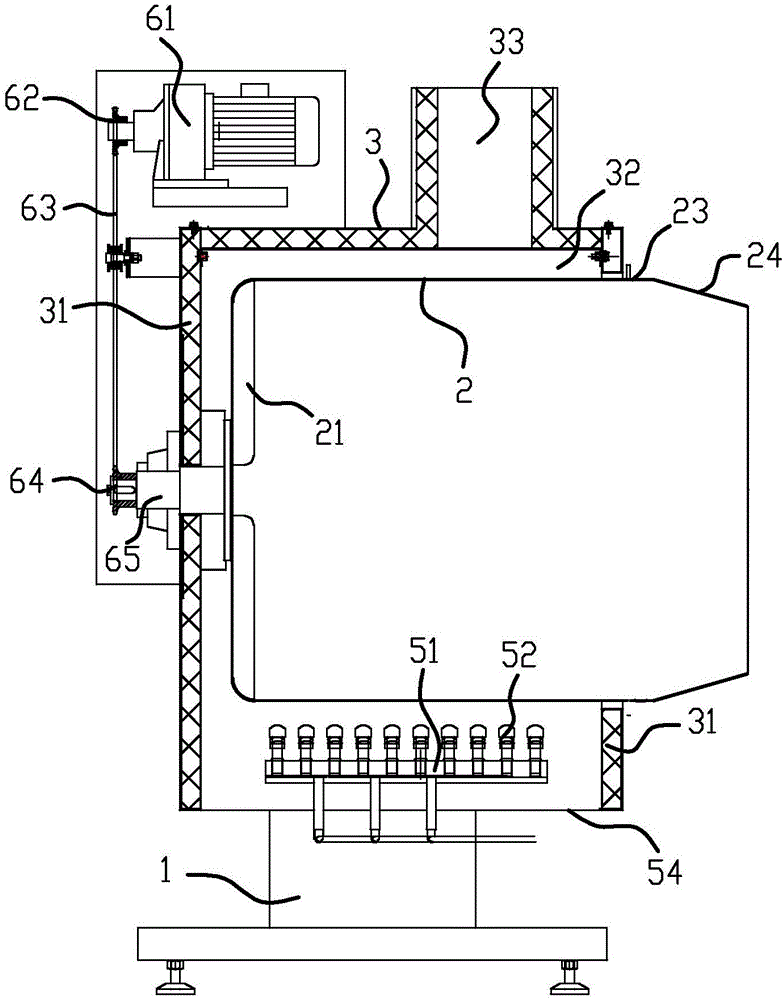

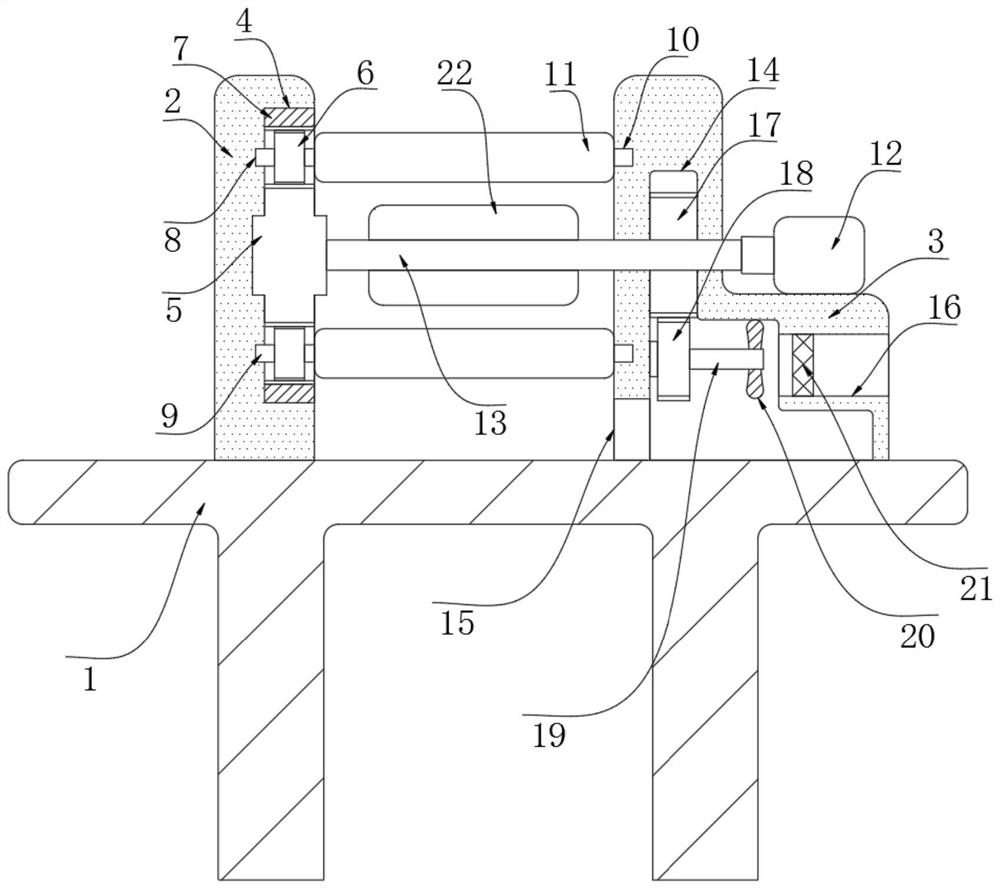

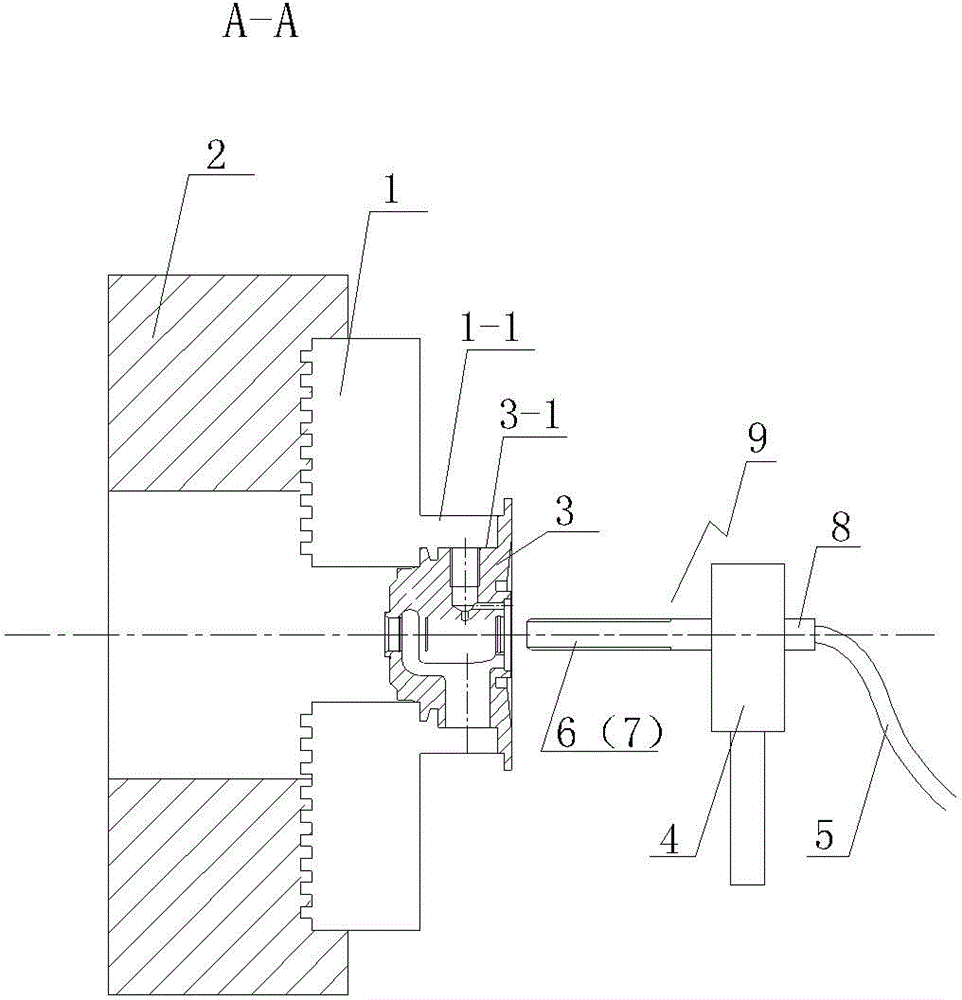

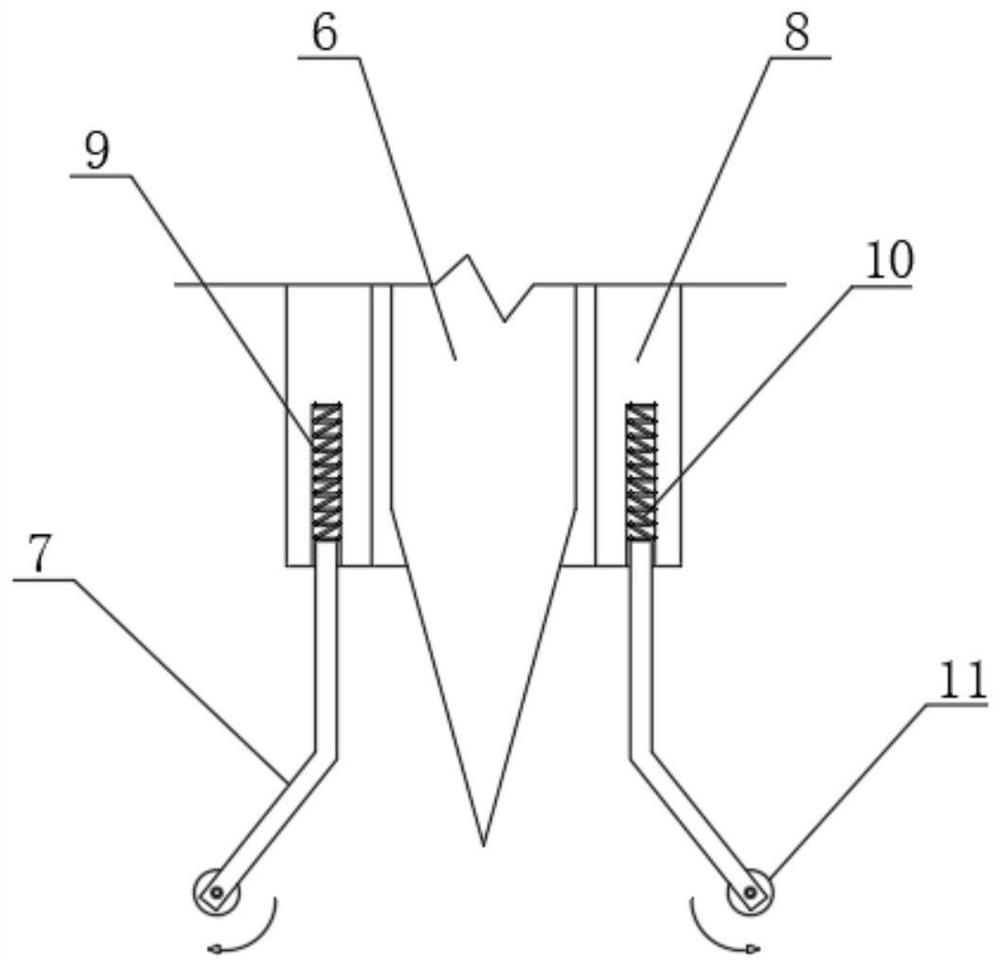

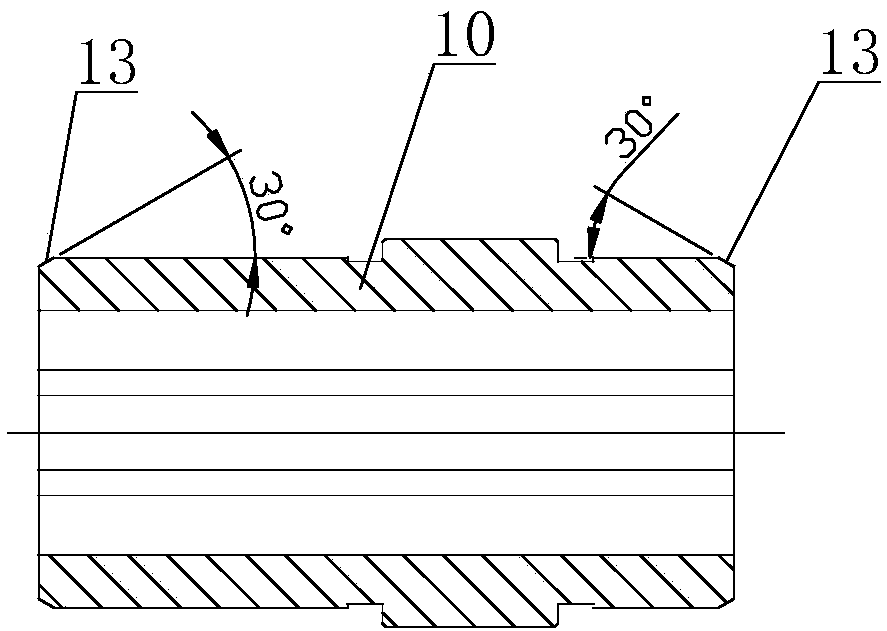

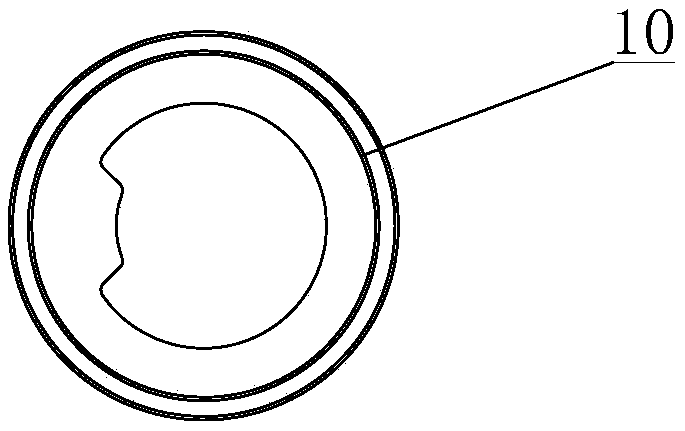

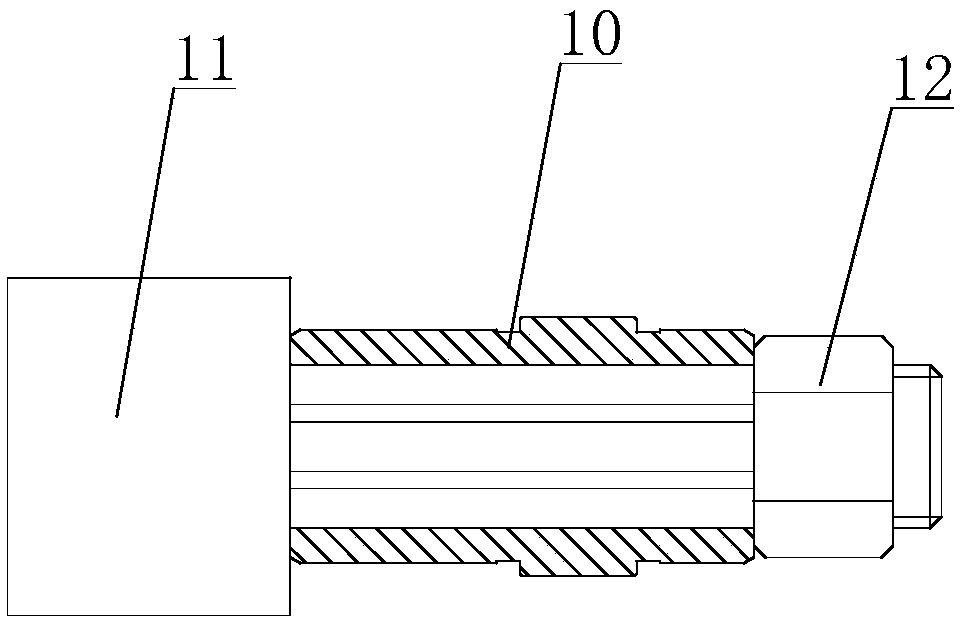

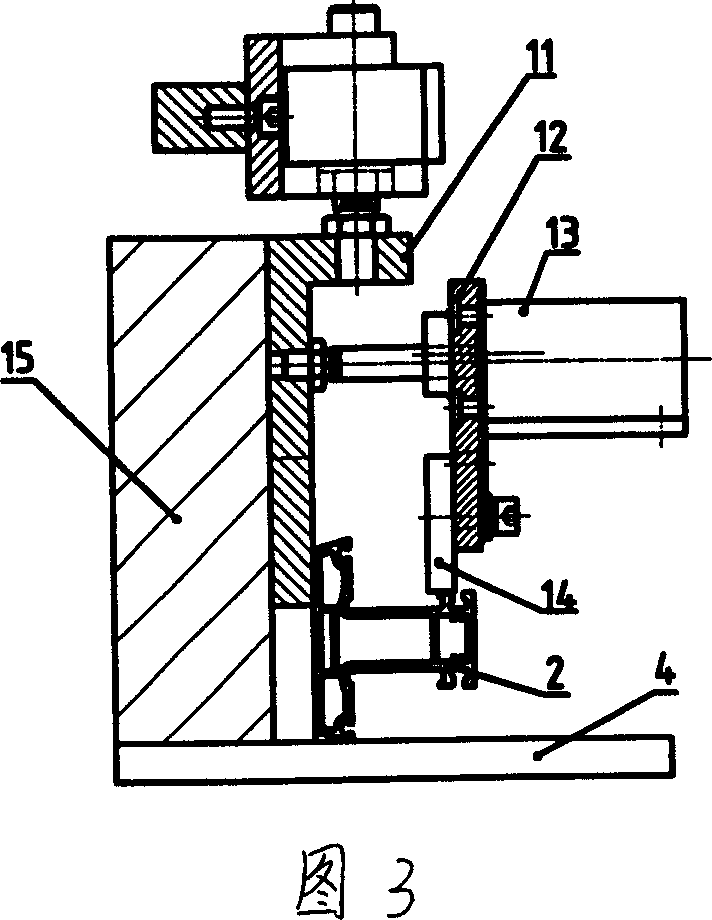

Numerical control machine tool for obliquely machining

InactiveCN102848204ADoes not affect processing qualityEnsure stabilityLarge fixed membersNumerical controlEngineering

The invention discloses a numerical control machine tool for obliquely machining. The numerical control machine tool comprises a machine tool body, a control panel, a main shaft and a tool rest feeding support plate, wherein the machine tool body is formed by a machine tool lathe bed and a guide rail worktable, the control panel is arranged in front of the machine tool body, the main shaft is arranged at the left side of the machine tool body, and the tool rest feeding support plate is arranged on the guide rail worktable; and the guide rail worktable is arranged on the machine tool lathe bed, the upper surface of the guide rail worktable is of an oblique face, and the tool rest feeding support plate is obliquely arranged on the oblique face of the guide rail worktable. Compared with traditional numerical control machine tools, the numerical control machine tool provided by the invention has the characteristics that the guide rail worktable has a certain oblique angle, and the tool rest feeding support plate mounted on the guide rail worktable simultaneously inclines for a certain degree to carry out machining; and the benefits of oblique machining are that on the premise that the machining quality is not influenced, the stability and the efficiency of the machining are guaranteed, and meanwhile, the numerical control machine tool is convenient to operate and use.

