Hobbing cutter main shaft mechanism of CNC gear hobbing machine

A gear hobbing machine and hob technology, applied in the field of gear hobbing machines, can solve the problems of low structural strength, relatively high requirements on spindle rigidity and rotational speed, and high manufacturing cost, achieve stability and anti-deformation ability, realize automatic production requirements, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

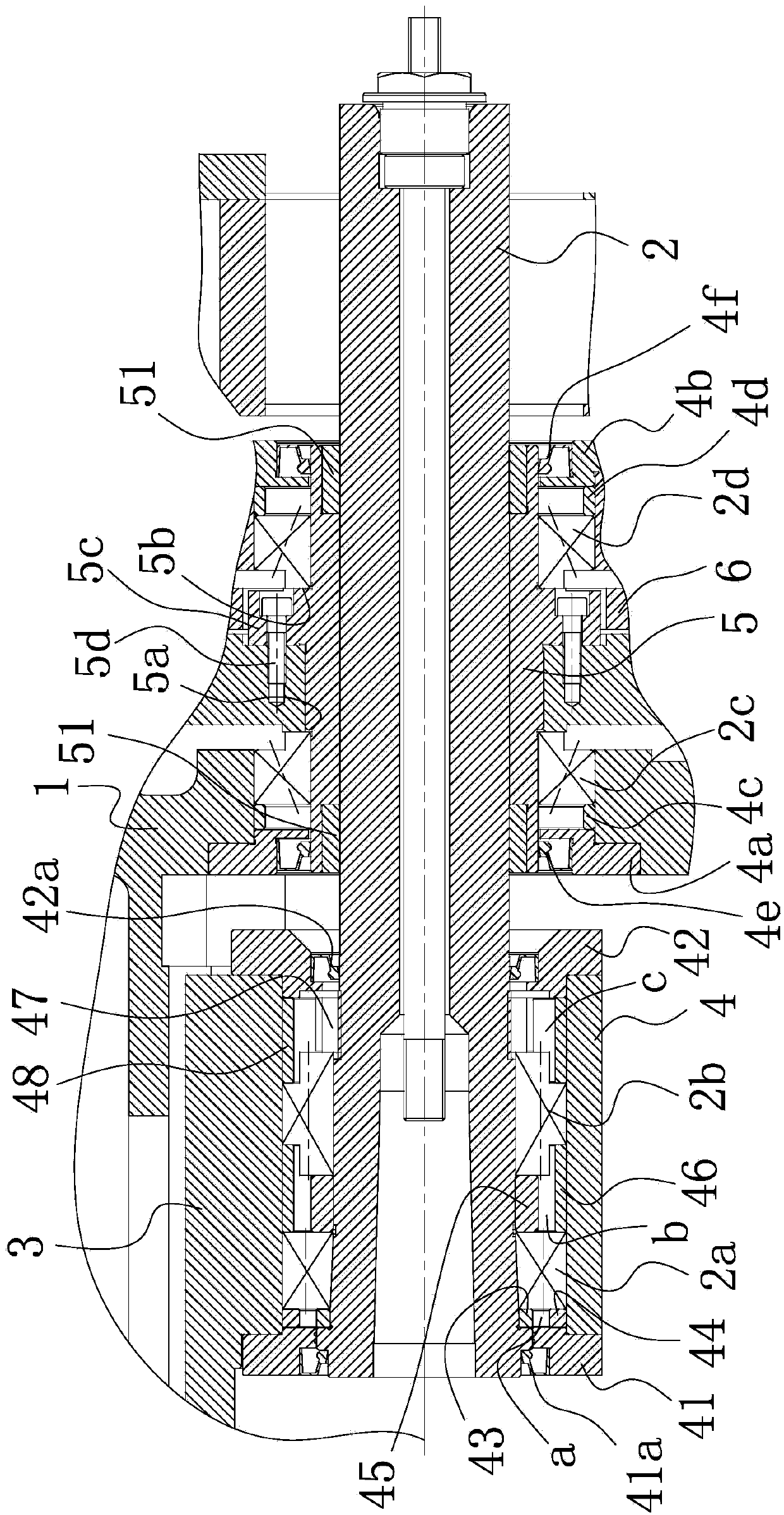

[0021] Such as figure 1 As shown, the hob spindle mechanism of the CNC gear hobbing machine includes a tool holder housing 1 and a hob cutter spindle 2 which is penetrated in the tool holder housing 1 and can rotate relative to the tool holder housing 1. The front end of the hob spindle 2 is inserted into the The tool holder housing 1 is suspended and set, the tail end passes through the tool holder housing 1 and the end extends to the outside of the tool holder housing 1, and a first rolling structure is provided between the tool holder housing 1 and the hob spindle 2 , a supporting plate 3 fixedly connected with the tool rest housing 1 is provided in the tool post housing 1, and a cylindrical tube that is fixedly connected with the supporting plate 3 and sleeved on the periphery of the free end of the hob spindle 2 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com