A new energy intelligent battery control core fully automatic intelligent manufacturing equipment

A technology of smart batteries and control cores, applied in secondary battery manufacturing, manufacturing tools, battery assembly machines, etc., can solve problems affecting product processing quality, low labor efficiency, affecting production efficiency, etc., and achieve good market application value , the effect of reducing manual labor and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

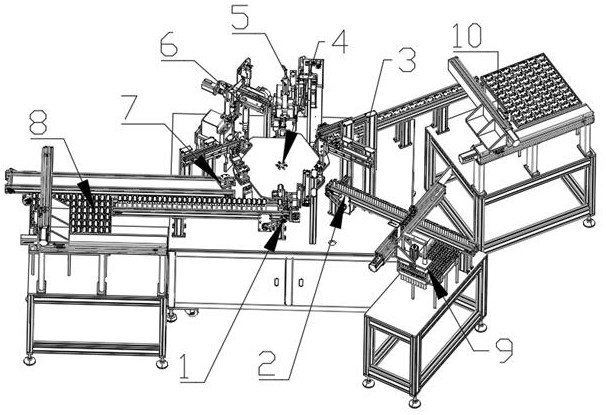

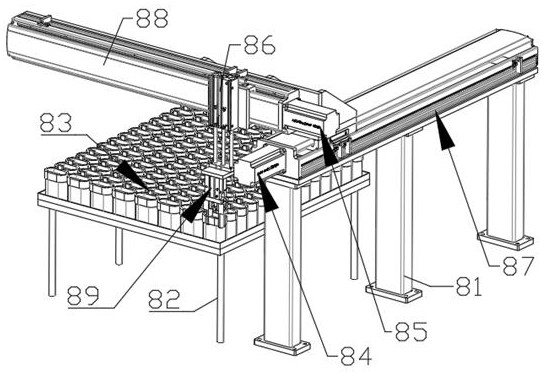

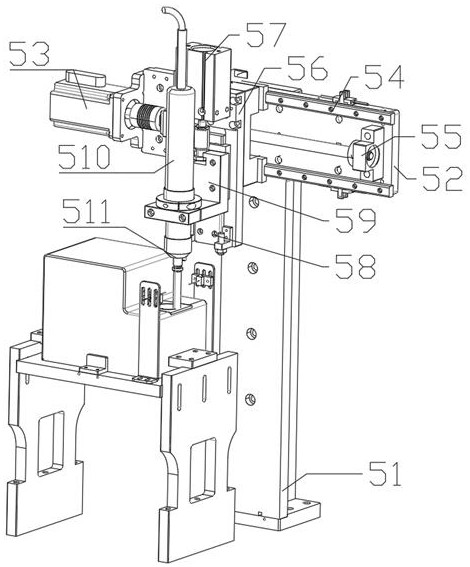

[0024] Such as Figure 1-Figure 4 One embodiment described: a new energy intelligent battery control core automatic intelligent manufacturing equipment, including a work frame, a first mobile frame, a second mobile frame and a third mobile frame, the first mobile frame is set in relation to the The left side of the work frame, the second mobile frame is arranged on the front side of the work frame, the third mobile frame is arranged on the right side of the work frame, and the shell feeding device 1 and the battery are respectively arranged on the work frame. Feeding device 2, top cover feeding device 3, rotating device 4, first locking device 5, second locking device 6 and unloading device 7, the rotating device 4 is arranged in the middle of the working frame, the Shell feeding device 1, battery feeding device 2, top cover feeding device 3, first locking device 5, second locking device 6 and unloading device 7 are arranged in the counterclockwise direction around the rotatin...

Embodiment 2

[0033] The difference between the second embodiment and the above is that the lift slide plate 59 is L-shaped.

Embodiment 3

[0034] The third embodiment is different from the above in that the rotating device 4 includes a rotating motor, a rotating rod, a reduction box, a rotating disk and a plurality of fixed seats, and the rotating motor and the reduction box are all arranged on the work frame, and the rotating The motor is connected to the reduction box, the bottom of the rotating rod is arranged in the middle of the reduction box, the top of the rotating rod is arranged on the lower surface of the rotating disk, and a plurality of fixing seats are arranged on the upper surface of the rotating disk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com