Owner:承群威

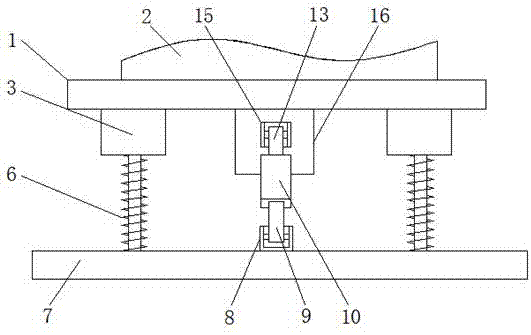

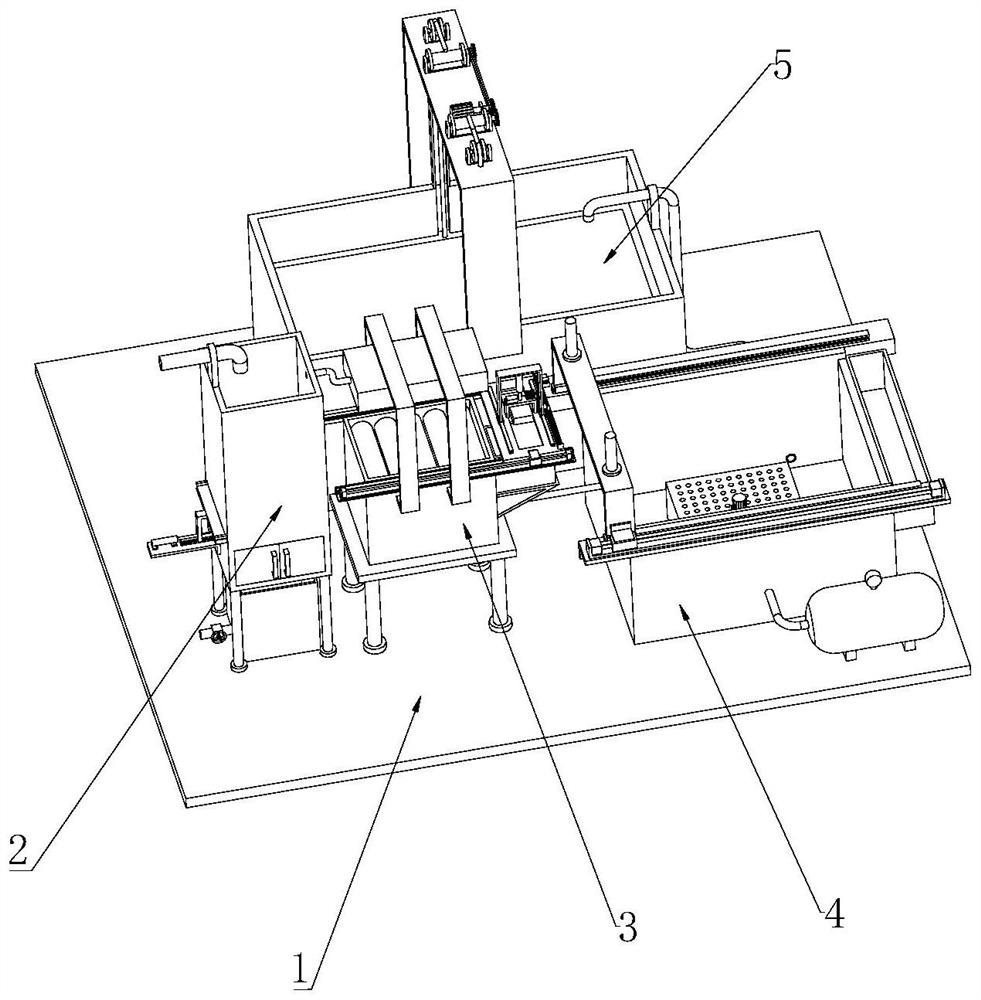

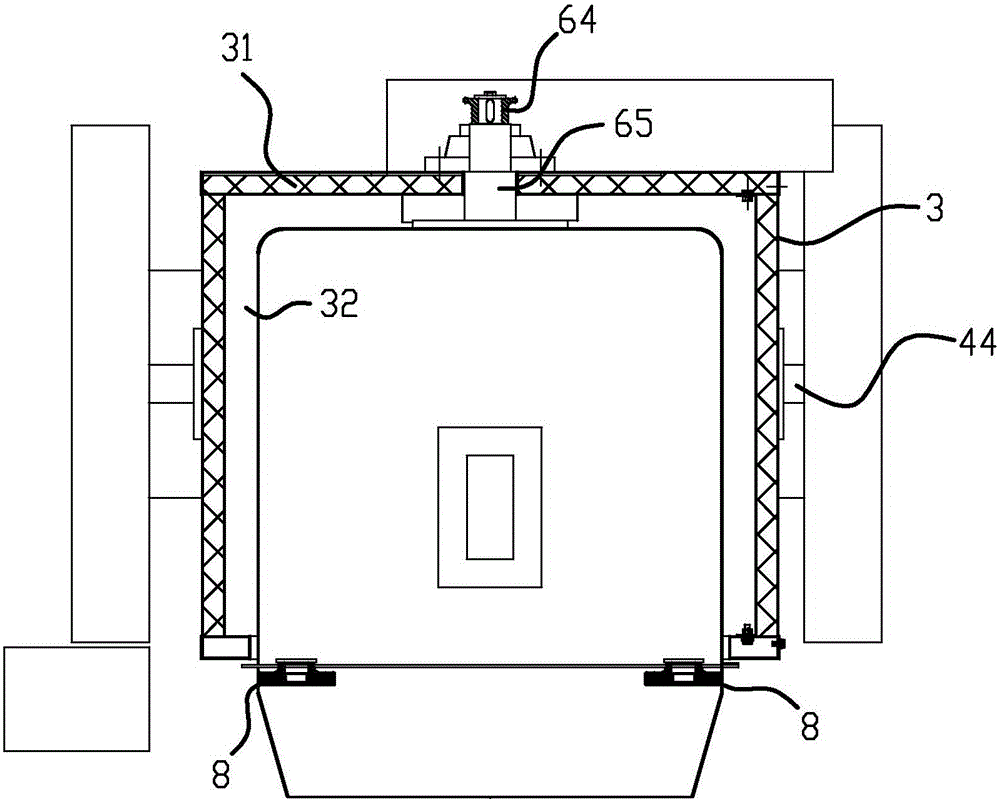

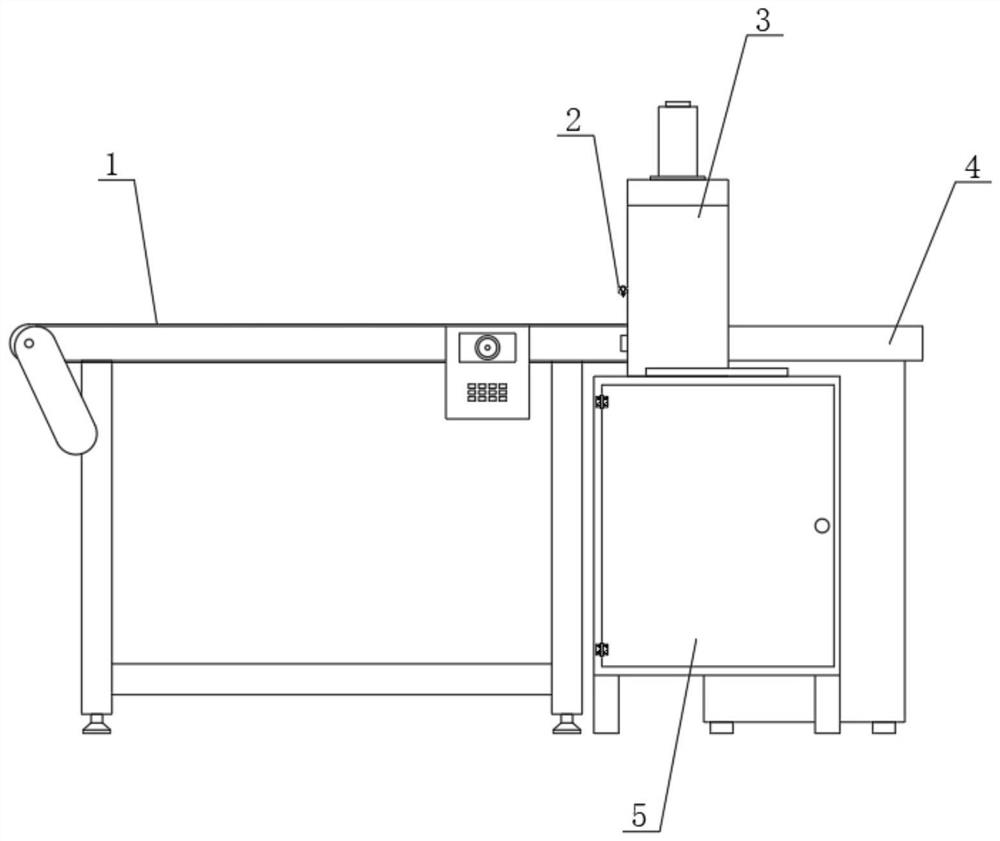

Leather processing equipment

InactiveCN107164582AReduce vibrationDoes not affect processing qualitySkins/hides/leather/fur manufacturing apparatusArchitectural engineering

The invention provides leather processing equipment, which relates to the field of leather processing. The leather processing equipment comprises a support plate, wherein the top of the support plate is fixedly connected with the bottom of a processing equipment body, L-shaped plates are fixedly installed at four corners of the bottom of the support plate, guide rods are arranged above the L-shaped plates, and the bottom ends of the guide rods penetrate through the L-shaped plates and extend below the L-shaped plates so as to be fixedly connected with the top of a base. According to the leather processing equipment, a buffer and a pressing rod which is movably connected with a second connecting base are arranged, a sliding rod, a movable block and a second spring which sleeve the surface of the sliding rod are arranged, and the guide rods and first springs which sleeve the surfaces of the guide rods are arranged, so that the support plate stably moves along the guide rods under the action of the buffer and the action of the movable block on the second spring along the surface of the sliding rod, vibration generated during processing can be effectively buffered, and finally, the processing quality cannot be influenced.

Owner:赵咪咪

Preparation method of black lithium niobate wafer

InactiveCN106929916AImprove securityLow equipment requirementsPolycrystalline material growthAfter-treatment detailsAir atmosphereEngineering

The invention discloses a preparation method of a black lithium niobate wafer. The black lithium niobate wafer to be treated is put in a container A, meanwhile a reducing agent is put in a container B, then the container A containing the black lithium niobate wafer and the container B containing the reducing agent are put in a thermal treatment furnace, reducing treatment is performed in air atmosphere at the reducing temperature, and cooling is performed to obtain the black lithium niobate wafer. The preparation method is simple and safe in operation, high in efficiency and low in cost and does not affect the surface processing quality of the wafer. By adopting the method, the electrical resistivity of the wafer is reduced on the premise that the piezoelectric property and single domain property of lithium niobate are not affected, the pyroelectric effect of the wafer itself is weakened or eliminated, and the absorbing capacity of a visual light zone is strengthened.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

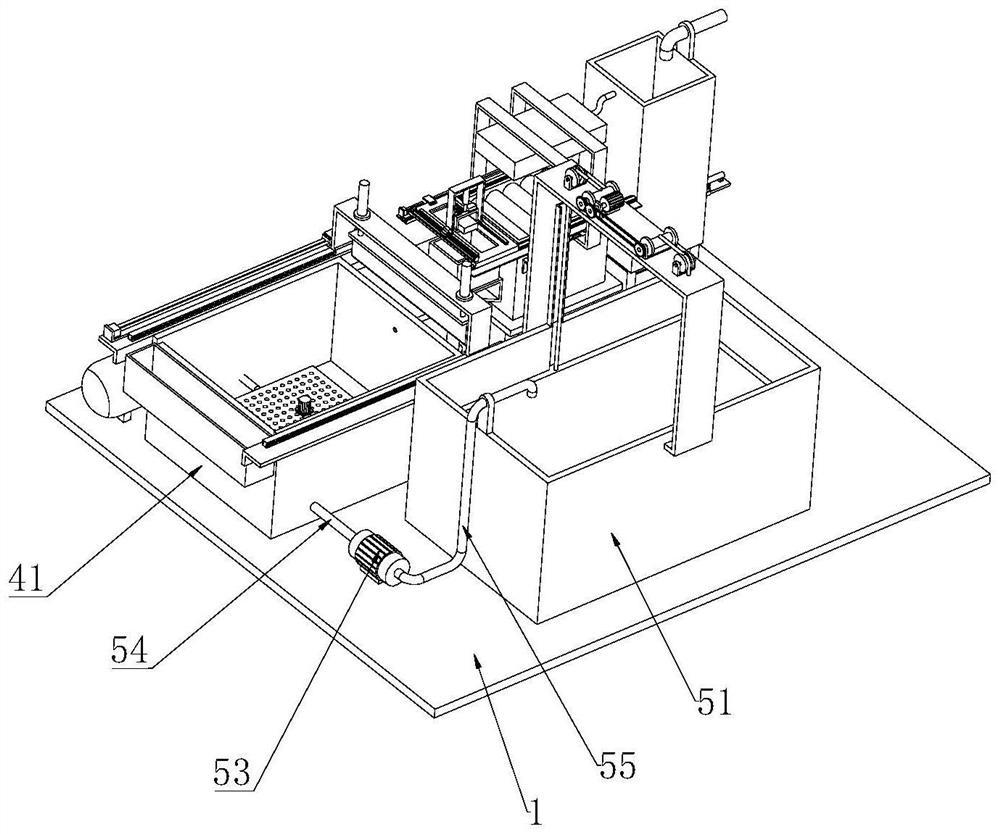

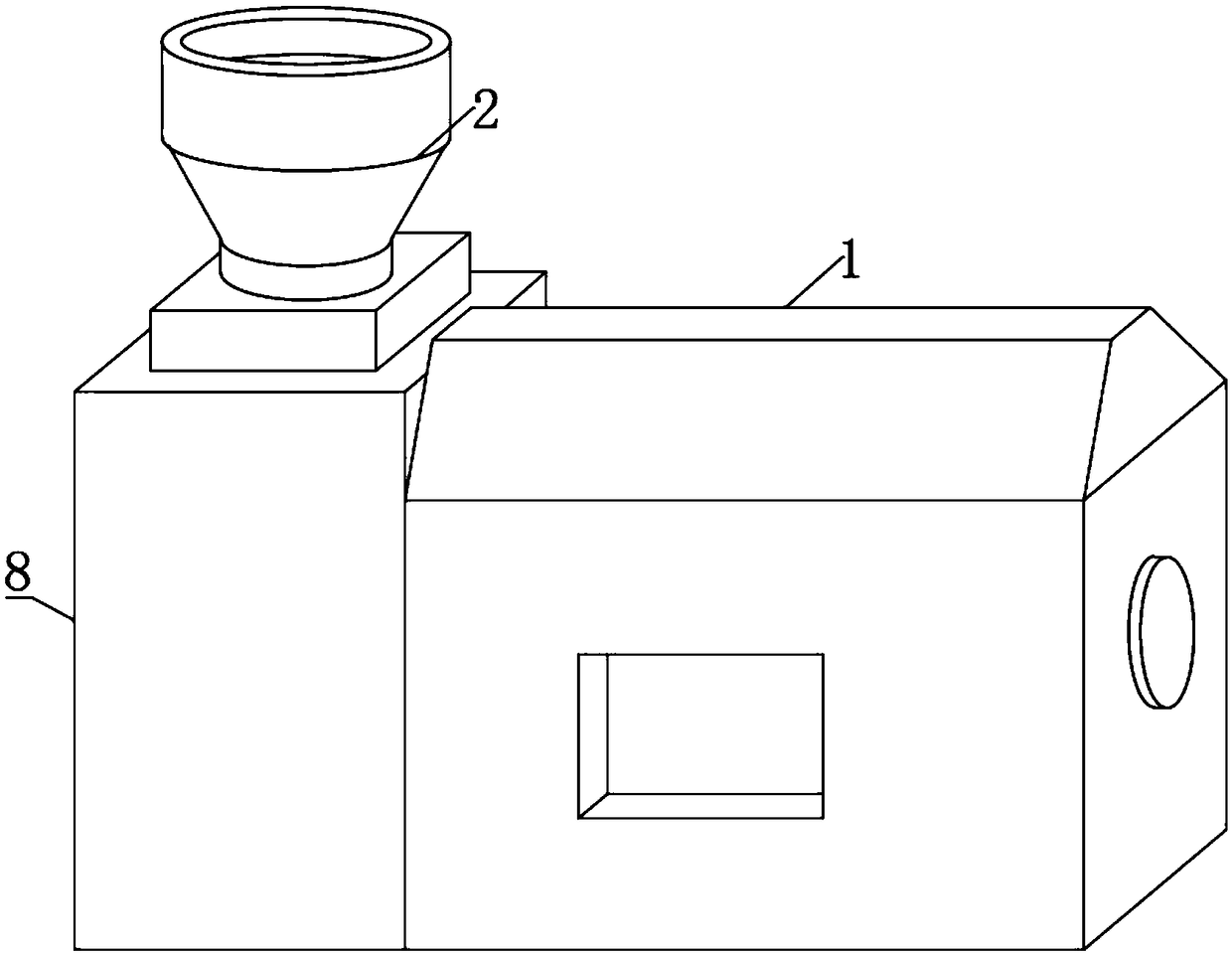

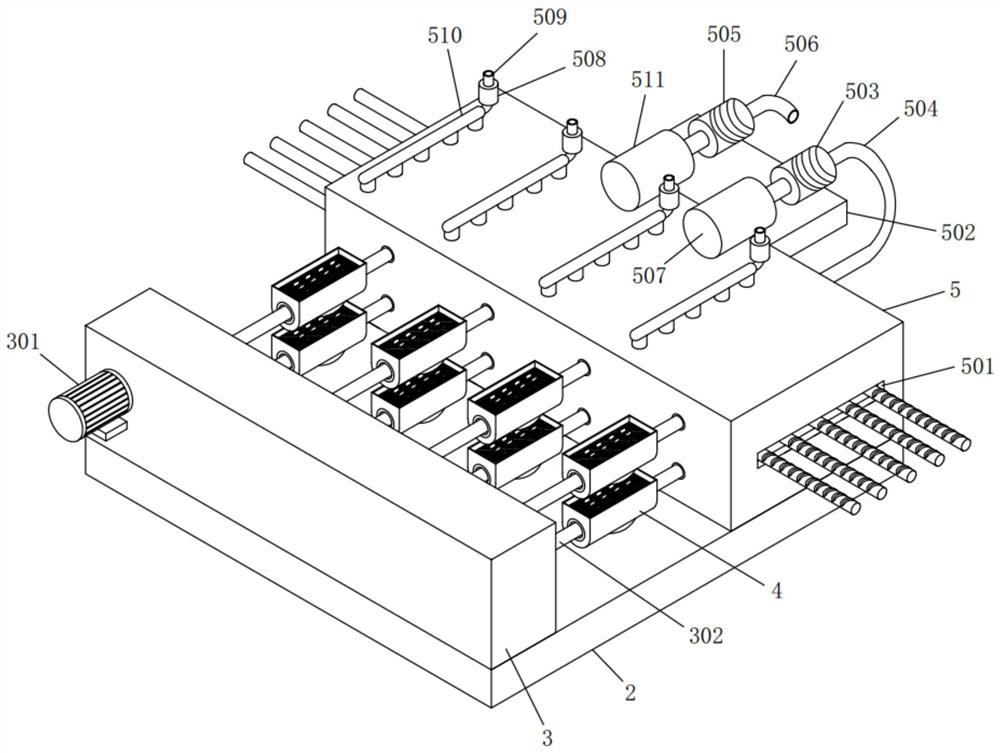

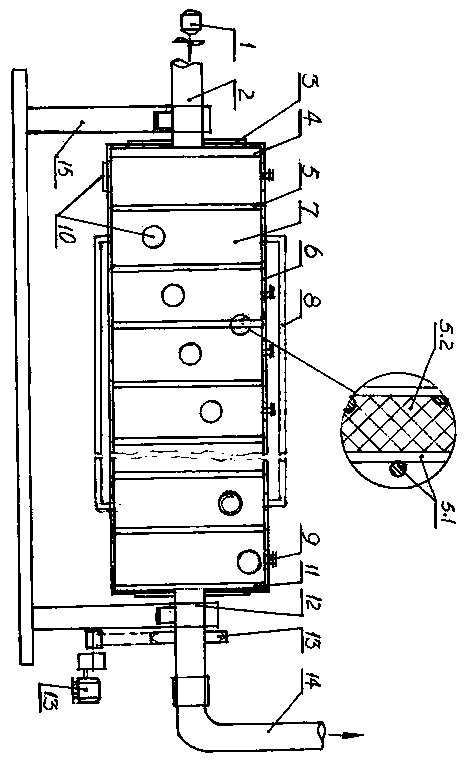

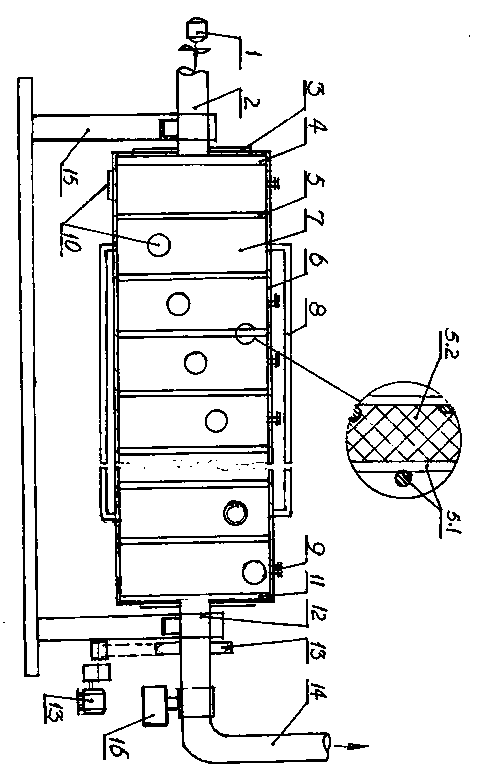

Industrial wastewater treatment device and use method thereof

InactiveCN114262113AImprove work efficiencyDoes not affect processing qualityWater contaminantsMultistage water/sewage treatmentIndustrial wastewater treatmentScrap

The invention relates to the technical field of wastewater treatment, in particular to an industrial wastewater treatment device and a using method thereof.The industrial wastewater treatment device comprises a fixing plate, a scrap iron precipitation mechanism, a scrap iron treatment mechanism, an aeration mechanism and a filtering mechanism, and the scrap iron precipitation mechanism, the scrap iron treatment mechanism and the aeration mechanism are sequentially arranged on the front side of the top of the fixing plate; the magnetic assembly is installed on the rear side of the top of the fixing plate, the iron scrap settling mechanism is installed on the rear side of the top of the fixing plate, the iron scrap treatment mechanism is communicated with the iron scrap settling mechanism, the aeration mechanism is communicated with the iron scrap treatment mechanism, and the filtering mechanism is installed on the rear side of the top of the fixing plate and is communicated with the aeration mechanism. The separated waste water is prevented from containing a small amount of scrap iron, insufficient scrap iron treatment is avoided, and the waste water treatment quality is not affected.

