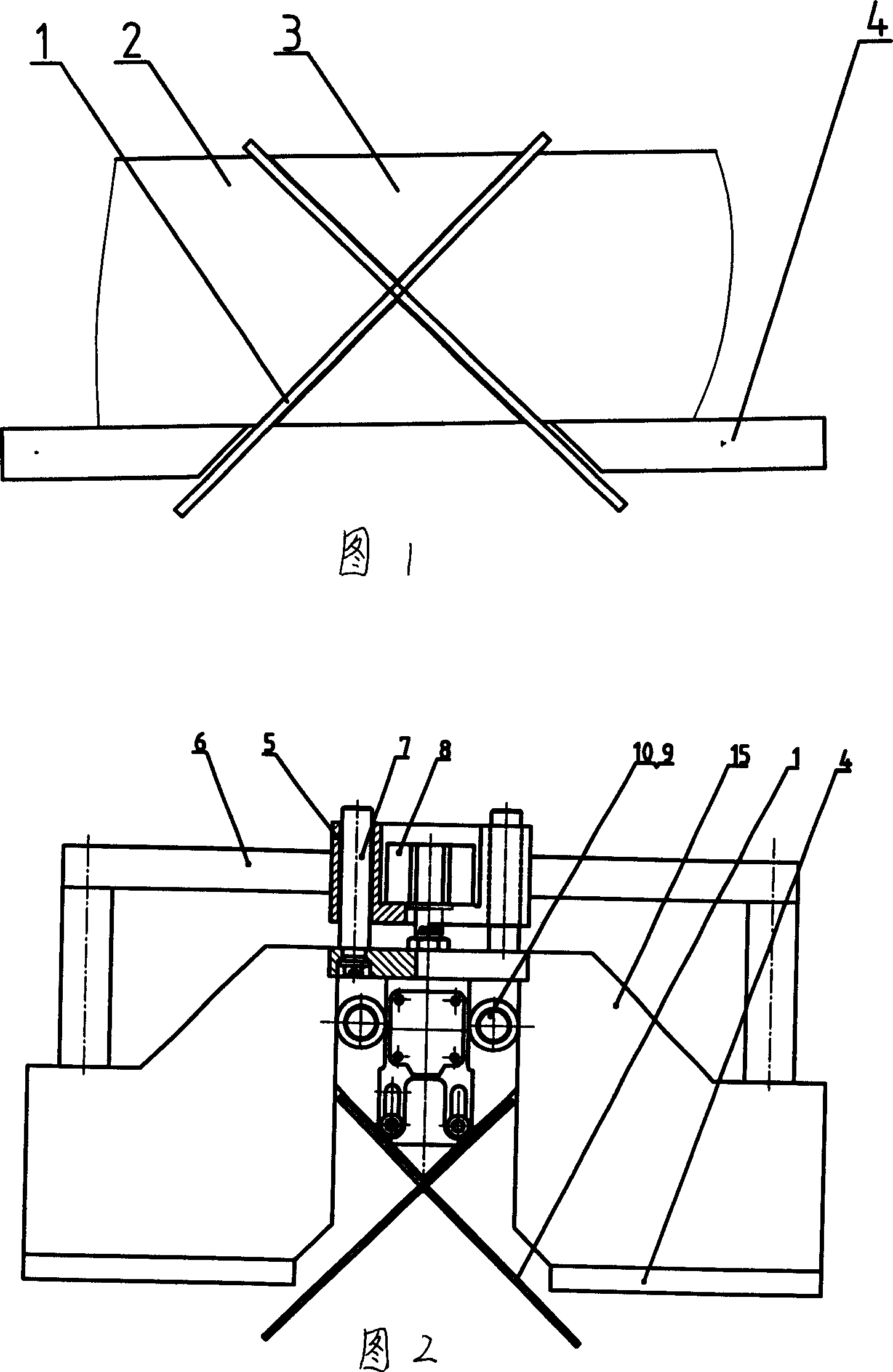

Residual material clamping device for muntin saw machine

A technology of clamping device and residual material, which is applied to the attachment of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve problems such as damage, personnel injury equipment, processing accuracy and surface quality defects, and solve the problem of splash damage. The effect of people, good versatility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

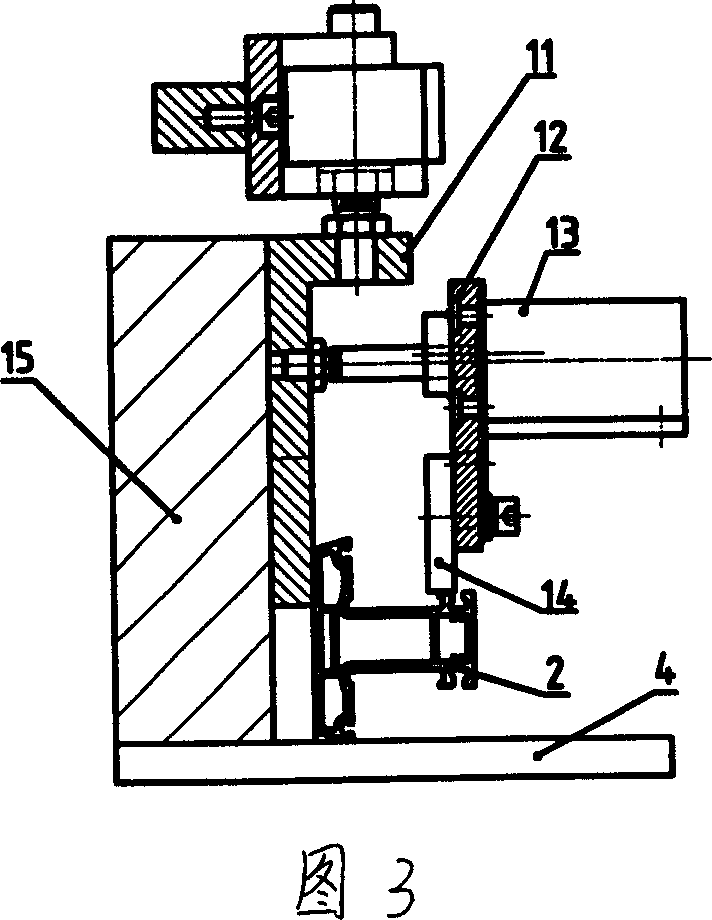

[0014] Fig. 2 and Fig. 3 are a kind of specific embodiment of the present invention. This embodiment includes a fixed crossbeam 6 and a movable crossbeam 15 located at its lower part, a vertical lifting device and a horizontal clamping device are fixed on the fixed crossbeam 6; the vertical lifting device includes a lifting cylinder 8, a lifting cylinder mounting seat fixed on the fixed crossbeam 6 5 and the vertically placed lifting guide shaft 7; the horizontal clamping device includes a clamping cylinder 13, a clamping cylinder mounting seat 12, a front adjusting plate 14 fixed on the clamping cylinder mounting base 12 and a rear fixed with the lifting guide shaft 7 Fixed plate 11, the rear fixed plate 11 is provided with horizontal clamping guide shaft 9, clamping guide sleeve 10, clamping cylinder mount 12 is fixed on the clamping guide shaft 9; The groove that the external shape of plate 11 matches.

[0015] The device is fixed on the fixed beam 6 of the machine tool th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com