Quakeproof support device for industrial robot

A technology of industrial robots and support devices, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as position deviation, noise generation, and impact on the working environment, so as to facilitate storage, reduce vibration force, and improve overall temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

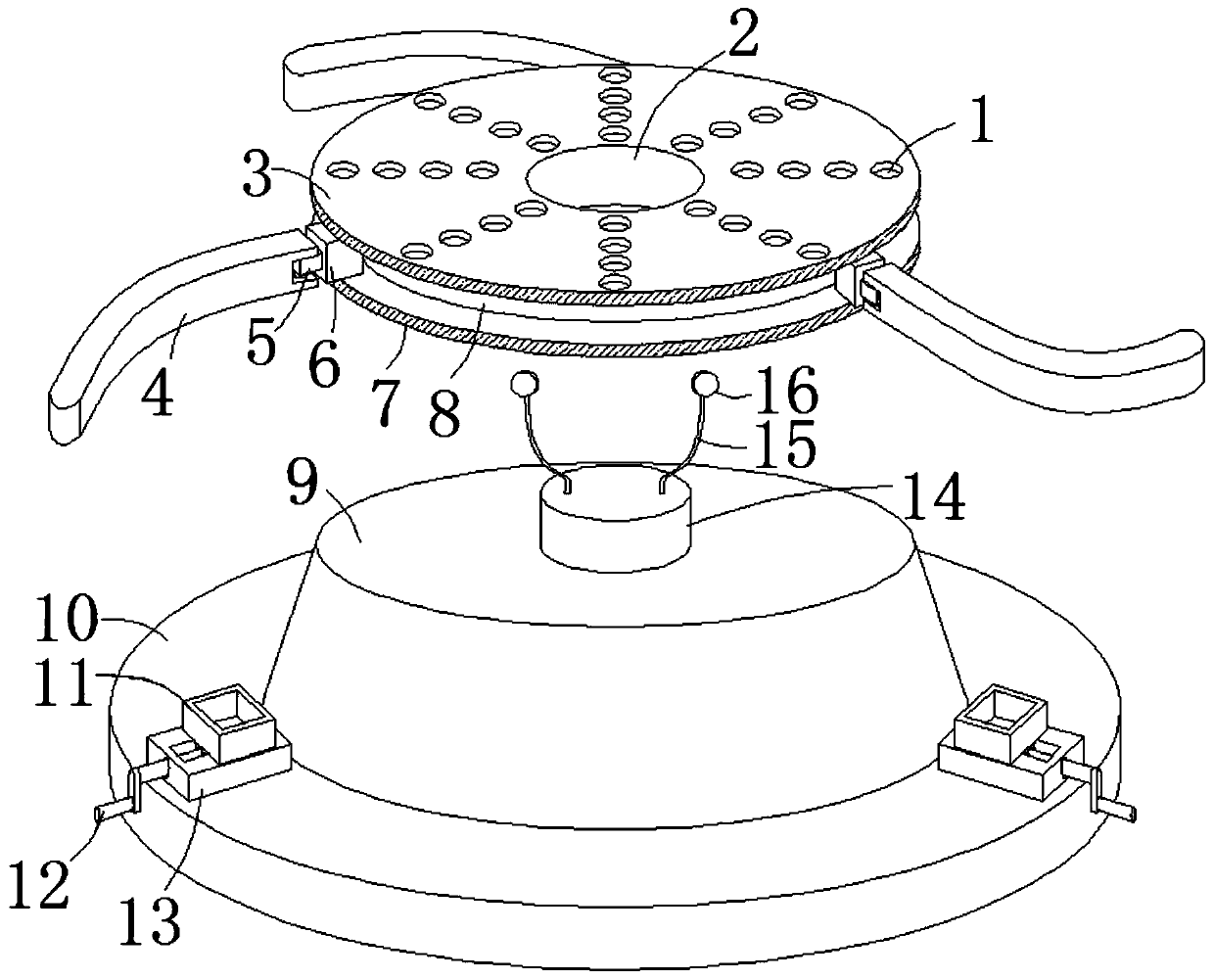

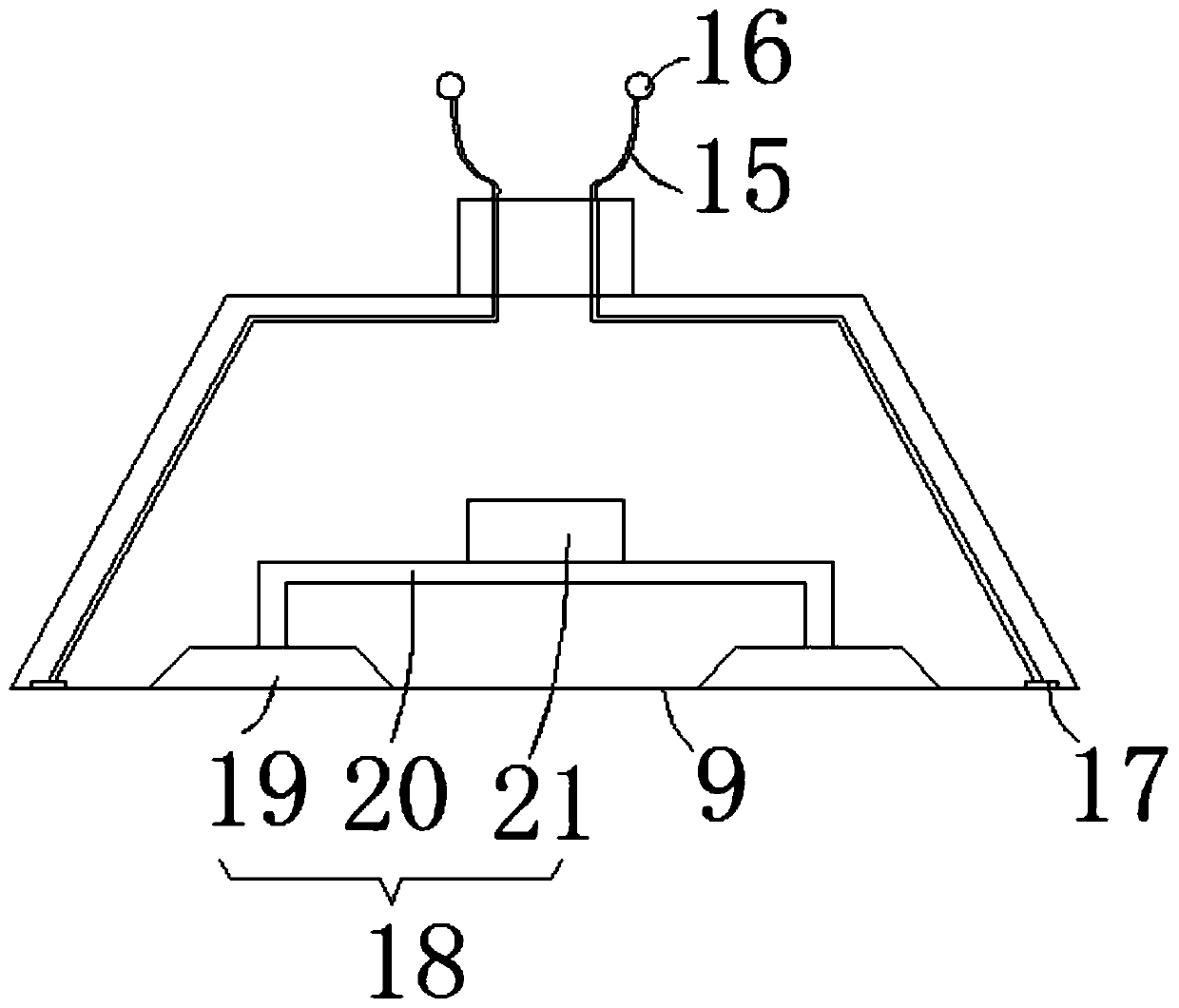

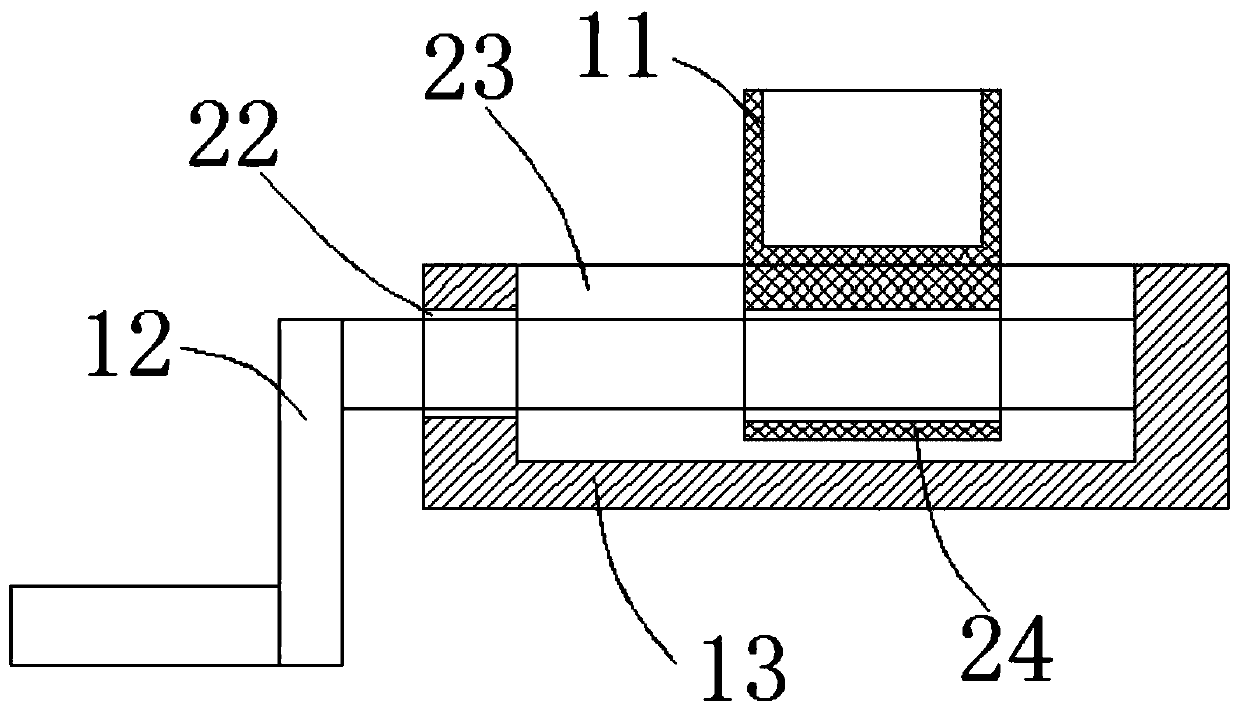

[0026] see Figure 1-4 , the present embodiment provides an anti-seismic support device for industrial robots, including a first support plate 3, a second support plate 7, a rubber seat 9, a chassis 10 and a placement box 11, the first support plate 3 and the second support plate Between the support plates 7, interlayer plates 8 are arranged, and the