Owner:潘冬升

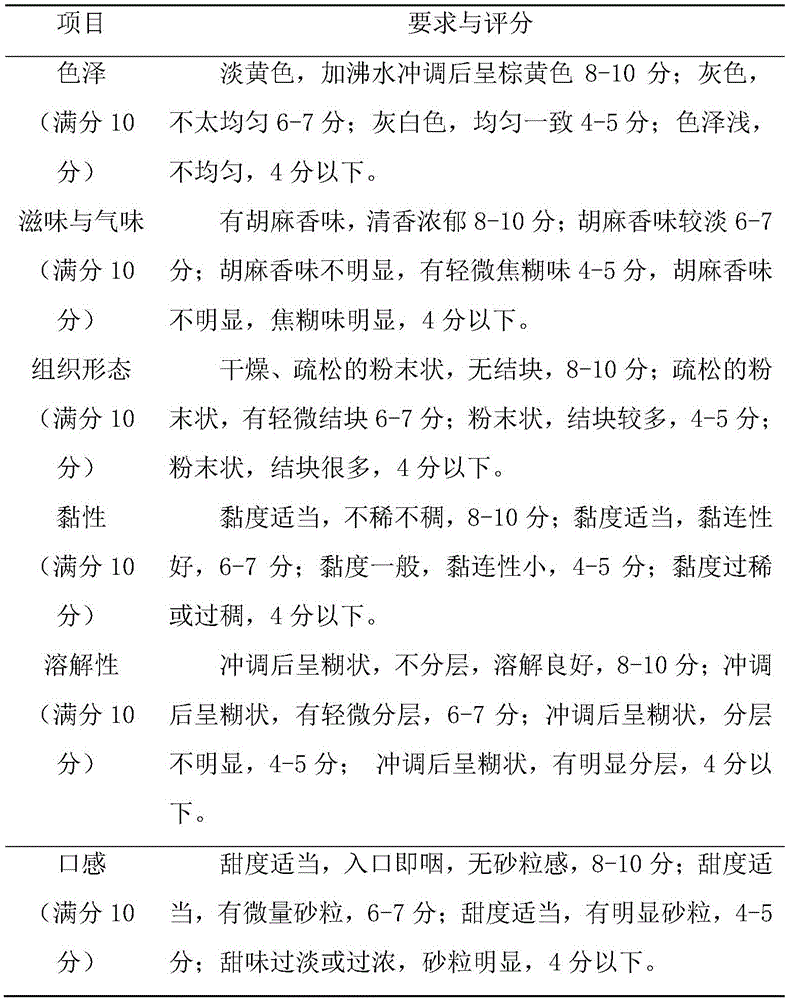

Linum usititatissimum linaceae paste and preparation method thereof

InactiveCN105558986ADoes not affect processing qualityEfficient removalFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentAgaricusFlavor

The invention discloses linum usititatissimum linaceae paste and a preparation method thereof. The linum usititatissimum linaceae paste is prepared from the following components in parts by weight: 10-20 parts of linum usititatissimum linaceae powder, 1-5 parts of red jujubes, 1-5 parts of Chinese wolfberry fruits, 1-5 parts of peanut kernels, 1-5 parts of walnut kernels, 1-4 parts of black beans, 1-4 parts of coix seeds, 15-25 parts of white granulated sugar, 40-55 parts of glutinous rice flour, 10-15 parts of maltodextrin, and 1-5 parts of cortinarius rufo-olivaceus essence. The linum usititatissimum linaceae paste prepared by the preparation method of the linum usititatissimum linaceae paste disclosed by the invention is rich in flavor, rich in nutrition, and good in edible mouth feel, has a long quality guarantee period, and is convenient, safe and hygienic to eat.

Owner:NINGXIA UNIVERSITY

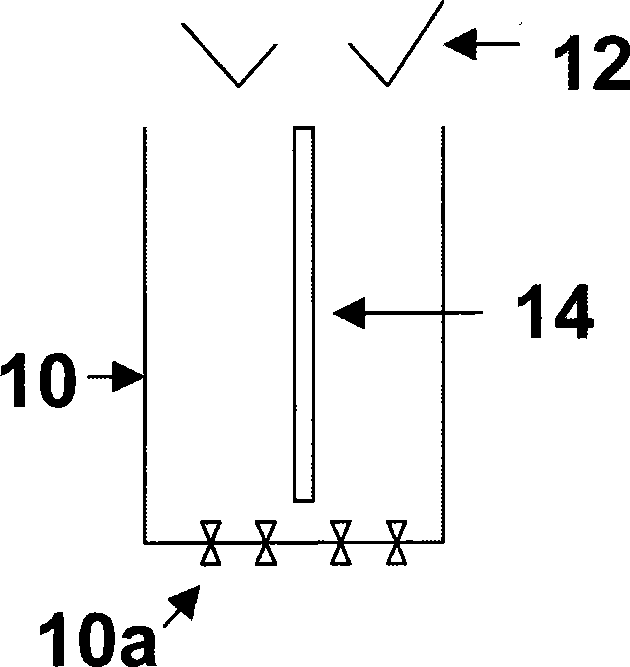

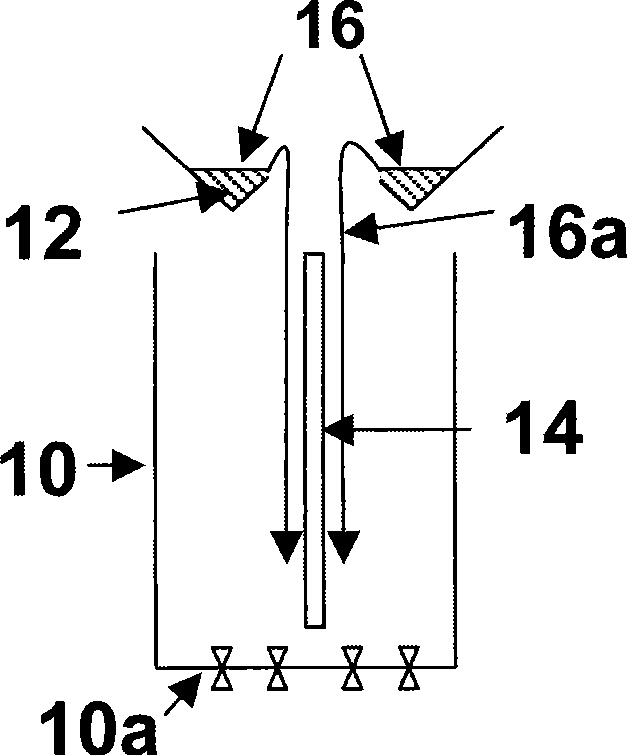

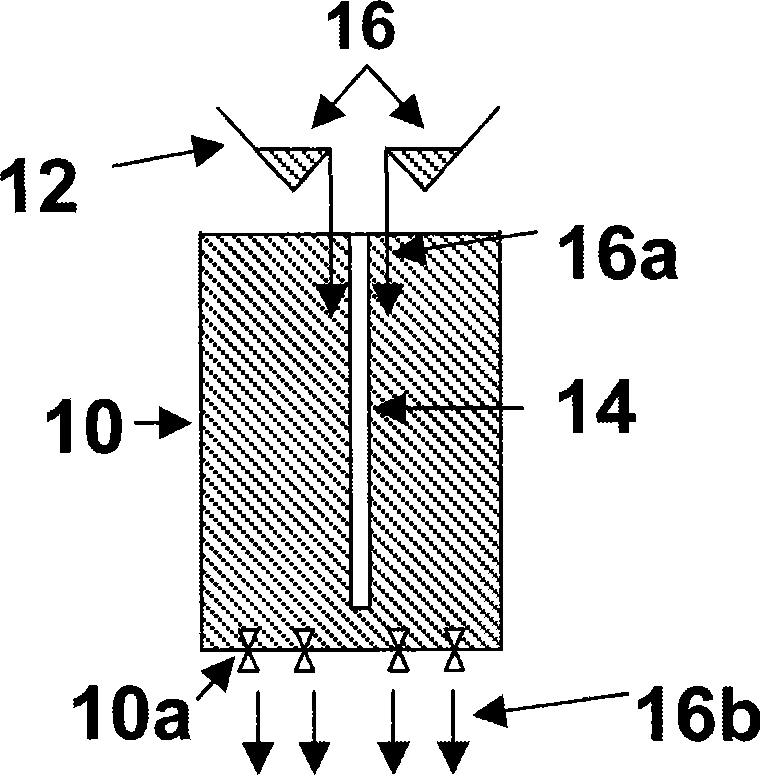

Superficial treatment system for glass

A superficial treatment system for glass mainly comprises a storage tank for soaking glass, a chemical solution releaser for releasing a chemical solution to the storage tank. When the chemical solution of the chemical solution releaser overflows naturally, the chemical solution flows into the storage tank and is excluded from a drain valve so as to use the chemical properties of the chemical solution to treat optical glass immerged in the storage tank, but resultant is not remained in the storage tank.

Owner:PHOTO JET INT

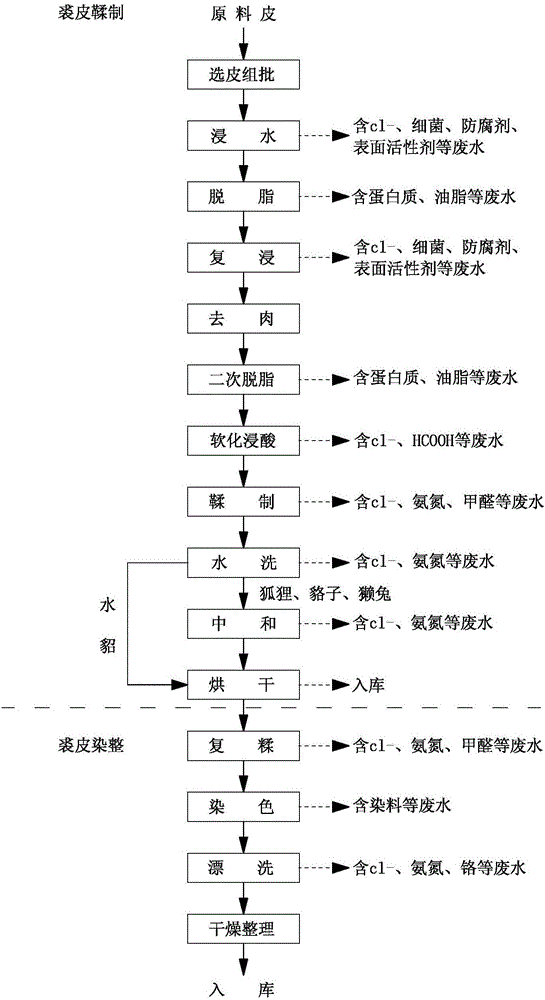

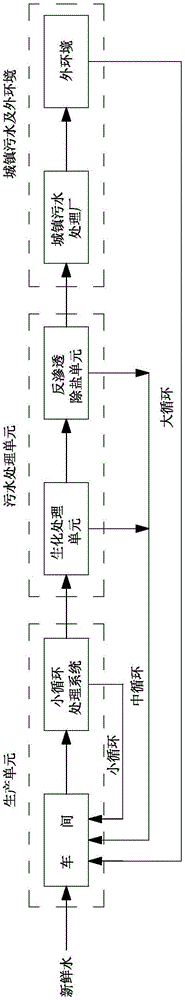

Method for treating and recycling fur tanning and dyeing wastewater

InactiveCN106145530AAchieve recyclingReduce processing difficultyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWater resourcesReclaimed water

The invention relates to the treatment of industrial wastewater and in particular to a method for treating and recycling fur tanning and dyeing wastewater. The method comprises process steps of small circulation, middle circulation, large circulation and the like. The technical problem in the prior art that tanning and fur processing wastewater is difficult to treat so that the wastewater is not prone to recycle is overcome. The method has the advantages that the recycling of water in a fur processing process is realized, the usage amount of materials including salt, chemicals and the like is greatly reduced, the wastewater treatment difficulty is reduced, the wastewater treatment cost is saved, water resources are saved and the like.

Owner:HEBEI PROVINCIAL ENVIRONMENTAL SCI RES +1

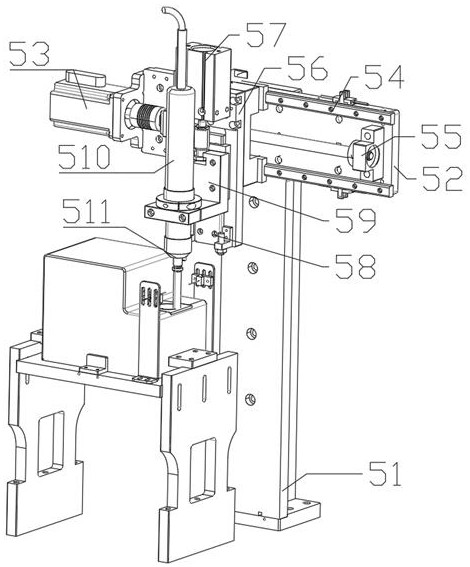

Automatic edge grinding machine for glass-ceramics

PendingCN107738156ARapid responseAccurate responseEdge grinding machinesGrinding carriagesLaser sensorVacuum pump

The invention discloses an automatic edge grinding machine for glass-ceramics. The automatic edge grinding machine comprises a positioning block, a suction cup, a vacuum pump and a machine body, wherein the positioning block is provided with an inclination sensor, and the suction cup is connected with the vacuum pump through an air pipe; the machine body comprises a rack, a workbench, a gantry, guide rails, a slide rail and a main shaft assembly, and the workbench is erected on the rack; the guide rails are arranged at both sides of the rack, and the gantry is positioned above the workbench and is erected on the guide rails; the slide rail is arranged on the gantry, and the main shaft assembly is arranged on the slide rail and comprises a laser two-dimensional sensor. The automatic edge grinding machine for the glass-ceramics provided by the invention has the advantages of accurately positioning the initial horizontal position of a workpiece, rapidly scanning the three-dimensional contours of the initial stage and machining process of the glass workpiece, enhancing the suction and stability of the suction cup through the vacuum pump, and improving the machining precision and effectof the workpiece.

Owner:广东科迪微晶玻璃实业有限公司

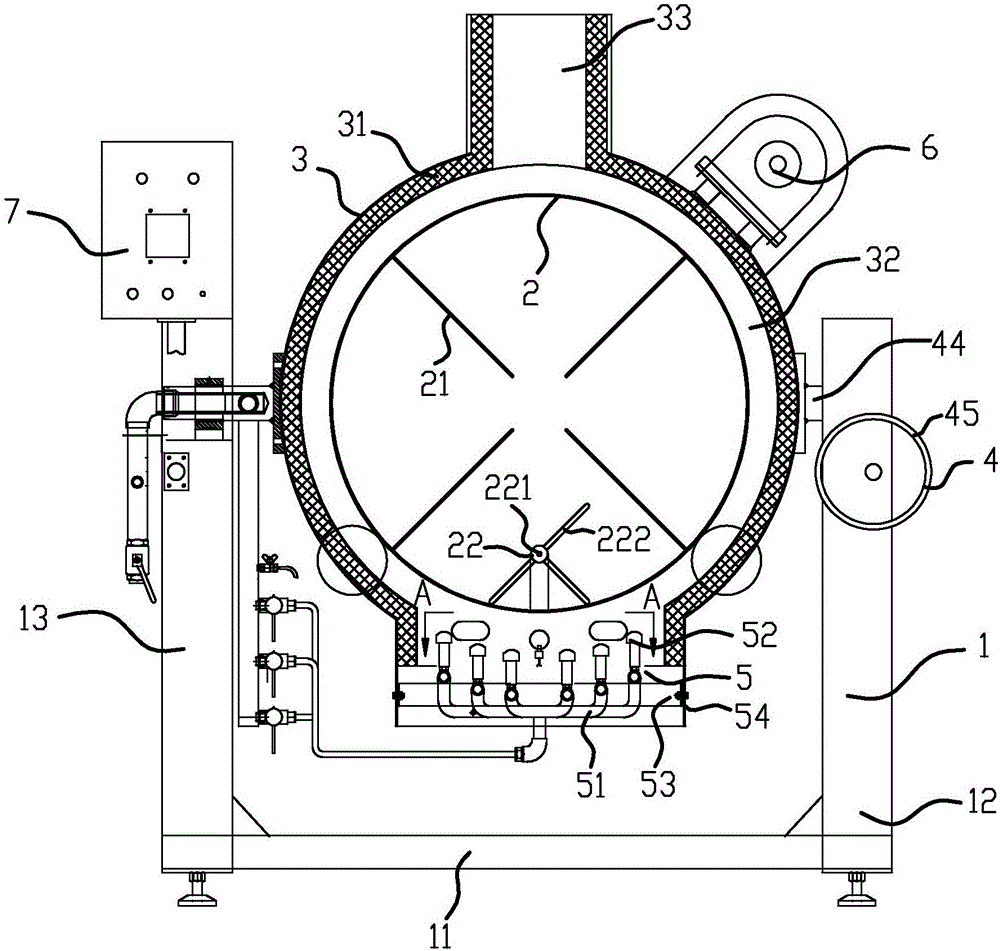

Horizontal-type automatic cooker

ActiveCN105030044ANot easy to run outImprove efficiencyWarming devicesCooking vessel supportBarrel ShapedEngineering

The invention provides a horizontal-type automatic cooker which belongs to the technical field of kitchen appliances and solves the problems that existing cooking devices have small adjustment scopes and a lot of use limitations. The horizontal-type automatic cooker comprises a rack, a pan body, a shell and a rotation device, wherein one side of the rack is equipped with a turnover device; the pan body is bucket-shaped, a stirring rod is firmly connected inside the pan body, and a plurality of turnover ribs are disposed on the inner wall of the pan body; the shell sleeves the outside of the pan body and is hinged and installed on the rack, the turnover device is connected to the shell and can drive the shell to rotate at an angle between 0 DEG and 90 DEG, a fuel gas device is installed on one side of the shell, and the pan body can be heated by the fuel gas device; and the rotation device is installed on the shell and can drive the pan body to rotate along the axis direction. The horizontal-type automatic cooker provided by the invention is advantageous in a large rotation scope and simple operations.

Owner:ZHEJIANG XIANGYING CENT KITCHEN EQUIP CO LTD

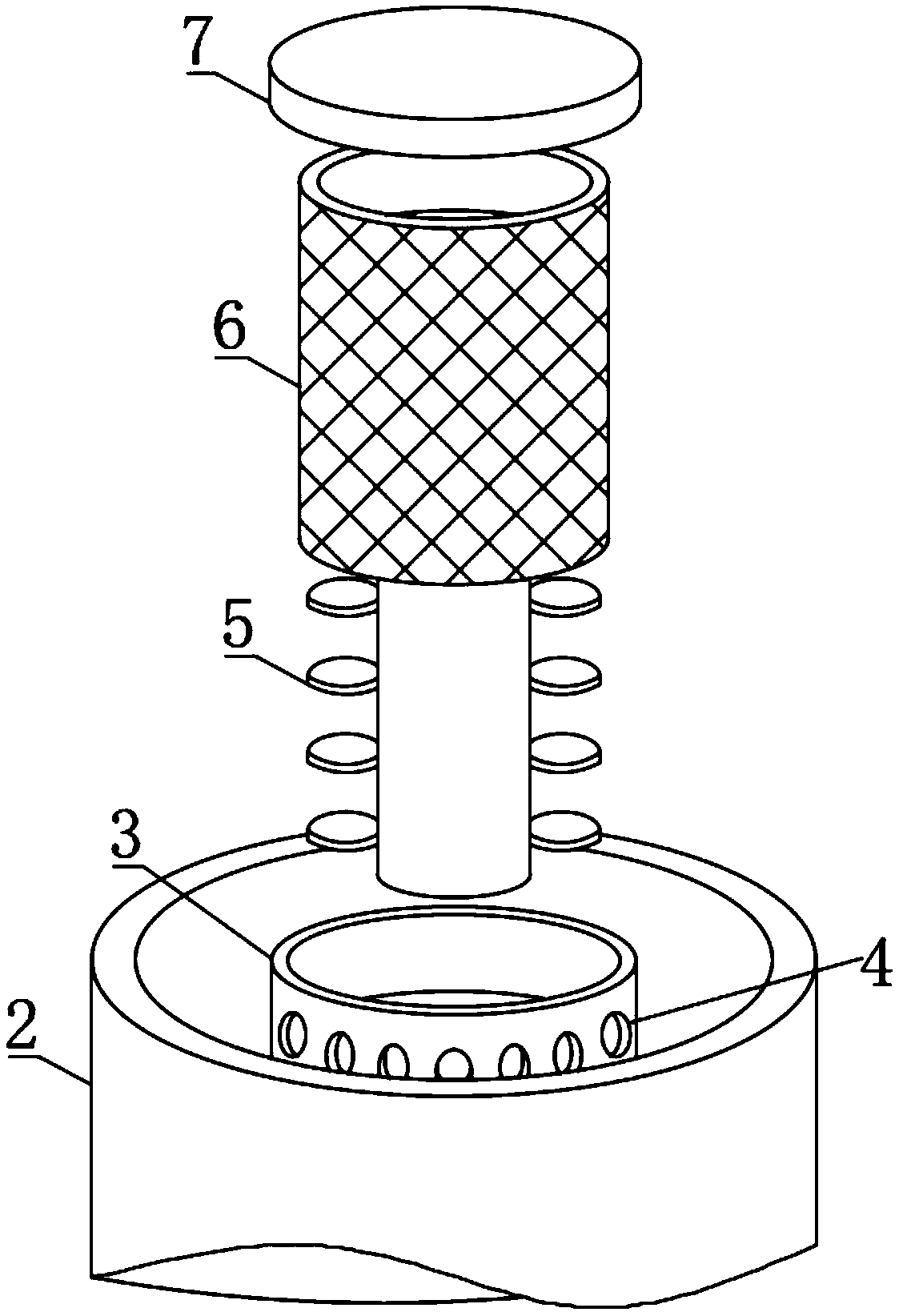

High-quality plastic product ingredient processing equipment

The invention discloses high-quality plastic product ingredient processing equipment, which comprises a processing device body, a feeding hopper, a processing box body and a fixing element, wherein the feeding hopper, the processing box body and the fixing element are arranged on the processing device body; the surface of the processing device body is fixedly connected with the feeding hopper; a sealed top plate is fixedly connected ontowith the surface of a filter net tube; the sealing top plate is screwed and connected ontowith the surface of a ventilation plate; a plurality of groups of buffer plates are fixedly connected ontowith the inner wall of the processing box body; an engaging groove is arranged inside an inner screen net tube and the rotating rod; rotating rods are engaged andconnected insidewith the interior of the tow groups of hinging grooves; a rotating sleeve is fixedly connected insidewith the interior of the connecting sleeve; the rotating rod is rotationally connected with the interior ofinside the rotating sleeve; the inner screen net tube and the rotating rod are clamped and connected; the rotating rod is rotationally connected with the insideinterior of a re-rotation sleeve; through the rotation on the rotating rod, the size of the screen hole can be changed; the replacement of different screen nets is not needed; the time is saved and the labor are savedis reduced; the use cost is reduced; the work efficiency is improved; the equipment is suitable for being popularized.

Owner:新昌县明拓机械有限公司

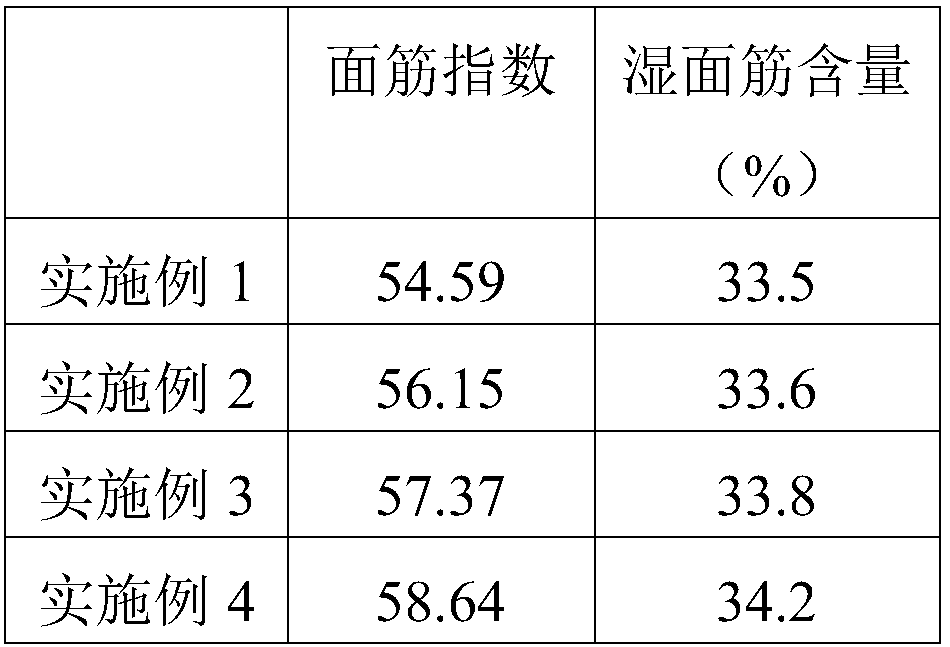

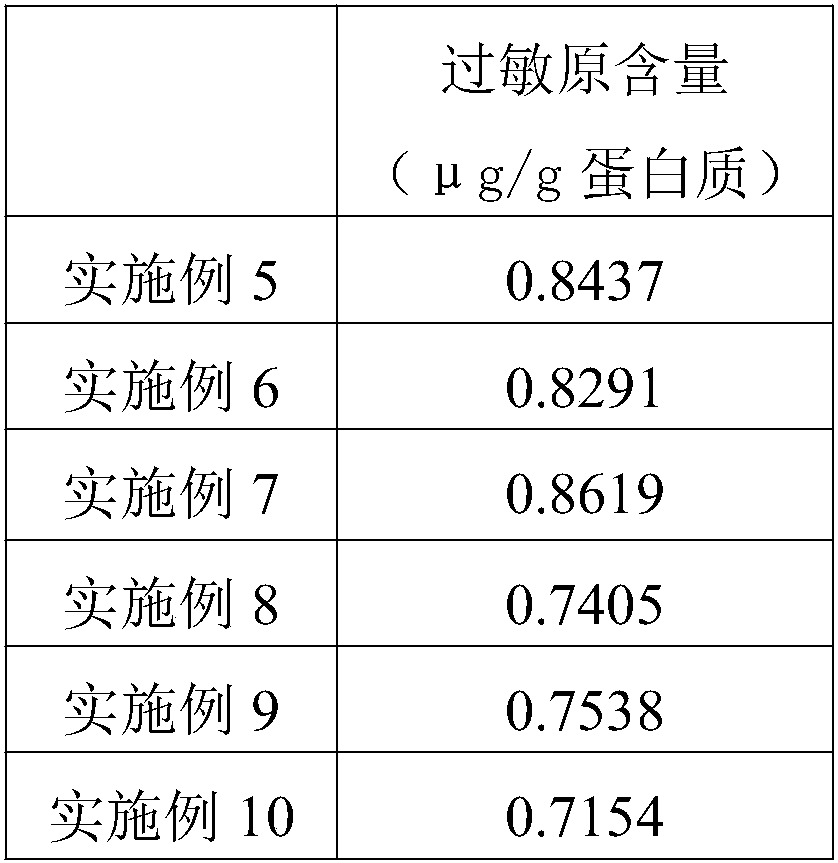

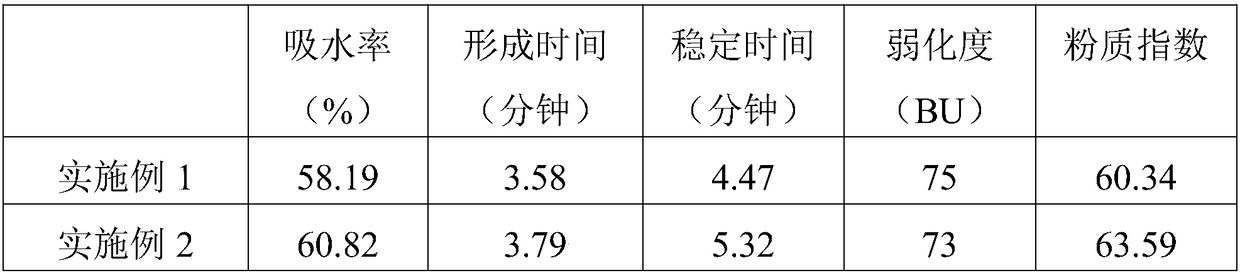

Nutritional low-sensitivity wheat flour

PendingCN108077728AHigh in nutrientsDoes not affect processing qualityNatural extract food ingredientsFood dryingBiotechnologyWheat germ

The invention discloses nutritional low-sensitivity wheat flour. The nutritional low-sensitivity wheat flour includes wheat flour, wheat germ powder and an anti-aging agent. According to the nutritional low-sensitivity wheat flour, allergens are removed from the wheat flour and the content of nutrients in the wheat flour is increased without affecting the processing quality of the wheat flour, sothat the nutritional low-sensitivity wheat flour with high nutrient content and rich trace elements is obtained.

Owner:何志方

Low-loss alternate sander

InactiveCN111604741AGuaranteed grinding effectGood grinding effectEdge grinding machinesDispersed particle filtrationGrindingFriction loss

The invention discloses a low-loss alternate sander. The low-loss alternate sander comprises a machining table, a transmission frame and a power table are fixed to the upper end of the machining table, a mounting groove is formed in the side wall of the transmission frame, a sun gear is rotationally connected with the center of the mounting groove, a gear ring is fixed to the side wall of the mounting groove, the gear ring and the sun gear are jointly engaged with a plurality of planetary gears, a guide groove is formed in the inner wall of the mounting groove, and a rotating rod in sliding connection with the inner wall of the guide groove is fixed to the side wall of each planetary gear. The low-loss alternate sander has the advantages that grinding rods synchronously move along with theplanetary gear train formed by combining the sun gear, the planetary gears and the gear ring, so that the positions of the grinding rods are continuously exchanged through slow revolution while the grinding rods rotate at a high speed for machining, the bottom machining position does not make contact with the same grinding rod for a long time, and therefore, the abrasive paper on each polishing rod cannot be subjected to centralized friction loss in a short time.

Owner:杨二春

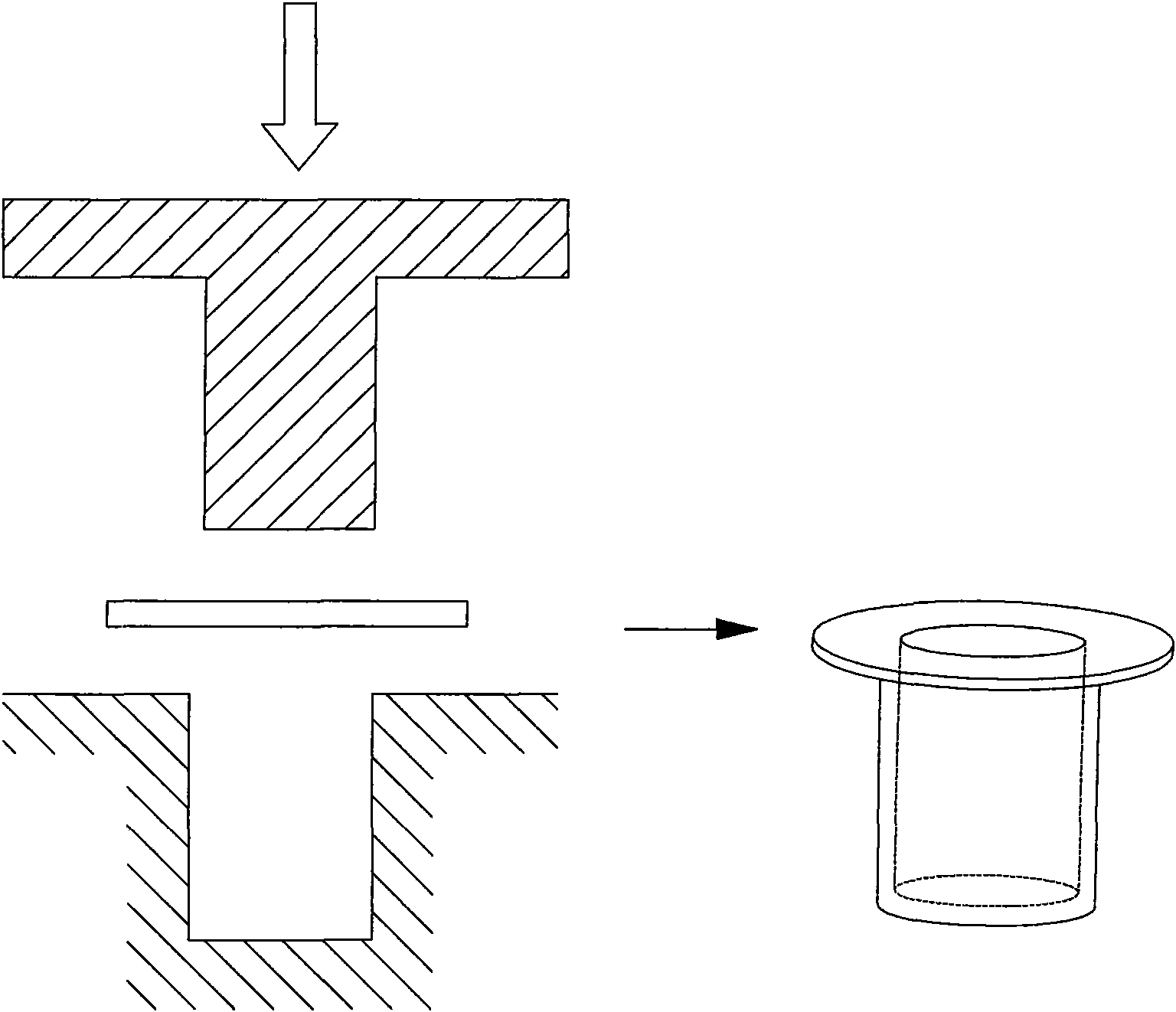

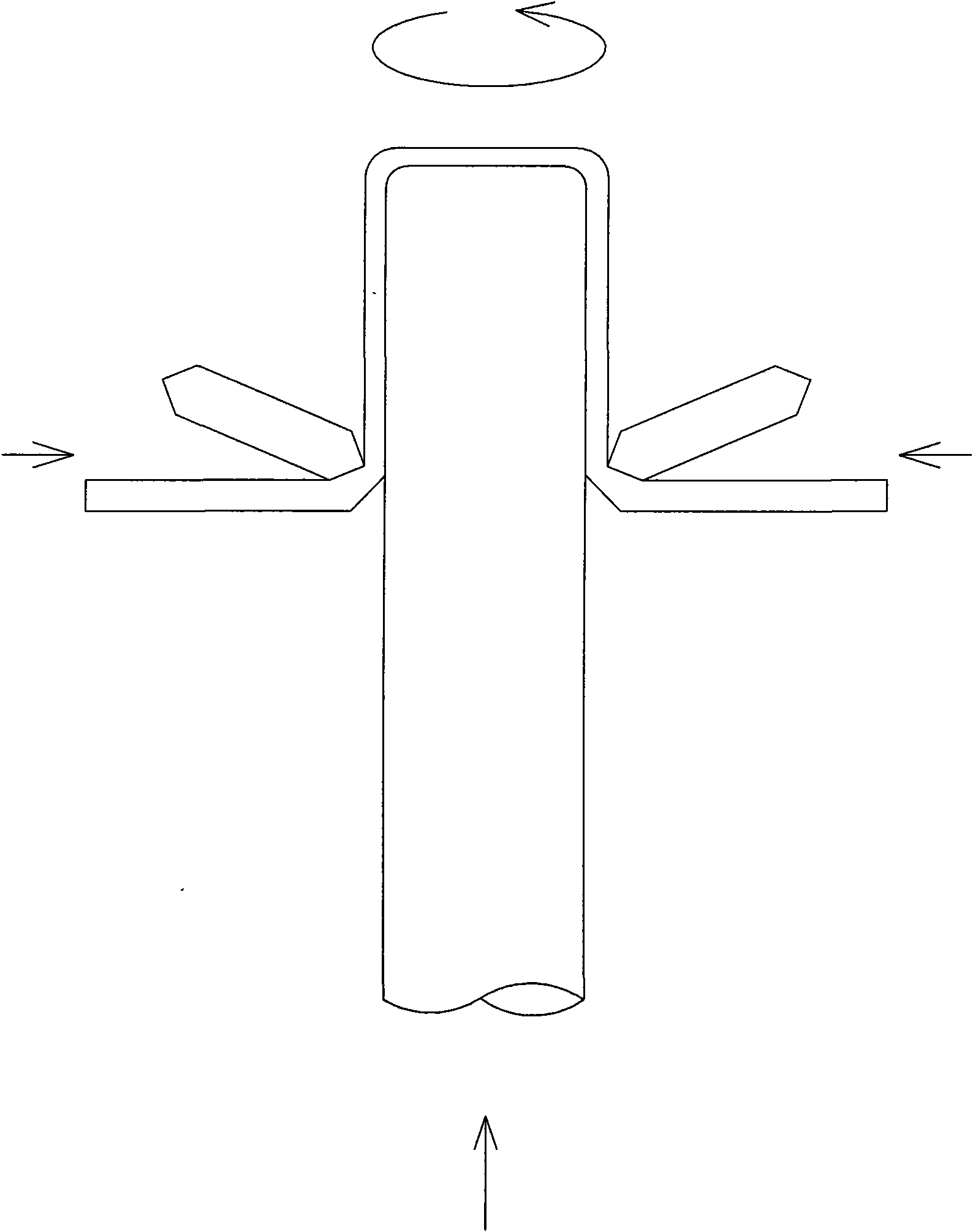

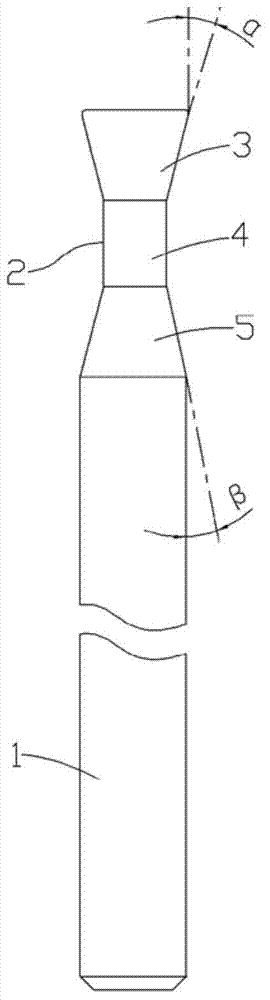

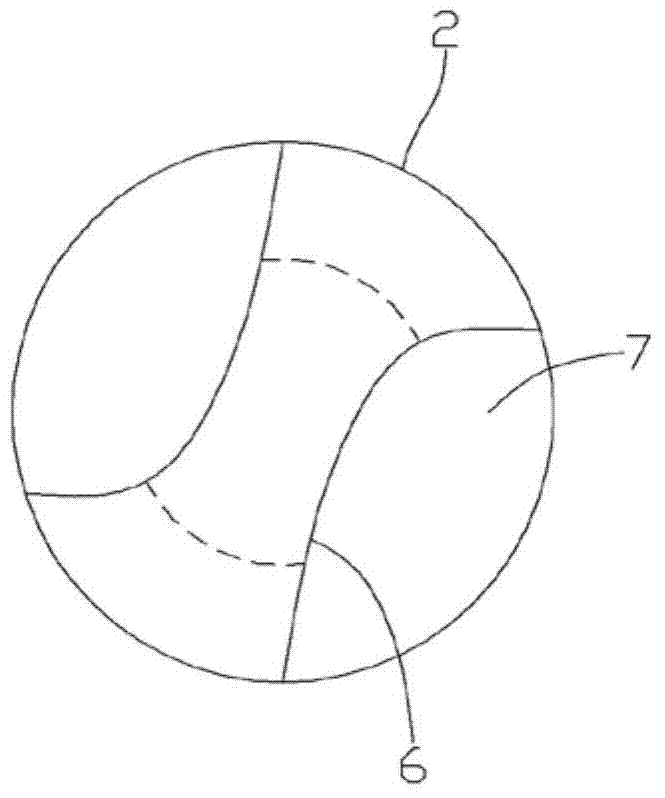

Vertical stripping processing technology for manufacturing seamless thin wall pipe

InactiveCN101559435ADoes not affect processing qualityMetal rolling arrangementsWork in processEngineering

The invention discloses a vertical stripping processing technology for manufacturing a seamless thin wall pipe, comprising the following steps: a. a machine tool with a perpendicular mold core column is prepared to be arranged; b. a thin wall plate is paved on the top of the mold core column; and c. through a perpendicular relative movement between a stripping roller and the mold core column, the thin wall plate is stripped. Three stripping rollers are provided, which are averagely distributed according to the circumference of the mold core column. In the process of stripping, the mold core column drives the thin wall plate continuously to turn; and the turning direction at every time is opposite to the rotation direction in the process of stripping at a former time. Cooling liquid is continuously splashed in the process of stripping. After the process of stripping, the manufactured thin wall pipe is processed by means of annealing and distressing. The mold core column is perpendicularly positioned instead of being transversely positioned previously; the thin wall plate is not needed to be processed into cap-shaped semi-finished products but directly into the desired thin wall pipe at one time; and the processing quality of the thin wall pipe can not be influenced by the function of the gravity.