diameter of the interlayer plates 8 is five-sixths of the diameter of the first support plates 3, and there are three positive and positive joints between the first support plates 3 and the edge positions of the second support plates 7. Triangular distribution of rotating blocks 6, and the side walls of the rotating blocks 6 are not attached to the side walls of the sandwich panel 8, the centers of the side walls of the three rotating blocks 6 are hinged with a rotating block 5, and the three rotating blocks 6 pass through the rotating blocks 5 The support rod 4 is pivotally connected, the center of the first support plate 3, the ...

Embodiment 2

[0029] see Figure 1-4, on the basis of Example 1, a further improvement is made: the first support plate 3 and the second support plate 7 face up and down, and the diameters are equal, and the appearance is beautiful and coordinated. The first support plate 3, the sandwich plate 8 and the second support plate 7 are located on the same central axis, which is convenient for installation. The three support rods 4 are all arc-shaped, and are adapted to the side walls of the interlayer board 8, which is convenient for receiving the support rods 4. The thickness of the three support rods 4 is larger than that of the first support plate 3 and The gap between the second support plate 7 is small 4mm, so that the support rod 4 is convenient to be received in the gap between the first support plate 3 and the second support plate 7, without taking up space, the upper ends of the two conductive strips 15 run through the convex block 14, and is connected with the first metal sheet 16, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com