Owner:刘江

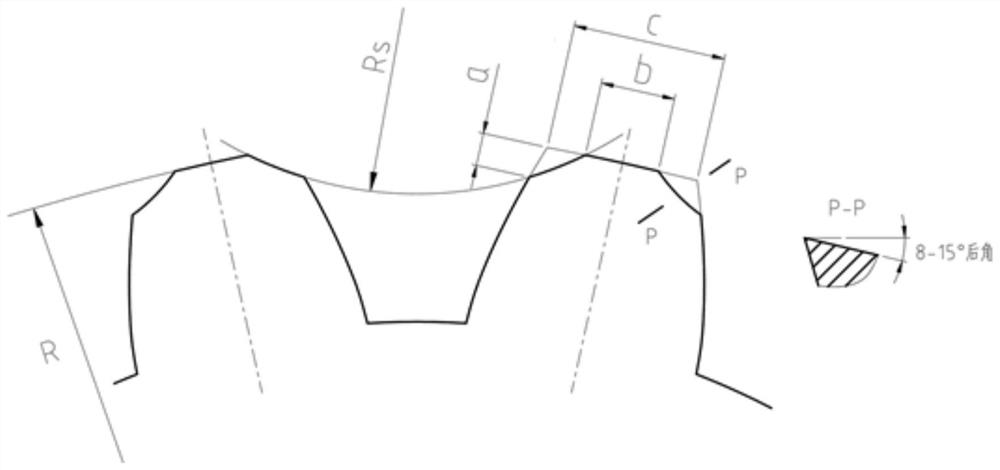

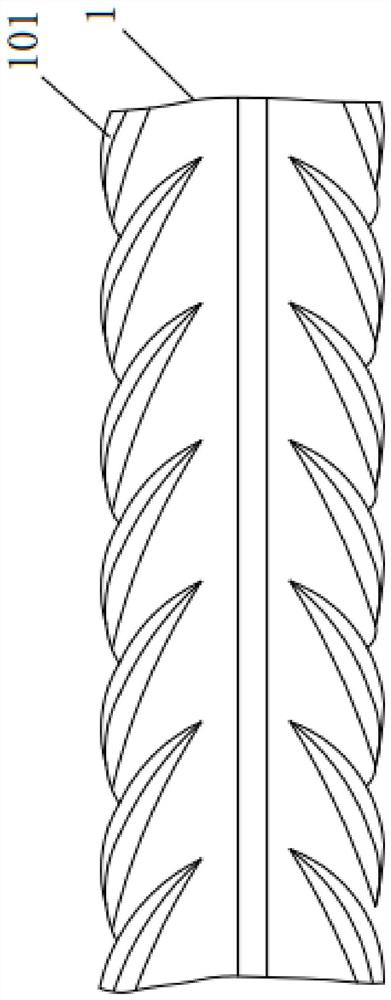

PC (Poly carbonate) milling cutter for plastics

The invention discloses a PC (Poly carbonate) milling cutter for plastics. The PC milling cutter comprises a cutter handle, wherein a cutter bit is formed on the cutter handle and is composed of a dovetail-groove-shaped cutting edge connecting part, a second vertical cutting edge part and a first inverted-dovetail-groove-shaped cutting edge part; the cutting edge connecting part is formed on the cutter handle, two ends of the second cutting edge part are connected on the cutting edge connecting part and the first cutting edge part respectively, two axe-shaped straight-tooth-shaped cutter teeth are formed on the top end surface of the first cutting edge part, a chip trough is formed between the adjacent cutter teeth, and the cutter teeth run through the first cutting edge part and the second cutting edge part. According to the PC milling cutter, the side edge of the milling cutter for cutting plastics is manufactured into an inwardly inclined shape, the surface area of the chip trough is reduced, and the tooth shape is manufactured into the axe shape, so that the large chip trough is formed, plastic cuttings can be discharged conveniently, and the cuttings cannot influence the processing quality while the milling cutter works.

Owner:SUZHOU WANYI KNIFE IND

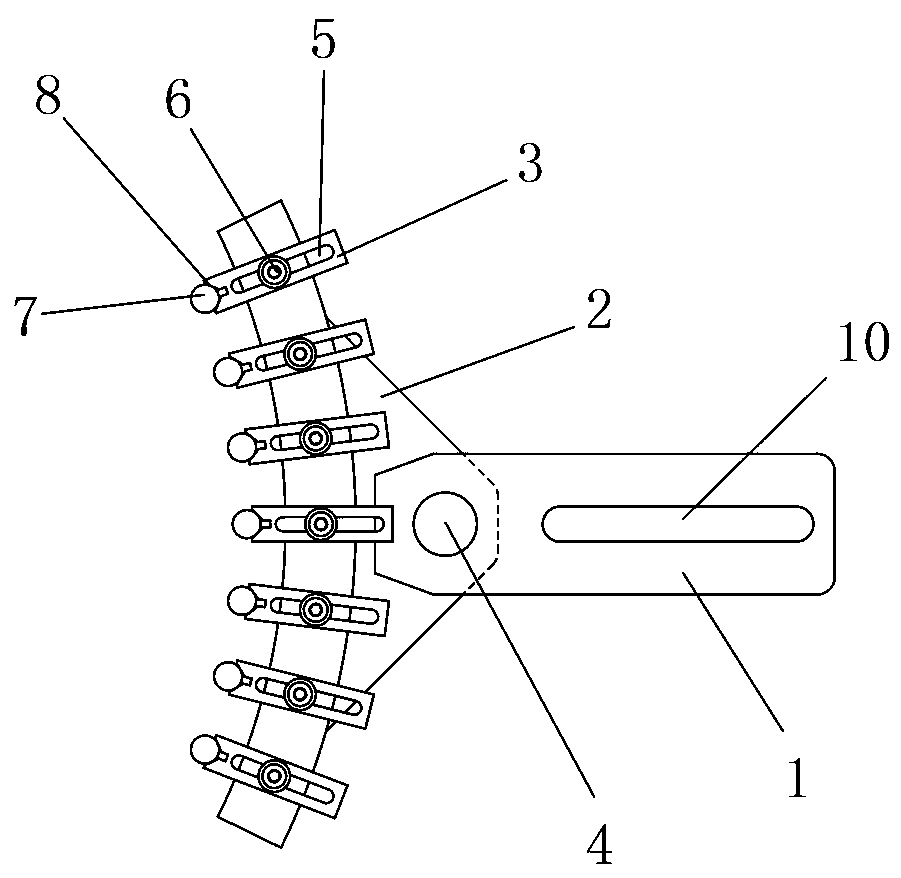

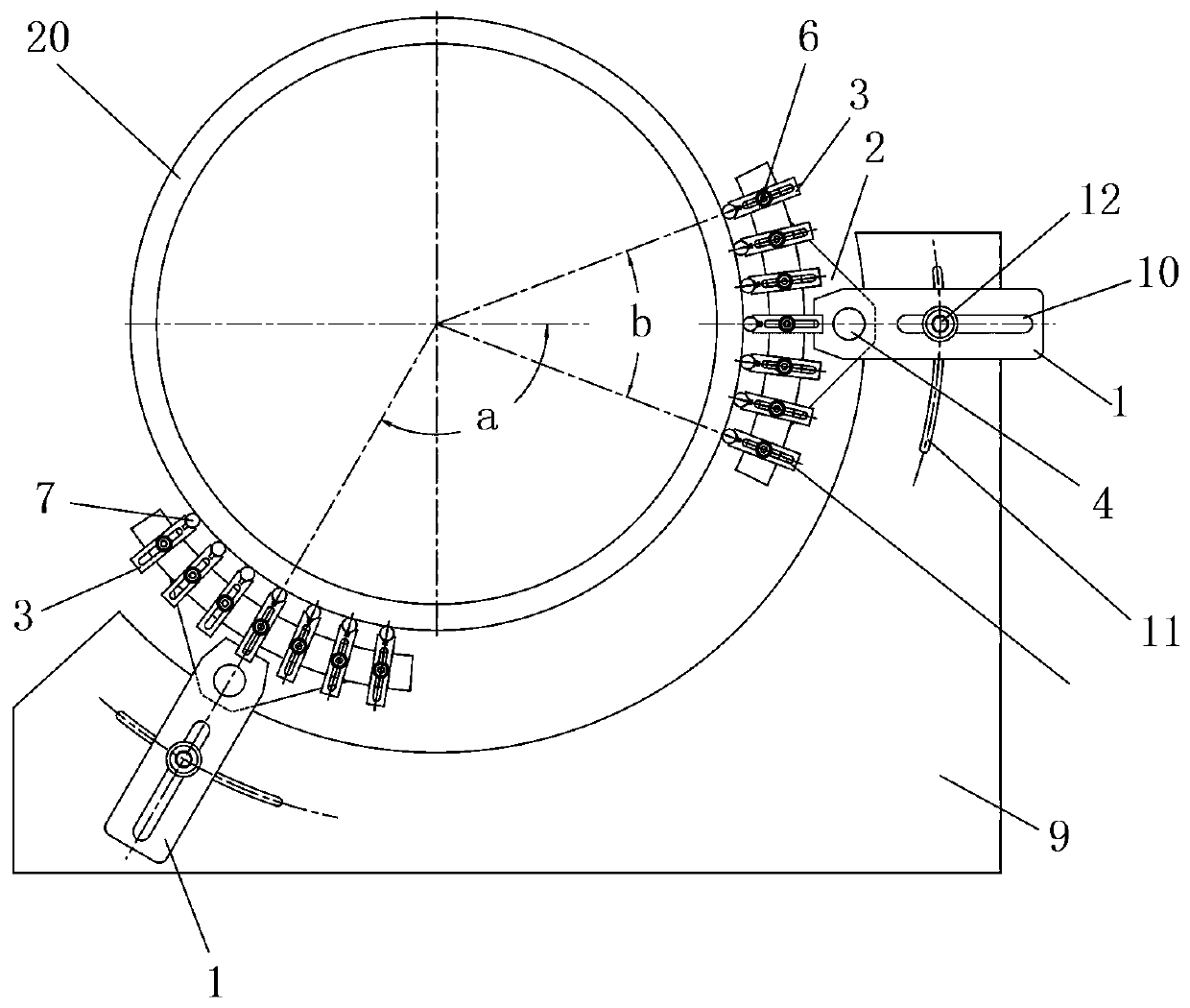

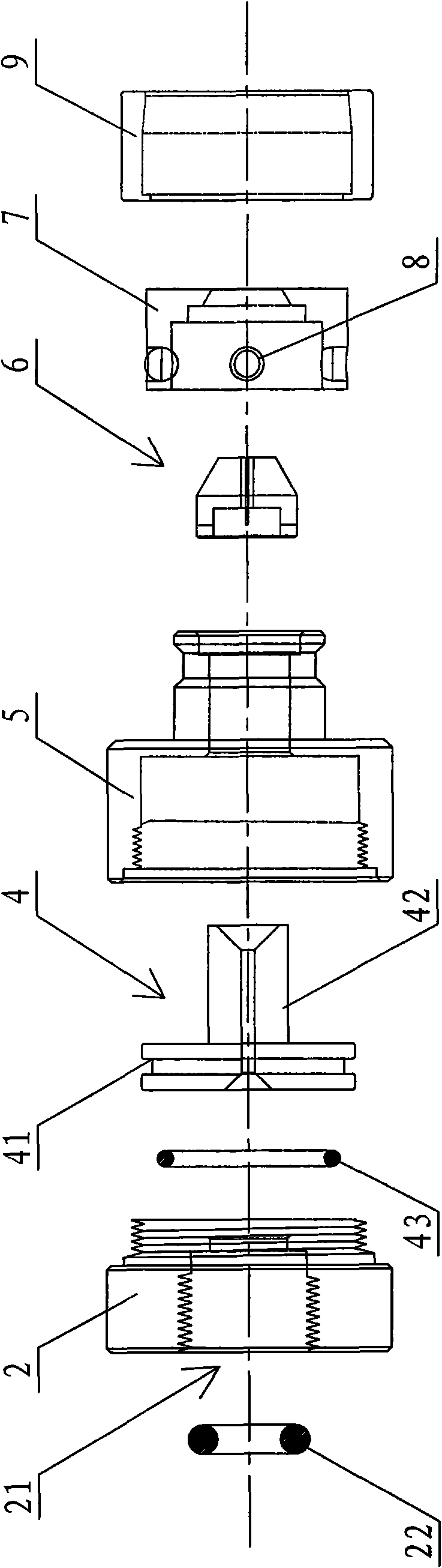

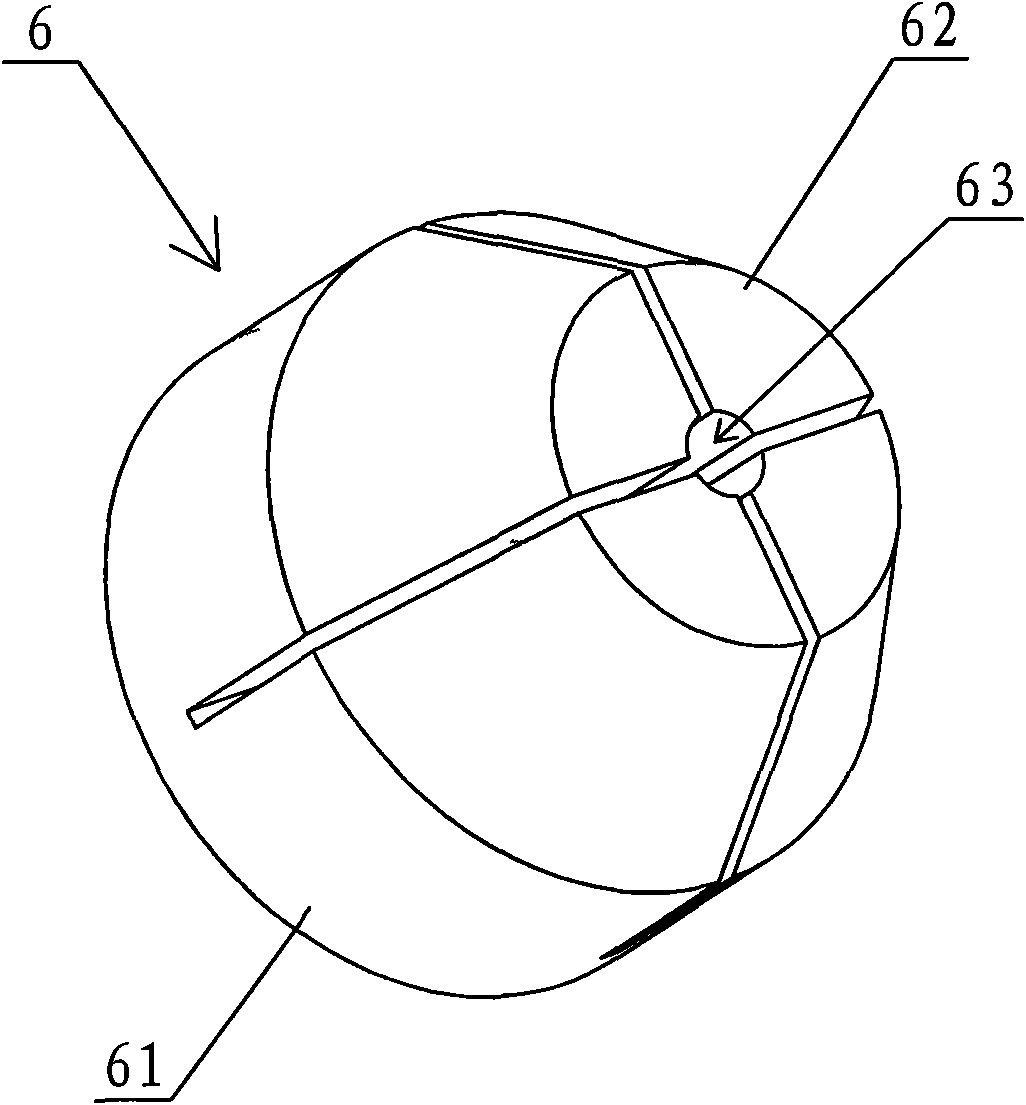

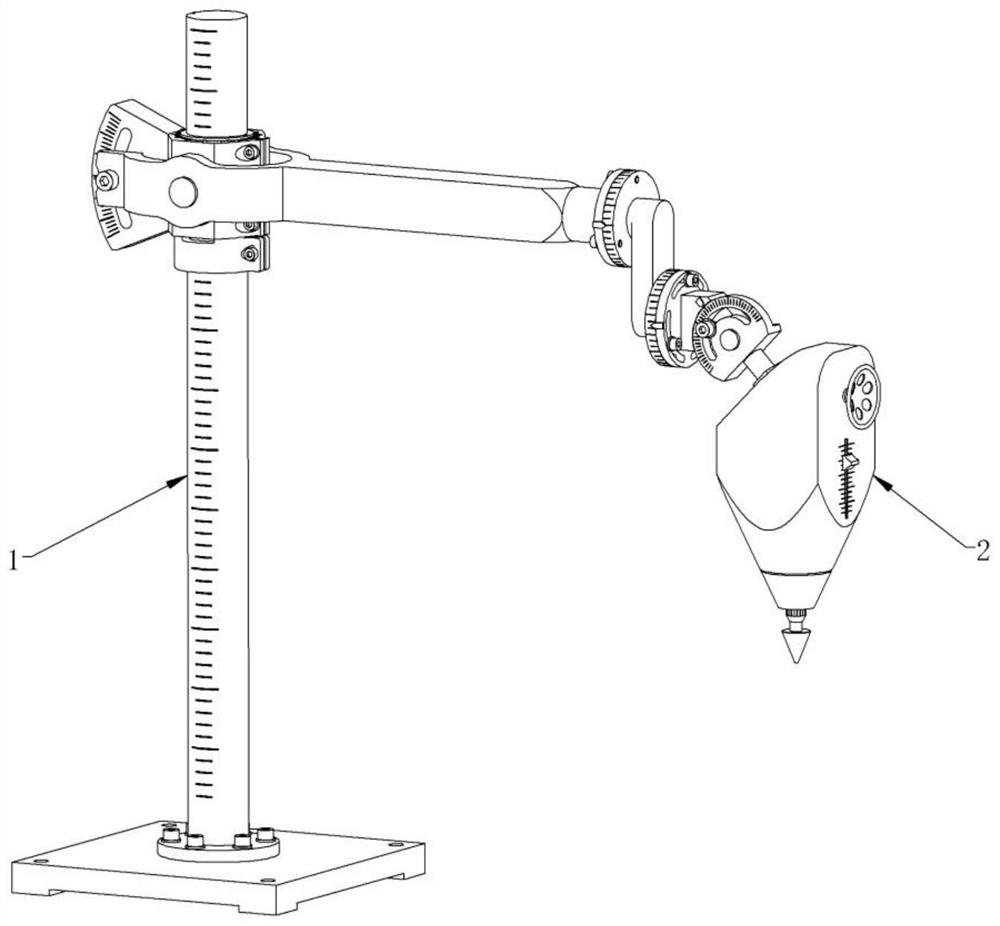

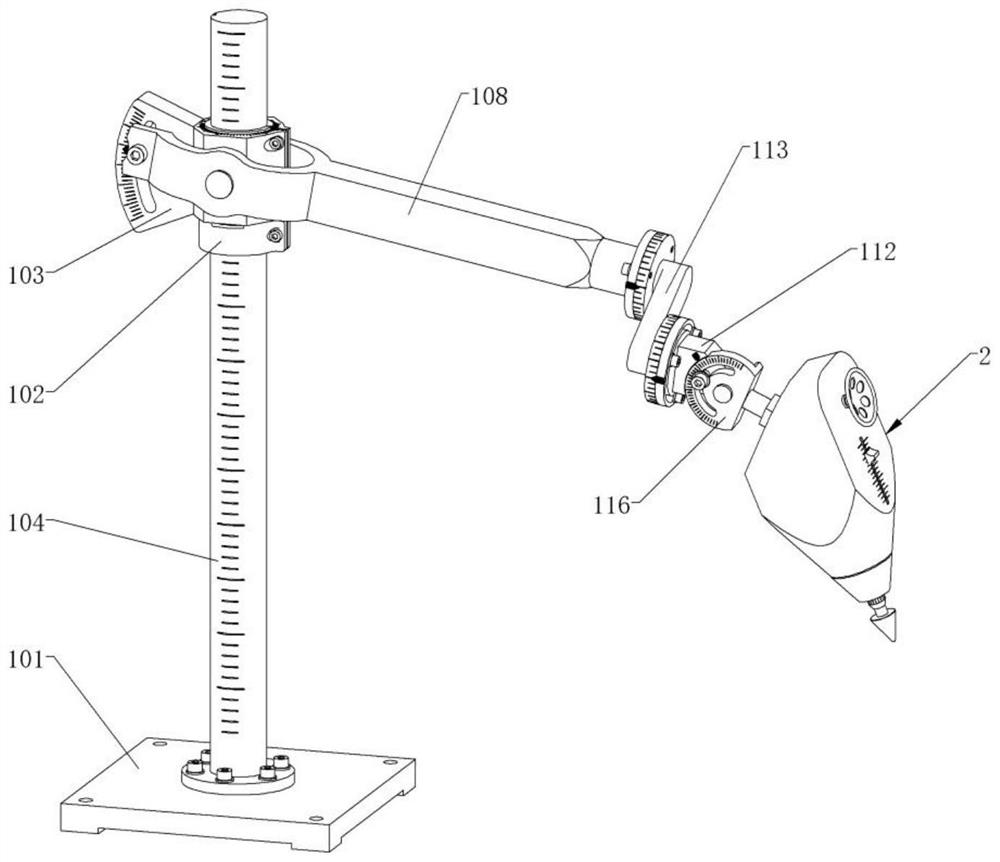

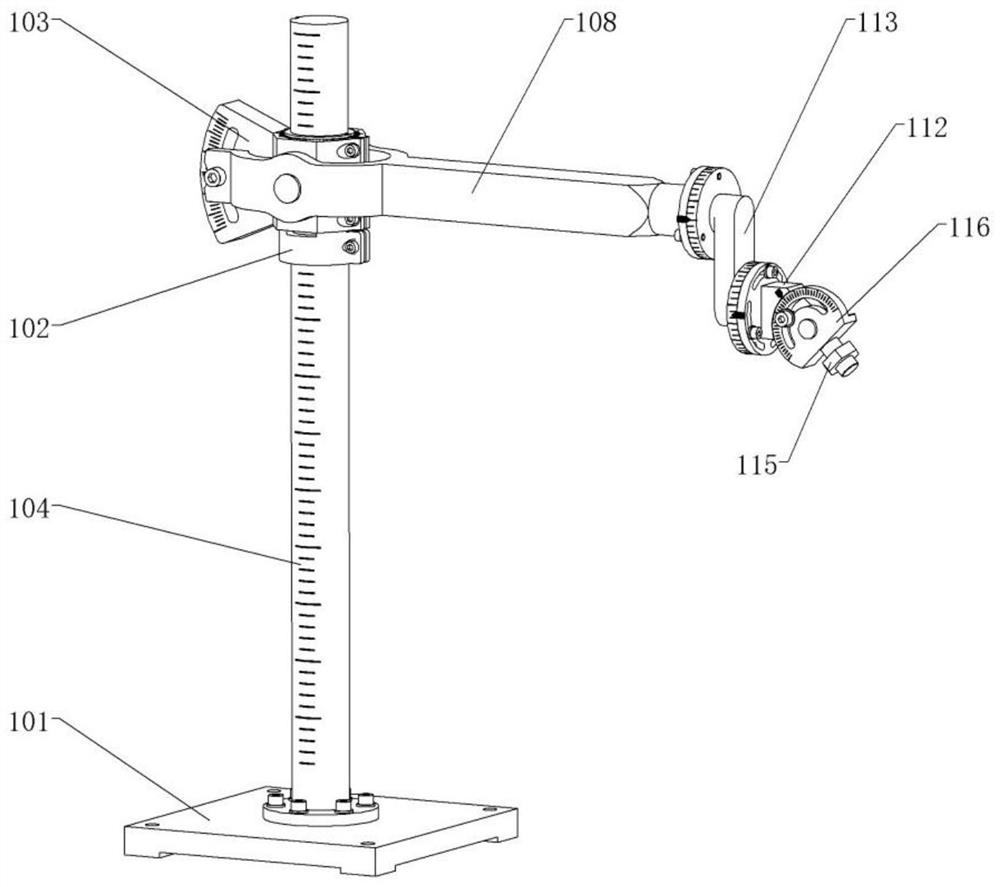

Multi-contact-point floatable electromagnetic centerless fixture support

The invention discloses a multi-contact-point floatable electromagnetic centerless fixture support. The multi-contact-point floatable electromagnetic centerless fixture support comprises a supportingbody, a support frame and a plurality of support heads; the support frame is rotatably fixed to the supporting body, the plurality of support heads are arranged on the support frame in a circular-arcmode, and the support heads and the support frame are slidably connected in the diameter direction of a circular arc; and hard round rods are arranged at the front ends of the support heads, and the axes of the hard round rods are perpendicular to the axes of the support heads.

Owner:上海特安一凯轴承有限公司

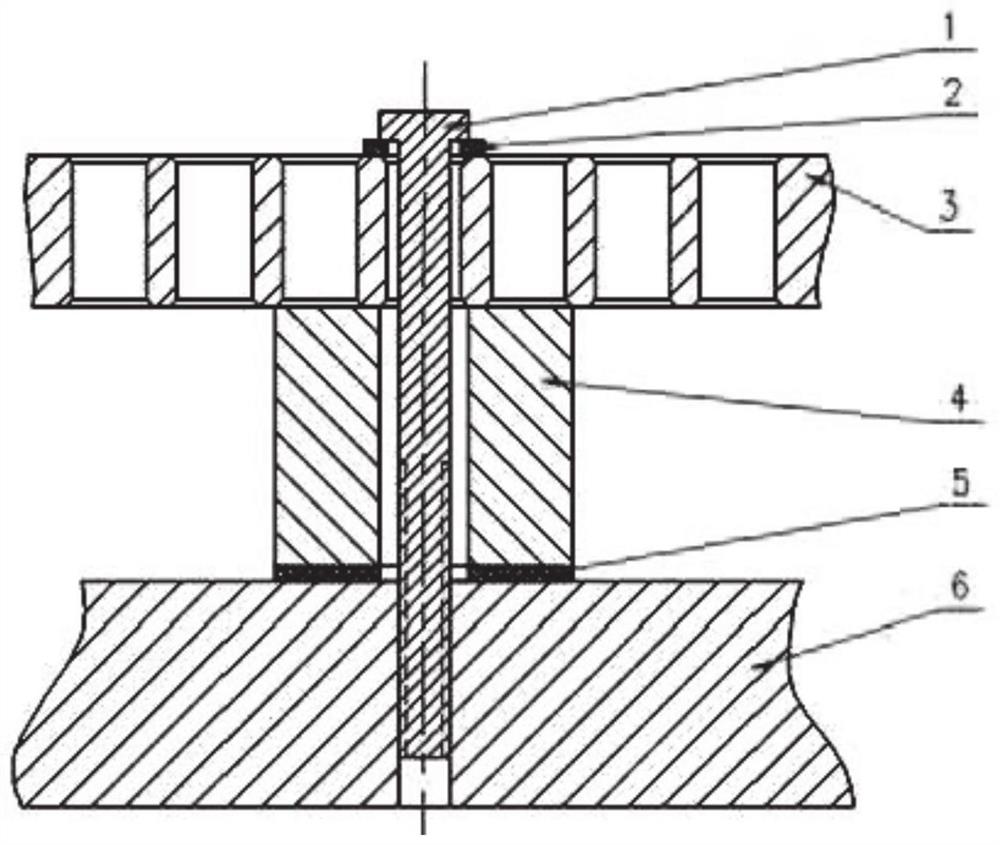

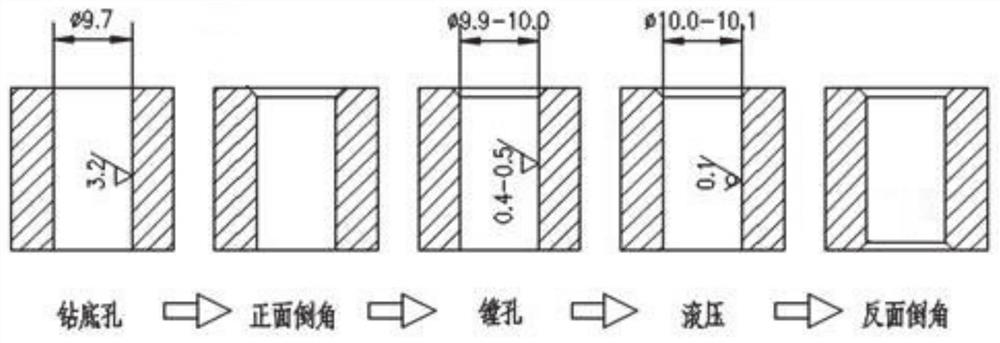

Machining process for improving roughness of inner hole of porous plate of chemical equipment

The invention belongs to the technical field of chemical equipment, and particularly relates to a machining process for improving the roughness of an inner hole of a porous plate of chemical equipment. The machining process aims to solve the problems that the porous plate deforms during machining and the smoothness of the inner hole is low. The machining process comprises the steps of adopting a positioning tool for fixing, and then machining the inner hole through a complete machining process of drilling, chamfering, boring and mirror surface rolling of an inner cooling drill bit so as to meet the requirement that the smoothness of the inner hole is Ra0.1. According to the machining process, the roughness of the inner hole of the porous plate can be improved, the roughness of the inner hole can be Ra0.1, and the circulation of viscous materials passing through the hole can be guaranteed; and the porous plate is not prone to deformation, and the machining quality is not affected.

Owner:LUXI IND EQUIP

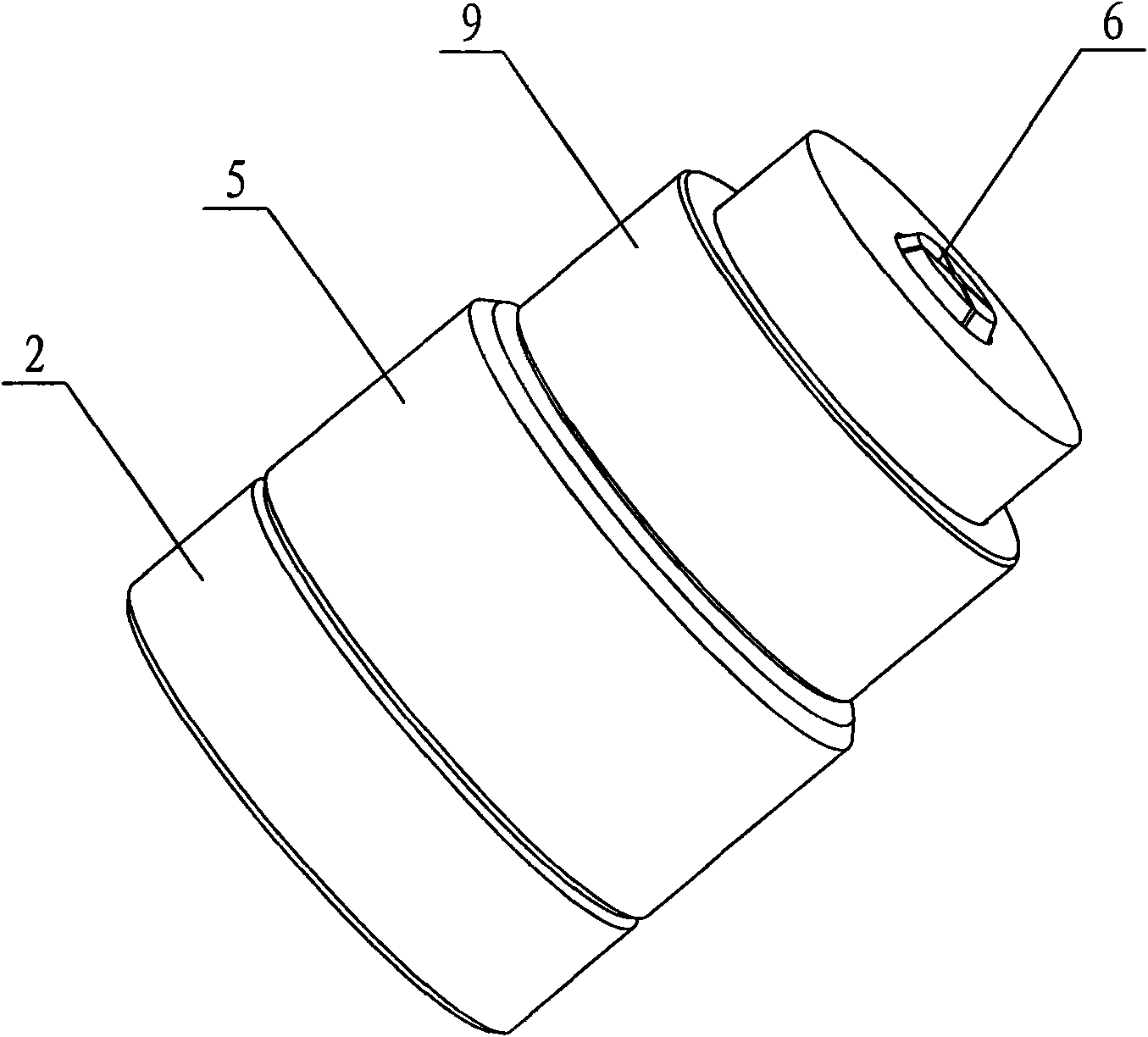

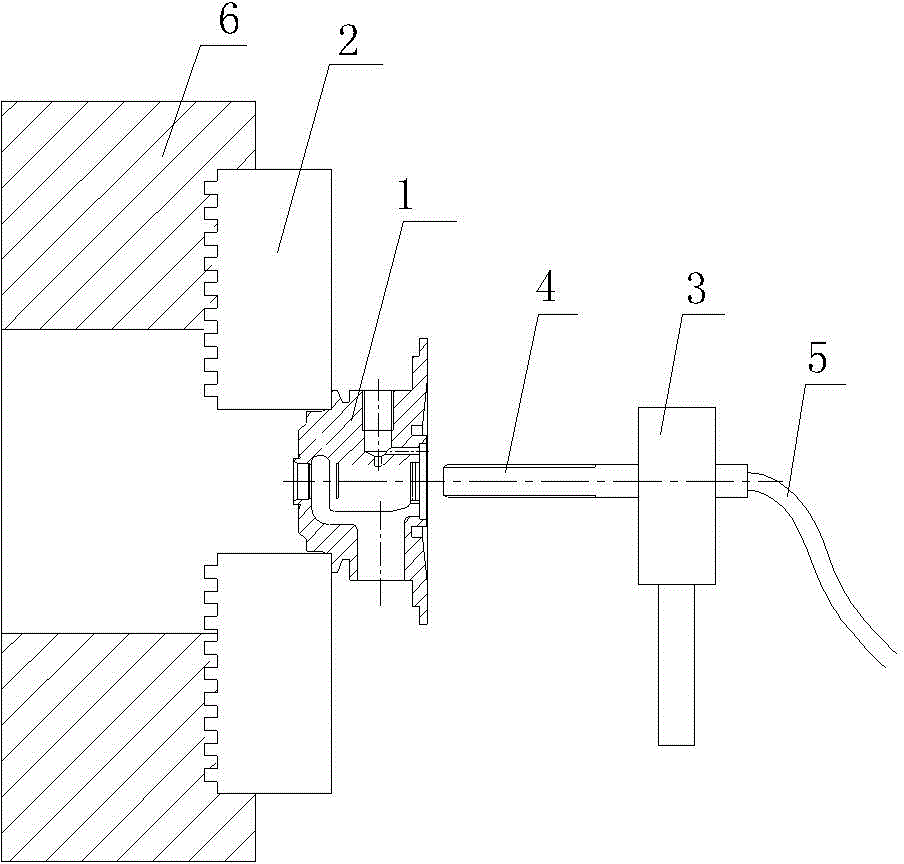

Water pressure nozzle-converging chuck

The invention relates to the electric spark punching field, and discloses a water pressure nozzle-converging chuck which comprises a piston and a piston cylinder sleeve, the piston cylinder sleeve is externally covered closely on the outer edge of the piston, the water-compressing nozzle-converging chuck also comprises a connector, an elastic converging nozzle and a converging nozzle sleeve through high pressure water, the piston base of the piston is connected with the connector, an oil cylinder structure is formed by the connector, the piston and the piston cylinder sleeve, the elastic converging nozzle comprises a converging nozzle base and is connected on the head part of a piston rod of the piston through the converging nozzle base which is provided with a plurality of elastic converging nozzle petals, a cone with a through-hole in the center is formed by the plurality of the converging nozzle petals, a converging nozzle is externally covered on the outer edge of the elastic converging nozzle and is closely matched with the elastic converging nozzle. The invention utilizes a high pressure water to clamp a copper tube, can be used conveniently, and has no adverse effect on the processing quality and the copper tube.

Owner:湖北可腾机械有限公司

Clamping claw structure of fixing intermediate body

InactiveCN103100761BGuaranteed stabilityDoes not affect processing qualityReaming devicesMechanical engineeringEngineering

The invention provides a clamping claw structure of a fixing intermediate body. The clamping claw structure of the fixing intermediate body is capable of solving problems in the prior art, and guaranteeing processing quality of holes of the intermediate body. The clamping claw structure of the fixing intermediate body comprises a quilting grinding tool and a clamping claw, a clamping plate is arranged at an claw end of the clamping claw, the inner side wall face of the clamping claw and the edge of the bottom of the intermediate body are matched with each other in a clamping mode, and the clamping claw structure of the fixing intermediate body is characterized in that an enveloping table is further arranged on the inner side edge of the clamping claw, and the inner wall face of the enveloping table wraps up the outer edge face of the intermediate body.

Owner:WUXI MINGZHU TURBOCHARGER MFG

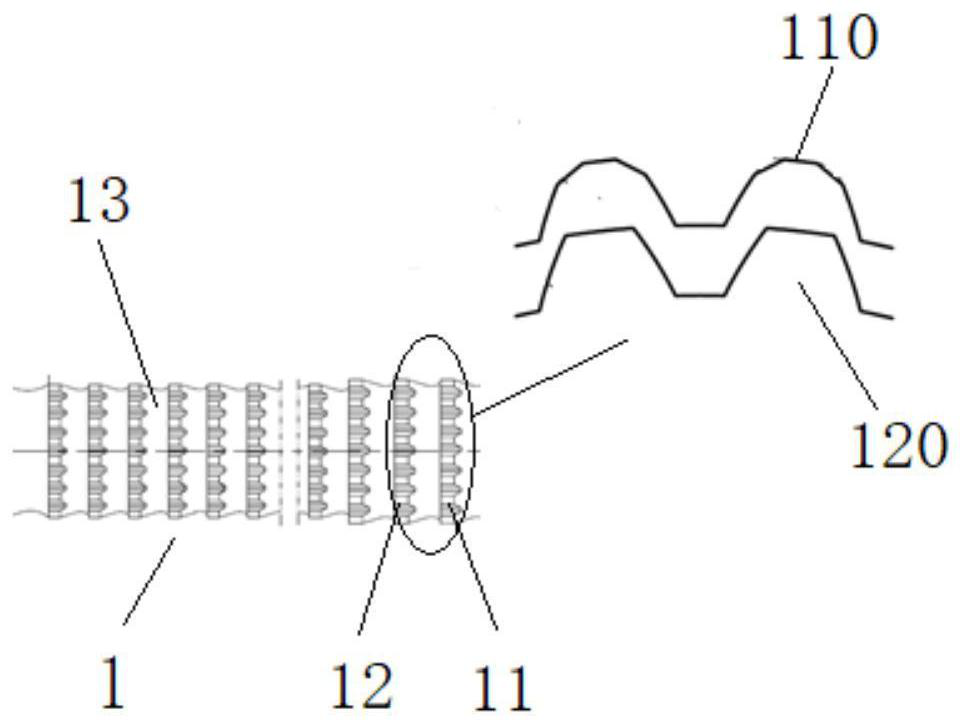

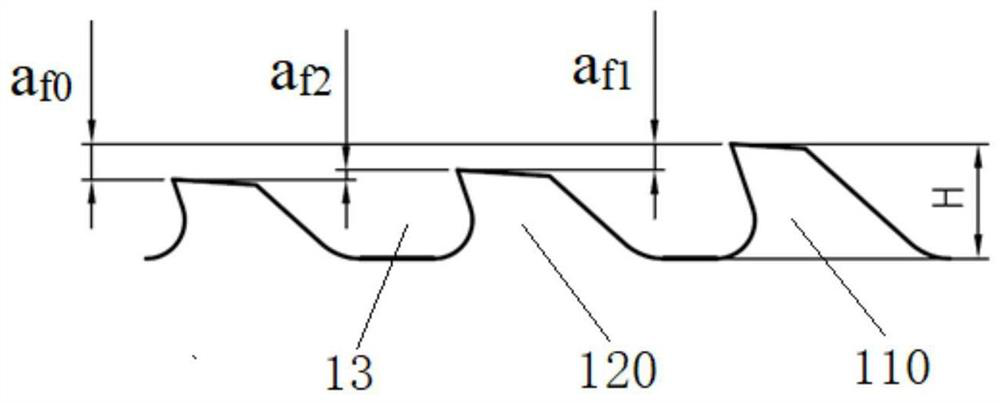

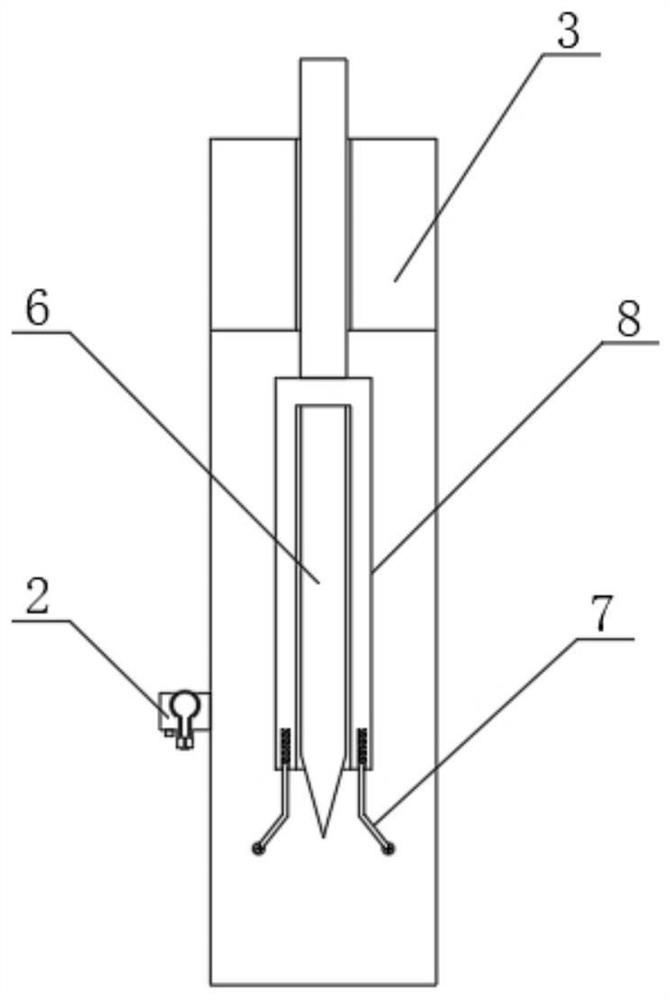

A rough and fine drawing structure spline broach and its design method

ActiveCN111633283BIncrease the number of single processingIncrease the frequency of sharpeningBroaching toolsGear teeth manufacturing toolsEngineeringBroaching

The invention discloses a rough and fine drawing structure spline broach and a design method thereof. The disclosed broach includes a spline cutting tooth, and the spline cutting tooth includes a plurality of concentrically arranged knife tooth rings along the cutting direction, two adjacent knife tooth rings form a group of knife tooth rings, and each group of knife tooth rings consists of a The rough broaching tooth ring and a finishing broaching tooth ring are composed of a rough broaching tooth top with concave fillets on both sides; The amount of lift is the same, and the tooth lift of each group of cutter rings is the same, and the tooth lift of the fine-drawn teeth of the same group of cutter rings is smaller than that of the rough-drawn teeth. The disclosed method is the design method of the broach of the present invention. This broach has a certain resistance to edge chipping. When chipping occurs, because the rough-drawing tooth does not participate in the formation of the final tooth profile, it will not affect the processing quality of the gear tooth surface; Small and durable.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

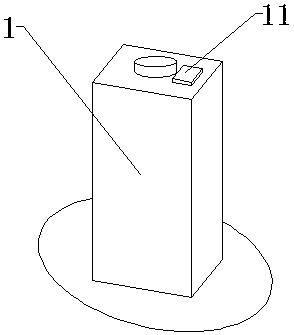

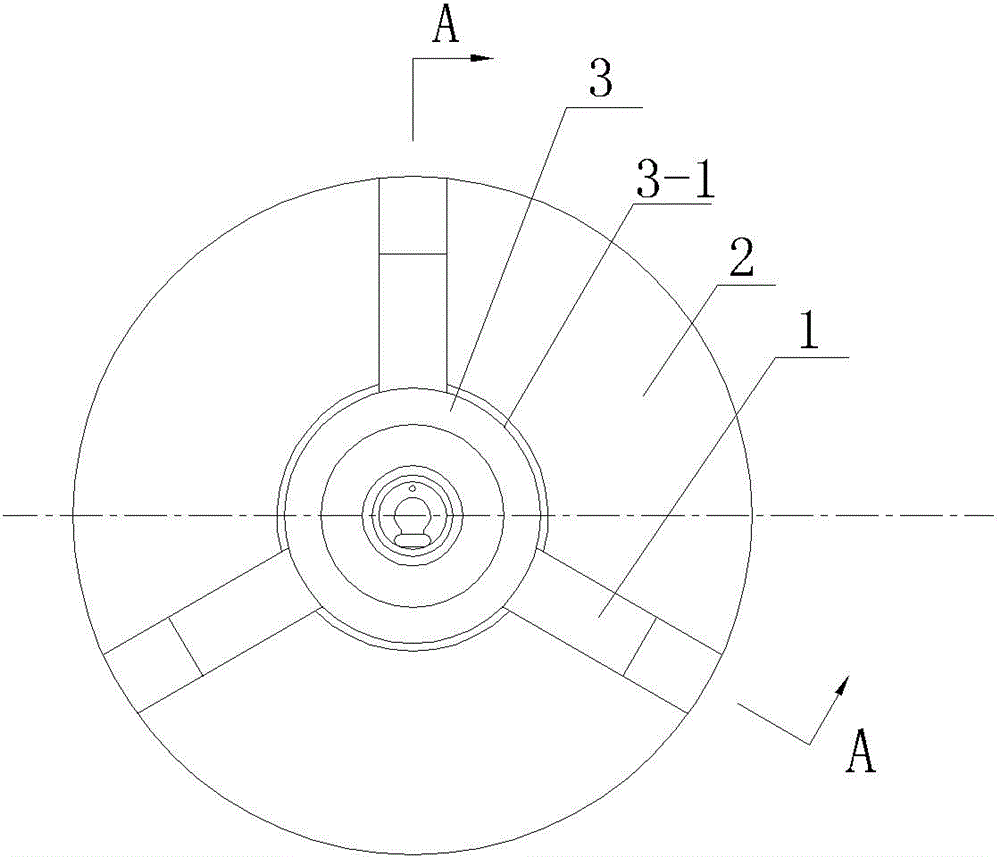

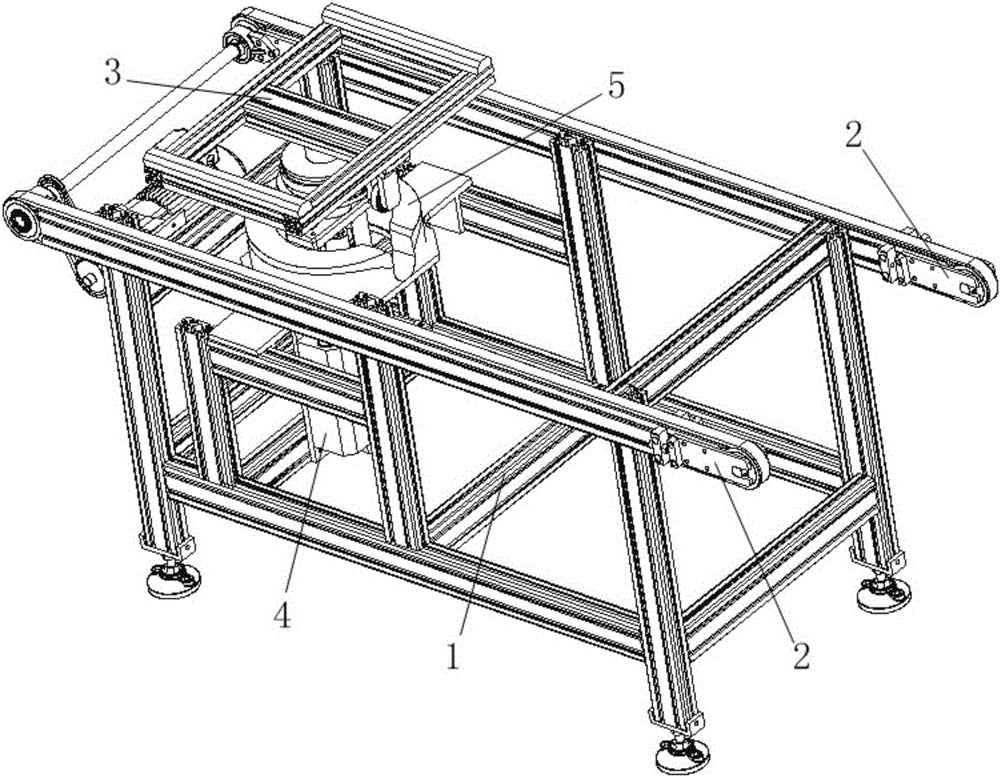

A lift operating table with automatic alignment function

ActiveCN104058245BRealize online inspectionGuaranteed positioning accuracyConveyor partsProduction linePolyurethane

The invention relates to the field of automotive glass processing, in particular to a lifting operating platform which is used on a skylight glass PU (Polyurethane) edge-cladding production line, specifically a lifting operating platform with an automatic straightening function. The lifting operating platform comprises a machine frame, glass transmission devices, a worktable, an air cylinder, an annular orientation device, a roller, a rotating shaft and a supporting seat, wherein the upper surface of the annular orientation device is an inclined face; a groove is formed in the lowest part of the upper surface; the roller is fixedly arranged on the lower surface of the worktable, and can freely rotate. By applying the lifting operating platform with the automatic straightening function, the online inspection can be realized without the need of carrying glass away from the production line; after the inspection is over, the glass can be recovered to an original state direction, so that the inflow direction of the glass is consistent with the outflow direction of the glass; the inspected glass does not need to be positioned again; not only is the positioning precision guaranteed without influencing the processing quality of a next procedure, but also the production efficiency is improved.

Owner:FUJIAN WANDA AUTOMOBILE GLASS IND

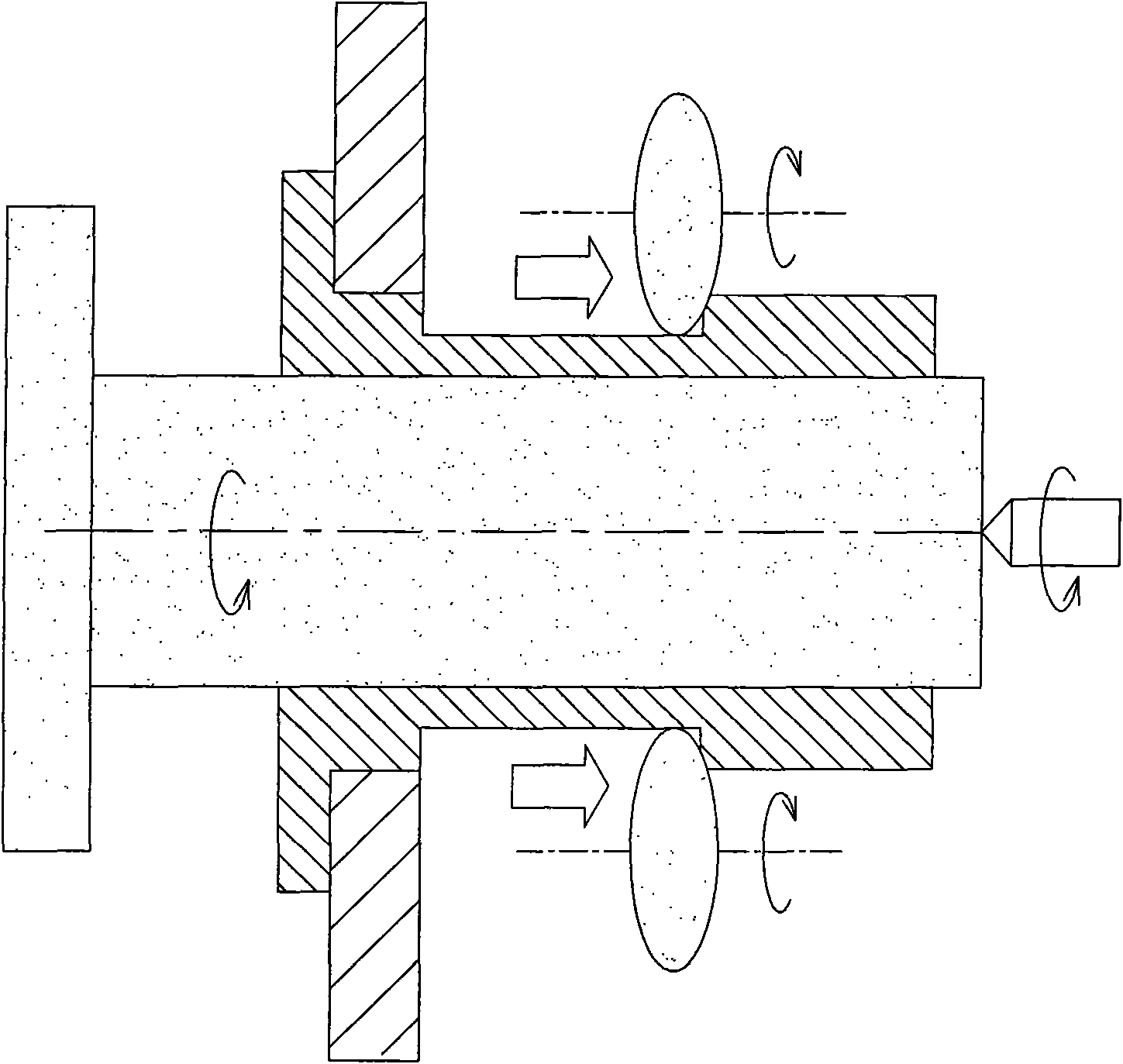

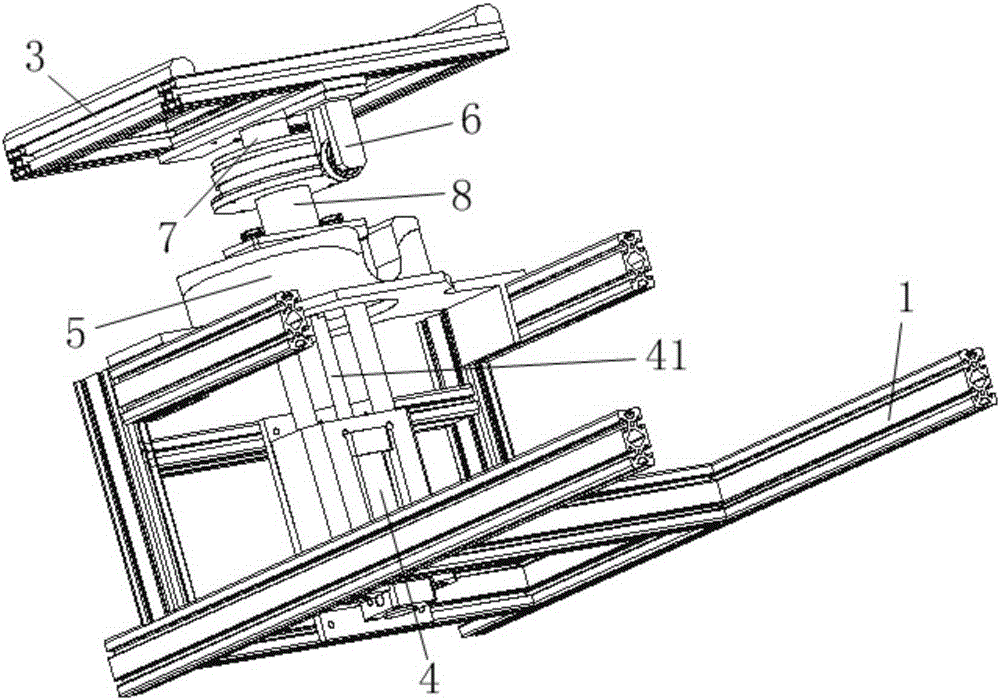

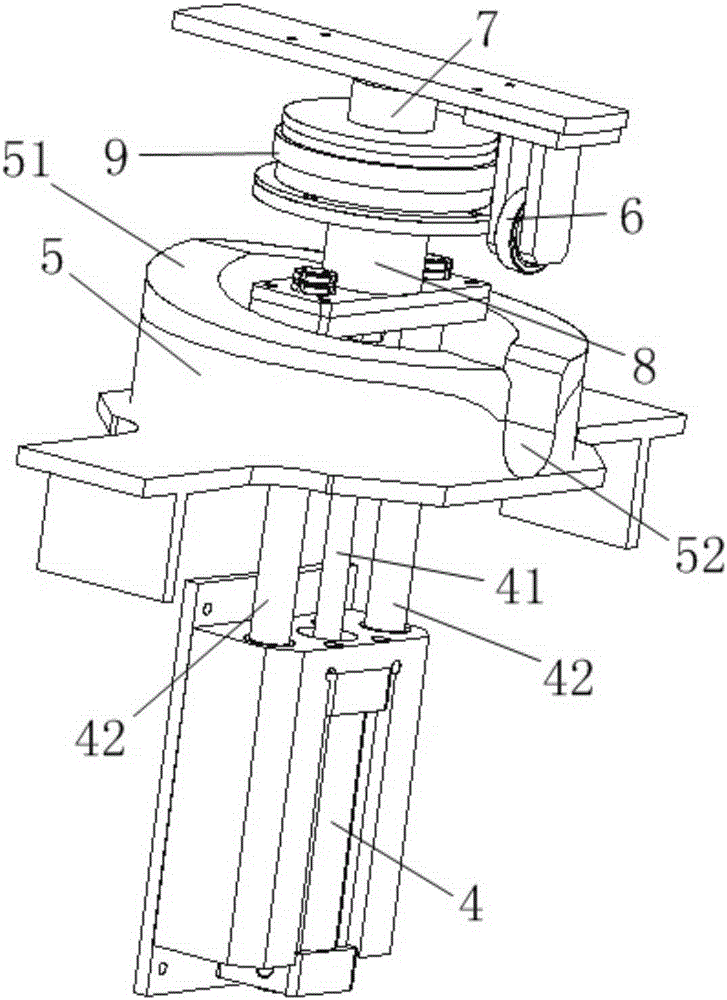

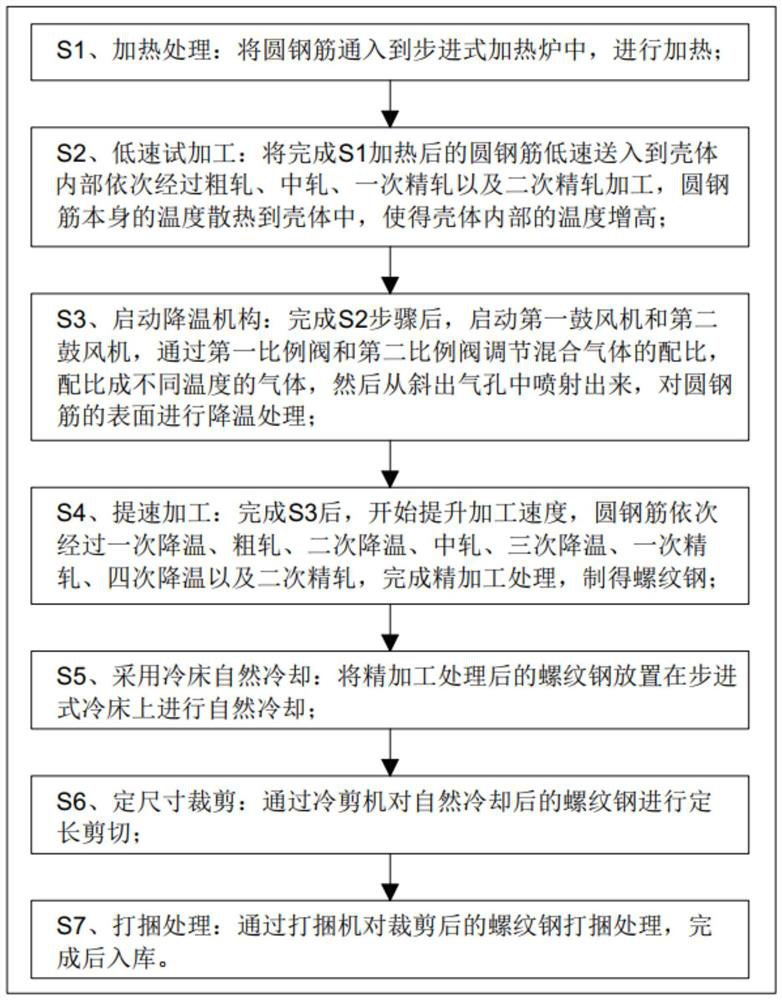

A rolling finishing method and processing device for hot-rolled steel

ActiveCN112916613BShorten the lengthDoes not affect processing qualityWork treatment devicesMetal rolling arrangementsEngineeringHeating furnace

The invention discloses a threaded steel hot-rolled manufacturing and rolling finishing method, which comprises the following steps: feeding round steel bars into a walking heating furnace for heating; feeding the heated round steel bars into the shell at low speed and sequentially After rough rolling, intermediate rolling, primary finishing rolling and secondary finishing rolling; start the first blower and the second blower, adjust the ratio of the mixed gas through the first proportional valve and the second proportional valve, and mix it into gases of different temperatures , and then spray out from the oblique air hole; start to increase the processing speed, the round steel bar successively undergoes one cooling, rough rolling, two cooling, intermediate rolling, three cooling, one finishing rolling, four cooling and two finishing rolling, and finishes finishing. Processing; the present invention reduces the temperature once by blowing air at the front of the rough rolling, intermediate rolling and finishing rolling, shortens the overall length of the process line, improves the processing efficiency, and does not cause sudden cooling of the temperature , will not affect the processing quality of rebar.

Owner:JIANGSU BINXIN STEEL GRP

Method of resuming transmission from breakpoints during online processing of CNC machine tool dnc

ActiveCN103149875BPrevent wrong actionDoes not affect processing qualityNumerical controlEngineeringMachine tool

The invention discloses a break-point resuming method of a numerical-control machine tool at the time of direct numerical control (DNC) machines online. The break-points resuming method is achieved by sequentially conducting the following steps of machine tool pause operation, latch of the current machine tool coordinate value and the spindle speed value, exception handling, recovery of spindle status, recovery of DNC online machining, recovery of mechanical coordinates of each shaft of the machine tool and execution of following procedures. According to the break-point resuming method of the numerical-control machine tool at the time of the DNC machines online, after abnormal conditions are handled, the machining procedure does not need to start from the beginning of the procedure, the procedure does not need to be deleted, the current position of the procedure, the current coordinate value of the machine tool and the spindle speed value do not need to be recorded manually, the machining efficiency is high, and the operation is convenient.

Owner:张军宁

Quality inspection machine capable of automatically classifying

PendingCN114770640AImprove safety performanceImprove protectionMetal working apparatusAdhesive glueThin membrane

The invention discloses a quality inspection machine capable of automatically classifying, which comprises a conveying belt, a material receiving plate is arranged in the direction of the discharging end of the conveying belt and is used for placing and collecting slit materials, a mounting frame is mounted at the end part, facing the direction of the conveying belt, of the material receiving plate, a tool apron is arranged on the inner side of the mounting frame, a cutter is mounted on the inner side of the tool apron, and the cutter is mounted on the inner side of the tool apron. The cutter holder is used for cutting, strip-shaped grooves are symmetrically formed in the bottom end face of the cutter holder, protection plates are inserted into the strip-shaped grooves, protection of the cutter is achieved through the protection plates, the phenomenon that the exposed cutter causes external damage in the production process is avoided, springs are further arranged between the protection plates and the strip-shaped grooves, and the springs are arranged in the strip-shaped grooves. The height of the protection plate can be conveniently adjusted according to the height of the tool apron, the two ends of the spring are bonded to the top end of the protection plate and the top end face of the interior of the strip-shaped groove through high-viscosity glue correspondingly, and a rolling shaft capable of rotating is further installed on the inner side of the bottom end of the protection plate and used for extending thin film products.

Owner:成都市温江区金桥包装有限公司

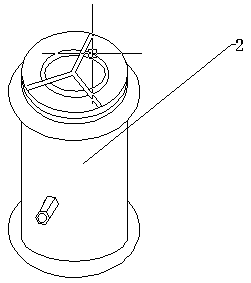

Inner thimble for grinding hollow shaft

PendingCN108857616ASimple structureIngenious designRevolution surface grinding machinesTailstockMorse taper

The invention discloses an inner thimble for grinding a hollow shaft. The inner thimble comprises a thimble rod body, wherein one end of the thimble rod has a Morse's taper, so that the end of the thimble rod can be sleeved into a grinding machine spindle or a grinding machine tailstock to be located; a hollow part is arranged at the other end of the thimble rod body, and the opening position of the hollow part is an inner taper angle which is matched with a chamfer at the end of a hollow output shaft; in location, the thimble rod body can abut against the chamfer at the end of the hollow output shaft through the inner taper angle to locate the hollow output shaft. The inner thimble for grinding the hollow shaft not only has a simple structure and an ingenious design, but also has quickness and convenience in location and can greatly improve the hollow output shaft processing efficiency under the premise that the processing quality is not affected.

Owner:JIANGNAN YIFAN MOTOR

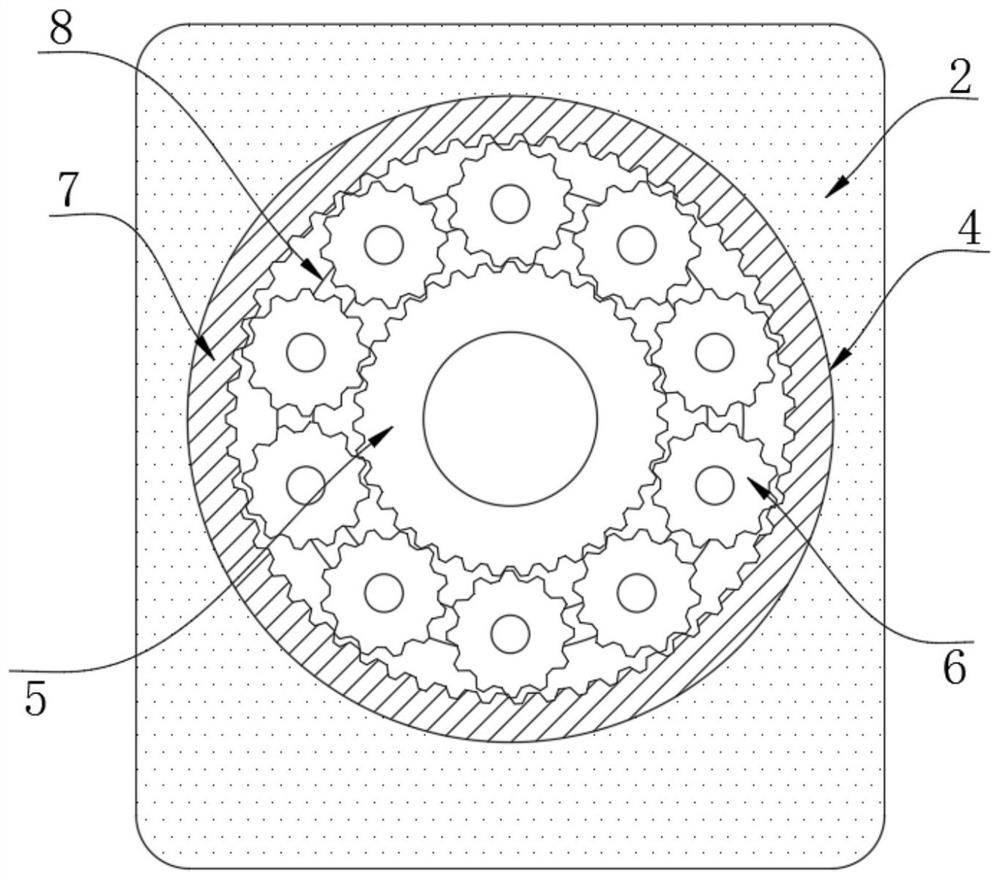

Finishing head for die repairing machine tool

InactiveCN112917380AImprove processing qualityShorten the travel timeGrinding drivesGrinding machinesGear wheelPolishing

The invention discloses a finishing head for a die repairing machine tool. The finishing head comprises a shell, a worm wheel, a central gear, an inner gear ring, planetary gears, a planetary carrier, a motor, a polishing head, a high-frequency electromagnetic induction coil, a thermal deformation part, a hand wheel and a worm, wherein the shell is a supporting main body, and the motor drives the polishing head to rotate. During manual feeding, feeding and retreating of the polishing head can be realized by rotating the hand wheel and through a fixed-axis gear train composed of the worm wheel, the central gear, the inner gear ring, the planetary gears, the planetary carrier, a moving shaft, a threaded shaft, a chain, a first chain wheel, a second chain wheel and the worm; during manual feeding, the moving speed of the polishing head is high, during thermal stress feeding, a feeding sliding block can be pushed rightwards, then the thermal deformation part is heated through the high-frequency electromagnetic induction coil, and micro feeding of the polishing head is realized according to the principle of thermal expansion and cold contraction; and manual feeding can be adopted in idle stroke, so that the moving time of the polishing head is shortened, and thermal stress feeding can be adopted in finishing of the surface of a die, so that the machining quality of the surface of the die is improved.

Owner:郜欣

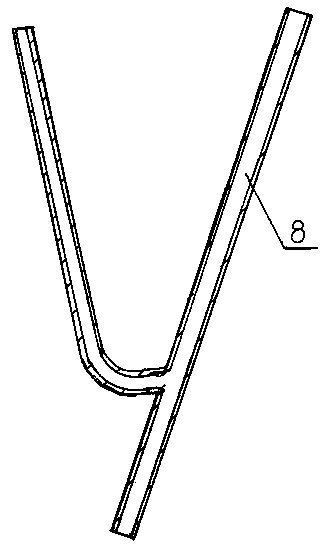

Residual material clamping device for muntin saw machine

InactiveCN1962144ADoes not affect machining accuracyDoes not affect processing qualityMetal sawing accessoriesFixed BeamIndustrial engineering

The invention relates to a clamper of left material of saw bed, wherein it comprises fixed beam and movable beam at the lower part; the fixed beam is fixed with a vertical lifter and a horizontal clamper; the lifter comprises a lifting cylinder, a lifting cylinder mounting base fixed on the fixed beam and a lifting guide axle; the horizontal clamper comprises a clamping cylinder, a clamping cylinder mounting base, a front adjusting plate fixed on the mounting base and a back fixing plate fixed with the lifting guide axle; the back fixing plate has horizontal clamping guide axle; the clamping cylinder mounting base is fixed on the clamping guide axle. The invention can horizontally clamp left material and vertically lift the left material without splashing material.

Owner:JINAN DECA MASCH CO LTD

Flue gas treatment device

InactiveCN111408271AHighlight substantive featuresSignificant progressDispersed particle separationThermodynamicsFlue gas

The invention discloses a flue gas treatment device, and relates to the technical field of flue gas treatment and environmental protection. According to the technical scheme, a flue gas input pipelineof the flue gas treatment device is arranged at the inlet end of a flue gas treatment chamber, and an inlet end air distribution plate is arranged at the end of the flue gas input pipeline; a plurality of treatment cavities are uniformly distributed in an inner cavity of the flue gas treatment chamber, and a carrier interlayer is arranged between every two adjacent treatment cavities; a conveyingpipeline is arranged between the second treatment cavity of the flue gas treatment chamber and the last but one treatment cavity at the tail end; the centers of the two ends of the flue gas treatmentchamber are each sleeved with a rolling bearing, and the rolling bearings are supported on the rack and connected with a power driving mechanism. Compared with the prior art, the device has the outstanding substantive characteristics and remarkable progress that the structure is more reasonable, secondary pollution is avoided, equipment operation is safe and reliable, and the flue gas treatment efficiency can be improved.

Owner:徐明好

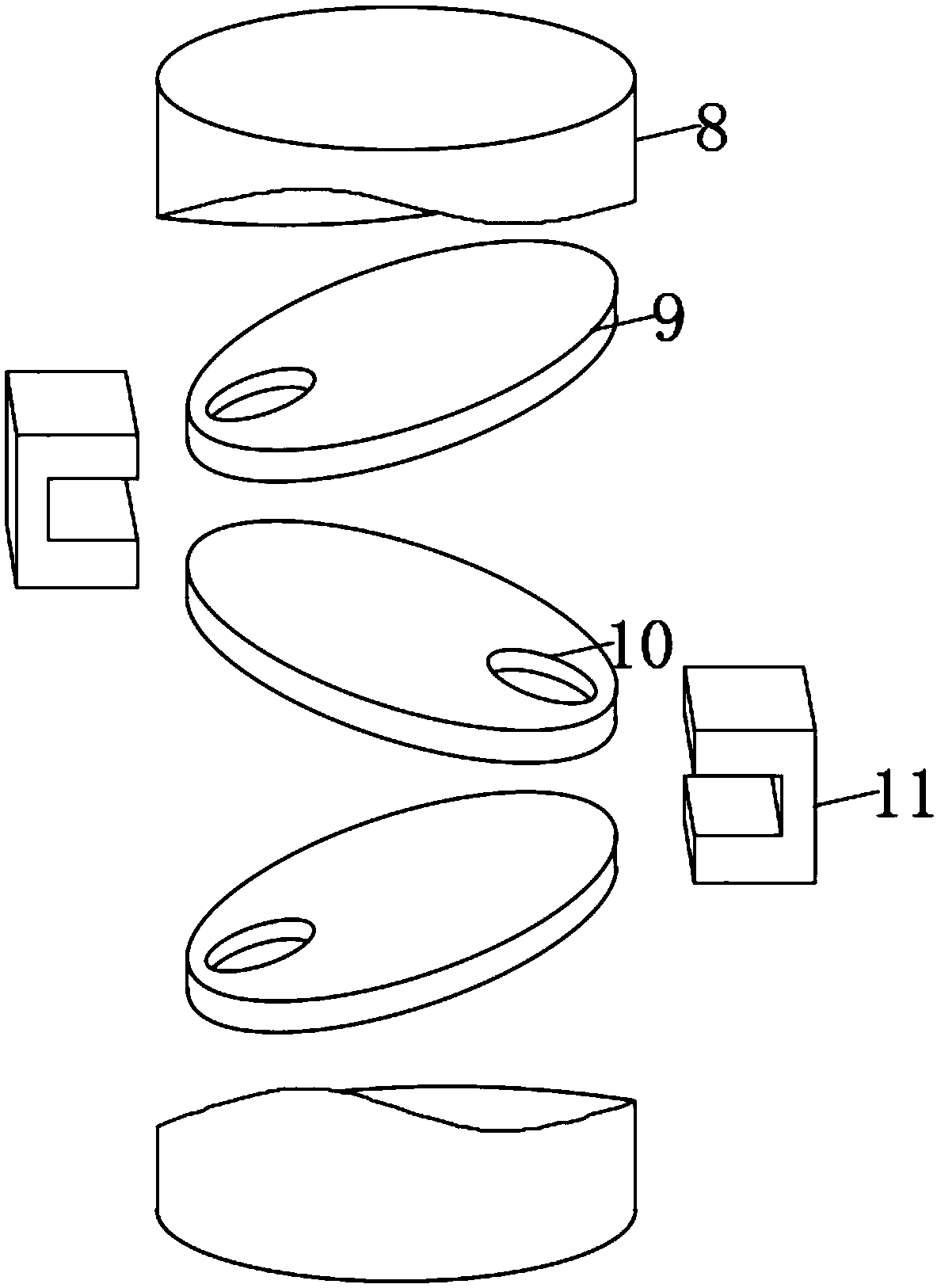

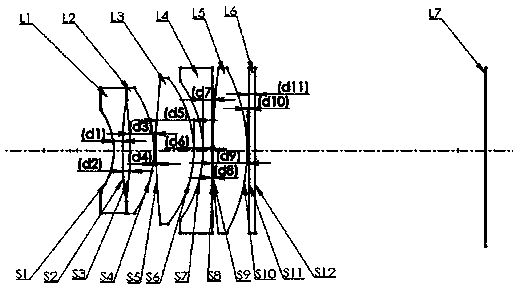

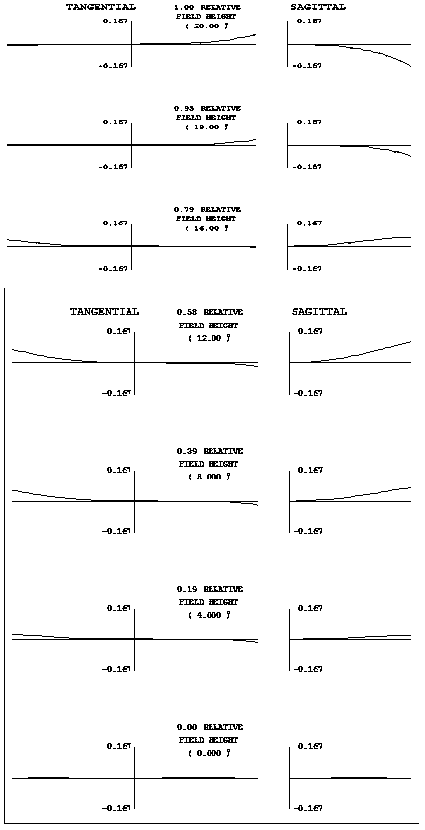

Infrared two-dimensional scanning mirror group

ActiveCN105892046BDoes not affect processing qualityGuaranteed processing effectOptical elementsCamera lensLight spot

The present invention provides an infrared two-dimensional scanning mirror group, including the first, second, third, fourth, fifth, and sixth lenses arranged in sequence in the incident direction of infrared laser, wherein the first lens is double-concave lens, the second lens is a meniscus lens, and the curved surface is bent toward the incident direction of the light, the third lens and the fifth lens are double-convex glass, the fourth lens is a plano-concave lens, and the sixth lens is a protective glass; The lens group is used for infrared lasers with an entrance pupil diameter of 30mm, a focal length of 275mm, and a wavelength of 1064nm. The processing range is 130mm*130mm processing area. The light spot of the infrared two-dimensional scanning mirror group of the present invention can meet a certain requirement in a certain area, so when there is a certain defocus, the processing quality will not be affected, the processing effect can be guaranteed, and the actual use requirements can be met.

Owner:WUHAN HGLASER ENG CO LTD

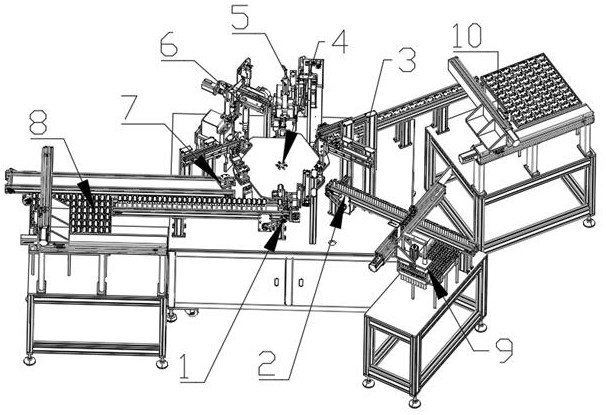

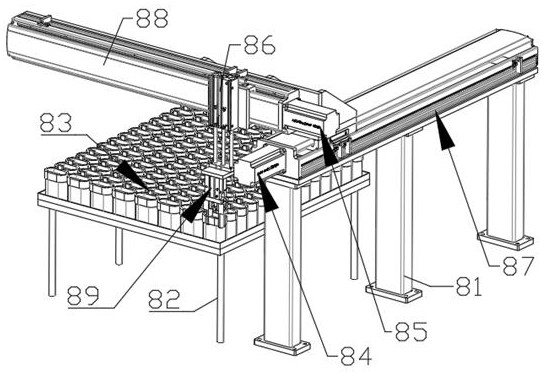

A new energy intelligent battery control core fully automatic intelligent manufacturing equipment

ActiveCN112719867BDoes not affect processing qualityExtended service lifeAssembling battery machinesFinal product manufactureNew energyControl engineering

The invention discloses a new energy intelligent battery control core automatic intelligent manufacturing equipment, which includes a working frame, a first moving frame, a second moving frame and a third moving frame, the first moving frame is set on the left side of the working frame, and the second The mobile frame is set on the front side of the working frame, the third mobile frame is set on the right side of the working frame, and the working frame is respectively equipped with a shell feeding device, a battery feeding device, a top cover feeding device, a rotating device, a first locking device, The second locking device and unloading device, the rotating device is set in the middle of the working frame, the shell loading device, the battery loading device, the top cover loading device, the first locking device, the second locking device and the unloading device in sequence Arranged counterclockwise to the periphery of the rotating device, the first mobile frame is provided with a shell transfer assembly, the second mobile frame is provided with a battery transfer assembly, and the third mobile frame is provided with a top cover transfer assembly, reducing Artificial labor increases production efficiency and reduces defective rate, which has good market application value.

Owner:深圳特威新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com